In this section, the method presented above is applied on stable and unstable processes with time delay. In addition to investigating all cases of SBL, the method is also applied to a process with equal numerator and denominators, which is not commonly encountered in literature.

5.1. Example 1

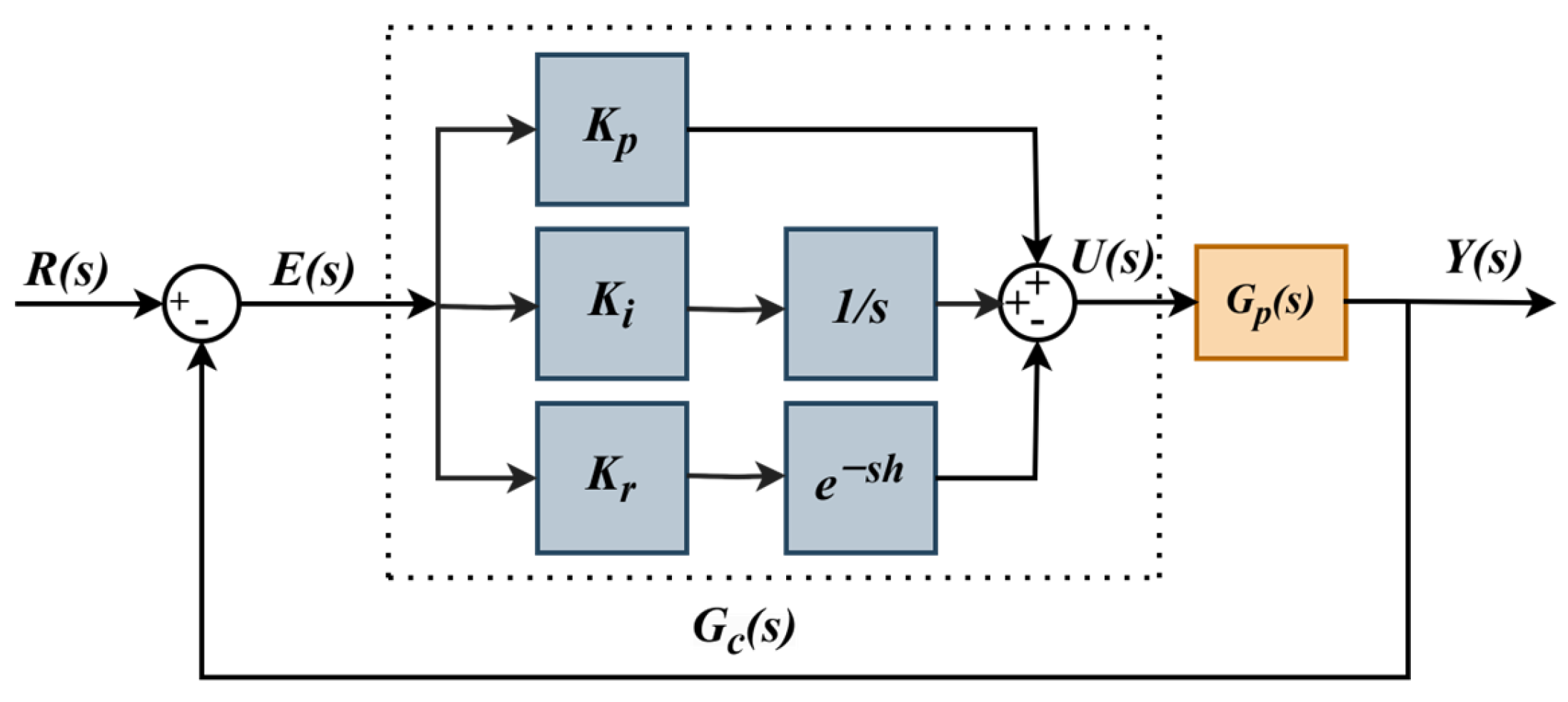

Let us examine the application of the methods described above on the 3rd-order stable time-delay process given in (26) in

Figure 1.

Before starting the analysis, the PIR controller time-delay value should be selected as a fixed value. For this example,

h = 1 was initially taken. Then, in order to draw

SBLs in the planes (

Ki,

Kr) for a fixed

Kp, (

Kr,

Kp) for a fixed

Ki value, and (

Kp,

Ki) for a fixed

Kr value, fixed

Kp, fixed

Ki, and fixed

Kr values should be selected. For this, the controller was initially selected as

, namely the PR controller (

Ki = 0). The

RRB line equation defined in Step 1 was updated for the system in (26) and obtained as

. As

n >

m, the

IRB line will not be formed. The

Kp(ω) and

Kr(ω)

CRB equations are obtained with the help of (24) and (25). Accordingly, the

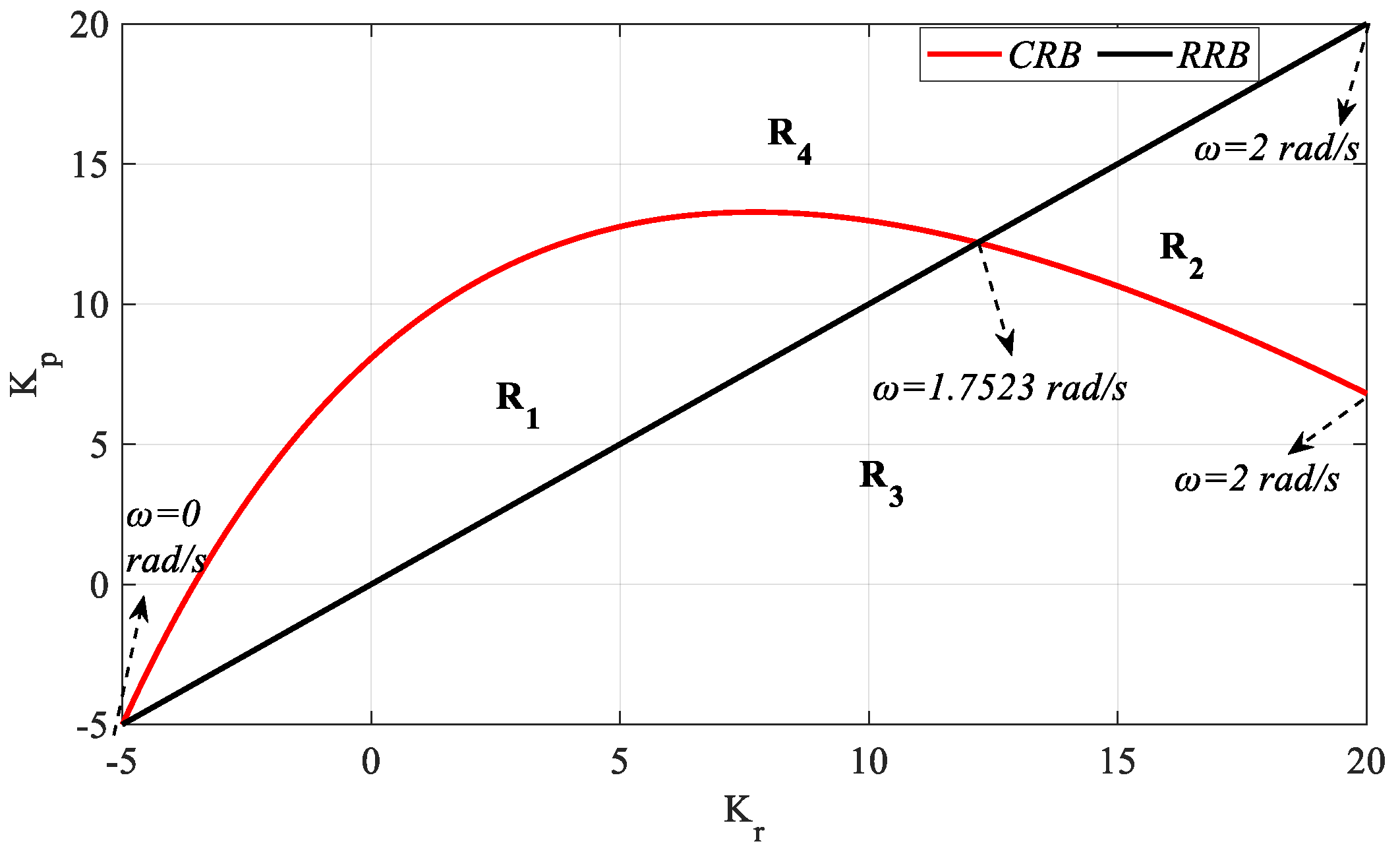

SBL curve was drawn as in

Figure 2 with the help of the

RRB and

CRB equations.

SBL is obtained for the frequency range

ω ∈ [0, 2] rad/s as in

Figure 2. Here, our aim was to find the entire (

Kr,

Kp) parameter region that makes the characteristic polynomial in (4) Hurwitz stable. For this purpose, the stability of (4) is examined by selecting the (

Kr,

Kp) parameter test points from the region bounded by the

CRB and

RRB lines and the regions outside this region. The test points (1.60, 3.16), (17.64, 13.22), (8.86, 4.3), and (6.5, 14.98) are selected from the determined

R1,

R2,

R3, and

R4 regions, respectively. The unit step responses obtained according to these test points are given in

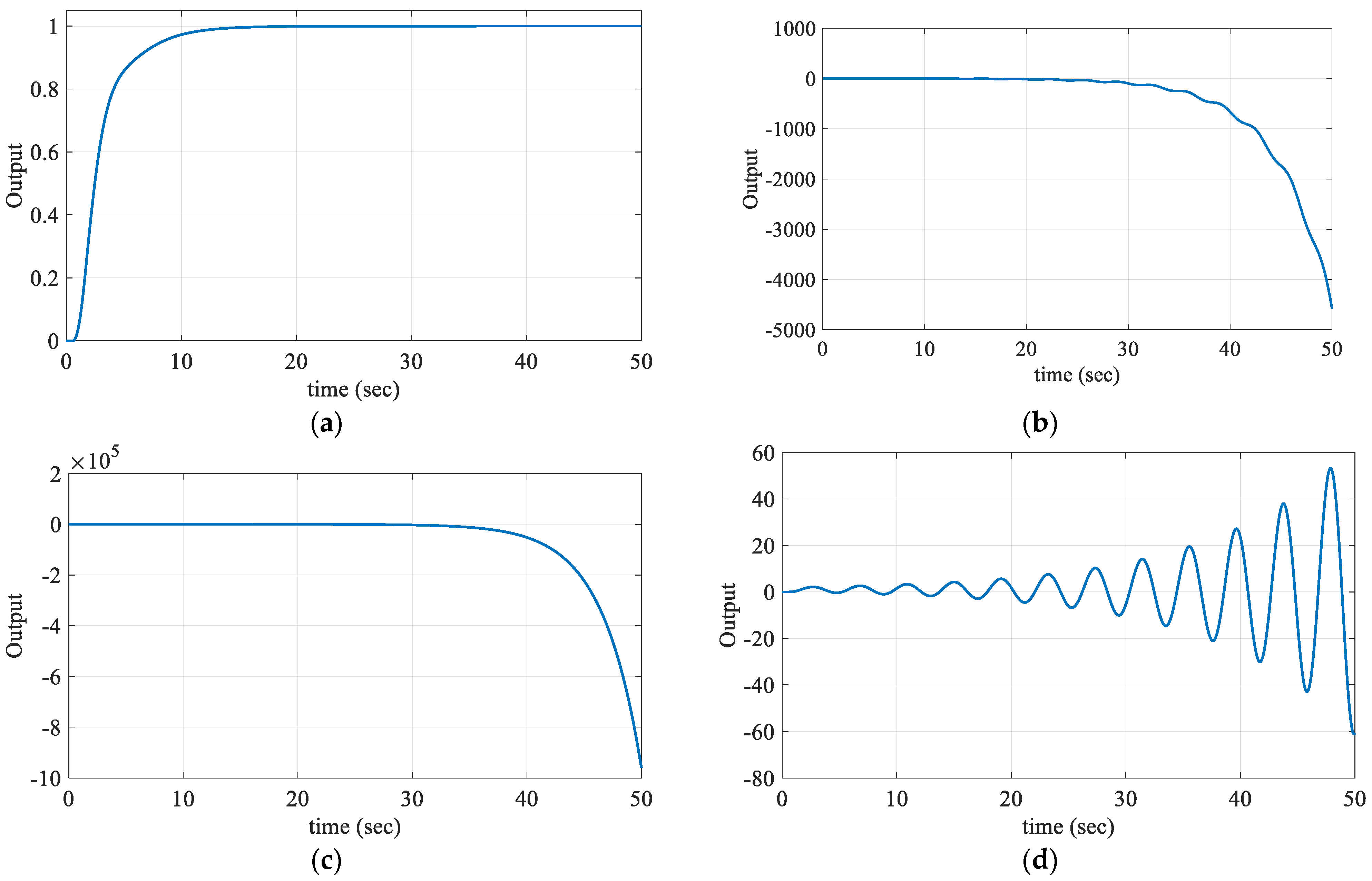

Figure 3.

As the characteristic equations written in (4) for the test points selected from the

R2,

R3, and

R4 regions have a right half-plane pole, these regions are unstable regions, as seen in

Figure 3b–d. The characteristic equation for the test point in the

R1 region has only a left half-plane pole. Therefore, the stable region is the

R1 region that covers the frequency range

ω ∈ [0, 1.7523] rad/s, that is, the region bounded by the

CRB and

RRB lines. Accordingly, the stability region drawn in the (

Kr,

Kp) plane for the PR controller is given in

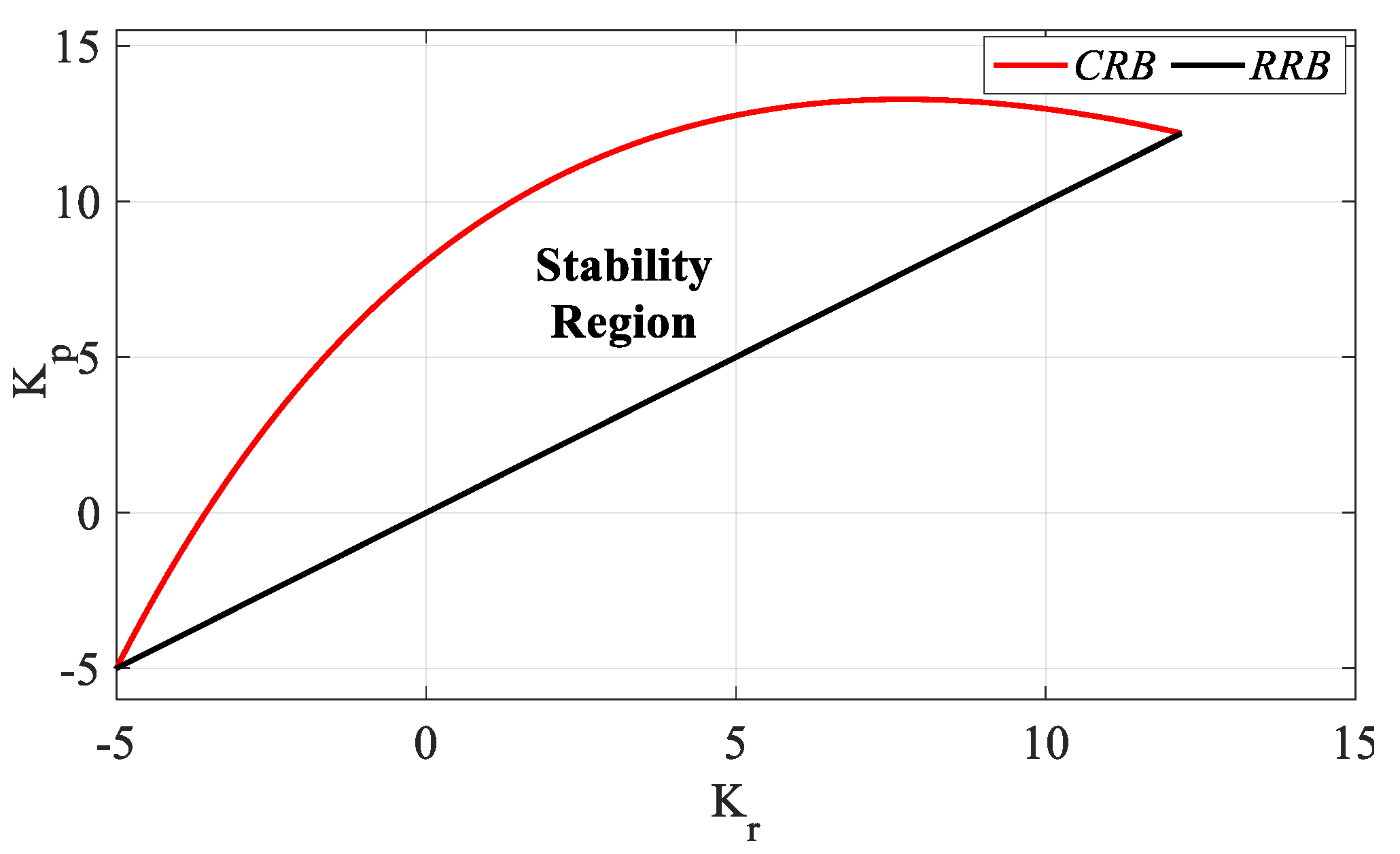

Figure 4.

When

Figure 4 is examined, the

Kp and

Kr controller parameter ranges that make the system stable are determined as [−5 13.28] and [−5 12.18], respectively. For the controller parameter range

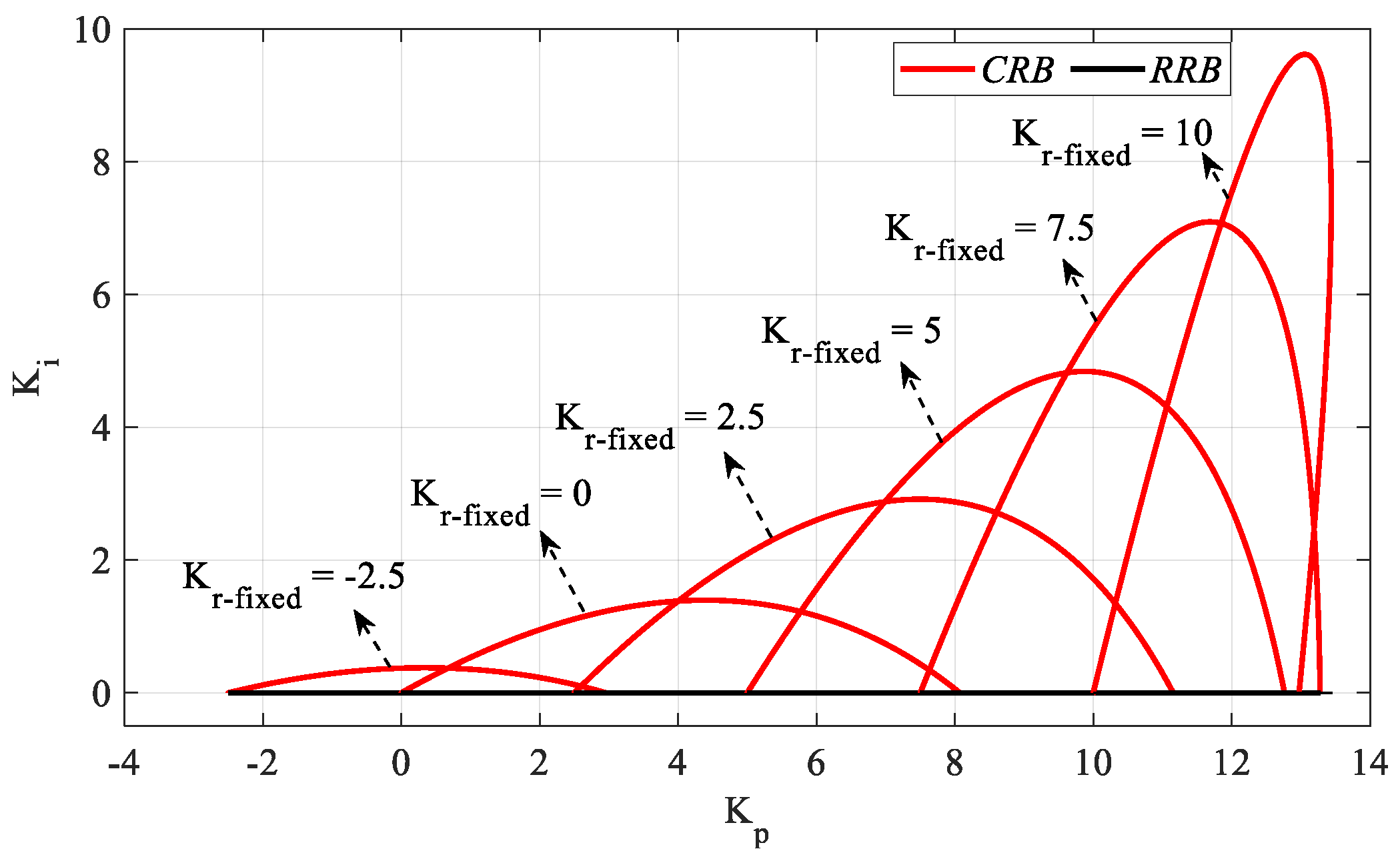

Kr_fixed = [−2.5:2.5:10], the

Kp-Ki SBL graphs are drawn as in

Figure 5 with the help of the

RRB defined with the

Ki = 0 line equation and with the

CRB equations calculated with the help of (16) and (17).

