Changes in Pore Structure and Gas Adsorption–Desorption Characteristics of Coal Under High-Voltage Electric Pulses

Abstract

1. Introduction

2. Experimental

2.1. Material Preparation

2.2. Experimental System

2.3. Experimental Procedures

- (1)

- The prepared coal blocks were submerged in tap water for 24 h to ensure complete saturation, thereby minimizing strength variations during HVEP treatment.

- (2)

- The coal blocks were placed horizontally, parallel to the bedding direction, at the base of an integrated stainless steel water tank. To prevent the movement of the coal blocks during the experiment, the water tank was securely welded to an outer stainless-steel layer. Positioning the coal blocks horizontally ensured that the electrical pulse shock wave aligned with the bedding plane of the coal layer, thereby effectively simulating the actual depositional environment of a coal reservoir.

- (3)

- The electrodes connected to the high-voltage cable were slowly placed in the water tank, ensuring that the electrode gaps aligned with the center of the coal blocks. A fixing bracket was used to secure the electrodes in a vertical position, ensuring that the shock wave release window remained centered on the coal blocks during discharge.

- (4)

- Water was added to the tank until it reached 20 cm above the coal blocks. The high-voltage charging power supply was subsequently turned on to charge the energy storage capacitor bank. Once the predetermined voltage was reached, the power supply was deactivated, and the discharge switch was triggered to start the HVEP discharge process. The oscilloscope data were recorded. After each discharge, the electrodes and brackets were inspected for looseness and re-secured if necessary. This process was repeated until the set number of discharges (five in this experiment) was completed. Finally, the coal blocks were removed, and the fracturing conditions were recorded.

- (5)

- The coal samples were replaced, and the discharge voltage was adjusted. Three discharge voltages—8, 10, and 12 kV—were selected for the fracturing experiments. The corresponding coal samples were labeled A1, A2, and A3. Coal samples that were not exposed to HVEPs were designated as A0. After the experimental procedure outlined in steps 2 to 4, all coal samples underwent HVEP treatment sequentially. The pore structure parameters of the coal samples were examined both before and after the HVEP treatment.

3. Results and Discussion

3.1. Impact of HVEPs on Coal Pore Morphology

3.2. Effect of HVEPs on the Coal Pore Structure

- (1)

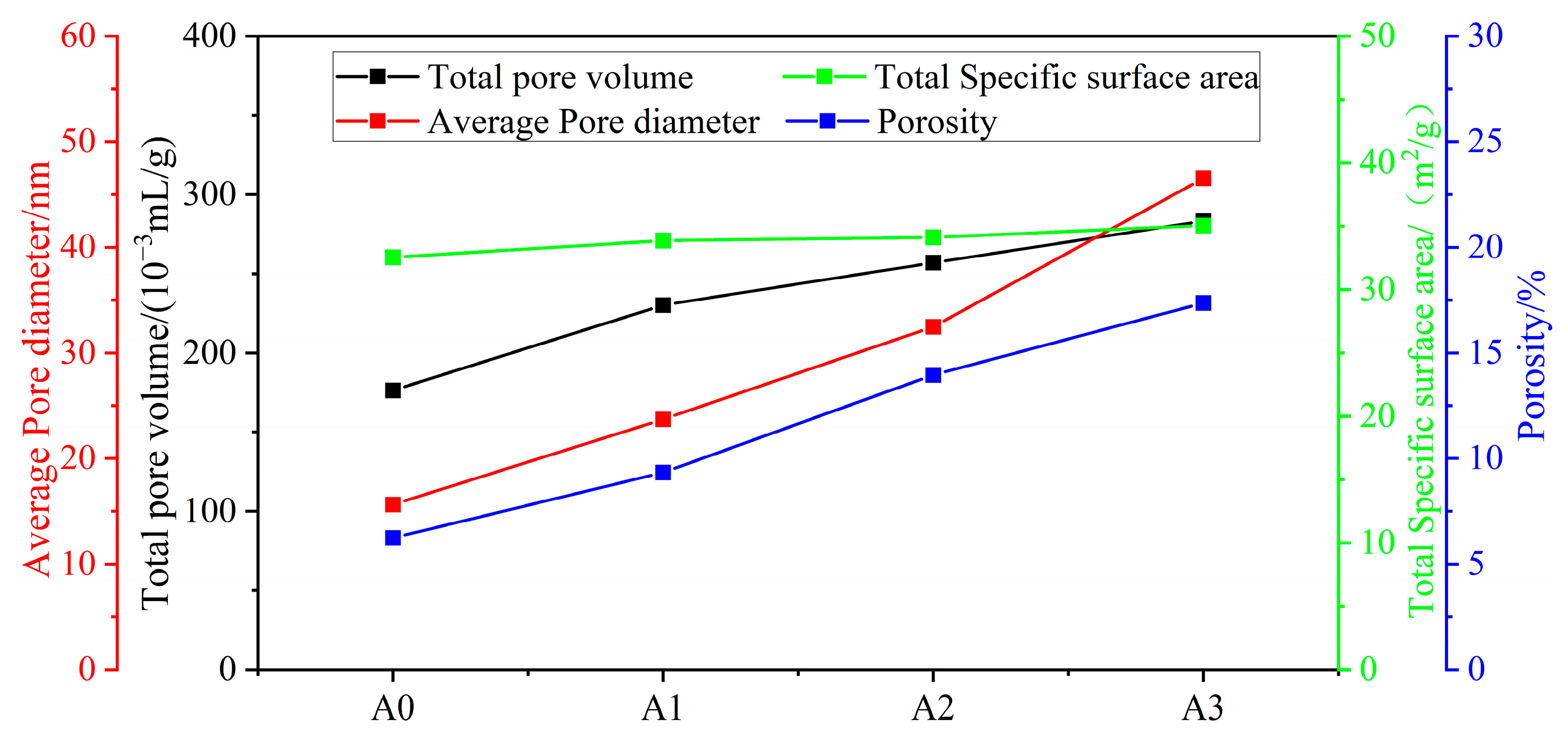

- Total pore volume, average pore diameter, and porosity

- (2)

