Degradation Law of Long-Term Performance in In-Service Emulsified Asphalt Cold Recycled Mixtures

Abstract

1. Introduction

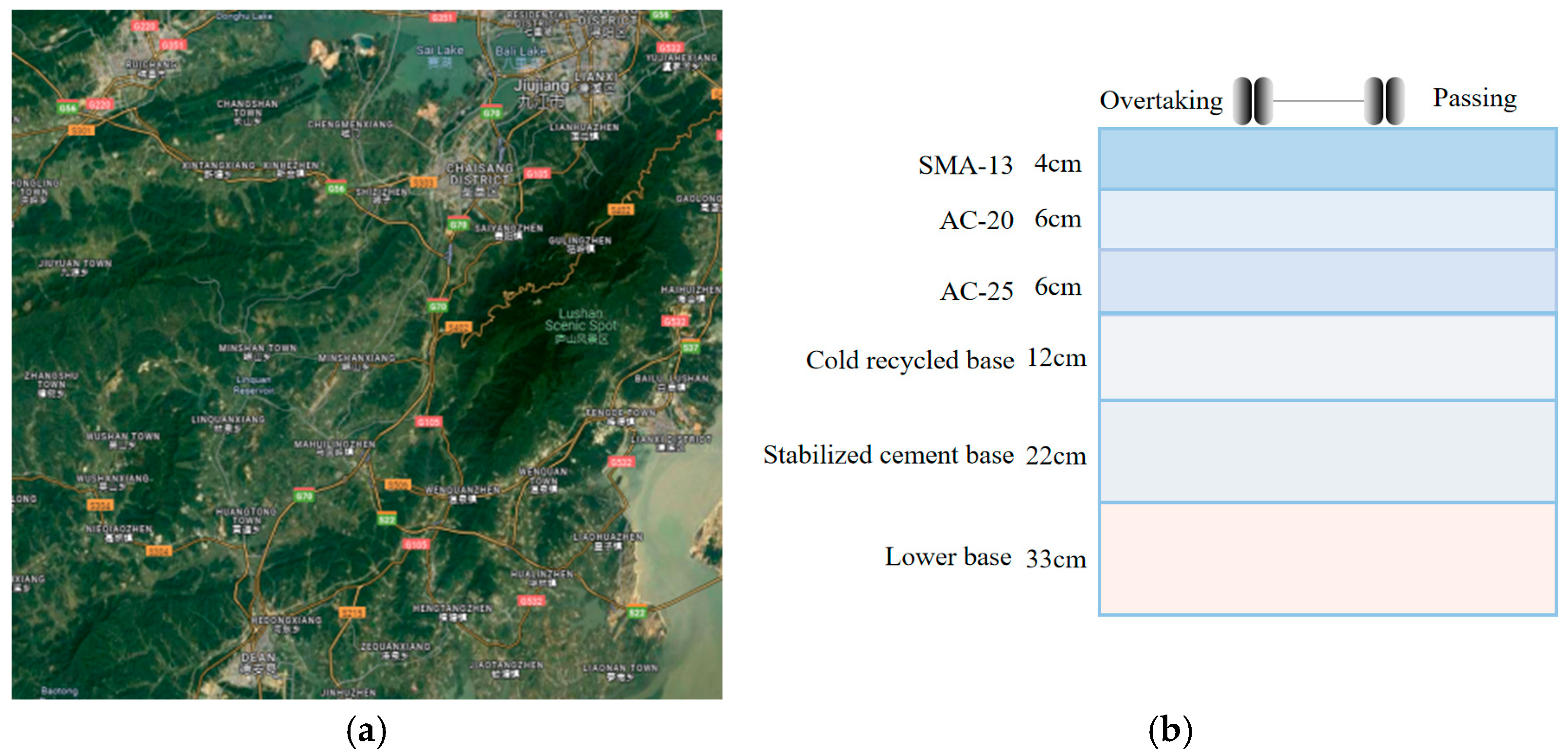

2. Raw Materials and Test Scheme

2.1. Sample Preparation

| Test Items | Unit | Results | Requirement | Test Method | |

|---|---|---|---|---|---|

| Residue on sieve (1.18 mm) | % | 0.03 | ≥0.1 | T0652-1993 [39] | |

| Particle charge | - | Cation | Cation | T0653-1993 [39] | |

| Demulsification rate | - | Slow breaking | Slow or medium breaking | T0658-1993 [39] | |

| Viscosity (Sabot viscosity Vs) | s | 24.98 | 7~100 | T0621-1993 [39] | |

| Evaporated residue content | % | 62.6 | ≤62 | T0651-1993 [39] | |

| Evaporated residue | Penetration 25 °C | 0.1 mm | 71.1 | 50~300 | T0604-2000 [39] |

| Ductility 15 °C | cm | 56.8 | ≤40 | T0605-1993 [39] | |

| Softening point 5 °C | °C | 45.8 | - | T0606-2000 [39] | |

| Solubility | % | — | ≤97.5 | T0607-1993 [39] | |

| Storage stability 1 d | % | 0.8 | ≥1 | T0655-1993 [39] | |

| Storage stability 5 d | % | — | ≥5 | T0655-1993 [39] | |

| Adhesion to coarse aggregate | - | >2/3 | ≤2/3 | T0654-1993 [39] | |

2.2. Test Methods and Evaluation Index

2.2.1. Evaluation Methods for Emulsified Asphalt Cold Recycled Mixture In-Service

- (1)

- Pavement surface condition index (PCI)

- (2)

- Riding quality index (RQI)

- (3)

- Rutting depth index (RDI)

- (4)

- Pavement structure strength index (PSSI)

