Research on the Pressure Relief Mechanism of Gently Inclined Long-Distance Lower Protective Layer Mining and Cooperative Gas Control Technology

Abstract

1. Introduction

2. Project Overview

2.1. Mine Overview

2.2. Working Face Overview

- (1)

- Protective Seam

- (2)

- Protected Seam

3. Theoretical Analysis of the Protective Range of Protective Layer Mining

3.1. Along the Dip Direction

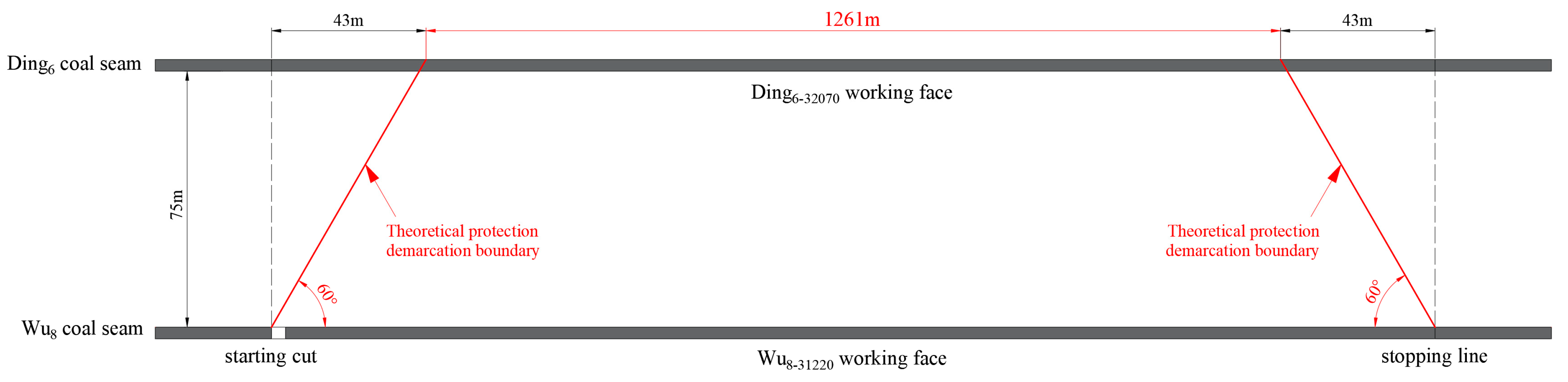

3.2. Along the Strike Direction

4. Field Parameter Testing Layout Plan

4.1. Gas Pressure Testing in the Ding6 Coal Seam

4.1.1. Borehole Layout

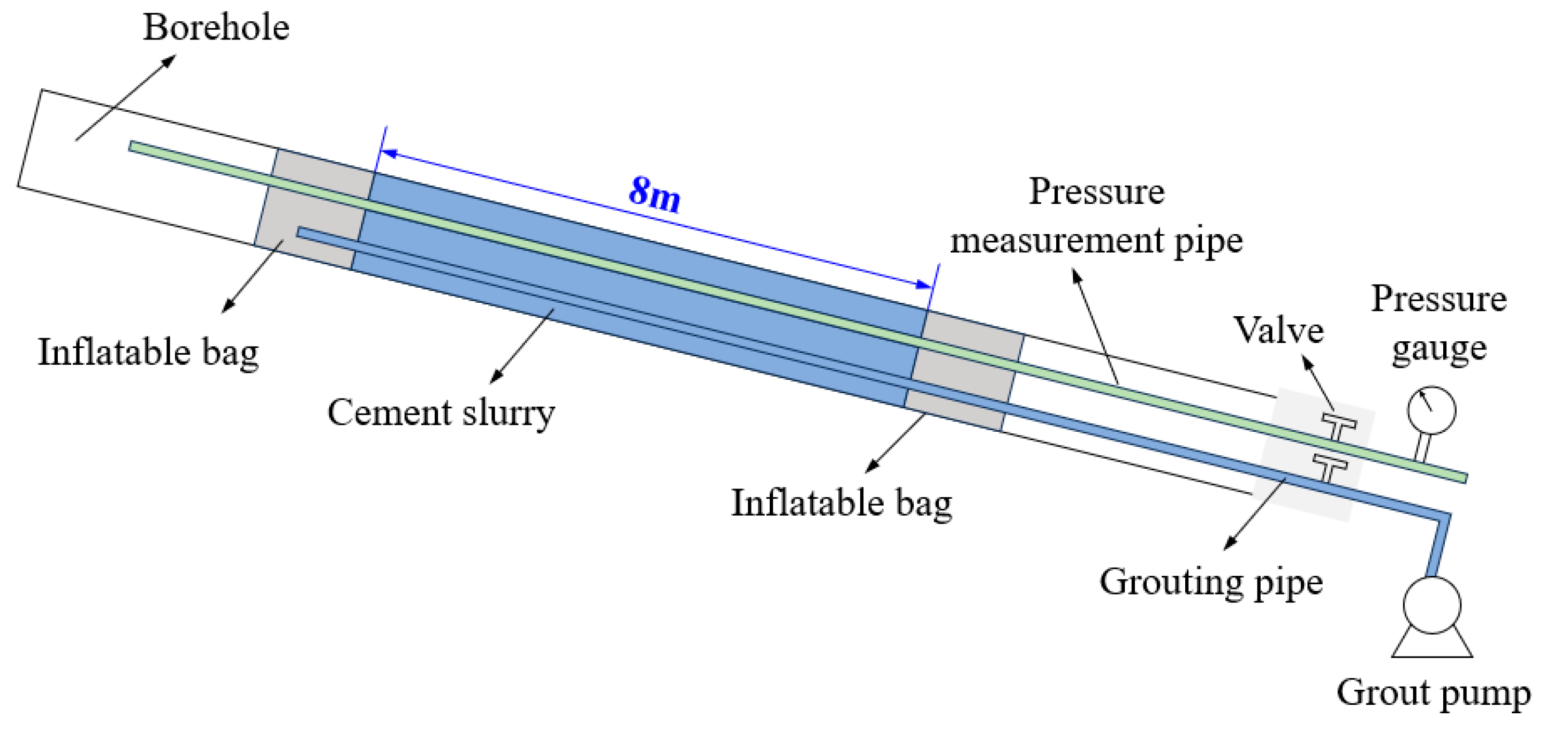

4.1.2. Sealing Method

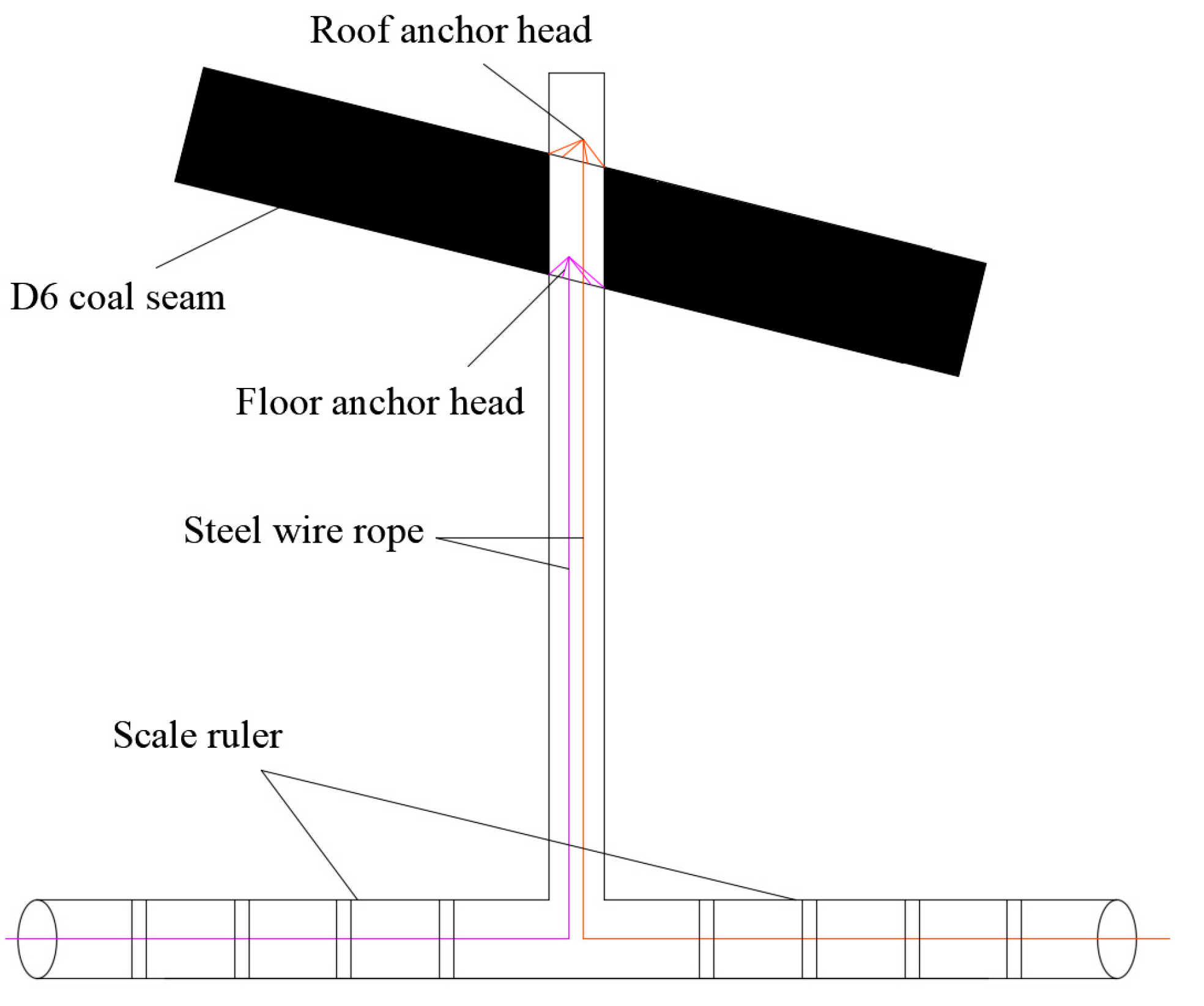

4.2. Expansion Deformation Testing in the Ding6 Coal Seam