- Specific surface area

3.3. Impact of HVEPs on Gas Adsorption Characteristics

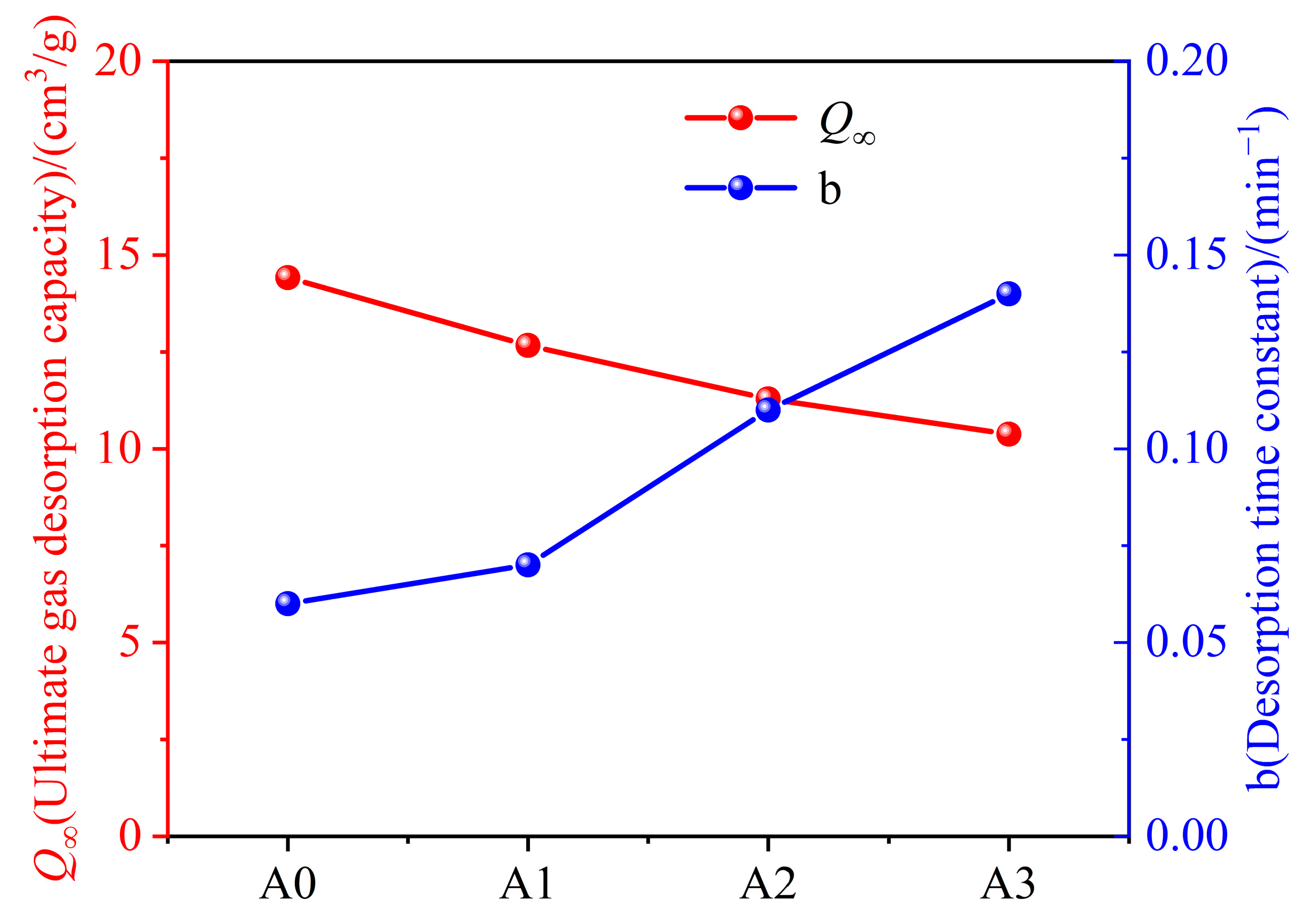

3.4. Impact of HVEPs on Gas