Abstract

Aiming at the mechanical failures of vertical centrifugal pumps generated under the combined effects of centrifugal force and fluid power, which are difficult to be accurately recognized by traditional diagnostic methods, a vertical centrifugal pump fault diagnosis method based on the combination of convolutional neural network (CNN) and bidirectional long and short-term memory neural network (BiLSTM) is proposed. Firstly, a recurrent neural network is introduced on the basis of a convolutional neural network, and a feature extraction and fault classification module is established, which can automatically extract spatial and temporal features from the original input signals and identify the key fault modes. Subsequently, a vertical centrifugal pump fault simulation test rig is built, and the vibration signals of the centrifugal pumps under different faults are collected and used to train the proposed diagnostic model. Finally, the diagnostic models constructed by CNN and BiLSTM are compared with a single CNN diagnostic model for fault identification of vibration signals under different fault conditions. The results of the study show that the accuracy of fault diagnosis reaches 100% by using the technique of multi-channel information fusion, which verifies the advantages of multi-channel data fusion. Moreover, the addition of BiLSTM on the basis of CNN is able to better extract and capture useful information from the time series data. In summary, the method proposed in this study can effectively improve the fault diagnosis accuracy and reliability of vertical centrifugal pumps, providing a feasible technical solution for equipment health monitoring in engineering practice.

1. Introduction

Pumps are widely used as energy conversion devices in industrial production processes, consuming more than 20% of electrical energy. Among them, centrifugal pumps account for more than 70% of the pump equipment and are widely used in many critical fields such as nuclear power, aviation, chemical industry, etc., which are crucial for production safety and efficiency. However, due to the harsh working environment and material characteristics, centrifugal pumps often malfunction, affecting their long-term stable operation and thus threatening production safety and efficiency [1,2,3,4,5,6]. Fault diagnosis technology can identify faults and provide early warning to avoid serious accidents by extracting features and classifying equipment vibration signals [7].

In recent years, data-driven fault diagnosis methods, based on data, have gradually become a research hotspot in the field of fault diagnosis [8]. Data-driven methods can be divided into traditional signal processing methods and deep learning-based methods. Traditional signal processing methods mainly extract time-domain, frequency-domain, and time–frequency-domain features from signals [9,10]. For example, fast Fourier transform can capture the changes in the spectrum from fault signals [11], and Hilbert–Huang transform and wavelet packet transform can extract time–frequency-domain features from vibration signals reflecting the time and frequency characteristics of the signals [12,13]. However, not all of the extracted features used will be useful for diagnosis, and these methods rely heavily on the experience of experts and increase the computational burden when a large number of fault samples are involved and when noise interference is present.

With the rapid development of artificial intelligence and the significant increase in the computing power of devices, deep learning-based methods can process massive data, and more and more deep learning methods are used in rotating machinery fault diagnosis. For example, Zhang et al. used one layer of large convolutional kernel and multiple layers of small convolutional kernel to extract the features of different frequency bands in the signal from the faulty bearing data, and the fault recognition rate reached 100% [14]. Zhuang et al. proposed a new Deep Morphological Convolutional Network (DMCNet) based on a convolutional neural network (CNN) to extract the features of diagnostic signals from gearboxes and achieve the diagnosis of faults through the method of kurtosis feature fusion [15]. Tian et al. realized the real-time detection of rolling bearing damage by deep convolutional neural network [16].

Although the CNN is able to extract useful features from the input, the characteristics of its own structure make it acquire features only at the spatial level. The vibration signals generated during the operation of centrifugal pumps are time series data, which also contain time-level features. Zhang et al. effectively extracted representative temporal features from the time series data by stacking the long short-term memory (LSTM) neural network, and verified the excellent performance of the proposed method through the public dataset [17]. Pan et al. achieved the recognition of bearing faults by automatically extracting the spatial features from the original signals of the faults through the CNN, and then inputting the features into LSTM to further extract the temporal features, and realized the recognition of bearing faults by using CNN [18]. Chen et al. realized the intelligent fault diagnosis of bearings by setting up two CNN with different sizes and numbers of layers to automatically learn the features from the input, and then used LSTM to classify the features, and the model was verified to have a better performance under the condition of strong noise interference [19].

