Comparative Analysis of Microscopic Pore Throat Heterogeneity in the Chang 6 Tight Sandstone Reservoir: Implications for Production Dynamics and Development Strategies in the Wuqi-Dingbian Region, Ordos Basin

Abstract

1. Introduction

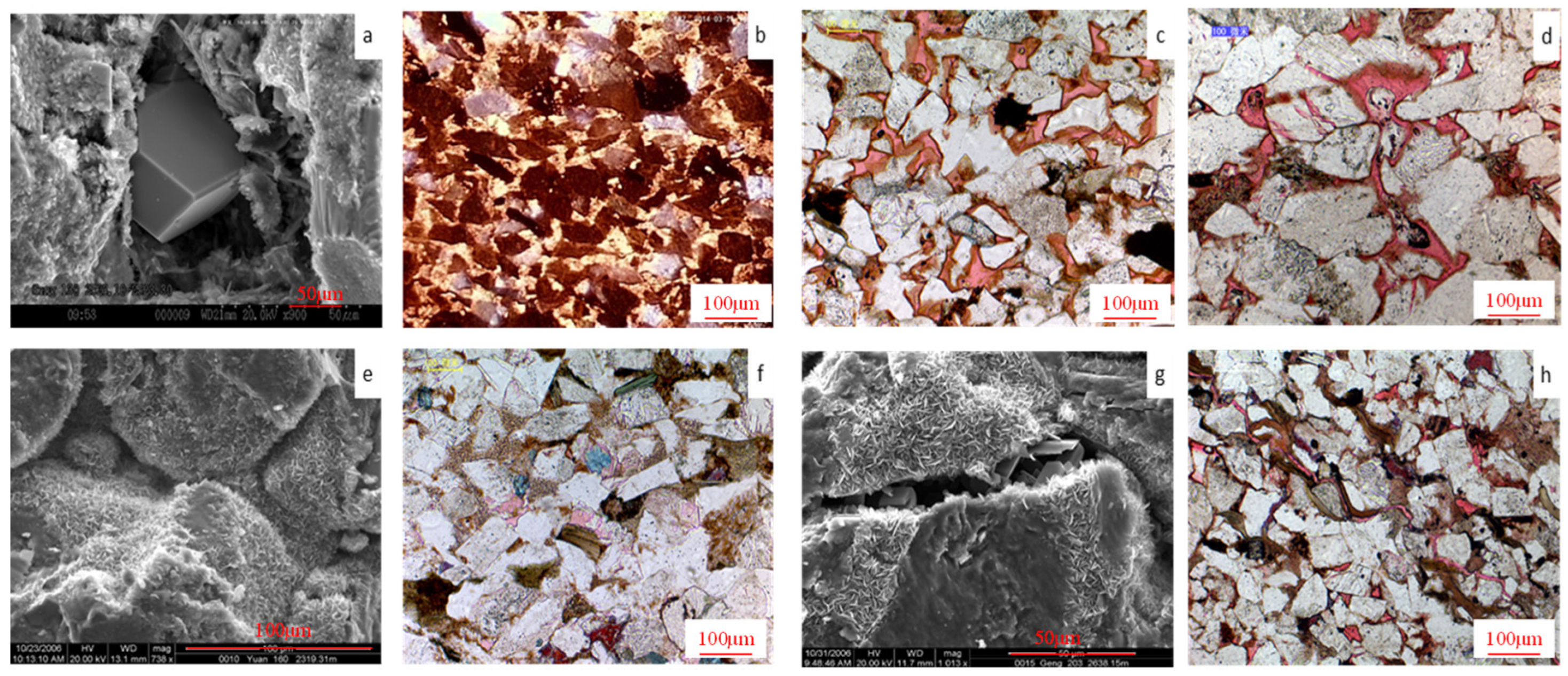

