Analysis of Enhanced Geothermal System Reservoir Parameters and Fractures on Heat Recovery Efficiency Based on a Single-Phase Conduction Model

Abstract

1. Introduction

2. Brief Description of the TH Coupling Model

2.1. Model Assumptions

- The reservoir fractured rock mass is a uniform, isotropic, and continuous porous medium [27].

- Due to the action of high pressure, the heat recovery fluid is in a saturated state underground with no phase change (i.e., it is a single-phase flow).

- We ignore the chemical reactions between the fluid and the reservoir rock and the stress movement inside the reservoir during heat exchange.

- We ignore the effects of gravity and capillary forces on the seepage of fluids in porous media.

- In the process of heat transfer in the reservoir rock mass, only the heat conduction and heat convection modes are considered.

- The fracture surface of the reservoir and the injection (production) wellbore in the thermal reservoir are regarded as porous media.

- When heat compensation is ignored, the contact surface between the surrounding rock and the heat storage is set as an adiabatic boundary. When heat compensation is taken into account, the interface between the surrounding rock and the heat reservoir is set as an open boundary.

2.2. EGS Heat Storage Heat and Mass Transfer Model

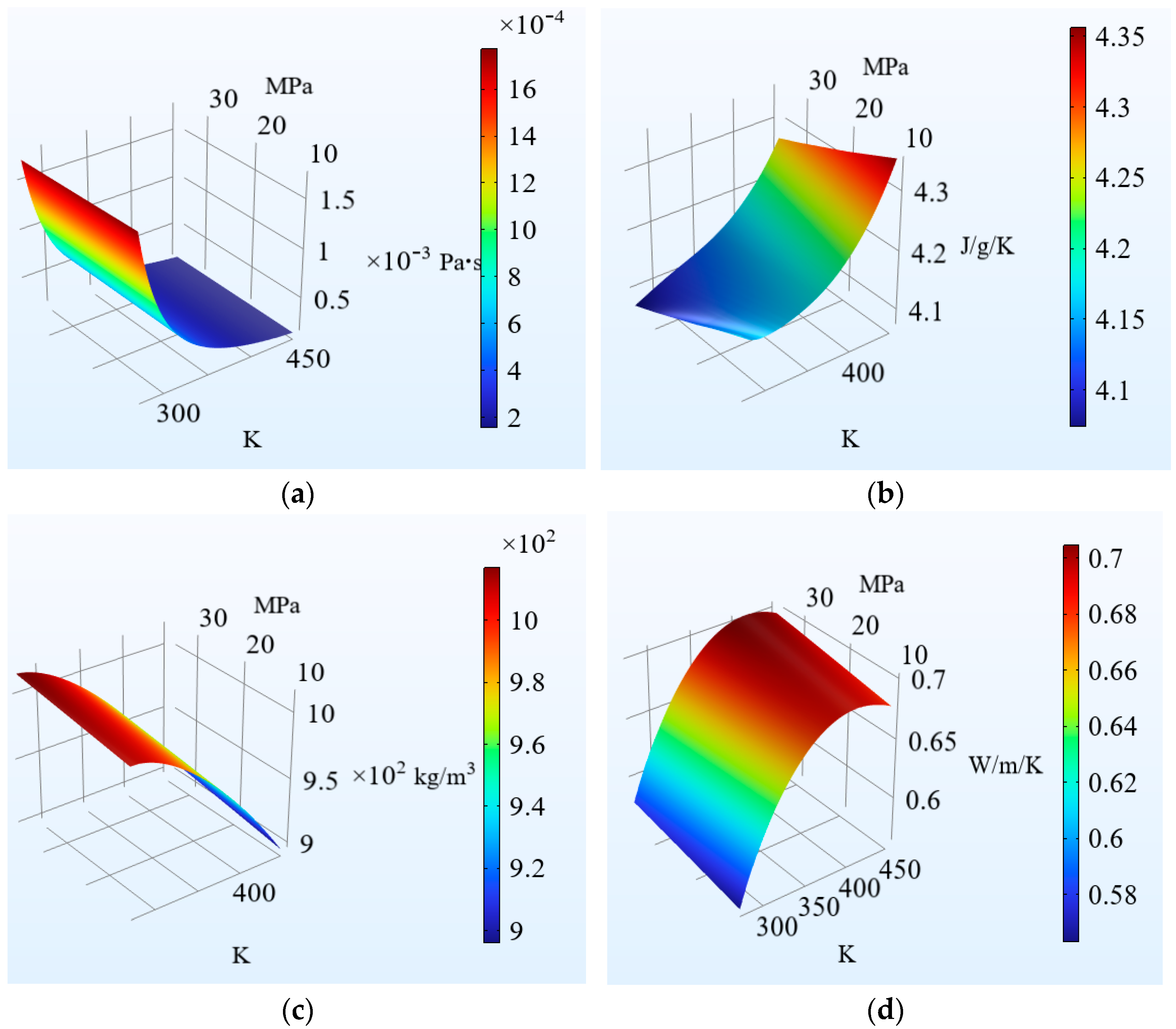

2.3. Relationship Between Temperature and Seepage

3. Geological Model and Geothermal Capacity Evaluation Index

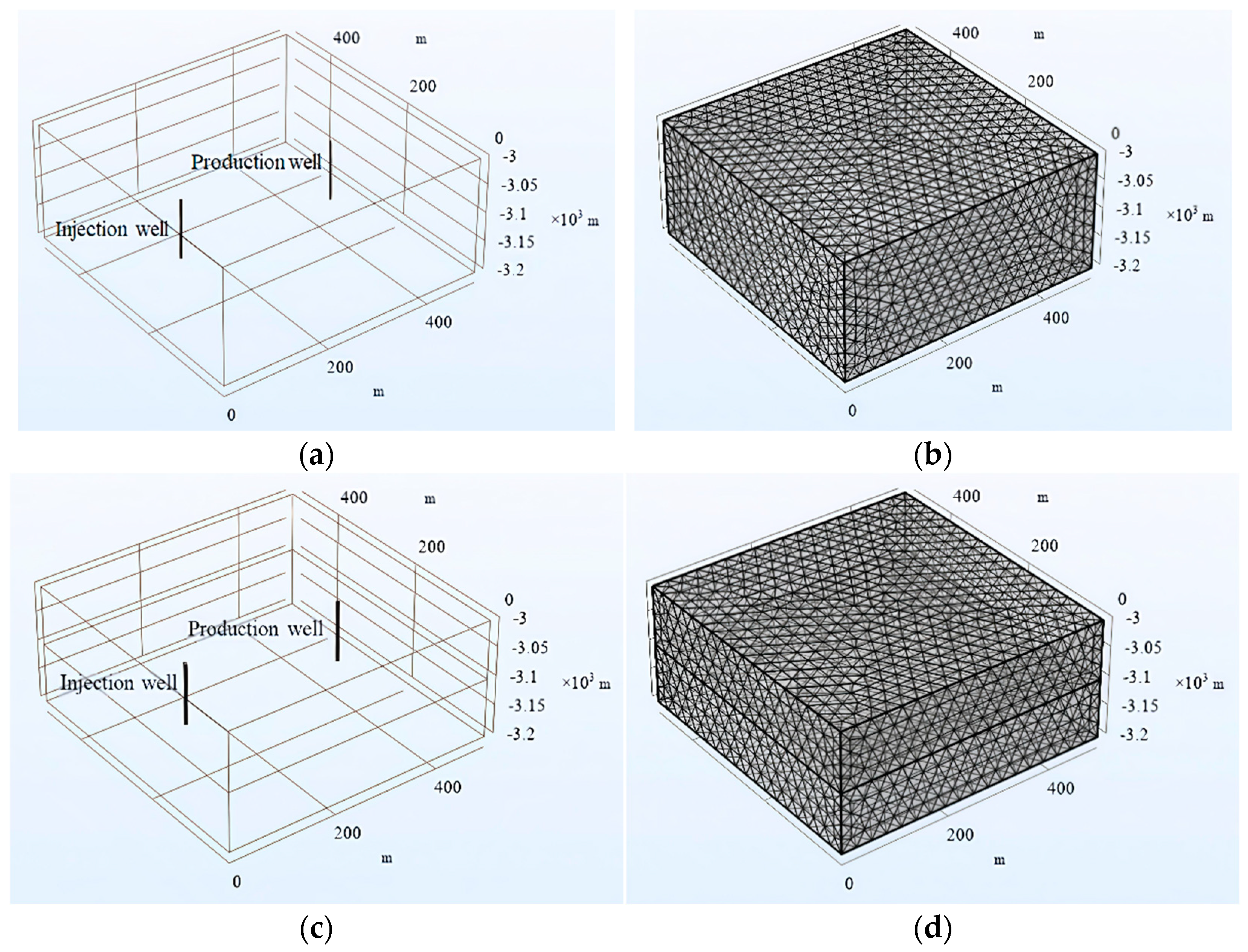

3.1. Geological Model

3.2. Evaluation Index of Geothermal Production

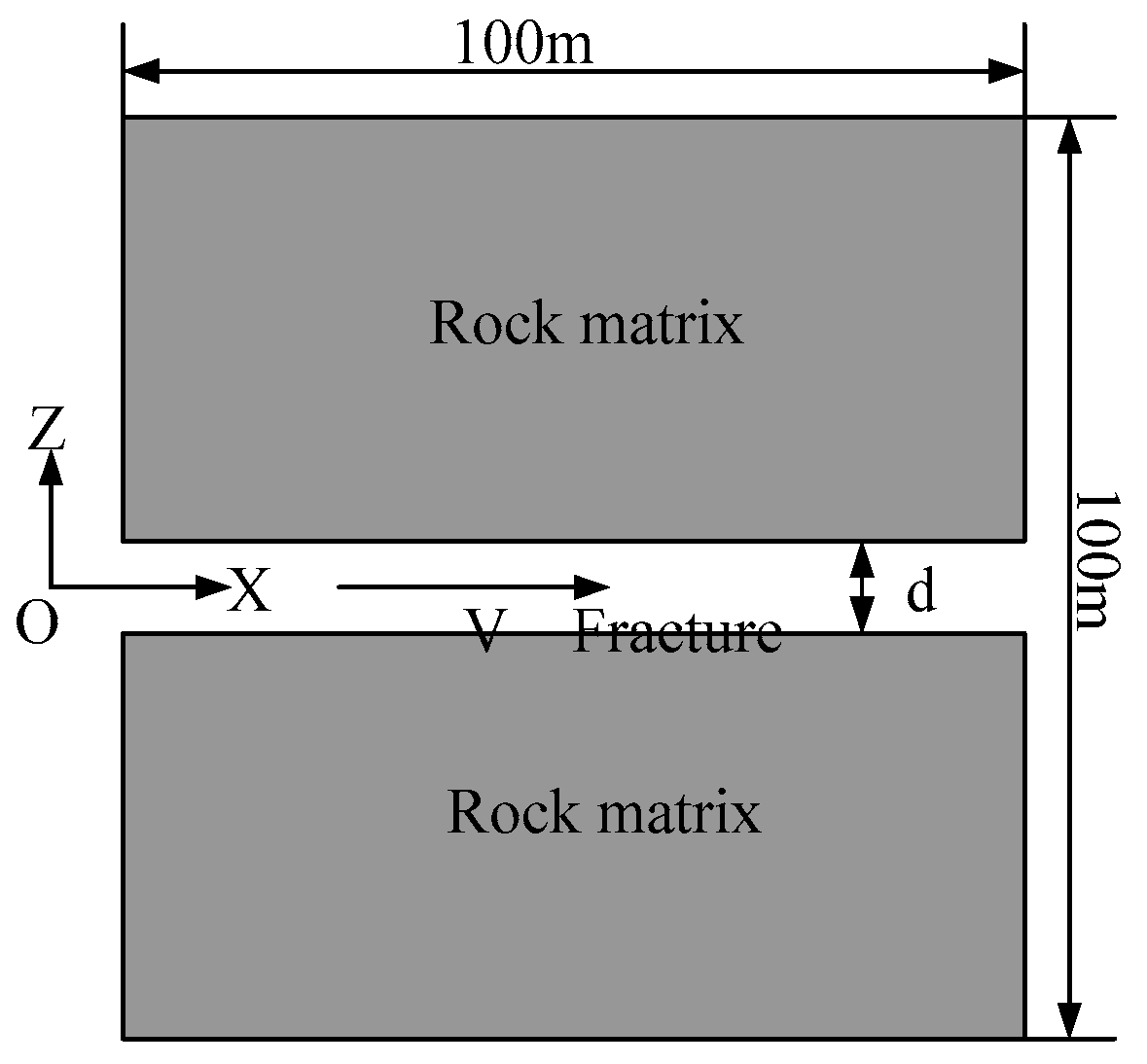

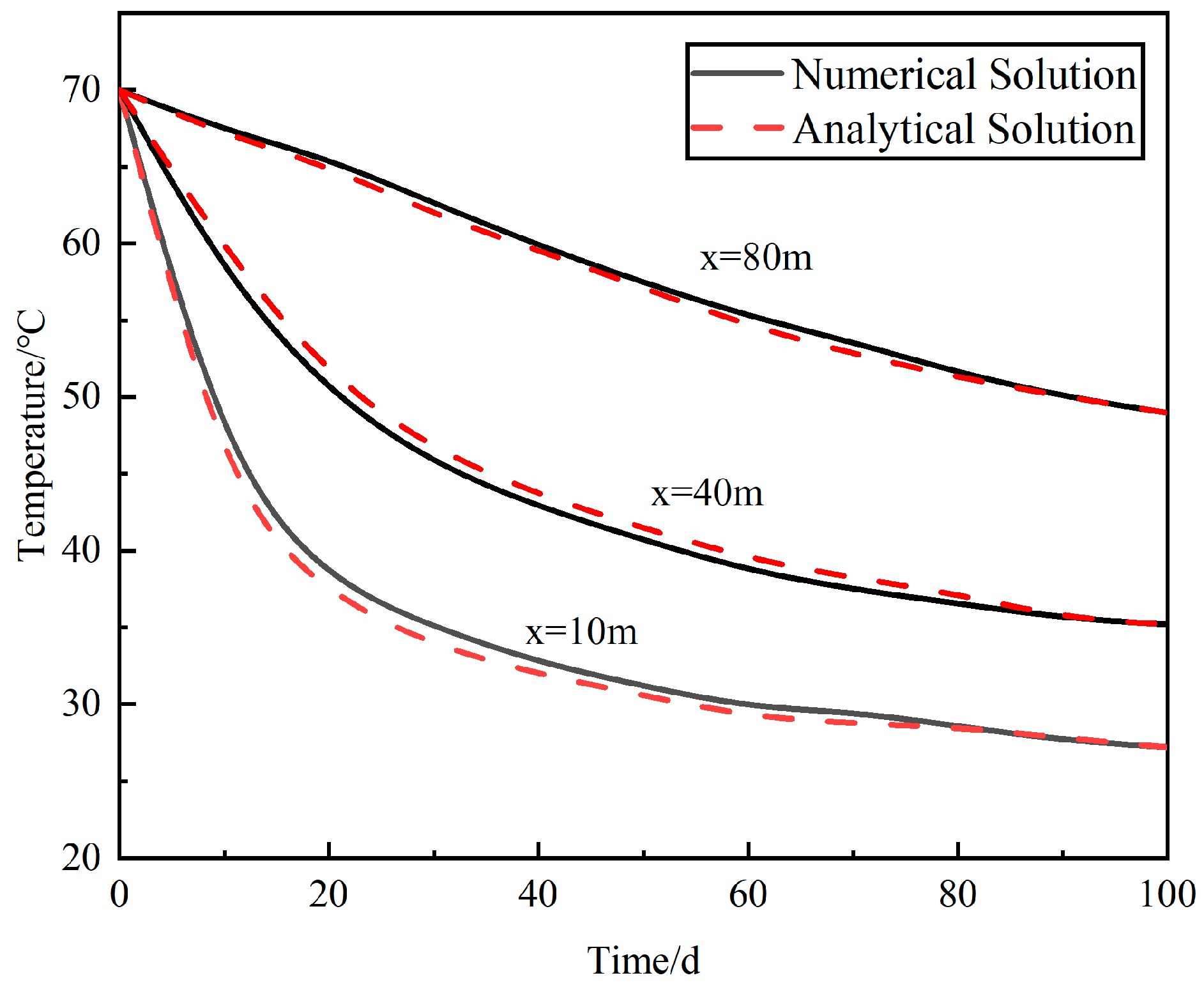

4. Validation of Numerical Model