Figure 5 is obtained by plotting the

Kp-Ki SBLs in the frequency range

ω ∈ [0,

ωmax] rad/s for

Kr_fixed = −2.5, 0, 2.5, 5, 7.5, and 10 values. According to the stability analyses for these

Kr_fixed values,

ωmax values were found to be 0.7846, 1.0749, 1.2782, 1.4355, 1.5636, and 1.6710 rad/s, respectively. It should be noted that, for

Kr_fixed = 0, the controller will become a PI controller, and the controller time delay

h will have no effect on the

SBL. It is also concluded that the stability range

Kp corresponding to each

Kr value in the

SBL curve in

Figure 4 is the same as the

Kp range in the

SBL curve drawn for the corresponding

Kr value in

Figure 5. For example, it is seen in

Figure 4 that the

Kp range corresponding to

Kr = 5 is [5 12.76]. When the

Kp-Ki SBL graph in

Figure 5 drawn for

Kr_fixed = 5 is analyzed, it is seen that the stable

Kp range is [5 12.76] again. With the same reasoning, as there is no

Kp range that makes the system stable for

Kr = −5 and

Kr = 12 values in

Figure 4, these are not plotted in

Figure 5.

The

Ki controller parameter range will be determined for an

SBL selected from the

SBL graphs of the system with the PIR controller designed for different

Kr_fixed values in

Figure 5. According to the

Kp-Ki SBL graph of the PIR controller designed for

Kr_fixed = 7.5 selected from

Figure 5, it is seen that the

Ki controller parameter range that makes the system stable is [0 7.09]. For different

Ki_fixed values to be selected from the

Ki controller parameter range,

SBL graphs are obtained with the help of an

RRB defined by

and a

CRB line to be drawn with the help of (19) and (20).

SBL curves for the controller parameter range

Ki_fixed = [0:1:7] are drawn as shown in

Figure 6.

Figure 6 was obtained by plotting

Kr-

Kp SBLs in the frequency range

ω ∈ [

ωmin,

ωmax] rad/s for

Ki_fixed = 0, 1, 2, 3, 4, 5, 6 and 7. Accordingly, in the stability analyses performed for these

Ki_fixed values, the frequency ranges that make the system stable are ω ∈ [0, 1.7523], [0.244, 1.73], [0.35, 1.715], [0.432, 1.7], [0.505, 1.665], [0.575, 1.64], [0.641, 1.61] and [0.706, 1.58], respectively. For

Ki_fixed = 0, the controller will become a PR controller, and the

RRB line defined by

is the determining factor of the stability boundary only in this case, as can be seen from

Figure 6. For

Ki ≠ 0, the

RRB line is not a determining factor of the stability boundary.

When the

Kp-

Ki SBL graph for

Kr_fixed = 7.5 was analyzed in

Figure 5, it was seen that, as the value of

Ki_fixed increases, the

Kp controller parameter range that makes the system stable decreases. In

Figure 6 of this analysis, it is seen that

Kr-

Kp SBLs become smaller for increasing

Ki_fixed values, that is, the controller parameter space that makes the system stable becomes limited.

From the

SBL plot for the PR controller in

Figure 4, the

Kp controller parameter range that makes the system stable was determined as [−5 13.28]. Accordingly, for a

Kp_fixed selected from the

Kp controller parameter space,

SBL is generated by an

RRB line defined by the equation

Ki = 0 and a

CRB line to be drawn with the help of (22) and (23). Accordingly,

SBL plots for the controller parameters of

Kp_fixed = [−2.5:2.5:12.5] are drawn as shown in

Figure 7.

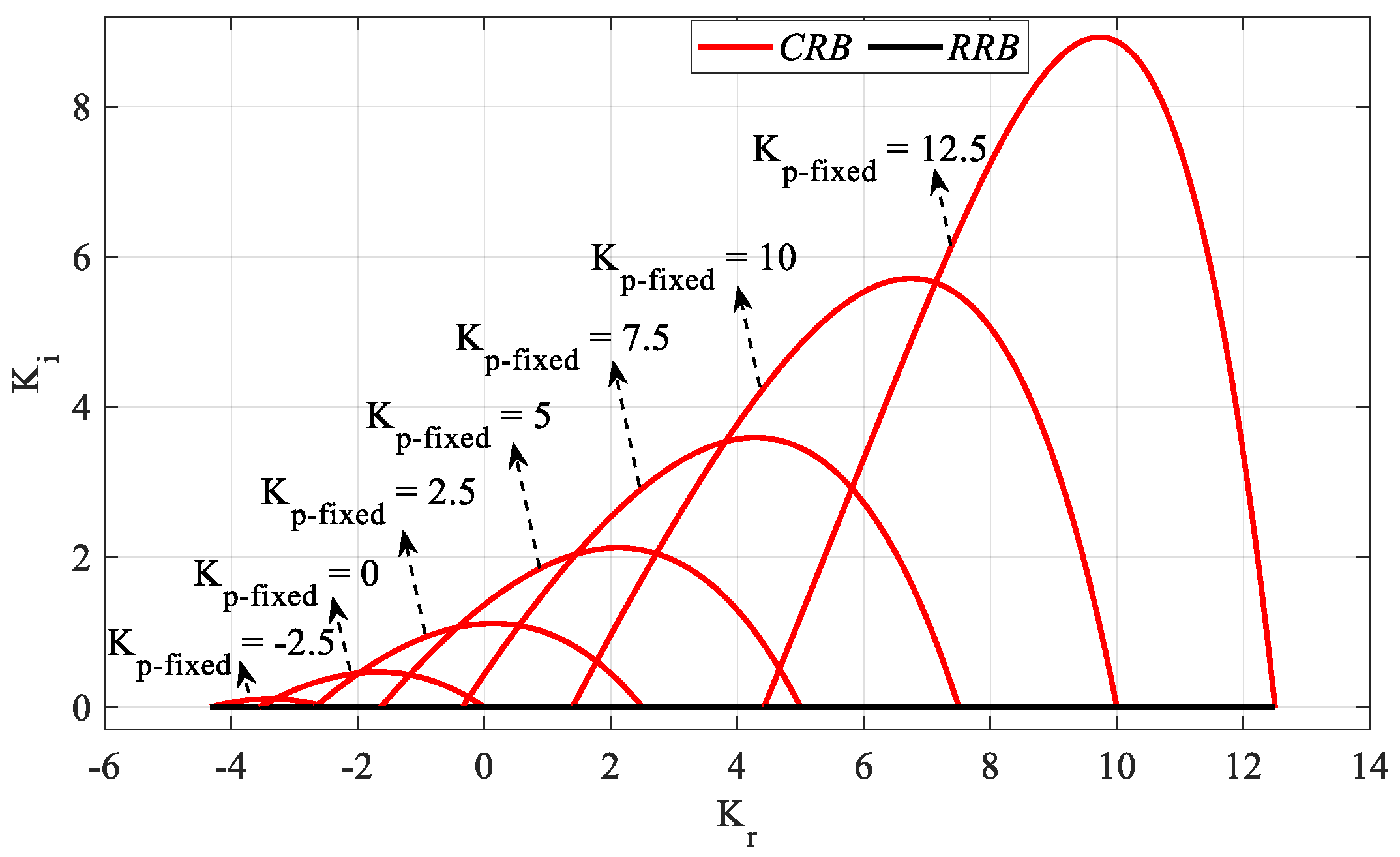

Figure 7 is obtained by plotting

Kr-Ki SBLs in the frequency range

ω ∈ [0,

ωmax] rad/s for

Kp_fixed = −2.5, 0, 2.5, 5, 7.5, 10, and 12.5 values. According to the stability analyses for these

Kp_fixed values,

ωmax values were found to be 0.4193, 0.6044, 0.7582, 0.901, 1.0415, 1.1953, and 1.4021 rad/s, respectively. It should be noted that, for

Kp_fixed = 0, the controller will become an IR controller. It is also concluded that the stability range

Kr corresponding to each

Kp value in the

SBL curve in

Figure 4 is the same as the

Kr range in the

SBL curve drawn for the corresponding

Kp_fixed value in

Figure 7. In

Figure 4, it is seen that the

Kr range corresponding to

Kp = 2.5 is [−2.67 2.5]. When the

Kr-Ki SBL graph in

Figure 7 drawn for

Kp_fixed = 2.5 is examined, it is seen that the stable

Kr range is the same. Therefore, there is no

Kr range that makes the system stable for

Kp = −5 and

Kp = 13.28 values in

Figure 4,

SBL plots for these values are not made in

Figure 7.

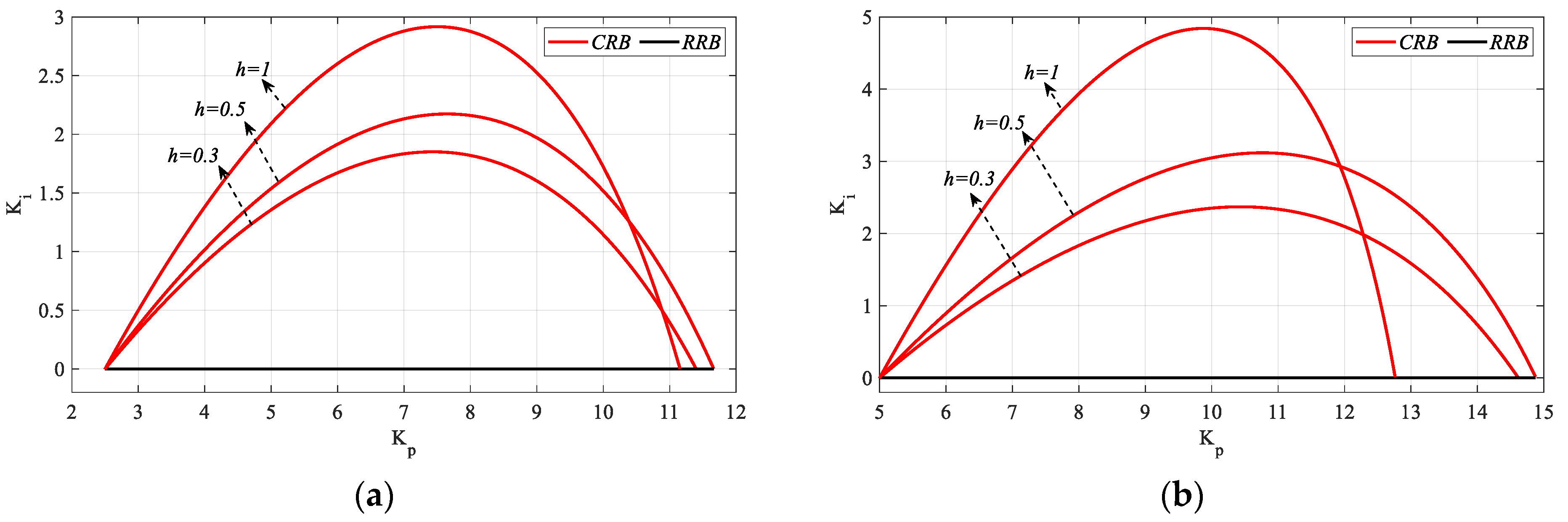

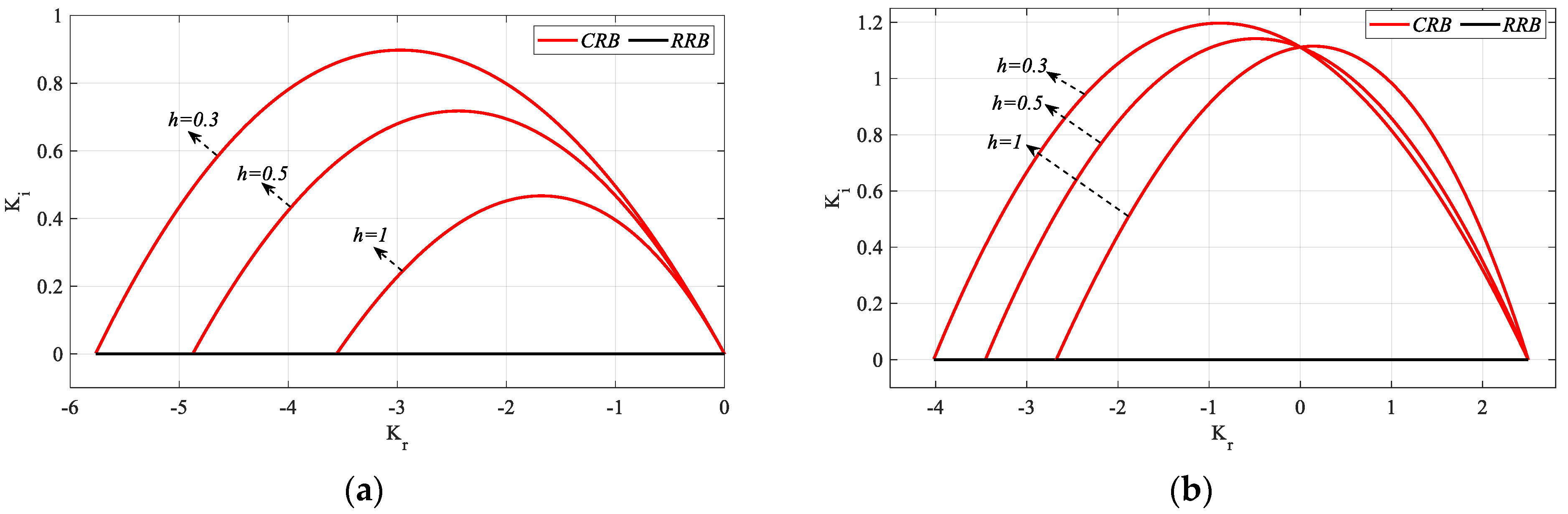

The above analyses were performed for the case where the controller time delay h is 1 s. SBL analyses should be repeated for different values of h to investigate the effect of the controller time delay on the stable controller parameter space. Therefore, three cases where the controller time delay is greater than, equal to, and less than the process time delay are analyzed in this study. The case where the controller time delay is greater than the process time delay is h = 1 as examined above, and the analyses are repeated for cases h = 0.5 (h = ) and h = 0.3 (h < ).

The analysis for

h = 1 in

Figure 2 is repeated for

h = 0.3 and

h = 0.5, and the frequency ranges that make the system stable are found as

ω ∈ [0, 2.3565] rad/s and

ω ∈ [0, 2.1386] rad/s, respectively. Accordingly, the

Kr and

Kp controller parameter ranges that make the system stable for

h = 0.3 are found to be [−16.67 47.913] and [−16.67 47.913], respectively, and [−10 26.68] and [−10 27.07] for

h = 0.5, respectively. It can be concluded that the stable controller parameter space will expand as the value of

h decreases. Then,

Kp-

Ki SBL plots for

Kr_fixed = 2.5 and 5 values selected from the stable controller parameter range are obtained as shown in

Figure 8. In

Figure 8a,

ωmax values for

h = 0.3, 0.5 and 1 are 1.1575, 1.2051 and 1.2782 rad/s respectively, and in

Figure 8b,

ωmax values for

h = 0.3, 0.5, and 1 are 1.2359, 1.3239, and 1.4355 rad/s respectively. For

Kr_fixed = 0, as the controller will become a PI controller, the value of

h will have no effect on

SBL and the

SBL curve will be the same as in

Figure 5.

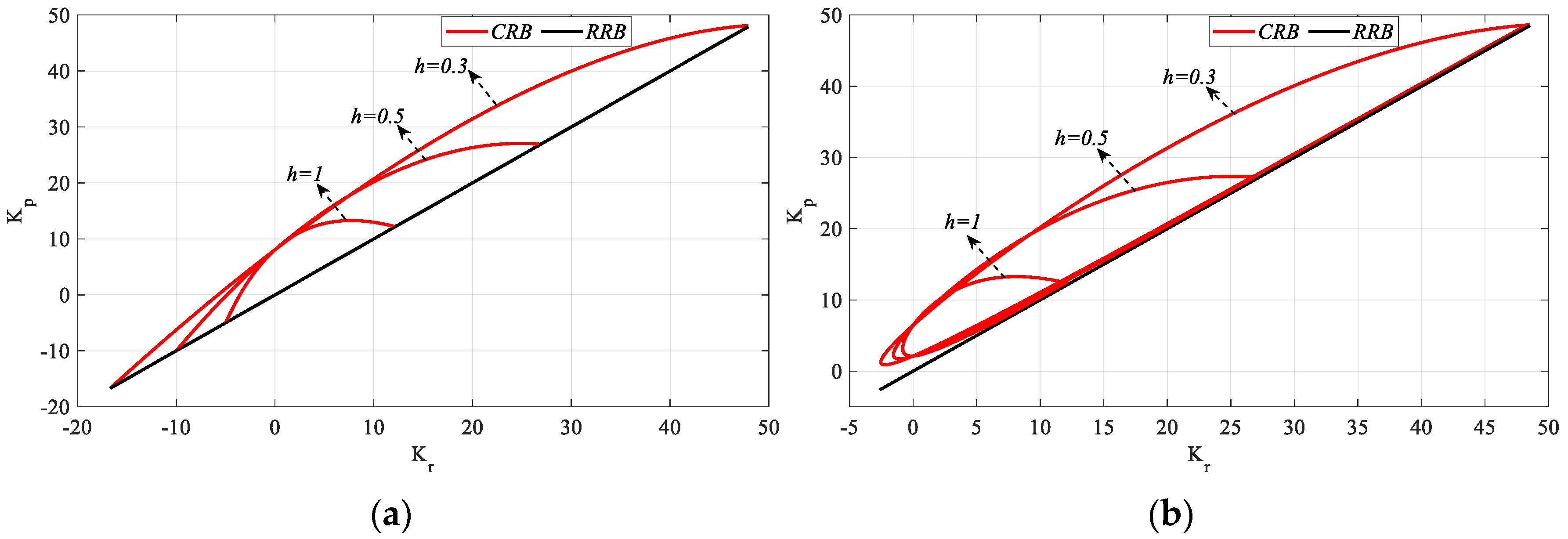

The

Kr-

Kp SBLs obtained for

Ki_fixed = 0 and 1 values selected from the range of common stable

Ki controller parameters for all

h values in

Figure 8 are shown in

Figure 9.

In

Figure 9a, the frequency ranges that make the system stable for

h = 0.3, 0.5 and 1 are

ω ∈ [0, 2.3565], [0, 2.1386] and [0, 2.1386] rad/s, respectively, while in

Figure 9b,

ω ∈ [0.2285, 2.35], [0.234, 2.13] and [0.244, 1.73] rad/s are found. Therefore, it can be said that the frequency range that stabilizes the system narrows as the value of

h increases. Accordingly, it is seen from

Figure 9 that the

SBL curves also narrow. Similarly,

Kr-

Ki SBL graphs were obtained for the

Kp_fixed = 0 and

Kp_fixed = 2.5 values selected from the stable

Kp controller parameter ranges shown in

Figure 8 and

Figure 10.

In

Figure 10a, the frequency ranges that make the system stable for

h = 0.3, 0.5, and 1 are

ω ∈ [0, 0.8614], [0, 0.7654] and [0, 0.6044] rad/s, respectively, while in

Figure 10b,

ω ∈ [0, 0.9303], [0, 0.8665] and [0, 0.7582] rad/s are found, respectively. Similar to the previous analyses, as the value of

h increases, the frequency range that makes the system stable narrows. Therefore, it is seen from

Figure 10 that the

SBL curves narrow as the

h value increases.

