Analyzing the Impact of Orifice Size and Retention Time in Private Tanks on Water Quality Indicators in Distribution Networks

Abstract

1. Introduction

Summary of the Literature

2. Materials and Methods

2.1. Demand-Driven Analysis (DDA) vs. Pressure-Driven Analysis (PDA)

2.2. Modelling with Integrated Private Tanks

- Vncons (t, Hn(t)) denotes consumer demand, delivered fully if pressure meets minimum service levels; otherwise, calculated using Torricelli’s law.

- Vnpriv-tank (t, Hn(t)) denotes the volume flowing into private tanks, depending on tank status and nodal pressure [29].

- Vnorif (t, Hn(t)) denotes the flow rate through free orifices like hydrants or pipe bursts, either known or pressure-dependent.

- Vntank (t, Hn(t)) denotes the volume flowing into or out of urban tanks, linked to system-wide water balance.

- Vnleak (t, Hn(t)) denotes leakage from the network, modelled as pressure-dependent outflows due to infrastructure flaws (e.g., cracks, joints).

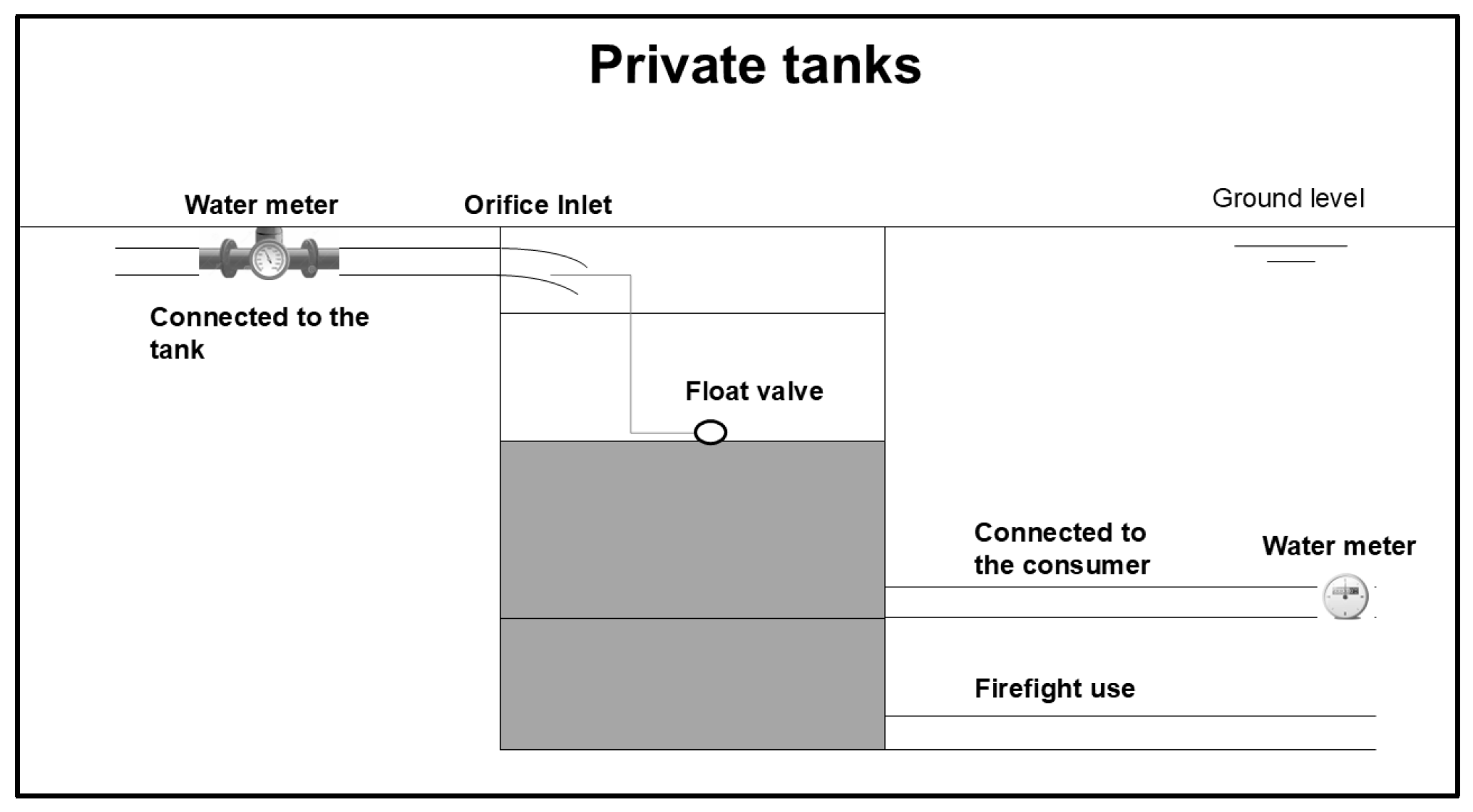

2.3. The Setup of Private Tanks

2.4. Modelling Flow to the Orifices of Private Tanks

2.5. Water Quality Model

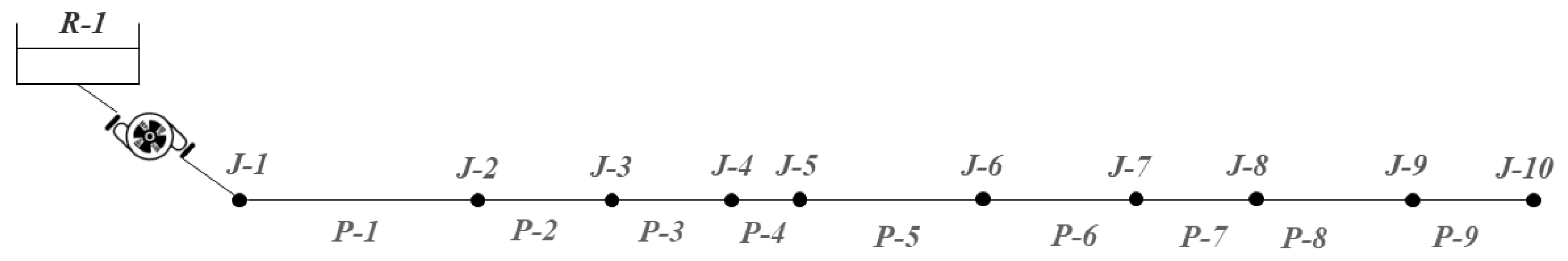

2.6. Sample Networks

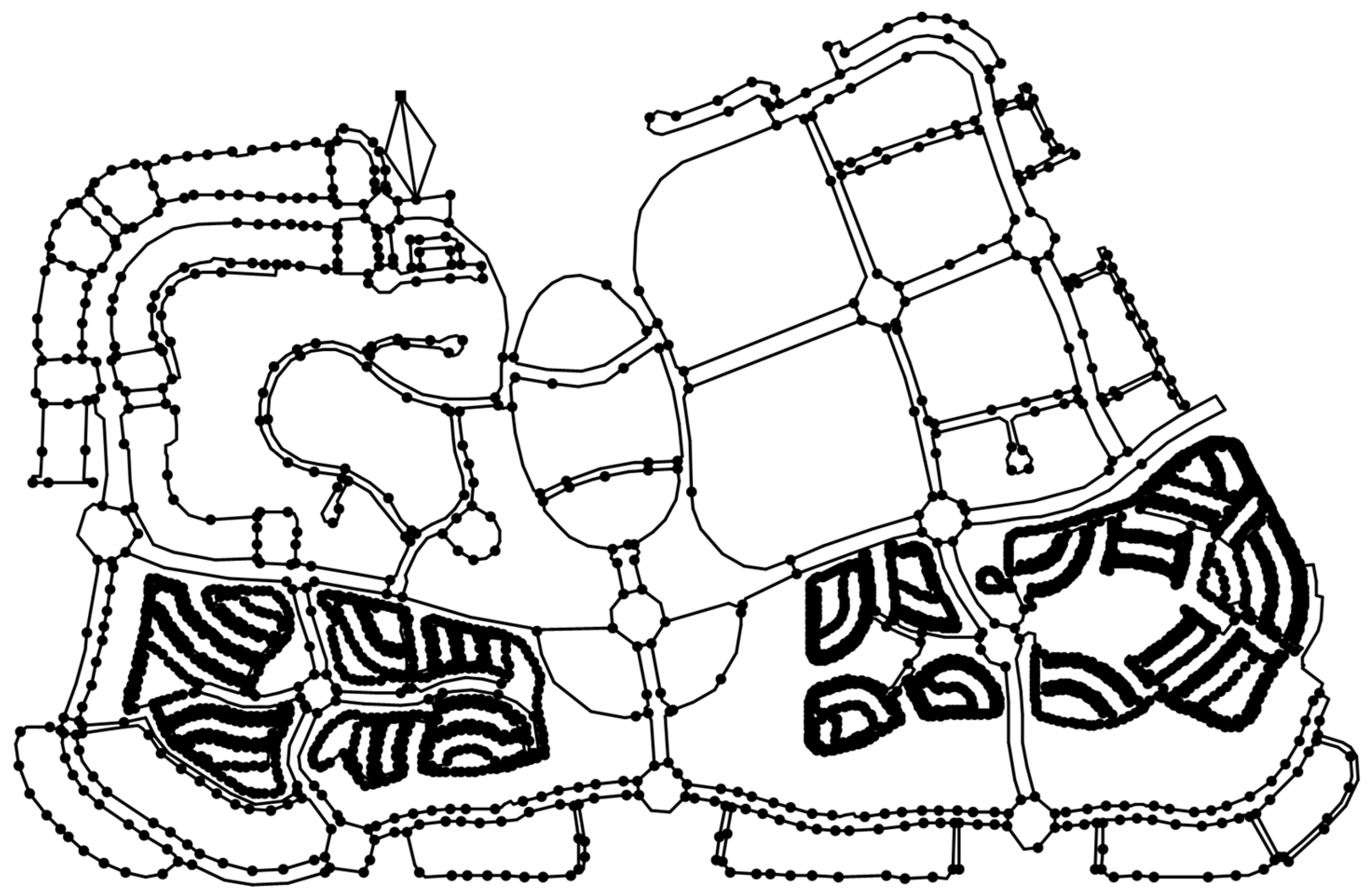

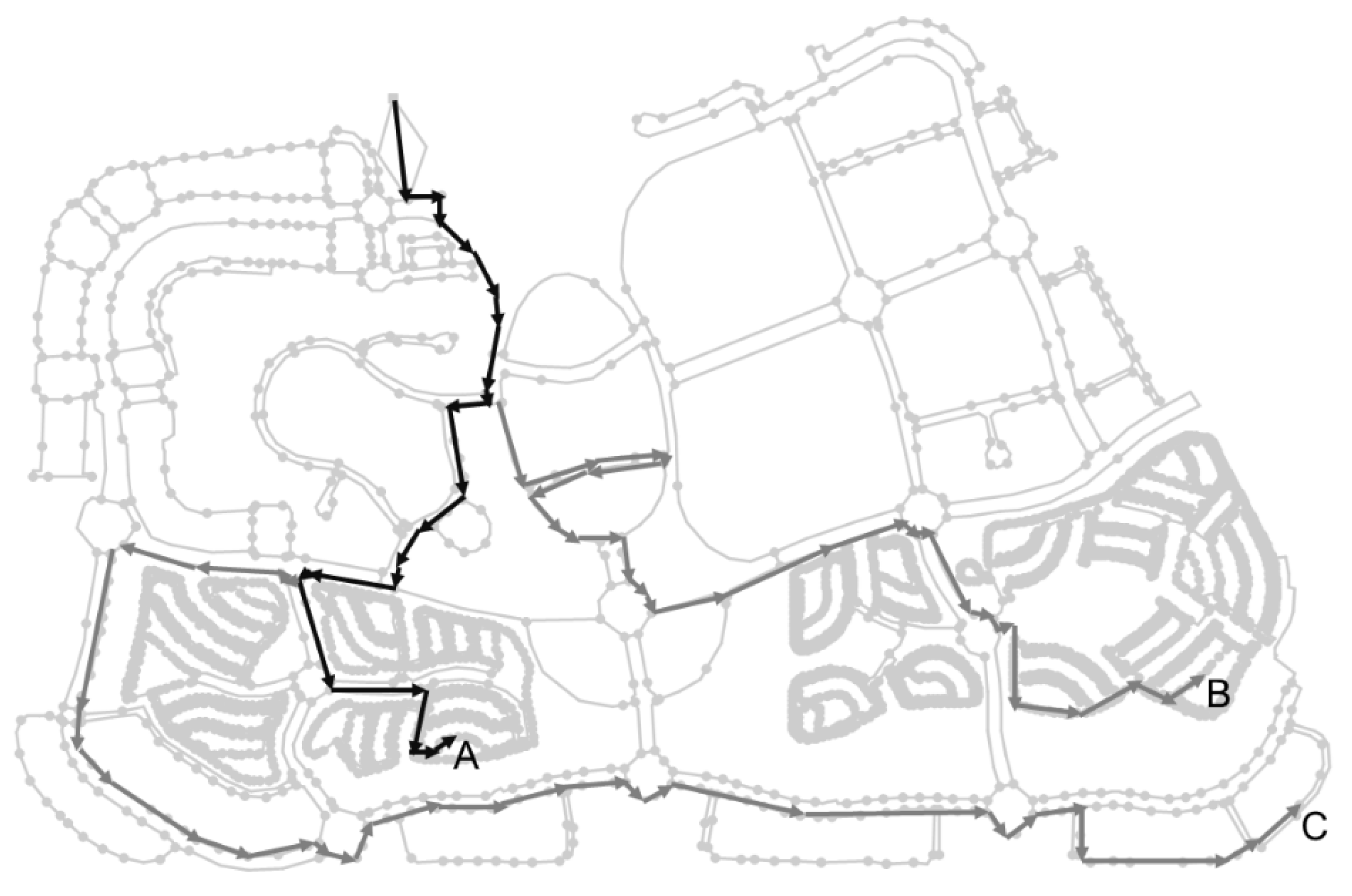

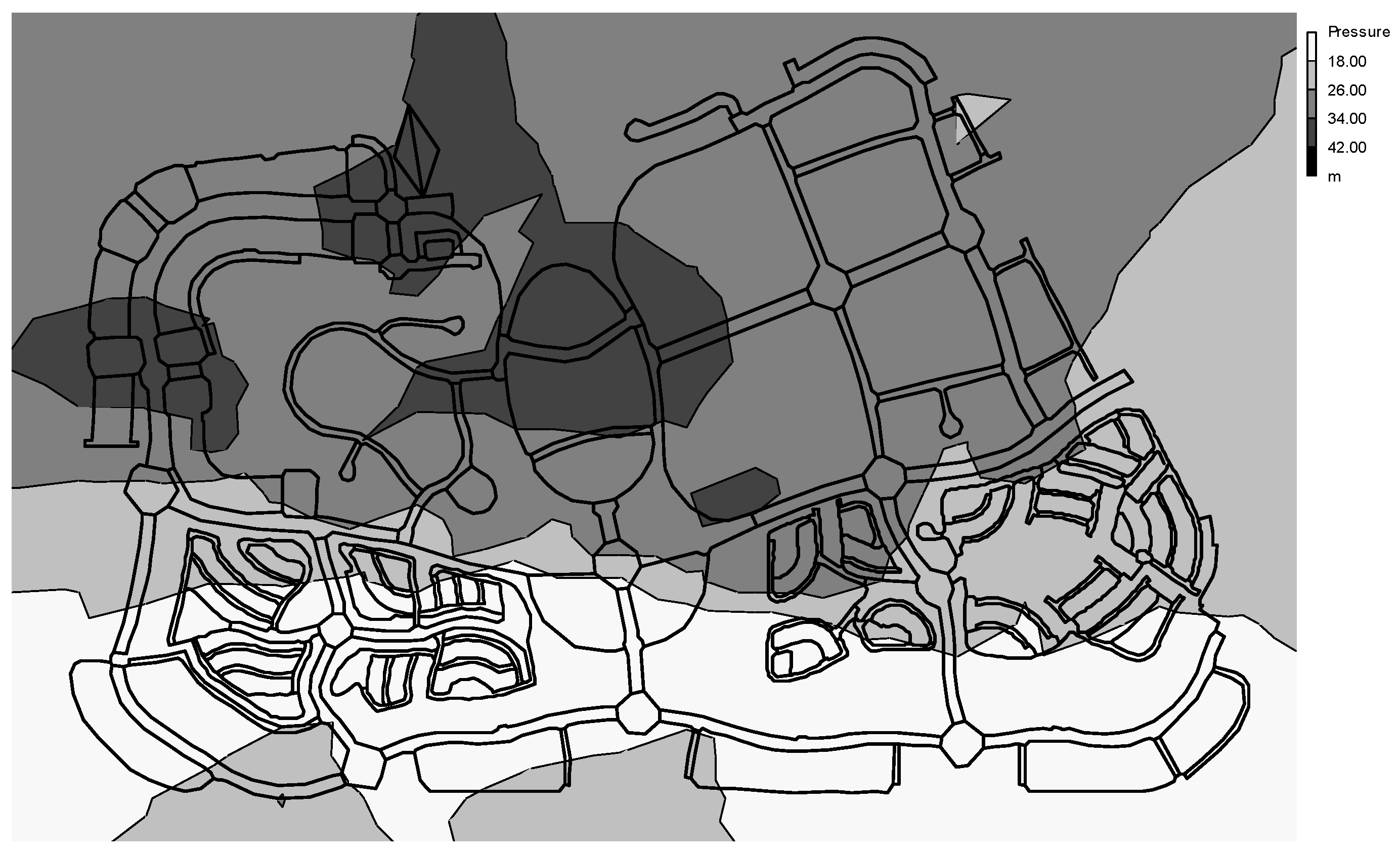

2.7. Real-World Network

2.8. Calibration Process

2.9. Procedure of the Application

- The value for chlorine concentration was updated to reflect any reaction that has occurred over the time interval.

- For each upstream junction, the water from the leading segments of the pipe with the flow was mixed to calculate the new value of chlorine concentration. The volume contributed from each segment would equal the product of the pipe flow and the time interval. With the upcoming flow, if the volume exceeded that of the segment, then the segment was removed, and the next one behind it started contributing to the volume.

- The new quality was calculated for every junction based on the total inflow mass divided by the total inflow volume.

- The concentration at the junction was changed based on the contribution of external water quality sources, such as networks with two reservoirs.

- Finally, a new segment was built in the pipes, and the flow came out of the node. The volume of this new segment was again calculated using the product of the flow rate and time interval. Its quality was equated to the new quality found for the junction.

