Comparative Analysis of the Reliability and Durability of TIC and NSK Ball Screws for Enhanced Process Optimization

Abstract

1. Introduction

2. Materials and Methods

2.1. Model and Material Description

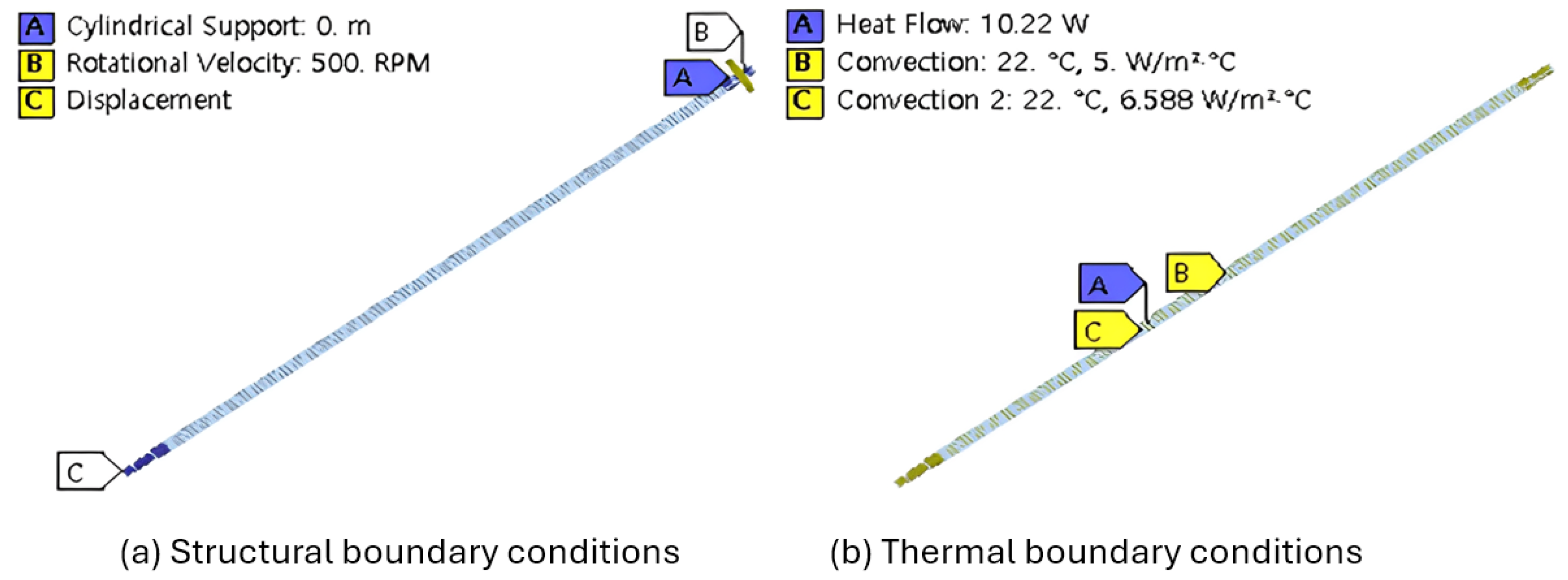

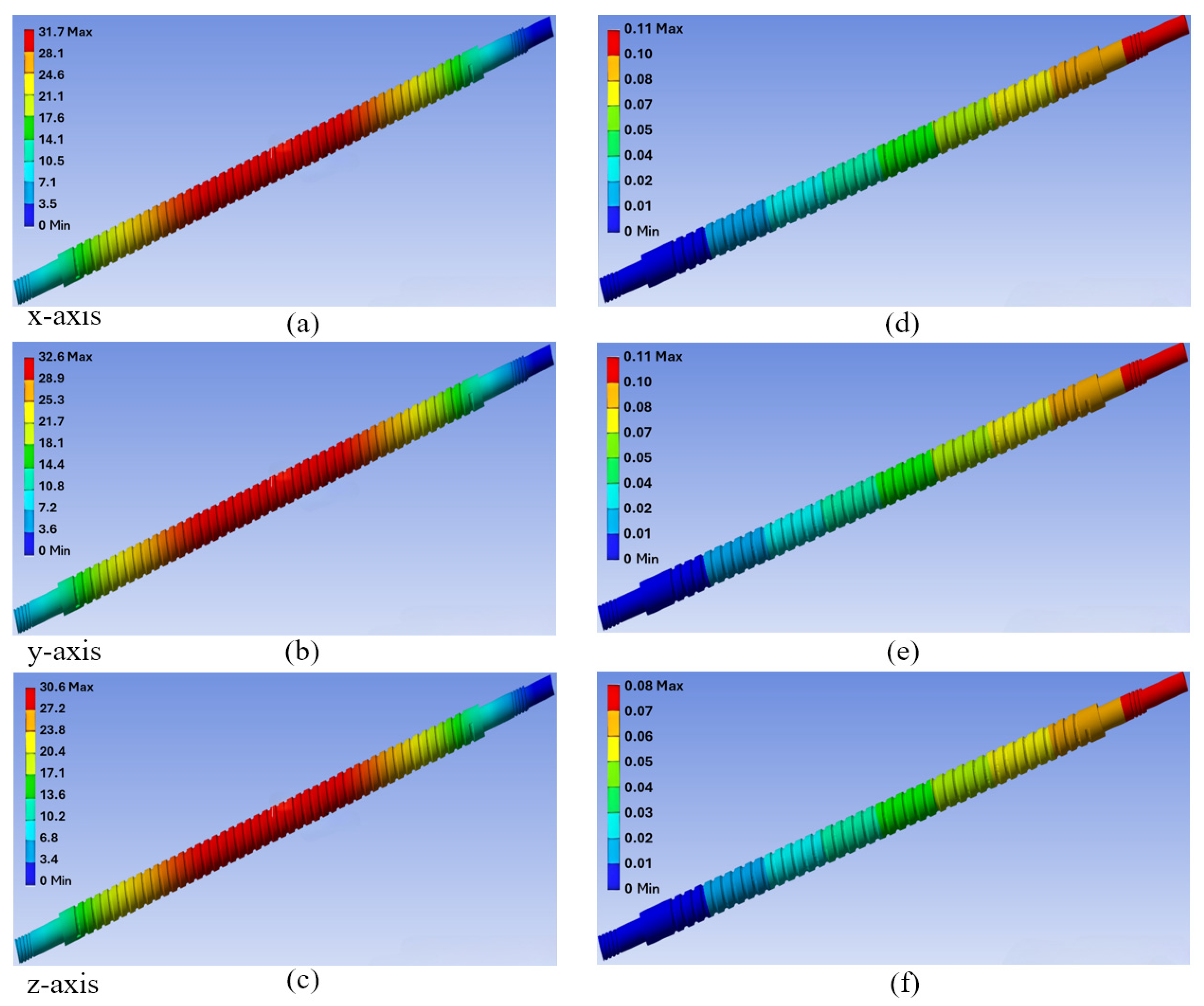

2.2. Simulation of NSK and TIC Ball Screw

2.3. Mechanical Tests

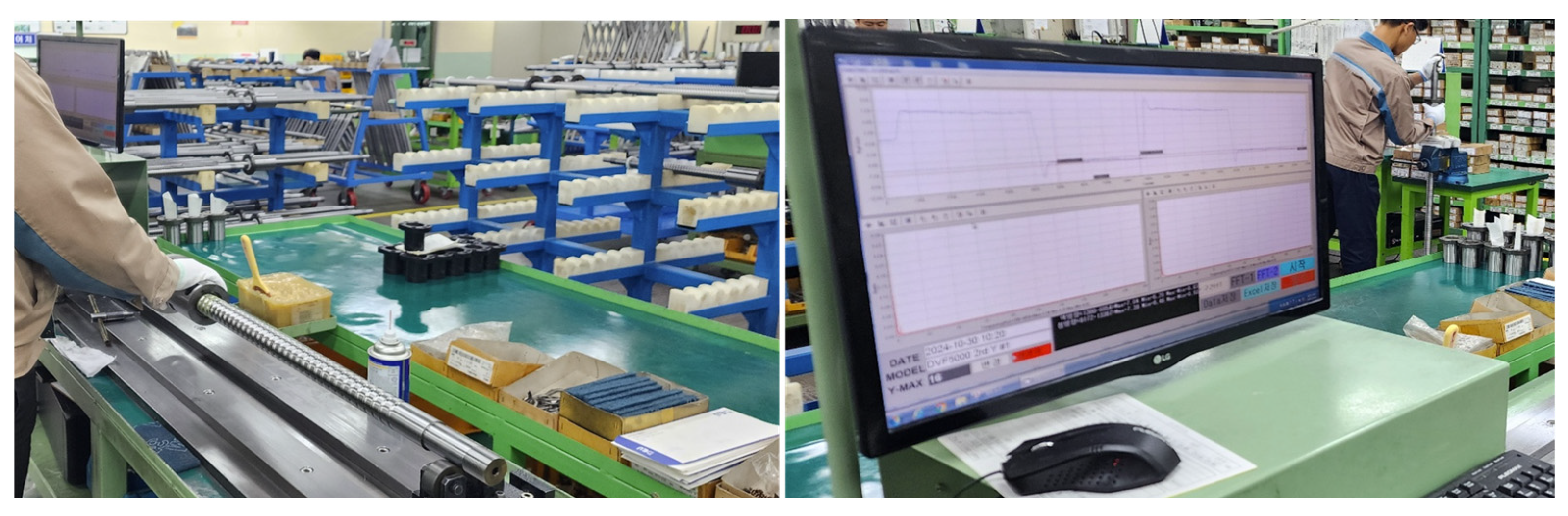

2.3.1. Thermal Displacement per 1 m of TIC Ball Screw

2.3.2. TIC Ball Screw Friction Torque Fluctuation Rate