Desorption Characteristics

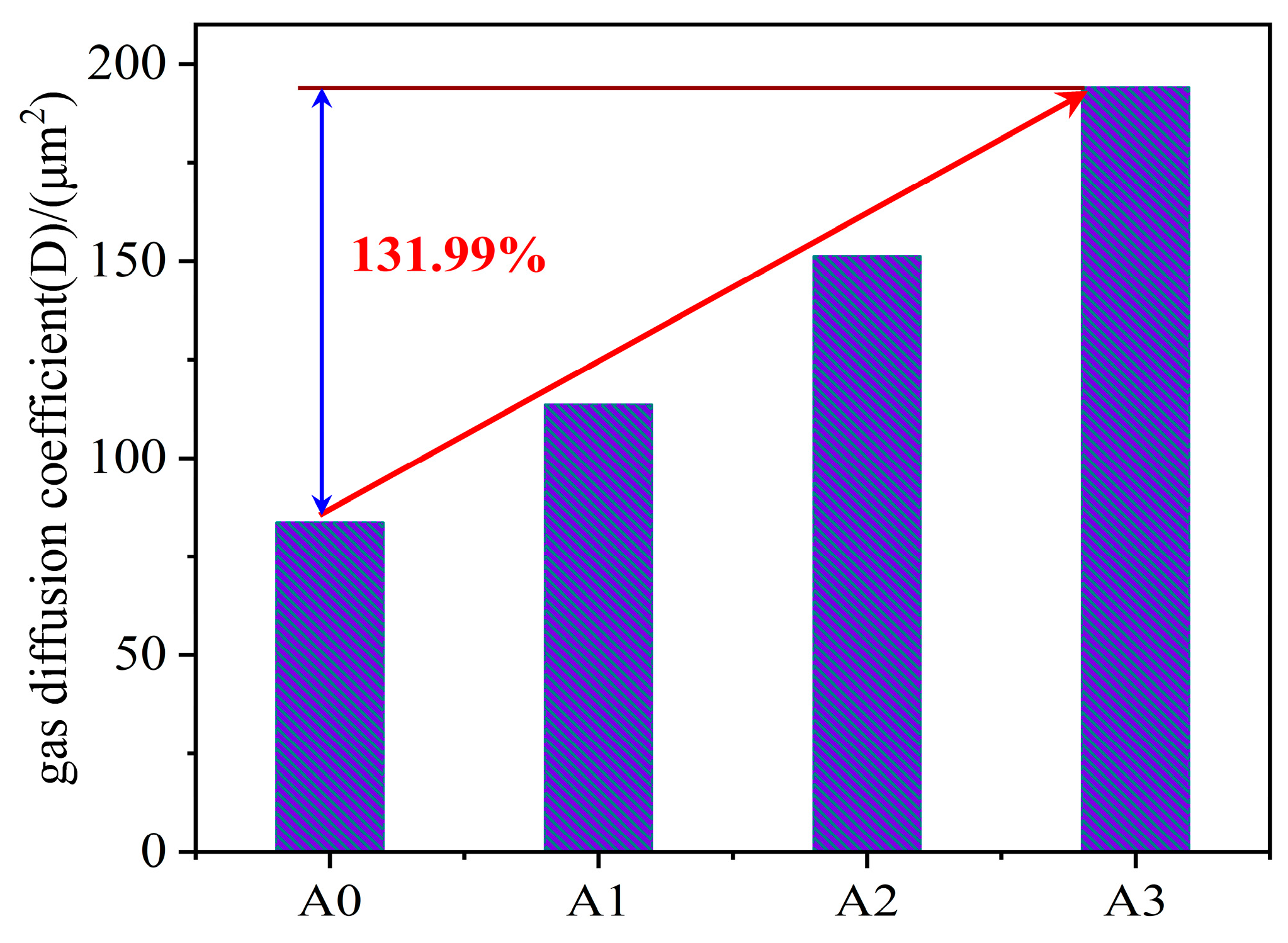

3.5. Impact of HVEPs on Gas Diffusion Characteristics

4. Conclusions

- (1)

