Evaluation of Pore-Fracture Structures and Gas Content in Deep Coal Reservoir of Yan’an Gas Field, Ordos Basin

Abstract

1. Introduction

2. Geological Background

3. Experimental Methods

4. Results and Discussion

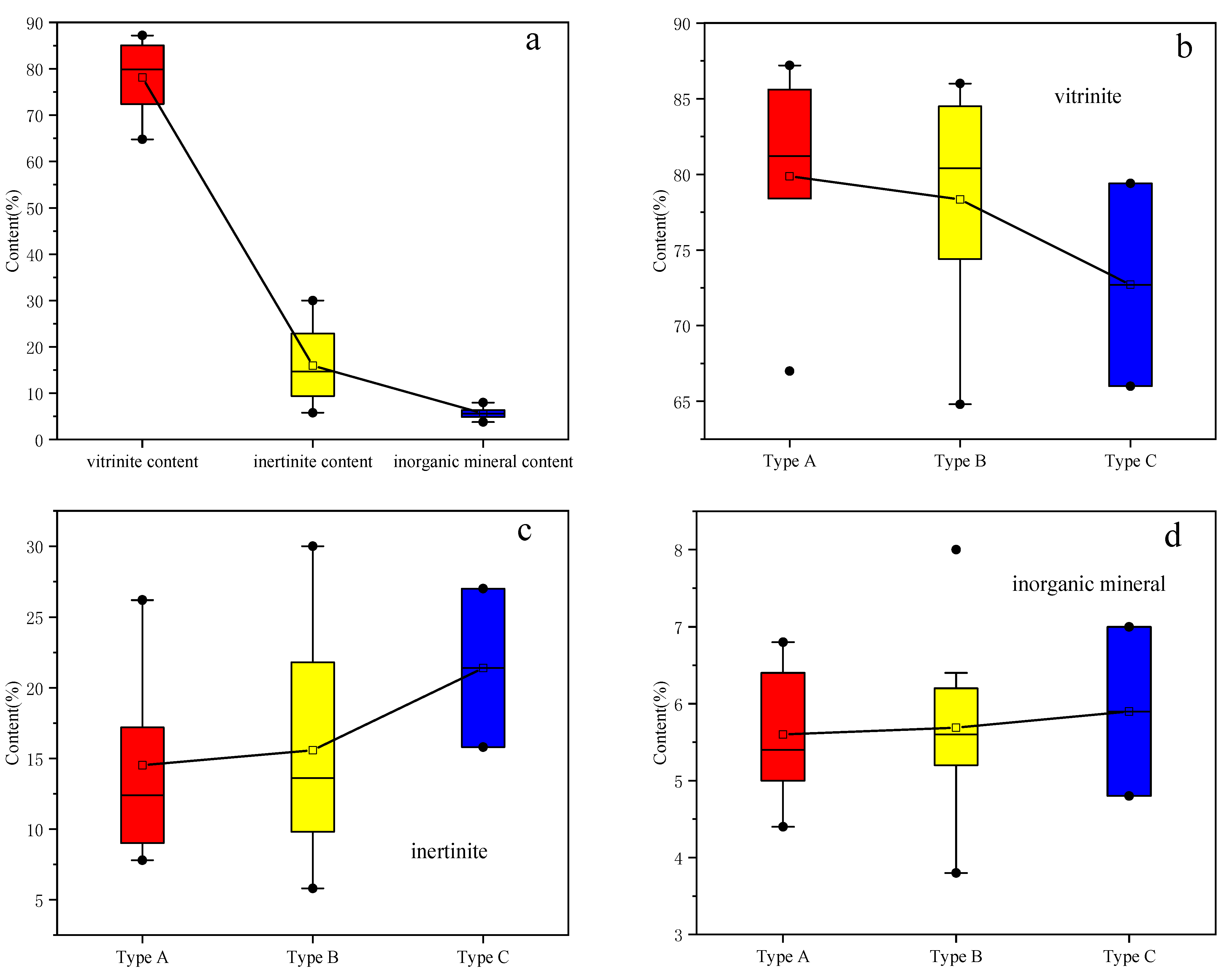

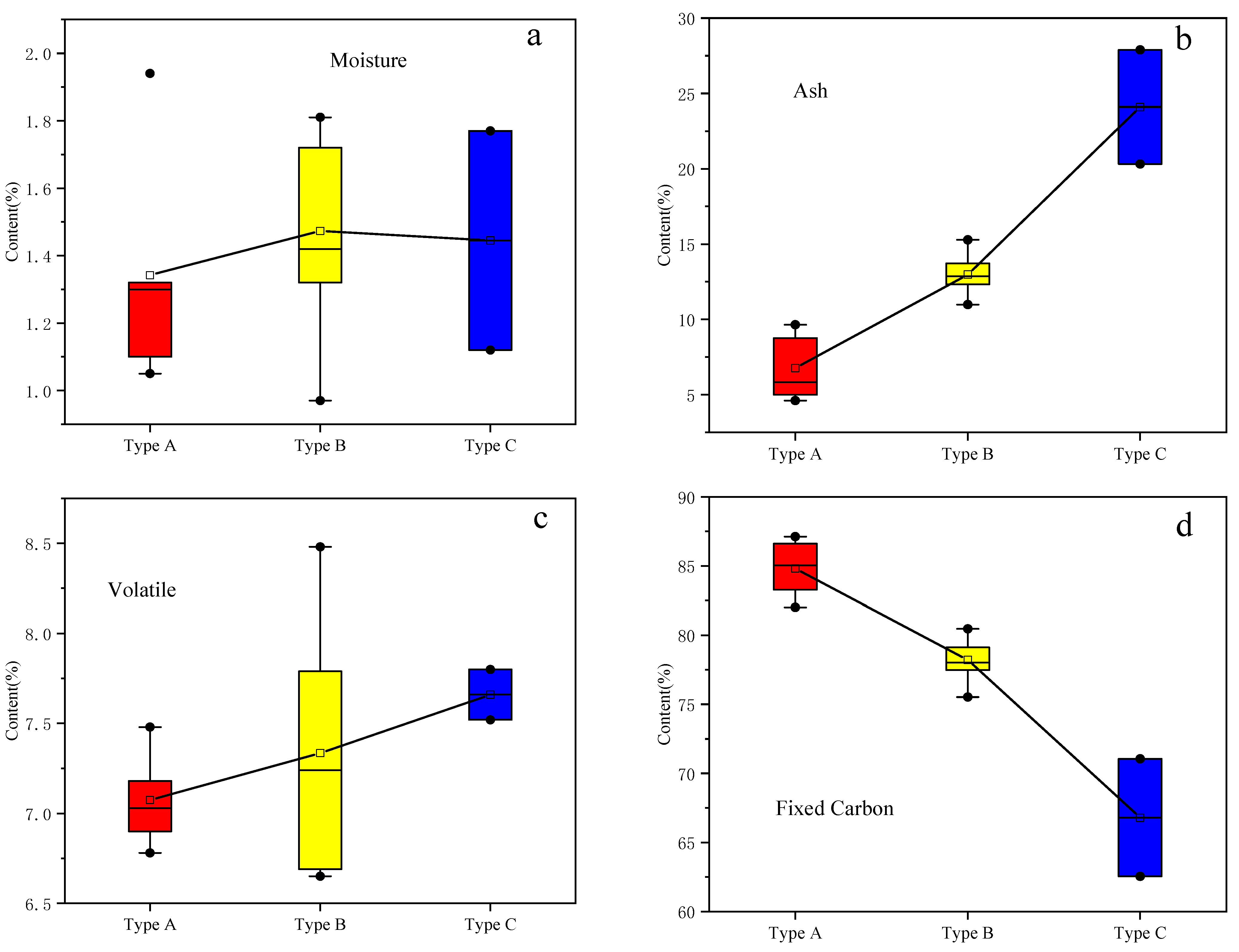

4.1. Classification of Coal Sample Types Based on Proximate Analysis, Coal Rank, and Maceral Composition

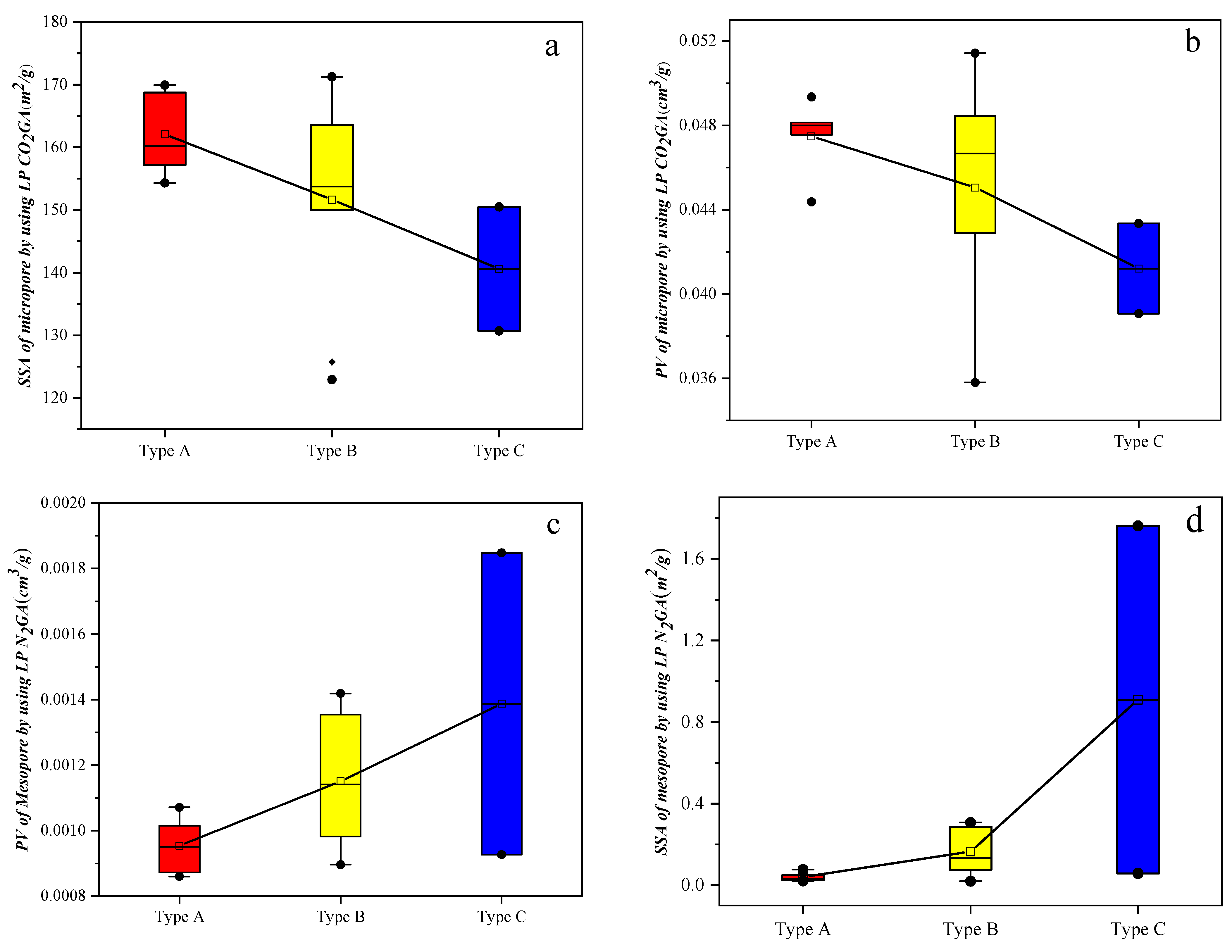