2. Sedimentary Petrological Characteristics

3. Pore Throat Structure and Reservoir Classification Evaluation

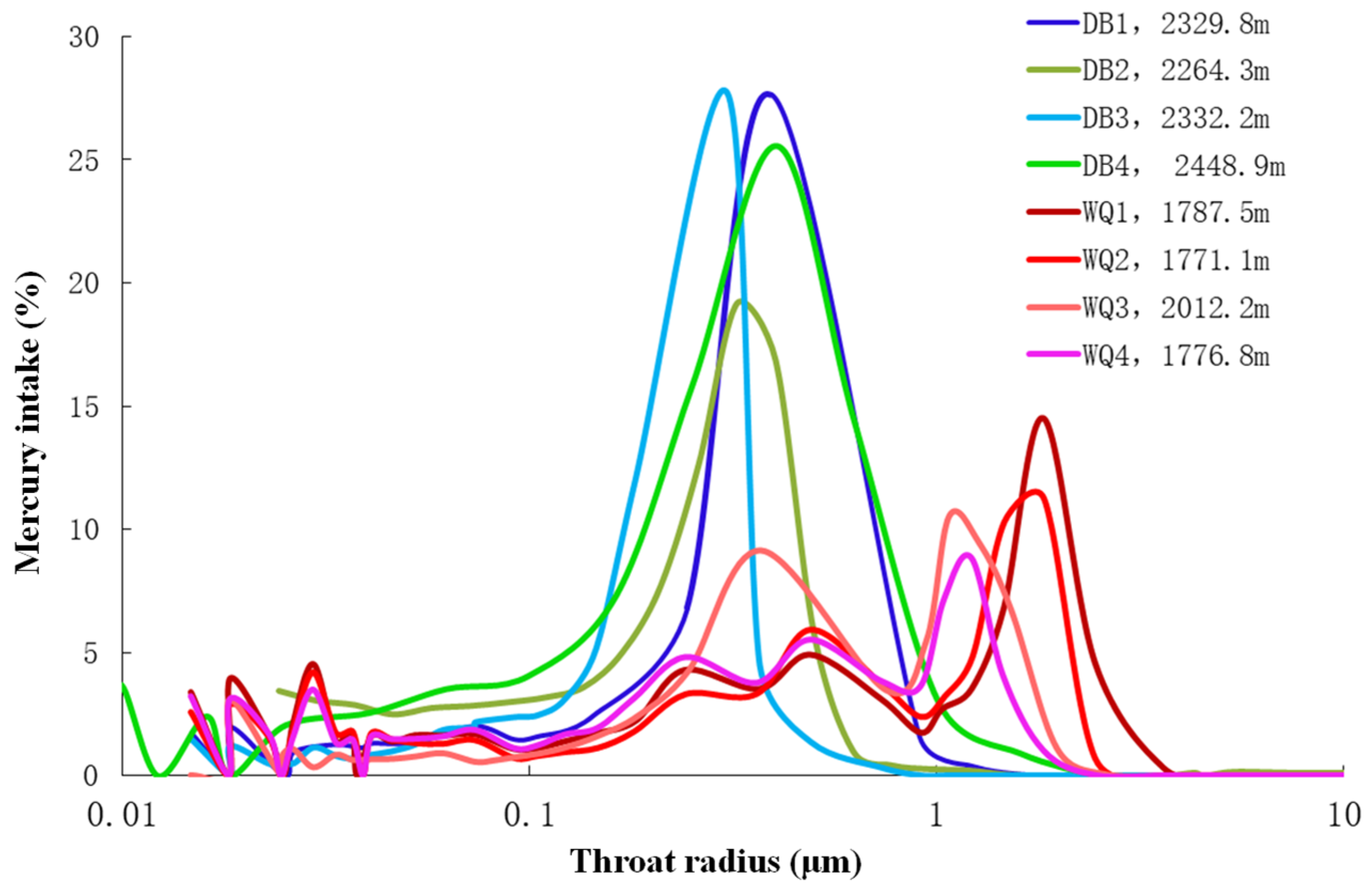

3.1. Pore Combination Type

3.2. Reservoir Classification Evaluation

- Higher proportion of premium reservoirs (Type I + II reservoirs: 67.6% vs. 57.7%).