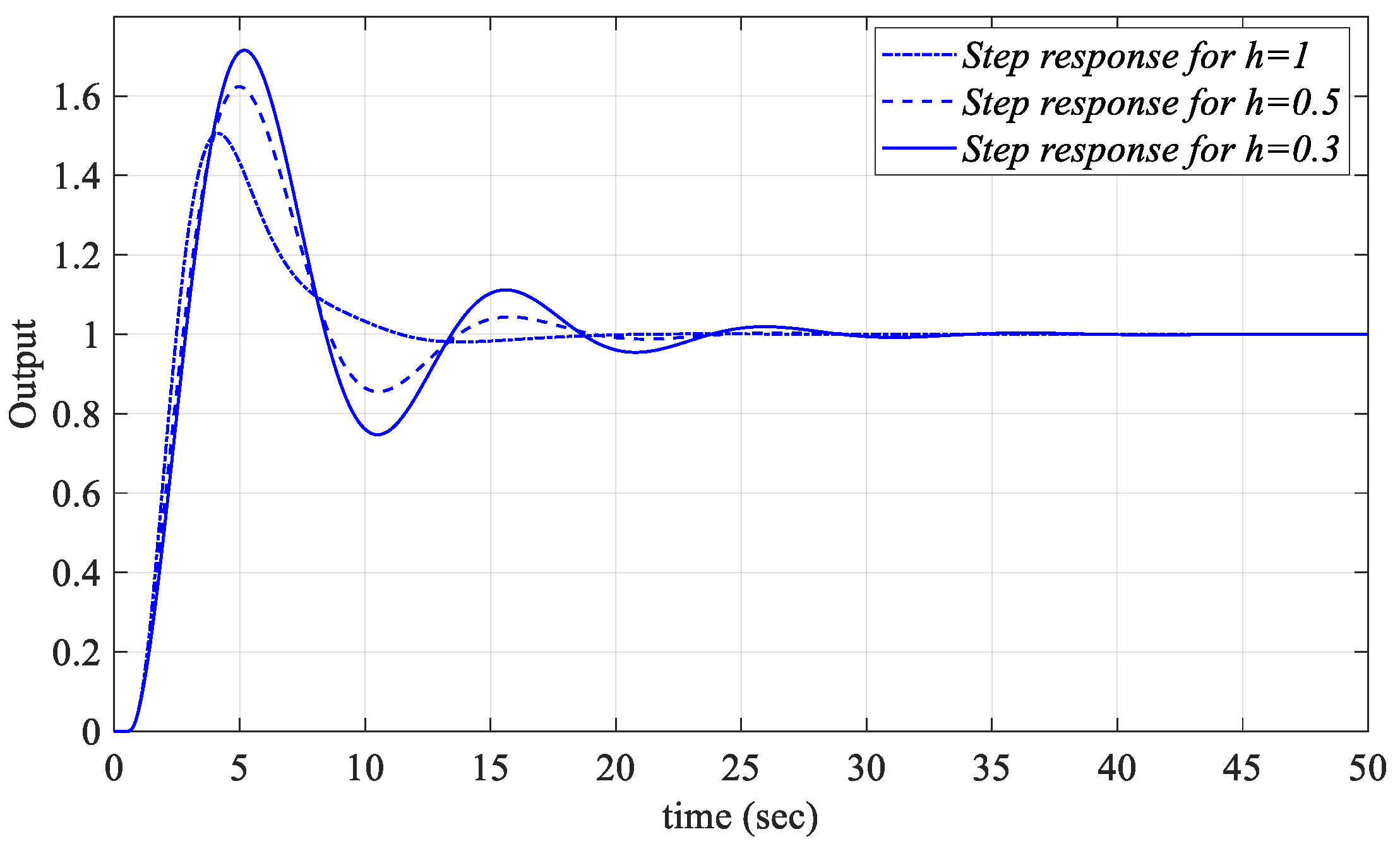

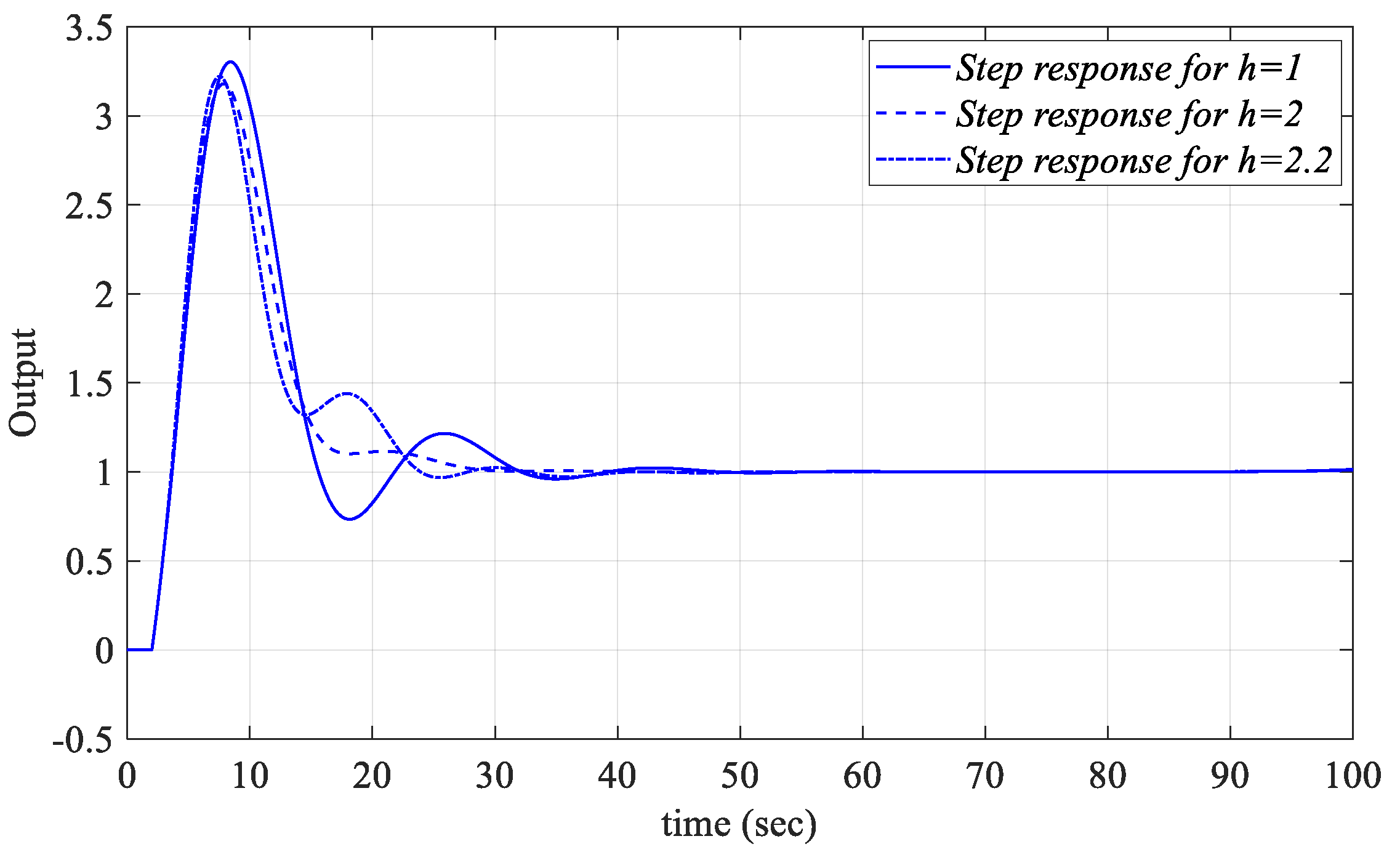

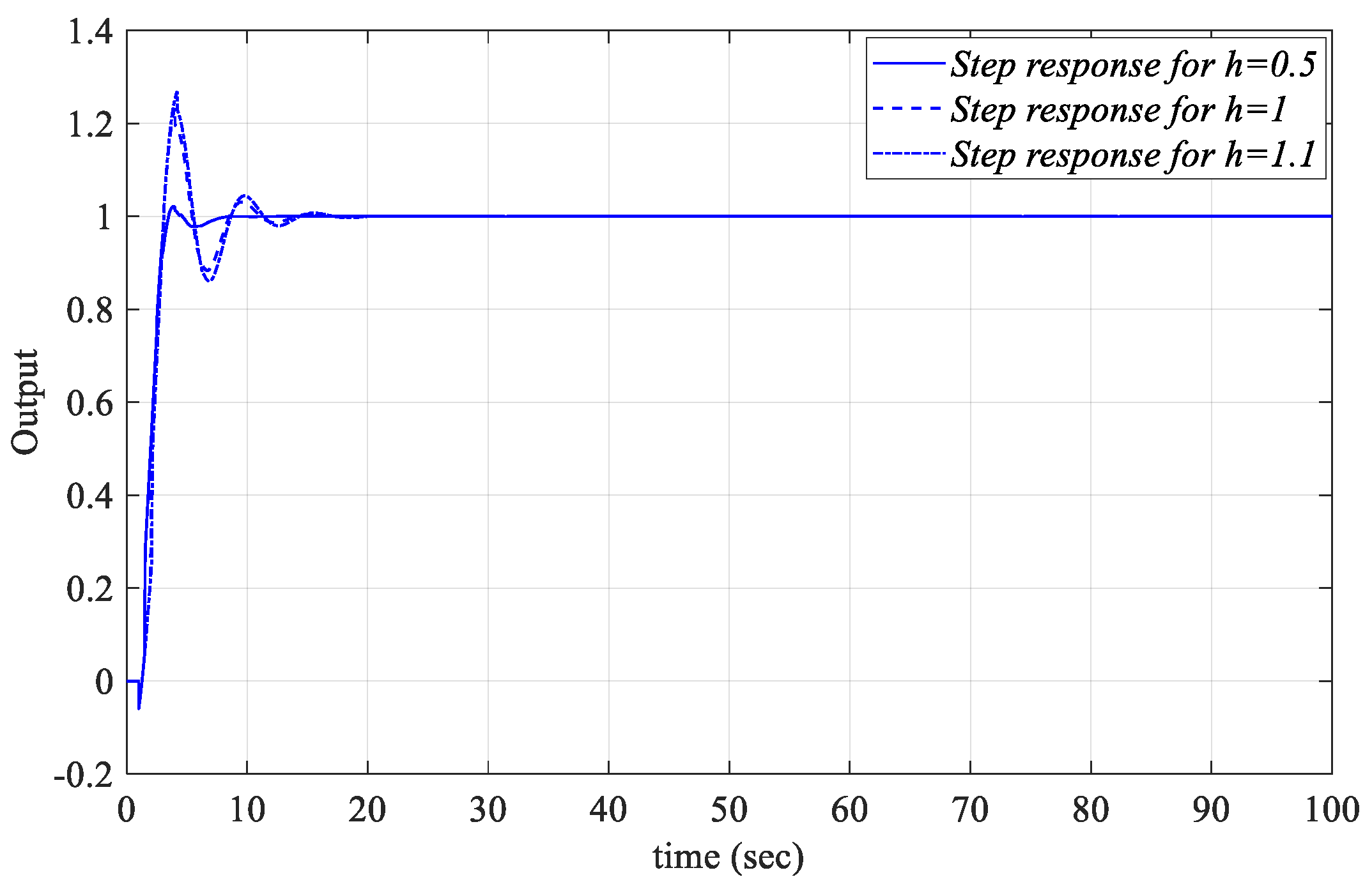

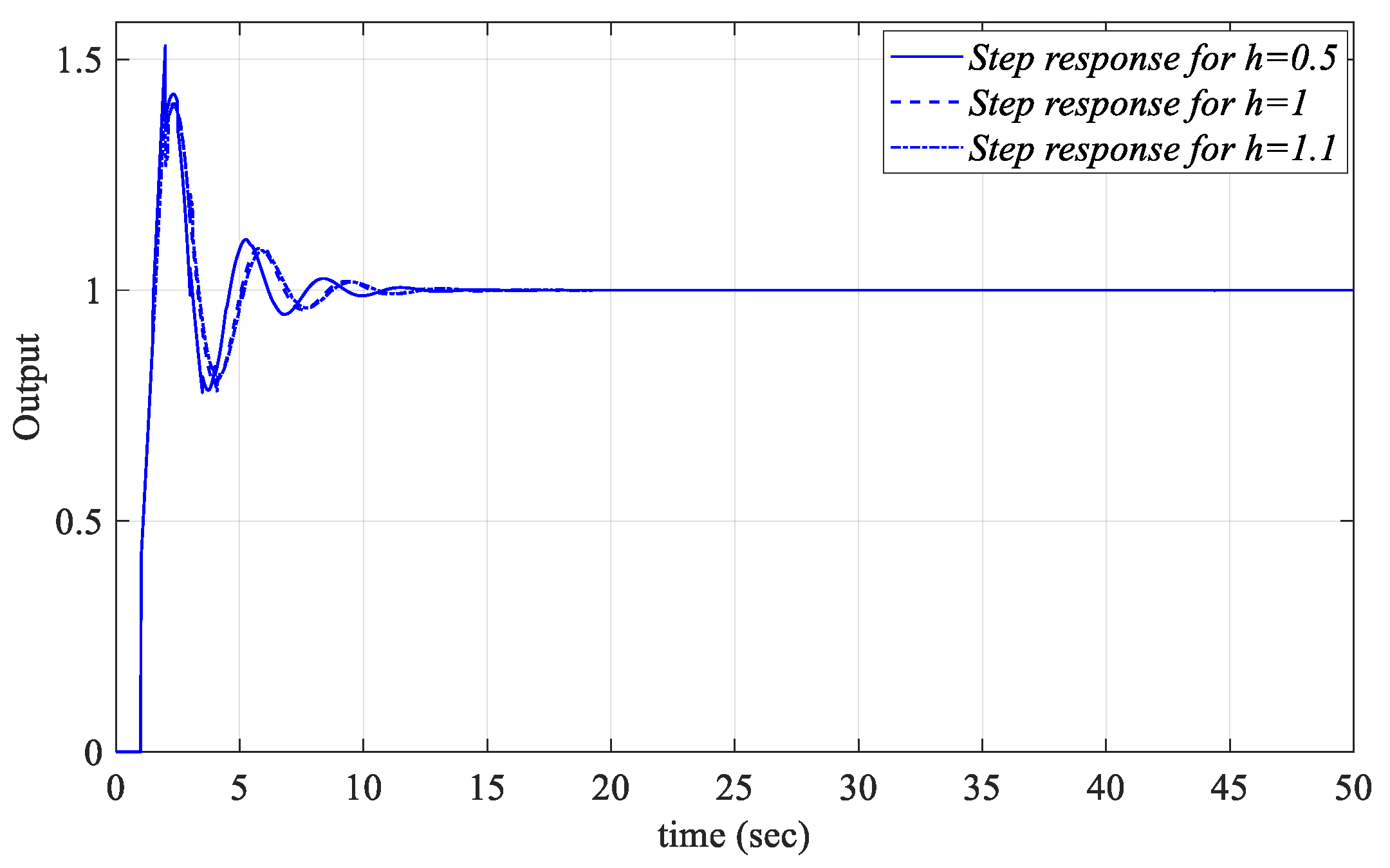

The unit step responses for different

Kp,

Ki, and

Kr values selected from the common regions of the

SBL curves obtained for

h = 0.3, 0.5, and 1 in respective

Figure 8a,

Figure 9b and

Figure 10b were analyzed. In this context, for

Kr_fixed = 2.5, PIR controllers were designed for the

Kp = 5.74 and

Ki = 0.76 values selected from the common region of the

Kp-

Ki SBL curves in

Figure 8a and the unit step responses obtained by implementing these PIR controllers to