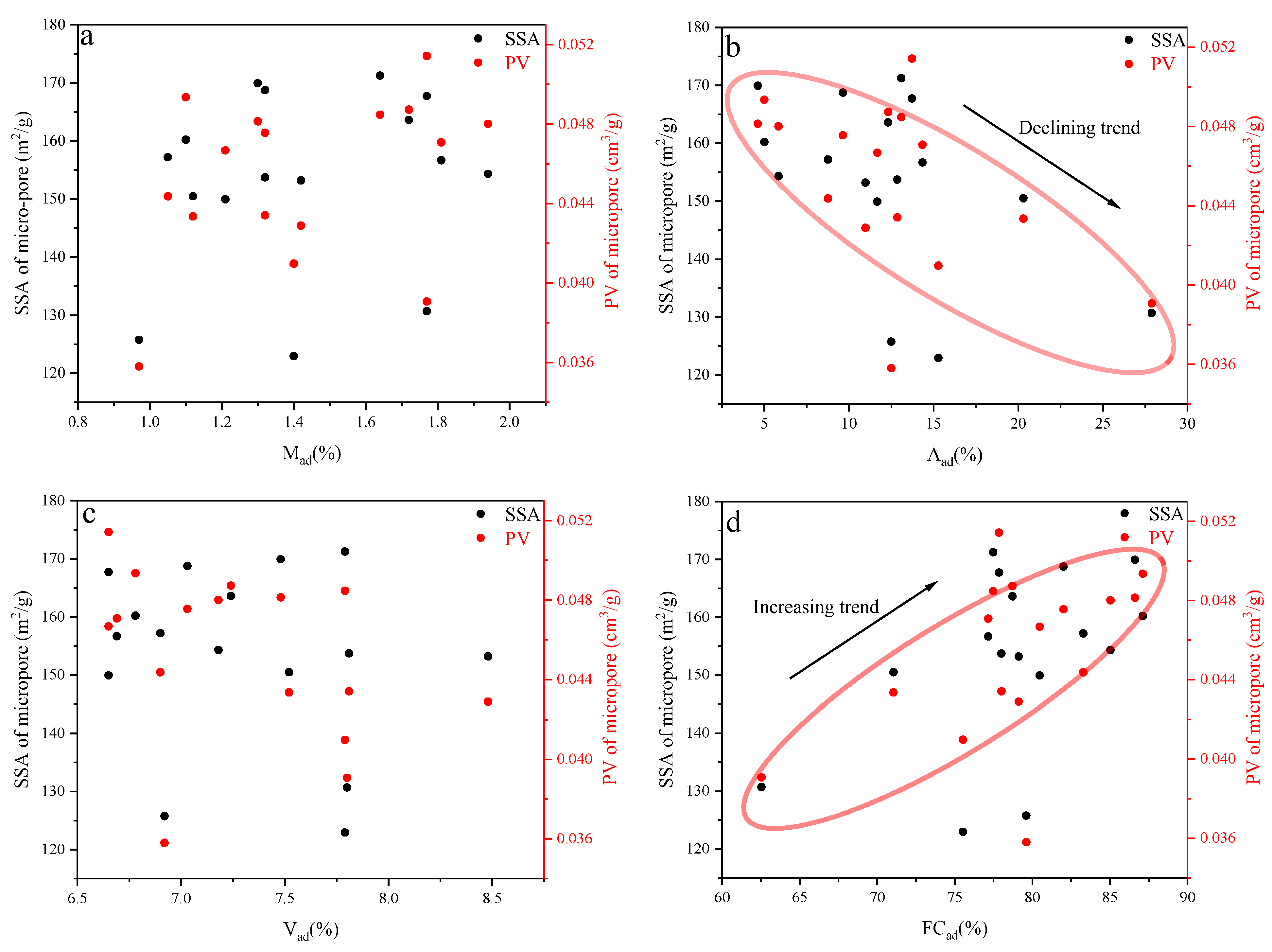

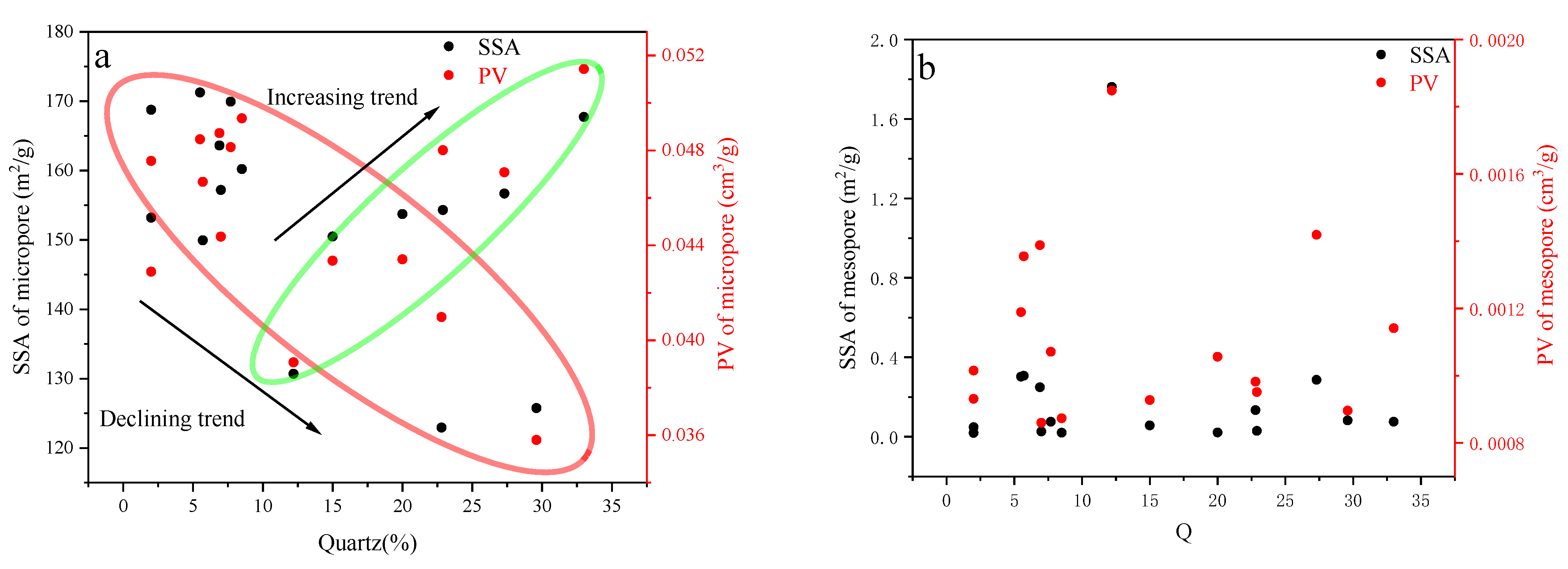

4.2. Analysis of the Key Influencing Factors on the Evolution of Pore-Fractures in Micropores and Mesopores Based on Pore Structure Experiments