5. Results and Analysis

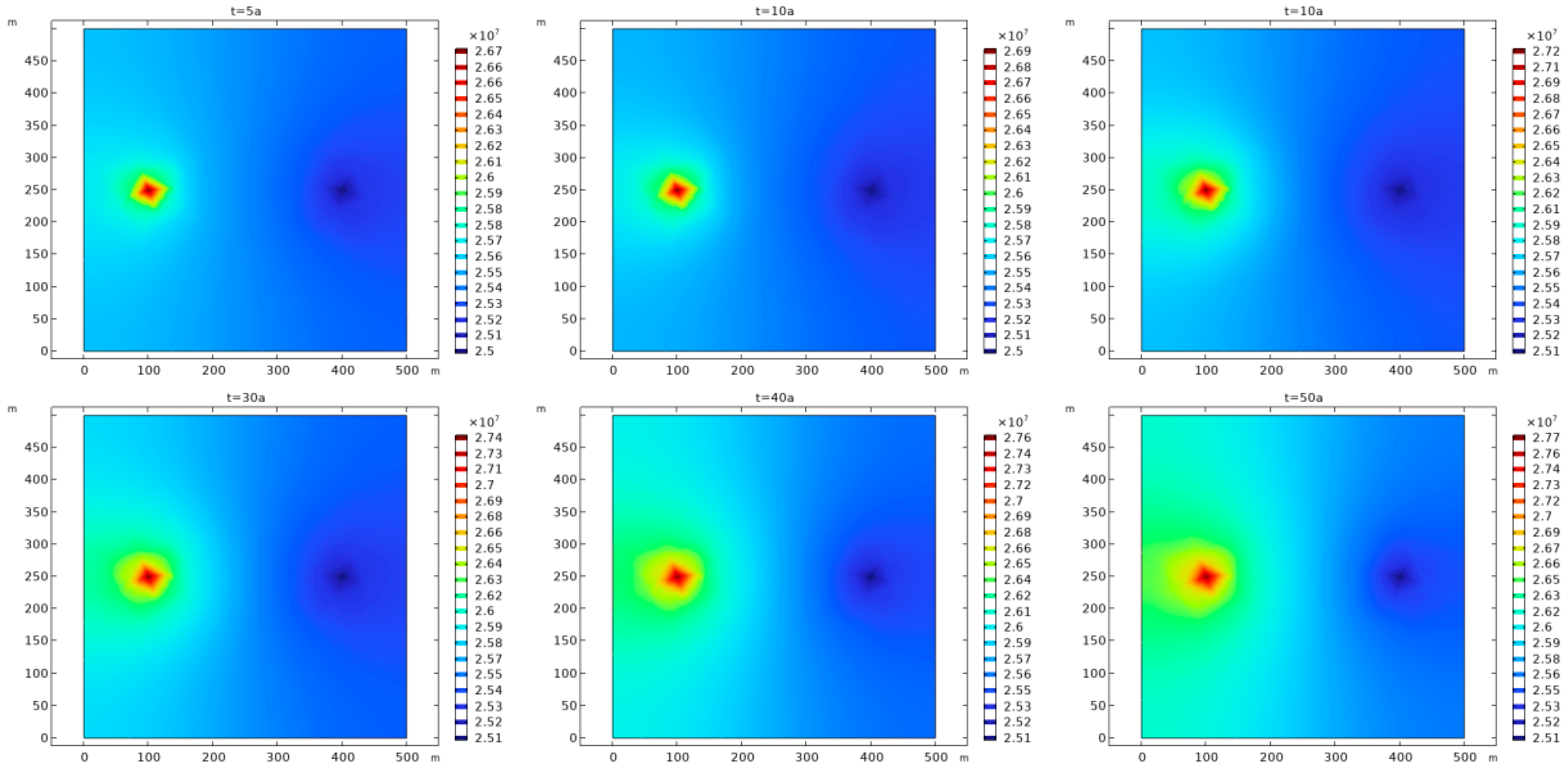

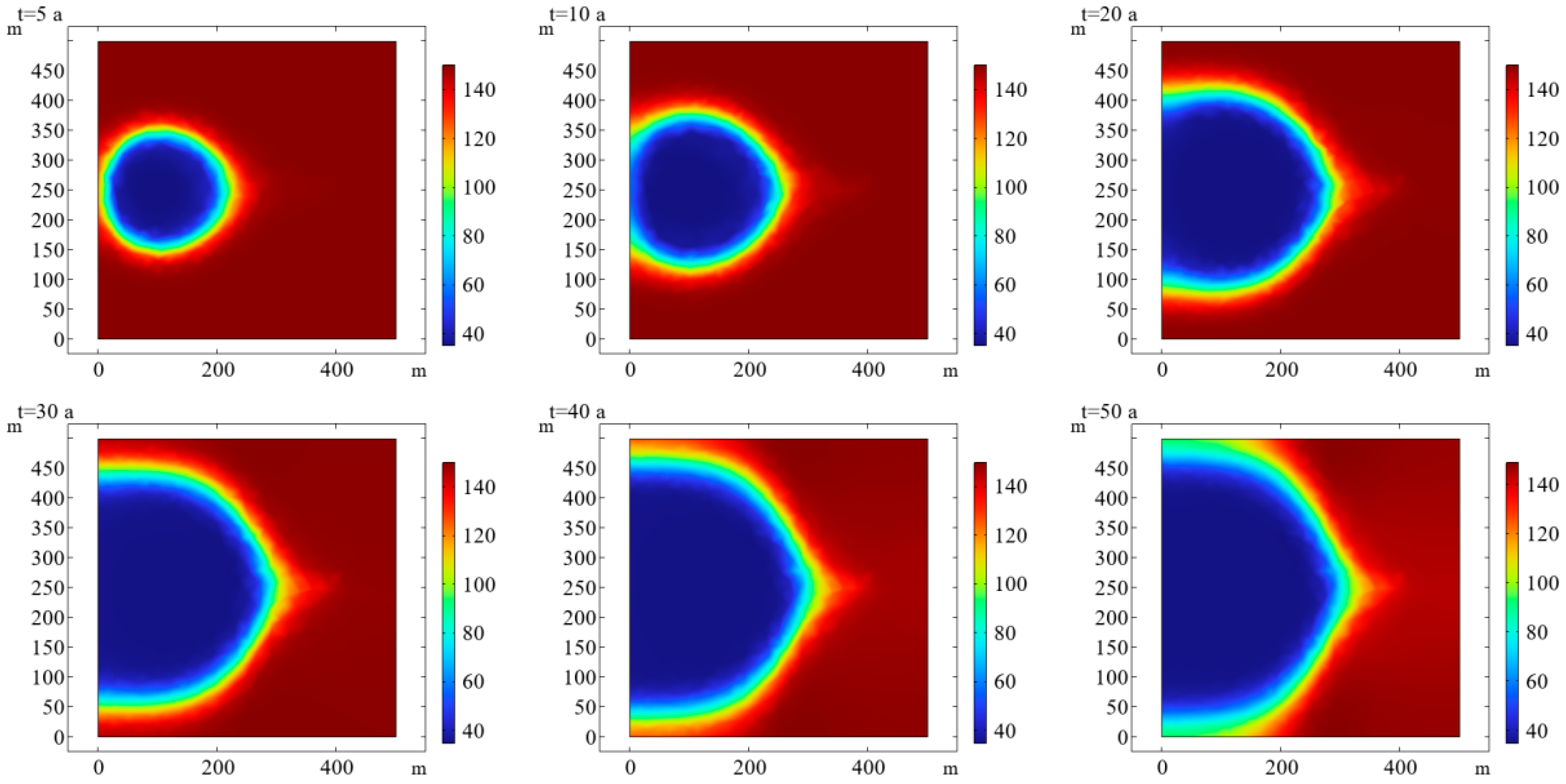

5.1. Spatiotemporal Evolution Characteristics of Pressure and Temperature Fields

5.2. Optimization of Thermal Reservoir Parameters

5.2.1. Porosity and Permeability of Heat Storage Matrix

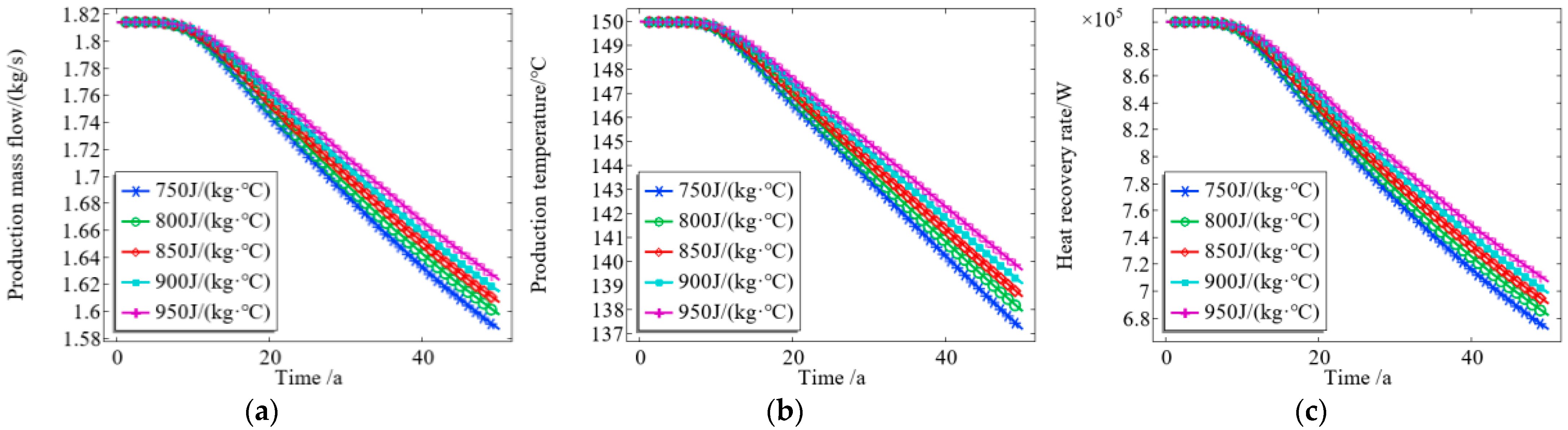

5.2.2. Thermal Conductivity and Specific Heat Capacity of Heat Storage Matrix

5.3. Effect of the Number of Fractures on the Development Effect of Heat Storage

6. Conclusions

- The slow recovery of geothermal reservoir pressure in the early stage of development is related to the temperature difference near the injection and production wells during this period. Therefore, the rate of pressure loss caused by production is greater than the rate of pressure recovery caused by injection in the early stage of development.