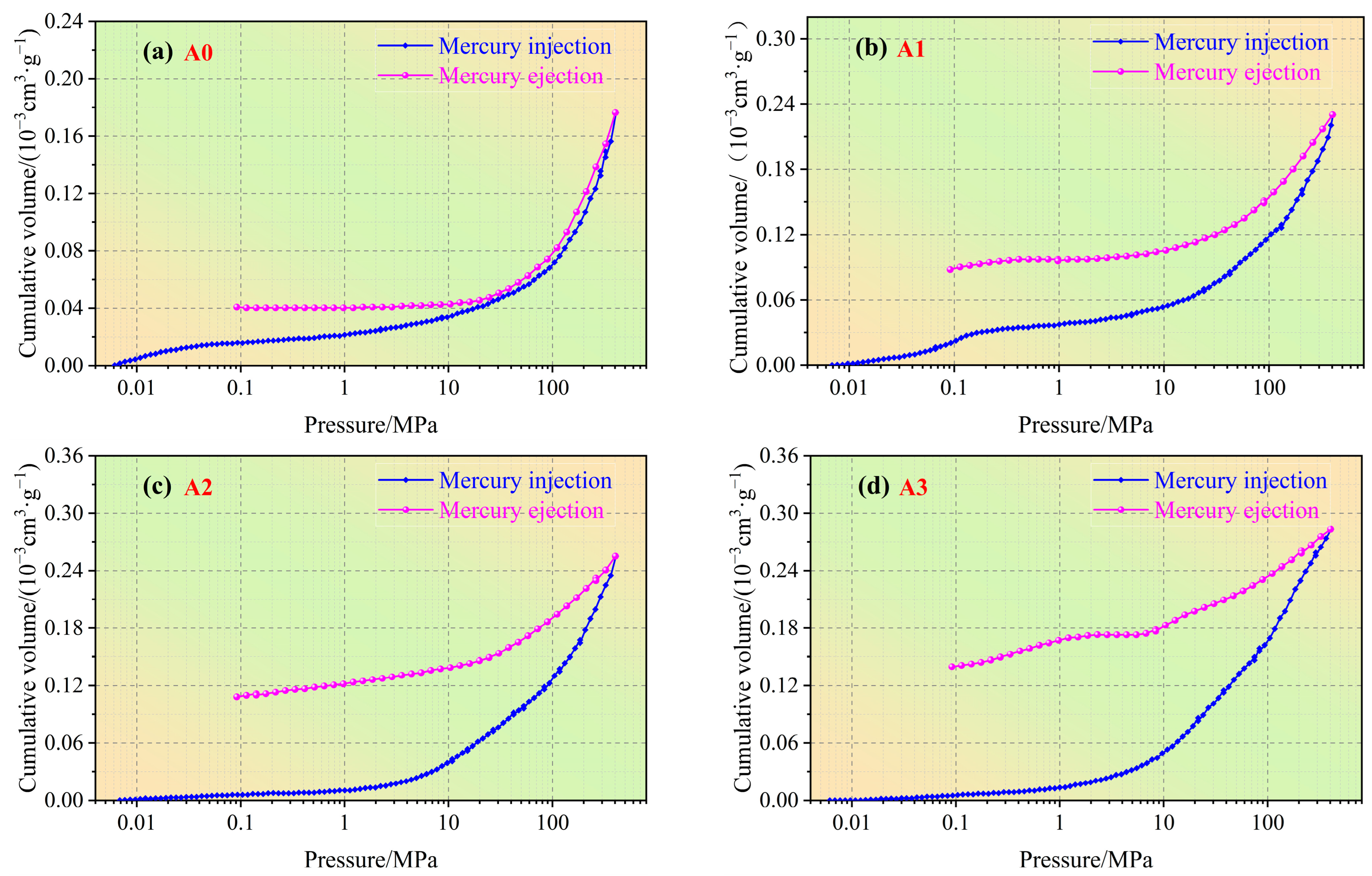

- The MIP results revealed that after HVEP treatment, some closed and semi-closed pores within the coal samples transformed into interconnected and open pores. Consequently, the pore quantity, average pore diameter, total pore volume, and total specific surface area of the coal samples increased, along with improved pore connectivity. After HVEP treatment, the adsorption pores in the coal samples slightly increased, while the seepage pores significantly increased, which facilitated the free flow of gas within the samples.

- (2)