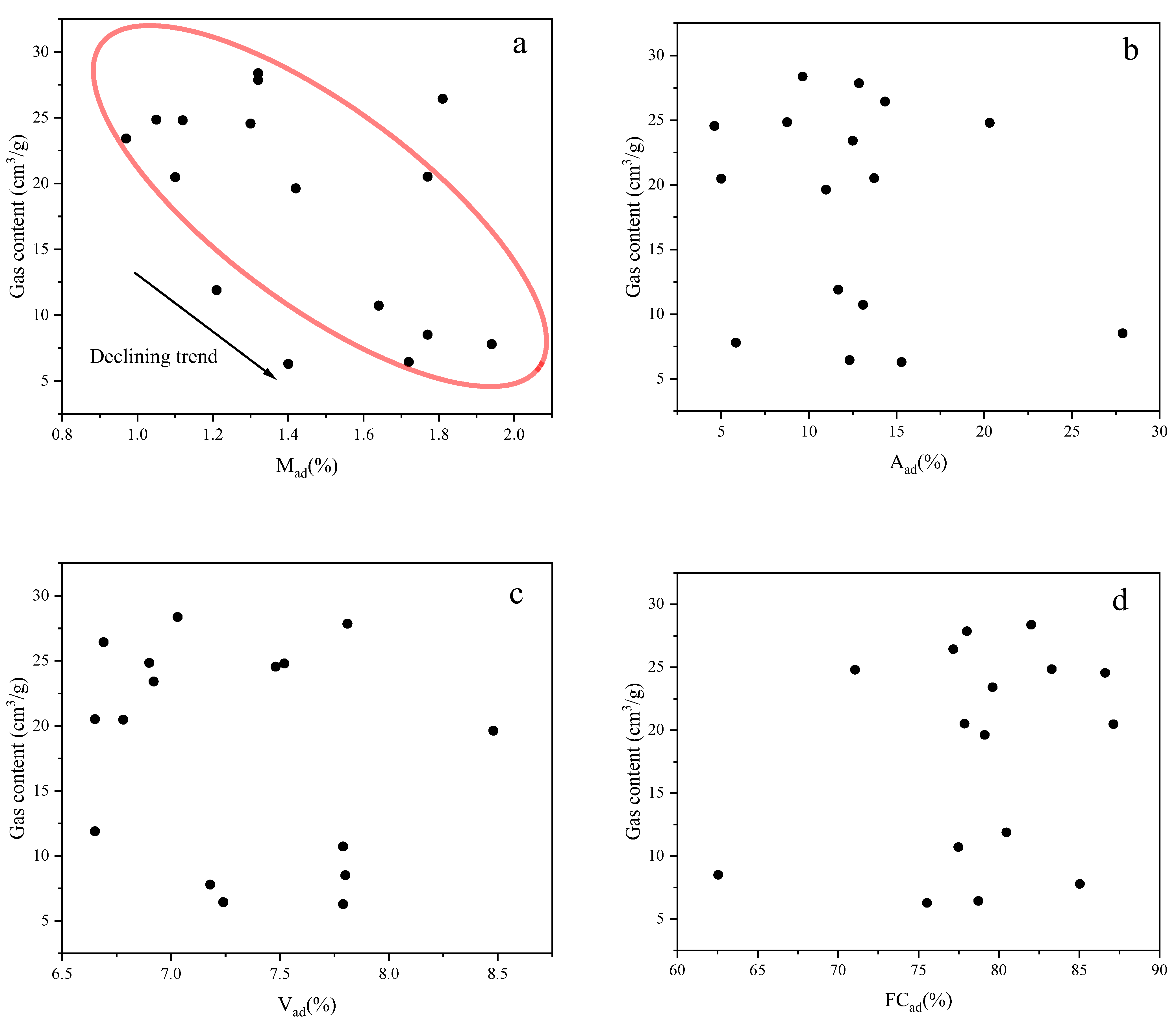

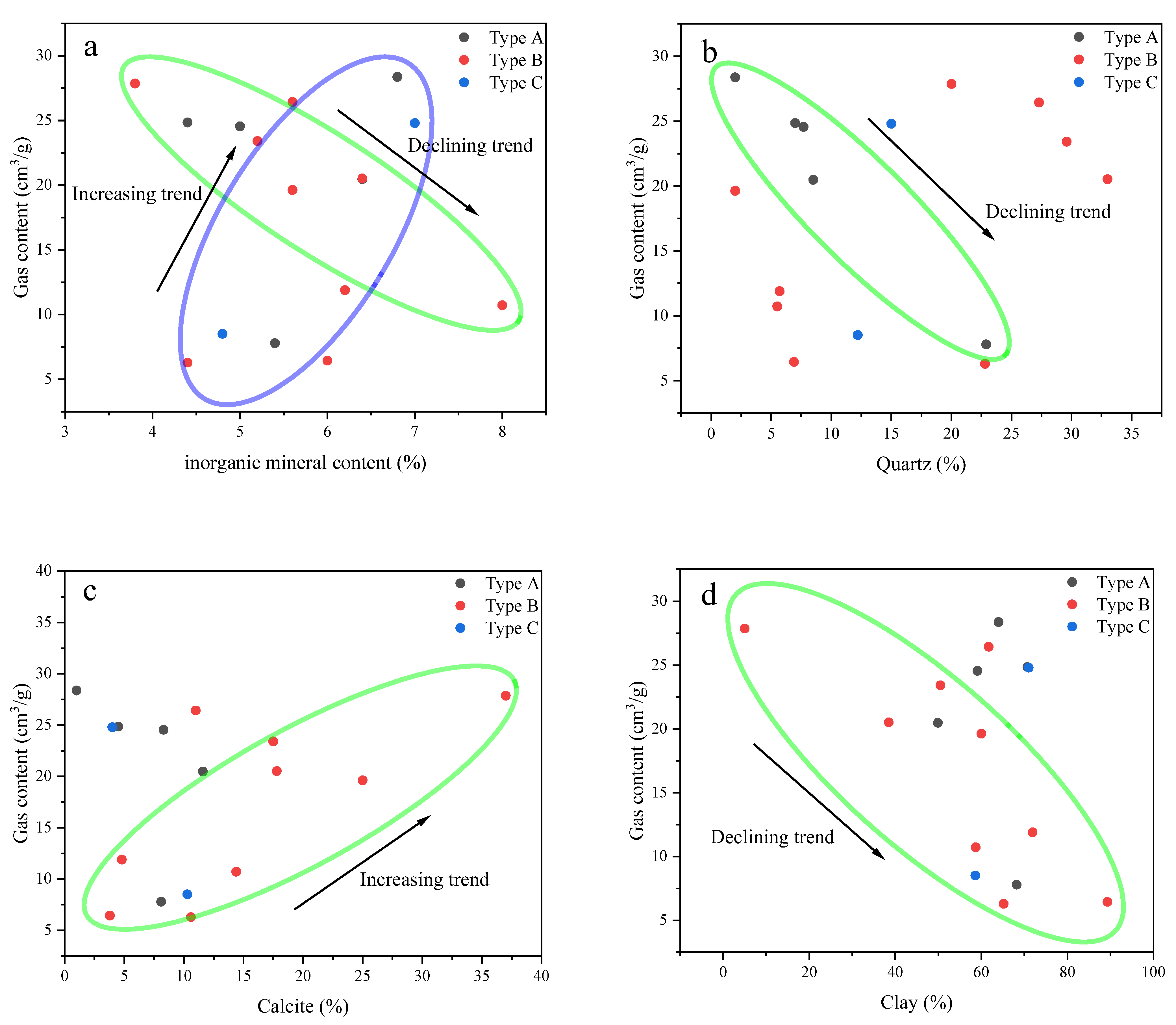

4.3. Analysis of the Key Influencing Factors of Methane Adsorption Capacity Based on the Desorption Experiment

5. Conclusions

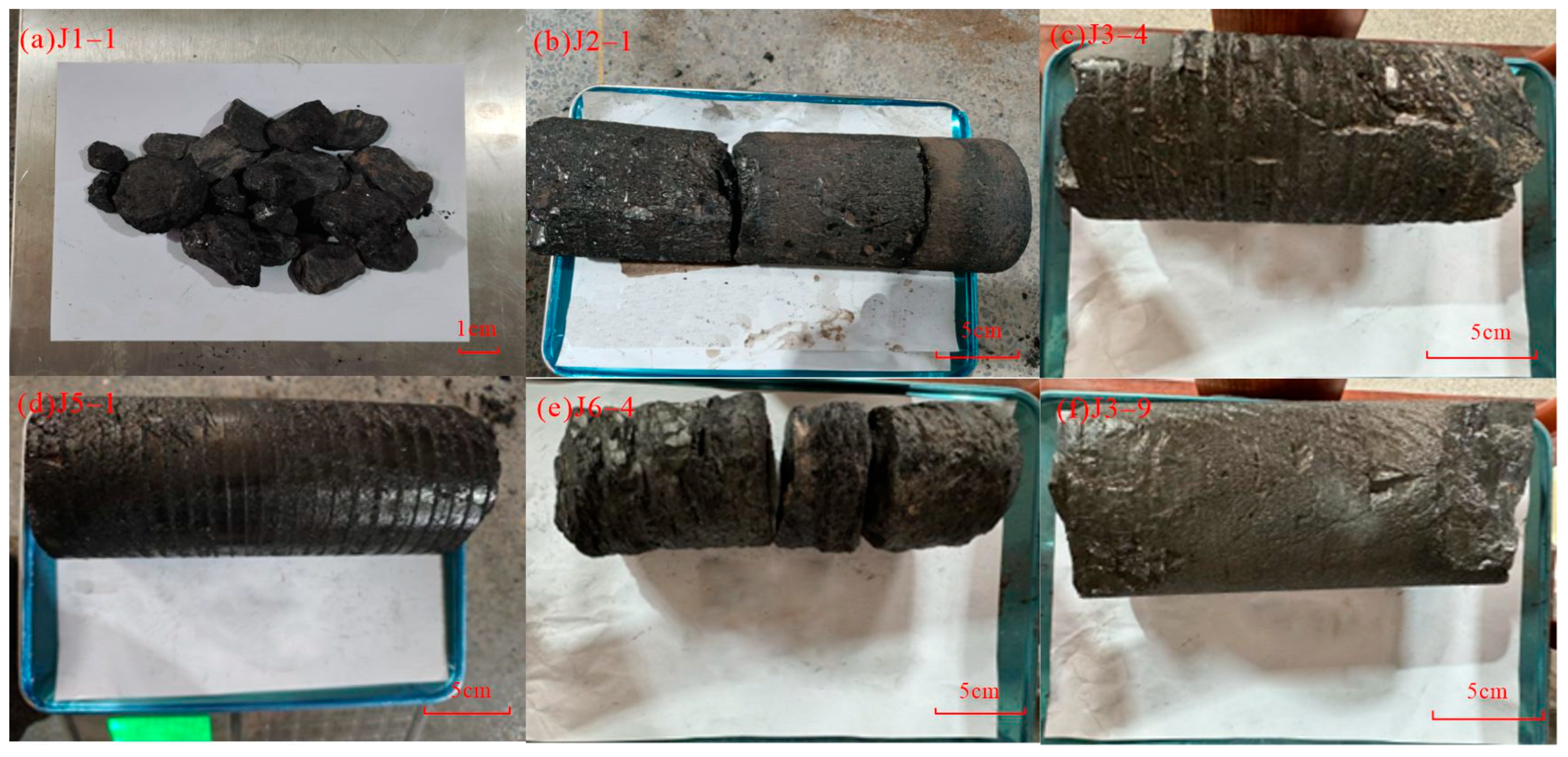

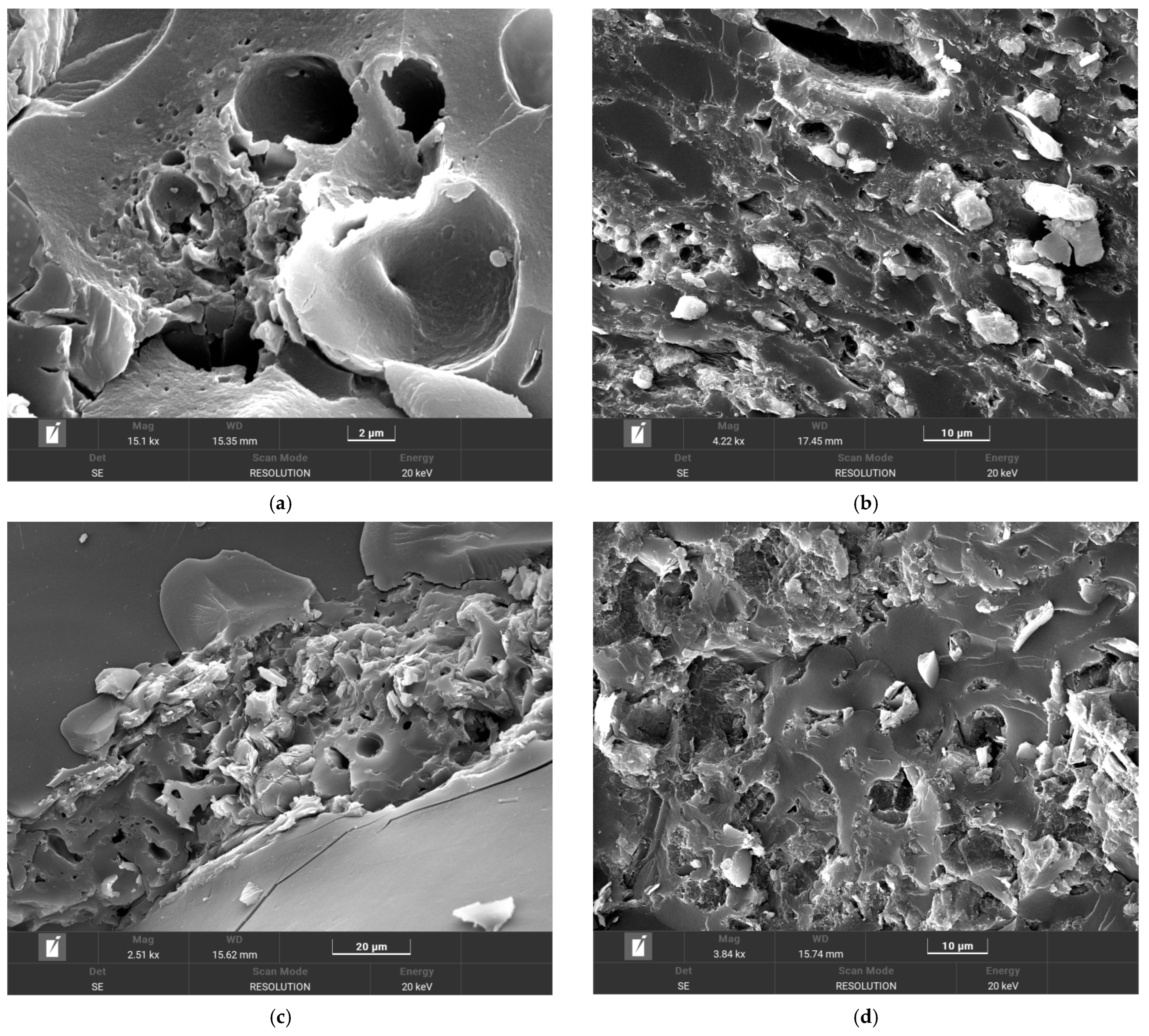

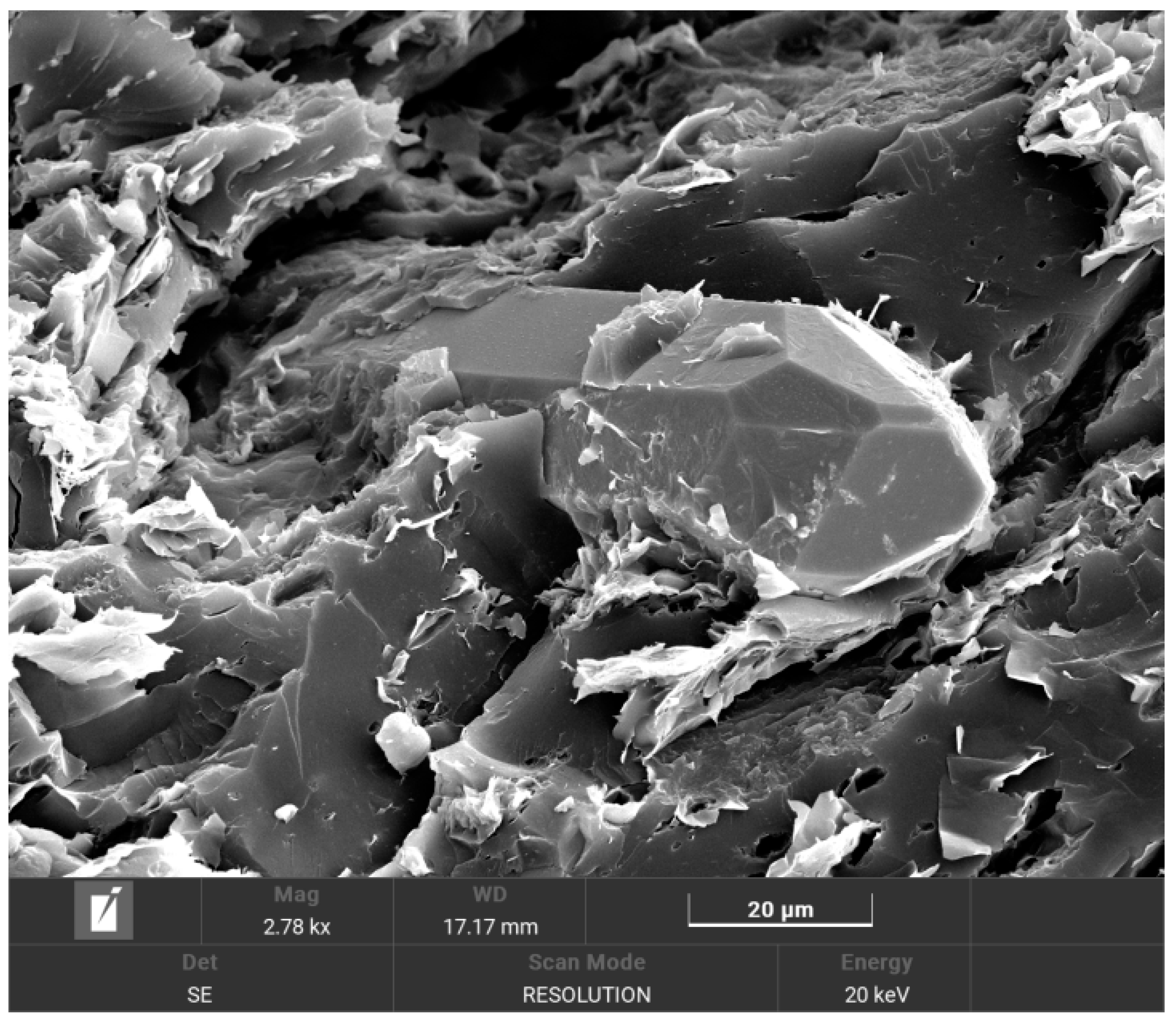

- Based on the SEM and hand specimen identification, the pore-fracture structure of the samples is relatively well developed. Calcite filling the fractures of samples can be seen in the hand specimens of samples. This indicates that the mineral composition has a very important influence on the evolution of the pore-fracture structure of samples.

- This study indicates that pore-fracture structure evolution is influenced by multiple factors, primarily ash content and fixed carbon. As ash content increases, mesopore surface area and volume rise across all sample types, with Type C showing the highest increase (78.1% in surface area and 12.4% in volume compared to Type A). Conversely, micropore characteristics decline, with Type C exhibiting a 4.8% drop in surface area and a 4.7% reduction in volume. The Ro,max of the samples is generally higher than 2.8%, which has a multifaceted impact on pore-fracture structure evolution.

- The gas content is mainly controlled by PV and SSA, with proximate analysis com-ponents and maceral compositions showing minimal direct influence. This suggests that the gas content results from the combined effects of material composition and pore-fracture structure evolution. Inorganic minerals like quartz and calcite indirectly affect gas content by influencing pore structure development—occupying spaces while also creating new pores, especially through calcite dissolution. Conversely, clay minerals generally hinder pore development by filling spaces with limited fracture-forming capacity.