- At the same time, the production mass flow rate will increase with an increase in permeability, while the enthalpy difference will decrease with increasing permeability. Therefore, during the operation of the system, the influence of permeability change on the heat extraction rate becomes smaller and smaller. The sensitivity of the heat extraction rate to permeability increases (decreases) with increasing (decreasing) permeability, and this change is very significant. The thermal conductivity of the matrix has almost no effect on the development of thermal reservoirs. The larger the specific heat capacity of the matrix, the more favorable it is for the development of thermal reservoirs.

- While cracks provide a dominant channel with less resistance to fluid flow in the reservoir, too many cracks further obscure the spread range of the fluid, such that a large area of heat in the heat reservoir may not be reached, thereby reducing the efficiency of heat extraction. Therefore, the rational utilization of fractures will be beneficial to the development of thermal reservoirs, while their unreasonable utilization will have negative impacts.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, S.; Shi, Y.; Fang, C.; Cao, Q.; Ren, L. Current situation and development direction of geothermal development and utilization in Chinese oilfields. Rocky Oil Gas Reserv. 2024, 36, 23–32. [Google Scholar]

- Aksoy, N.; Şimşek, C.; Gunduz, O. Groundwater contamination mechanism in a geothermal field: A case study of Balcova, Turkey. J. Contam. Hydrol. 2009, 103, 13–28. [Google Scholar] [CrossRef] [PubMed]

- Russo, S.; Civita, M. Open-loop groundwater heat pumps development for large buildings: A case study. Geothermics 2009, 38, 335–345. [Google Scholar] [CrossRef]

- Freedman, V.; Waichler, S.; Mackley, R.; Horner, J.A. Assessing the thermal environmental impacts of an groundwater heat pump in southeastern Washington State. Geothermics 2012, 42, 65–77. [Google Scholar] [CrossRef]

- Nam, Y.; Ooka, R. Numerical simulation of ground heat and water transfer for groundwater heat pump system based on real-scale experiment. Energy Build. 2010, 42, 69–75. [Google Scholar] [CrossRef]

- Xu, C.; Dowd, P.; Tian, Z. A simplified coupled hydro-thermal model for enhanced geothermal systems. Appl. Energy 2015, 140, 135–145. [Google Scholar] [CrossRef]

- Zhai, H.; Su, Z.; Ling, L.; Wu, N. Numerical simulation study of EGS development in the Desert Peak geothermal field in the United States based on the parallel multi-fracture model. Adv. Geophys. 2017, 32, 546–552. [Google Scholar]