2.10. Simulation

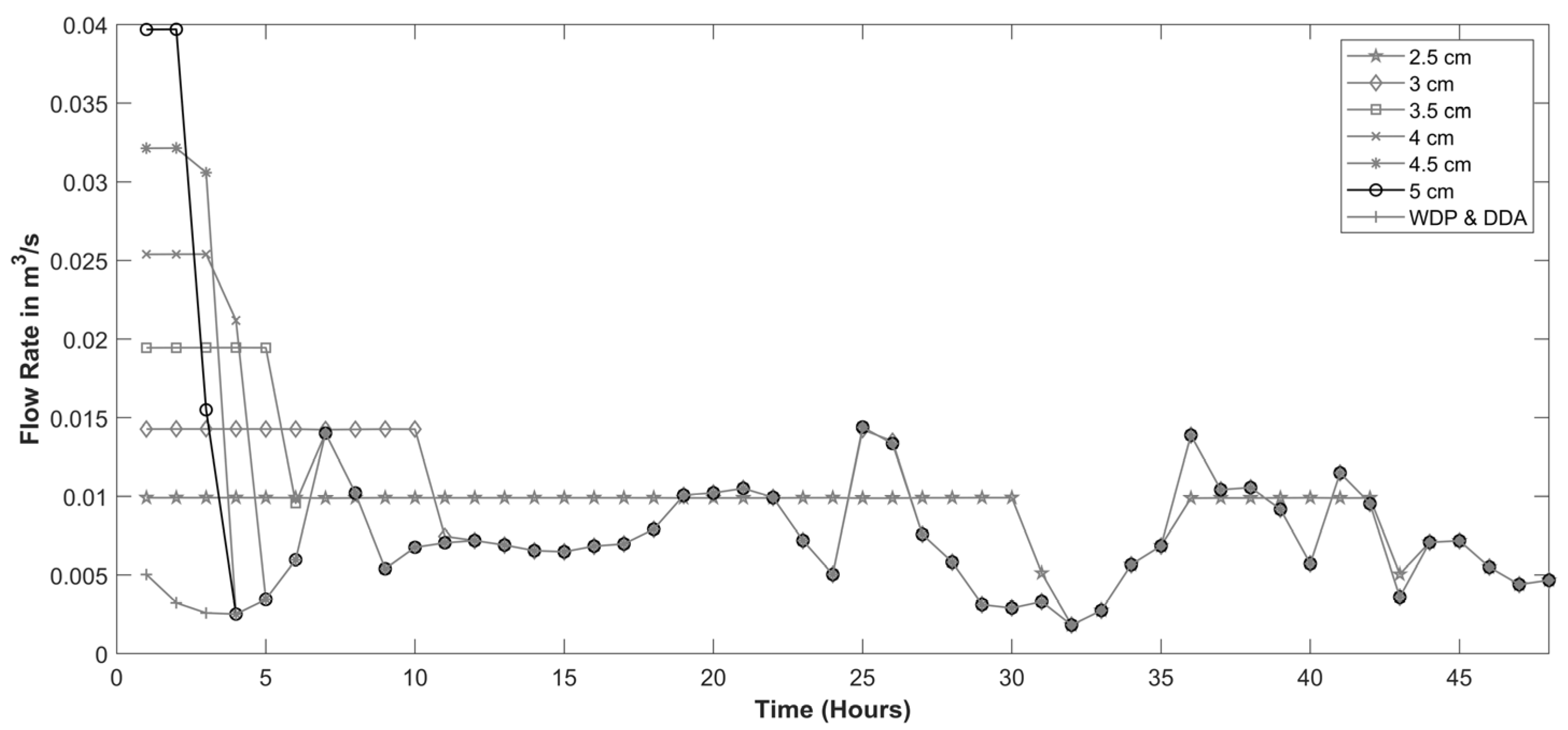

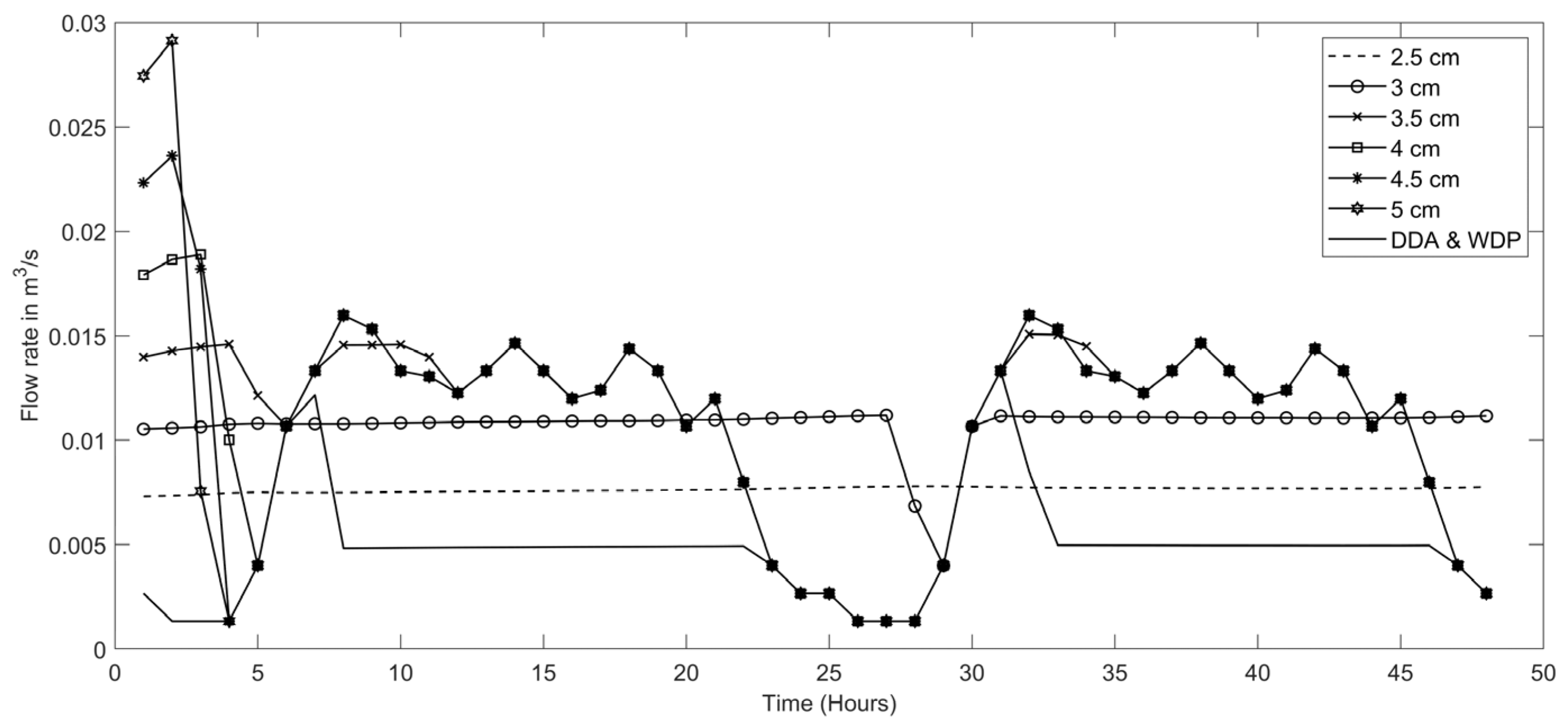

- Networks 1, 2, and DSO were run using DDA in EPANET, followed by the integration of private tanks using different orifice sizes and retention times under PDA.

- The water quality parameters (wall coefficient, bulk coefficient, limiting concentration and wall correlation) were selected based on this region.