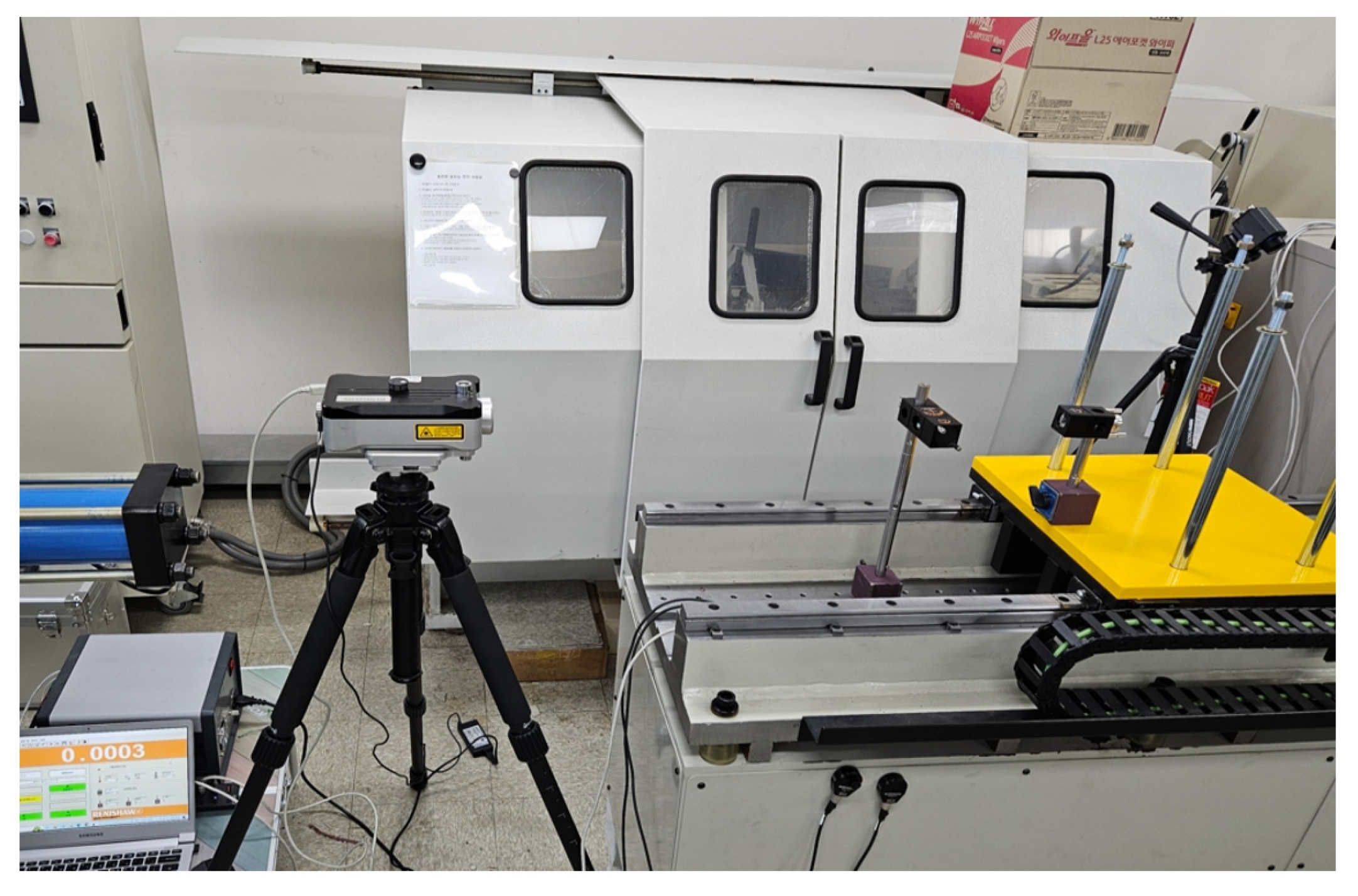

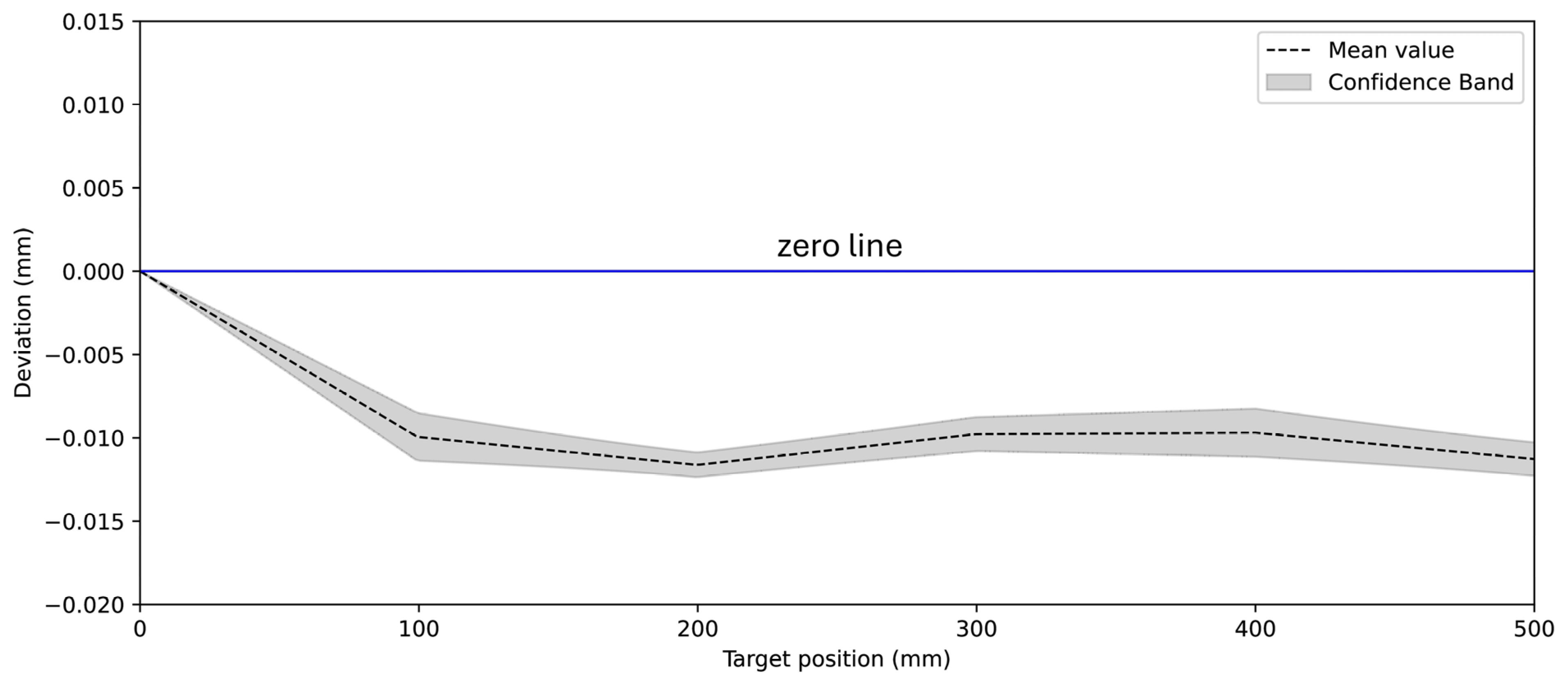

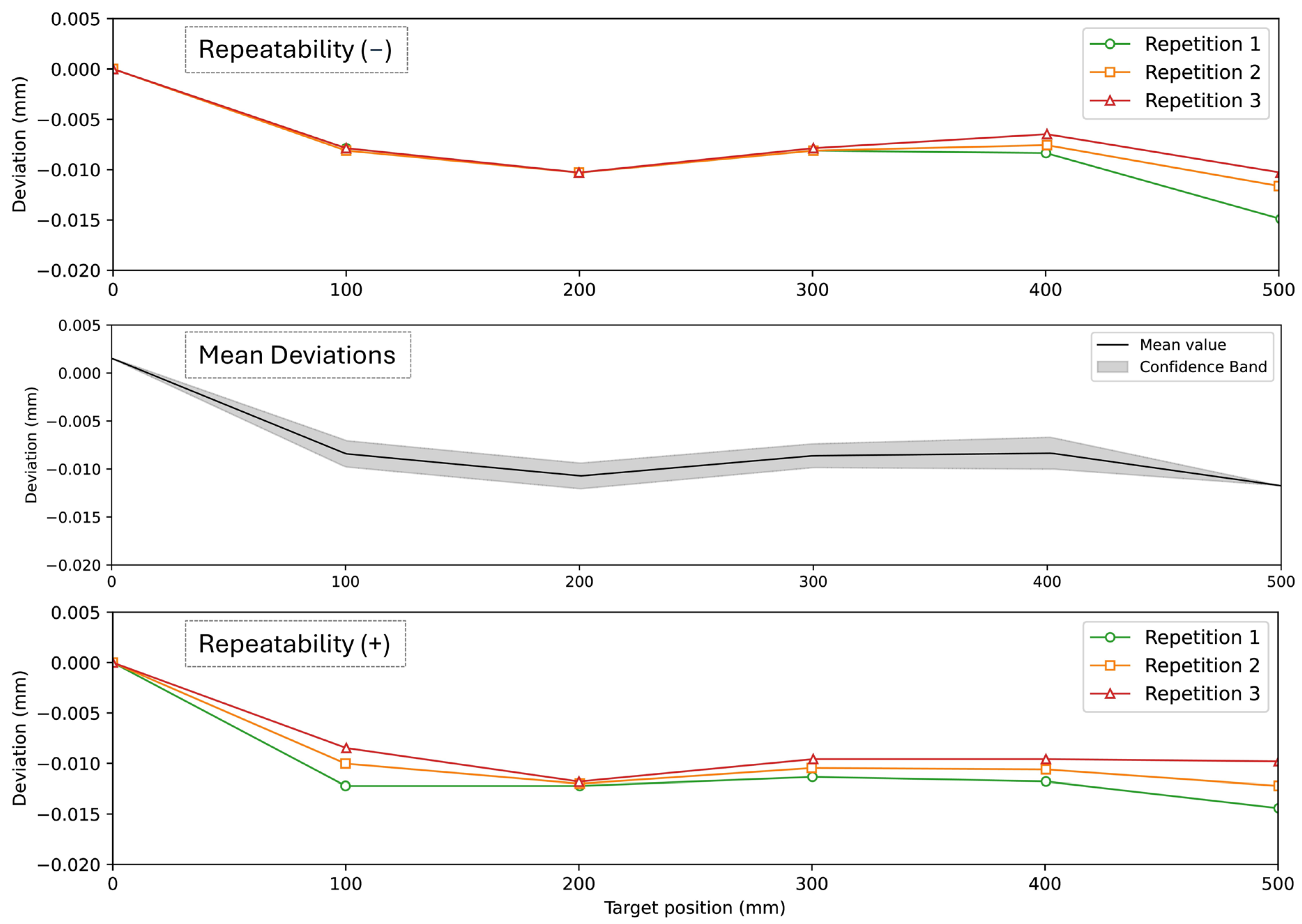

2.3.3. Test Bench Positioning Repeatability

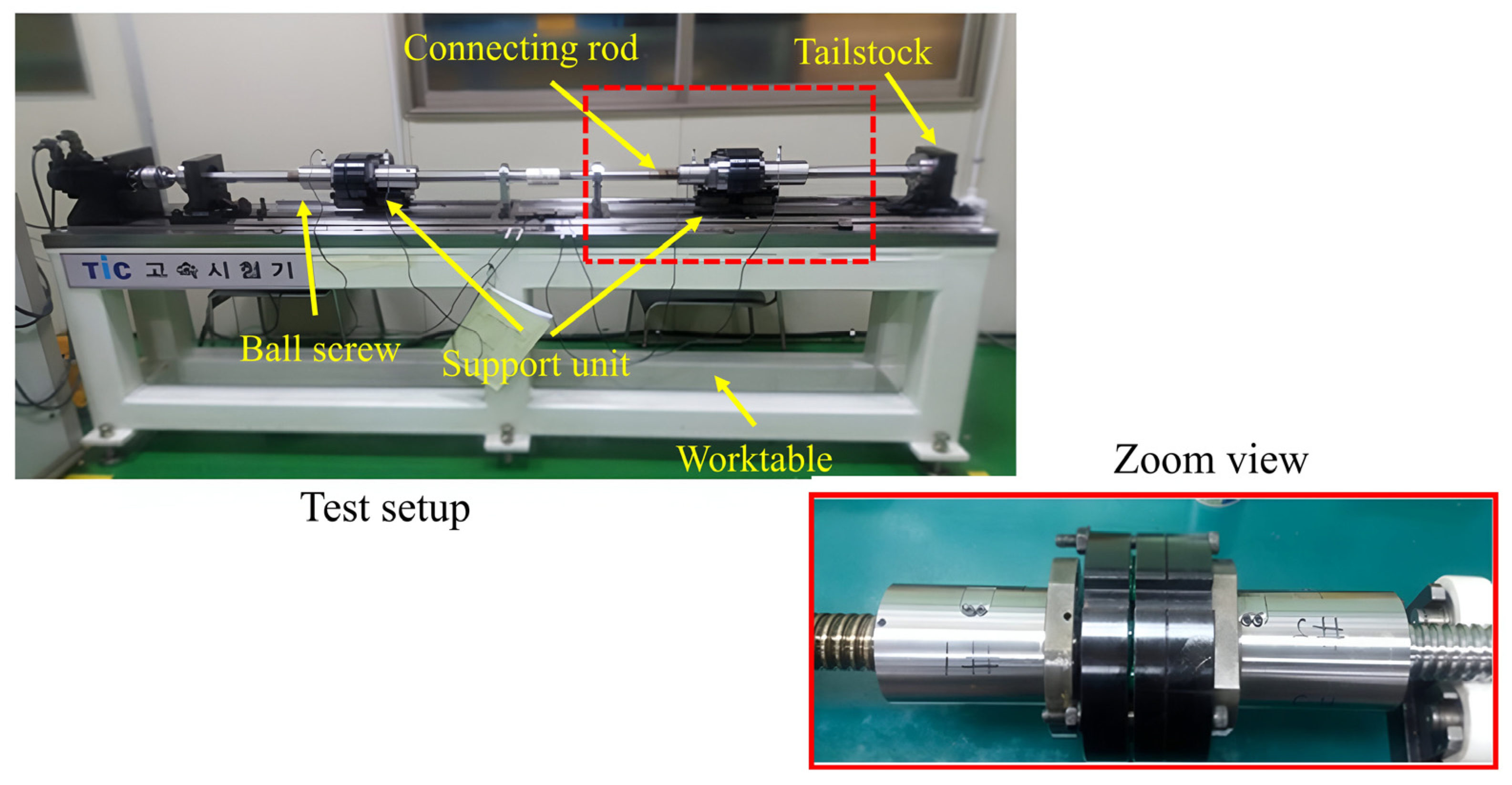

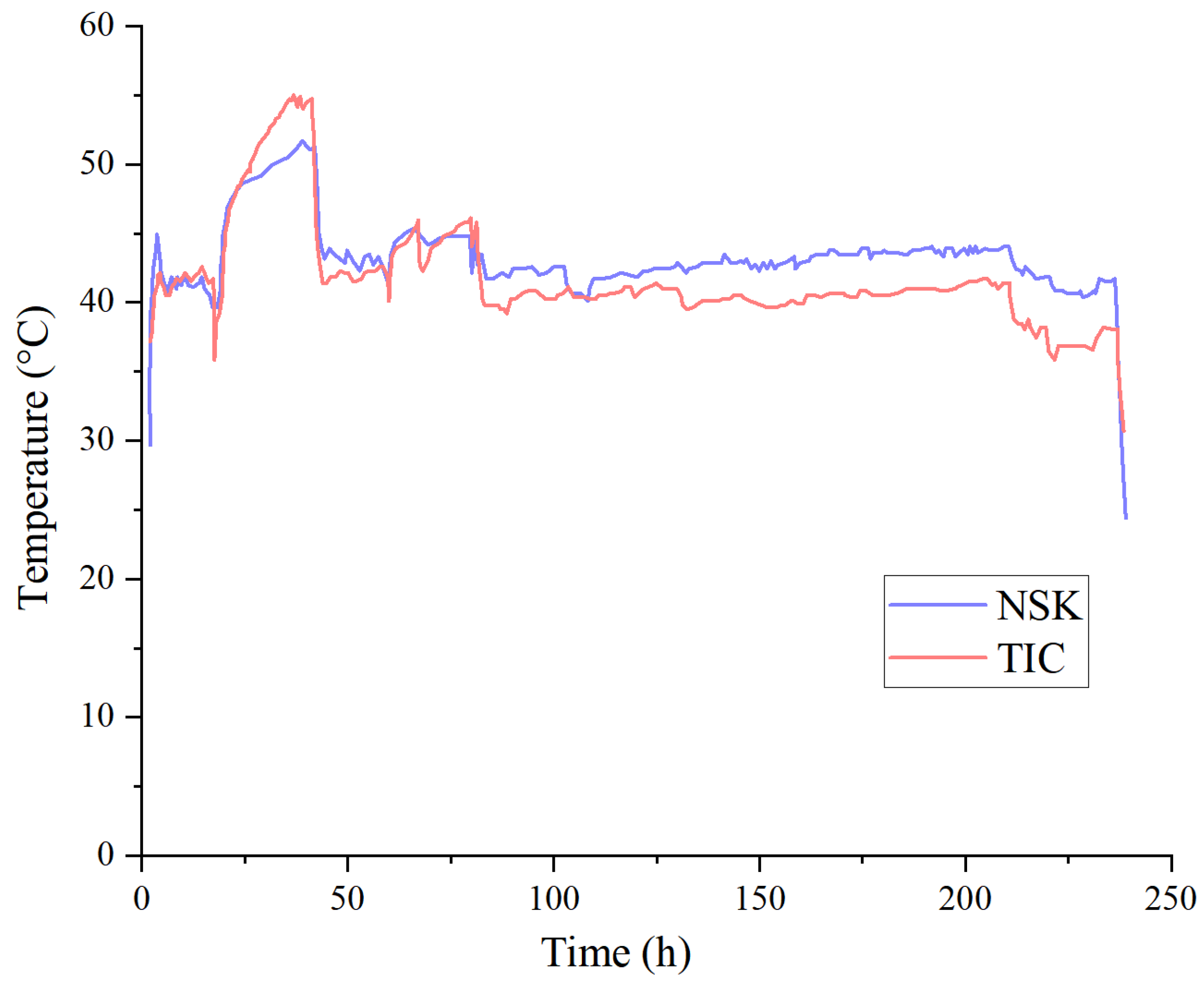

2.3.4. Accelerated Life Test

3. Results

3.1. Simulation Results of NSK and TIC Ball Screw

3.2. Mechanical Test Results

3.2.1. Thermal Displacement Test Results

3.2.2. Friction Torque Fluctuation Test Results

3.2.3. Positioning Repeatability Test Results