In summary, for the problem of difficult traditional feature extraction in centrifugal pump fault diagnosis, this paper proposes a fault diagnosis method based on the combination of CNN and bidirectional long and short-term memory neural network (BiLSTM) on the relevant basis of previous research. The experimental results show that the method has higher accuracy and noise immunity compared with the traditional method and single model, providing an efficient solution for equipment fault diagnosis in complex industrial scenarios.

The rest of the paper is organized as follows: the Section 2 briefly introduces CNN and LSTM and the cnn-LSTM network proposed in this paper; the Section 3 describes the experimental setup and dataset partitioning of this paper; the Section 4 trains the proposed model and analyzes the experimental results; and the Section 5 summarizes and concludes the paper.

2. Basic Theory of Diagnosis

2.1. CNN

CNN is a deep feed-forward neural network with local connectivity, weight sharing, etc. A standard CNN consists of an input layer, a convolutional layer, a pooling layer, a fully connected layer, and an output layer. It can extract fault features from the original input signal using convolutional operations. The convolutional and pooling layers alternate in each hidden layer of the CNN, where the convolutional layer extracts features by performing convolutional operations on the original input signal using multiple filters (or kernels) with the same weights. The mathematical expression for the convolution operation is as follows:

where denotes the convolution operation; and are the nth layer, the ith convolution kernel weight matrix, and the bias term, respectively; is the output feature of the previous layer; is the activation function of the convolutional layer; and is the output after activation after convolution of the nth layer and the ith convolution kernel.

In order to simplify the network complexity and reduce the amount of computation, we usually add pooling after convolution to downscale the features extracted by convolution. In order to highlight the most important local information in the feature map, we generally use the method of maximum pooling, whose mathematical expression is as follows:

where is the element of the pooling kernel range for the features extracted from the nth layer, the ith convolutional kernel; is the element in the feature map extracted from the (n + 1)st layer and the ith convolution kernel after pooling; and is the jth pooling region.

2.2. BiLSTM

LSTM, as a variant of a recurrent neural network (RNN), solves the problem that RNN is prone to gradient vanishing and exploding during training, and is able to better capture and convey long-term dependencies between signals. However, LSTM has only a unidirectional propagation process and can only rely on accessing the cubic information in the forward sequence and cannot capture information from the subsequent sequences. BiLSTM, on the other hand, consists of LSTMs that are responsible for forward and reverse directions, respectively, and is capable of preserving the forward and reverse features of a sequence at a given time. As a result, BiLSTM is better able to take into account the overall information of the historical data, enhances the features extracted from the original sequence, contributes to more effective learning and training of the cubic data, and improves the accuracy of the model output.

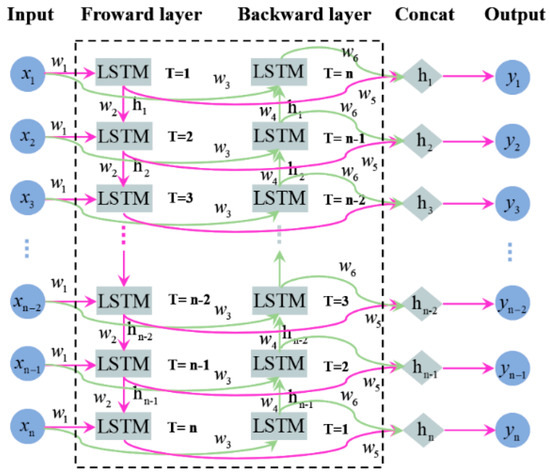

The structure of BiLSTM is shown in Figure 1, where the timing data are input into BiLSTM, forward and reverse computations are performed separately, and the output of the hidden layer is stored at each step, after which the forward and reverse hidden layer outputs are merged in order to generate the final output. The forward and reverse computation formulas are as follows:

where is the input to BiLSTM; is the weight of the nth layer; are the hidden layer outputs of BiLSTM forward and reverse, respectively; is the final output of BiLSTM; and and are the corresponding activation functions.

Figure 1.

Structure of BiLSTM network.