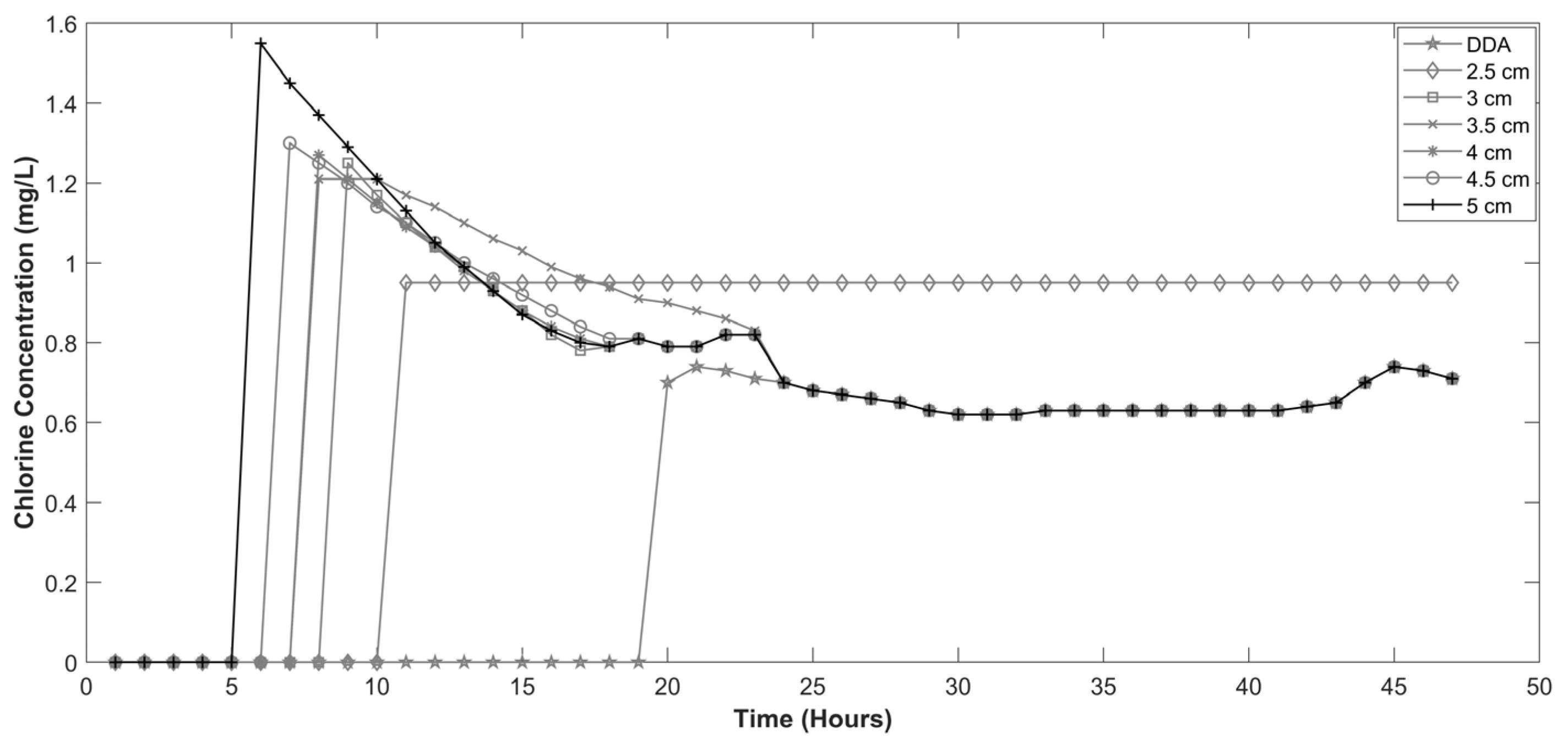

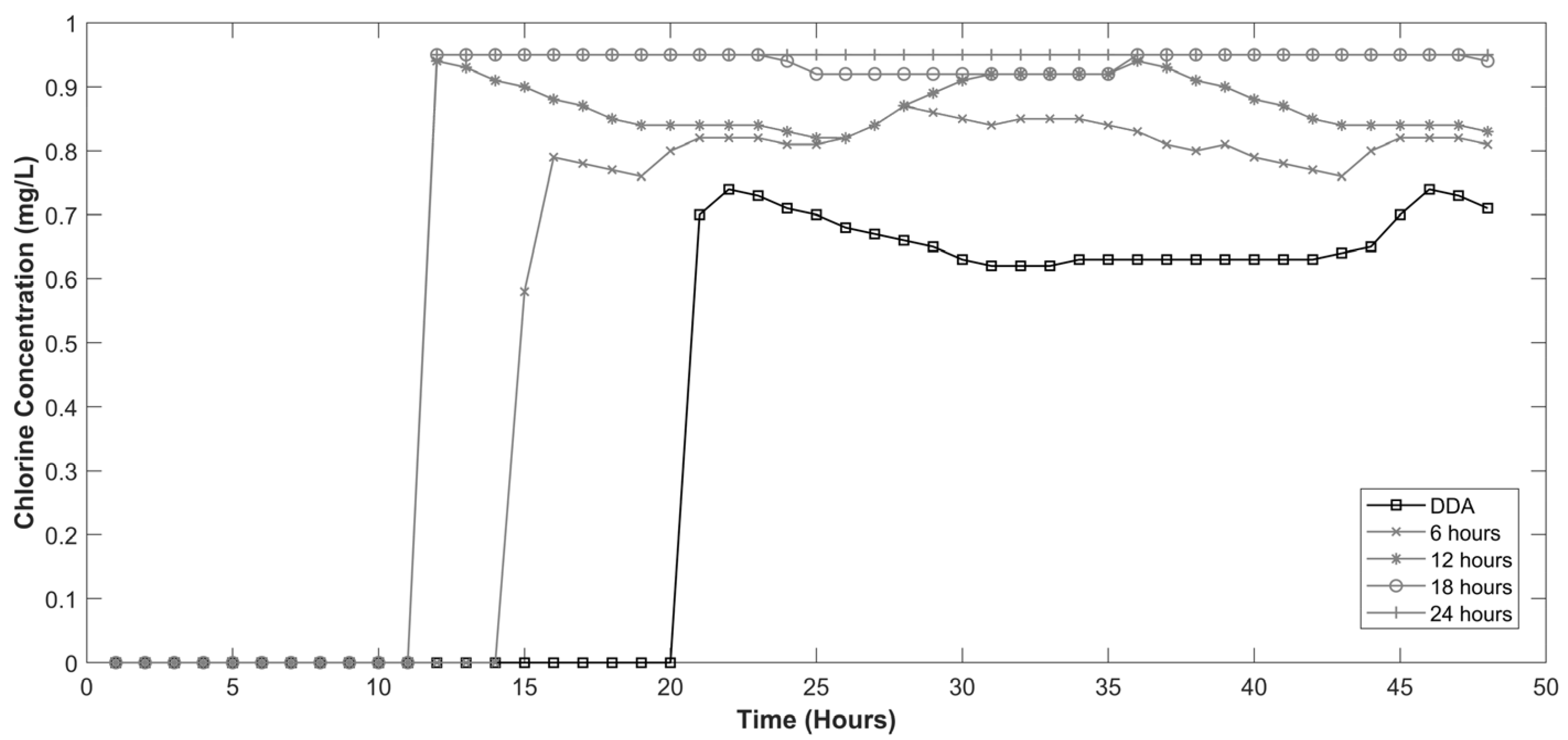

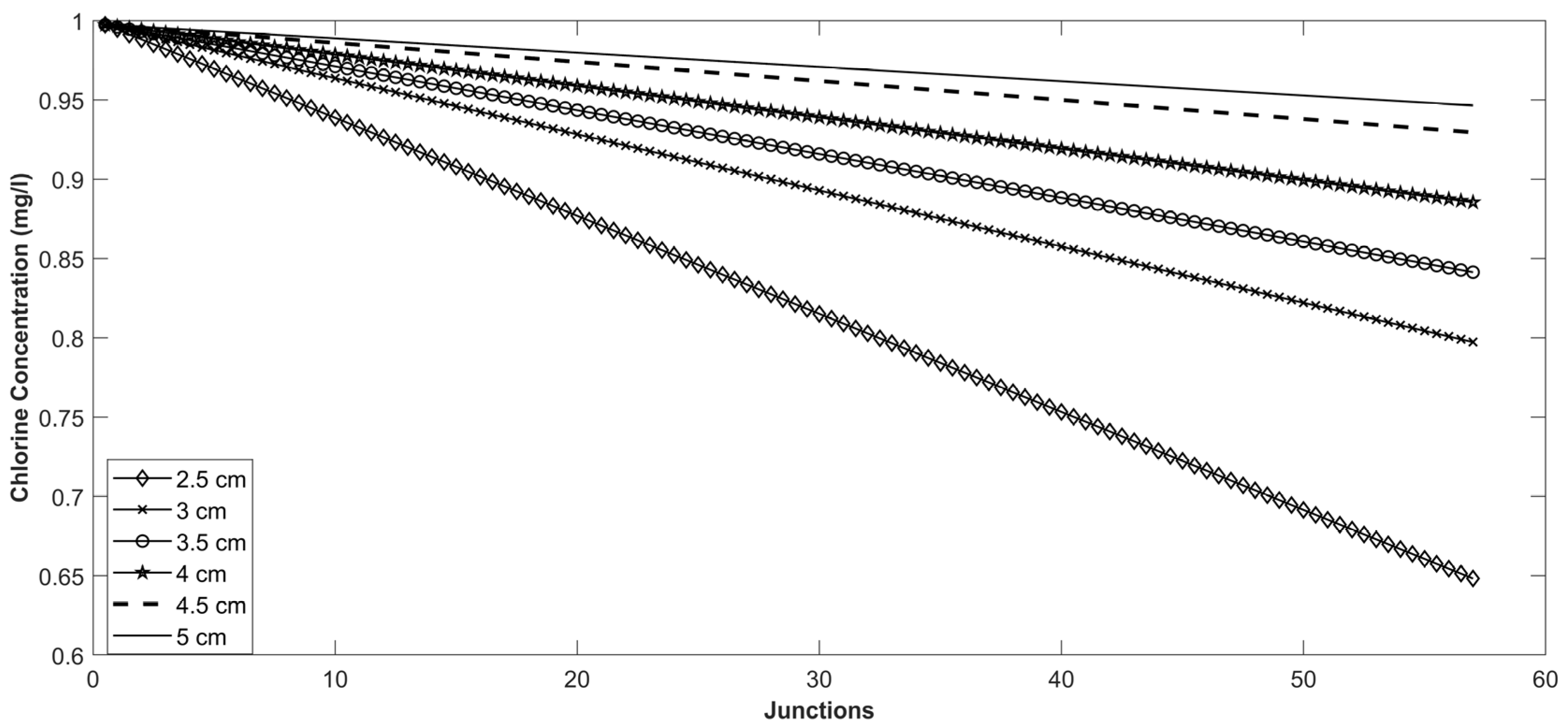

- The selected range of orifice size varied from 2 cm to 5 cm; the retention time varied from 6 h to 24 h.

- Each variation of orifice size was tested using LTA while keeping the retention time constant.

- Then, the same water quality simulation was performed by changing the retention time of the private tanks whilst keeping the orifice size the same.