4.3. Design of Pressure Relief Gas Extraction Boreholes in the Ding6 Coal Seam

Pressure Relief Gas Drainage System Design for Ding6 Coal Seam

5. Analysis of the Effect of Remote Protective Layer Mining

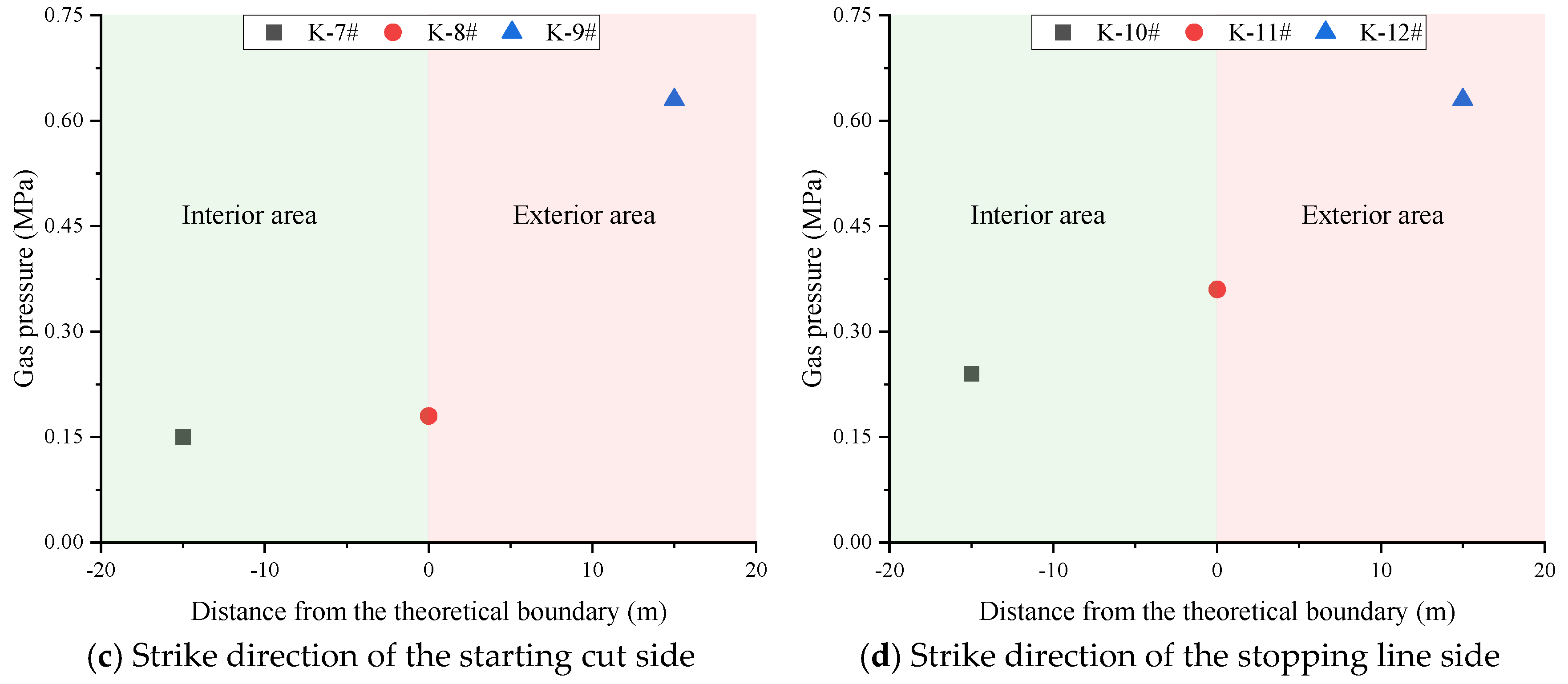

5.1. Gas Pressure in the Ding6 Coal Seam

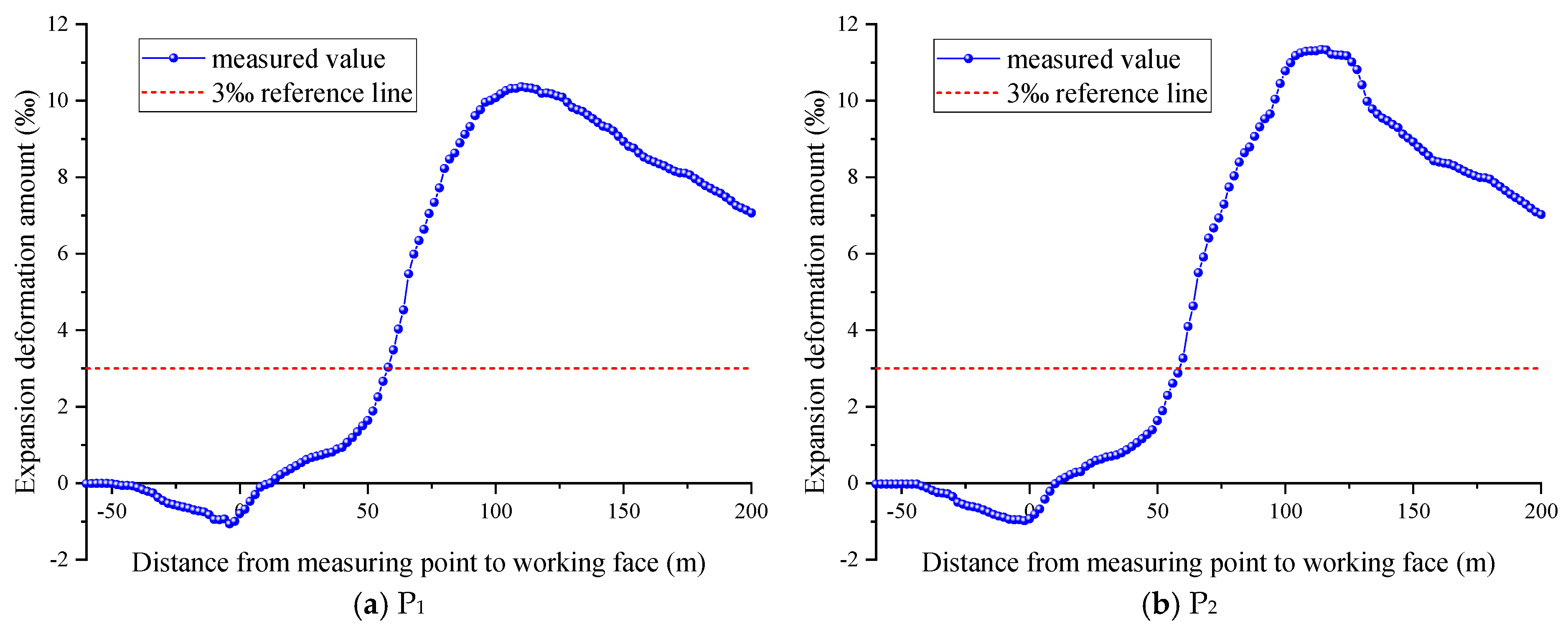

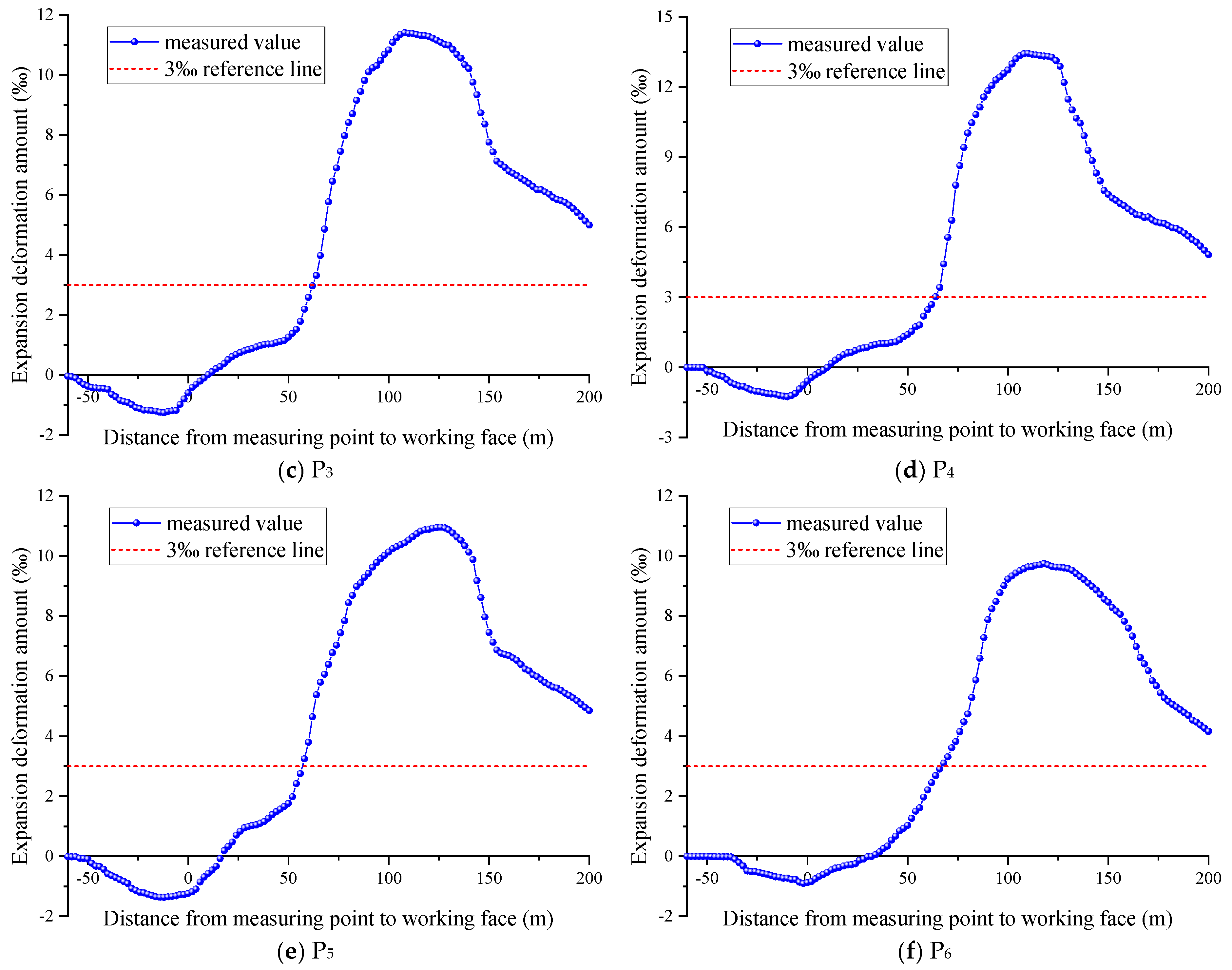

5.2. Expansion Deformation of the Ding6 Coal Seam

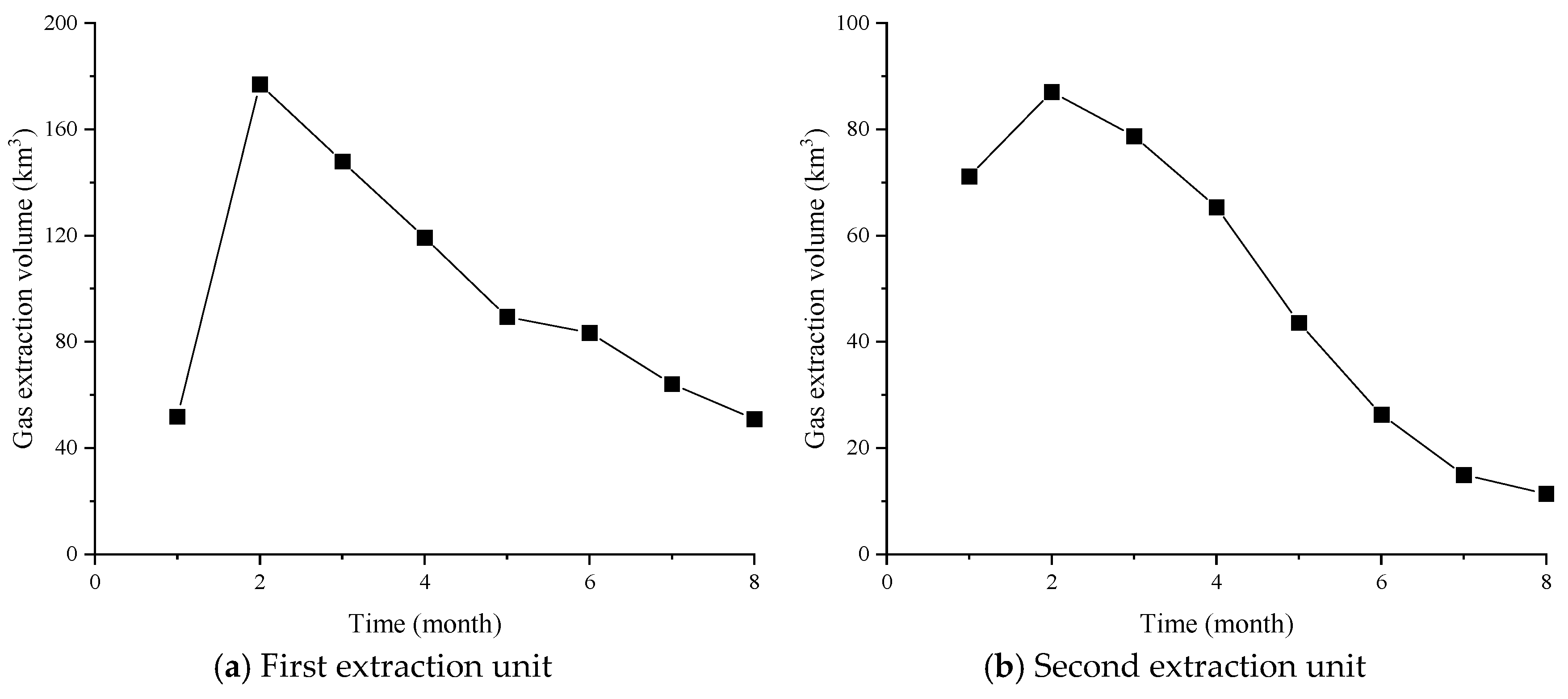

5.3. Pressure Relief Gas Extraction Volume in the Ding6 Coal Seam

6. Conclusions

- (1)

- Gas pressure distribution analysis reveals consistent measurements (0.15–0.36 MPa) along both dip and strike directions within the pressure relief boundary and 15 m interior zone. Notably, these values