2.3. CNN-BiLSTM

Although the use of CNNs enables automatic feature extraction of inputs and allows end-to-end information processing, the use of a single neural network model to process time series data may not produce the desired classification results. Therefore, a CNN-BiLSTM network for feature extraction and classification of faulty vibration signals of vertical centrifugal pumps is proposed by combining the feature extraction capability of CNN and the processing capability of BiLSTM for nonlinear time series data.

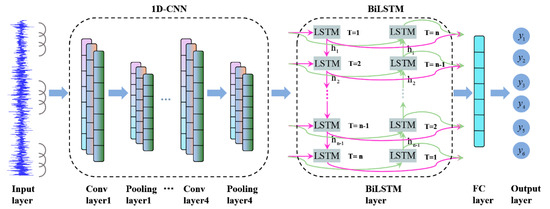

The structure of CNN-BiLSTM is shown in Figure 2, which is divided into 1D-CNN and BiLSTM modules, including one input layer, four convolutional layers, four max-pooling layers, one BiLSTM layer, one fully connected layer, as well as one output layer, and the activation function of the convolutional layer and fully connected layer is the relu function; other specific parameters are shown in Table 1. The time series data are subjected to maximum–minimum normalization before input to prevent the model from overfitting in the training process. After four layers of convolution and pooling operation, the time series data can be obtained from where the nonlinear features are hidden in the original data. After being processed by the 1D-CNN module, the extracted features are fed into the BiLSTM network for time-correlated bidirectional capture of the time series signals. After that, the features captured by BiLSTM are connected to the fully connected layer, and finally, after softmax activation function, the classification of vertical centrifugal pump fault signal features is obtained.

Figure 2.

Structure of CNN-BiLSTM network.

Table 1.

Main structural parameters of CNN-BiLSTM network.

3. Experiments and Datasets

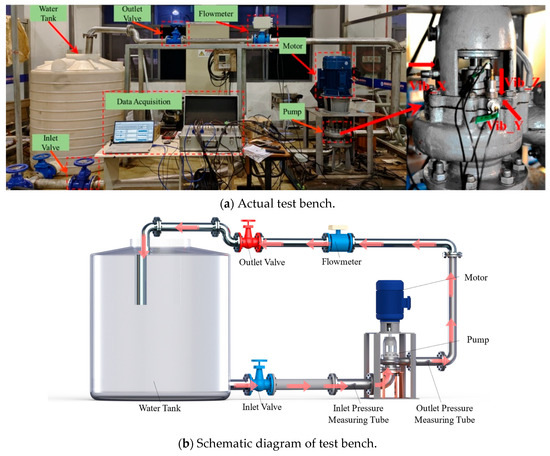

In order to assess the performance of the method proposed in this paper, setup a vertical centrifugal pump fault simulation experimental rig as shown in Figure 3, using the specific performance parameters of the pump under test as shown in Table 2 and the specific parameters of the experimental setup shown in Table 3. The data used in this paper for the vibration acceleration signal data, each with fault category determination and in different locations on the experimental bench, had three acceleration sensors installed to collect the vibration amplitude of vertical centrifugal pump operation engineering, which were then converted into voltage signals, with a sampling frequency of 10 KHz and sampling time of 10 s.

Figure 3.

Vertical centrifugal pump failure test bench.

Table 2.

Centrifugal pump performance parameters.

Table 3.

Specific parameters of experimental setup.

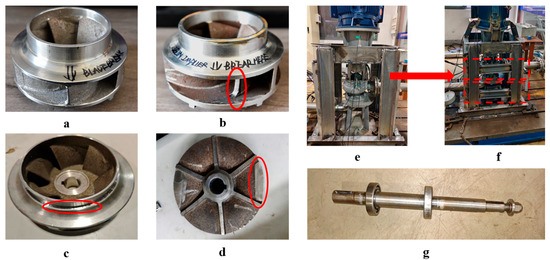

In order to simulate the failure of vertical centrifugal pumps in the process of actual engineering applications, the centrifugal pump components such as impeller and other mechanical machining act as the faulty parts, as shown in Figure 4, including experiencing impeller vane damage, impeller mouth ring wear, impeller mass eccentricity, shaft bending, and experimental platform instability of the five fault states.