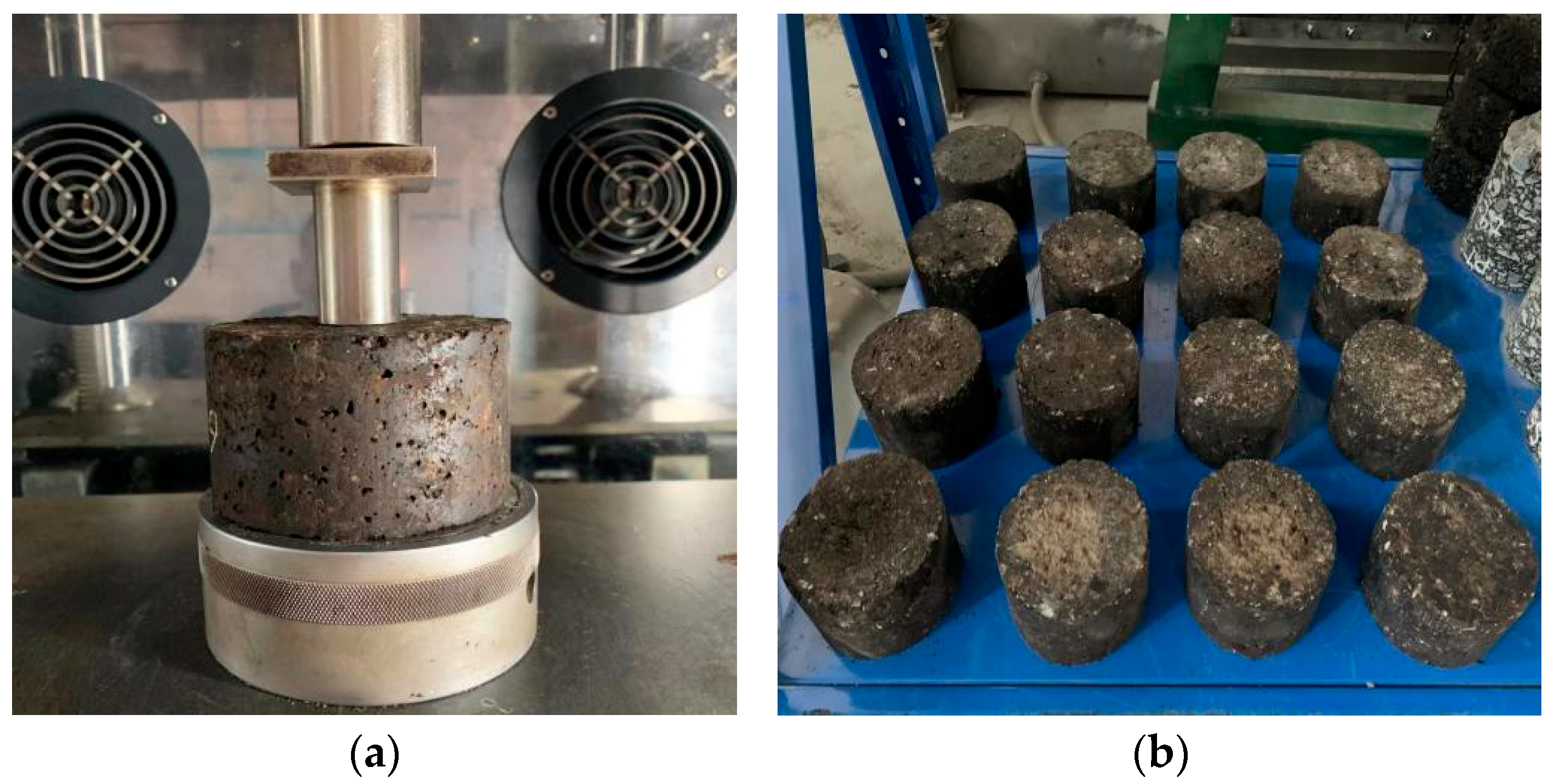

2.2.2. Test Methods and Evaluation for the Performance of Cold Recycled Mixtures

- (1)

- High-temperature performance test

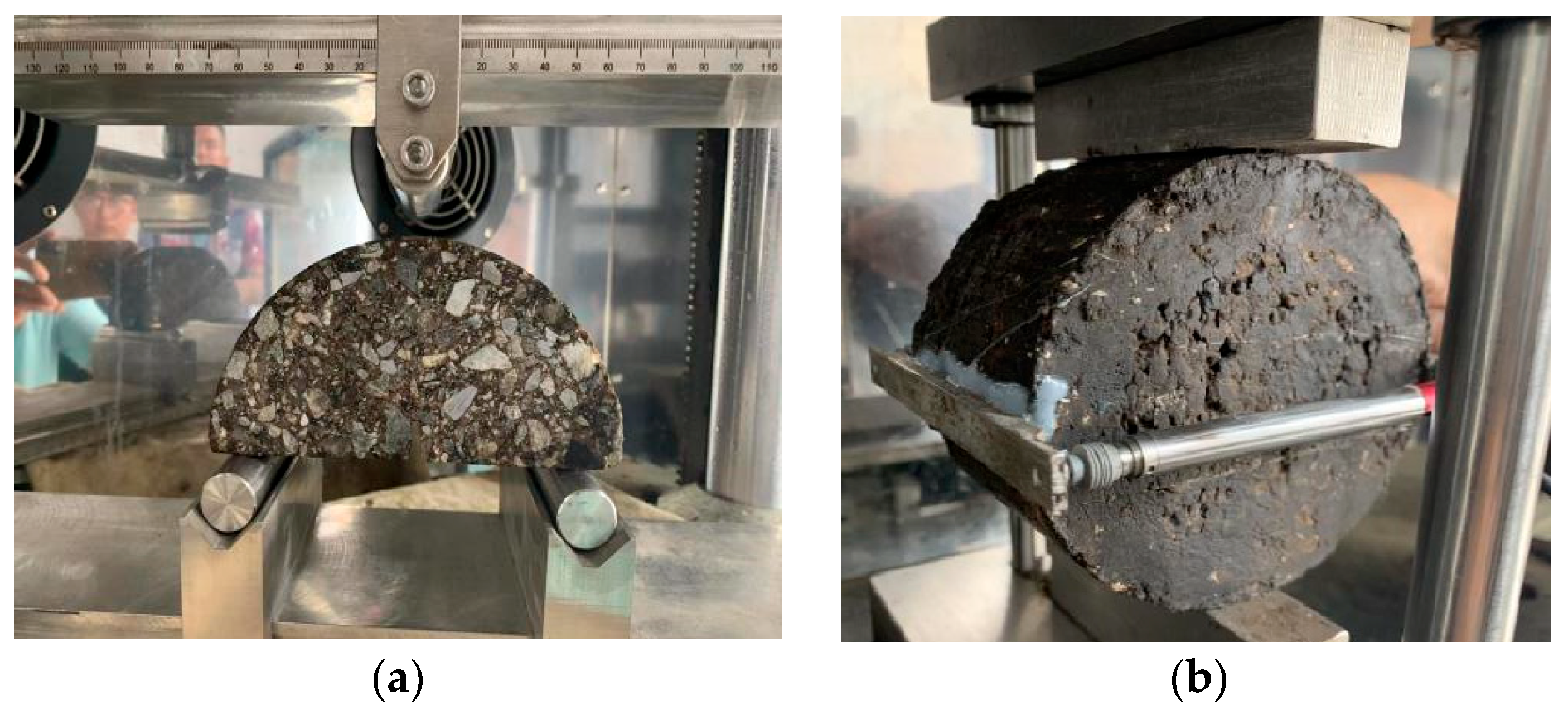

- (2)

- Low-temperature performance test

- (3)

- Fatigue performance test

- (4)

- Water sensitivity test

- (5)

- Mechanical performance test

2.3. Experimental Scheme

- (1)

- The technical condition of cold recycled pavement changes with service life

- (2)