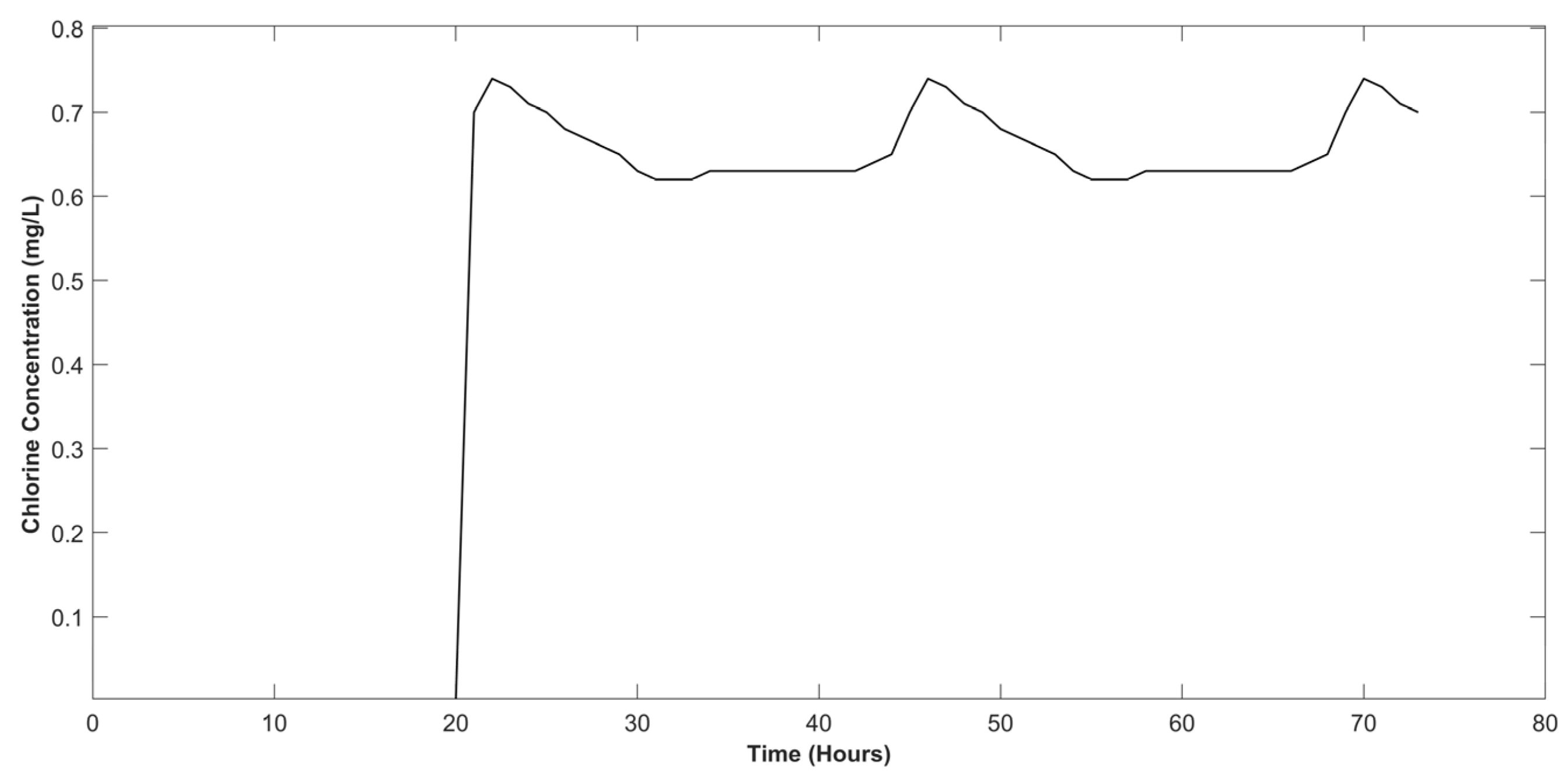

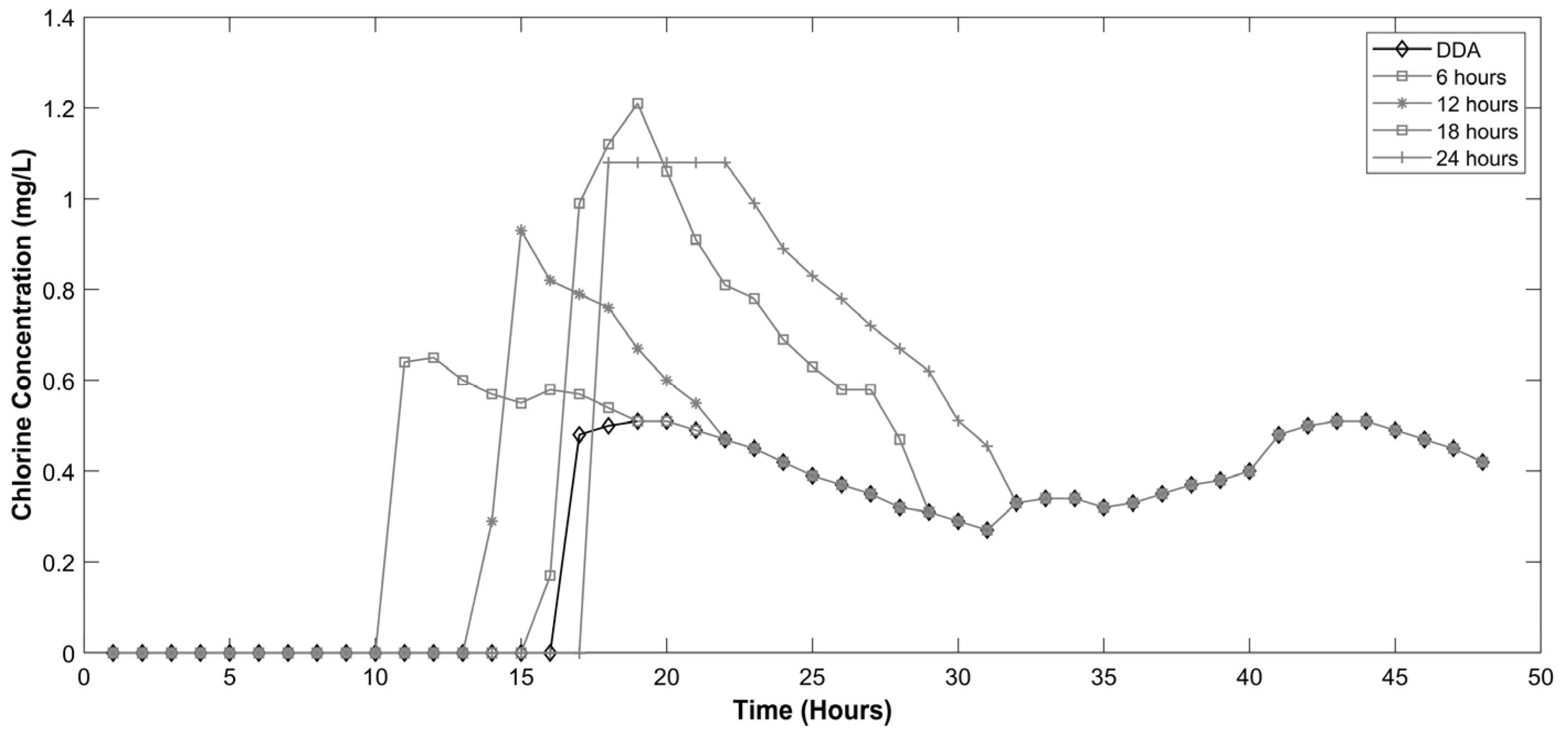

- A comparison of chlorine concentrations over time was graphed for the different scenarios.

3. Results and Discussion

3.1. Impact of Orifice Size on Chlorine Concentration

3.2. Impact of Retention Time on Chlorine Concentration

3.3. Reliability Analysis for the Real-Time Network

3.4. Error Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| WDN | Water Distribution Network |

| DSO | Dubai Silicon Oasis |

| LTA | Lagrangian Time-Driven Method |

| PDA | Pressure-Driven Analysis |

| DDA | Demand-Driven Analysis |

| EDM | Lagrangian Event Driven Method |

| WDP | Water Demand Profile |

| DEWA | Dubai Electricity and Water Authority |

| GIS | Geographic Information System |

| LCM | Linear Compartment Model |

| EPS | Extended Period Simulation |

References

- García-Ávila, F.; Avilés-Añazco, A.; Ordoñez-Jara, J.; Guanuchi-Quezada, C.; Flores del Pino, L.; Ramos-Fernández, L. Modeling of residual chlorine in a drinking water network in times of pandemic of the SARS-CoV-2 (COVID-19). Sustain. Environ. Res. 2021, 31, 12. [Google Scholar] [CrossRef]

- Boulos, P.F.; Altman, T.; Jarrige, P.A.; Collevati, F. Discrete simulation approach for network-water-quality models. J. Water Resour. Plan. Manag. 1995, 121, 49–60. [Google Scholar] [CrossRef]

- Mau, R.E.; Boulos, P.F.; Bowcock, R.W. Modelling distribution storage water quality: An analytical approach. Appl. Math. Model. 1996, 20, 329–338. [Google Scholar] [CrossRef]

- Hallam, N.B.; West, J.R.; Forster, C.F.; Powell, J.C.; Spencer, I. The decay of chlorine associated with the pipe wall in water distribution systems. Water Res. 2002, 36, 3479–3488. [Google Scholar] [CrossRef]