Figure 4.

(a) Normal impeller, (b) impeller blade breakage, (c) impeller mouth ring wear, (d) impeller mass eccentricity, (e) base instability, (f) base stability, (g) shaft bending.

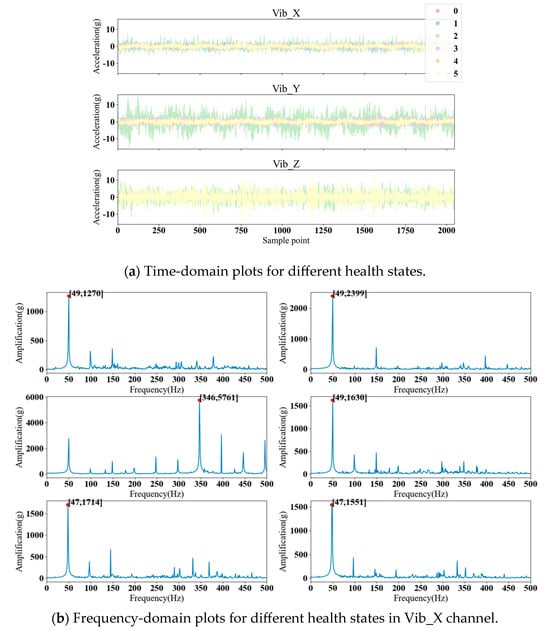

The vibration signals corresponding to the six health states across different channels are shown in Figure 5. It can be observed that the time-domain signals vary under different health conditions, making it challenging to directly identify fault types from these signals. Similarly, in the frequency-domain, although the vibration amplitude is noticeable not only at the fundamental frequency and industrial frequency (6 times the fundamental frequency) but also at other frequencies, it remains difficult to pinpoint specific fault causes based solely on frequency-domain characteristics. To address this challenge, this paper proposes an intelligent fault diagnosis method for vertical centrifugal pumps based on a CNN-BiLSTM architecture.

Figure 5.

The example samples of the raw vibration signals.

In order to increase the dataset and improve the diagnostic accuracy of the model, data enhancement will be performed using overlapping sampling. The sample length of each data is 2048, with roughly 10 revolutions of vibration signal length, 100 data points are slid between each sample, and there are 980 samples for each fault state, which makes a total of 5880 data samples that are divided into the training set and the test set according to 7:3; the specific division results are shown in Table 4.

Table 4.

Dataset segmentation.

4. An Analysis of the Results of the Experiment

4.1. Troubleshooting Flow

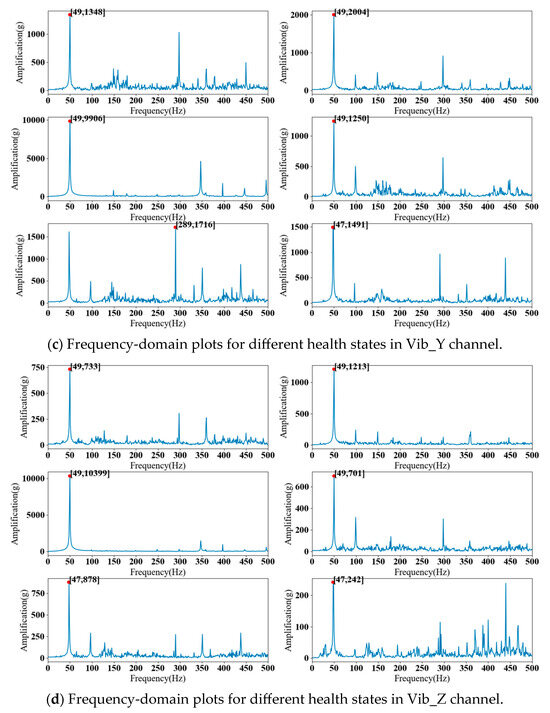

Experiments were conducted according to the described methods in Section 2 of this paper to collect the vibration signals of centrifugal pumps under six different faults, and then the model was trained and tested according to the steps shown in Figure 6.

Figure 6.

Flowchart of diagnostic.

- (1)

- Divide the dataset, increase the data for the acquired vibration signals, and then divide it into a training set and test set according to the ratio of 7:3.