represent only 23.81–57.14% of the gas pressure observed 15 m beyond the boundary, demonstrating significant pressure attenuation. This spatial pattern conclusively validates the effective pressure relief performance achieved through Wu8-31220 mining operations, establishing optimal preconditions for subsequent gas drainage implementation.

- (2)

- With the advance of the Wu8-31220 working face, the overlying Ding6 coal seam shows a change law of first compression and then expansion. Within the protective range demarcation boundary, the maximum expansion deformation reaches 9.89~13.55‰. Under the conditions of a borehole spacing of 20 m and extraction lasting 8 months, the pressure relief gas extraction effect of the Ding6-32070 working face is significant, with the extraction volume accounting for 31.22% of the gas reserves, effectively reducing the gas content of the working face, lowering the risk of gas overrun, and ensuring the safe production of the mine.

- (3)

- In the dip direction, the pressure relief angle of the Wu8 coal seam on the intake roadway side is 77°, and the pressure relief range of the Ding6 coal seam is staggered inward by 17.3 m from the intake roadway. On the return roadway side, the pressure relief angle is 83°, and the pressure relief range of the Ding6 coal seam is staggered inward by 9.2 m from the return roadway. In the horizontal direction, the horizontal pressure relief angles of the Wu8 coal seam on the starting cut and the stopping line are both 60°, and the pressure relief range of the Ding6 coal seam is staggered inward by 43 m from both the starting cut and the stopping line. These precise pressure relief ranges and angle data provide an important theoretical basis for optimizing protective layer mining design and rationally arranging gas extraction boreholes. This methodology effectively resolves the spatial–temporal coordination challenges between gas extraction efficiency and operational safety in deep protective layer mining operations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, Y.; Li, H.; Huang, J.; Zhang, R.; Wang, S.; Hong, Y.; Yang, Y. Influence of coal deformation on the knudsen number of gas flow in coal seams. Energy 2021, 233, 121161. [Google Scholar] [CrossRef]

