3.1. Surface Topography and Roughness

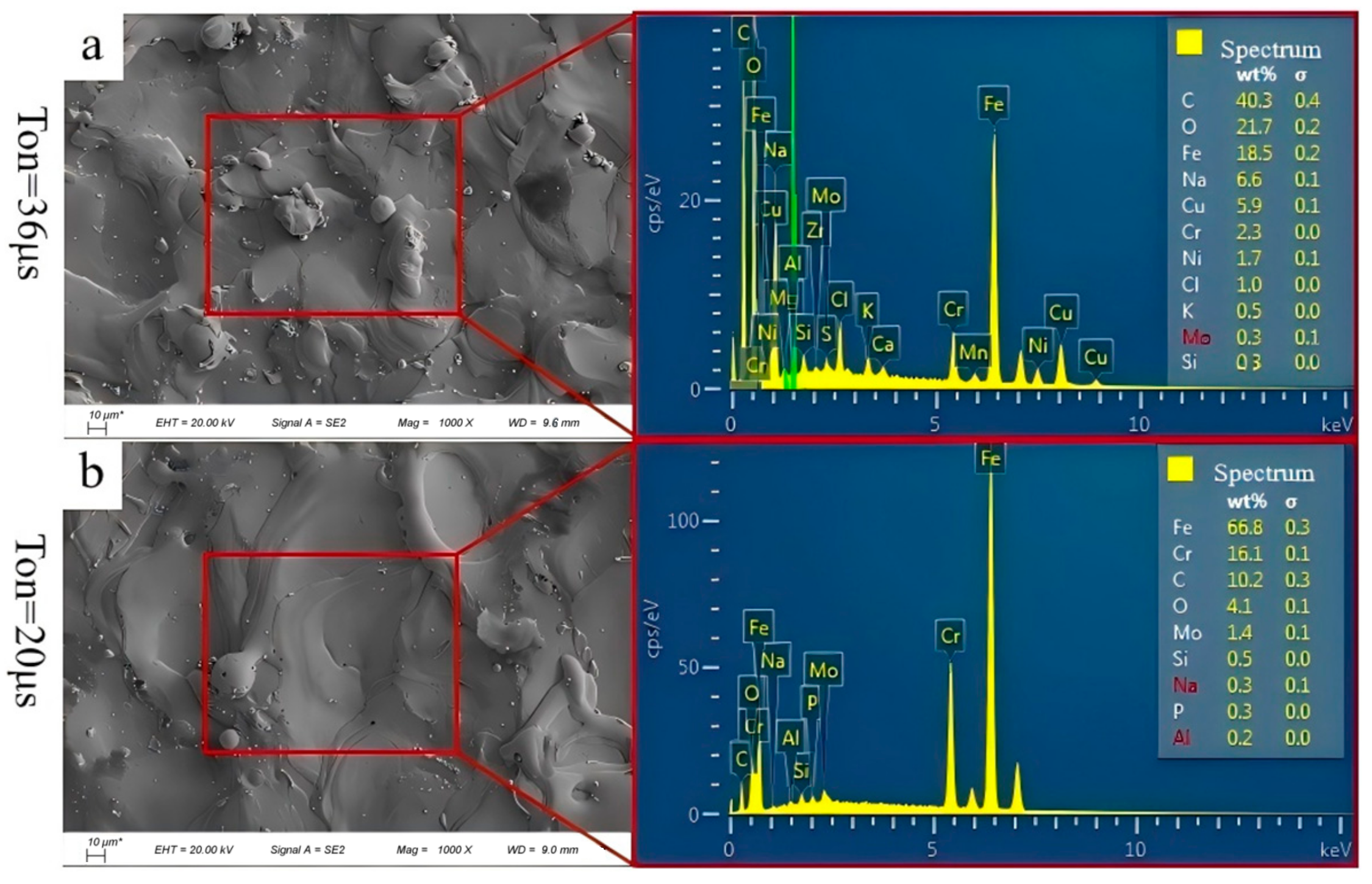

Figure 4 presents the SEM results regarding the morphology of the machined surface under two different working conditions. There are some similarities between the SEM results for 9Cr18MoV stainless steel and those for pure metals such as tungsten titanium, including microcracks, microspheres, and microvias. During WEDM, a significant amount of heat is instantaneously generated, reaching extremely high temperatures (6000–10,000 °C), causing localized melting and vaporization of metal. The volcanic lava-like crenelation morphology on the sample surface is formed by the rapid cooling of the surface of the material under the influence of discharge energy, resulting in a recast layer [

20].