Figure 1 are shown in

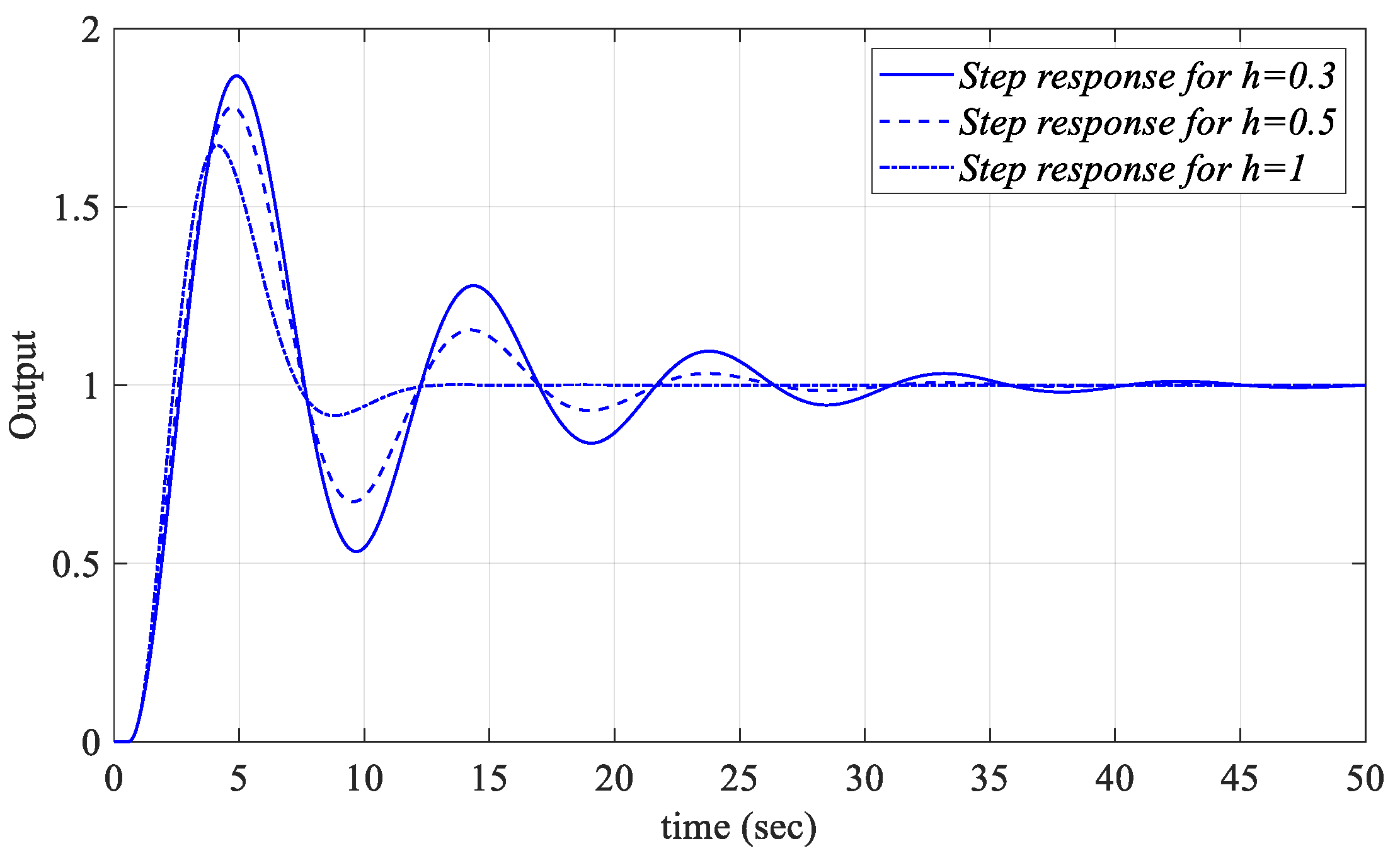

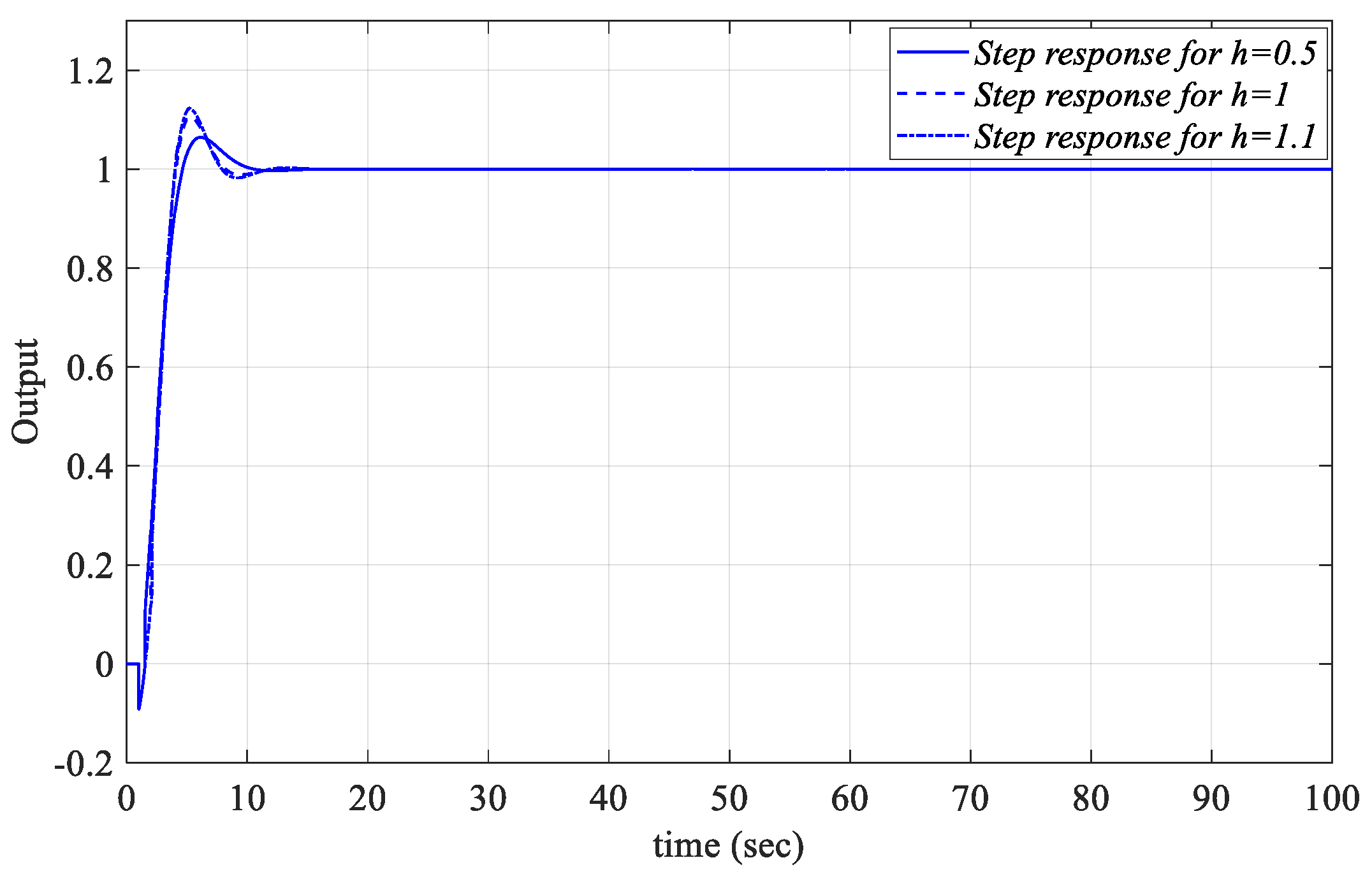

Figure 11. The unit step responses for the

Kr = 2.256 and

Kp = 5.9 controller parameter values selected from the

Kr-

Kp SBL plot in

Figure 9b for

Ki_fixed = 1 and for different

h values are shown in

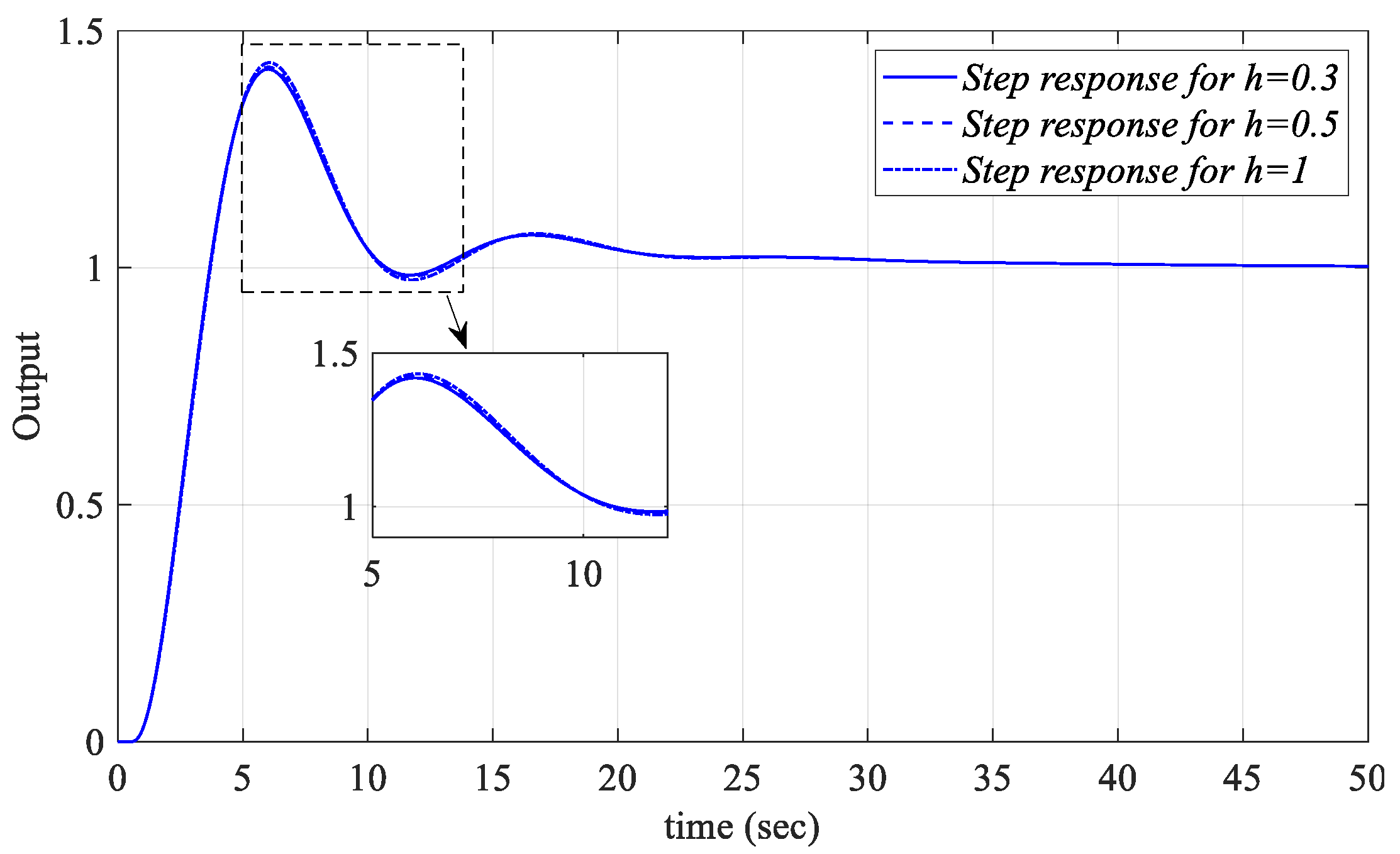

Figure 12. Similarly, controller parameter values

of Kr = −0.13 and

Ki = 0.18 are selected from the

Kr-Ki SBL plot in

Figure 10b, which was obtained for

Kp_fixed = 2.5 and unit step responses for

h = 0.3, 0.5, and 1 are presented in

Figure 13.

When

Figure 11,

Figure 12 and

Figure 13 are analyzed, it can be said that the PIR controllers designed for different values of

h and different values of

Kp,

Ki, and

Kr selected from the stable controller parameter regions will control the closed-loop system in

Figure 1 successfully.

5.2. Example 2

The unstable first order plus time delay (UFOPTD) process given in (27) was selected from the literature [

36,

49,

50].

Initially, h = 1 was taken at the beginning. Then, to draw SBLs for a fixed Kp value in the (Ki, Kr) plane, for a fixed Ki value in the (Kr, Kp) plane and for a fixed Kr value in the (Kp, Ki) plane, fixed Kp, fixed Ki and fixed Kr values must be respectively selected in the planes. For this purpose, the controller was initially selected as a PR controller (Ki = 0).

The

RRB equation defined in Step 1 is updated for the system in (27) and obtained as

. As

n > m, there will be no

IRB line. The

CRB equations

Kp(ω) and

Kr(ω)are obtained from (24) and (25), respectively. Accordingly, with the help of the

RRB and

CRB equations, the

SBL curve is drawn as shown in

Figure 14.

As can be seen from

Figure 14, the stability region for the PR controller is found as the intersection region of the

RRB and

CRB lines covering the frequency range

ω ∈ [0, 1.7523] rad/s. Accordingly, the

Kp and

Kr controller parameter ranges that make the system stable are determined as [−0.25 1.22] and [−0.5 0.93], respectively.

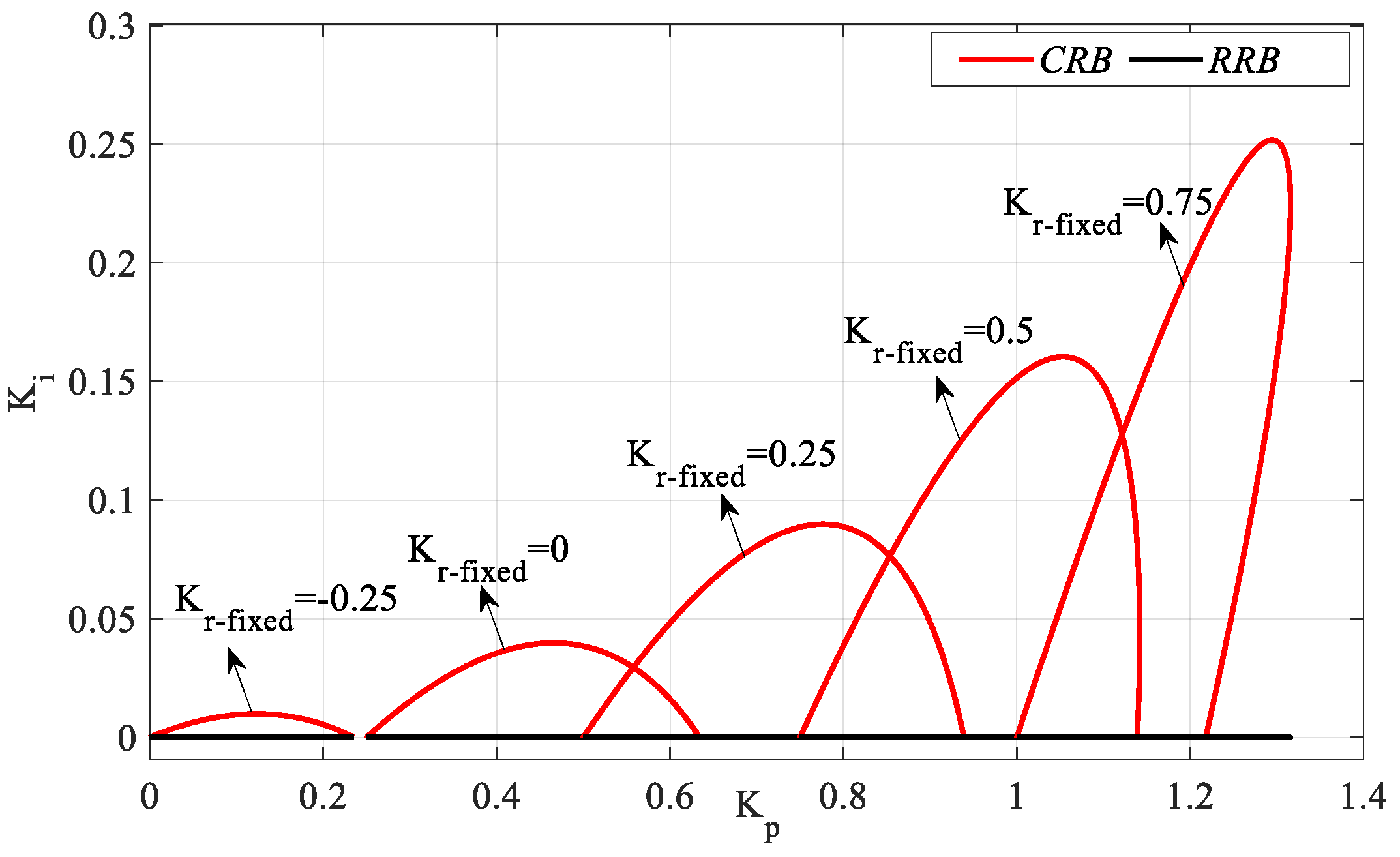

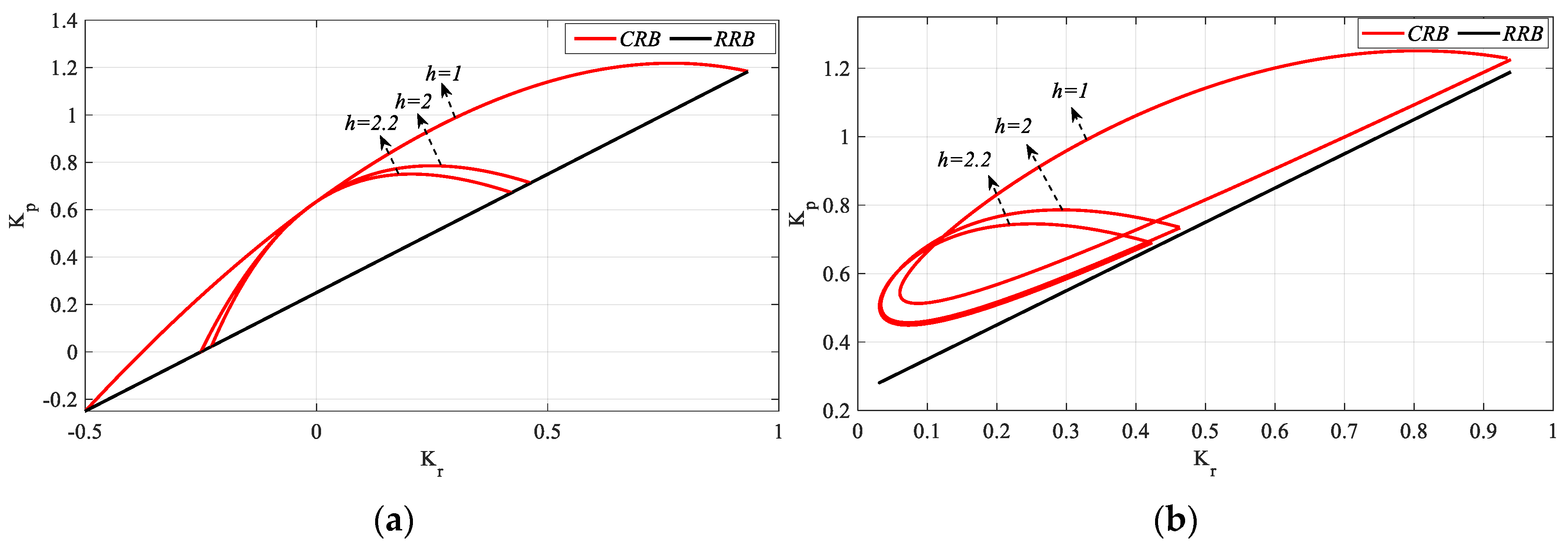

SBL graphs for the controller parameter range

Kr_fixed = [−0.25:0.25:0.75] are drawn as shown in

Figure 15 with the

RRB defined by the line equation

Ki = 0 and the

CRB equations calculated by (16) and (17).

Figure 15 was obtained by plotting the

Kp-Ki SBLs in the frequency range

ω ∈ [0,

ωmax] rad/s for

Kr_fixed = −0.25, 0, 0.25, 0.5, and 0.75. According to the stability analyses for these

Kr_fixed values,

ωmax values were found to be 0.4043, 0.5828, 0.7291, 0.8627, and 0.9923 rad/s, respectively. The

Ki controller parameter range will be determined for an

SBL selected from the

SBL curves of the system with a PIR controller designed for different

Kr_fixed values in

Figure 15. Accordingly, according to the

SBL graph of the PIR controller designed for

Kr_fixed = 0.75, the

Ki controller parameter range that makes the system stable is [0 0.25]. For different

Ki_fixed values to be selected from the

Ki controller parameter range,

SBL graphs are obtained with the help of an

RRB defined by

and a

CRB line to be drawn with the help of (19) and (20). Accordingly,

SBL plots for the controller parameter range

Ki_fixed = [0:0.05:0.25] are drawn as shown in

Figure 16.

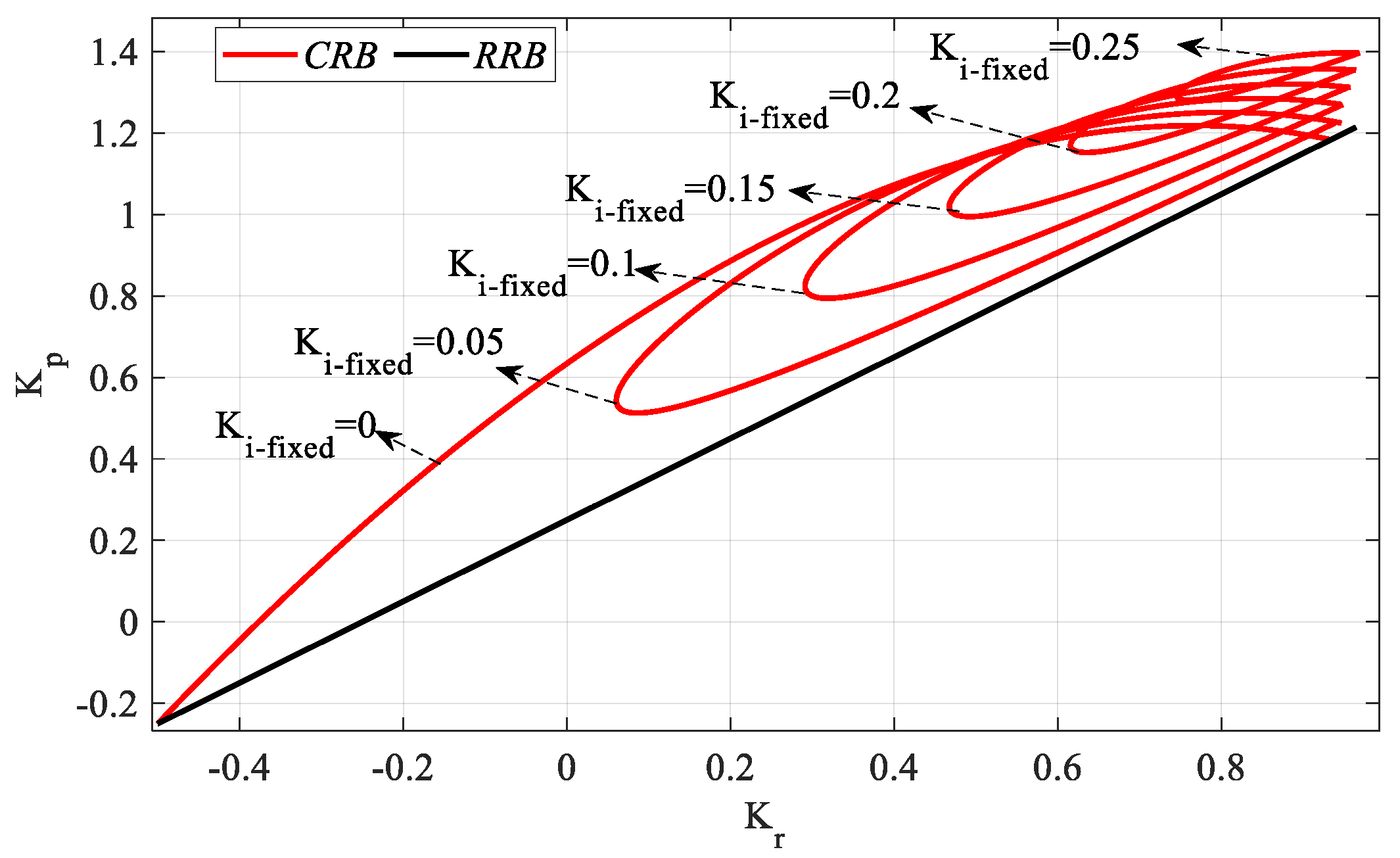

Figure 16 is obtained by plotting

Kr-Kp SBLs in the frequency range

ω ∈ [

ωmin,

ωmax] rad/s for

Ki_fixed = 0, 0.05, 0.1, 0.15, 0.2, and 0.25. For these

Ki_fixed values, the frequency ranges that make the system stable are ω ∈ [0, 1.0894], [0.1908, 1.068], [0.276, 1.036], [0.347, 1.009], [0.414, 0.975], and [0.482, 0.932], respectively. It is seen that the stable

Kr-Kp controller parameter region becomes smaller as the value of

Ki_fixed increases. In addition, the

RRB line defined by the equation of

is the determining factor of the stability boundary only in the case where

Ki_fixed = 0, as seen in

Figure 16.