- Guo, J.; Chen, C.; Liu, Y.; Wen, H.; Quan, Y. Response characteristics of molecular active structure of coal of different metamorphic degree to extractant. Energy 2025, 320, 135372. [Google Scholar] [CrossRef]

- Shen, S.; Wang, H.; Ren, T.; Wang, Z. Research on the pore structure and gas adsorption/desorption characteristics of tectonic coal in minor fault zone: Implications for coal and gas outbursts. Powder Technol. 2025, 456, 120846. [Google Scholar] [CrossRef]

- Yue, J.; Xu, J.; Zhang, J.; Shi, B.; Zhang, M.; Li, Y.; Wang, C. Gas displacement characteristics during the water wetting process of gas-bearing coal and microscopic influence mechanism. Sci. Total Environ. 2024, 949, 175034. [Google Scholar] [CrossRef]

- Dazhao, S.; Qiang, L.; Liming, Q.; Jianguo, Z.; Khan, M.; Yujie, P.; Yingjie, Z.; Man, W.; Minggong, G.; Taotao, H. Experimental study on resistivity evolution law and precursory signals in the damage process of gas-bearing coal. Fuel 2024, 362, 130798. [Google Scholar] [CrossRef]

- Jin, Y.; Tong, X.; Zheng, X.; Li, Y.; Dong, B. Risk assessment of coal and gas outbursts driven by the theory of three types of hazards coupled with 80 accident cases. Saf. Sci. 2025, 184, 106771. [Google Scholar] [CrossRef]

- Qiu, L.; Dang, J.; Zhang, J.; Wang, M.; Liu, Q.; Si, L.; Jiang, Z.; Khan, M. Investigating nonlinear resistivity characteristics and mechanisms of coal during various loading stages. J. Appl. Geophys. 2025, 238, 105705. [Google Scholar] [CrossRef]

- Anani, A.; Adewuyi, S.O.; Risso, N.; Nyaaba, W. Advancements in machine learning techniques for coal and gas outburst prediction in underground mines. Int. J. Coal Geol. 2024, 285, 104471. [Google Scholar] [CrossRef]

- Li, M.; Lu, S.; Wei, C.; Li, Z.; Ye, Q.; Zhang, Y. Study on energy instability mechanism of composite coal seam based on the coupling effect of damage and unsteady diffusion. Fuel 2025, 379, 133051. [Google Scholar] [CrossRef]

- Wang, C.; Liu, L.; Li, X.; Xu, C.; Li, K. Mechanism of gas pressure action during the initial failure of coal containing gas and its application for an outburst inoculation. Int. J. Min. Sci. Technol. 2023, 33, 1511–1525. [Google Scholar] [CrossRef]

- Yang, G.; Song, D.; Wang, M.; Qiu, L.; He, X.; Khan, M.; Qian, S. New insights into dynamic disaster monitoring through asynchronous deformation induced coal-gas outburst mechanism of tectonic and raw coal seams. Energy 2024, 295, 131063. [Google Scholar] [CrossRef]

- Li, W.; Jia, T.; Zhu, Y.; Guo, S. Study on the influence of stress distribution in fault structural zones on coal and gas outbursts. Min. Metall. Explor. 2025, 42, 719–735. [Google Scholar] [CrossRef]

- Zhao, Y.; Song, D.; Qiu, L.; Khan, M.; He, X.; Li, Z.; Peng, Y.; Wang, A. An efficient coal and gas outburst hazard prediction method using an improved limit equilibrium model and stress field detection. Int. J. Coal Sci. Technol. 2025, 12, 23. [Google Scholar] [CrossRef]

- Vassilyev, I.; Mendakulov, Z.; Imansakipova, B.; Aitkazinova, S.; Issabayev, K.; Imansakipova, N.; Madimarova, G. Acoustic emission spectrum for mine hazards identification and prevention. Sci. Rep. 2025, 15, 6408. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Wang, P.; Wang, E.; Chen, D.; Li, C. Characteristics of coal resources in china and statistical analysis and preventive measures for coal mine accidents. Int. J. Coal Sci. Technol. 2023, 10, 22. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Tian, C.; Wang, Q.; Shi, Z.; Sun, Y.; Wang, K. Study on influencing factors and prevention measures of coal-rock-gas compound dynamic disaster in deep coal mine mining. Sci. Rep. 2025, 15, 2080. [Google Scholar] [CrossRef]

- Yang, W.; Wang, W.; Jia, R.; Walton, G.; Sinha, S.; Chen, Q.; Lin, B.; Jiao, X. Parameter optimization of coal face blasting for coal and gas outburst control. Bull. Eng. Geol. Environ. 2023, 82, 80. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, E. Risk identification for coal and gas outburst in underground coal mines: A critical review and future directions. Gas Sci. Eng. 2023, 118, 205106. [Google Scholar] [CrossRef]

- Zhou, A.; He, Y.; Wang, K.; Li, B.; Wang, Y.; Yang, Y. Hydraulic fracture propagation in soft coal composite reservoirs: Mechanical responses and energy dissipation mechanisms. Int. J. Min. Sci. Technol. 2025, 35, 573–588. [Google Scholar] [CrossRef]

- Cheng, X.; Zhao, G.; Li, Y.; Meng, X.; Tu, Q. Key technologies and engineering practices for soft-rock protective seam mining. Int. J. Min. Sci. Technol. 2020, 30, 889–899. [Google Scholar] [CrossRef]

