An Overview of the Technological Evolution of Organic Waste Management over the Last Decade

Abstract

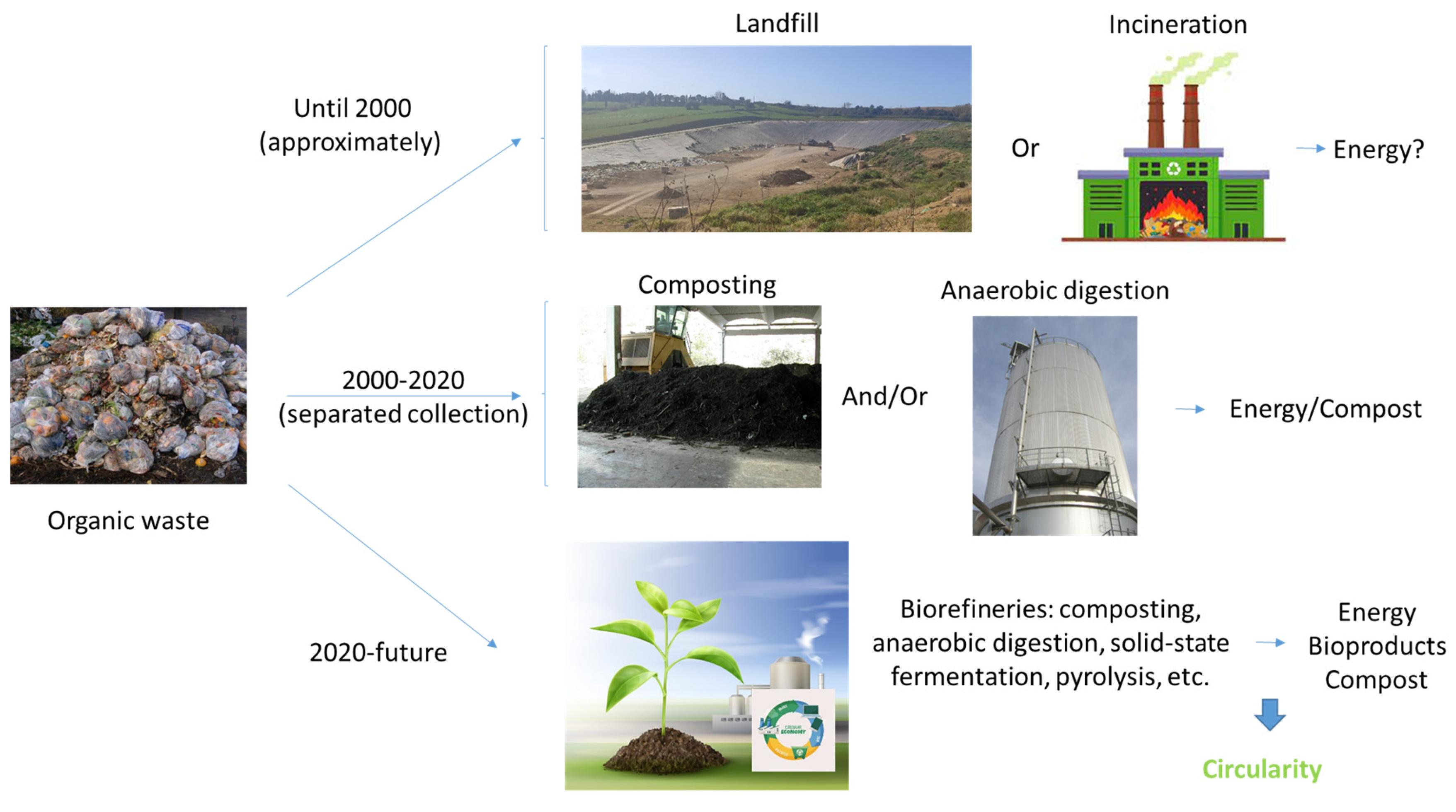

1. Introduction

- (1)

- Anaerobic digestion (AD) has received increased attention because of our complex global geopolitical situation, which has exponentially increased the use of additives to improve the performance of the process in terms of biomethane yield and production. Nanomaterials, in their different forms, and biochar are the most studied cases [6,7].

- (2)

- The growing need for nature-based, biodegradable, and non-impacting biomaterials to substitute their chemically synthetized twins has promoted the use of solid-state fermentation (SSF) far beyond its biological definition as the biological solid-state aerobic transformation of organic biodegradable waste into bioproducts that permits the substitution of raw sources of materials and energy [8]. In this general view, it is important to keep in mind that SSF has its roots in another biotechnology, composting, which is also becoming popular again because of the increasing need for environmentally friendly organic biofertilizers [9].