3.2.4. Results of Accelerated Life Test

4. Discussion

- The TIC ball screw demonstrated superior thermal performance, with a maximum temperature of 32.6 °C in simulations, compared to 34 °C for the NSK. Similarly, the thermal deformation was also lower in TIC (119.34 µm) versus NSK (174 µm).

- Furthermore, durability testing, the ball screws were subjected to constant work, amounting to 245 h. In this test, although the thermal equilibrium was achieved almost at the same time, TIC had the average lower temperature compared to the NSK ball screw.

- In the quality verification testing of TIC ball screws, positioning repeatability showed a mean deviation of 4.99 μm, while maximum thermal displacement was 13.5 μm after 2000 cycles of reciprocating motion. The friction torque results were also satisfactory, with a maximum fluctuation rate of 19.9%.

5. Future Recommendation

- Further research can be done to optimize the material properties to enhance the thermal and mechanical properties of the ball screws.

- While the presented ANSYS simulation shows promising results, further refinements can be made in the simulation model where more complex boundary conditions can be used to simulate real-world operations.

- To better understand the tradeoffs between TIC and NSK ball screws, life cycle cost analysis should be done that will investigate factors such as maintenance, repair and replacement cost, etc.

- The effects of manufacturing processes such as heat treatment, surface coating etc. on ball screws can be discussed to strengthen the comparison.

- Advance monitoring techniques such as AI-driven monitoring and feedback system can be utilized to increase the efficiency and the quality control in ball screw manufacturing for process optimization.

- While the ALT spanned 245 h (~54% of theoretical life), it was sufficient to observe stabilization trends and early degradation. Future studies will explore extended testing (≥1000 h) to assess long-term durability.