- (2)

- To train the model, follow the parametric model described in Section 2. The training parameters are set as follows: batch size bach size = 64, learning rate = 0.0001, loss function is cross-entropy loss function, and optimizer is Adam.

- (3)

- Model testing, where the test set is fed into the trained model and the model is validated using accuracy, precision, recall, and F1-score.

4.2. Analysis of Results

4.2.1. Influence of Different Channel Vibration Signals on Diagnostic Results

As can be seen from Figure 5, when the centrifugal pump fails, the energy of the vibration impact generated in different directions is not equal, and the fault characteristics implied by different directions may affect the diagnosis. In order to validate the impact of different directions of data on the model performance and also to fully utilize the collected data, the signals of a single channel and the fusion of the signals of the three channels were inputted into the CNN, respectively, for model training. The parameter settings of the CNN in the experiment are consistent with those of the proposed CNN-BiLSTM network.

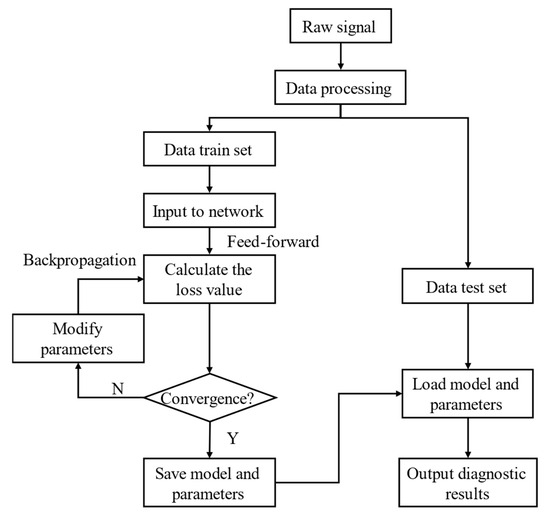

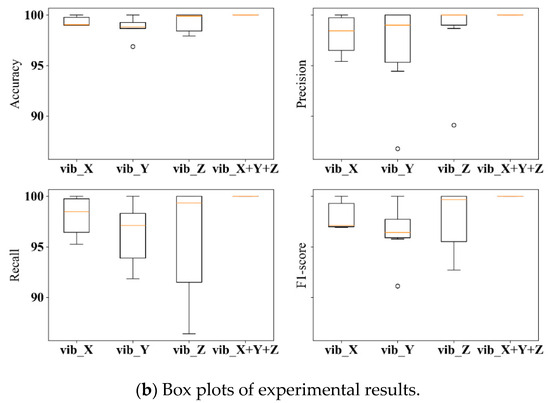

The results of the model testing and validation are shown in Table 5, although the accuracy rate reaches more than 98.75% on a single channel, the results are poor for the accuracy rate, precision rate, recall rate, and F1-score, while for the diagnostic effect of the three-channel information fusion, it can be seen that the accuracy rate, precision rate, recall rate, and F1-score reach 100%, which indicates that the multi-channel information fusion helps to improve the performance of the model as well as its generalization ability.

Table 5.

Diagnostic results for different channels of CNN.

In Figure 7a, the confusion matrix between the true and predicted values during the experiment is shown. Figure 7b shows the box plots of the accuracy, precision, recall, and F1-score results of the model with different channel information, and it can be seen that the vibration signals generated in the Z-direction when the centrifugal pump malfunctions are more complicated, which makes its diagnostic results worse than those of the vibration data in the other two directions, followed by the data in the Y-direction. However, the use of multi-channel information fusion technology can be a good solution to this problem, which shows that the multi-channel information fusion method proposed in this paper can better reflect the fault state of the centrifugal pump.

Figure 7.

Plots of experimental results.

4.2.2. Comparative Analysis of Models

Since the features extracted by the CNN from the input signal are spatial level information and the input signal is temporal data, in order to obtain the temporal level information, the BiLSTM module is added after the feature extraction module to obtain the temporal level features in the signal.