Comparative analysis of the SEM images reveals distinct differences in surface morphology between

Figure 4a,b. The combination of machining process parameters in

Figure 4a is T

on = 36 μs, T

off = 3 μs, IP = 11 A, and WS = 4; the combination of machining process parameters in

Figure 4b is T

on = 36 μs, T

off = 7 μs, IP = 7 A, and WS = 6. The surface in

Figure 4a exhibits significantly greater complexity, characterized by a higher density of microspheres, micropores, and adhered debris particles. This morphological variation is primarily due to enhanced discharge energy associated with increased peak current levels, which generates a substantial amount of thermal energy during the machining process. These elevated thermal conditions promote the extensive melting and vaporization of the stainless steel material [

21]. These thermal effects ultimately compromise the material’s surface integrity, manifesting as increased R

a values.

Figure 5 presents a comparison of SEM images of the machined surfaces under pulse widths of 36 μs and 20 μs, respectively. Through comparative analysis, it is evident that the surface morphology in (b) (T

on = 20 μs) is significantly smoother than that in (a) (T

on = 36 μs). Defects such as microspheres, micropores, and protrusions are notably reduced in the right image [

22]. This phenomenon can be attributed to changes in discharge energy: as T

on increases, the discharge energy also increases, leading to a significant rise in the heat released during the machining process. Under these conditions, the 9Cr18MoV material undergoes more pronounced melting and vaporization, resulting in a greater accumulation of substrate material upon cooling and ultimately forming a rougher surface morphology [

23]. Additionally, based on the EDS image on the left, the content of metallic elements such as Fe and Cr decreases under high-pulse conditions, as these elements are more prone to oxidation or evaporation at high temperatures. In contrast, the Mo content remains relatively stable, while the O content increases. This change can be attributed to the thickening of the surface oxide layer and the increase in oxide content as the pulse width increases, leading to a relative reduction in metallic element content. These results indicate that pulse width has a significant impact on surface quality, with lower pulse widths contributing to a smoother surface morphology.