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jia, H.M.; Hu, Q.J.; Zhang, C.; He, S.; Sang, L.J.; Li, J.; Liu, C.C. Characteristics and development practice of deep coalbed methane reservoir in the southern part of Ningwu Basin. J. China Univ. Min. Technol. 2025, 54, 149-160+185,1–13. [Google Scholar]

- Shen, J.; Li, K.X.; Zhang, H.W.; Shabbiri, K.; Hu, Q.J.; Zhang, C. The geochemical characteristics, origin, migration and accumulation modes of deep coal-measure gas in the west of Linxing block at the eastern margin of Ordos Basin. J. Nat. Gas Sci. Eng. 2021, 91, 103965. [Google Scholar] [CrossRef]

- Zhao, Z.; Xu, W.L.; Zhao, Z.Y.; Yi, S.W.; Yang, W.; Zhang, Y.Q.; Zhang, W.B.; Shi, Y.P.; Zhang, C.L.; Gao, J.R. Geological characteristics and exploration breakthrough of coalmeasure gas in the Benxi Formation of the Carboniferous system in the Ordos Basin. Pet. Explor. Dev. 2024, 51, 234–247+259. [Google Scholar] [CrossRef]

- Li, Y.; Xu, F.Y.; Tang, S.H.; Wang, Y.B.; Meng, S.Z.; Xu, Q.; Tang, S.H. Progress and development direction of coalbed methane exploration and development in the Ordos Basin. Nat. Gas Ind. 2024, 44, 63–79. [Google Scholar]

- Li, M.R.; Shi, Y.H.; Fan, L.Y.; Dai, X.D.; Jing, X.Y.; Zhang, Y. Comparison of main gas reservoir characteristics between coalmeasure gas and tight sandstone gas in the 8# coal seam of the Upper Paleozoic Benxi Formation in the Ordos Basin. Oil Gas Geol. 2024, 45, 1590–1604. [Google Scholar]