- (3)

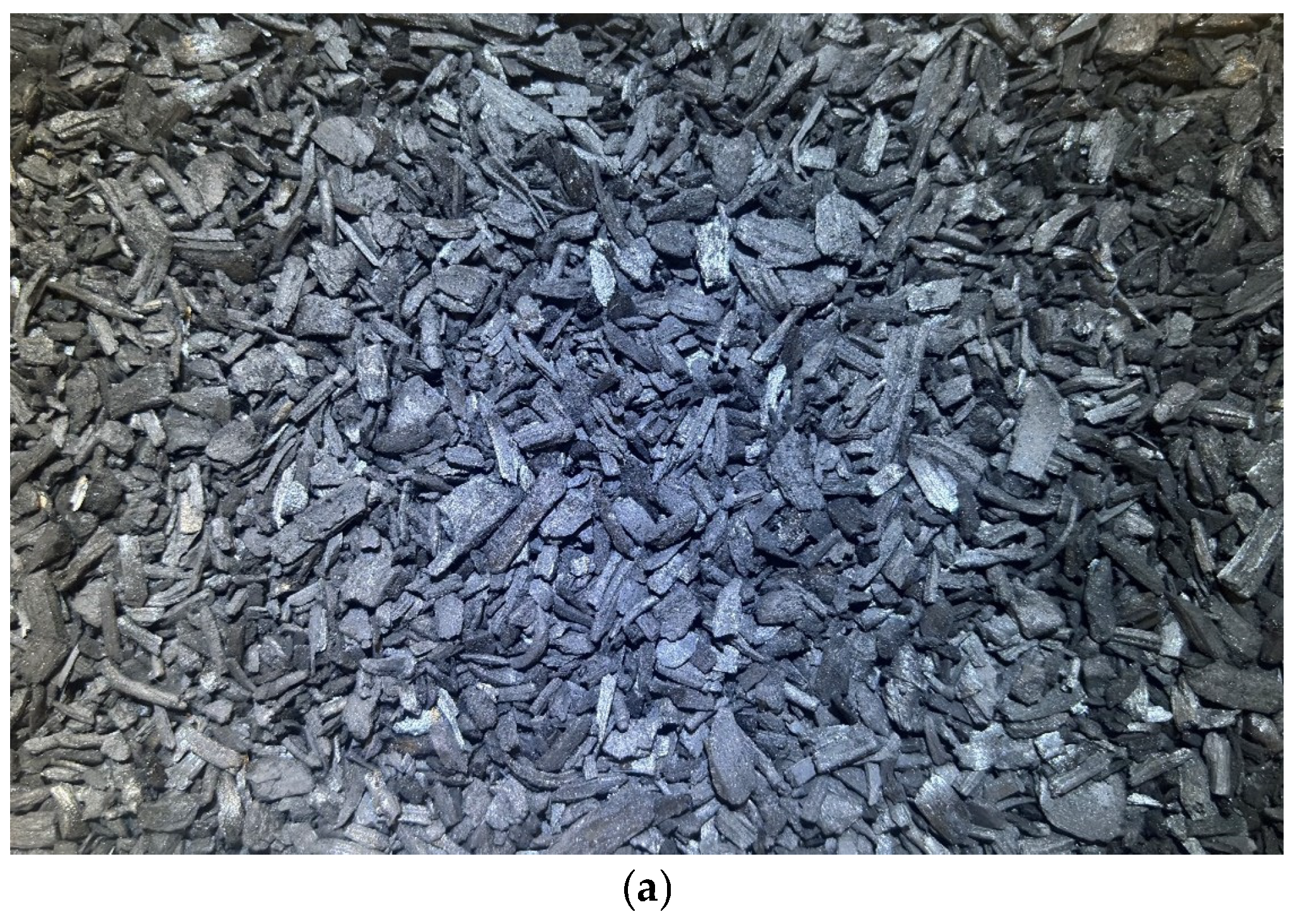

- Thermal treatment technologies are also receiving growing attention. In previous decades, they were practically restricted to incineration on a commercial scale, which has now been demoted in favor of other technologies. This is the particular case of pyrolysis, which is energy-neutral and produces biochar, which is gaining a predominant role in a wide number of applications [10] (The European Biochar Industry Consortium, 2024): fertilization, water and wastewater treatment, waste treatment, heterogeneous catalysis, and construction materials, among others.

2. Organic Waste as a Source of Bioproducts and Bioenergy

3. Towards a Second Transition in Organic Waste Management: Technologies, Bioproducts, and Renewable Energy

3.1. The Rise of Anaerobic Digestion

3.1.1. Biogas and Biomethane

3.1.2. Advanced Additives: Nanomaterials and Biochar

3.1.3. Digestate: Problem or Opportunity?

3.2. The Emerging Role of Solid-State Fermentation

3.2.1. SSF Unlocks the Potential of Organic Solid Waste, Including Digestate

3.2.2. Solid Fermentation for Solid Applications

3.3. Pyrolysis as Predominant Thermal Treatment for Biochar Production

3.3.1. Pyrolysis as a Source of Biochar

3.3.2. Understanding Biochar

3.3.3. The Potential Role of Biochar in Modern Waste Management

Anaerobic Digestion

Composting

4. General Perspective

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Venugopal, V. Green Processing of Seafood Waste Biomass towards Blue Economy. Curr. Res. Environ. Sustain. 2022, 4, 100164. [Google Scholar] [CrossRef]

- Sustainable Development. THE 17 GOALS. Available online: https://sdgs.un.org/goals (accessed on 20 October 2024).