- Chhipi-Shrestha, G.; Mohammadiun, S.; Ishaq, S.; Hu, G.; Mian, H.; Pokhrel, S.; Hewage, K.; Sadiq, R. Modeling hydraulics and water quality in distribution networks: A review of existing mathematical techniques and software. In Water Engineering Modeling and Mathematic Tools; Elsevier: Amsterdam, The Netherlands, 2021; pp. 187–212. [Google Scholar]

- Chun, D.G.; Selznick, H.L. Computer modeling of distribution system water quality. In Computer Applications in Water Resources; ASCE: Reston, VA, USA, 1985; pp. 448–456. [Google Scholar]

- Males, R.M.; Grayman, W.M.; Clark, R.M. Modeling water quality in distribution systems. J. Water Resour. Plan. Manag. 1988, 114, 197–209. [Google Scholar] [CrossRef]

- Murphy, S.B. Modeling Chlorine Concentrations in Municipal Water Systems. Doctoral Dissertation, College of Engineering, Montana State University-Bozeman, Bozeman, MT, USA, 1985. [Google Scholar]

- Shah, M.; Sinai, G. Steady state model for dilution in water networks. J. Hydraul. Eng. 1988, 114, 192–206. [Google Scholar] [CrossRef]

- Wood, D.J.; Ormsbee, L.E. Supply identification for water distribution systems. J.-Am. Water Work. Assoc. 1989, 81, 74–80. [Google Scholar] [CrossRef]

- Fowler, A.G.; Jones, P. Simulation of water quality in water distribution systems. In Proceedings of the Water Quality Modeling in Distribution Systems 1991, Cincinnati, OH, USA, 4–5 February 1991; pp. 4–5. [Google Scholar]

- Rossman, L.; Boulos, P.; Altman, T. Discrete Volume-Element Method for Network Water-Quality Models. J. Water Resour. Plan. Manag. 1993, 119, 505–517. [Google Scholar] [CrossRef]

- Clark, R.M.; Grayman, W.M.; Males, R.M.; Hess, A.F. Modeling contaminant propagation in drinking-water distribution systems. J. Environ. Eng. 1993, 119, 349–364. [Google Scholar] [CrossRef]

- Liou, C.P.; Kroon, J.R. Modeling the propagation of waterborne substances in distribution networks. J.-Am. Water Work. Assoc. 1987, 79, 54–58. [Google Scholar] [CrossRef]