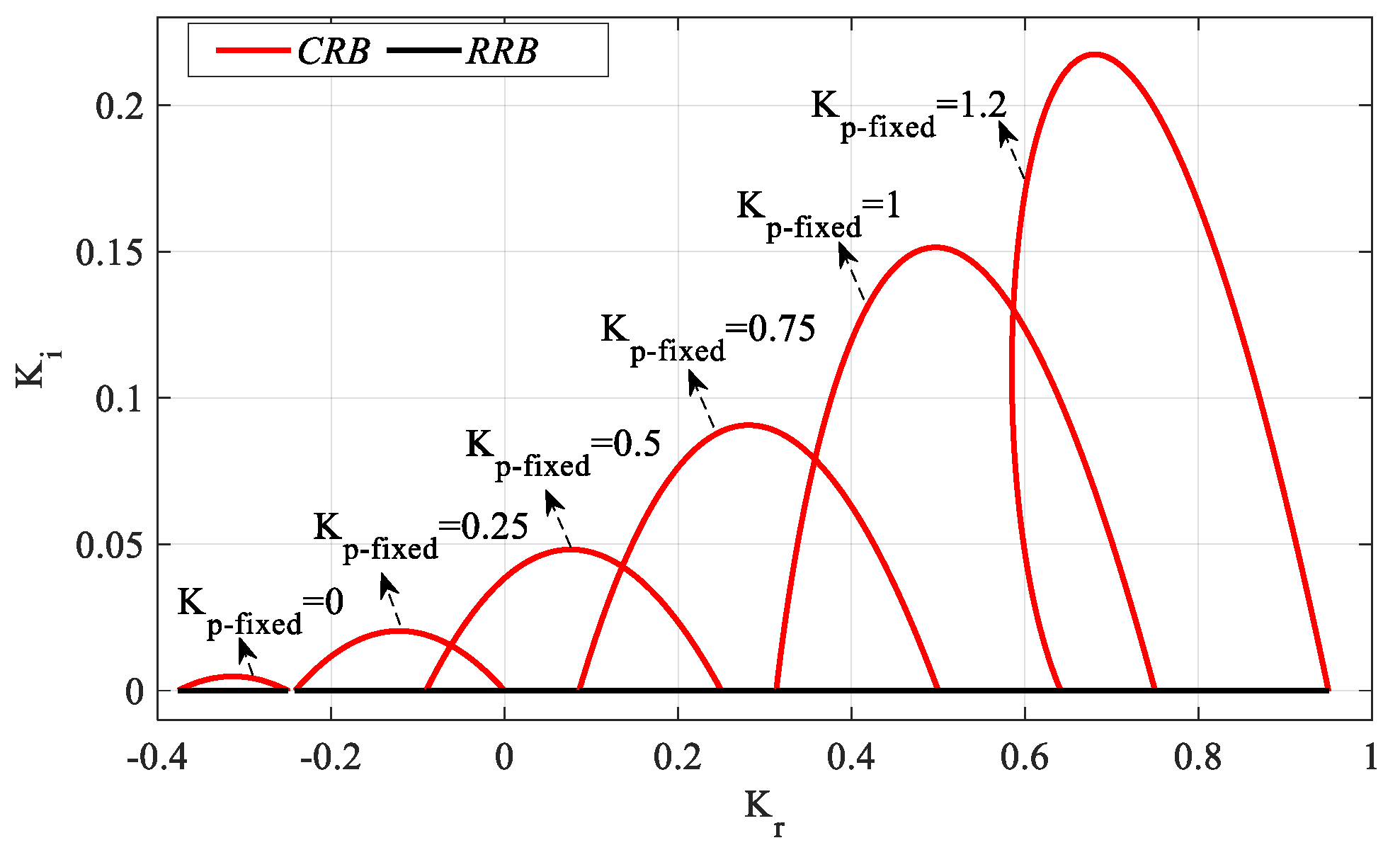

From the

SBL curve for the PR controller in

Figure 14, the

Kp controller parameter range that makes the system stable was determined as [−0.25 1.22]. Accordingly, for a

Kp_fixed selected from the

Kp controller parameter space,

SBL is generated by an

RRB line defined by the equation

Ki = 0 and a

CRB line to be drawn with the help of (22) and (23). Accordingly,

SBL curves for the controller parameter range

Kp_fixed = [0:0.25:1.2] are drawn as shown in

Figure 17.

Figure 17 was obtained by plotting

Kr-Ki SBLs in the frequency range

ω ∈ [0,

ωmax] rad/s for

Kp_fixed = 0, 0.25, 0.5, 0.75, 1, and 1.2. In the stability analyses for these

Kp_fixed values,

ωmax values were found to be 0.2816, 0.4113, 0.5236, 0.6353, 0.7637, and 0.9359 rad/s, respectively. It is seen that the stable

Kr-Ki controller parameter region increases as the value of

Kp_fixed increases. The above analyses were performed for

h = 1, and the analyses were repeated to reflect the effect of different values of

h on

SBL. In this regard, the cases of

h >

,

h =

, and

h <

are examined. Although the case of

h <

is

h = 1 as examined above, the analyses are repeated for the cases of

h = 2 (

h =

) and

h = 2.2 (

h <

).

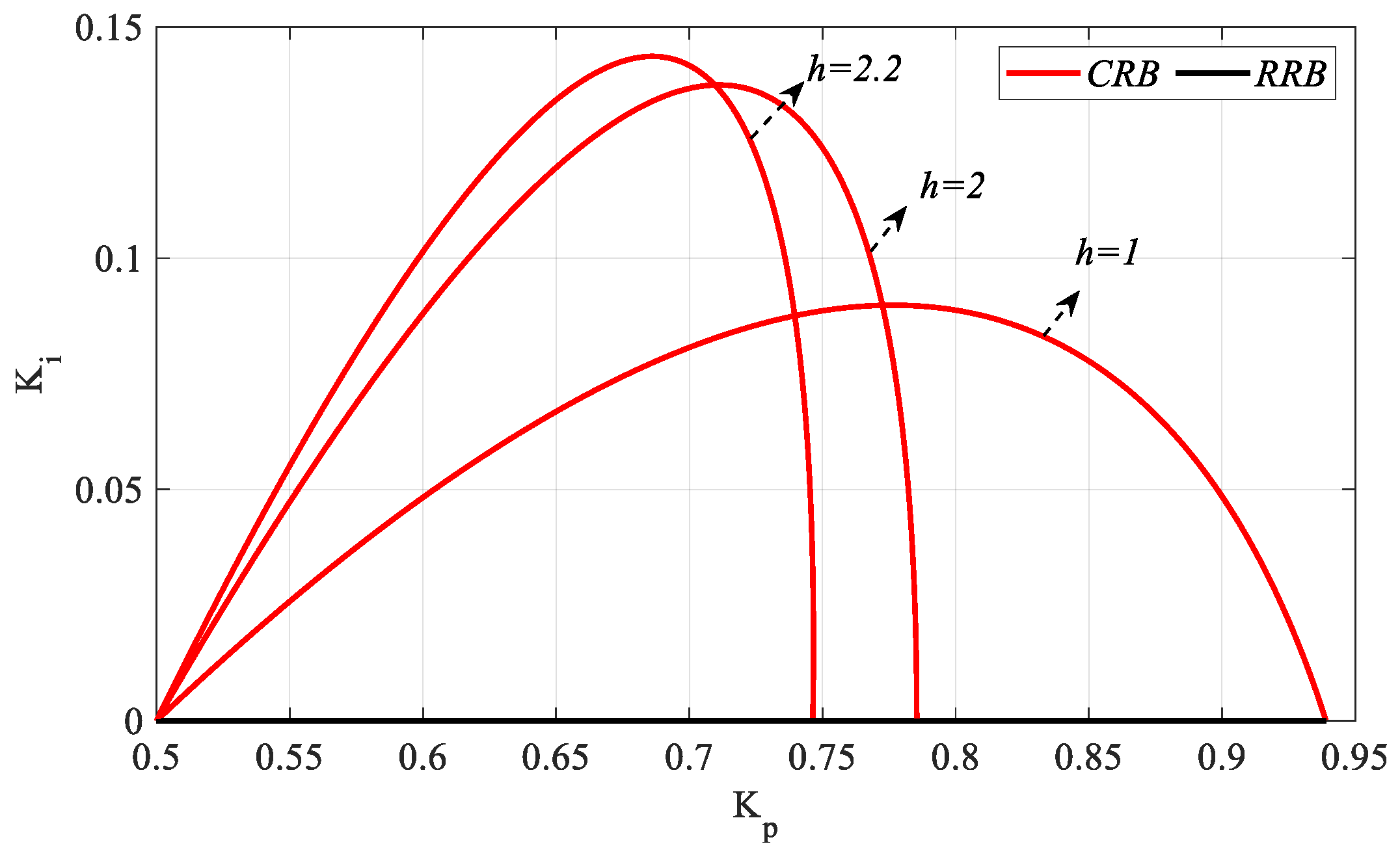

The analysis for

h = 1 in

Figure 14 was repeated for

h = 2 and

h = 2.2, and the frequency ranges that make the system stable were found to be

ω ∈ [0, 9015] rad/s and [0, 0.8721] rad/s, respectively. Accordingly, the

Kr and

Kp parameter ranges that stabilize the system for

h = 2 are [−0.25 0.46] and [0 0.785], respectively, and for

h = 2.2 are [−0.17 0.42] and [0.024 0.75], respectively. It can be concluded that, as the value of

h increases, the stable PR controller parameter region narrows. For

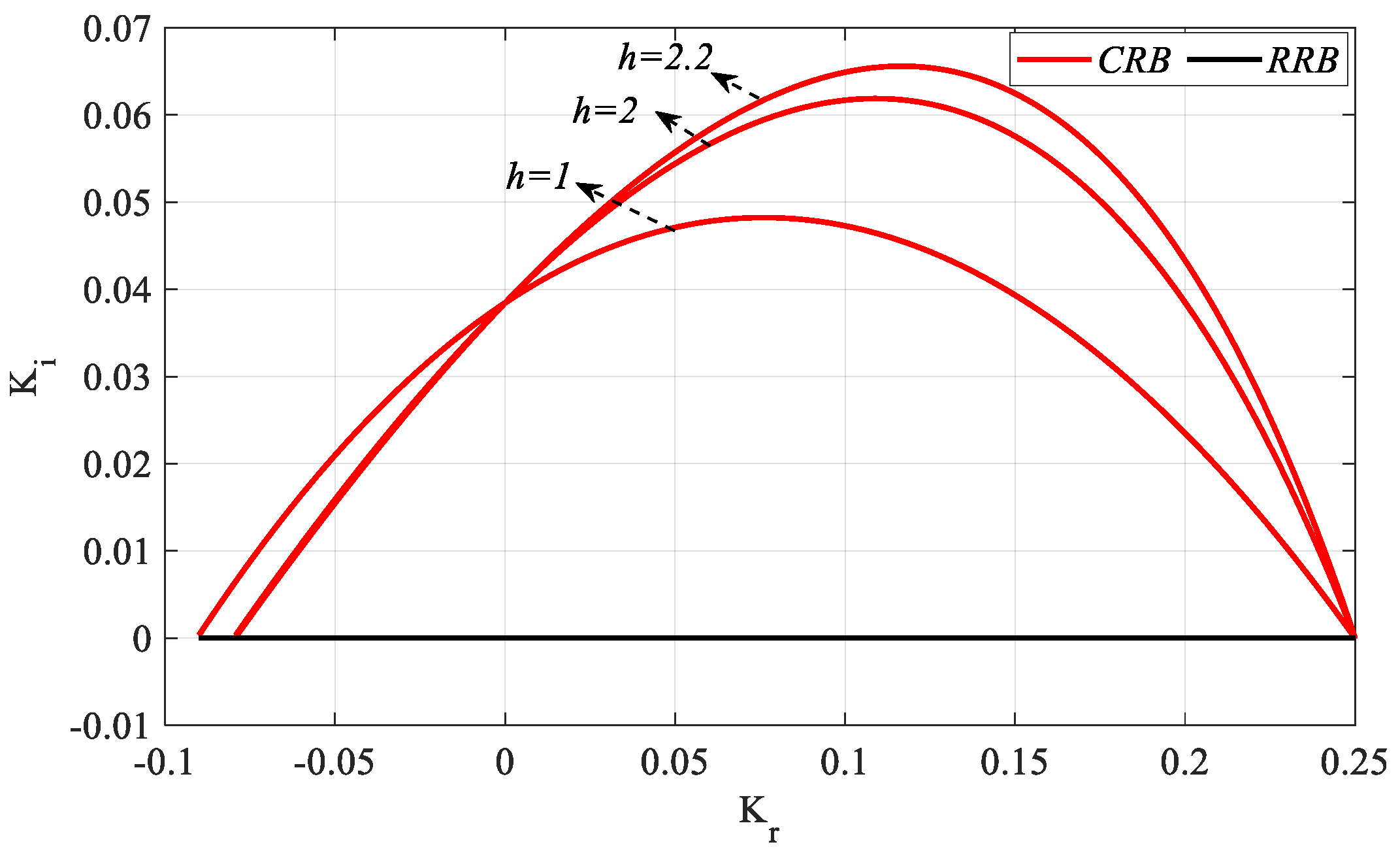

Kr_fixed = 2.5 selected from the stable

Kr controller parameter range,

Kp-

Ki SBL curves are obtained as shown in

Figure 18. In

Figure 18,

ωmax values for

h = 1, 2, and 2.2 are found to be 0.7291, 0.7853, and 0.7835 rad/s, respectively. It is seen that, as

h increases, the stable

Kp controller parameter region narrows, and the stable

Ki controller parameter region expands. Moreover, as the controller will become a PI controller for

Kr = 0, the value of

h will have no effect on

SBL, and the

SBL curve will be the same as in

Figure 14.

As demonstrated in

Figure 18, the

SBL curves obtained for

h = 1, 2, and 2.2 were analyzed, and

Ki_fixed = 0 and 0.05 values were selected considering the common stable

Ki controller parameter ranges and

Kr-

Kp SBL graphs for these

Ki_fixed values, as illustrated in

Figure 19.

As demonstrated in

Figure 19a, the frequency ranges that stabilize the system for

h = 1, 2, and 2.2 are

ω ∈ [0, 1.0894], [0, 0.9015], and [0, 0.8721] rad/s, respectively. Similarly,

Figure 19b illustrates the corresponding frequency ranges for

ω ∈ [0.1908, 1.068], [0.193, 0.879], and [0.193, 0.85] rad/s. Therefore, it can be said that the frequency range that stabilizes the system narrows as the value of

h increases. Accordingly, it is seen from

Figure 19 that the

SBL curves also narrow. In

Figure 19a, when

Ki_fixed = 0, the controller becomes a PR controller. The

RRB line, defined by the equation

, is thus a determining factor for the stability boundary. In

Figure 19b, however, the

RRB line is not a determining factor of the stability boundary; it is only shown as an approximate boundary line for the purpose of enhancing the comprehensibility of the

SBL representation. A similar representation is employed for

Kr-

Ki SBL plots for

Kp_fixed = 0.5, a parameter that is selected from the stable

Kp controller parameter range (see

Figure 20).

In

Figure 20, the frequency ranges

ω ∈ [0, 0.5236], [0, 0.4884], and [0, 0.4822] rad/s are found for

h = 1, 2, and 2.2, respectively. It is seen that, as the

h value increases, the

Kr range that makes the system stable remains almost the same, whereas the stable

Ki parameter space increases. For

Kp_fixed = 0, the controller becomes an IR controller. However, if the

SBLs obtained for

h = 2 and 2.2 in

Figure 19a are analyzed, it is seen that there is no stable

Kr controller parameter range corresponding to

Kp = 0. From this, it can be concluded that an IR controller that makes the system stable at

h = 2 and 2.2 cannot be designed for the

Gp2 process.

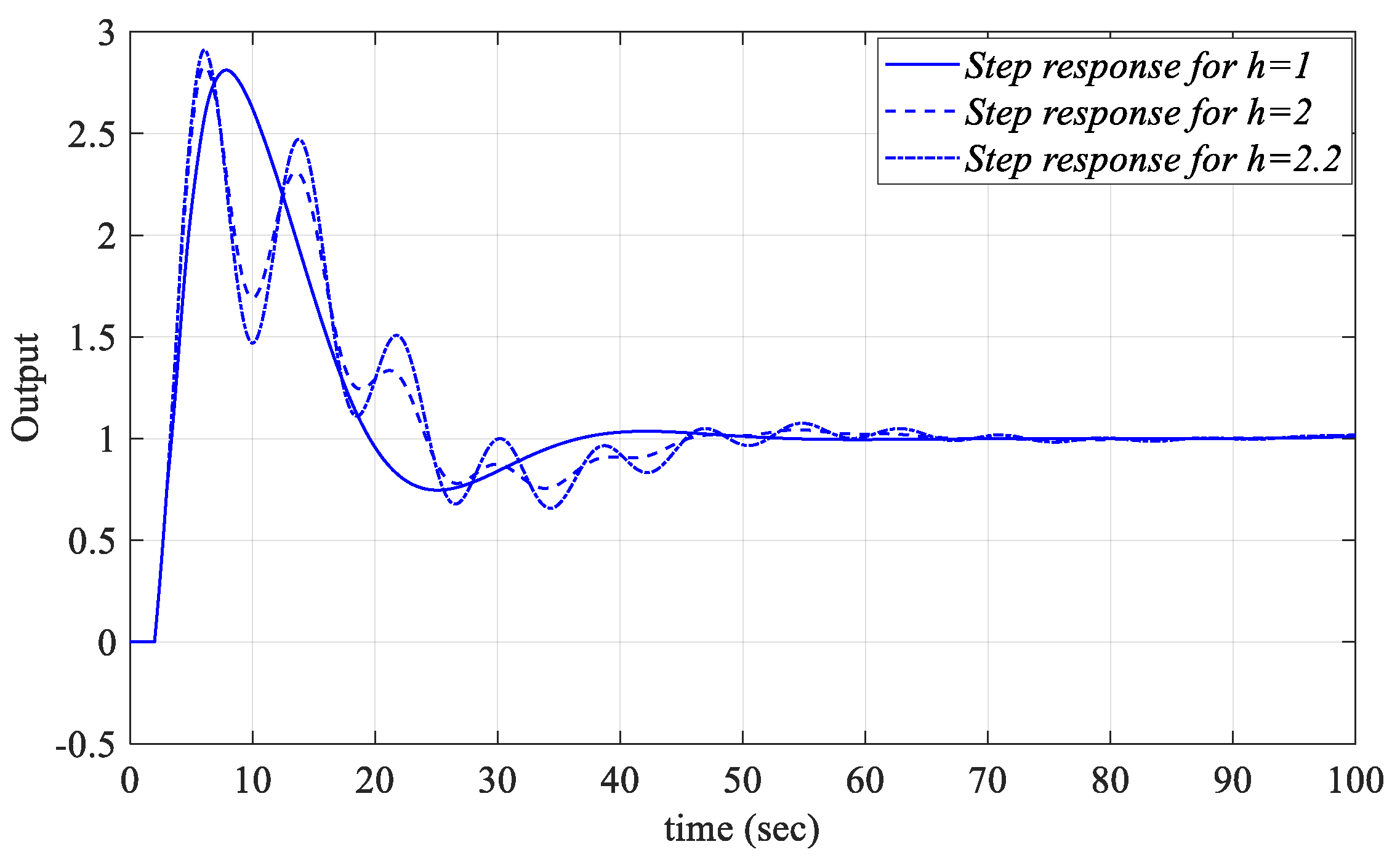

The unit step responses for

Kp,

Ki, and

Kr values selected from the common stability regions of the

SBL curves obtained for

h = 1, 2, and 2.2 in the respective

Figure 18,

Figure 19b and

Figure 20 are analyzed. The PIR controllers designed according to these parameters are expected to control the