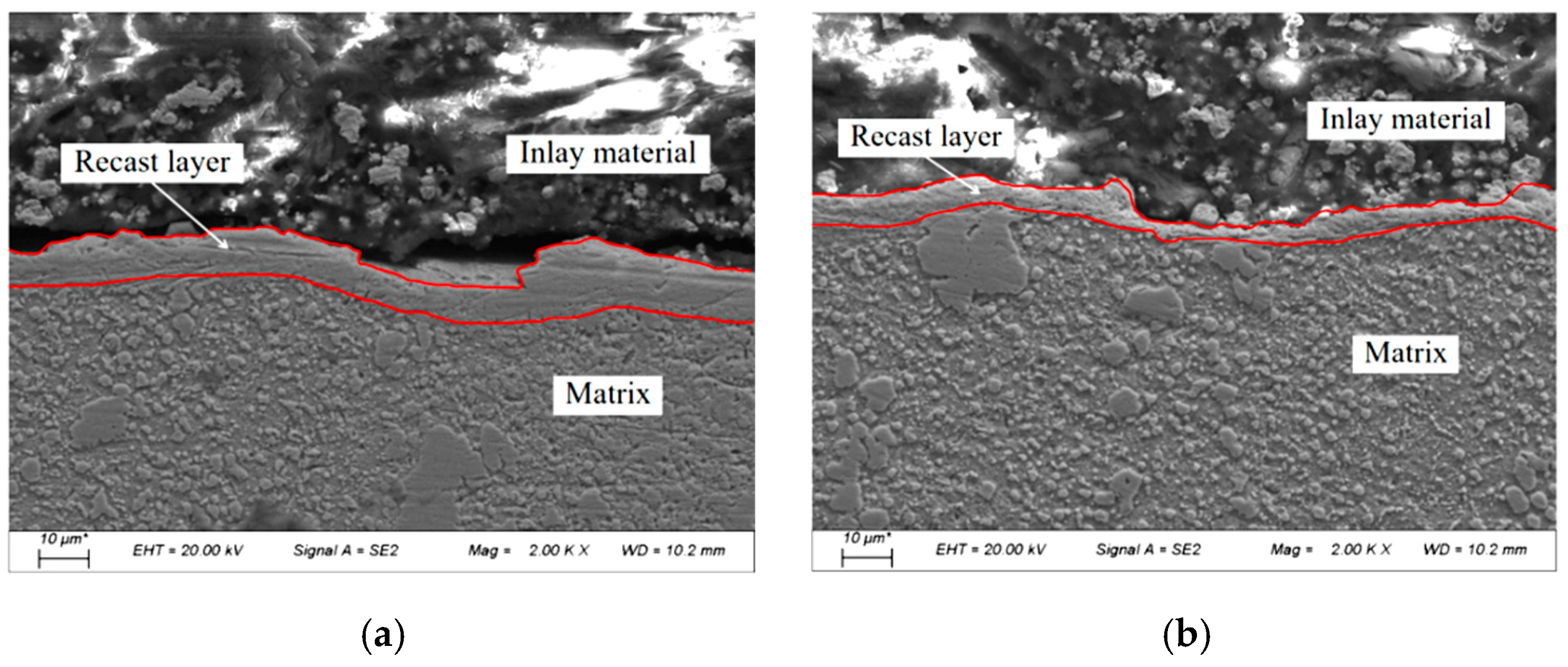

3.2. Surface Recast Layer

After WEDM, the recast layer on a material’s surface exhibits unique and complex morphological characteristics. The recast layer generally covers the machined surface but shows variations in thickness in certain areas. The surface is not entirely smooth but displays a certain degree of undulation, resembling a “hilly terrain” at a microscopic scale.

In this experiment, a total of eight groups of sample recasting layers were measured, and two typical recasting layers were selected, as shown in

Figure 6, for analysis. In the images, it can be observed that the recast layer in

Figure 6a is thicker than that in

Figure 6b, with more pronounced microscopic protrusions and depressions. These protrusions and depressions have sharp edges and irregular shapes, further exacerbating surface unevenness and resulting in a higher R

a value for the layer in

Figure 6a. The thicker recast layer in

Figure 6a is likely due to this layer’s higher IP compared to that in

Figure 6b, injecting more energy into the workpiece surface during discharge pulses. This leads to deeper discharge craters [

24]. The deepening of discharge craters increases the volume of metal debris within the discharge gap, reducing the breakdown strength of the working fluid. After the discharge ends, the melted and vaporized material cools and solidifies, causing more debris to accumulate on the surface and increasing the thickness of the recast layer. Additionally, the heat generated during discharge cannot be fully expelled with the debris, leading to heat accumulation and repeated discharges at the same locations, further deteriorating the machining environment. However, if the IP is too low, the discharge energy becomes insufficient, reducing the amount of melting and vaporization on the material’s surface and resulting in a thinner recast layer. This may lead to issues such as low machining efficiency [

25]. Therefore, in practical WEDM applications, it is essential to carefully control electrical parameters to achieve ideal process metrics and machining outcomes.

3.3. Signal-to-Noise Ratio Analysis

To minimize the interference of random factors in repeated experiments and extract as much valid information as possible from the experimental results, the SNR analysis method was introduced. By calculating the SNR values corresponding to each set of experimental results, data analysis can be performed to account for controllable factors while reducing the influence of random disturbances, thereby improving the accuracy of the computational analysis. In the SNR method, system responses are categorized into three types: nominal is the best, the larger the better, and the smaller the better. For CE, a larger value is desirable, so the larger-the-better characteristic is applied, and the SNR can be calculated using Equation (3). For R

a, a smaller value is preferred, so the smaller-the-better characteristic is used, and the SNR can be calculated using Equation (4). A higher SNR value indicates better experimental results.

Equation (3): The larger the better.

Equation (4): The smaller the better.