- Expanding the study by testing additional ball screw models from various manufacturers to further improve the studied results.

Author Contributions

Funding

Data Availability Statement

Declaration of Generative AI and AI-Assisted Technologies in the Writing Process

Conflicts of Interest

Abbreviations

| ALT | Accelerated Life Test |

| NSK | Nippon Seiko Kabushiki-gaisha |

| TIC | Tongil Industries Co |

| CNC | Computer Numerical Control |

| FEM | Finite Element Method |

| CAD | Computer-Aided Design |

| AISI | American Iron and Steel Institute |

| SCM | Steel Chromium Molybdenum |

| JIS | Japanese Industrial Standards |

| ASTM | American Society for Testing and Materials |

| ISO | International Organization for Standardization |

References

- Shi, H.; Ma, C.; Yang, J.; Zhao, L.; Mei, X.; Gong, G. Investigation into Effect of Thermal Expansion on Thermally Induced Error of Ball Screw Feed Drive System of Precision Machine Tools. Int. J. Mach. Tools Manuf. 2015, 97, 60–71. [Google Scholar] [CrossRef]

- Mayr, J.; Jedrzejewski, J.; Uhlmann, E.; Alkan Donmez, M.; Knapp, W.; Härtig, F.; Wendt, K.; Moriwaki, T.; Shore, P.; Schmitt, R.; et al. Thermal Issues in Machine Tools. CIRP Ann. 2012, 61, 771–791. [Google Scholar] [CrossRef]

- Venugopal, R.; Barash, M.; Shaw, M.C. Thermal Effects on the Accuracy of Numerically Controlled Machine Tools. CIRP Ann. 1986, 35, 255–258. [Google Scholar] [CrossRef]

- Zhang, L.-C.; Ou, Y.; Feng, H.-T. Prediction of the Thermal Elongation of the Ball Screw Mechanism under Various Rotational Speeds. Int. J. Precis. Eng. Manuf. 2021, 22, 1221–1228. [Google Scholar] [CrossRef]

- Weck, M.; Zangs, L. Computing the Thermal Behaviour of Machine Tools Using the Finite Element Method-Possibilities and Limitations. In Proceedings of the Sixteenth International Machine Tool Design and Research Conference, Manchester, UK, 10–12 September 1975; Macmillan Education UK: London, UK, 1976; pp. 185–194. [Google Scholar]

- Xu, Z.Z.; Liu, X.J.; Kim, H.K.; Shin, J.H.; Lyu, S.K. Thermal Error Forecast and Performance Evaluation for an Air-Cooling Ball Screw System. Int. J. Mach. Tools Manuf. 2011, 51, 605–611. [Google Scholar] [CrossRef]

- Min, X.; Jiang, S. A Thermal Model of a Ball Screw Feed Drive System for a Machine Tool. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2011, 225, 186–193. [Google Scholar] [CrossRef]

- Li, Z.; Fan, K.; Yang, J.; Zhang, Y. Time-Varying Positioning Error Modeling and Compensation for Ball Screw Systems Based on Simulation and Experimental Analysis. Int. J. Adv. Manuf. Technol. 2014, 73, 773–782. [Google Scholar] [CrossRef]

- Feng, W.; Li, Z.; Gu, Q.; Yang, J. Thermally Induced Positioning Error Modelling and Compensation Based on Thermal Characteristic Analysis. Int. J. Mach. Tools Manuf. 2015, 93, 26–36. [Google Scholar] [CrossRef]

- Li, X.; Dong, C.; Chen, C.; Wu, T.; Tan, W. Temperature Model of Ball Screw and Its Thermal Error Prediction under Single Heat. Opt. Precis. Eng. 2012, 20, 337–343. [Google Scholar] [CrossRef]

- Oyanguren, A.; Larrañaga, J.; Ulacia, I. Thermo-Mechanical Modelling of Ball Screw Preload Force Variation in Different Working Conditions. Int. J. Adv. Manuf. Technol. 2018, 97, 723–739. [Google Scholar] [CrossRef]

- Huang, S.; Feng, P.; Xu, C.; Ma, Y.; Ye, J.; Zhou, K. Utilization of Heat Quantity to Model Thermal Errors of Machine Tool Spindle. Int. J. Adv. Manuf. Technol. 2018, 97, 1733–1743. [Google Scholar] [CrossRef]

- Gong, X.; Zhao, J.; Zhao, C.; Li, C.; Hao, J.; Xu, M. Dynamic Modeling and Nonlinear Characteristic Analysis of the Cross-Axis Ball Screw Feed System Considering Thermal Deformation. Nonlinear Dyn. 2025, 113, 14515–14560. [Google Scholar] [CrossRef]

- Li, P.; Jia, X.; Feng, J.; Davari, H.; Qiao, G.; Hwang, Y.; Lee, J. Prognosability Study of Ball Screw Degradation Using Systematic Methodology. Mech. Syst. Signal Process. 2018, 109, 45–57. [Google Scholar] [CrossRef]