- Performance degradation of in-service emulsified asphalt cold recycled mixture

3. Annual Traffic Volume Investigation

4. Test Results and Analysis

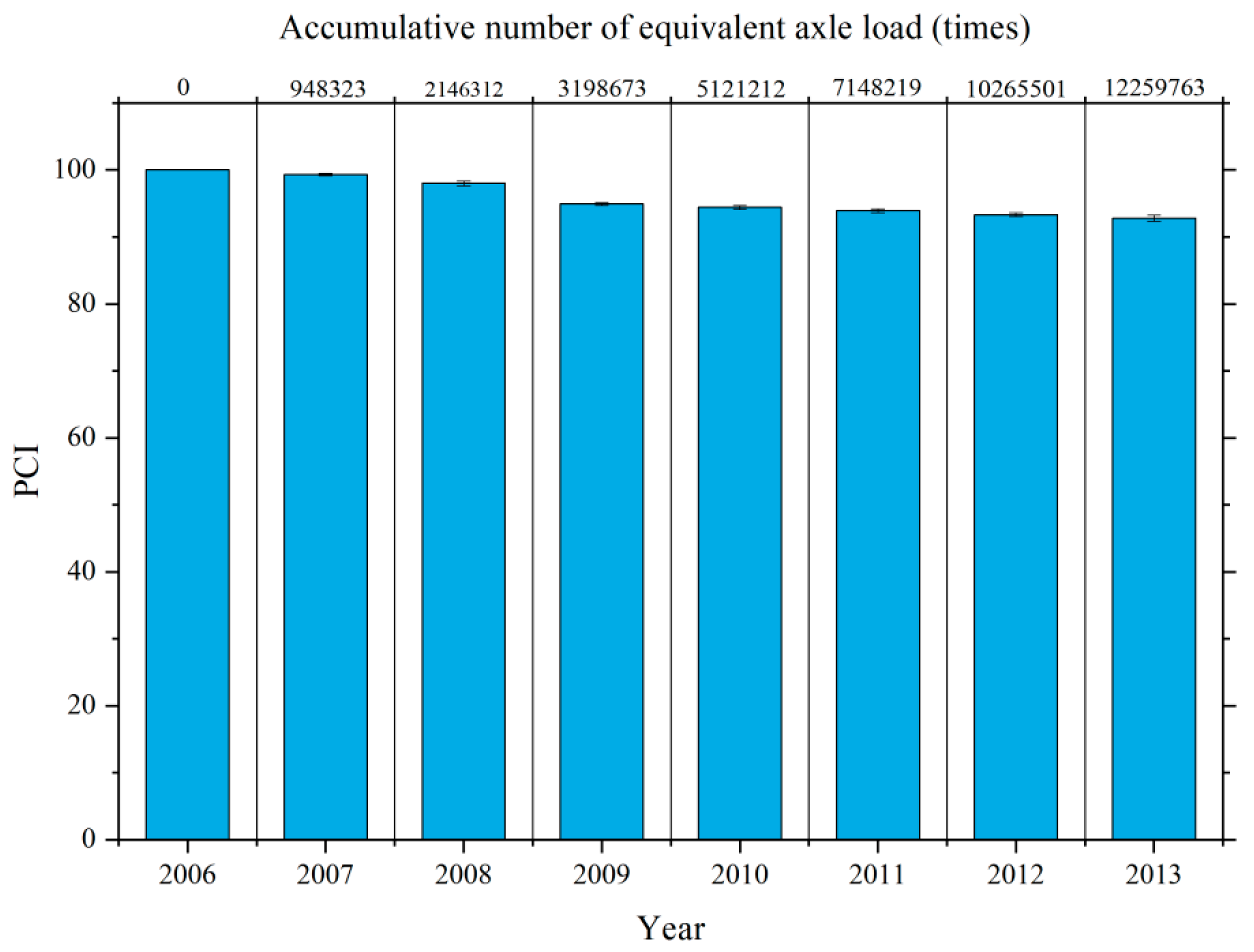

4.1. Technical Status of Emulsified Asphalt Cold Recycled Pavement in Service

4.1.1. Pavement Surface Condition Index (PCI)

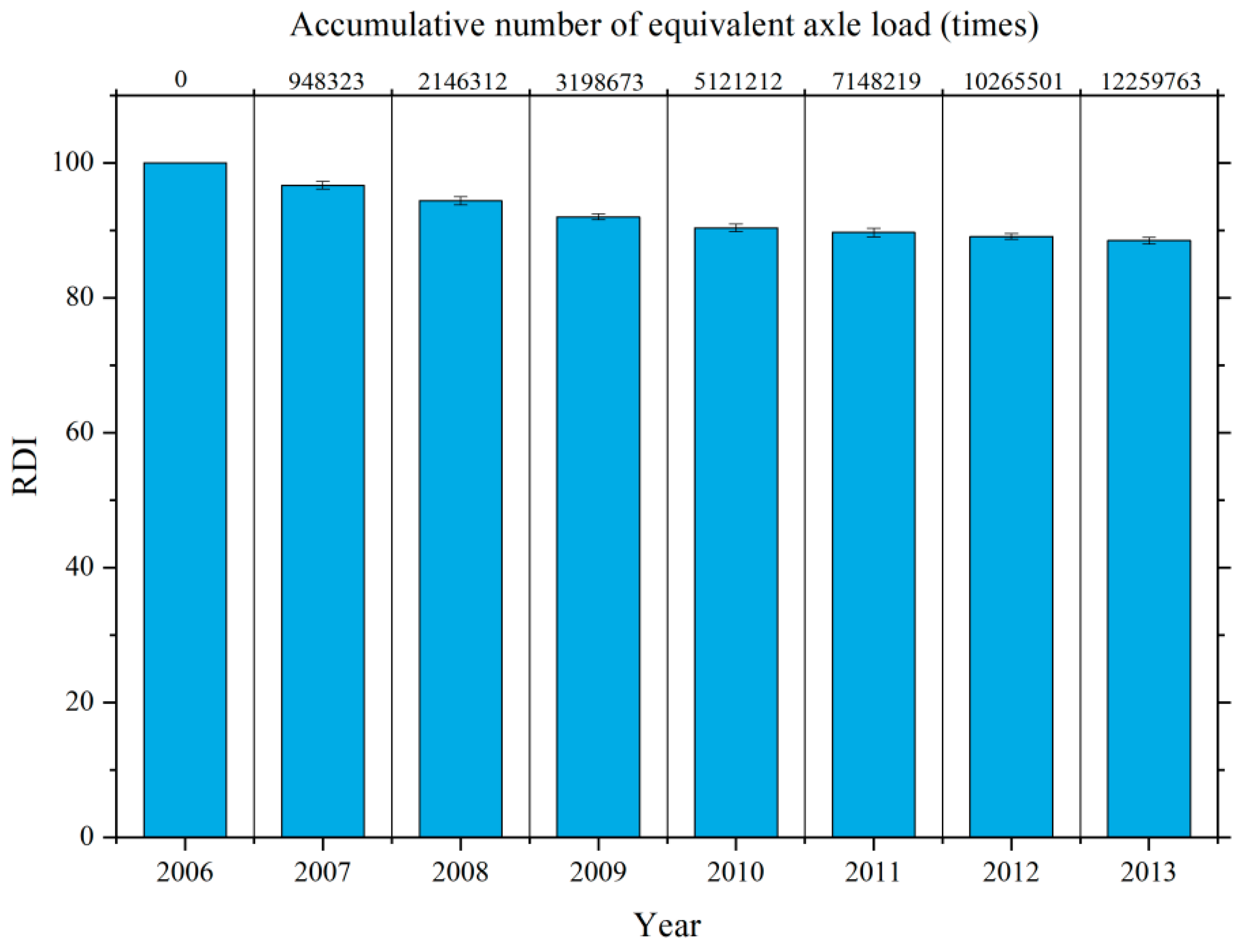

4.1.2. Rutting Depth Index (RDI)

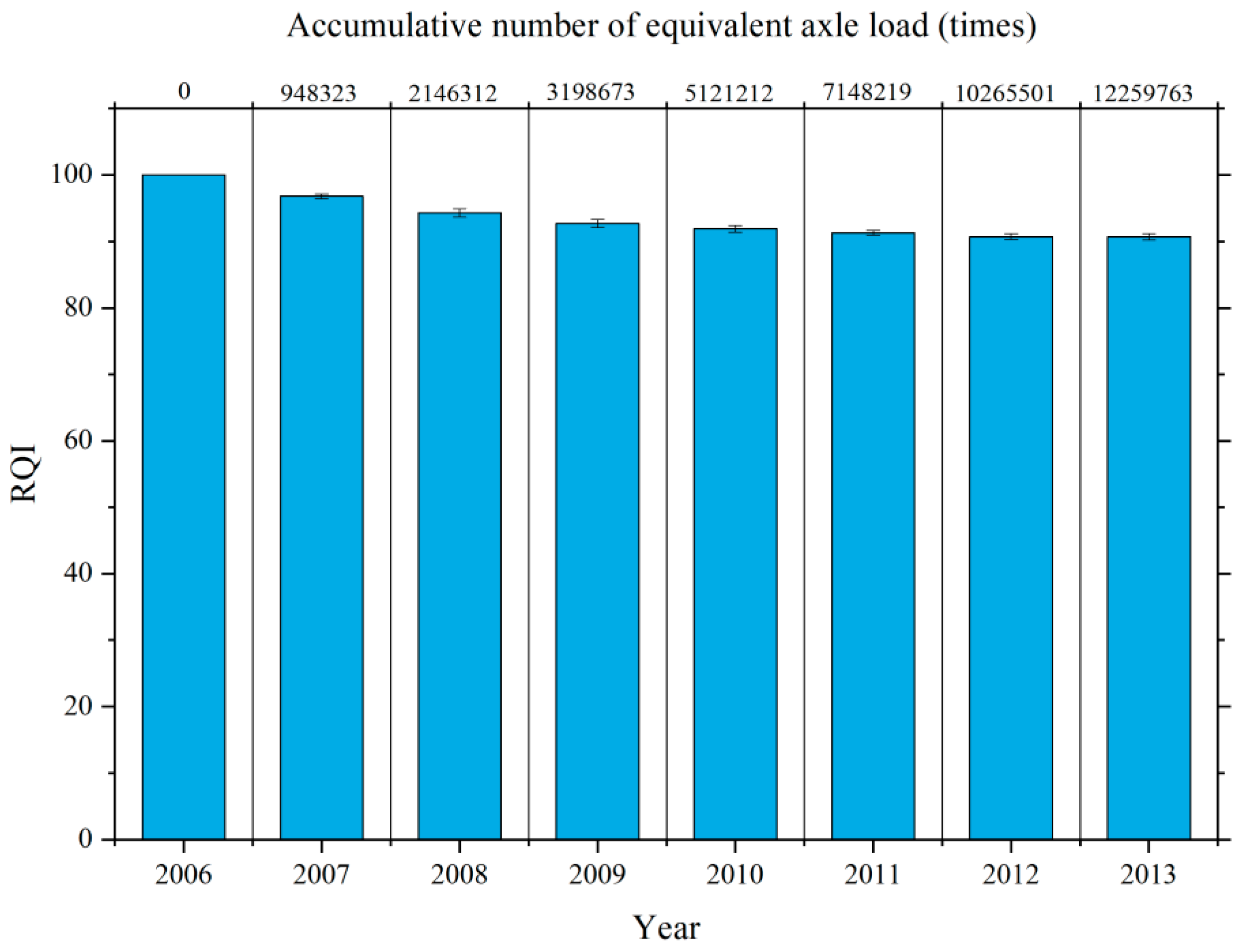

4.1.3. Riding Quality Index (RQI)

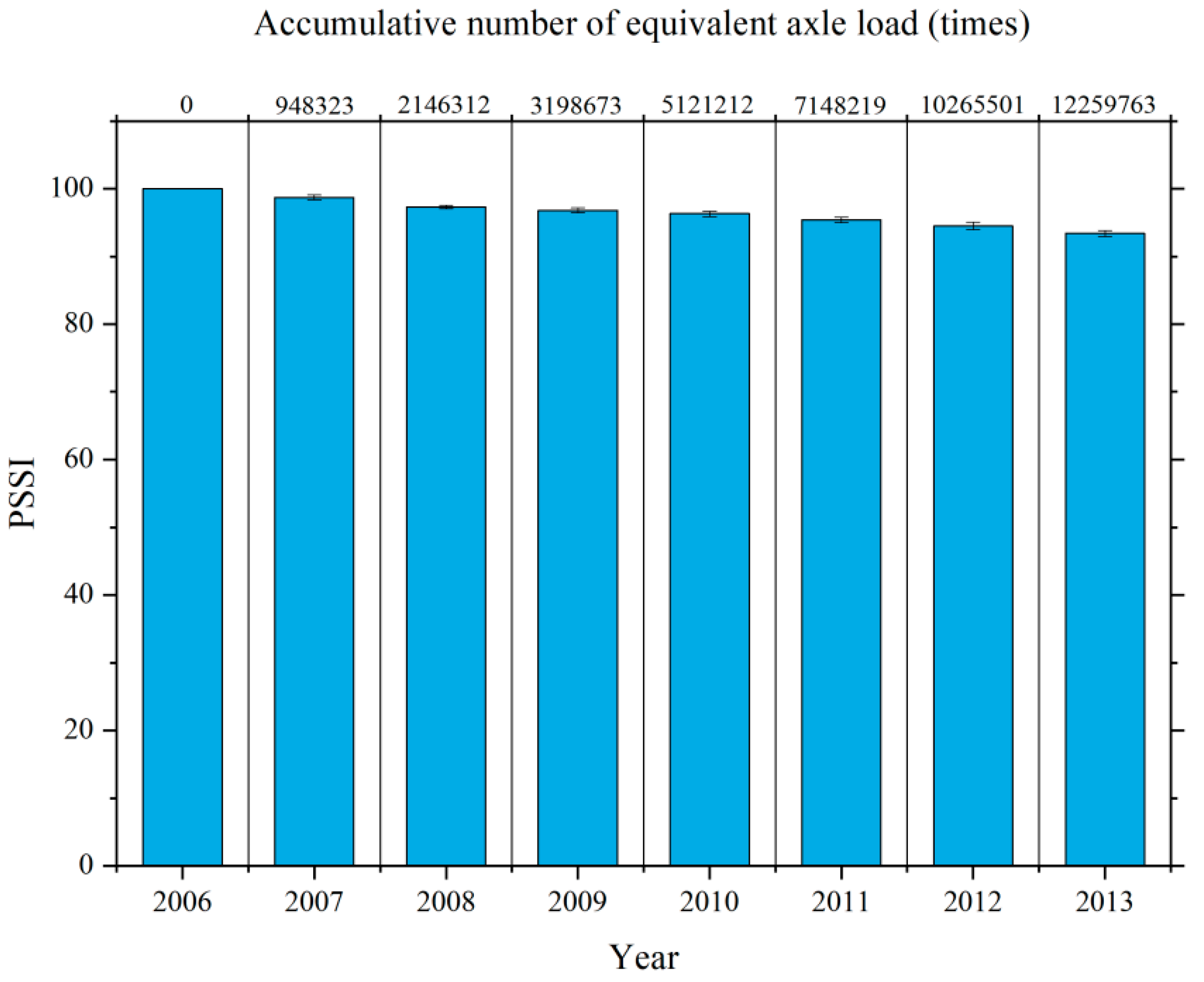

4.1.4. Pavement Structural Strength Index (PSSI)

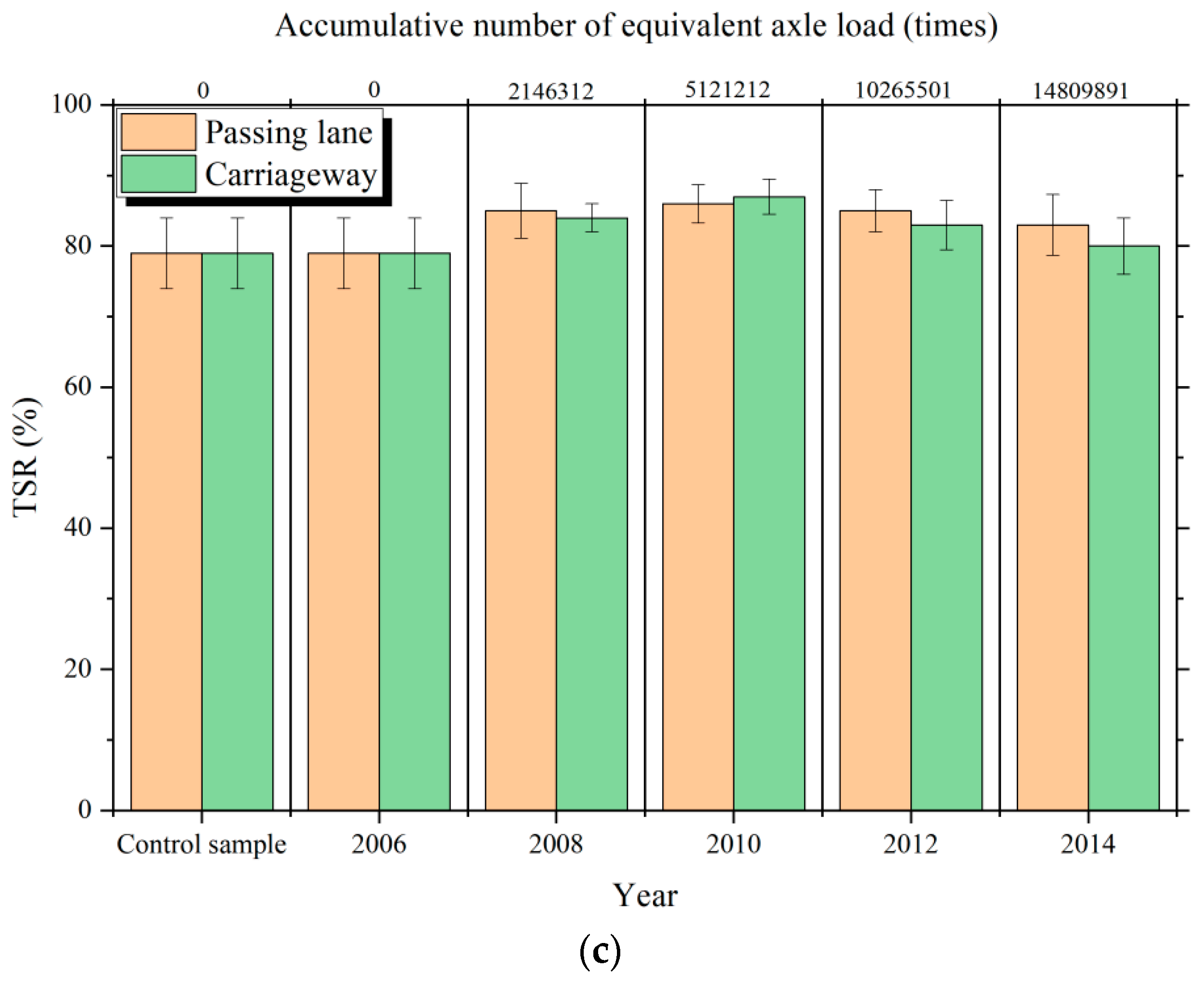

4.2. Performance Test Results of In-Service Emulsified Asphalt Cold Recycled Mixture

4.2.1. Mechanical Properties