- Stephen, J.L.; Periyasamy, B. Innovative Developments in Biofuels Production from Organic Waste Materials: A Review. Fuel 2018, 214, 623–633. [Google Scholar] [CrossRef]

- Alibardi, L.; Astrup, T.F.; Asunis, F.; Clarke, W.P.; De Gioannis, G.; Dessì, P.; Lens, P.N.L.; Lavagnolo, M.C.; Lombardi, L.; Muntoni, A.; et al. Organic Waste Biorefineries: Looking towards Implementation. Waste Manag. 2020, 114, 274–286. [Google Scholar] [CrossRef]

- Tian, H.; Li, J.; Yan, M.; Tong, Y.W.; Wang, C.H.; Wang, X. Organic Waste to Biohydrogen: A Critical Review from Technological Development and Environmental Impact Analysis Perspective. Appl. Energy 2019, 256, 113961. [Google Scholar] [CrossRef]

- Barrena, R.; Moral-Vico, J.; Font, X.; Sánchez, A. Enhancement of Anaerobic Digestion with Nanomaterials: A Mini Review. Energies 2022, 15, 5087. [Google Scholar] [CrossRef]

- Manga, M.; Aragón-Briceño, C.; Boutikos, P.; Semiyaga, S.; Olabinjo, O.; Muoghalu, C.C. Biochar and Its Potential Application for the Improvement of the Anaerobic Digestion Process: A Critical Review. Energies 2023, 16, 4051. [Google Scholar] [CrossRef]

- Sánchez, A. A Perspective of Solid-State Fermentation as Emergent Technology for Organic Waste Management in the Framework of Circular Bioeconomy. ACS Sustain. Resour. Manag. 2024, 1, 1630–1638. [Google Scholar] [CrossRef]

- US Composting Council. Benefits of Compost. Available online: https://www.compostingcouncil.org/page/CompostBenefits (accessed on 20 October 2024).

- The European Biochar Industry Consortium. Beyond Carbon Sequestration: The Wide-Ranging Applications of Biochar. Available online: https://www.biochar-industry.com/2023/2023-biochar-use-cases/ (accessed on 20 October 2024).

- Artola, A.; Font, X.; Moral-Vico, J.; Sánchez, A. The Role of Solid-State Fermentation to Transform Existing Waste Treatment Plants Based on Composting and Anaerobic Digestion into Modern Organic Waste-Based Biorefineries, in the Framework of Circular Bioeconomy. Front. Chem. Eng. 2024, 6, 1463785. [Google Scholar] [CrossRef]

- Campuzano, R.; González-Martínez, S. Characteristics of the Organic Fraction of Municipal Solid Waste and Methane Production: A Review. Waste Manag. 2016, 54, 3–12. [Google Scholar] [CrossRef]

- Molina-Peñate, E.; Artola, A.; Sánchez, A. Organic Municipal Waste as Feedstock for Biorefineries: Bioconversion Technologies Integration and Challenges. Rev. Environ. Sci. Bio/Technol. 2022, 21, 247–267. [Google Scholar] [CrossRef]

- Wojnowska-Baryła, I.; Bernat, K.; Zaborowska, M. Strategies of Recovery and Organic Recycling Used in Textile Waste Management. Int. J. Environ. Res. Public Heath 2022, 19, 5859. [Google Scholar] [CrossRef]

- Klüpfel, C.; Yuan, B.; Biller, P.; Herklotz, B. Hydrothermal Liquefaction as a Treatment Technology for Anaerobic Digestate: A Review. Renew. Sustain. Energy Rev. 2025, 210, 115156. [Google Scholar] [CrossRef]

- Losantos, D.; Sarra, M.; Caminal, G. OPFR Removal by White Rot Fungi: Screening of Removers and Approach to the Removal Mechanism. Front. Fungal Biol. 2024, 5, 1387541. [Google Scholar] [CrossRef]

- Romio, C.; Ward, A.J.; Møller, H.B. Characterization and Valorization of Biogas Digestate and Derived Organic Fertilizer Products from Separation Processes. Front. Sustain. Food Syst. 2024, 8, 1415508. [Google Scholar] [CrossRef]

- Khasraw, D.; Martin, C.; Herbert, J.; Li, Z. A Comprehensive Literature Review of Biomass Characterisation and Application for Iron and Steelmaking Processes. Fuel 2024, 368, 131459. [Google Scholar] [CrossRef]

- Cho, E.J.; Trinh, L.T.P.; Song, Y.; Lee, Y.G.; Bae, H.J. Bioconversion of Biomass Waste into High Value Chemicals. Bioresour. Technol. 2020, 298, 122386. [Google Scholar] [CrossRef]

- Li, H.; Feng, K. Life Cycle Assessment of the Environmental Impacts and Energy Efficiency of an Integration of Sludge Anaerobic Digestion and Pyrolysis. J. Clean. Prod. 2018, 195, 476–485. [Google Scholar] [CrossRef]

- Oiza, N.; Moral-Vico, J.; Sánchez, A.; Oviedo, E.R.; Gea, T. Solid-State Fermentation from Organic Wastes: A New Generation of Bioproducts. Processes 2022, 10, 2675. [Google Scholar] [CrossRef]

- Liu, J.; Huang, S.; Chen, K.; Wang, T.; Mei, M.; Li, J. Preparation of Biochar from Food Waste Digestate: Pyrolysis Behavior and Product Properties. Bioresour. Technol. 2020, 302, 122841. [Google Scholar] [CrossRef]

- US EPA. How Does Anaerobic Digestion Work? Available online: https://www.epa.gov/agstar/how-does-anaerobic-digestion-work (accessed on 3 November 2024).