Gp2 model in

Figure 1 stably for the cases

h = 1, 2, and 2.2. For

Kr_fixed = 0.25,

Kp = 0.6598, and

Ki = 0.0214, values were selected from the common region of the

Kp-

Ki SBL graphs drawn for

h = 1, 2 and 2.2 in

Figure 18, and the PIR controllers designed for these values were applied to

Figure 1. The unit step responses were obtained as shown in

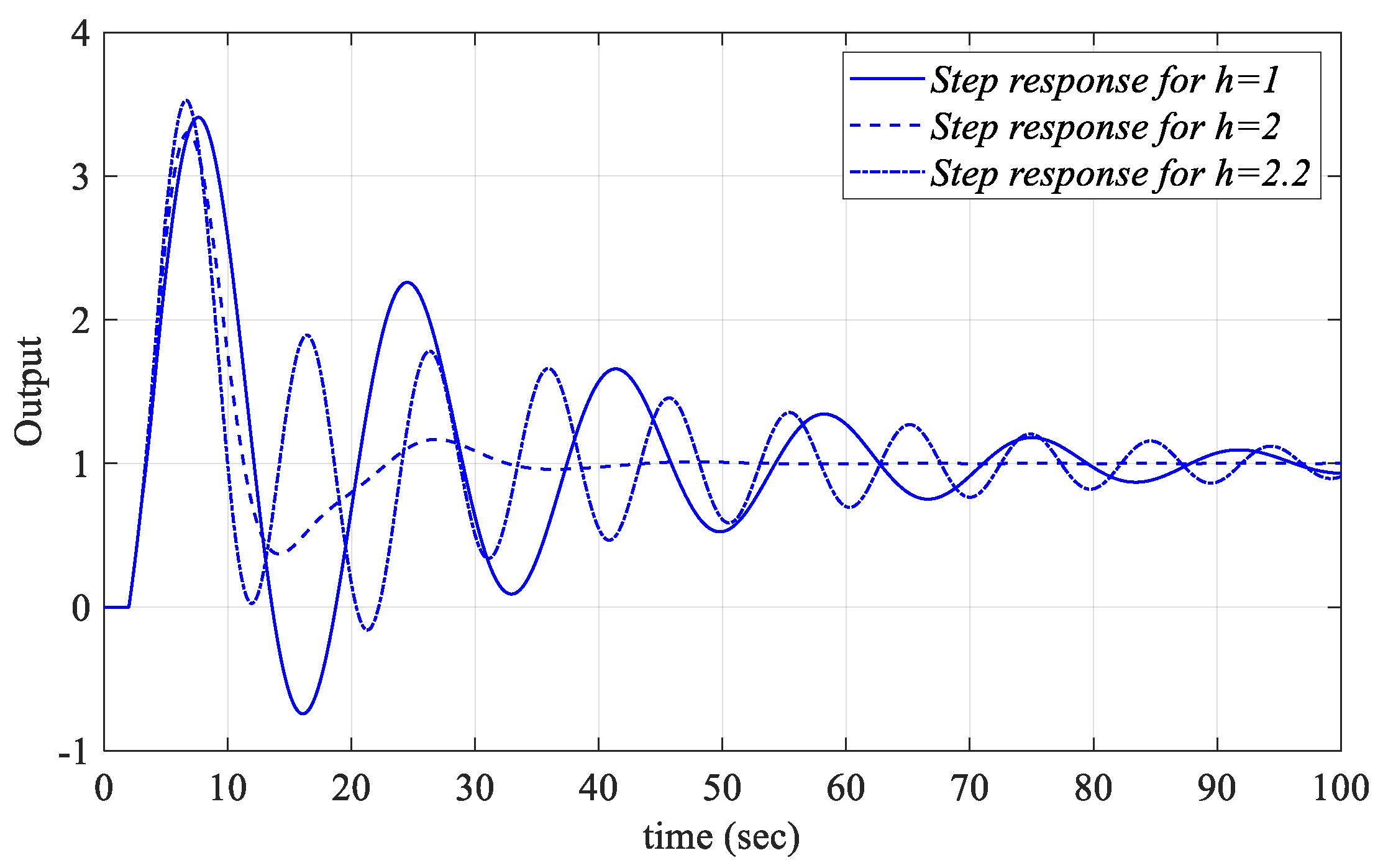

Figure 21. For

Ki_fixed = 0.05, PIR controllers were designed for the

Kp = 0.5984 and

Kr = 0.16 controller parameter values selected from the

Kr-

Kp SBL plot in

Figure 19b and unit step responses for different

h values are shown in

Figure 22. In a similar manner,

Kr = 0.0187 and

Ki = 0.073 controller parameter values are selected from the

Kr-

Ki SBL graph in

Figure 20, obtained for

Kp_fixed = 0.5. Unit step responses for

h = 1, 2, and 2.2 are presented as in

Figure 23.

When the unit step responses in

Figure 21,

Figure 22 and

Figure 23 are examined, it is seen that the PIR controllers, designed for the controller parameters selected from the common stability regions of the

SBL curves drawn for the cases

h = 1, 2 and 2.2, control the

Gp2 unstable time-delay process in

Figure 1 in a stable manner.

5.3. Example 3

As

IRB lines are only observed in processes with equal orders of numerator and denominator polynomials, (28) is chosen for analysis. The FOPTD

Gp3(

s) process is analyzed through

Figure 1.

Before starting the analysis, the PR controller time-delay value is taken as

h = 1. The defined

RRB equation is updated for the process in (28) and obtained as

. According to the

IRB rule defined in (11), as

n =

m,

IRB lines are expected to be formed, and one or some of these lines are expected to play a role in determining the stability region. Accordingly, this is achieved with the help of the

IRB1, IRB2, IRB3, and

IRB4 equations, which can be seen, respectively, as follows:

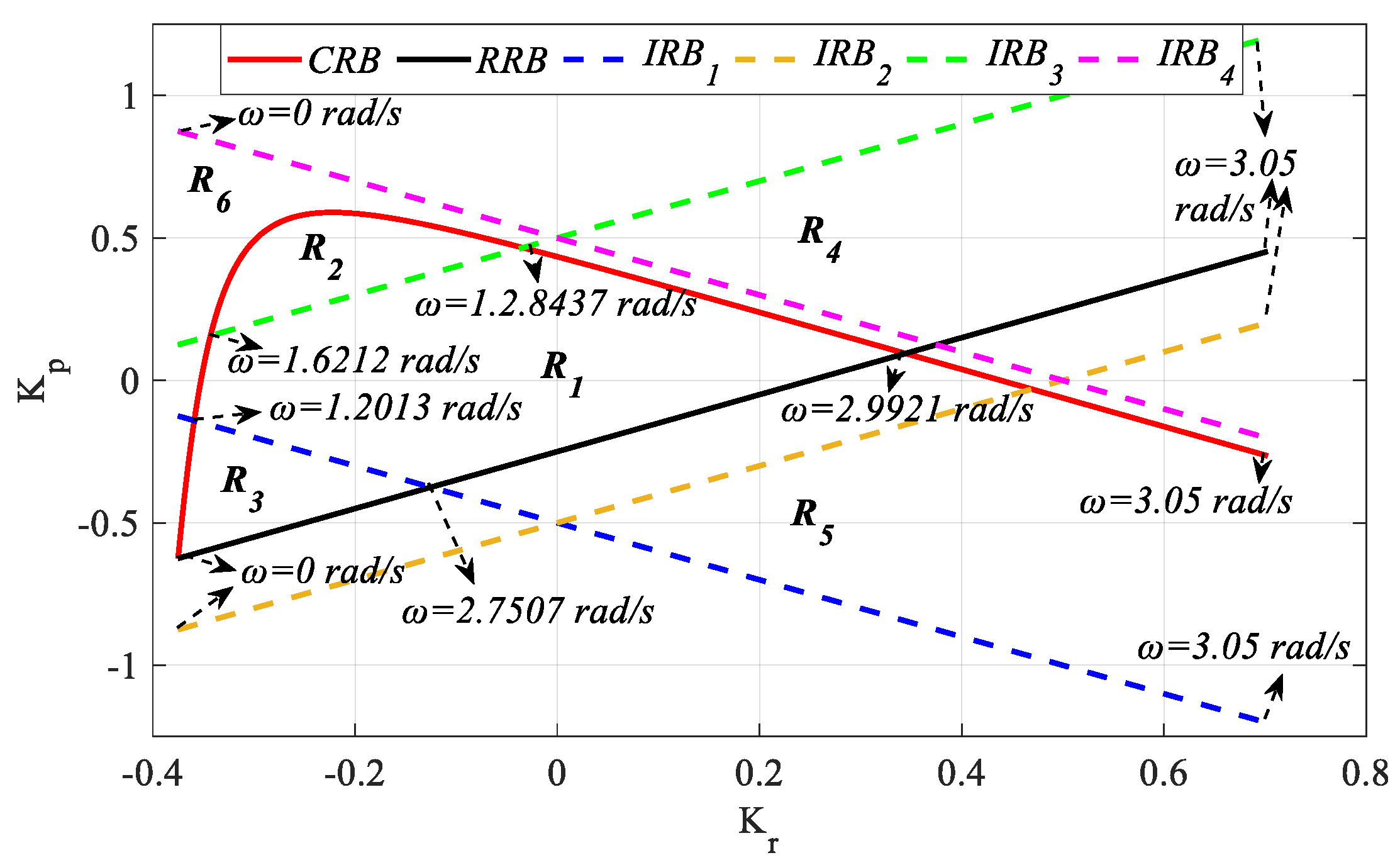

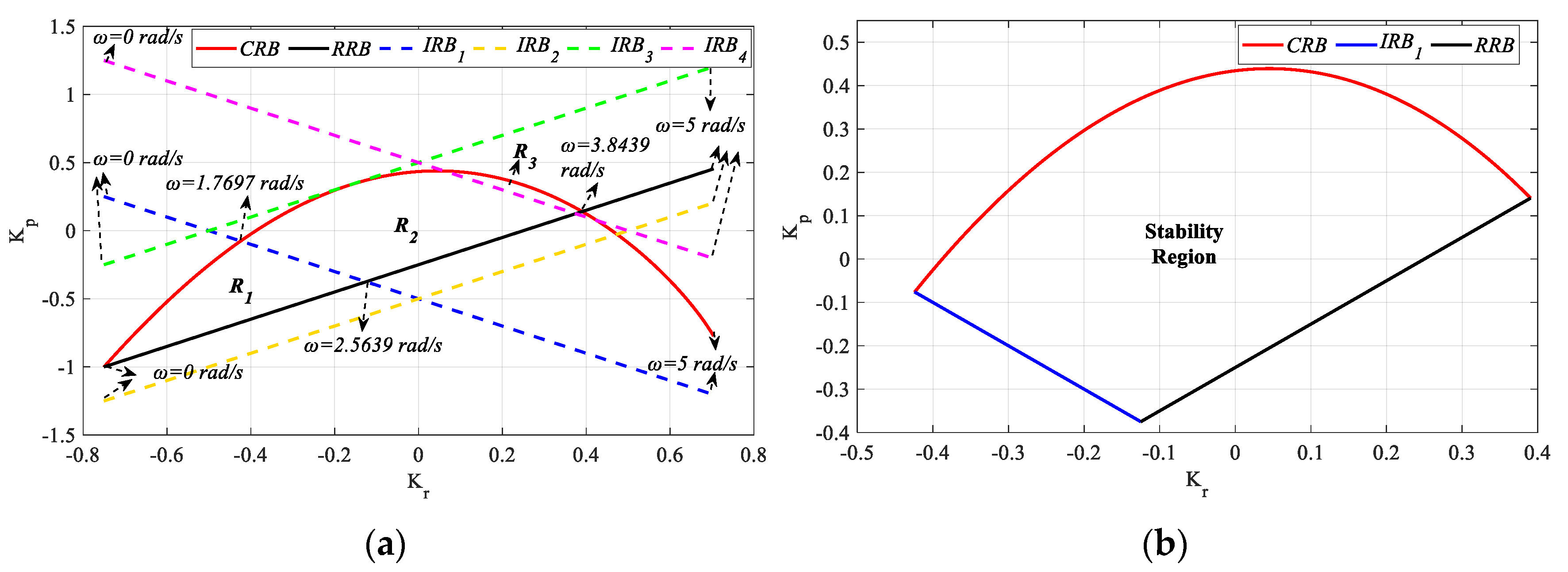

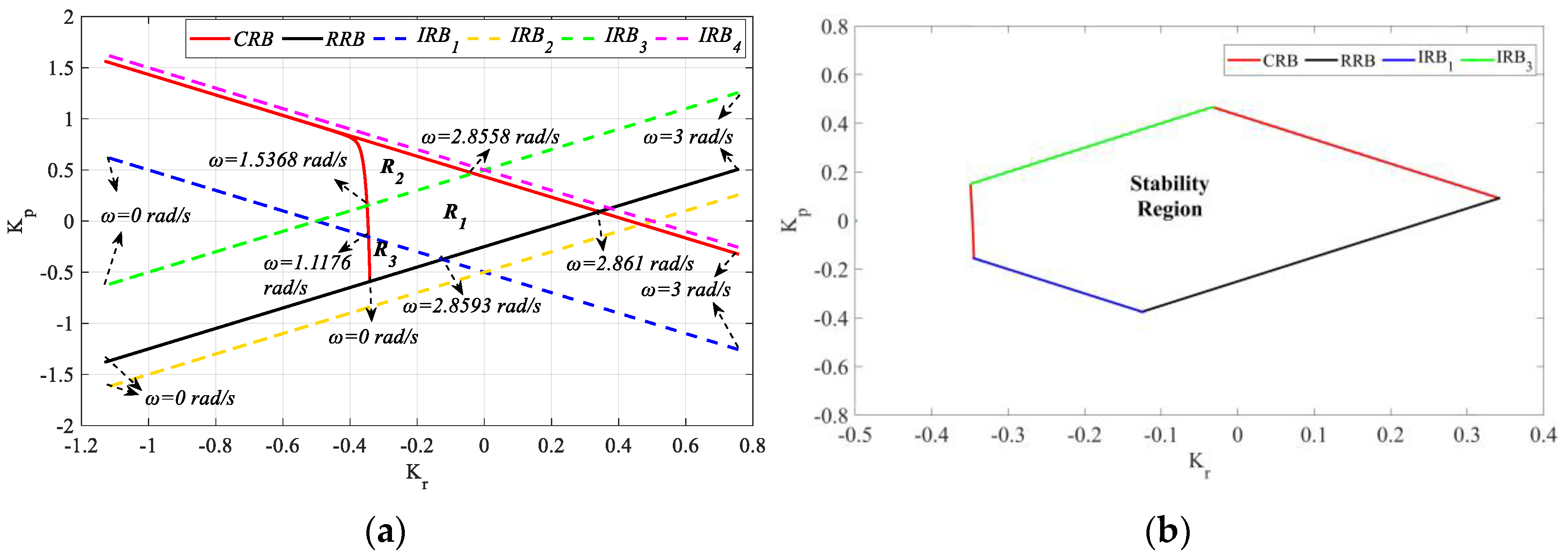

To determine the stable region, the

SBL curve for the frequency range

ω ∈ [0, 3.05] rad/s was plotted as shown in

Figure 24 with the help of

RRB,

IRB, and

CRB equations.

It has been explained in

Section 3.2 that, in processes with an equal order of numerators and denominators as in (28) (

n =

m),

IRB lines can affect stability, but not all

IRB lines always affect stability. Therefore, when determining the stable controller parameter region in such time-delay processes, all

IRB lines calculated by (11) are plotted. Then, regions are determined according to the intersection of

RRB,

IRB, and

CRB lines, and the stability test of these regions is performed. In

Figure 24, it is aimed to find the (

Kr,

Kp) parameter region that stabilizes, via Hurwitz stabilization, the characteristic polynomial in (4) from the

SBL obtained for the frequency range

ω ∈ [0, 3.05]. For this reason, the (

Kr,

Kp) parameter test points were selected from the region bounded by the

RRB,

IRB, and

CRB lines and the regions outside this region, and the stability of (4) was analyzed. Test points (−0.00046, 0.03), (−0.1857, 0.3838), (−0.3018, −0.2868), (0.2346, 0.5074), (0.2926, −0.4368), and (−0.3350, 0.6132) were selected from the determined

R1,

R2,

R3,

R4,

R5 and

R6 regions, respectively. The plotted unit step responses for these test points are presented in

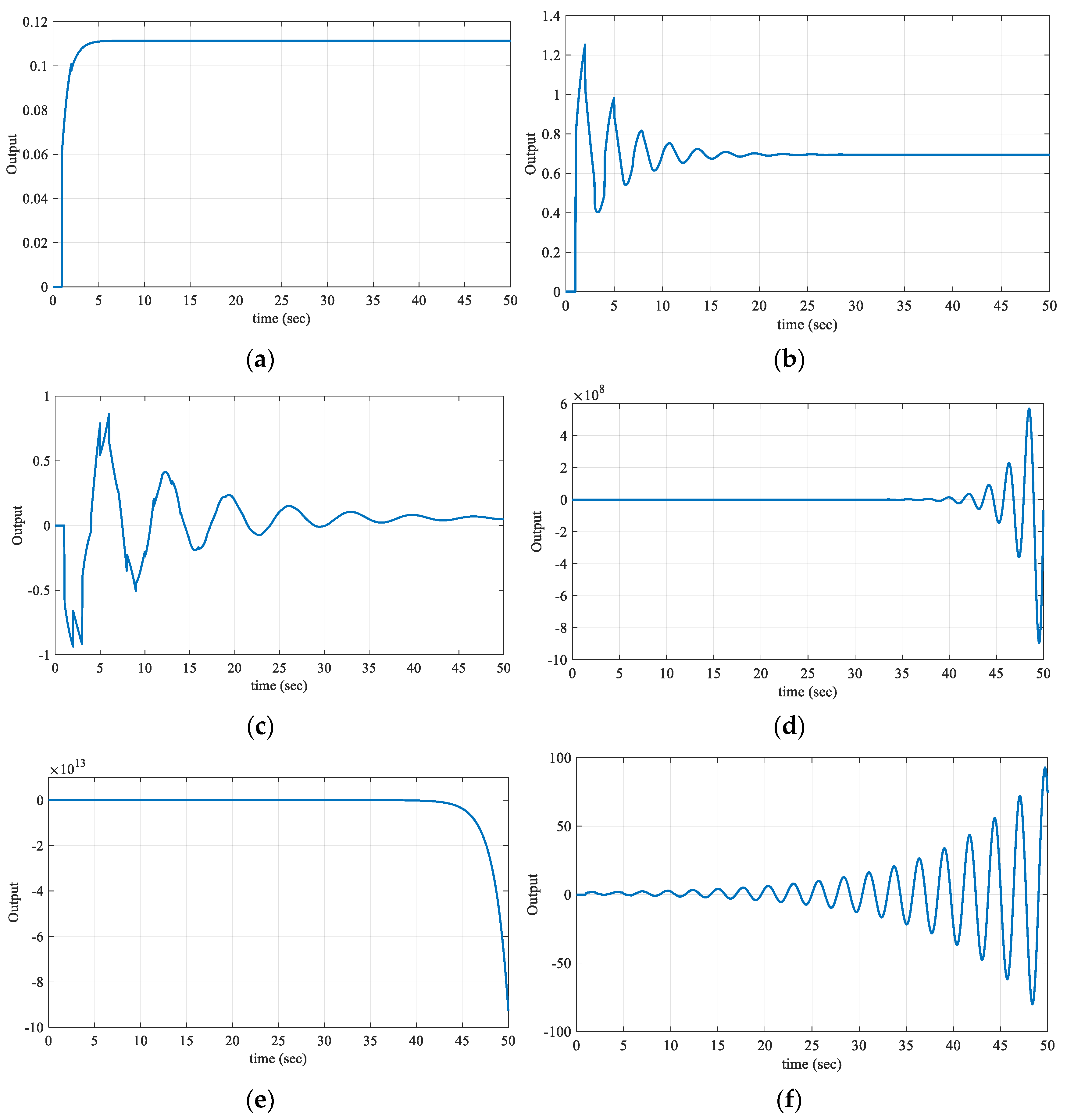

Figure 25.

When the unit step responses in

Figure 25 obtained for the regions in

Figure 24 are analyzed, it is seen that the characteristic equations for the test point in regions

R1,

R2, and

R3 have only the left half-plane pole, thus, they are stable regions. As the characteristic equations written in (4) for the test points selected from the

R4,

R5, and

R6 regions have the right half-plane pole, these regions are unstable regions, as shown in

Figure 25. In other words, the PR controller to be designed for a (

Kr,

Kp) controller parameter pair selected from these regions (

R4,

R5, and

R6) will not provide the stability of the system in (28). Therefore, the stable region is the

R1,

R2, and

R3 regions covering the frequency range

ω ∈ [0, 2.9921] rad/s, i.e., the regions bounded by the

CRB and

RRB lines. Here, the boundary lines obtained by equations

IRB2 and

IRB4 do not intersect the

CRB and

RRB lines and therefore do not affect the stable region. Although the boundary lines obtained with the

IRB1 and

IRB3 equations intersect with

CRB and

RRB lines, they do not affect stability.