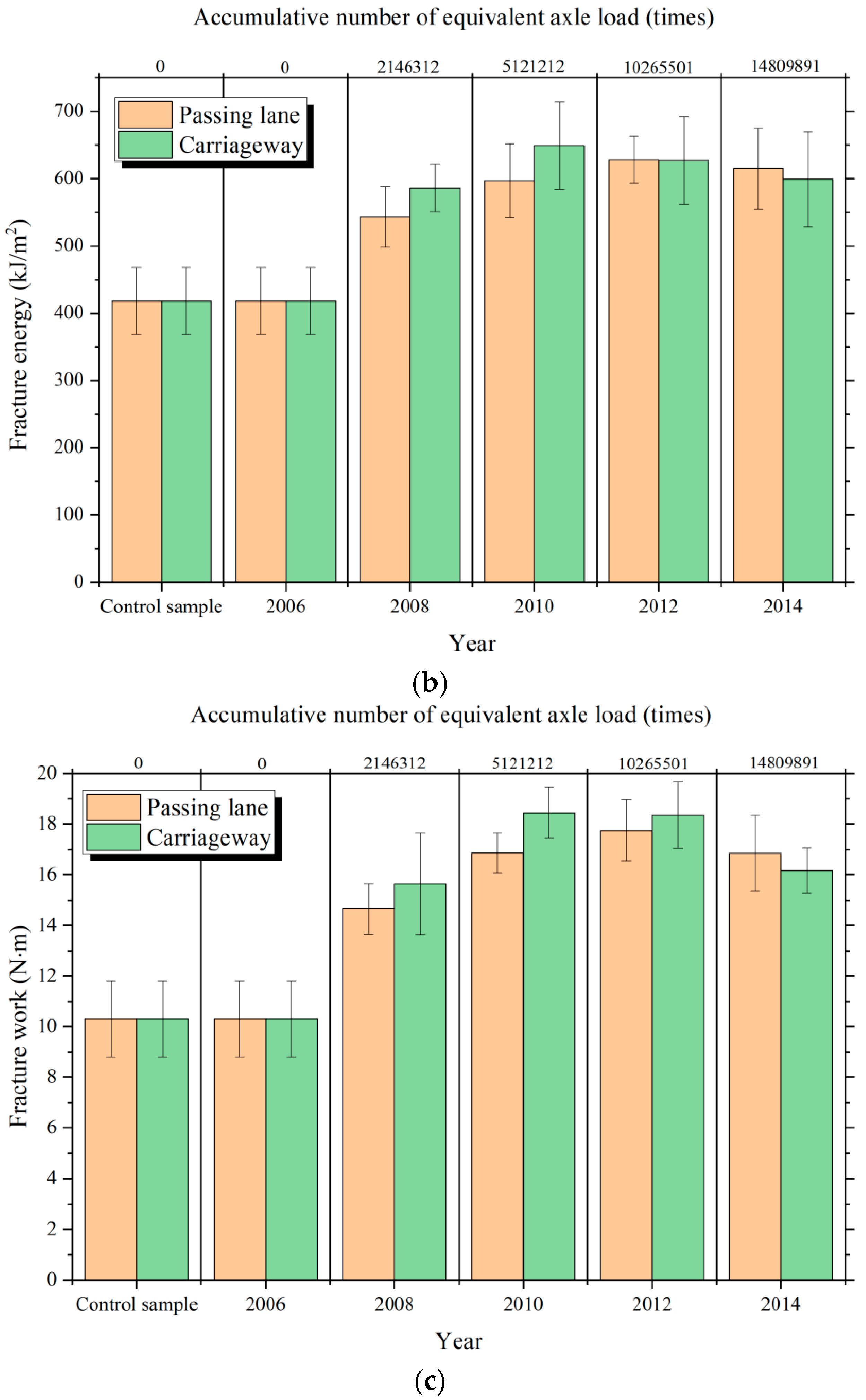

4.2.2. High-Temperature and Low-Temperature Performance

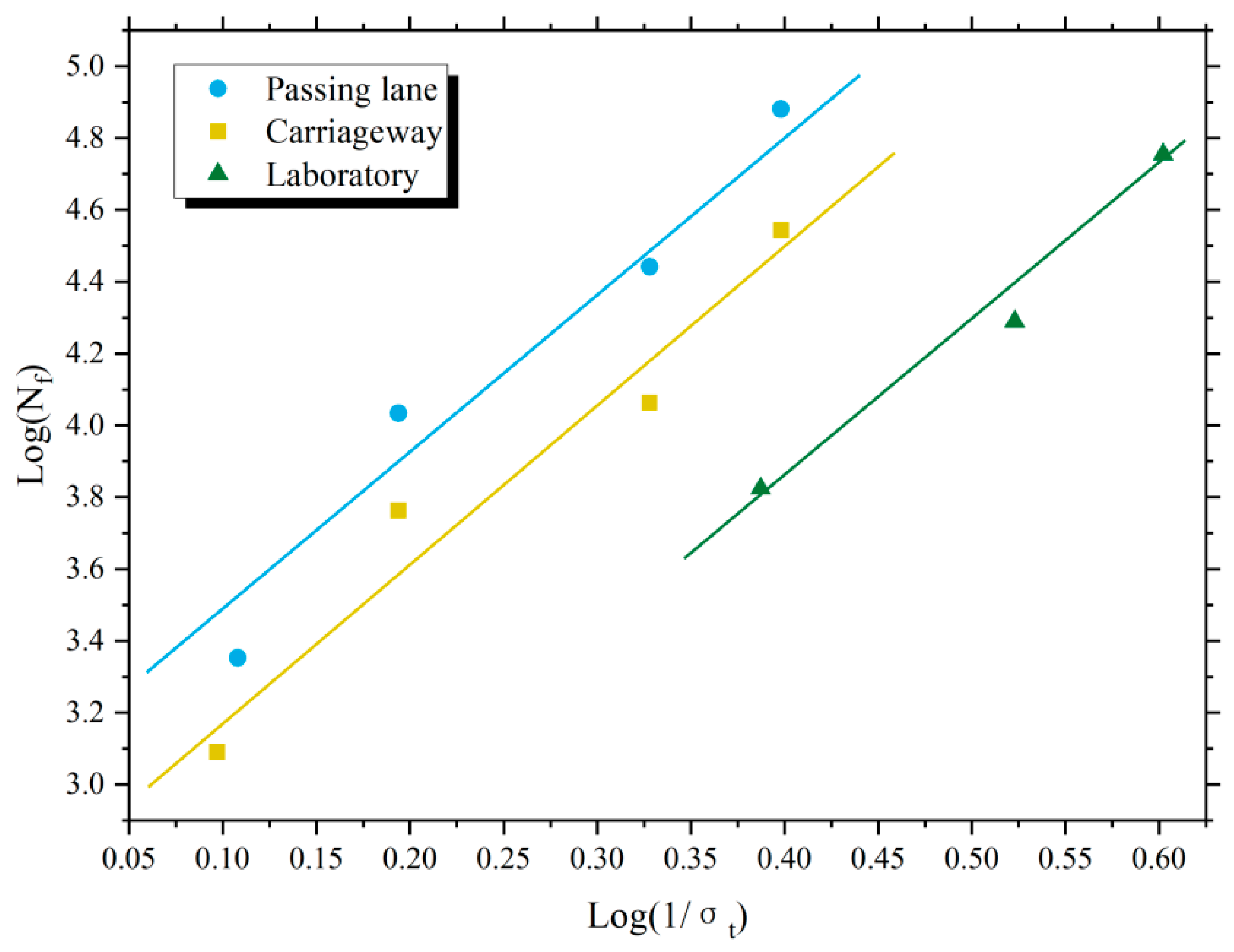

4.2.3. Fatigue Performance

5. Conclusions

- (1)

- After seven years of service with a cumulative equivalent axle load of 12,259,763, PCI, RQI, RDI, and PSSI of emulsified asphalt cold recycled pavement decreased to 92.6 (excellent), 90.1 (excellent), 88.5 (good), and 93.4 (excellent), respectively. This indicates that the emulsified asphalt cold recycled pavement exhibited excellent durability and good service level.

- (2)

- As service time increased, the indirect tensile strength and unconfined compressive strength of the cold recycled layer increased under the effect of loads and environmental factors. On the contrary, the TSR, shear strength, fracture work, and fracture energy initially improved before descending. At the same time, the splitting strength, unconfined compressive strength, shear strength, fracture energy, and fracture work of pavement core samples increased by approximately 63%, 21%, 52%, 43%, and 57%, respectively, after seven years of service compared with laboratory samples.

- (3)

- The residual fatigue life of the emulsified asphalt cold recycled mixture in the passing lane surpassed that of carriageway under the same maximum tensile stress at the center of the samples. The fatigue life of emulsified asphalt cold recycled mixture in the laboratory is inferior to that of in-service. It indicates that the fatigue life of the cold recycled mixture increased during the service period.

- (4)

- During the early stage of strength development in emulsified asphalt cold recycled mixture, the reclaimed asphalt pavement (RAP) primarily is used as “black aggregate”. Throughout the paving stage, the old asphalt recovers its bonding strength by cement hydration, secondary hot compaction, and diffusion between new and aged asphalt. This significantly enhanced the performance of mixtures. The increase in strength and various road performance of the cold recycled layer during the servicing period outweighs the loss incurred by vehicle load and environmental factors, ultimately manifesting as the increase of fatigue life.