In the formulae, S/N represents the signal-to-noise ratio (SNR) of the process target, n is the total number of experimental samples (in this study, n = 16), and y

i is the sample data for the i-th level factor. In the Taguchi analysis response table, the difference between the maximum and minimum average response values for a factor is referred to as Delta. A larger Delta value for a given factor indicates that it has a greater influence on the evaluation metric, and thus the factor ranks higher in importance [

26].

By substituting the experimental results regarding CE and R

a into the respective formulas, the corresponding SNR values were calculated, as shown in

Table 4. Since each factor has four levels and there are 16 experimental groups in total, each level corresponds to four sets of SNR values.

The mean SNR values for CE were calculated for each level of each factor based on the corresponding four experimental groups, and the results are plotted in

Figure 7. In

Figure 7, the following trends can be observed: As T

on increases, CE initially rises and then decreases. As T

off increases, CE shows a declining trend. As IP increases, CE initially rises and then stabilizes. As WS increases, CE first decreases and then increases. Additionally, the plots indicate that the IP has the largest range of mean SNR values, suggesting that IP has the most significant influence on CE. This is because the peak current determines the energy intensity of a single pulse. A higher peak current implies greater energy release, which can melt the material more rapidly, thereby improving CE.

The optimal parameter combination for maximizing CE was determined by selecting the levels corresponding to the highest mean SNR values for each factor. The optimal parameter combination is as follows: Ton: 28 μs, Toff: 3 μs, IP: 11 A, and WS: Level 3.

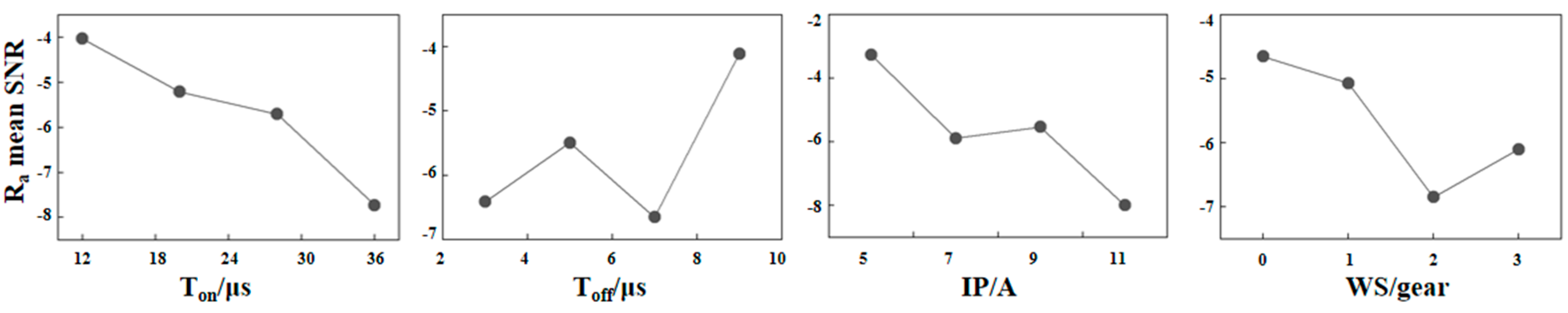

The mean SNR values for R

a were calculated for each level of each factor based on the corresponding four experimental groups, and the results are plotted in

Figure 8. In

Figure 8, the following trends can be observed: As T

on increases, R

a shows a declining trend. As T

off increases, R

a initially rises, then decreases, and finally rises again. As IP increases, R

a first decreases and then increases. As WS increases, R

a gradually decreases. Furthermore, the plots indicate that the IP has the largest range of mean SNR values, suggesting that IP has the most significant influence on R

a. This is because a higher peak current generates larger discharge craters, leading to an increase in R

a. Therefore, the greater the peak current, the more pronounced the surface roughness. The optimal parameter combination for minimizing R

a was determined by selecting the levels corresponding to the highest mean SNR values for each factor. The optimal parameter combination is as follows: T

on: 12 μs, T

off: 9 μs, IP: 5 A, and WS: Level 0.