- Subbarao, P.M.V.; D’ Silva, T.C.; Adlak, K.; Kumar, S.; Chandra, R.; Vijay, V.K. Anaerobic Digestion as a Sustainable Technology for Efficiently Utilizing Biomass in the Context of Carbon Neutrality and Circular Economy. Environ. Res. 2023, 234, 116286. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, G.; Xue, L.; Zuo, J.; Chen, T.; Vuppaladadiyam, A.; Duan, H. Anaerobic Digestion Based Waste-to-Energy Technologies Can Halve the Climate Impact of China’s Fast-Growing Food Waste by 2040. J. Clean. Prod. 2020, 277, 123490. [Google Scholar] [CrossRef]

- Gadirli, G.; Pilarska, A.A.; Dach, J.; Pilarski, K.; Kolasa-Więcek, A.; Borowiak, K. Fundamentals, Operation and Global Prospects for the Development of Biogas Plants—A Review. Energies 2024, 17, 568. [Google Scholar] [CrossRef]

- Ciuła, J.; Generowicz, A.; Gronba-Chyła, A.; Wiewiórska, I.; Kwaśnicki, P.; Cygnar, M. Analysis of the Efficiency of Landfill Gas Treatment for Power Generation in a Cogeneration System in Terms of the European Green Deal. Sustainability 2024, 16, 1479. [Google Scholar] [CrossRef]

- Finecomess, S.A.; Gebresenbet, G. Future Green Energy: A Global Analysis. Energies 2024, 17, 3039. [Google Scholar] [CrossRef]

- Gaska, K.; Generowicz, A.; Gronba-Chyła, A.; Ciuła, J.; Wiewiórska, I.; Kwaśnicki, P.; Mala, M.; Chyła, K. Artificial Intelligence Methods for Analysis and Optimization of CHP Cogeneration Units Based on Landfill Biogas as a Progress in Improving Energy Efficiency and Limiting Climate Change. Energies 2023, 16, 5732. [Google Scholar] [CrossRef]

- Gkotsis, P.; Kougias, P.; Mitrakas, M.; Zouboulis, A. Biogas Upgrading Technologies—Recent Advances in Membrane-Based Processes. Int. J. Hydrogen Energy 2023, 48, 3965–3993. [Google Scholar] [CrossRef]

- Angelidaki, I.; Karakashev, D.; Batstone, D.J.; Plugge, C.M.; Stams, A.J.M. Biomethanation and Its Potential. Methods Enzymol. 2011, 494, 327–351. [Google Scholar] [CrossRef]

- Cavana, M.; Leone, P. Biogas Blending into the Gas Grid of a Small Municipality for the Decarbonization of the Heating Sector. Biomass Bioenergy 2019, 127, 105295. [Google Scholar] [CrossRef]

- Ziganshina, E.E.; Bulynina, S.S.; Ziganshin, A.M. Anaerobic Digestion of Chicken Manure Assisted by Carbon Nanotubes: Promotion of Volatile Fatty Acids Consumption and Methane Production. Fermentation 2022, 8, 641. [Google Scholar] [CrossRef]

- Casals, E.; Barrena, R.; Gonzalez, E.; Font, X.; Sánchez, A.; Puntes, V. Historical Perspective of the Addition of Magnetic Nanoparticles into Anaerobic Digesters (2014–2021). Front. Chem. Eng. 2021, 3, 745610. [Google Scholar] [CrossRef]

- Hijazi, O.; Abdelsalam, E.; Samer, M.; Attia, Y.A.; Amer, B.M.A.; Amer, M.A.; Badr, M.; Bernhardt, H. Life Cycle Assessment of the Use of Nanomaterials in Biogas Production from Anaerobic Digestion of Manure. Renew. Energy 2020, 148, 417–424. [Google Scholar] [CrossRef]

- Kan, T.; Strezov, V.; Evans, T.J. Lignocellulosic Biomass Pyrolysis: A Review of Product Properties and Effects of Pyrolysis Parameters. Renew. Sustain. Energy Rev. 2016, 57, 1126–1140. [Google Scholar] [CrossRef]

- Prochnow, F.D.; Cavali, M.; Dresch, A.P.; Belli, I.M.; Libardi, N.; de Castilhos, A.B. Biochar: From Laboratory to Industry Scale—An Overview of Scientific and Industrial Advances, Opportunities in the Brazilian Context, and Contributions to Sustainable Development. Processes 2024, 12, 1006. [Google Scholar] [CrossRef]

- Parra-Orobio, B.A.; Soto-Paz, J.; Oviedo-Ocaña, E.R.; Vali, S.A.; Sánchez, A. Advances, Trends and Challenges in the Use of Biochar as an Improvement Strategy in the Anaerobic Digestion of Organic Waste: A Systematic Analysis. Bioengineered 2023, 14, 2252191. [Google Scholar] [CrossRef]

- Zhao, W.; Yang, H.; He, S.; Zhao, Q.; Wei, L. A Review of Biochar in Anaerobic Digestion to Improve Biogas Production: Performances, Mechanisms and Economic Assessments. Bioresour. Technol. 2021, 341, 125797. [Google Scholar] [CrossRef]