- (5)

- Currently, cold recycling technology is being widely adopted in large-scale applications. However, there remains a lack of performance monitoring during the pavement service life, resulting in insufficient feedback from field data to validate laboratory findings. Notably, the selection of design modulus values for cold recycled structural layers still lacks reliable theoretical support. Therefore, it has become an urgent research priority to accurately characterize the modulus degradation mechanisms in in-service cold recycled pavements and establish scientifically justified laboratory-derived design parameters.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Han, Z.; Liu, Z.; Jiang, Y.; Wu, P.; Li, S.; Sun, G.; Zhang, L. Engineering properties and air void characteristics of cold recycled mixtures with different compaction methods. J. Build. Eng. 2023, 77, 107430. [Google Scholar] [CrossRef]

- Hu, M.; Lyu, L.; Pahlavan, F.; Han, P.; Sun, D.; Fini, E.H. Toward Sustainable Non-Emitting Asphalts: Understanding Diffusion–Adsorption Mechanisms of Hazardous Organic Compounds. Adv. Sustain. Syst. 2025, 9, 2400868. [Google Scholar] [CrossRef]

- Li, M.; Han, Z.; Cheng, H.; Yang, R.; Yuan, J.; Jin, T. Low-temperature performance improvement strategies for high RAP content recycled asphalt mixtures: Focus on RAP gradation variability and mixing process. Fuel 2025, 387, 134362. [Google Scholar] [CrossRef]

- Xing, C.; Tang, S.; Chang, Z.; Han, Z.; Li, H.; Zhu, B. A comprehensive review on the plant-mixed cold recycling technology of emulsified asphalt: Raw materials and factors affecting performances. Constr. Build. Mater. 2024, 439, 137344. [Google Scholar] [CrossRef]

- Li, M.; Yuan, J.; Jin, T.; Wang, W.; Sun, Y.; Cheng, H. Investigation of performance evolution in recycled asphalt mixtures: The impact of virgin and RAP binder blending. Constr. Build. Mater. 2025, 469, 140519. [Google Scholar] [CrossRef]

- Pang, Y.; Li, H.; Han, Z.; Wu, P.; Lin, H. Performance evaluation of asphalt mixture reinforced by lignin and ceramic fiber. J. Eng. Res. 2023; in press. [Google Scholar]

- Wu, B.; Han, Z.; Mao, Y.; Wang, S.; Zhao, H.; Zhang, S.; Li, M. Influence of Pavement Material and Structure on Low-Temperature Crack Resistance for Double-Layer Asphalt Surface One-Time Paving. Materials 2025, 18, 1037. [Google Scholar] [CrossRef] [PubMed]

- Han, Z.; Pang, Y.; Lin, H. Improvement of Cold Recycled Mixture Performance Based on Improved Density Test Method and RAP Characteristics. J. Wuhan Univ. Technol. Sci. Ed. 2025, 40, 79–87. [Google Scholar] [CrossRef]

- Yu, X.; Han, Z.; Cai, Y.; Liu, L.; Sun, L. Study on low-temperature index and improvement measures of emulsified asphalt cold recycled mixture. Materials 2022, 15, 7867. [Google Scholar] [CrossRef] [PubMed]

- Deng, C.; Jiang, Y.; Han, Z.; Lin, H.; Fan, J. Effects of Paving Technology, Pavement Materials, and Structures on the Fatigue Property of Double-Layer Pavements. Adv. Mater. Sci. Eng. 2020, 2020, 5038370. [Google Scholar] [CrossRef]

- Han, Z.; Jiang, D.; Liu, L.; Sun, L. Low-Temperature Performance Improvement Measures for Emulsified Asphalt Cold Recycled Mixture: A Comparative Study. J. Mater. Civ. Eng. 2023, 35, 04023108. [Google Scholar] [CrossRef]

- Zhu, C.; Zhang, H.; Huang, L.; Wei, C. Long-term performance and microstructure of asphalt emulsion cold recycled mixture with different gradations. J. Clean. Prod. 2019, 215, 944–951. [Google Scholar] [CrossRef]

- Kong, L.; Ren, D.; Zhou, S.; He, Z.; Ai, C.; Yan, C. Evaluating the evolution of fiber-reinforced emulsified asphalt cold-recycled mixture damage using digital image correlation. Int. J. Pavement Eng. 2023, 24, 2176495. [Google Scholar] [CrossRef]

- Wu, M.; Xu, G.; Luan, Y.; Zhu, Y.; Ma, T.; Zhang, W. Molecular dynamics simulation on cohesion and adhesion properties of the emulsified cold recycled mixtures. Constr. Build. Mater. 2022, 333, 127403. [Google Scholar] [CrossRef]

- Chen, T.; Luan, Y.; Ma, T.; Zhu, J.; Huang, X.; Ma, S. Mechanical and microstructural characteristics of different interfaces in cold recycled mixture containing cement and asphalt emulsion. J. Clean. Prod. 2020, 258, 120674. [Google Scholar] [CrossRef]

- Zhao, H.; Ren, J.; Chen, Z.; Luan, H.; Yi, J. Freeze and thaw field investigation of foamed asphalt cold recycling mixture in cold region. Case Stud. Constr. Mater. 2021, 15, e00710. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, S.; Ren, J.; Wang, Y.; Wang, C. Fatigue characteristics and prediction of cement-stabilized cold recycled mixture with road-milling materials considering recycled aggregate composition. Constr. Build. Mater. 2021, 301, 124122. [Google Scholar] [CrossRef]

- Gao, L.; Ni, F.; Ling, C.; Yan, J. Evaluation of fatigue behavior in cold recycled mixture using digital image correlation method. Constr. Build. Mater. 2016, 102, 393–402. [Google Scholar] [CrossRef]

- Raschia, S.; Perraton, D.; Graziani, A.; Carter, A. Influence of low production temperatures on compactability and mechanical properties of cold recycled mixtures. Constr. Build. Mater. 2020, 232, 117169. [Google Scholar] [CrossRef]

- Xiao, F.; Yao, S.; Wang, J.; Li, X.; Amirkhanian, S. A literature review on cold recycling technology of asphalt pavement. Constr. Build. Mater. 2018, 180, 579–604. [Google Scholar] [CrossRef]

- Dong, S.; Wang, D.; Hao, P.; Zhang, Q.; Bi, J.; Chen, W. Quantitative assessment and mechanism analysis of modification approaches for cold recycled mixtures with asphalt emulsion. J. Clean. Prod. 2021, 323, 129163. [Google Scholar] [CrossRef]

- Du, S. Effect of different fibres on the performance properties of cold recycled mixture with asphalt emulsion. Int. J. Pavement Eng. 2022, 23, 3444–3453. [Google Scholar] [CrossRef]

- Luan, Y.; Ma, T.; Wang, S.; Ma, Y.; Xu, G.; Wu, M. Investigating mechanical performance and interface characteristics of cold recycled mixture: Promoting sustainable utilization of reclaimed asphalt pavement. J. Clean. Prod. 2022, 369, 133366. [Google Scholar] [CrossRef]

- Jiang, J.; Ni, F.; Zheng, J.; Han, Y.; Zhao, X. Improving the high-temperature performance of cold recycled mixtures by polymer-modified asphalt emulsion. Int. J. Pavement Eng. 2020, 21, 41–48. [Google Scholar] [CrossRef]

- Lin, J.; Hong, J.; Xiao, Y. Dynamic characteristics of 100% cold recycled asphalt mixture using asphalt emulsion and cement. J. Clean. Prod. 2017, 156, 337–344. [Google Scholar] [CrossRef]

- Ren, J.; Zhang, L.; Zhao, H.; Zhao, Z.; Wang, S. Determination of the fatigue equation for the cement-stabilized cold recycled mixtures with road construction waste materials based on data-driven. Int. J. Fatigue 2022, 158, 106765. [Google Scholar] [CrossRef]

- Pettinari, M.; Simone, A. Effect of crumb rubber gradation on a rubberized cold recycled mixture for road pavements. Mater. Des. 2015, 85, 598–606. [Google Scholar] [CrossRef]