- Lei, W.; Du, X.; Zhang, D.; Wang, J.; Yang, R.; Zheng, C.; Huang, X.; Wang, S.; Zhao, J.; Cao, J. Sensitivity analysis of geological mining influencing factors on the pressure relief effect of upper protective layer mining. Energy Sci. Eng. 2024, 12, 4703–4719. [Google Scholar] [CrossRef]

- Yang, W.; Zhang, W.; Lin, B.; Si, G.; Zhang, J.; Wang, J. Integration of protective mining and underground backfilling for coal and gas outburst control: A case study. Process Saf. Environ. 2022, 157, 273–283. [Google Scholar] [CrossRef]

- Lu, A.; Song, D.; Li, Z.; He, X.; Dou, L.; Xue, Y.; Yang, H. Numerical simulation study on pressure-relief effect of protective layer mining in coal seams prone to rockburst hazard. Rock. Mech. Rock. Eng. 2024, 57, 6421–6440. [Google Scholar] [CrossRef]

- Zhang, H.; Wen, Z.; Yao, B.; Chen, X. Numerical simulation on stress evolution and deformation of overlying coal seam in lower protective layer mining. Alex. Eng. J. 2020, 59, 3623–3633. [Google Scholar] [CrossRef]

- Xie, H.; Li, X.; Cai, J.; Wang, S.; Feng, C. Evolution of fissures and pressure discharge of gas caused by mining of the upper protective layer of a coal seam. Sci. Rep. 2023, 13, 2561. [Google Scholar] [CrossRef]

- Yang, W.; Lin, B.; Qu, Y.; Zhao, S.; Zhai, C.; Jia, L.; Zhao, W. Mechanism of strata deformation under protective seam and its application for relieved methane control. Int. J. Coal Geol. 2011, 85, 300–306. [Google Scholar] [CrossRef]

- Wang, H.; Wang, E.; Li, Z.; Shen, R.; Liu, X.; Zhang, Q.; Li, B. Study and application of dynamic inversion model of coal seam gas pressure with drilling. Fuel 2020, 280, 118653. [Google Scholar] [CrossRef]

- Liu, C.; Man, Z.Y.; Li, M.L. Study on the dynamic evolution of mining-induced stress and displacement in the floor coal-rock induced by protective layer mining. Minerals 2024, 14, 1084. [Google Scholar] [CrossRef]

- Cheng, Z.; Pan, H.; Zou, Q.; Li, Z.; Chen, L.; Cao, J.; Zhang, K.; Cui, Y. Gas flow characteristics and optimization of gas drainage borehole layout in protective coal seam mining: A case study from the shaqu coal mine, Shanxi province, China. Nat. Resour. Res. 2021, 30, 1481–1493. [Google Scholar] [CrossRef]

- Li, L.; Wu, G.Y.; Liu, Q.Z. Study on overburden movement and fissure evolution law of protective layer mining in shallow coal seam. Energies 2022, 15, 1831. [Google Scholar] [CrossRef]

- Jin, K.; Cheng, Y.; Wang, W.; Liu, H.; Liu, Z.; Zhang, H. Evaluation of the remote lower protective seam mining for coal mine gas control: A typical case study from the zhuxianzhuang coal mine, huaibei coalfield, china. J. Nat. Gas Sci. Eng. 2016, 33, 44–55. [Google Scholar] [CrossRef]

- Wang, L.; Lu, Z.; Chen, D.; Liu, Q.; Chu, P.; Shu, L.; Ullah, B.; Wen, Z. Safe strategy for coal and gas outburst prevention in deep-and-thick coal seams using a soft rock protective layer mining. Saf. Sci. 2020, 129, 104800. [Google Scholar] [CrossRef]

- Li, Y.; Yu, K.; Wan, Z.; Zhang, Y.; Wang, Z.; Shi, P.; Zhen, Z.; Zhang, B. Regional structural controls on a hydrothermal geothermal system in the eastern pingdingshan coalfield, China: A comprehensive review. Geothermics 2024, 123, 103131. [Google Scholar] [CrossRef]

- Ullah, B.; Cheng, Y.; Wang, L.; Hu, B.; Jiskani, I.M.; Hassan, F.U.; Shahani, N.M.; Ali, M. Experimental and theoretical analyses to predict coal and gas outburst using desorption indices of drill cuttings. Arab. J. Geosci. 2022, 15, 665. [Google Scholar] [CrossRef]

- Chai, Y.J.; Dou, L.M.; He, J.; Ma, X.T.; Lu, F.Z.; He, H. Limitations of upper protective layers as pressure relief measures for extra-thick coal seam mining: Insights from a case study. Energies 2024, 17, 1446. [Google Scholar] [CrossRef]

- Shang, Y.Q.; Wang, Y.; Zhang, L.; Wu, G.Y.; Kong, D.Z.; Zhang, P.F.; Jia, T.P. Impact of lower protective coal seam mining on overlying strata: Deformation, pressure relief, and permeability enhancement. Int. J. Geomech 2024, 24, 04024178. [Google Scholar] [CrossRef]

- Xiao, J.; Chen, X.X.; Li, S.G.; Bi, R.Q.; Chen, Z.H. Analyzing the optimization of unloading gas extraction drilling arrangement based on stress distribution in the protected layer. Sustainability 2024, 16, 2133. [Google Scholar] [CrossRef]