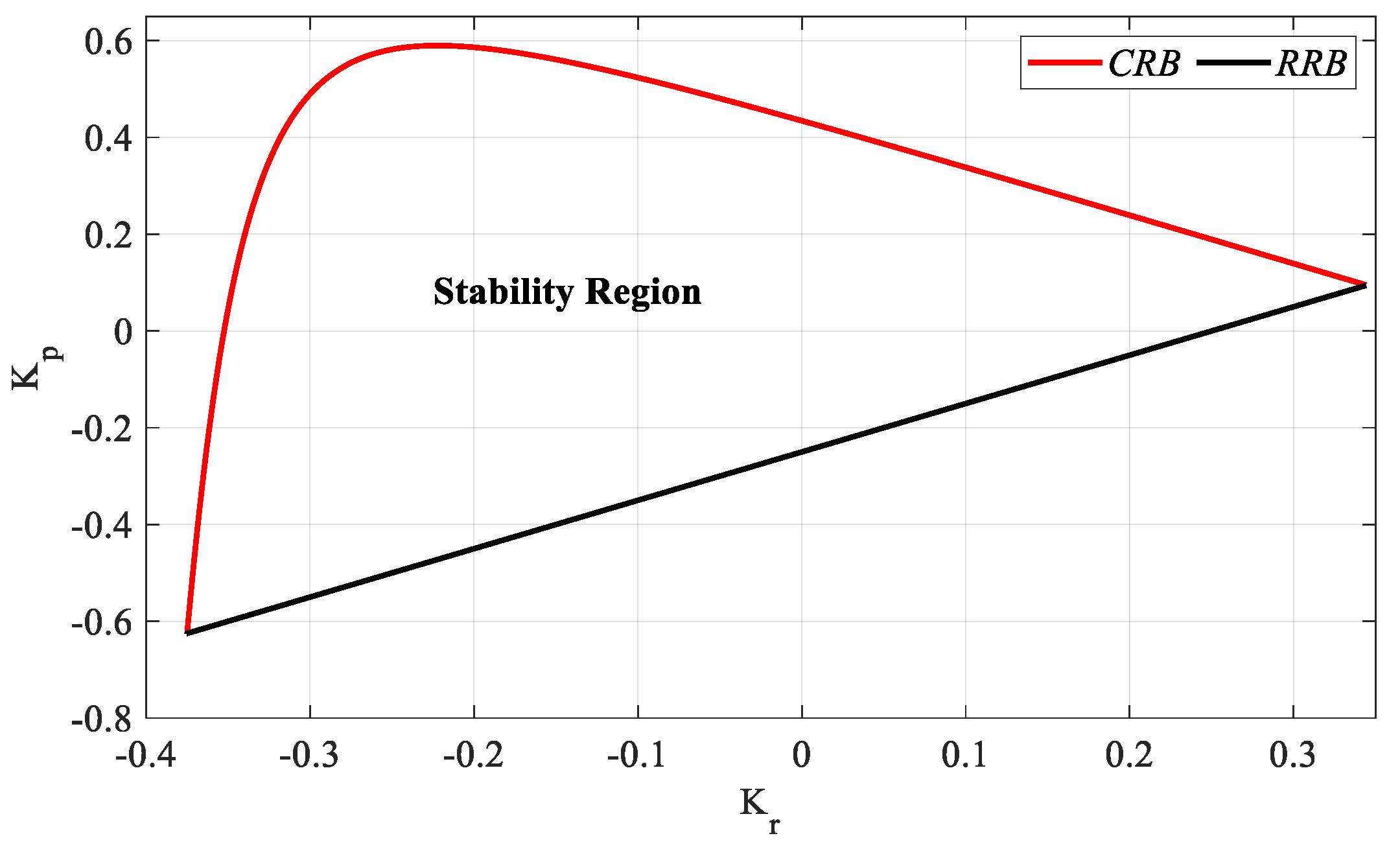

Accordingly, considering the frequencies of the boundary points where the

CRB and

RRB lines intersect, the stable controller parameter region of the system in (28) for

h = 1 is drawn as shown in

Figure 26.

As can be seen from

Figure 26, the stability region for the PR controller is found as the intersection area of the

RRB and

CRB lines. Accordingly, the

Kp and

Kr controller parameter ranges that make the system stable are determined as [−0.625 0.59] and [−0.375 0.344], respectively. Accordingly,

SBL graphs for the controller parameter range

Kr_fixed = [−0.3:0.1:0.3] are drawn as shown in

Figure 27, with the

RRB defined by the line equation

Ki = 0 and the

CRB equations calculated by (16) and (17).

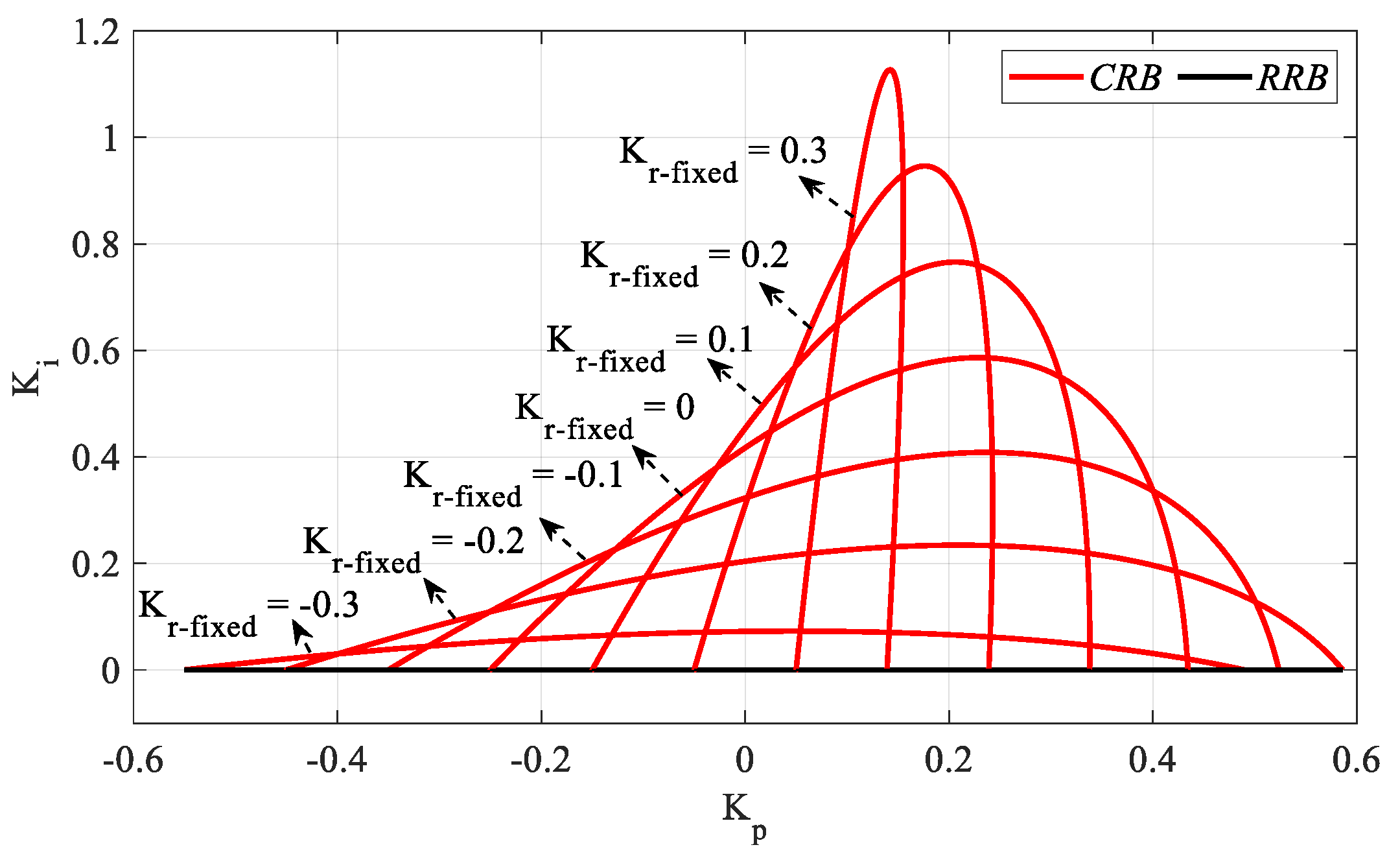

Figure 27 was obtained by plotting the

Kp-Ki SBLs in the frequency range

ω ∈ [0,

ωmax] rad/s for

Kr_fixed = −0.3, −0.2, −0.1, 0, 0.1, 0.2, and 0.3. Accordingly, the

ωmax values for these

Kr_fixed values are 2.1707, 2.6155, 2.7816, 2.868, 2.9212, 2.9570, and 2.9829 rad/s, respectively. The stable

Ki controller parameter range will be determined for an

SBL selected from the

SBL graphs of the system with a PIR controller designed for different

Kr_fixed values in

Figure 27. Therefore, according to the

SBL graph of the PIR controller designed for

Kr_fixed = −0.1, the

Ki controller parameter range that makes the system stable is [0 0.408].

SBL graphs for

Ki_fixed values to be selected from the

Ki controller parameter range are obtained with the help of the

RRB line defined by

, a

CRB line to be drawn with the help of (19) and (20), and

IRB lines to be obtained with the help of (11), if any. Accordingly,

SBL plots for the controller parameter range

Ki_fixed = [0:0.1:0.4] are drawn as shown in

Figure 28.

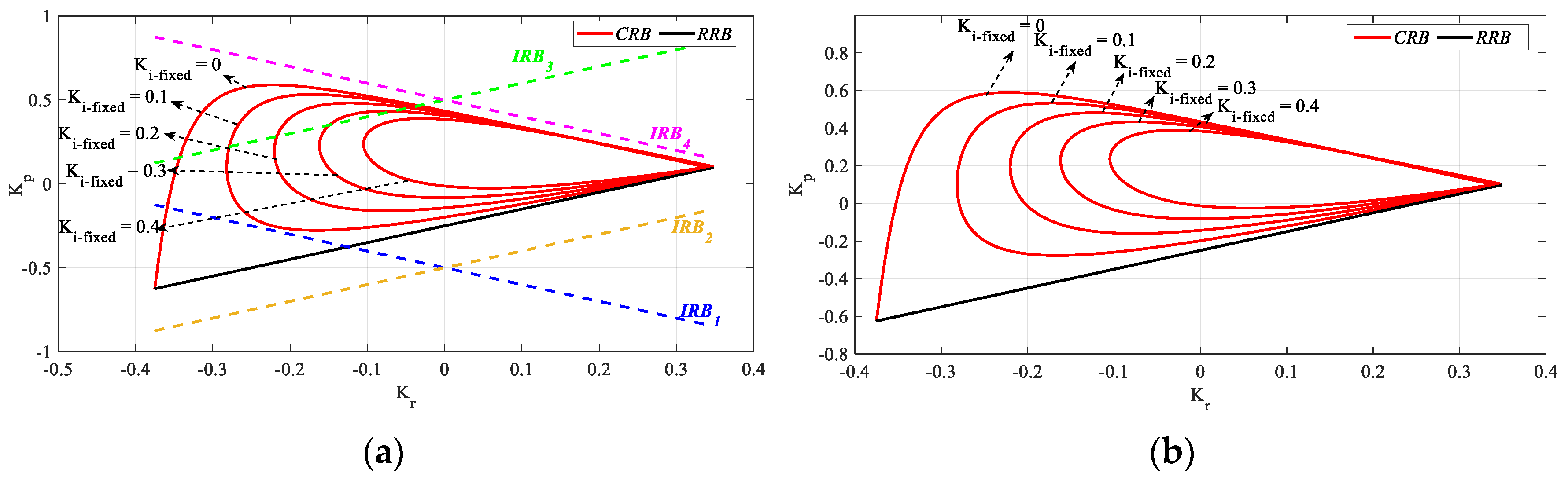

Figure 28 was obtained by plotting

Kr-Kp SBLs in the frequency range

ω ∈ [

ωmin,

ωmax] rad/s for

Ki_fixed = 0, 0.1, 0.2, 0.3, and 0.4. For these

Ki_fixed values, the frequency ranges that make the system stable are

ω ∈ [0, 2.9921], [0.378, 0.947], [0.54, 2.9], [0.672, 2.853], and [0.79, 2.803] rad/s, respectively. It is seen that the stable

Kr-Kp controller parameter region becomes smaller as the

Ki_fixed value increases.

It is seen from

Figure 28 that the

RRB line defined by the equation of

is the determinant of the stability boundary only in the case of

Ki_fixed = 0. Moreover, in the stability analysis in

Figure 24 for

Ki ≠ 0, it was shown that the

IRB2 and

IRB4 boundary lines do not intersect the

CRB and

RRB lines and do not affect the stable region. The

IRB1 and

IRB3 boundary lines intersect the

CRB and

RRB lines, but do not affect stability. The positions of these

IRB1,

IRB2,

IRB3, and

IRB4 boundary lines at

Ki ≠ 0 are shown in

Figure 28a. According to the stability analyses performed here, it is seen that these lines do not separate the system in (28) into unstable regions, and that the stability regions of the system with a PIR controller designed according to different

Ki_fixed values are shown in

Figure 28b.

From the

SBL graph for the PR controller in

Figure 26, the

Kp controller parameter range that makes the system stable was determined as [−0.625 0.59]. Accordingly, for a

Kp_fixed selected from the

Kp controller parameter space,

SBL is generated by an

RRB line defined by the equation

Ki = 0 and a

CRB line to be drawn with the help of (16) and (17). Accordingly,

SBL graphs for the controller parameter range

Kp_fixed = [−0.6:0.2:0.4] are drawn as shown in

Figure 29.

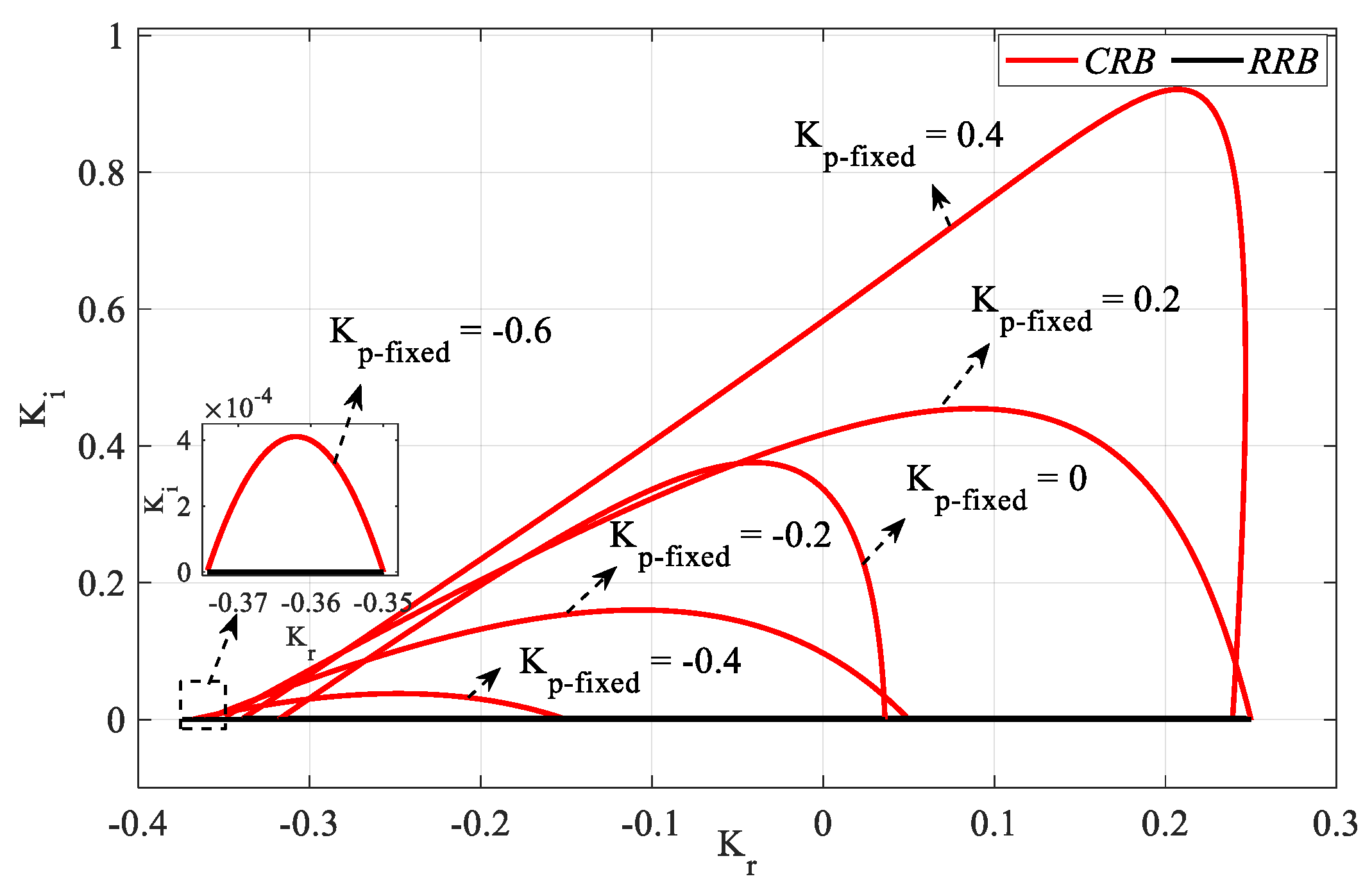

Figure 29 was obtained by plotting

Kr-Ki SBLs in the frequency range

ω ∈ [

ωmin,

ωmax] rad/s for

Kp_fixed = −0.6, −0.4, −0.2, 0, 0.2, and 0.4. In the stability analyses for these

Kp_fixed values, the frequency ranges

ω ∈ [0, 0.2555], [0, 0.7869], [0, 1.1146], [0, 1.4009], [1.6831, 2.9681] and [1.9666, 2.89] rad/s were found, respectively. It is seen that the stable

Kr-Ki controller parameter region increases as the value of

Kp_fixed increases.

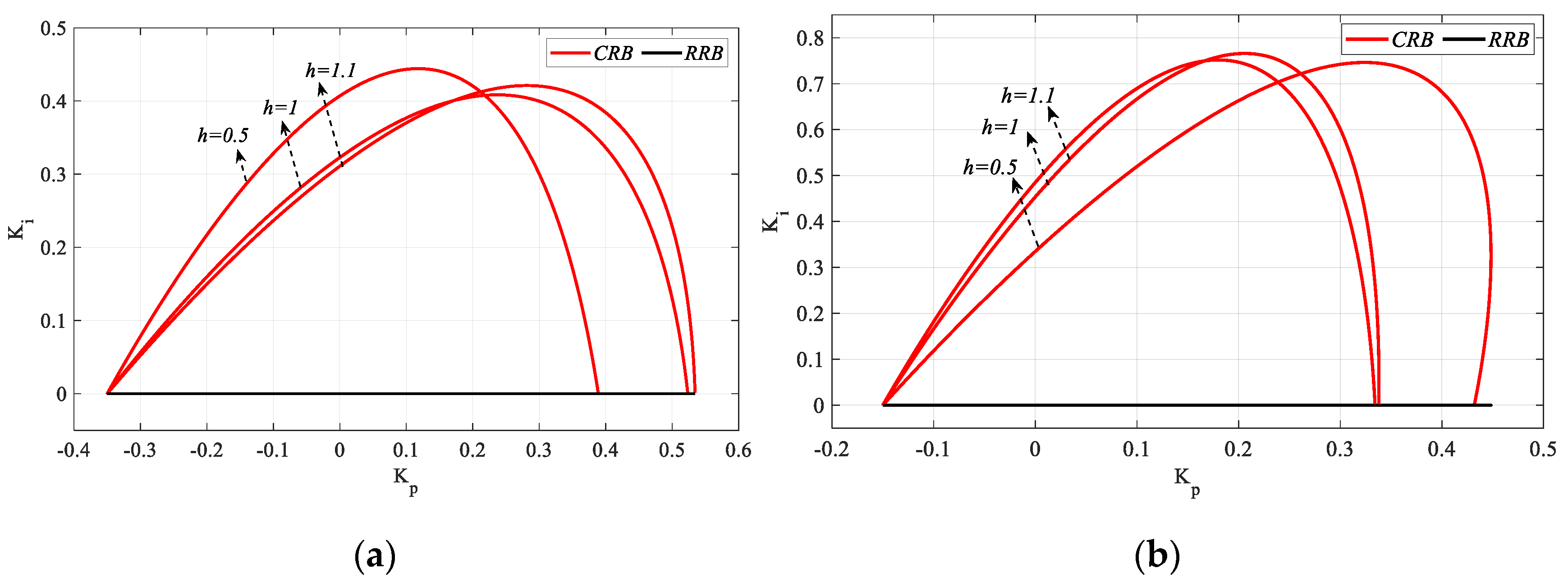

The above analyses were performed for h = 1, and the analyses were repeated to interpret the effect of different values of h on SBL. In this regard, the cases of h > , h = , and h < are examined. Although the case of h = is h = 1 as examined above, the analyses for the cases of h = 0.5 (h < ), and h = 1.1 (h > ) are repeated as follows.