- Luo, L.; Cao, W.L.; Jiang, F.M. Enhanced fractal bifurcation network model for heat extraction in geothermal systems. J. Eng. Thermophys. 2015, 36, 388–392. [Google Scholar]

- Shan, D.D.; Yan, T.; Li, W.; Zhao, H.; Lu, G. Numerical Simulation and Analysis of Thermal-Hydraulic Coupling in A Single-Fracture Thermal Reservoir. Contemp. Chem. Ind. 2020, 49, 716–719+723. [Google Scholar]

- Lei, H.; Jin, G.; Li, J.; Shi, Y.; Feng, B. Coupled Thermal-Hydrodynamic Processes for Geothermal Energy Exploitation in Enhanced Geothermal System at Songliao Basin, China. J. Jilin Univ. (Earth Sci. Ed.) 2014, 44, 1633–1646. [Google Scholar]

- AbuAisha, M.; Loret, B. Influence of hydraulic fracturing on impedance and efficiency of thermal recovery from HDR reservoirs. Geomech. Energy Environ. 2016, 7, 10–25. [Google Scholar] [CrossRef]

- Bujakowski, W.; Barbacki, A.; Miecznik, M.; Pająk, L.; Skrzypczak, R.; Sowiżdżał, A. Modelling geothermal and operating parameters of EGS installations in the lower triassic sedimentary formations of the central Poland area. Renew. Energy 2015, 80, 441–453. [Google Scholar] [CrossRef]

- Hu, J.; Su, Z.; Wu, N.Y.; Zhai, H.Z.; Zeng, Y.C. Analysis of the temperature field of water-rock coupled with heat flow in an enhanced geothermal system. Adv. Geophys. 2014, 29, 1391–1398. [Google Scholar]

- Chen, B.; Song, E.; Cheng, X. Numerical calculation method of discrete fracture network model for seepage heat transfer in two-dimensional fractured rock. J. Rock Mech. Eng. 2014, 33, 43–51. [Google Scholar]

- Qu, Z.; Zhang, W.; Guo, T.; Sun, J. Numerical simulation of heat mining performance of hot dry rocks with fracture network based on a local thermal non-equilibrium model. J. China Univ. Pet. (Nat. Sci. Ed.) 2019, 43, 90–98. [Google Scholar]

- Xiao, P.; Yan, F.F.; Du, B.; Tian, H.; Liu, H.W.; Zhu, Z.N. Numerical simulation of parallel multi-fracture heat transfer process in horizontal wells for enhanced geothermal systems. Renew. Energy 2019, 37, 1091–1099. [Google Scholar]

- Wang, H.; Wang, L.; Cheng, Z. Influence Factors on EGS Geothermal Reservoir Extraction Performance. Geofluids 2022, 2022, 5174456. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, M.; Wang, G.; Ma, P. Evaluation of heat extraction performance of multi-well injection enhanced geothermal system. Appl. Therm. Eng. 2022, 201, 117808. [Google Scholar] [CrossRef]

- Yu, G.; Liu, C.; Zhang, L.; Fang, L. Parameter sensitivity and economic analyses of an interchange-fracture enhanced geothermal system. Adv. Geo-Energy Res. 2021, 5, 166–180. [Google Scholar] [CrossRef]

- Liu, S.; Taleghani, A.D. Analysis of an enhanced closed-loop geothermal system. Geoenergy Sci. Eng. 2023, 231, 212296. [Google Scholar] [CrossRef]

- Liu, S.; Taleghani, A.D.; Ji, K. An advanced closed-loop geothermal system to substantially enhance heat production. Energy Convers. Manag. 2024, 322, 119168. [Google Scholar] [CrossRef]

- Yao, J.; Zhang, X.; Sun, Z.; Huang, Z.; Liu, J.; Li, Y.; Xin, Y.; Yan, X.; Liu, W. Numerical simulation of the heat extraction in 3D-EGS with thermal-hydraulic-mechanical coupling method based on discrete fractures model. Geothermics 2018, 74, 19–34. [Google Scholar] [CrossRef]

- Cai, X.; Deng, Q.; Xu, K.; Zhong, X.; Yang, M. Impact of dual-fracture location on heat extraction from Enhanced geothermal system in low-permeability reservoirs. Appl. Therm. Eng. 2025, 259, 124754. [Google Scholar] [CrossRef]

- Suo, Y.; Guan, W.; Dong, M.; Zhang, R.; Wang, K.; He, W.; Fu, X.; Pan, Z.; Guo, B. Study on the heat extraction patterns of fractured hot dry rock reservoirs. Appl. Therm. Eng. 2025, 262, 125286. [Google Scholar] [CrossRef]

- Song, X.; Shi, Y.; Li, G.; Yang, R.; Wang, G.; Zheng, R.; Li, J.; Lyu, Z. Numerical simulation of heat extraction performance in enhanced geothermal system with multilateral wells. Appl. Energy 2018, 218, 325–337. [Google Scholar] [CrossRef]

- Chen, Z.; Huang, L.; Li, X.; Liu, Z.; Chen, J. Numerical investigations of mechanical behavior and permeability evolution in mine geothermal reservoir with blasting fractures using fully coupled thermal–hydraulic-mechanical modeling. Appl. Therm. Eng. 2024, 252, 123596. [Google Scholar] [CrossRef]