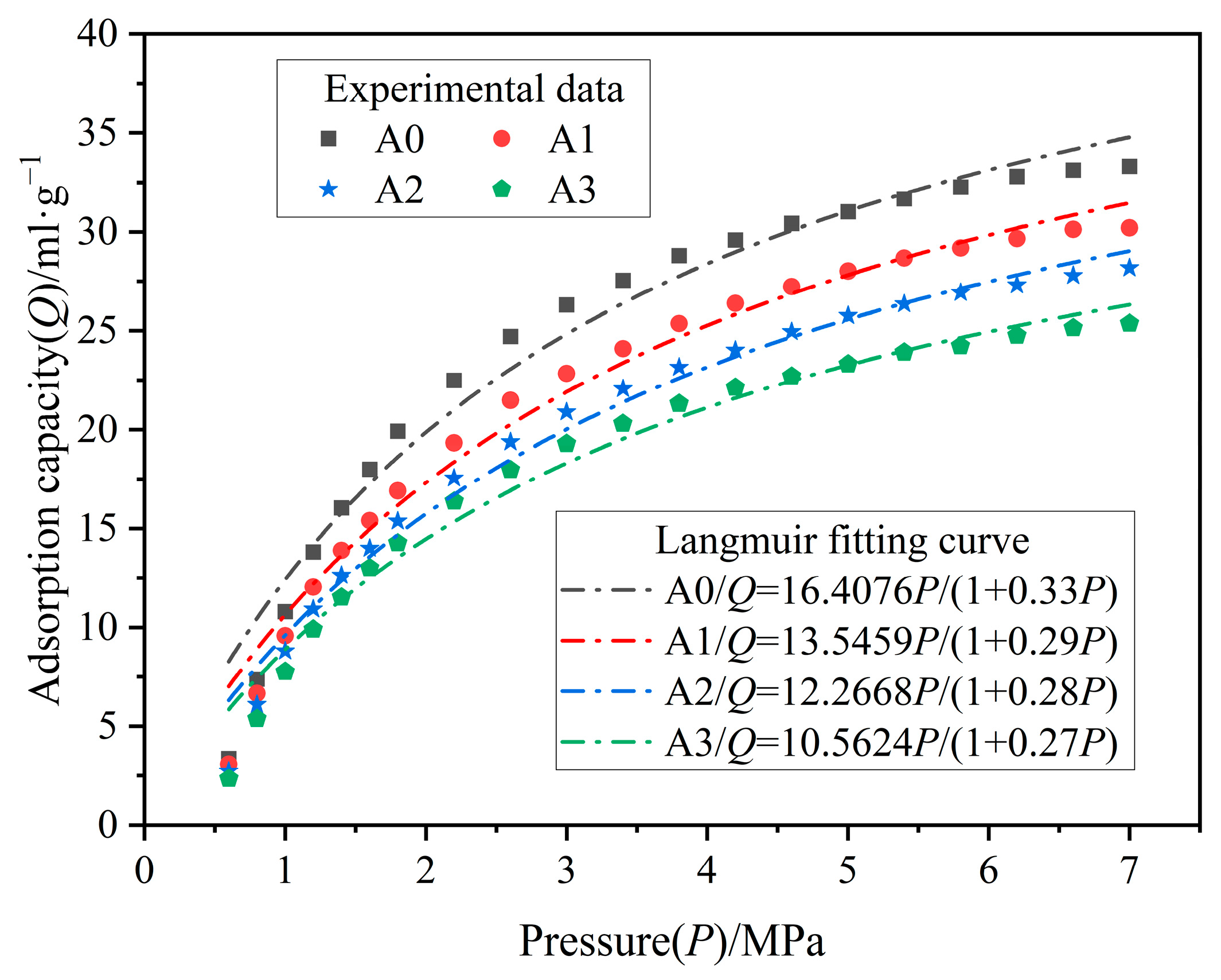

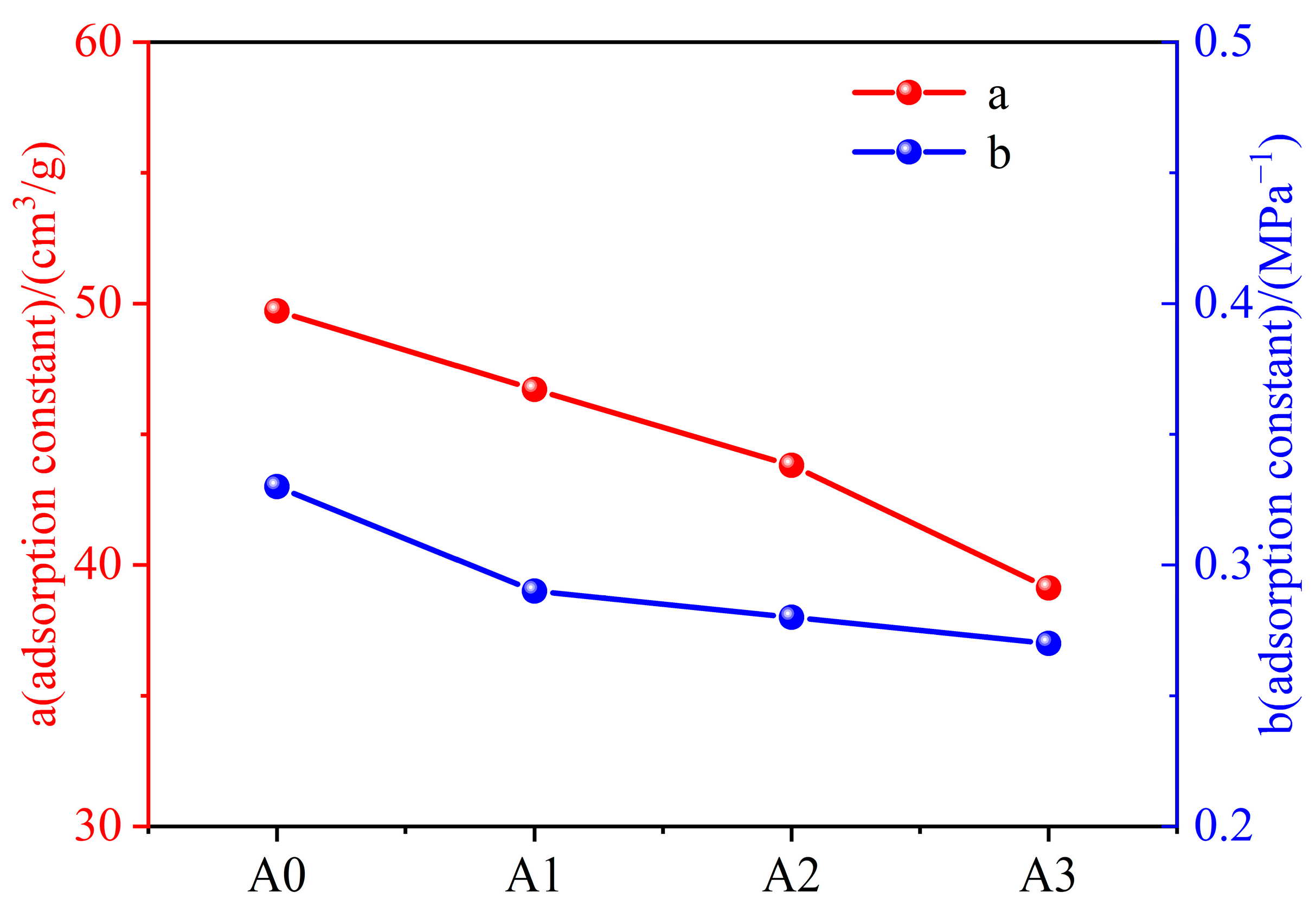

- The HVEP-treated coal samples exhibited significantly smaller ultimate gas adsorption capacity and a lower gas adsorption rate than the untreated samples. These results indicate that HVEPs significantly inhibited gas adsorption in the coal samples.