- Zhang, L.; Lim, E.Y.; Loh, K.C.; Ok, Y.S.; Lee, J.T.E.; Shen, Y.; Wang, C.H.; Dai, Y.; Tong, Y.W. Biochar Enhanced Thermophilic Anaerobic Digestion of Food Waste: Focusing on Biochar Particle Size, Microbial Community Analysis and Pilot-Scale Application. Energy Convers. Manag. 2020, 209, 112654. [Google Scholar] [CrossRef]

- Shen, R.; Yao, Z.; Yu, J.; Luo, J.; Zhao, L. Enhanced Performance and Microbial Communities of Anaerobic Digestion with Biochar in Pilot-Scale Continuous Stirred-Tank Reactors: Effects of Substrate Concentration and Hydraulic Retention Time. Sustain. Energy Fuels 2022, 6, 5324–5336. [Google Scholar] [CrossRef]

- García-Prats, M.; González, D.; Sánchez, A. Characterization of Biochars of Different Origin and Application to the Anaerobic Digestion of Source-Selected Organic Fraction of Municipal Solid Waste under Batch Conditions and at Different Dosages. Front. Chem. Eng. 2024, 6, 1384495. [Google Scholar] [CrossRef]

- Doyeni, M.O.; Stulpinaite, U.; Baksinskaite, A.; Suproniene, S.; Tilvikiene, V. The Effectiveness of Digestate Use for Fertilization in an Agricultural Cropping System. Plants 2021, 10, 1734. [Google Scholar] [CrossRef]

- Czekała, W.; Nowak, M.; Piechota, G. Sustainable Management and Recycling of Anaerobic Digestate Solid Fraction by Composting: A Review. Bioresour. Technol. 2023, 375, 128813. [Google Scholar] [CrossRef]

- Guerra-Gorostegi, N.; González, D.; Puyuelo, B.; Ovejero, J.; Colón, J.; Gabriel, D.; Sánchez, A.; Ponsá, S. Biomass Fuel Production from Cellulosic Sludge through Biodrying: Aeration Strategies, Quality of End-Products, Gaseous Emissions and Techno-Economic Assessment. Waste Manag. 2021, 126, 487–496. [Google Scholar] [CrossRef]

- Fu, S.F.; Wang, D.H.; Xie, Z.; Zou, H.; Zheng, Y. Producing Insect Protein from Food Waste Digestate via Black Soldier Fly Larvae Cultivation: A Promising Choice for Digestate Disposal. Sci. Total Environ. 2022, 830, 154654. [Google Scholar] [CrossRef]

- Cucina, M.; Castro, L.; Font-Pomarol, J.; Escalante, H.; Muñoz-Muñoz, A.; Ferrer, I.; Garfí, M. Vermifiltration as a Green Solution to Promote Digestate Reuse in Agriculture in Small-Scale Farms. J. Environ. Manag. 2024, 368, 122164. [Google Scholar] [CrossRef]

- Fornito, S.; Puliga, F.; Leonardi, P.; Di Foggia, M.; Zambonelli, A.; Francioso, O. Degradative Ability of Mushrooms Cultivated on Corn Silage Digestate. Molecules 2020, 25, 3020. [Google Scholar] [CrossRef] [PubMed]

- Zhong, Y.; Ruan, Z.; Zhong, Y.; Archer, S.; Liu, Y.; Liao, W. A Self-Sustaining Advanced Lignocellulosic Biofuel Production by Integration of Anaerobic Digestion and Aerobic Fungal Fermentation. Bioresour. Technol. 2015, 179, 173–179. [Google Scholar] [CrossRef] [PubMed]

- Monlau, F.; Sambusiti, C.; Ficara, E.; Aboulkas, A.; Barakat, A.; Carrère, H. New Opportunities for Agricultural Digestate Valorization: Current Situation and Perspectives. Energy Environ. Sci. 2015, 8, 2600–2621. [Google Scholar] [CrossRef]

- Xia, A.; Murphy, J.D. Microalgal Cultivation in Treating Liquid Digestate from Biogas Systems. Trends Biotechnol. 2016, 34, 264–275. [Google Scholar] [CrossRef]

- Rodríguez, P.; Cerda, A.; Font, X.; Sánchez, A.; Artola, A. Valorisation of Biowaste Digestate through Solid State Fermentation to Produce Biopesticides from Bacillus thuringiensis. Waste Manag. 2019, 93, 63–71. [Google Scholar] [CrossRef]

- Molina-Peñate, E.; del Carmen Vargas-García, M.; Artola, A.; Sánchez, A. Filling in the Gaps in Biowaste Biorefineries: The Use of the Solid Residue after Enzymatic Hydrolysis for the Production of Biopesticides through Solid-State Fermentation. Waste Manag. 2023, 161, 92–103. [Google Scholar] [CrossRef]

- Czekała, W. Solid Fraction of Digestate from Biogas Plant as a Material for Pellets Production. Energies 2021, 14, 5034. [Google Scholar] [CrossRef]

- Hölker, U.; Lenz, J. Solid-State Fermentation—Are There Any Biotechnological Advantages? Curr. Opin. Microbiol. 2005, 8, 301–306. [Google Scholar] [CrossRef]