- Li, J. Numerical Simulation Study of Geothermal Mining Characteristics of CO2 Plume Geothermal System. Master’s Thesis, Beijing University of Technology, Beijing, China, 2018. [Google Scholar]

- Yuan, A. Study on Heat Transfer Characteristics of Enhanced Geothermal System Based on Heat Flow Coupling. Master’s Thesis, Anhui University of Architecture, Hefei, China, 2022. [Google Scholar]

- Wang, L. Numerical Simulation and Optimization of Wellbore-Multi-Fractured Reservoir Heat Flow Coupling. Master’s Thesis, Anhui University of Architecture, Hefei, China, 2023. [Google Scholar]

- Aliyu, M.D.; Chen, H.P. Sensitivity analysis of deep geothermal reservoir: Effect of reservoir parameters on production temperature. Energy 2017, 129, 101–113. [Google Scholar] [CrossRef]

- Qu, Z.Q.; Zhang, W.; Guo, T.K.; Sun, J.; Gong, F.C.; Tian, Y.; Li, X.L. Research on the influence law of reservoir parameters and laminar joints on geothermal production capacity based on COMSOL. Adv. Geophys. 2017, 32, 2374–2382. [Google Scholar]

- Gong, L.; Qin, X.; Lu, J.; Gao, Y.; Meng, L.; Yuan, H.; Lu, Q.; Yin, X. Fracture development characteristics and distribution prediction of carbonate buried hill reservoirs in Nanpu Sag, Bohai Bay Basin. Nat. Gas Geosci. 2024, 35, 925–937. [Google Scholar]

- Wu, Z.; Tang, H.; An, F. Discussion on the genesis of stratigraphic joints in tight sandstone gas reservoirs in Xinchang, West Sichuan. Pet. Explor. Dev. 2003, 2, 109–111. [Google Scholar]

- He, Z.; Liu, B.; Wang, P. Genesis of Jurassic laminar joints and their influence on reservoirs in Yongjin area, Junggar Basin. Oil Gas Geol. Recovery 2011, 18, 15–17+112. [Google Scholar]

| Type | Numeric Value | Type | Numeric Value |

|---|---|---|---|

| Thickness of heat storage | 200 m | Injection–production well spacing | 300 m |

| Thermal storage density | 2600 kg/m3 | Thermal storage permeability | 45.5 mD |

| Porosity, heat storage, thermal conductivity | 2.5 W/(m·K) | Heat storage−specific heat capacity | 800 J/(kg·K) |

| porosity | 0.155 | Geothermal gradient | 0.0398 K/m |

| Formation primitive pressure | 30 MPa | Surface temperature | 25 °C |

| Injection temperature | 35 °C | Fracture permeability | 1 × 10−12 m2 |

| Thermal conductivity of fractures | 1.5 W/(m·K) | Fracture−specific heat capacity | 800 J/(kg·K) |

| Fracture porosity | 0.6 | Fracture roughness coefficient | 1.6 |

| Production well pressure | 25 MPa |

| Symbol | Reference Significance | Numeric Value |

|---|---|---|

| Ti | Initial temperature | 70 °C |

| Te | Infuse water temperature | 20 °C |

| ue | Injection flow rate | 0.01 m/s |

| d | Fracture width | 3 mm |

| λs | Bedrock thermal conductivity | 3 W/(m·K) |

| ρf | Fracture water density | 1000 kg/m3 |

| cf | Specific heat capacity of fracture water | 4200 J/(kg·K) |

| ρs | Bedrock density | 2700 kg/m3 |

| Cs | Specific heat capacity of bedrock | 1000 J/(kg·K) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, Y.; Wei, J.; Fu, M.; Fang, L.; Li, X. Analysis of Enhanced Geothermal System Reservoir Parameters and Fractures on Heat Recovery Efficiency Based on a Single-Phase Conduction Model. Processes 2025, 13, 1135. https://doi.org/10.3390/pr13041135

Luo Y, Wei J, Fu M, Fang L, Li X. Analysis of Enhanced Geothermal System Reservoir Parameters and Fractures on Heat Recovery Efficiency Based on a Single-Phase Conduction Model. Processes. 2025; 13(4):1135. https://doi.org/10.3390/pr13041135

Chicago/Turabian StyleLuo, Yuting, Juyan Wei, Meilong Fu, Li Fang, and Xudong Li. 2025. "Analysis of Enhanced Geothermal System Reservoir Parameters and Fractures on Heat Recovery Efficiency Based on a Single-Phase Conduction Model" Processes 13, no. 4: 1135. https://doi.org/10.3390/pr13041135

APA StyleLuo, Y., Wei, J., Fu, M., Fang, L., & Li, X. (2025). Analysis of Enhanced Geothermal System Reservoir Parameters and Fractures on Heat Recovery Efficiency Based on a Single-Phase Conduction Model. Processes, 13(4), 1135. https://doi.org/10.3390/pr13041135