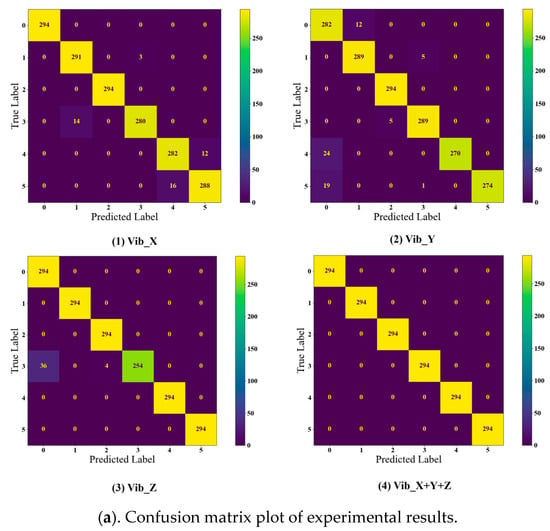

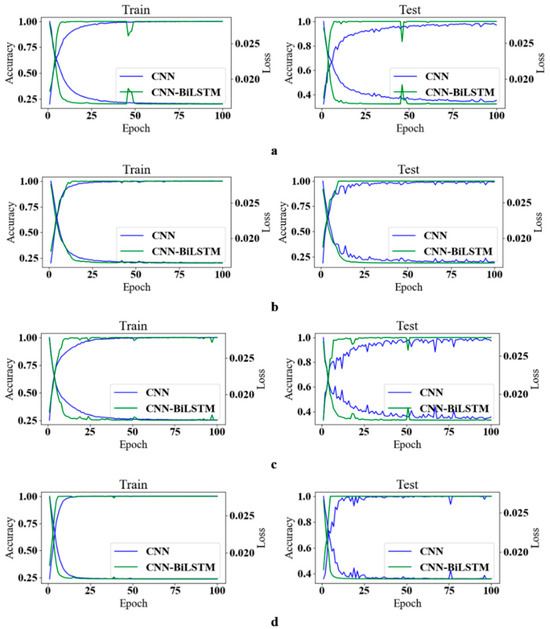

The changes in the accuracy and loss values during training and validation of the CNN and CNN-BiLSTM models are shown in Figure 8. For the accuracy and loss values of individual channels, it can be seen that the accuracy of the CNN and CNN-BiLSTM models increases rapidly and gradually stabilizes during the training process, while the value of the loss function decreases rapidly and converges gradually without overfitting and underfitting, with CNN-BiLSTM converging faster than CNN. And the accuracy is 1.98%, 3.74%, and 2.27% higher than CNN in X, Y, and Z directions, respectively, which indicates that the introduction of BiLSTM on the basis of CNN can effectively make up for the lack of CNN’s processing of time series data, thus improving the overall performance of the model in fault diagnosis. In the process of model validation, it can be seen that the accuracy and loss value of the CNN model fluctuate, while the accuracy and loss value of the CNN-BiLSTM model are smoother and more accurate than that of the CNN model. Comparing the accuracy and loss values of single-channel information and multi-channel information fusion model training, it can be seen that the accuracy of multi-channel information fusion fault diagnosis is higher than that of single-channel, which further verifies the reliability of the model proposed in this paper.

Figure 8.

Accuracy and loss values for CNN and CNN-BiLSTM for different channel data: (a) vib_X, (b) vib_Y, (c) vib_Z, (d) vib_X + Y+Z.