3.4. Grey Correlation Method for Multi-Objective Optimization Analysis

For different evaluation dimensions, the influence of factors varies. That is, the optimal factor combination for surface roughness may not necessarily be the best for cutting speed [

27]. In practical WEDM of 9Cr18MoV, it is essential to consider both CE and R

a comprehensively. Therefore, multi-objective optimization analysis is necessary. In this study, we employed the GRA method, a multi-factor statistical analysis approach in which sample data are used to describe the strength, magnitude, and order of relationships between factors through grey relational degrees. The calculation process for grey relational degrees is as follows [

28]: The comparison sequence consists of a set of data under the two optimization indicators in

Table 4, where x

e(k) represents the SNR values for CE and R

a, respectively. Here, e = 1, 2: When e = 1, x

e(k) corresponds to the CE optimization indicator. When e = 2, x

e(k) corresponds to the R

a optimization indicator. k is the sequence number of the experimental trials.

The reference sequence represents the ideal value for the e-th optimization indicator. The maximum SNR values from the two optimization indicators are set as the reference sequence, i.e., = (35.485, −0.906).

- 2.

Data Normalization

Since the dimensions and magnitudes of the data for each factor may differ, it is necessary to perform dimensionless processing on the data. The normalization formula for the comparison sequence is as follows [

29]:

Equation (5): Normalized formula.

In the formula, ye(k) represents the dimensionless normalized value for the e-th indicator in the k-th experiment, where k = 1, 2, 3, …, 16.

- 3.

Calculate Grey Relational Coefficients

The formula for calculating the grey relational coefficient ξ

e(k) is as follows [

30]:

Equation (6): Grey correlation coefficient.

In the formula, represents the maximum difference between the two levels, m represents the minimum difference between the two levels, and ρ is the distinguishing coefficient.

The value of ρ is calculated according to Equation (7), as follows [

30]:

Equation (7): Distinguishing coefficient.

Since this experiment involved two optimization indicators, a distinguishing coefficient ρ was calculated for each pair of indicators. Therefore, the final distinguishing coefficient used in this study is ρ = 0.178.

- 4.

Determine the Weights of Grey Relational Coefficients

The weights of the grey relational coefficients were determined using the Analytic Hierarchy Process (AHP). Based on expert analysis, the importance of CE relative to R

a was set to 3, while the importance of R

a relative to CE was set to 1/3. This establishes the evaluation matrix Q. By calculating the maximum eigenvalue λ

max and its corresponding eigenvector x of matrix Q and normalizing the results, the weight matrix β was obtained [

31].

The evaluation matrix Q is shown in Equation (8). The maximum eigenvalue λ

max = 2, and the eigenvector x is shown in Equation (9). The weight matrix β is shown in Equation (10).

Equation (8): Evaluation matrix.

Equation (9): Eigenvector x.

Equation (10): Weight matrix.

Therefore, the weight for CE is β1 = 0.75, and the weight for Ra is β2 = 0.25. This indicates that the most important optimization indicator in this study is CE.

- 5.

Calculate Grey Relational Grades

The larger the relational grade, the higher the degree of association between the comparison sequence and the reference sequence. The formula for calculating the grey relational grade is as follows [

32]:

Equation (11): Grey relational grade.

In the formula, βe represents the weight of the e-th optimization indicator, and rk represents the grey relational grade value.

The analysis results are shown in

Table 5. Based on the grey relational grade values in

Table 5, the average grey relational grades for each level of the four process parameters were calculated, and a range analysis was performed. The results are presented in

Table 6. The order corresponding to the extent of the influence of the machining process parameters on the CE and R

a evaluation indicators is as follows: T

off, WS, IP, and T

on.

According to the GRA method, a higher average grey relational grade indicates that the corresponding level of the factor yields better target responses, making it the optimal level for that factor [

33]. Based on

Table 5 and

Table 6, the optimal process parameter combination for multi-objective optimization was determined: T

on, 28 μs; Toff, 3 μs; IP, 9 A; and WS, Level 3. Under these machining conditions, the comprehensive grey relational grade for CE and Ra reaches its maximum value, 0.856, demonstrating the feasibility of the multi-objective optimization model based on the grey relational analysis method.