- Enhanced productivity with Type I reservoirs yielding 15.8 tonnes/day, contrasting Dingbian’s 11.6 tonnes/day from Type II reservoirs.

4. The Influence of Different Reservoir Pore Throat Structures

4.1. The Impact on Reservoir Properties

4.2. Analysis of Differences in Capacity Characteristics

- The W block demonstrates a 73.2% effective displacement efficiency through optimized waterflood patterns (0.7 PV injected), sustaining 85% of initial productivity over a 12-month period.

- The D block requires specialized stimulation (multistage fracturing + nanofluid imbibition) to achieve 42.1% recovery efficiency, with 58% production decline within the first 6 months.

- NW-derived volcanic lithics (W block: 15.7 vol%) promote chlorite coating preservation (8–12% coverage) inhibiting quartz cementation.

- NE-sourced metamorphic fragments (D block: 6.3 vol%) enhance pressure dissolution, generating 18–22% tighter grain packing.

5. Conclusions

- (1)

- The Chang 6 reservoir in the Wu–Ding area of the Ordos Basin is characterized by well-sorted grains and moderate rounding. Kaolinite, chlorite, and calcite dominate its mineral composition. While the W and D blocks share similar petrological components, their contents differ significantly. Higher proportions of feldspar, clasts, and carbonate cementation in the D block enhance compaction and cementation, reducing original porosity. Residual intergranular and dissolution pores dominate the reservoir, with dissolution–intergranular and micro-pores being the primary pore types. The W block exhibits higher intergranular pore content and total specific pore volume than D block.

- (2)

- Based on capillary pressure curves and pore throat parameters, the Chang 6 reservoir is classified into four structural types. Type I and II reservoirs, predominant in the W block’s northeastern source system, feature low-to-moderate driving pressure, diverse throat sizes, high large-throat proportions, and favorable connectivity. Type III and IV reservoirs, with medium-to-high driving pressure and concentrated fine throats, show poorer mercury saturation and connectivity due to limited large pores.

- (3)

- Permeability strongly correlates with pore throat structure parameters. The W block’s reservoirs exhibit a broad, multi-peak throat distribution with higher large-pore proportions, enhancing flow capacity. In contrast, the D block’s narrow, single-trough throat distribution restricts permeability. The proportion of large throats is critical in low-permeability reservoirs, directly influencing macroscopic flow dynamics.

- (4)

- Microscopic pore structure significantly impacts reservoir productivity. The W block’s high water saturation and liquid yield, coupled with stable production, reflect its abundant large pores, favoring water injection efficiency. Conversely, the D block’s low water saturation, limited liquid yield, and rapid initial decline likely stem from narrow pore distribution and inadequate displacement pathways, hindering sustained production.

- (5)

- Variations in lithology, compaction, and pore structure under diverse geological conditions directly affect reservoir permeability and hydrocarbon migration. Effective development strategies must account for these structural differences. Tailored well networks and injection–production methods should be optimized based on reservoir-specific characteristics to maximize resource recovery and operational efficiency.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zou, C.; Qiu, Z.; Zhang, J.; Li, Z.; Wei, H.; Liu, B.; Wang, X.; Chen, G.; Yang, F.; Liu, Y.; et al. Unconventional petroleum sedimentology: A key to understanding unconventional hydrocarbon accumulation. Engineering 2022, 18, 62–78. [Google Scholar]

- Yao, J.; Deng, X.; Zhang, Y.; Hu, T.; Chen, M.; Pu, L. Characteristics of tight oil in Triassic Yanchang formation, Ordos Basin. Pet. Explor. Dev. 2013, 40, 161–169. [Google Scholar]

- Sun, Z.; Zhu, H.; Jiang, T.; Xu, C.; Yang, X.; Liu, Q.; Wang, L.; Chen, Y.; Zhang, W.; Li, J.; et al. Decoding the complex fluvial-lacustrine sedimentary interactions: Insights from the Neogene Guantao Formation in the Bohai Bay Basin and Modern Poyang Lake, China. Mar. Pet. Geol. 2024, 168, 107007. [Google Scholar] [CrossRef]