- Grayman, W.M.; Clark, R.M.; Males, R.M. Modeling distribution-system water quality; dynamic approach. J. Water Resour. Plan. Manag. 1988, 114, 295–312. [Google Scholar] [CrossRef]

- Tansley, N.S.; Brammer, L.F. Chlorine residual modelling in distribution: The improvement of taste and the maintenance of effective disinfection. In Integrated Computer Applications in Water Supply (Vol. 2) Applications and Implementations for Systems Operation and Management; John Wiley and Sons Ltd.: West Sussex, UK, 1994; pp. 111–126. [Google Scholar]

- Kiéné, L.; Lu, W.; Lévi, Y. Relative importance of the phenomena responsible for chlorine decay in drinking water distribution systems. Water Sci. Technol. 1998, 38, 219–227. [Google Scholar] [CrossRef]

- Lu, W.; Kiéné, L.; Lévi, Y. Chlorine demand of biofilms in water distribution systems. Water Res. 1999, 33, 827–835. [Google Scholar] [CrossRef]

- Ostfeld, A.; Kogan, D.; Shamir, U. Reliability simulation of water distribution systems–single and multiquality. Urban Water 2002, 4, 53–61. [Google Scholar] [CrossRef]

- Gupta, R.; Dhapade, S.; Ganguly, S.; Bhave, P.R. Water quality based reliability analysis for water distribution networks. ISH J. Hydraul. Eng. 2012, 18, 80–89. [Google Scholar] [CrossRef]

- Tryby, M.E.; Boccelli, D.L.; Uber, J.G.; Rossman, L.A. Facility location model for booster disinfection of water supply networks. J. Water Resour. Plan. Manag. 2002, 128, 322–333. [Google Scholar] [CrossRef]

- Kang, D.; Lansey, K. Real-time optimal valve operation and booster disinfection for water quality in water distribution systems. J. Water Resour. Plan. Manag. 2010, 136, 463–473. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, G.; Yang, Z. Analysis of water quality characteristic for water distribution systems. J. Water Reuse Desalin. 2019, 9, 152–162. [Google Scholar] [CrossRef]

- Belcaid, A.E.; Taghlabi, F.; Tounsi, A. Chlorine Decay Modeling in a Water Distribution Network in Mohammedia City, Morocco. Ecol. Eng. Environ. Technol. (EEET) 2023, 24, 269–278. [Google Scholar] [CrossRef]

- Giustolisi, O.; Ciliberti, F.G.; Berardi, L.; Laucelli, D.B. Leakage Management Influence on Water Age of Water Distribution Networks. Water Resour. Res. 2023, 59, e2021WR031919. [Google Scholar] [CrossRef]

- García-Avila, F.; Asitimbay-Barbecho, G.; Espinoza-Bustamante, M.; Valdiviezo-Gonzales, L.; Sánchez-Cordero, E.; Cabello-Torres, R.; Gutiérrez-Ortega, H. Water age in drinking water distribution systems: A case study comparing tracers and EPANET. Case Stud. Chem. Environ. Eng. 2024, 10, 100817. [Google Scholar] [CrossRef]

- Li, Z.; Liu, H.; Zhang, C.; Fu, G. Real-time water quality prediction in water distribution networks using graph neural networks with sparse monitoring data. Water Res. 2024, 250, 121018. [Google Scholar] [CrossRef] [PubMed]

- Giustolisi, O.; Berardi, L.; Laucelli, D. Generalizing WDN simulation models to variable tank levels. J. Hydroinform. 2012, 14, 562–573. [Google Scholar] [CrossRef]

- Giustolisi, O.; Berardi, L.; Laucelli, D. Modeling Local Water Storages Delivering Customer Demands in WDN Models. J. Hydraul. Eng. 2014, 140, 89–104. [Google Scholar] [CrossRef]

- DEWA. Guide to Water Supply Regulations-Issue 5; Dubai Electricity and Water Authority: Dubai, United Arab Emirates, 2020. [Google Scholar]

- Rizvi, S.; Rustum, R.; Giustolisi, O.; Wright, G.; Arthur, S.; Berardi, L. Effects of Orifice Diameter and Retention Time of Local Tanks on the Reliability and Carbon Footprint of Water Distribution Networks. J. Water Resour. Plan. Manag. 2021, 147, 05021023. [Google Scholar] [CrossRef]

- Slavik, I.; Oliveira, K.R.; Cheung, P.B.; Uhl, W. Water quality aspects related to domestic drinking water storage tanks and consideration in current standards and guidelines throughout the world–a review. J. Water Health 2020, 18, 439–463. [Google Scholar] [CrossRef]

- Cvelihárová, D.; Pauliková, A.; Kopilčáková, L.; Eštoková, A.; Stefanova, M.G.; Dománková, M.; Šutiaková, I.; Kusý, M.; Moravčíková, J.; Hazlinger, M. Optimization of the Interaction Transport System—Transported Medium to Ensure the Required Water Quality. Water 2023, 15, 2573. [Google Scholar] [CrossRef]

- Liu, B.; Reckhow, D.A.; Li, Y. A two-site chlorine decay model for the combined effects of pH, water distribution temperature and in-home heating profiles using differential evolution. Water Res. 2014, 53, 47–57. [Google Scholar] [CrossRef]

| Retention Time | Orifice Sizes | |||||

|---|---|---|---|---|---|---|

| 2.5 cm | 3 cm | 3.5 cm | 4 cm | 4.5 cm | 5 cm | |

| 6 h | 91% | 92% | 92% | 94% | 94% | 95% |

| 12 h | 94% | 95% | 95% | 96% | 96% | 97% |

| 18 h | 97% | 98% | 98% | 98% | 98% | 98% |

| 24 h | 98% | 99% | 99% | 100% | 100% | 100% |

| Sample Network | Real-World Network | |||

|---|---|---|---|---|

| 1 | 2 | DSO | ||

| Chlorine Concentration (mg/L) | Maximum Change | 0.12 | 0.24 | 0.54 |

| Average Change | 0.12 | 0.15 | 0.29 | |

| SD | 0 | 0.45 | 0.87 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rizvi, S.; Rustum, R. Analyzing the Impact of Orifice Size and Retention Time in Private Tanks on Water Quality Indicators in Distribution Networks. Processes 2025, 13, 1674. https://doi.org/10.3390/pr13061674

Rizvi S, Rustum R. Analyzing the Impact of Orifice Size and Retention Time in Private Tanks on Water Quality Indicators in Distribution Networks. Processes. 2025; 13(6):1674. https://doi.org/10.3390/pr13061674

Chicago/Turabian StyleRizvi, Syed, and Rabee Rustum. 2025. "Analyzing the Impact of Orifice Size and Retention Time in Private Tanks on Water Quality Indicators in Distribution Networks" Processes 13, no. 6: 1674. https://doi.org/10.3390/pr13061674

APA StyleRizvi, S., & Rustum, R. (2025). Analyzing the Impact of Orifice Size and Retention Time in Private Tanks on Water Quality Indicators in Distribution Networks. Processes, 13(6), 1674. https://doi.org/10.3390/pr13061674