- (3)

- HVEPs facilitated gas desorption dynamics within the coal samples. In the early stage of desorption, the HVEP-treated coal samples had a higher gas desorption capacity and desorption rate than the untreated samples. This suggests that HVEPs promoted the rapid desorption and release of gas from the coal.

- (4)

- After HVEP treatment, the coal samples exhibited a significantly higher gas diffusion coefficient, indicating a reduction in their resistance to gas diffusion after desorption. This enhancement facilitated gas diffusion and migration within the coal seam, thereby promoting CBM extraction.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| HVEPs | High-voltage electrical pulses |

| CBM | Coalbed methane |

| MIP | Mercury intrusion porosimetry |

| AC | Alternating current |

| DC | Direct-current |

References

- Wang, X.; Hao, F.; Xu, H.; Zhu, C.; Jiang, T.; Jiang, Y. Static expansion fracturing mechanism for enhancing gas permeability in low permeability coal seams. Sci. Rep. 2024, 14, 25046. [Google Scholar] [CrossRef] [PubMed]

- Ye, P.; Li, B.; Ren, C.; Song, H.; Fu, J.; Wu, X. Investigation on damage-permeability model of dual-porosity coal under thermal-mechanical coupling effect. J. Nat. Gas Sci. Eng. 2024, 123, 205229. [Google Scholar] [CrossRef]

- Lu, S.; Li, M.; Ma, Y.; Wang, S.; Zhao, W. Permeability changes in mining-damaged coal: A review of mathematical models. J. Nat. Gas Sci. Eng. 2022, 106, 104739. [Google Scholar] [CrossRef]

- Shu, L.; Wang, K.; Liu, Z.; Zhao, W.; Zhu, N.; Lei, Y. A novel physical model of coal and gas outbursts mechanism: Insights into the process and initiation criterion of outbursts. Fuel 2022, 323, 124305. [Google Scholar] [CrossRef]

- Huang, L.; Li, B.; Wu, B.; Li, C.; Wang, J.; Cai, H. Study on the extension mechanism of hydraulic fractures in bedding coal. Theor. Appl. Fract. Mec. 2024, 131, 104431. [Google Scholar] [CrossRef]

- Li, H.; Lin, B.; Yang, W.; Zheng, C.; Hong, Y.; Gao, Y.; Wu, S. Experimental study on the petrophysical variation of different rank coals with microwave treatment. Int. J. Coal Geol. 2016, 154, 82–91. [Google Scholar] [CrossRef]

- Akhondzadeh, H.; Keshavarz, A.; Awan, F.; Zamani, A.; Iglauer, S.; Lebedev, M. Coal cleat network evolution through liquid nitrogen freeze-thaw cycling. Fuel 2022, 314, 123069. [Google Scholar] [CrossRef]

- Ma, S.; Zong, Q. Exploration and application of microbial method to enhance the effect of hydraulic fracturing on coal seam permeability enhancement and gas extraction. Energ. Explor. Exploit. 2024, 42, 837–855. [Google Scholar] [CrossRef]

- He, Y.; Li, X.; Xue, F.; Sui, H.; Xie, H.; Xu, C.; Li, X. Research on how acidification affects the coal’s microscopic pore structure in the Guizhou mining region. Energy Sci. Eng. 2024, 12, 2322–2340. [Google Scholar] [CrossRef]

- Li, C.; Yao, H.; Xin, C.; Li, H.; Guan, J.; Liu, Y. Changes in pore structure and permeability of middle–high rank coal subjected to liquid nitrogen freeze–thaw. Energy Fuels 2020, 35, 226–236. [Google Scholar] [CrossRef]

- Yutkin, L.A. Electrohydraulic Effect; Armed Services Technical Information Agency: Moscow, Russia, 1955. [Google Scholar]

- Yu, Y.; Kang, Z.; Shen, Y. Unconventional reservoir stimulation method based on electrohydraulic discharge shock and frequency resonance technology. Geoenergy Sci. Eng. 2025, 244, 213454. [Google Scholar] [CrossRef]

- Wang, J.; Xue, Q.; Du, X.; Cao, Y.; Yu, J.; Zhou, P.; Jiang, H. Study on the unplugging technology through electric explosion controllable shock wave. J. Energy Res. Technol. 2021, 143, 053005. [Google Scholar] [CrossRef]

- Chen, W.; Maurel, O.; Reess, T.; Ferron, A.S.; Borderie, C.; Cabot, G.; Jacques, A. Experimental study on an alternative oil stimulation technique for tight gas reservoirs based on dynamic shock waves generated by pulsed arc electrohydraulic discharges. J. Petrol. Sci. Eng. 2012, 88, 67–74. [Google Scholar] [CrossRef]

- Zhang, X.; Lin, B.; Zhu, C.; Yan, F.; Liu, T.; Liu, T.; Li, Y. Petrophysical variation of coal treated by cyclic high-voltage electrical pulse for coalbed methane recovery. J. Petrol. Sci. Eng. 2019, 178, 795–804. [Google Scholar] [CrossRef]

- Zhang, X.; Lin, B.; Li, Y.; Zhu, C.; Li, Q. Analysis of fractal dimension of coal subjected to electrical breakdown based on nuclear magnetic resonance. J. Nat. Gas Sci. Eng. 2020, 79, 103345. [Google Scholar] [CrossRef]

- Zhang, X.; Lin, B.; Shen, J. Experimental research on the effect of plasma on the pore-fracture structures and adsorption-desorption of coal body. Fuel 2022, 307, 121809. [Google Scholar] [CrossRef]