4.2.3. Model Visualization

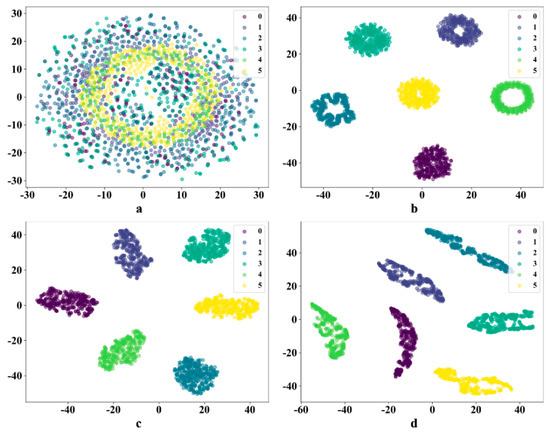

In order to intuitively understand the learning process of the vibration signal features of the model proposed in this paper, the T-SNE (T-Stochastic Neighbor Embedding) dimensionality reduction method is used to visually express the outputs of each layer in the two-dimensional feature space, as shown in Figure 9. It can be seen that it is difficult to distinguish the different faults generated by the centrifugal pump from the raw unprocessed signal. However, as the model of the signal for fault feature extraction, the different faults are more distinguishable, but some fault states are more scattered. After BiLSTM, it can be seen that the fault data of the various labels are well aggregated together, which further illustrates that the method proposed in this paper is effective in centrifugal pump fault diagnosis.

Figure 9.

t-SNE visualization clustering results: (a) Raw signal, (b) CNN, (c) BiLSTM, (d) Fc layer.

5. Conclusions

In order to accurately and efficiently identify the fault conditions occurring during the operation of centrifugal pumps, this paper proposes a centrifugal pump fault diagnosis model with CNN-BiLSTM, utilizes the method to diagnose faults on centrifugal pumps, and builds a test rig to verify the feasibility of the proposed fault diagnosis method The diagnostic results show the following:

- (1)

- The proposed method has a compact network structure and accepts raw signal inputs, which can automatically learn features from raw signals, avoiding the dependence on expert experience. Meanwhile, the diagnostic results show that the proposed diagnostic method can accurately diagnose different faults of centrifugal pumps.

- (2)

- By comparing the CNN and CNN-BiLSTM models, it was found that CNN-BiLSTM converges faster than CNN. The accuracy in X, Y, and Z directions is 1.98%, 3.74%, and 2.27% higher than that of CNN, respectively, which suggests that the proposed method can effectively make up for the shortcomings of CNN’s temporal data processing, and improve the overall performance of the model in fault diagnosis.

- (3)

- The method of multi-channel data fusion can effectively improve the accuracy of fault recognition. Using three channels of vibration data, the recognition accuracy reaches 100%, which indicates that the proposed method can learn the relevant fault information from the signals of different channels and verifies the advantages of multi-channel data fusion.

Author Contributions

Methodology, Y.Z. and Q.F.; Software, Q.H., D.H. and H.Q.; Validation, H.L.; Formal analysis, H.L.; Resources, Y.Z., Q.H. and Q.F.; Writing—original draft, F.T.; Writing—review & editing, F.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China grant number (U20A20292, 52371322). The APC was funded by National Natural Science Foundation of China grant number (U20A20292, 52371322).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Authors Yifan Zhi, Qian Huang were employed by the company China Nuclear Power Engineering Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. The company had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

Nomenclature

| CNN | convolutional neural network | the input to BiLSTM | |

| LSTM | long short-term memory | the weight of the bilstm nth layer | |

| BiLSTM | bidirectional long short-term memory | the hidden layer outputs of BiLSTM forward respectively | |

| the convolution operation | the hidden layer outputs of BiLSTM reverse respectively | ||

| the ith convolution kernel weight matrix | the final output of BiLSTM | ||

| the ith bias term | the true label | ||

| the output feature of the previous layer | the predict label | ||

| the activation function | the cross-entropy loss function loss value | ||

| the activation function | the number of true-positive | ||

| the element of the pooling kernel | the number of true-negative | ||

| the element in the feature map | the number of false-positive | ||

| the jth pooling region | the number of false-negative |

References

- An, C.; Li, H.; Chen, Y.; Zhu, R.; Fu, Q.; Wang, X. Research on flow resistance characteristics of reactor coolant pump under large break LOCA at inlet. Nucl. Eng. Des. 2022, 395, 111856. [Google Scholar] [CrossRef]

- Arun Shankar, V.K.; Umashankar, S.; Paramasivam, S.; Hanigovszki, N. A comprehensive review on energy efficiency enhancement initiatives in centrifugal pumping system. Appl. Energy 2016, 181, 495–513. [Google Scholar] [CrossRef]

- Fu, Q.; Zhang, F.; Zhu, R.; He, B. A systematic investigation on flow characteristics of impeller passage in a nuclear centrifugal pump under cavitation state. Ann. Nucl. Energy 2016, 97, 190–197. [Google Scholar] [CrossRef]