- Escamilla-Alvarado, C.; Pérez-Pimienta, J.A.; Ponce-Noyola, T.; Poggi-Varaldo, H.M. An Overview of the Enzyme Potential in Bioenergy-Producing Biorefineries. J. Chem. Technol. Biotechnol. 2017, 92, 906–924. [Google Scholar] [CrossRef]

- Chablé-Villacis, R.; Olguin-Maciel, E.; Toledano-Thompson, T.; Alzate-Gaviria, L.; Ruiz, H.A.; Tapia-Tussell, R. Enzymatic Hydrolysis Assisted with Ligninocellulolytic Enzymes from Trametes hirsuta Produced by Pineapple Leaf Waste Bioconversion in Solid-State Fermentation. Biomass Convers. Biorefinery 2023, 13, 9095–9106. [Google Scholar] [CrossRef]

- Zou, L.; Qi, Z.; Cheng, H.; Yu, B.; Li, Y.Y.; Liu, J. Advanced Anaerobic Digestion of Household Food Waste Pretreated by in Situ-Produced Mixed Enzymes via Solid-State Fermentation: Feasibility and Application Perspectives. Environ. Res. 2024, 252, 119137. [Google Scholar] [CrossRef] [PubMed]

- Mejias, L.; Ruiz, D.; Molina-Peñate, E.; Barrena, R.; Gea, T. Bacillus thuringiensis Derived Biopesticides from Biowaste Digestate at 290-L Demonstration Scale through Solid-State Fermentation. Environ. Technol. Innov. 2025, 37, 103974. [Google Scholar] [CrossRef]

- Alias, C.; Bulgari, D.; Gobbi, E. It Works! Organic-Waste-Assisted Trichoderma spp. Solid-State Fermentation on Agricultural Digestate. Microorganisms 2022, 10, 164. [Google Scholar] [CrossRef] [PubMed]

- Knesebeck, M.; Schäfer, D.; Schmitz, K.; Rüllke, M.; Benz, J.P.; Weuster-Botz, D. Enzymatic One-Pot Hydrolysis of Extracted Sugar Beet Press Pulp after Solid-State Fermentation with an Engineered Aspergillus niger Strain. Fermentation 2023, 9, 582. [Google Scholar] [CrossRef]

- de Moura Dickel, J.D.; Carvalho, J.K.; Silveira, M.A.D.; Menegotto dos Santos, P.; Rodrigues, M.L.F.; Fagundes-Klen, M.R.; Rosa, C.A.; Johann, S.; Buzanello, C.V.; da Silva de Lucca, R.A.; et al. Aspergillus sclerotiorum Lipolytic Activity and Its Application in Bioremediation of High-Fat Dairy Wastewater Environments. Environ. Sci. Pollut. Res. 2023, 30, 35517–35527. [Google Scholar] [CrossRef]

- Solano Porras, R.C.; Ghoreishi, G.; Sánchez, A.; Barrena, R.; Font, X.; Ballardo, C.; Artola, A. Solid-State Fermentation of Green Waste for the Production of Biostimulants to Enhance Lettuce (Lactuca sativa L.) Cultivation under Water Stress: Closing the Organic Waste Cycle. Chemosphere 2025, 370, 143919. [Google Scholar] [CrossRef]

- Sala, A.; Artola, A.; Barrena, R.; Sánchez, A. Harnessing Packed-Bed Bioreactors’ Potential in Solid-State Fermentation: The Case of Beauveria bassiana Conidia Production. Fermentation 2024, 10, 481. [Google Scholar] [CrossRef]

- Yu, S.; Dong, H. Uncover Cost-Benefit Disparity of Municipal Solid Waste Incineration in Chinese Provinces. Sustainability 2020, 12, 697. [Google Scholar] [CrossRef]

- AlMokmesh, S.F.; AlKhulaifi, K.A.; AlMutairi, A.S.; Al-Ajmi, A.S. Incineration Innovation: A Path to Efficient and Sustainable Municipal Solid Waste Management in Kuwait. Processes 2024, 12, 1873. [Google Scholar] [CrossRef]

- Prajapati, P.; Varjani, S.; Singhania, R.R.; Patel, A.K.; Awasthi, M.K.; Sindhu, R.; Zhang, Z.; Binod, P.; Awasthi, S.K.; Chaturvedi, P. Critical Review on Technological Advancements for Effective Waste Management of Municipal Solid Waste—Updates and Way Forward. Environ. Technol. Innov. 2021, 23, 101749. [Google Scholar] [CrossRef]

- Pecchi, M.; Baratieri, M. Coupling Anaerobic Digestion with Gasification, Pyrolysis or Hydrothermal Carbonization: A Review. Renew. Sustain. Energy Rev. 2019, 105, 462–475. [Google Scholar] [CrossRef]

- Altıkat, A.; Alma, M.H.; Altıkat, A.; Bilgili, M.E.; Altıkat, S. A Comprehensive Study of Biochar Yield and Quality Concerning Pyrolysis Conditions: A Multifaceted Approach. Sustainability 2024, 16, 937. [Google Scholar] [CrossRef]

- Salma, A.; Fryda, L.; Djelal, H. Biochar: A Key Player in Carbon Credits and Climate Mitigation. Resources 2024, 13, 31. [Google Scholar] [CrossRef]

- Deng, X.; Teng, F.; Chen, M.; Du, Z.; Wang, B.; Li, R.; Wang, P. Exploring Negative Emission Potential of Biochar to Achieve Carbon Neutrality Goal in China. Nat. Commun. 2024, 15, 1085. [Google Scholar] [CrossRef] [PubMed]

- International Biochar Initiative (IBI). Why Biochar. Available online: https://biochar-international.org/why-biochar/ (accessed on 20 October 2024).