- Zhu, C.; Lu, X.; Lin, B.; Yan, F.; Guo, C.; Hong, Y.; Zhang, X. Experimental study on the microscopic characteristics affecting methane adsorption on anthracite coal treated with high-voltage electrical pulses. Adsorpt. Sci. Technol. 2018, 36, 170–181. [Google Scholar] [CrossRef]

- Lu, H.; Liu, Y.; Nie, B.; Chen, X.; Xu, X. Crack propagation characteristics of coal samples utilizing high-voltage electrical pulses. ACS Omega 2021, 6, 34395–34405. [Google Scholar] [CrossRef]

- Li, C.; Nie, B.; Zhang, Z.; Liu, X.; Zhao, Z.; Zhang, C.; Lu, W. Experimental study of the structural damage to coal treated by a high-voltage electric pulse discharge in water. Energy Fuels 2022, 36, 6280–6291. [Google Scholar] [CrossRef]

- Li, H.; Qin, Y.; Zhang, Y.; Shi, Q.; Zhou, X. Experimental study on the effect of strong repetitive pulse shockwave on the pore structure of fat coal. J. China Coal Soc. 2015, 40, 915–921. [Google Scholar]

- Shi, Q.; Qin, Y.; Li, H.; Qiu, A.; Zhang, Y.; Zhou, X.; Zheng, S. Response of pores in coal to repeated strong impulse waves. J. Nat. Gas Sci. Eng. 2016, 34, 298–304. [Google Scholar] [CrossRef]

- Lin, B.; Zhong, L.; Zhang, X.; Ni, Z. Effect of high voltage pulse on micro-pore structure of bituminous coal. J. Min. Saf. Eng. 2022, 39, 380–386. [Google Scholar]

- Xu, Y.; Ni, Z.; Lin, B. Influence of plasma breakdown on pores and fractures in bituminous coal: A new characterization method of breakdown energy. Gas Sci. Eng. 2024, 125, 205296. [Google Scholar] [CrossRef]

- Ni, Z.; Lin, B.; Zhang, X.; Cao, X.; Zhong, L.; Gao, Y. Experimental study on the effect of high-voltage electrical pulses on the nanoscale pore structure of coal. Fuel 2021, 306, 121621. [Google Scholar] [CrossRef]

- Jiang, C.; Huang, C.; Wu, J.; Wang, D.; Nie, B.; Wang, A.; Zhu, Y. Optimization Effects of Ionic Solutions on Coal Fracturing Using High-Voltage Electric Pulse. Energy Fuels 2025, 39, 3528–3539. [Google Scholar] [CrossRef]

- Lin, B.; Zhang, X.; Yan, F.; Zhu, C.; Guo, C. Improving the conductivity and porosity of coal with NaCl solution for high-voltage electrical fragmentation. Energy Fuels 2018, 32, 5010–5019. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, W.; Lin, B.; Yan, F. Effects of different conductive ions on pore-structure evolution of medium-and high-rank coal bodies induced by electric pulses. Fuel 2021, 293, 120437. [Google Scholar] [CrossRef]

- Bao, X.; Guo, J.; Liu, Y.; Zhao, G.; Cao, J.; Wu, J.; Zhao, J. Damage characteristics and laws of micro-crack of underwater electric pulse fracturing coal-rock mass. Theor. Appl. Fract. Mec. 2021, 111, 102853. [Google Scholar] [CrossRef]

- Yan, F.; Lin, B.; Zhu, C.; Guo, C.; Zhou, Y.; Zou, Q.; Liu, T. Using high-voltage electrical pulses to crush coal in an air environment: An experimental study. Powder Technol. 2016, 298, 50–56. [Google Scholar] [CrossRef]

- Yan, F.; Xu, J.; Lin, B.; Peng, S.; Zou, Q.; Zhang, X. Effect of moisture content on structural evolution characteristics of bituminous coal subjected to high-voltage electrical pulses. Fuel 2019, 241, 571–578. [Google Scholar] [CrossRef]

- Yan, F.; Xu, J.; Lin, B.; Peng, S.; Zou, Q.; Zhang, X. Changes in pore structure and permeability of anthracite coal before and after high-voltage electrical pulses treatment. Powder Technol. 2019, 343, 560–567. [Google Scholar] [CrossRef]

- Ma, S. Research on coal seam permeability improvement by high-voltage electric pulse discharge. Saf. Coal Mines 2019, 50, 15–18. [Google Scholar]

- Xodot, B. Coal and Gas Outburst; China Industrial Press: Beijing, China, 1966. [Google Scholar]

- Bukka, V.; Sarin, P. Effects of Particle Size Reduction on the Pore Structure and Accessibility in Natural Porous Materials. Energy Fuels 2024, 38, 9578–9587. [Google Scholar] [CrossRef]

- Rahman, T.; Hazra, B.; Vishal, V. Pore structure evolution of Jharia coal for potential underground coal thermal treatment and associated CO2 sequestration. Fuel 2025, 381, 133577. [Google Scholar] [CrossRef]

- Okolo, G.; Everson, R.; Neomagus, H.; Roberts, M.; Sakurovs, R. Comparing the porosity and surface areas of coal as measured by gas adsorption, mercury intrusion and SAXS techniques. Fuel 2015, 141, 293–304. [Google Scholar] [CrossRef]