- Ren, J.; Wang, S.; Zang, G. Effects of recycled aggregate composition on the mechanical characteristics and material design of cement stabilized cold recycling mixtures using road milling materials. Constr. Build. Mater. 2020, 244, 118329. [Google Scholar] [CrossRef]

- Mamlouk, M.S.; Ayoub, N.F. Evaluation of Long-Term Behavior of Cold Recycled Asphalt Mixture. Transp. Res. Rec. 1983, 64–66. [Google Scholar]

- Graziani, A.; Godenzoni, C.; Cardone, F.; Bocci, M. Effect of curing on the physical and mechanical properties of cold-recycled bituminous mixtures. Mater. Des. 2016, 95, 358–369. [Google Scholar] [CrossRef]

- Lida, A. The effects of added softening agents upon the behavior of cold recycled asphalt mixtures. NASA STI/Recon Tech. Rep. N 1980, 82, 13268. [Google Scholar]

- Sebaaly, P.E.; Bazi, G.; Hitti, E.; Weitzel, D.; Bemanian, S. Performance of cold in-place recycling in Nevada. Transp. Res. Rec. J. Transp. Res. Board 2004, 1896, 162–169. [Google Scholar] [CrossRef]

- Deng, J.L. Research on Interface Strength Mechanism of Emulsified Asphalt Cold Recycled Mixture. Master’s Thesis, Southeast University, Nanjing, China, 2019. [Google Scholar]

- Chen, Z. Research on Long-Term Performance of Cold Regenerated Mixtures Based on Time-Temperature Equivalence. Master’s Thesis, Southeast University, Nanjing, China, 2019. [Google Scholar]

- Tian, Y.; Wang, H. Properties of in-service foam asphalt cold recycled mixture. Highway 2019, 1, 223–231. [Google Scholar]

- Liu, N. Study on Medium and Long-Term Performance of Cold Recycled Mixture of Foamed Asphalt and Emulsified Asphalt. Ph.D. Dissertation, Chang’an University, Xi’an, China, 2012. [Google Scholar]

- Liu, L.; Han, Z.; Wu, P.; Zheng, G.; Sun, L. Study on the laboratory mixing and compaction methodology of emulsified asphalt cold recycled mixture. Front. Mater. 2020, 7, 231. [Google Scholar] [CrossRef]

- Hebei Provincial Administration for Market Regulation. Technical Specification for Cold Recycling of Emulsified Asphalt in Highway Pavement Construction; China Communications Press: Beijing, China, 2020. [Google Scholar]

- JTG F40-2004; Technical Standards of the Chinese Technical Specifications for Construction of Highway Asphalt Pavements. China Communication Press: Beijing, China, 2004.

- DB13/T-2020; Technical Specification for Cold Recycled Construction of Emulsified Asphalt on Highway Asphalt Pavements. National Library of Standards: Beijing, China, 2020.

- JTG E20-2011; Test Specification for Asphalt and Asphalt Mixtures in Highway Engineering. China Communication Press: Beijing, China, 2011.

- JTG 5210-2018; Technical Evaluation Standards for Highway Conditions. China Communication Press: Beijing, China, 2018.

- Jenkins, K.J.; Long, F.M.; Ebels, L.J. Foamed bitumen mixes shear performance? Int. J. Pavement Eng. 2007, 8, 85–98. [Google Scholar] [CrossRef]

- Tian, T.; Jiang, Y.; Yi, Y.; Nie, C. The splitting fatigue properties of ultra-large particle size asphalt mixture under the coupling effect of temperature and load. Eng. Fract. Mech. 2025, 319, 110990. [Google Scholar] [CrossRef]

- Sun, L.; Cheng, H.; Liu, L.; Cao, W. Fatigue performance of in-service emulsified asphalt cold recycled mixtures. J. Tongji Univ. Nat. Sci. 2017, 45, 1648–1654+1687. [Google Scholar]

| Vehicle Type | Number of Seats or Load Capacity | Average Axle Load Equivalency Factor |

|---|---|---|

| Class 3 Bus | 20–39 seats | 0.12 |

| Class 4 Bus | ≥40 seats | 0.48 |

| Class 1 Truck | ≤2 tons | 0.12 |

| Class 2 Truck | 2.1–5 tons | 0.43 |

| Class 3 Truck | 5.1–10 tons | 1.12 |

| Class 4 Truck | 10.1–15 tons | 2.50 |

| Class 5 Truck | ≥15.1 tons | 5.00 |

| Class 1 Container Vehicle | 20′ container | 2.33 |

| Class 2 Container Vehicle | 40′ container | 6.22 |

| Type | Stress Ratio (%) | Maximum Tensile Stress at the Center of the Sample (MPa) | Fatigue Life (Times) | Average Value (Times) | Standard Deviation |

|---|---|---|---|---|---|

| Passing lane | 0.25 | 0.40 | 79,968 | 76,038 | 16,542 |

| 90,262 | |||||

| 57,885 | |||||

| 0.30 | 0.47 | 20,900 | 27,680 | 5982 | |

| 29,923 | |||||

| 32,216 | |||||

| 0.40 | 0.64 | 9450 | 10,814 | 1936 | |

| 13,030 | |||||

| 9962 | |||||

| 0.50 | 0.78 | 2330 | 2256 | 1172 | |

| 3390 | |||||

| 1048 | |||||

| Carriageway | 0.25 | 0.4 | 38,300 | 34,963 | 3124 |

| 32,106 | |||||

| 34,482 | |||||

| 0.30 | 0.47 | 10,700 | 11,580 | 2689 | |

| 14,600 | |||||

| 9441 | |||||

| 0.40 | 0.64 | 4280 | 5798 | 1633 | |

| 5587 | |||||

| 7527 | |||||

| 0.50 | 0.80 | 860 | 1234 | 492 | |

| 1050 | |||||

| 1792 | |||||

| Laboratory | 0.25 | 0.25 | 46,590 | 56,833 | 15,520 |

| 49,220 | |||||

| 74,690 | |||||

| 0.30 | 0.30 | 16,926 | 19,470 | 2981 | |

| 18,733 | |||||

| 22,750 | |||||

| 0.40 | 0.41 | 5612 | 6680 | 1614 | |

| 8537 | |||||

| 5892 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, B.; Wang, S.; Ma, Z.; Zhao, H.; Zhu, H. Degradation Law of Long-Term Performance in In-Service Emulsified Asphalt Cold Recycled Mixtures. Processes 2025, 13, 1561. https://doi.org/10.3390/pr13051561

Wu B, Wang S, Ma Z, Zhao H, Zhu H. Degradation Law of Long-Term Performance in In-Service Emulsified Asphalt Cold Recycled Mixtures. Processes. 2025; 13(5):1561. https://doi.org/10.3390/pr13051561

Chicago/Turabian StyleWu, Bingyang, Shuai Wang, Ziqi Ma, Hui Zhao, and Hengkang Zhu. 2025. "Degradation Law of Long-Term Performance in In-Service Emulsified Asphalt Cold Recycled Mixtures" Processes 13, no. 5: 1561. https://doi.org/10.3390/pr13051561

APA StyleWu, B., Wang, S., Ma, Z., Zhao, H., & Zhu, H. (2025). Degradation Law of Long-Term Performance in In-Service Emulsified Asphalt Cold Recycled Mixtures. Processes, 13(5), 1561. https://doi.org/10.3390/pr13051561