- Huang, D.J.; Zhou, G.X.; Yang, Z.B.; Gu, J.Y.; Jing, X.Y.; Wang, J.N. Geochemical characteristics and geological response of gaswater production from deep coal-measure gas wells in the Ordos Basin. Oil Gas Geol. 2024, 45, 1617–1627. [Google Scholar]

- Gensterblum, Y.; Merkel, A.; Busch, A.; Krooss, B.M.; Littke, R. Gas saturation and CO2 enhancement potential of coalbed methane res-ervoirs as a function of depth. AAPG Bull. 2014, 98, 395–420. [Google Scholar] [CrossRef]

- Chatterjee, R.; Paul, S. Classification of coal reservoir for coal bed methane exploitation in central part of Jharia coalfield, India—A statistical approach. Fuel 2013, 111, 20–29. [Google Scholar] [CrossRef]

- Qin, Y.; Shen, J. On the fundamental issues of deep coalbed methane geology. Acta Petrol. Sin. 2016, 37, 125–136. [Google Scholar]

- Zhu, Q.Y.; Du, X.J.; Zhang, T.; Yu, H.M.; Liu, X.B. Investigation into the variation characteristics and influencing factors of coalbed methane gas content in deep coal reservoir. Sci. Rep. 2024, 14, 18813. [Google Scholar]

- Xiao, C.Y.; Han, D.L.; Zhang, J.J.; Chen, S.Z.; Qin, Z.Y.; Vandeginste, V. Effect of Coal Rank and Coal Facies on Nanopore-Fracture Structure Heterogeneity in Middle-Rank Coal Reservoirs. ACS Omega 2024, 9, 33279–33292. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Zhou, G.X.; Jing, X.Y.; Zhang, J.Y.; Wu, C.J. Fractal characteristics and reservoir formation mechanism of deep coal-measure in the Benxi Formation in the central-eastern Ordos Basin. J. Xi’an Shiyou Univ. (Nat. Sci. Ed.) 2024, 39, 1–11. [Google Scholar]

- Ouyang, Z.; Wang, H.; Sun, B.; Liu, Y.; Fu, X.; Dou, W.; Du, L.; Zhang, B.; Luo, B.; Yang, M.; et al. Quantitative prediction of deep coalbed methane content in DaningJixian Block, Ordos Basin, China. Processes 2023, 11, 3093. [Google Scholar] [CrossRef]