- Elnour, A.Y.; Alghyamah, A.A.; Shaikh, H.M.; Poulose, A.M.; Al-Zahrani, S.M.; Anis, A.; Al-Wabel, M.I. Effect of Pyrolysis Temperature on Biochar Microstructural Evolution, Physicochemical Characteristics, and Its Influence on Biochar/Polypropylene Composites. Appl. Sci. 2019, 9, 1149. [Google Scholar] [CrossRef]

- García-Prats, M.; Olivera-Begué, E.; González, D.; Sánchez, A. Biochar: An Emerging Material for the Improvement of Biological Treatment of Organic Waste. Waste Manag. Bull. 2024, 2, 120–126. [Google Scholar] [CrossRef]

- Chiappero, M.; Norouzi, O.; Hu, M.; Demichelis, F.; Berruti, F.; Di Maria, F.; Mašek, O.; Fiore, S. Review of Biochar Role as Additive in Anaerobic Digestion Processes. Renew. Sustain. Energy Rev. 2020, 131, 110037. [Google Scholar] [CrossRef]

- Nie, W.; He, S.; Lin, Y.; Cheng, J.J.; Yang, C. Functional Biochar in Enhanced Anaerobic Digestion: Synthesis, Performances, and Mechanisms. Sci. Total Environ. 2024, 906, 167681. [Google Scholar] [CrossRef] [PubMed]

- Kumar, M.; Dutta, S.; You, S.; Luo, G.; Zhang, S.; Show, P.L.; Sawarkar, A.D.; Singh, L.; Tsang, D.C.W. A Critical Review on Biochar for Enhancing Biogas Production from Anaerobic Digestion of Food Waste and Sludge. J. Clean. Prod. 2021, 305, 127143. [Google Scholar] [CrossRef]

- Masebinu, S.O.; Akinlabi, E.T.; Muzenda, E.; Aboyade, A.O. A Review of Biochar Properties and Their Roles in Mitigating Challenges with Anaerobic Digestion. Renew. Sustain. Energy Rev. 2019, 103, 291–307. [Google Scholar] [CrossRef]

- Wang, Y.; Akdeniz, N. Mathematical Modeling of Biochar’s Role in Elevating Co-Composted Poultry Carcass Temperatures. Waste Manag. 2024, 173, 40–50. [Google Scholar] [CrossRef]

- Firmino, M.V.; Trémier, A. Investigation of Biochar Ratio, Pyrolysis Temperature and Digestate Type Impact Over Nitrogen Losses Along Digestate Composting. Waste Biomass Valori. 2024, 15, 4807–4821. [Google Scholar] [CrossRef]

- Hestrin, R.; Enders, A.; Lehmann, J. Ammonia Volatilization from Composting with Oxidized Biochar. J. Environ. Qual. 2020, 49, 1690–1702. [Google Scholar] [CrossRef]

- Pagans, E.; Barrena, R.; Font, X.; Sánchez, A. Ammonia Emissions from the Composting of Different Organic Wastes. Dependency on Process Temperature. Chemosphere 2006, 62, 1534–1542. [Google Scholar] [CrossRef]

- Barrena, R.; Canovas, C.; Sánchez, A. Prediction of Temperature and Thermal Inertia Effect in the Maturation Stage and Stockpiling of a Large Composting Mass. Waste Manag. 2006, 26, 953–959. [Google Scholar] [CrossRef]

- Nguyen, M.K.; Lin, C.; Hoang, H.G.; Sanderson, P.; Dang, B.T.; Bui, X.T.; Nguyen, N.S.H.; Vo, D.V.N.; Tran, H.T. Evaluate the Role of Biochar during the Organic Waste Composting Process: A Critical Review. Chemosphere 2022, 299, 134488. [Google Scholar] [CrossRef]

- González, D.; Colón, J.; Sánchez, A.; Gabriel, D. A Systematic Study on the VOCs Characterization and Odour Emissions in a Full-Scale Sewage Sludge Composting Plant. J. Hazar. Mat. 2019, 373, 733–740. [Google Scholar] [CrossRef]

- Sánchez-Monedero, M.A.; Sánchez-García, M.; Alburquerque, J.A.; Cayuela, M.L. Biochar Reduces Volatile Organic Compounds Generated during Chicken Manure Composting. Bioresour. Technol. 2019, 288, 121584. [Google Scholar] [CrossRef]

- Abdallah, M.; Abu Talib, M.; Feroz, S.; Nasir, Q.; Abdalla, H.; Mahfood, B. Artificial Intelligence Applications in Solid Waste Management: A Systematic Research Review. Waste Manag. 2020, 109, 231–246. [Google Scholar] [CrossRef] [PubMed]