- Xu, N.; Tang, W.; Chen, Y.; Bao, D.; Guo, Y. Modeling Analysis and Experimental Study for the Friction of a Ball Screw. Mech. Mach. Theory 2015, 87, 57–69. [Google Scholar] [CrossRef]

- Oh, K.-J.; Cao, L.; Chung, S.-C. Explicit Modeling and Investigation of Friction Torques in Double-Nut Ball Screws for the Precision Design of Ball Screw Feed Drives. Tribol. Int. 2020, 141, 105841. [Google Scholar] [CrossRef]

- Zhao, J.; Qi, B.; Song, X.; Jiang, H.; Dong, P. A Modeling Method for Predicting Friction Torque of the Preload Double-Nut Ball Screw Based on Thermal Elastohydrodynamic Lubrication. Int. J. Adv. Manuf. Technol. 2023, 124, 4231–4251. [Google Scholar] [CrossRef]

- Zhang, Y.; Cui, P.; Yang, J.; Wang, Z.; Pu, W. Dynamic Grease Lubrication and Friction Behavior of Ball Screw Mechanism in High-Frequency Reciprocating Motion. Tribol. Int. 2023, 178, 108068. [Google Scholar] [CrossRef]

- Xie, Y.; Liu, C.; Huang, L.; Duan, H. Ball Screw Fault Diagnosis Based on Wavelet Convolution Transfer Learning. Sensors 2022, 22, 6270. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, C.; Nie, C.; Feng, H. Remaining Useful Life Prediction of Ball Screw Based on Integrating Preload and Precision. Meas. Sci. Technol. 2024, 35, 025016. [Google Scholar] [CrossRef]

- Chen, P.; Ma, Z.; Xu, C.; Zhang, M.; Li, H.; Zheng, K.; Jin, Y. Scale-Aware Domain Adaptation for Surface Defects Detection on Machine Tool Components in Contaminant Measurements. IEEE Trans. Instrum. Meas. 2025, 74, 3502109. [Google Scholar] [CrossRef]

- Yang, J.; Li, C.; Xu, M.; Zhang, Y. Analysis of Thermal Error Model of Ball Screw Feed System Based on Experimental Data 2021. Int. J. Adv. Manuf. Technol. 2022, 119, 7415–7427. [Google Scholar] [CrossRef]

- Chen, W.-M.; Cai, Y.-H.; Yu, Y.; Geng, X.; Ma, X. Optimal Mesh Criteria in Finite Element Modeling of Human Foot: The Dependence of Multiple Model Outputs on Mesh Density and Loading Boundary Conditions. J. Mech. Med. Biol. 2021, 21, 2140034. [Google Scholar] [CrossRef]

- ISO/CD 3408-5; Ball Screws—Part 5: Static and Dynamic Axial Load Ratings and Operational Life. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- Stoica, A.; Stan, G. Influence of the Ball Screw Stiffness on the Positioning Accuracy of the CNC Machine Tools. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1182, 012076. [Google Scholar] [CrossRef]

| Properties | AISI4150 | SCM445H |

|---|---|---|

| Density (kg/m3) | 7850 | 7700 |

| Poisson’s ratio | 0.27–0.3 | 0.27–0.3 |

| Tensile strength (MPa) | 731 | 650–880 |

| Thermal conductivity (W/m·K) | 44.5 | 36 |

| Yield strength (MPa) | 380 | 350–550 |

| Specific heat capacity (J/g-°C) | 0.47 | 0.46 |

| Coefficient of thermal expansion (K−1) | 1.3 × 10⁻⁵ | 10 × 10⁻⁶ |

| Young’s modulus (GPa) | 190 | 200 |

| Specification | TIC Ball Screw | NSK Ball Screw |

|---|---|---|

| Z-axis model | YEF4010-R700-C3-1091 | W4007P-105PSS-C3Z10 |

| Ball diameter (mm) | 6.35 | 6.35 |

| Preload method | Oversize Preload | Oversize Preload |

| Number of turns | 3.75 Turns × 2 | 5.75 Turns |

| Lead (mm) | 10 | 10 |

| Accuracy grade | C3 | C3 |

| Preload amount (kgf) | 3.0 | 5.0 |

| Basic dynamic load rating (kgf) | 4590 | 3741 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, O.; Jung, D.W.; Jeong, J.H. Comparative Analysis of the Reliability and Durability of TIC and NSK Ball Screws for Enhanced Process Optimization. Processes 2025, 13, 1514. https://doi.org/10.3390/pr13051514

Ali O, Jung DW, Jeong JH. Comparative Analysis of the Reliability and Durability of TIC and NSK Ball Screws for Enhanced Process Optimization. Processes. 2025; 13(5):1514. https://doi.org/10.3390/pr13051514

Chicago/Turabian StyleAli, Osama, Dong Won Jung, and Ji Hyun Jeong. 2025. "Comparative Analysis of the Reliability and Durability of TIC and NSK Ball Screws for Enhanced Process Optimization" Processes 13, no. 5: 1514. https://doi.org/10.3390/pr13051514

APA StyleAli, O., Jung, D. W., & Jeong, J. H. (2025). Comparative Analysis of the Reliability and Durability of TIC and NSK Ball Screws for Enhanced Process Optimization. Processes, 13(5), 1514. https://doi.org/10.3390/pr13051514