- Liu, B.; Huang, W.H.; Ao, W.H.; Zhang, S.R.; Wu, J.; Xu, Q.L.; Teng, J. Adsorption characteristics of high-rank coal and its influencing factors: A case study of the Shizhuang Block in the Qinshui Basin. J. Xi’an Shiyou Univ. (Nat. Sci. Ed.) 2014, 29, 31–37+5–6. [Google Scholar]

- Mastalerz, M.; Drobniak, A.; Schimmelmann, A. Changes in optical properties, chemistry, and micropore and mesopore characteristics of bituminous coal at the contact with dikes in the Illinois Basin. Int. J. Coal Geol. 2009, 77, 310–319. [Google Scholar] [CrossRef]

- Karacan, C.Ö.; Ruiz, F.A.; Cotè, M.; Phipps, S. Coal mine methane: A review of capture and utilization practices with benefits to mining safety and to greenhouse gas reduction. Int. J. Coal Geol. 2011, 86, 121–156. [Google Scholar] [CrossRef]

- Yang, Y.Y. Influence of Indosinian Qinling orogeny on the sedimentary characteristics of the Yanc-hang Formation in the Ordos Basin. Coal Geol. Explor. 2004, 5, 7–9. [Google Scholar]

- Zeng, L.B.; Li, Z.X.; Shi, C.E.; Wang, Z.G.; Zhao, J.Y.; Wang, Y.K. Characteristics and genesis of fractures in the ultra-low permeability sandstone reservoirs of the Upper Triassic Yanchang Formation in the Ordos Basin. Acta Geol. Sin. 2007, 2, 174–180. [Google Scholar]

- Chen, Z.J.; Ren, Z.L.; Zhao, J.Z.; Zhao, X.Y.; Gao, X.P.; Qiang, T.; Lei, Y.Y.; Liu, T. Characteristics and types analysis of tight gas reservoirs in the second member of the Shanxi Formation in the Yan’an Gas Field, Ordos Basin. J. Cent. South Univ. (Sci. Technol.) 2016, 47, 1625–1636. [Google Scholar]

- Yu, T.J.; Quan, M.; Luo, W.Q.; Jin, H.; Wan, Y.P.; Tang, M.M.; Chen, G. Semi-quantitative prediction of reservoir thickness using seismic multi-attributes: A case study of the Shan 2 reservoir in the southeastern Ordos Basin. J. Xi’an Shiyou Univ. (Nat. Sci. Ed.) 2024, 39, 50–58+70. [Google Scholar]

- Chang, X.C.; Han, R.Y.; Zhang, J.J.; Vandeginste, V.; Zhang, X.Y.; Liu, Y.; Han, S.B. Prediction of coal body structure of deep coal reservoirs using logging curves: Principal component analysis and evaluation of factors influencing coal body structure distribution. Nat. Resour. Res. 2024, 34, 1023–1044. [Google Scholar] [CrossRef]

- Mahamud, M.M.; Menéndez, J.M.; Álvarez, A. Fractal Analysis of CO2 and N2 Adsorption Data to Assess Textural Changes during Char Gasification. Fuel Process. Technol. 2019, 189, 15–27. [Google Scholar] [CrossRef]

- Han, S.B.; Xie, L.F.; Du, X.; Xiang, C.H.; Huang, J.; Tang, Z.Y.; Wang, C.S.; Horsfield, B.; Mahlstedt, N. Insights into organic metagenesis using Raman spectroscopy and high resolution mass spectrometry: A case study of the Shahezi formation, deep Songliao basin, China. Int. J. Coal Geol. 2023, 265, 104153. [Google Scholar] [CrossRef]

- Rai, S.; Rai, A.; Kumar, K.; Naik, A.S.; Singh, N.S.; Srivastava, D.K.; Singh, P.K. Study of micro-structures and their relation with occurrence of mineral matter in Ramagundam Coals, Godavari Basin, India: Implications on coal and hydrocarbon industries. J. Geol. Soc. India 2022, 98, 88–92. [Google Scholar] [CrossRef]

- Han, S.B.; Bai, S.T.; Tang, Z.Y.; Rui, Y.R.; Gong, D.J.; Zhang, J.C. Nitrogen-rich gas shale logging evaluation and differential gas-bearing characterization of lower Cambrian formation in northern Guizhou, south China. Mar. Pet. Geol. 2020, 115, 104270. [Google Scholar] [CrossRef]

- Wang, B.W.; Li, W. Study on the influence of ash content on coal pore structure based on smallangle X-ray scattering. Saf. Coal Mines 2017, 1, 149–153. [Google Scholar]

- Yang, G.; Qin, Y.; Wu, C.F.; Li, S.H. Pore structure characteristics of low-rank coal in the Xishanyao Formation of the Heshuo Tuoluogai Basin, Xinjiang. Coal Sci. Technol. 2017, 45, 123–130. [Google Scholar]

- Hao, S.X.; Wang, C.Y.; Jiang, C.F. Influence of fixed carbon on pore structure and methane adsorption capacity of coal. J. China Coal Soc. 2012, 37, 1477–1482. [Google Scholar]

- Zhao, X.L.; Tang, D.Z.; Xu, H.; Tao, S.; Chen, Z.L. Influence of coal metamorphism on the development of pore systems in coal reservoirs. J. China Coal Soc. 2010, 35, 1506–1511. [Google Scholar]

- Alpern, B.; De Sousa, M.L.; Flores, D. A progress report on the Alpern Coal Classification. Int. J. Coal Geol. 1989, 13, 1–19. [Google Scholar] [CrossRef]

- Hazra, B.; Wood, D.A.; Panda, M.; Sethi, C.; Vishal, V.; Chandra, D.; Ostadhassan, M. Pore Structural Complexities and Gas Storage Capacity of Indian Coals with Various Thermal Maturities. Energy Fuels 2025, 39, 5818–5831. [Google Scholar] [CrossRef]

- Niu, X.B.; Fan, L.Y.; Yan, X.X.; Zhou, G.X.; Zhang, H.; Jing, X.Y.; Zhang, M.B. Enrichment conditions and resource potential of coal-measure gas in the Ordos Basin. Pet. Explor. Dev. 2024, 51, 972–985. [Google Scholar] [CrossRef]

- Xu, H.; Tang, D.Z.; Tao, S.; Li, S.; Tang, S.L.; Chen, S.D.; Zong, P.; Dong, Y. Differences in geological conditions and formation mechanisms of deep and shallow coalbed methane. Coal Geol. Explor. 2024, 52, 33–39. [Google Scholar]