- Li, T.; Wang, S.; Zio, E.; Shi, J.; Ma, Z. A numerical approach for predicting the remaining useful life of an aviation hydraulic pump based on monitoring abrasive debris generation. Mech. Syst. Signal Process. 2020, 136, 106519. [Google Scholar] [CrossRef]

- Patra, J.; Pandey, N.K.; Muduli, U.K.; Natarajan, R.; Joshi, J. Hydrodynamic study of flow in the rotor region of annular centrifugal contactors using CFD simulation. Chem. Eng. Commun. 2013, 200, 471–493. [Google Scholar] [CrossRef]

- Ye, W.; Geng, C.; Luo, X. Unstable flow characteristics in vaneless region with emphasis on the rotor-stator interaction for a pump turbine at pump mode using large runner blade lean. Renew. Energy 2022, 185, 1343–1361. [Google Scholar] [CrossRef]

- Zhang, M.; Jiang, Z.; Feng, K.J.M.S.; Processing, S. Research on variational mode decomposition in rolling bearings fault diagnosis of the multistage centrifugal pump. Mech. Syst. Signal Process. 2017, 93, 460–493. [Google Scholar] [CrossRef]

- Hoang, D.-T.; Kang, H.-J. A survey on Deep Learning based bearing fault diagnosis. Neurocomputing 2019, 335, 327–335. [Google Scholar] [CrossRef]

- Lei, Y. Intelligent Fault Diagnosis and Remaining Useful Life Prediction of Rotating Machinery; Elsevier Inc.: Amsterdam, The Netherlands, 2016; pp. 17–66. [Google Scholar]

- Liu, R.; Yang, B.; Zio, E.; Chen, X.J.M.S.; Processing, S. Artificial intelligence for fault diagnosis of rotating machinery: A review. Mech. Syst. Signal Process. 2018, 108, 33–47. [Google Scholar] [CrossRef]

- Cooley, J.W.; Lewis, P.A.W.; Welch, P.D. The Fast Fourier Transform and Its Applications. IEEE Trans. Educ. 1969, 12, 27–34. [Google Scholar] [CrossRef]

- Peng, Z.K.; Tse, P.W.; Chu, F.L. A comparison study of improved Hilbert–Huang transform and wavelet transform: Application to fault diagnosis for rolling bearing. Mech. Syst. Signal Process. 2005, 19, 974–988. [Google Scholar] [CrossRef]

- Zhu, R.; Li, Y.; Huang, Q.; Li, S.; Zhang, X.; Li, H.; Fu, Q. Research on Vertical SEC Centrifugal Pump Multi-Fault Diagnosis Based on WPT–SVM. Energies 2023, 16, 7653. [Google Scholar] [CrossRef]

- Zhang, W.; Peng, G.; Li, C.; Chen, Y.; Zhang, Z. A New Deep Learning Model for Fault Diagnosis with Good Anti-Noise and Domain Adaptation Ability on Raw Vibration Signals. Sensors 2017, 17, 425. [Google Scholar] [CrossRef] [PubMed]

- Ye, Z.; Yu, J. Deep morphological convolutional network for feature learning of vibration signals and its applications to gearbox fault diagnosis. Mech. Syst. Signal Process. 2021, 161, 107984. [Google Scholar] [CrossRef]

- Tian, Y.; Liu, X. A deep adaptive learning method for rolling bearing fault diagnosis using immunity. Tsinghua Sci. Technol. 2019, 24, 750–762. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, J.; Zou, J.; Fan, S. A Novel Fault Diagnosis Method based on Stacked LSTM. IFAC-PapersOnLine 2020, 53, 790–795. [Google Scholar] [CrossRef]

- Pan, H.; He, X.; Tang, S.; Meng, F. An Improved Bearing Fault Diagnosis Method using One-Dimensional CNN and LSTM. J. Mech. Eng. 2018, 64, 443–452. [Google Scholar]

- Chen, X.; Zhang, B.; Gao, D. Bearing fault diagnosis base on multi-scale CNN and LSTM model. J. Intell. Manuf. 2021, 32, 971–987. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).