- Zhu, J.; He, F.; Zhang, Y.; Zhang, R.; Zhang, B. Fractal analysis in pore size distributions of different bituminous coals. Sci. Rep. 2019, 9, 18162. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.; Li, J.; Zhou, F.; Shi, B. Experimental study on the competitive adsorption characteristics of N2, CO2 and O2 with various CO2/N2 blend ratios in coal. Int. J. Hydrogen Energy 2024, 59, 924–936. [Google Scholar] [CrossRef]

- Alafnan, S.; Awotunde, A.; Glatz, G.; Adjei, S.; Alrumaih, I.; Gowida, A. Langmuir adsorption isotherm in unconventional resources: Applicability and limitations. J. Petrol. Sci. Eng. 2021, 207, 109172. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, G.; Wang, X.; Lv, R.; Liu, H.; Lin, J.; George, B.; Chang, P. A fractal Langmuir adsorption equation on coal: Principle, methodology and implication. Chem. Eng. J. 2024, 488, 150869. [Google Scholar] [CrossRef]

- Bobin, V.; Kozyreva, E. Coal Bed Pressure, Gas Content, Sorptional Capacity of Coal Bed, and the Langmuir Equation. Coke Chem. 2024, 67, 232–237. [Google Scholar] [CrossRef]

- Liu, W.; Han, D.; Guo, M.; Li, R.; Zhong, W. Evaluation of adsorbed and free gas in the coal matrix during desorption processes: Insights from experimental and numerical methods. Fuel 2024, 376, 132739. [Google Scholar] [CrossRef]

- Li, Z.; Chen, J.; Li, L.; Peng, J. Experiment, modelling, mechanism and significance of multiscale and dynamic diffusion-permeability of gas through micro-nano series pores in coal. J. China Coal Soc. 2023, 48, 1551–1566. [Google Scholar]

- Nie, B.; Liu, X.; Guo, J.; Zhu, F. Effect of moisture on gas desorption and diffusion in coal mass. J. China Univ. Min. Technol. 2015, 44, 781–787. [Google Scholar]

- Thimons, E.; Kissell, F. Diffusion of methane through coal. Fuel 1973, 52, 274–280. [Google Scholar] [CrossRef]

| Sample | Proximate Analysis (wt%) | Coal Rank | Ultimate Analysis (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Cad | Had | Oad | Nad | Aad | Vdaf | Mad | FCad | ||

| QY | 88.68 | 3.61 | 4.78 | 2.93 | Bituminous | 21.19 | 11.84 | 6.59 | 60.38 |

| Coal Sample | Total Pore Volume (10−3 mL/g) | Average Pore Diameter (nm) | Total Specific Surface Area (m2/g) | Pore Volume (10−3 mL/g) | Porosity (%) | Pore Proportion (%) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Micropore | Transition Pore | Mesopore | Macropore | Adsorption Pore | Seepage Pore | |||||

| A0 | 176.32 | 15.62 | 32.55 | 83.80 | 60.26 | 25.92 | 6.33 | 6.24 | 81.71 | 18.29 |

| A1 | 230.26 | 23.71 | 33.86 | 87.07 | 72.57 | 55.33 | 15.30 | 9.33 | 68.33 | 30.67 |

| A2 | 257.05 | 32.47 | 34.12 | 90.87 | 75.62 | 69.75 | 20.81 | 13.96 | 64.77 | 35.23 |

| A3 | 283.24 | 46.53 | 35.05 | 97.79 | 83.07 | 78.06 | 24.32 | 17.37 | 63.85 | 36.15 |

| Coal Sample | Fitting Formula | Fitting Degree R2 | Slope K | D/(μm2·min) |

|---|---|---|---|---|

| A0 | η = 0.1447t0.5 | 0.9576 | 0.1447 | 83.678 |

| A1 | η = 0.1686t0.5 | 0.9461 | 0.1686 | 113.603 |

| A2 | η = 0.1946t0.5 | 0.9641 | 0.1946 | 151.342 |

| A3 | η = 0.2204t0.5 | 0.9338 | 0.2204 | 194.132 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Xu, G.; Yao, H.; Xin, C.; Liu, F. Changes in Pore Structure and Gas Adsorption–Desorption Characteristics of Coal Under High-Voltage Electric Pulses. Processes 2025, 13, 1662. https://doi.org/10.3390/pr13061662

Li C, Xu G, Yao H, Xin C, Liu F. Changes in Pore Structure and Gas Adsorption–Desorption Characteristics of Coal Under High-Voltage Electric Pulses. Processes. 2025; 13(6):1662. https://doi.org/10.3390/pr13061662

Chicago/Turabian StyleLi, Changxing, Guosheng Xu, Huanying Yao, Chengpeng Xin, and Fei Liu. 2025. "Changes in Pore Structure and Gas Adsorption–Desorption Characteristics of Coal Under High-Voltage Electric Pulses" Processes 13, no. 6: 1662. https://doi.org/10.3390/pr13061662

APA StyleLi, C., Xu, G., Yao, H., Xin, C., & Liu, F. (2025). Changes in Pore Structure and Gas Adsorption–Desorption Characteristics of Coal Under High-Voltage Electric Pulses. Processes, 13(6), 1662. https://doi.org/10.3390/pr13061662