- Yao, P.; Zhang, J.J.; Lv, D.W.; Vandeginste, V.; Chang, X.C.; Zhang, X.Y.; Wang, D.D.; Han, S.B.; Liu, Y. Effect of water occurrence in coal reservoirs on the production capacity of coalbed methane by using NMR simulation technology and production capacity simulation. Geoenergy Sci Eng. 2024, 243, 213353. [Google Scholar] [CrossRef]

| Sample No. | Types | Depth, m | Vitrinite (%) | Liptinite (%) | Inertinite (%) | Inoriganic Mineral (%) | Ro,max,% | Mad,% | Aad,% | Vad,% | FCad,% |

|---|---|---|---|---|---|---|---|---|---|---|---|

| J5-2 | A | 2103.56 | 87.2 | 7.8 | 0 | 5 | 2.87 | 1.3 | 4.61 | 7.48 | 86.61 |

| J5-5 | A | 2165.16 | 81.2 | 12.4 | 0 | 6.4 | 3.04 | 1.1 | 5 | 6.78 | 87.12 |

| J2-1 | A | 3001.45 | 85.6 | 9 | 0 | 5.4 | 3.08 | 1.94 | 5.84 | 7.18 | 85.04 |

| J5-4 | A | 2164.8 | 78.4 | 17.2 | 0 | 4.4 | 3.03 | 1.05 | 8.76 | 6.9 | 83.29 |

| J3-9 | A | 2746.63 | 67 | 26.2 | 0 | 6.8 | 3.05 | 1.32 | 9.64 | 7.03 | 82.01 |

| J3-3 | B | 2670.63 | 70.4 | 24 | 0 | 5.6 | 2.91 | 1.42 | 10.98 | 8.48 | 79.12 |

| J2-4 | B | 3076.87 | 84.5 | 5.8 | 0 | 6.2 | 3.25 | 1.21 | 11.67 | 6.65 | 80.47 |

| J6-4 | B | 2468.25 | 80.4 | 13.6 | 0 | 6 | 3.25 | 1.72 | 12.32 | 7.24 | 78.72 |

| J5-1 | B | 2102.66 | 64.8 | 30 | 0 | 5.2 | 2.92 | 0.97 | 12.5 | 6.92 | 79.61 |

| J3-5 | B | 2677.5 | 74.4 | 21.8 | 0 | 3.8 | 2.94 | 1.32 | 12.86 | 7.81 | 78.01 |

| J2-6 | B | 3082.35 | 86 | 6 | 0 | 8 | 3.26 | 1.64 | 13.09 | 7.79 | 77.48 |

| J6-2 | B | 2390.4 | 76.4 | 17.2 | 0 | 6.4 | 3.2 | 1.77 | 13.72 | 6.65 | 77.86 |

| J6-3 | B | 2467.95 | 82.4 | 12 | 0 | 5.6 | 3.21 | 1.81 | 14.34 | 6.69 | 77.16 |

| J2-2 | B | 3002.82 | 85.8 | 9.8 | 0 | 4.4 | 3.05 | 1.4 | 15.28 | 7.79 | 75.53 |

| J3-7 | C | 2745.65 | 66 | 27 | 0 | 7 | 2.97 | 1.12 | 20.31 | 7.52 | 71.05 |

| J6-1 | C | 2389.8 | 79.4 | 15.8 | 0 | 4.8 | 3.09 | 1.77 | 27.89 | 7.8 | 62.54 |

| Sample No. | Quartz (%) | Plagioclase (%) | Calcite (%) | Ankerite (%) | Siderite (%) | Barite (%) | Halite (%) | Total Clay (%) |

|---|---|---|---|---|---|---|---|---|

| J5-2 | 7.7 | / | 8.3 | / | / | 16.7 | 8.2 | 59.1 |

| J5-5 | 8.5 | / | 11.6 | 9.7 | / | 20.3 | / | 49.9 |

| J2-1 | 22.9 | / | 8.1 | 0.6 | / | / | 0.2 | 68.2 |

| J5-4 | 7 | / | 4.5 | / | / | 17.8 | / | 70.7 |

| J3-9 | 2 | / | 1 | 3 | / | 29 | / | 64 |

| J3-3 | 2 | / | 25 | 5 | 5 | / | / | 60 |

| J2-4 | 5.7 | / | 4.8 | 0.2 | / | 16.4 | 1 | 71.9 |

| J6-4 | 6.9 | / | 3.8 | / | / | / | / | 89.3 |

| J5-1 | 29.6 | / | 17.5 | / | 2.4 | / | / | 50.5 |

| J3-5 | 20 | / | 37 | 2 | / | 31 | / | 5 |

| J2-6 | 5.5 | / | 14.4 | 0.3 | / | 19.9 | 1.2 | 58.7 |

| J6-2 | 33 | 6.9 | 17.8 | 1.9 | 0.9 | / | 1 | 38.5 |

| J6-3 | 27.3 | / | 11 | / | / | / | / | 61.7 |

| J2-2 | 22.8 | / | 10.6 | 0.2 | / | / | 1.2 | 65.2 |

| J3-7 | 15 | / | 4 | 1 | 2 | 5 | / | 71 |

| J6-1 | 12.2 | 4 | 10.3 | 4.9 | / | 10 | / | 58.6 |

| Types | Sample No. | Mesoporous | Micropore | ||

|---|---|---|---|---|---|

| Specific Surface Area (m2/g) | Pore Volume (cm3/g) | Specific Surface Area (m2/g) | Pore Volume (cm3/g) | ||

| Type A | J5-2 | 0.0758 | 0.0011 | 169.9290 | 0.0481 |

| J5-5 | 0.0199 | 0.0009 | 160.2140 | 0.0494 | |

| J2-1 | 0.0294 | 0.0010 | 154.3130 | 0.0480 | |

| J5-4 | 0.0264 | 0.0009 | 157.2010 | 0.0444 | |

| J3-9 | 0.0480 | 0.0010 | 168.7510 | 0.0476 | |

| Type B | J3-3 | 0.0187 | 0.0009 | 153.2070 | 0.0429 |

| J2-4 | 0.3068 | 0.0014 | 149.9420 | 0.0467 | |

| J6-4 | 0.2488 | 0.0014 | 163.6040 | 0.0487 | |

| J5-1 | 0.0823 | 0.0009 | 125.7500 | 0.0358 | |

| J3-5 | 0.0214 | 0.0011 | 153.7270 | 0.0434 | |

| J2-6 | 0.3024 | 0.0012 | 171.2460 | 0.0485 | |

| J6-2 | 0.0753 | 0.0011 | 167.7270 | 0.0514 | |

| J6-3 | 0.2867 | 0.0014 | 156.6710 | 0.0471 | |

| J2-2 | 0.1339 | 0.0010 | 122.9360 | 0.0410 | |

| Type C | J3-7 | 0.0570 | 0.0009 | 150.4830 | 0.0434 |

| J6-1 | 1.7609 | 0.0018 | 130.6960 | 0.0391 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Wan, Y.; Gao, H.; Fan, J.; Li, S.; Qiao, L. Evaluation of Pore-Fracture Structures and Gas Content in Deep Coal Reservoir of Yan’an Gas Field, Ordos Basin. Processes 2025, 13, 1177. https://doi.org/10.3390/pr13041177

Wang Z, Wan Y, Gao H, Fan J, Li S, Qiao L. Evaluation of Pore-Fracture Structures and Gas Content in Deep Coal Reservoir of Yan’an Gas Field, Ordos Basin. Processes. 2025; 13(4):1177. https://doi.org/10.3390/pr13041177

Chicago/Turabian StyleWang, Zhenchuan, Yongping Wan, Hongtao Gao, Jinlan Fan, Shan Li, and Liang Qiao. 2025. "Evaluation of Pore-Fracture Structures and Gas Content in Deep Coal Reservoir of Yan’an Gas Field, Ordos Basin" Processes 13, no. 4: 1177. https://doi.org/10.3390/pr13041177

APA StyleWang, Z., Wan, Y., Gao, H., Fan, J., Li, S., & Qiao, L. (2025). Evaluation of Pore-Fracture Structures and Gas Content in Deep Coal Reservoir of Yan’an Gas Field, Ordos Basin. Processes, 13(4), 1177. https://doi.org/10.3390/pr13041177