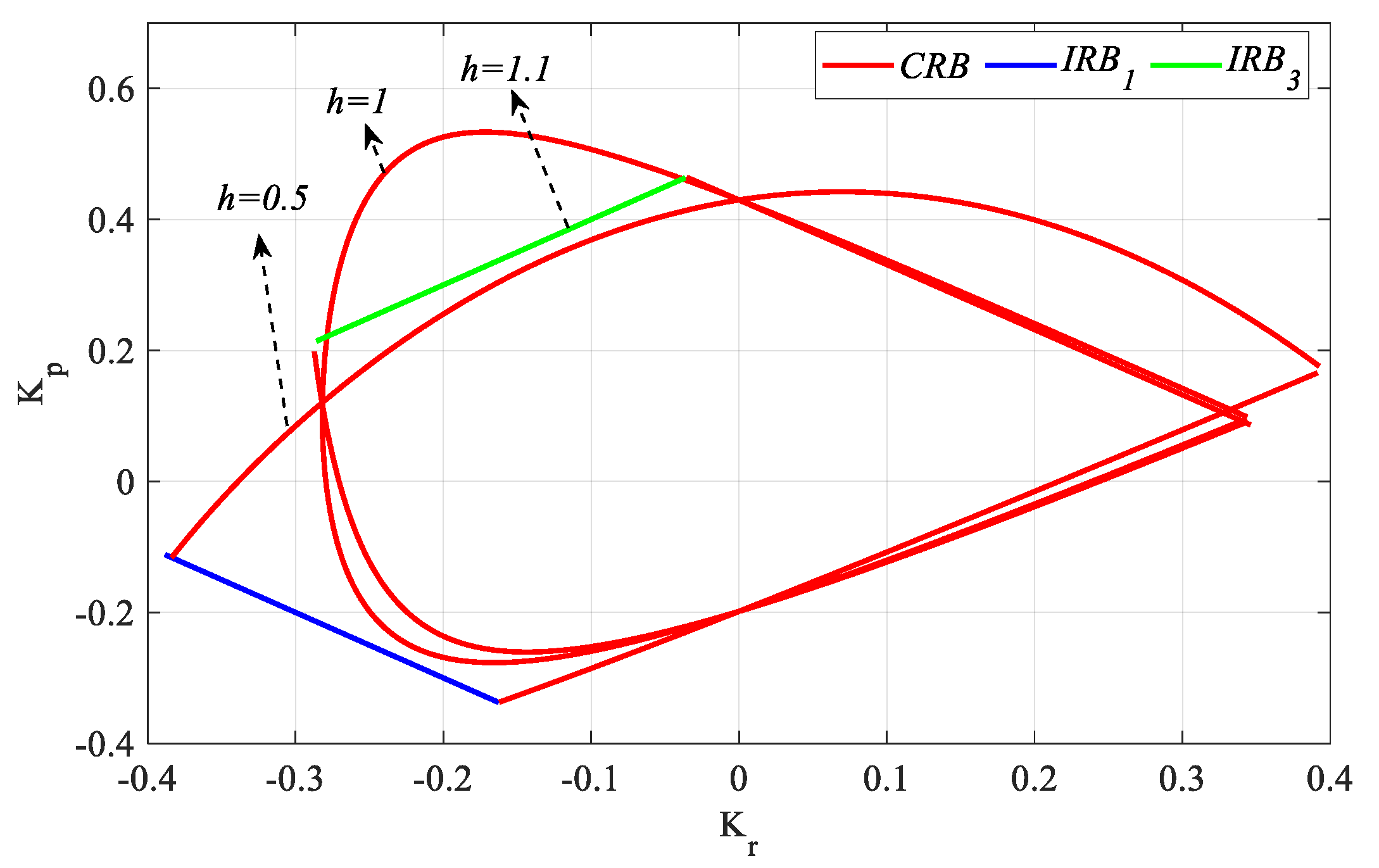

In

Figure 30a, the

SBL graph for the PR controller is drawn for

h = 0.5 in the frequency range

ω ∈ [0, 5] rad/s. As can be seen from

Figure 30a, lines

CRB,

RRB,

IRB1, and

IRB4 intersect each other, while lines

IRB2 and

IRB3 are tangent to

CRB and

RRB. Stability analysis was performed for the three closed regions (

R1,

R2 and

R3) resulting from the intersection of the

CRB,

RRB,

IRB1, and

IRB4 lines. It was observed that the PR controllers designed for

Kr-

Kp selected from the closed

R2 and

R3 regions make the process in (28) stable, while the controller parameter pair selected from the

R1 region makes the system unstable. As a result of this analysis for

h <

, it was seen that the

CRB,

RRB, and

IRB1 lines affect stability, while the

IRB4 line does not. The

IRB2 and

IRB3 lines did not play a role in determining the stability as they passed tangentially to

CRB and

RRB. Accordingly, the stability region for

h = 0.5 is drawn in

Figure 30b by considering the frequencies of the boundary points where the

CRB,

RRB and

IRB1 lines intersect.

Figure 31a shows the

SBL curve for

h = 1.1 in the frequency range

ω ∈ [0, 3] rad/s. As can be seen from

Figure 31a, the lines

CRB,

RRB,

IRB1, and

IRB3 intersect each other, and the lines

IRB2 and

IRB4 are tangential to

CRB and

RRB. Stability analysis was performed for the three closed regions (

R1,

R2 and

R3) resulting from the intersection of the

CRB,

RRB,

IRB1 and

IRB3 lines and it was observed that the PR controllers designed for the controller parameter pair (

Kr,

Kp) selected only in the

R1 region make the process in (28) stable, while the controller parameter pair selected in the

R2 and

R3 regions make it unstable. As a result of this analysis for

h >

, it is seen that

CRB,

RRB,

IRB1, and

IRB3 lines affect stability.

IRB2 and

IRB4 lines did not play a role in determining stability as they passed tangentially to

CRB and

RRB. Accordingly, the stable region was found to be the closed

R1 region, and the stability region for

h = 1.1 was drawn in

Figure 31b by considering the frequencies of the boundary points where the

CRB, RRB, IRB1, and

IRB3 lines intersect.

From

Figure 30b and for

h = 0.5, the

Kp and

Kr controller parameter ranges that stabilize the system are [−0.37 0.44] and [−0.42 0.38], respectively. Similarly, from

Figure 31b, the

Kp and

Kr controller parameter range that makes the process stable for

h = 1.1 is determined as [−0.4 0.41] and [−0.35 0.34], respectively. For the

Kr_fixed = −0.1 and 0.1 values selected from the common stable controller parameter range,

RRB is defined by

Ki = 0 and

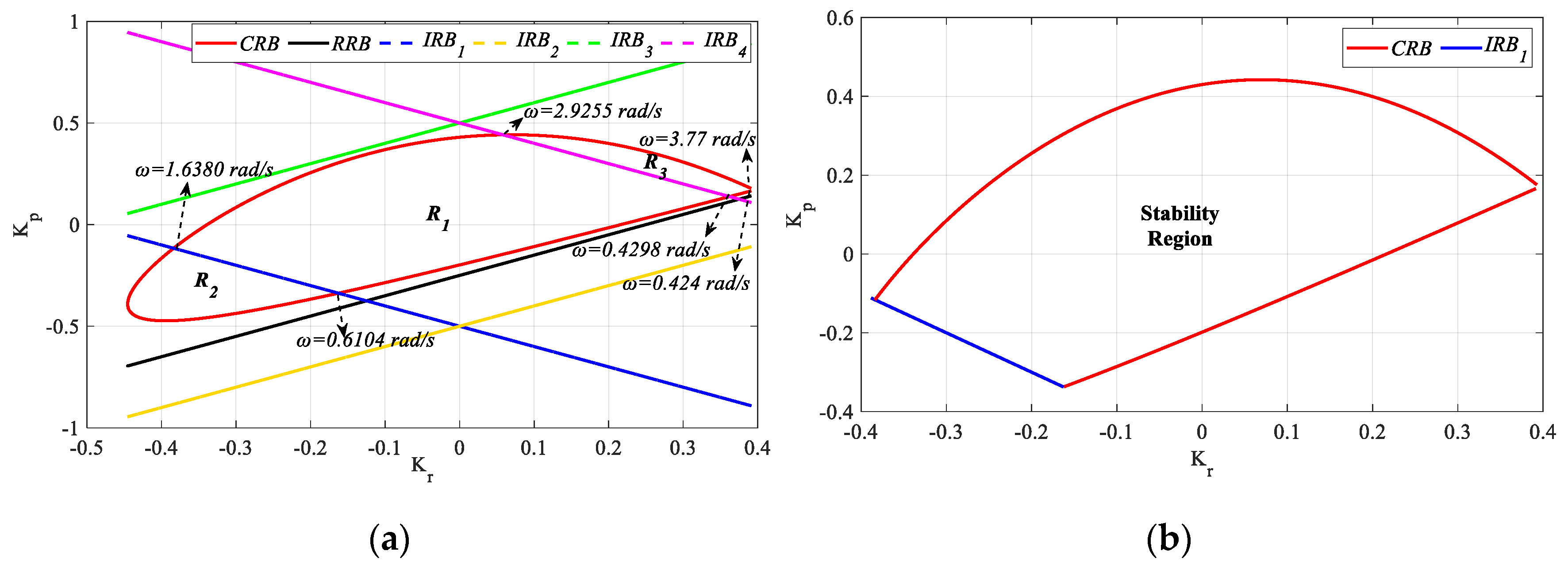

CRB equations are calculated with the help of (16) and (17).

Kp-Ki SBL plots are obtained as shown in

Figure 32.

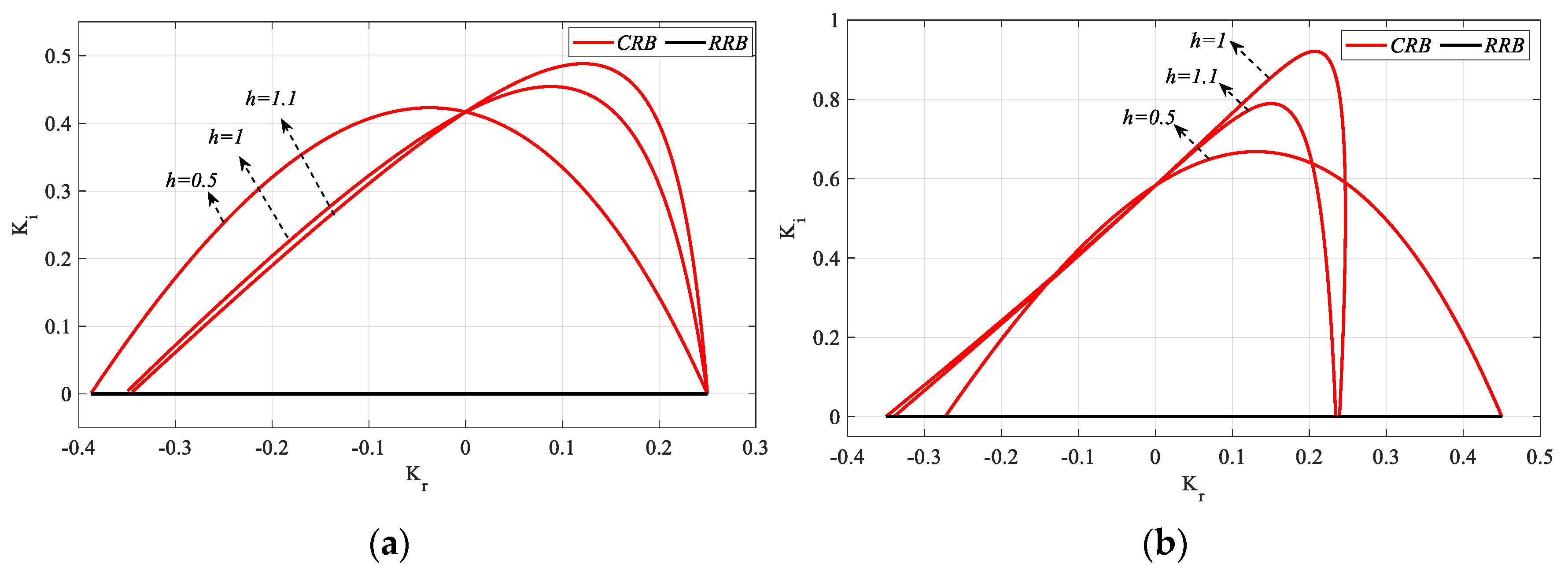

In

Figure 32a, the

ωmax values for

Kr_fixed = −0.1 and

h = 0.5, 1, and 1.1 are 2.6255, 2.7816, and 2.8717 rad/s respectively, and in

Figure 32b, the

ωmax values for

Kr_fixed = 0.1 and

h = 0.5, 1 and 1.1 are 3.1093, 2.9212, and 2.8646 rad/s respectively. As the controller will turn into a PI controller for

Kr = 0, the value of

h will have no effect on

SBL, and it will be the same as

Kr_fixed = 0 in

Figure 27. The

Kr-

Kp SBL curves and stability regions for

Ki_fixed = 0.1 and

h = 0.5 and 1.1, which are selected from the common stable controller parameter ranges of the

SBL curves in

Figure 32, are presented in

Figure 33 and

Figure 34.

In

Figure 33a, the

CRB curve for

Ki_fixed = 0.1 and

h = 0.5 is plotted in the frequency range

ω ∈ [0.424, 3.77] rad/s. In the analysis for

Ki_fixed = 0 in

Figure 30a, it was found that the boundary lines determining the stability were the

CRB,

RRB, and

IRB1 lines. When the same analysis was performed for

Ki_fixed = 0.1, it was found that

CRB and

IRB1 lines affect stability, while

RRB does not affect stability as a result of it not intersecting with

CRB. Accordingly, considering the frequency points where the

CRB and

IRB1 lines intersect, the stable controller region for

Ki_fixed = 0.1 and

h = 0.5 is obtained as shown in

Figure 33b. Similarly, the

CRB curve for

Ki_fixed = 0.1 and

h = 1.1 in the frequency range

ω ∈ [0.37, 2.8174] rad/s is obtained as shown in

Figure 34a. In the analysis for

Ki_fixed = 0 in

Figure 31a, it was found that the boundary lines determining the stability were

CRB,

RRB,

IRB1, and

IRB3 lines. When the analysis was repeated for

Ki_fixed = 0.1, it was found that only

CRB and

IRB3 lines affected stability, and that

IRB1 and

RRB did not affect stability because of they do not intersect with

CRB. Accordingly, considering the frequency points where the

CRB and

IRB3 lines intersect, the stable controller region for

Ki_fixed = 0.1 and

h = 1.1 is obtained as shown in

Figure 34b.

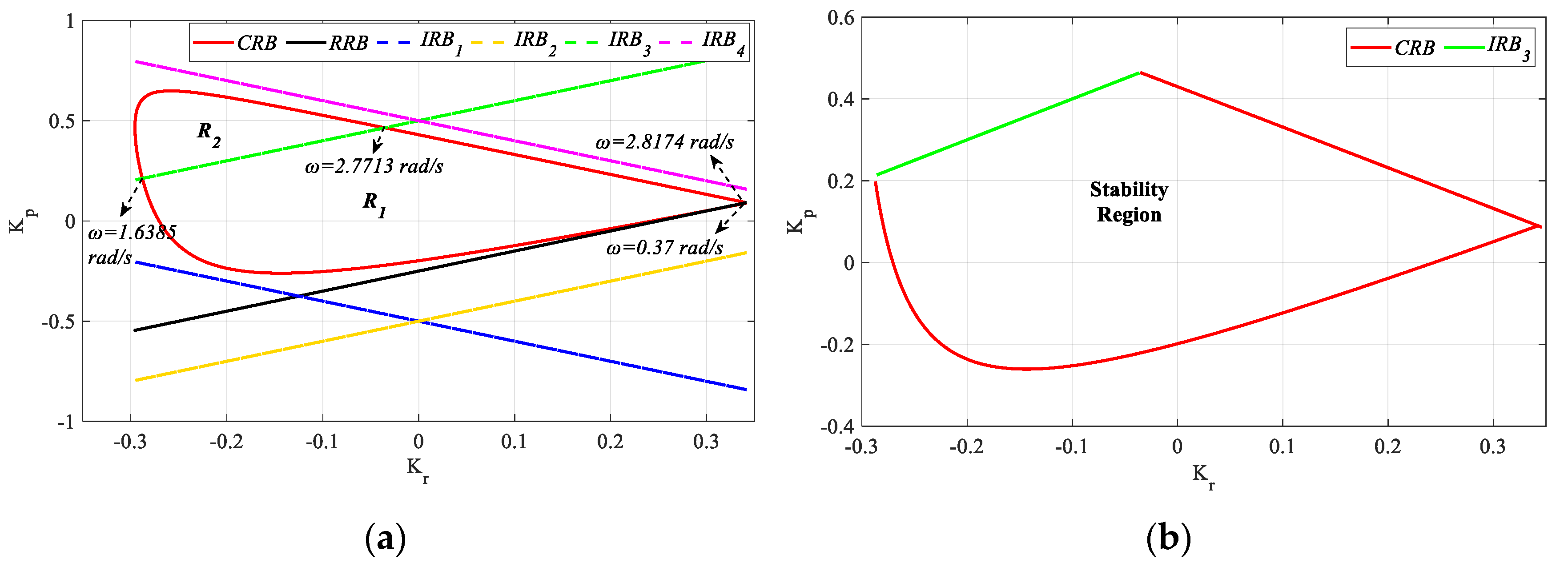

With the values obtained from

Figure 28b,

Figure 33b and

Figure 34b, the

SBL for the stable controller parameter regions for

Ki_fixed = 0.1 and

h = 0.5, 1, and 1.1 are drawn as in

Figure 35.

When

Figure 35 is examined, the stable

Kr-

Kp parameter region narrows as the

h value increases in the case of

Ki_fixed = 0.1. From

Figure 26,

Figure 30 and

Figure 31, the stable

Kp controller parameter ranges were found to be [−0.37 0.44], [−0.625 0.59], and [−0.4 0.41] for

h = 0.5, 1, and 1.1, respectively. Accordingly,

Kr-Ki SBL graphs for

Kp_fixed 0 and 0.2 selected from these stable regions were obtained and are shown in

Figure 36.

As illustrated in

Figure 36a, the frequency ranges that ensure system stability for

h = 0.5, 1, and 1.1 are presented as

ω ∈ [0, 1.8759], [0, 1.4009], and [0, 1.3341] rad/s, respectively. Similarly,

Figure 36b demonstrates the corresponding frequency ranges for

h = 0.5, 1, and 1.1, namely

ω ∈ [1.6831, 2.9681] and [1.6029, 2.8635] rad/s. When

Figure 36a is examined, as the

h value increases when

Kp_fixed = 0, the stable

Kr parameter range decreases relatively, while the stable

Ki parameter range increases. Similarly, in the analysis made for

Kp_fixed = 0.2 in

Figure 36b, it is seen that, as the

h value increases, the stable

Kr range decreases significantly, while the stable

Ki range increases. The unit step responses of the

SBL curves obtained for

h = 0.5, 1, and 1.1 in

Figure 32a,

Figure 35 and

Figure 36b were analyzed for

Kp,

Ki, and

Kr values selected from the common stability regions. It can thus be expected of the PIR controllers designed for the parameters selected from these regions that they will ensure the stabilizing of the

Gp3 process in

Figure 1 in the instances

h = 0.5, 1, and 1.1. In this context, the unit step responses of the control system given in

Figure 1 obtained by applying the PIR controllers designed for

Kp =−0.0297 and

Ki =0.1183 values selected from the common region of the

Kp-Ki SBL curves drawn by taking

h=0.5, 1 and 1.1 values in

Figure 32.a when

Kr_fixed =−0.1 are shown in

Figure 37. The PIR controllers are designed for the controller parameter values

Kp = −0.0544 and

Kr = −0.0460, which are selected from the

Kr-Kp SBL graph in

Figure 35, drawn for

Ki_fixed = 0.1. The unit step responses for different

h values are shown in

Figure 38. Similarly, the controller parameter values

Ki = 0.2833 and

Kr = −0.0460 are selected from the

Kr-

Ki SBL curve in

Figure 36b, obtained for

Kp_fixed = 0.2, and the unit step responses for

h = 0.5, 1, and 1.1 are presented as in

Figure 39.

When

Figure 37,

Figure 38 and

Figure 39 are examined, it is seen that the PIR controllers designed for the parameters selected from the common stability regions of the

SBL curves drawn for the cases

h = 0.5, 1 and 1.1 control the

Gp3 time-delay process with a first-order transfer function in the numerator and denominator in

Figure 1 in a stable manner.