- Peng, N.B.; Zhang, C.L.; Feng, R.M.; Arif, A.; Chen, X.; Zhang, W.D.; Zhang, S.; Feng, M.J. Analysis of dynamic evolution of surrounding rock movement and stress-fracture in the upward and repeated mining of close-distance coal seams. Adv. Civ. Eng. 2024, 2024, 5548837. [Google Scholar] [CrossRef]

- Shi, Z.S.; Zhao, H.W.; Qin, B.; Liang, B.; Hao, J.F. Experimental study on rock strata movement and stope stress distribution law under mining height regulation. Energy Sci. Eng. 2024, 12, 1531–1550. [Google Scholar] [CrossRef]

- Ma, J.H.; Hou, C.; Hou, J.T. Numerical and similarity simulation study on the protection effect of composite protective layer mining with gently inclined thick coal seam. Shock Vib. 2021. [Google Scholar] [CrossRef]

- National Coal Mine Safety Administration. Detailed Rules for Preventing Coal and Gas Outbursts; China Coal Industry Publishing House: Beijing, China, 2019. Available online: https://www.gov.cn/xinwen/2019-08/21/content_5423024.htm (accessed on 15 July 2024).

| Coal Seam Dip Angle α/° | Pressure Relief Angle δ/° | |||

|---|---|---|---|---|

| δ1 | δ2 | δ3 | δ4 | |

| 0 | 80 | 80 | 75 | 75 |

| 10 | 77 | 83 | 75 | 75 |

| 20 | 73 | 87 | 75 | 75 |

| 30 | 69 | 90 | 77 | 70 |

| 40 | 65 | 90 | 80 | 70 |

| 50 | 70 | 90 | 80 | 70 |

| 60 | 72 | 90 | 80 | 70 |

| 70 | 72 | 90 | 80 | 72 |

| 80 | 73 | 90 | 78 | 75 |

| 90 | 75 | 90 | 75 | 80 |

| Borehole No. | Borehole Collar Location | Terminal Borehole Position | Azimuth Angle/° | Dip Angle/° | Borehole Diameter/mm | Sealing Depth/m | Borehole Length/m | |

|---|---|---|---|---|---|---|---|---|

| K1 | Wu8-31220 high-level drainage roadway | 400 m from the opening | 15 m inside the demarcation boundary | 191 | 55 | 94 | 85 | 90 |

| K2 | On the demarcation boundary | 191 | 65 | 94 | 80 | 84 | ||

| K3 | 15 m outside the demarcation boundary | 191 | 70 | 94 | 80 | 85 | ||

| K4 | Wu8-31200 intake roadway | 610 m from the opening | 15 m inside the demarcation boundary | 11 | 59 | 94 | 78 | 82 |

| K5 | 600 m from the opening | On the demarcation boundary | 11 | 69 | 94 | 72 | 77 | |

| K6 | 590 m from the opening | 15 m outside the demarcation boundary | 11 | 81 | 94 | 72 | 76 | |

| K7 | Wu8-31220 high-level drainage roadway | 65 m from the starting cut | 15 m inside the demarcation boundary | 191 | 60 | 94 | 85 | 90 |

| K8 | 50 m from the starting cut | On the demarcation boundary | 191 | 55 | 94 | 80 | 85 | |

| K9 | 35 m from the starting cut | 15 m outside the demarcation boundary | 191 | 55 | 94 | 82 | 86 | |

| K10 | Wu8-31220 high-level drainage roadway | 127 m from the return airway | 15 m inside the demarcation boundary | 191 | 57 | 94 | 79 | 82 |

| K11 | 112 m from the return airway | On the demarcation boundary | 191 | 55 | 94 | 82 | 86 | |

| K12 | 97 m from the return airway | 15 m outside the demarcation boundary | 191 | 60 | 94 | 80 | 85 | |

| Test Point | Distance from Wu8-31220 Starting Cut/m | Actual Maximum Expansion Deformation/‰ |

|---|---|---|

| P1 | 350 | 10.83 |

| P2 | 550 | 11.32 |

| P3 | 800 | 12.63 |

| P4 | 1000 | 13.55 |

| P5 | 1100 | 11.13 |

| P6 | 1200 | 9.89 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tong, Y.; Liu, Q.; Wang, Q.; Zhu, C.; Wu, Y. Research on the Pressure Relief Mechanism of Gently Inclined Long-Distance Lower Protective Layer Mining and Cooperative Gas Control Technology. Processes 2025, 13, 1656. https://doi.org/10.3390/pr13061656

Tong Y, Liu Q, Wang Q, Zhu C, Wu Y. Research on the Pressure Relief Mechanism of Gently Inclined Long-Distance Lower Protective Layer Mining and Cooperative Gas Control Technology. Processes. 2025; 13(6):1656. https://doi.org/10.3390/pr13061656

Chicago/Turabian StyleTong, Yanjun, Qian Liu, Qinming Wang, Chuanjie Zhu, and Yue’e Wu. 2025. "Research on the Pressure Relief Mechanism of Gently Inclined Long-Distance Lower Protective Layer Mining and Cooperative Gas Control Technology" Processes 13, no. 6: 1656. https://doi.org/10.3390/pr13061656

APA StyleTong, Y., Liu, Q., Wang, Q., Zhu, C., & Wu, Y. (2025). Research on the Pressure Relief Mechanism of Gently Inclined Long-Distance Lower Protective Layer Mining and Cooperative Gas Control Technology. Processes, 13(6), 1656. https://doi.org/10.3390/pr13061656