- Olawade, D.B.; Fapohunda, O.; Wada, O.Z.; Usman, S.O.; Ige, A.O.; Ajisafe, O.; Oladapo, B.I. Smart Waste Management: A Paradigm Shift Enabled by Artificial Intelligence. Waste Manag. Bull. 2024, 2, 244–263. [Google Scholar] [CrossRef]

- Pinhal Luqueci Thomaz, I.; Fernando Mahler, C.; Pereira Calôba, L. Artificial Intelligence (AI) Applied to Waste Management: A Contingency Measure to Fill out the Lack of Information Resulting from Restrictions on Field Sampling. Waste Manag. Bull. 2023, 1, 11–17. [Google Scholar] [CrossRef]

| Parameter | OFMSW | Solid Digestate | Agricultural Waste | Wood Waste |

|---|---|---|---|---|

| Humidity (%) | 72.8 ± 7.6 | 71.3 ± 4.5 a | - | - |

| TS (%) | 27.2 ± 7.6 | 28.7 ± 4.5 a | - | - |

| VS (% TS) | 84.6 ± 9.9 | 87.4 ± 4.9 a | 74.7 ± 1.2 c | 79.8 ± 3.6 c |

| KN (g/kg) | 7.9 ± 5.4 | 6.4 ± 1.4 a | - | - |

| TP (g/kg) | 1.7 ± 2.5 | 2.5 ± 2.1 a | - | - |

| C (% TS) | 46.6 ± 4.4 | 34.9 ± 8.6 b | 37.1 ± 1.2 c | 41.9 ± 2.3 c |

| H (% TS) | 6.6 ± 0.6 | 5.0 ± 1.8 b | 4.5 ± 0.2 c | 4.9 ± 0.4 c |

| N (% TS) | 2.9 ± 0.6 | 3.3 ± 2.0 b | 0.7 ± 0.2 c | 0.4 ± 0.1 c |

| S (% TS) | 0.3 ± 0.2 | 0.9 ± 1.3 b | 0.1 ± 0.0 c | 0.1 ± 0.0 c |

| Fats (%VS) | 17.5 ± 6.6 | 3.8 ± 2.2 a | - | - |

| Protein (%VS) | 17.7 ± 5.5 | 11.9 ± 3.0 a | - | - |

| Raw fiber (%VS) | 29.2 ± 15.0 | 30.4 ± 5.9 a | - | - |

| Lignin (%VS) | 9.7 ± 5.3 | 24.1 ± 4.2 a | 17.6 ± 5.2 d | 22.3 ± 7.6 d |

| Carbohydrates (%VS) | 55.5 ± 10.1 | 57.7 ± 7.9 a | 64.8 ± 7.9 d | 71.5 ± 8.5 d |

| Data range | 43 samples from 22 countries | 20 AD processes with different substrates | 8 different types of crops | 8 different types of wood |

| References | [12] | a [17]; b [15] | c [18]; d [19] | |

| Parameter | Composting | Anaerobic Digestion | Pyrolysis | Solid-State Fermentation (SSF) |

|---|---|---|---|---|

| Energy balance | − − − | + + + | + | − − |

| Cost | + | + + | + + + | + + |

| Revenue | −/+ | + | + + | + + + |

| Scalability (TRL) | 9 | 9 | 9 | 5–7 |

| Environmental impact | + + | + + + | + | + + + |

| Carbon sequestration | + | / | + + + | / |

| Technology | Objective | Challenges | References |

|---|---|---|---|

| Cultivation of insects | Protein production | Scale-up and economic analysis Some pilot plants are in operation | [46] |

| Vermicomposting | Vermicompost as high-quality fertilizer | Sensibility of earthworms to inhibitory substances and waste self-heating | [47] |

| Mushroom cultivation | Mushroom production | Highly controlled process: moisture, temperature, and absence of light | [48] |

| Fungal (submerged) fermentation | Biofuel (biodiesel or bioethanol) production | Liquid medium, not natural for fungi Pretreatment of digestate Sterile conditions | [49,50] |

| Microalgal cultivation | Production of high-value biomass | High cost Scale-up is surface-intensive Sensitive to contamination or environmental variations | [51] |

| SSF | A wide variety of bioproducts: biostimulants, biopesticides, etc. | Scale-up Purification and downstream | [52,53] |

| Pyrolysis | Production of biochar | High moisture content reduces the efficiency of the process | [22] |

| Pelletizing | Biofuel production | Limited experience Loss of nutrients | [54] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Molina-Peñate, E.; Sánchez, A. An Overview of the Technological Evolution of Organic Waste Management over the Last Decade. Processes 2025, 13, 940. https://doi.org/10.3390/pr13040940

Molina-Peñate E, Sánchez A. An Overview of the Technological Evolution of Organic Waste Management over the Last Decade. Processes. 2025; 13(4):940. https://doi.org/10.3390/pr13040940

Chicago/Turabian StyleMolina-Peñate, Esther, and Antoni Sánchez. 2025. "An Overview of the Technological Evolution of Organic Waste Management over the Last Decade" Processes 13, no. 4: 940. https://doi.org/10.3390/pr13040940

APA StyleMolina-Peñate, E., & Sánchez, A. (2025). An Overview of the Technological Evolution of Organic Waste Management over the Last Decade. Processes, 13(4), 940. https://doi.org/10.3390/pr13040940