- Law, B.E.; Curtis, J.B. Introduction to unconventional petroleum systems. AAPG Bull. 2002, 86, 1851–1852. [Google Scholar]

- Clarkson, C.R.; Jensen, J.L.; Blasingame, T.A. Reservoir engineering for unconventional gas reservoirs: What do we have to consider? In SPE Unconventional Resources Conference/Gas Technology Symposium; SPE: The Woodlands, TX, USA, 2011; p. SPE-145080. [Google Scholar]

- Sun, L.; Zhu, R.; Zhang, T.; Cai, Y.; Feng, Z.; Bai, B.; Wang, D.; Liu, W.; Zhou, Q.; Chen, X.; et al. Advances and trends of non-marine shale sedimentology: A case study from Gulong Shale of Daqing Oilfield, Songliao Basin, NE China. Pet. Explor. Dev. 2024, 51, 1367–1385. [Google Scholar]

- Pan, J.; Liu, S.; Yang, Y.; Liu, L.; Zhang, J.; Chen, D. Study progress of origin of fine-grained sedimentary rocks in deep-water area of lacustrine basin: Taking Yangchang Formation in Ordos Basin as an example. Pet. Geol. Exp. 2014, 36, 706–711. [Google Scholar]

- Yang, J.; Yang, Y.; Dong, J. Sedimentation during the transgression period in late Triassic Yanchang formation, Ordos Basin. Pet. Explor. Dev. 2010, 37, 181–187. [Google Scholar]

- Wang, Q.; Zhuo, X.; Chen, G.; Shi, J.; Wang, D. Diagenetic evolution and high-quality reservoir in Chang 6 sandstone in the western Ordos Basin. Acta Pet. Sin. 2005, 26, 17–23. [Google Scholar]

- Zheng, R.; Wang, H.; Han, Y.; Wang, C.; Niu, X. Sedimentary facies characteristics and sandbody distribution of Chang 6 member in Jiyuan area of Ordos Basin. Lithol. Reserv. 2008, 20, 21–26. [Google Scholar]

- Wei, W.; Azmy, K.; Zhu, X. Impact of diagenesis on reservoir quality of the lacustrine mixed carbonate-siliciclastic-volcaniclastic rocks in China. J. Asian Earth Sci. 2022, 233, 105265. [Google Scholar]

- Gao, Y.; Wang, M.; Li, Y.; Jiang, Z.; Deng, Y.; Qin, J. Multi-scale pore structure characterization of lacustrine fine-grained mixed sedimentary rocks and its controlling factors: A case study of Lucaogou Formation in Jimusar Sag. Energy Fuels 2022, 37, 977–992. [Google Scholar] [CrossRef]

- Mahmoodabadi, R.M. Assessment of linking diagenesis history to sequence stratigraphy evidences (systems tract), (a case study: Sarvak Formation in one of the super oil fields, SW, IRAN). Carbonates Evaporites 2023, 38, 59. [Google Scholar] [CrossRef]

- Tong, Q.; He, D.; Xia, Z.; Huang, J.; Li, Y.; Xu, F.; Guo, S. Research on sand body architecture at the intersection of a bidirectional sedimentary system in the Jiyuan area of Ordos Basin. Sci. Rep. 2023, 13, 1226. [Google Scholar] [CrossRef]

- Yao, J.; Liu, L.; Yang, Y.; Sun, H.; Zhang, L. Characterizing multi-scale shale pore structure based on multi-experimental imaging and machine learning. Nat. Gas Ind. B 2023, 10, 361–371. [Google Scholar] [CrossRef]

- Zhao, C. Petrophysical Studies on Woodford Shale in Oklahoma and Wolfcamp Shale in Texas: A Multiple-Approach Methodology. Ph.D. Thesis, The University of Texas at Arlington, Arlington, TX, USA, 2022. [Google Scholar]

- Guan, D.; Xu, X.; Li, Z.; Zheng, L.; Tan, C.; Yao, Y.; Guan, D.; Xu, X.; Li, Z.; Zheng, L.; et al. Current Status of Hydrocarbon Generation from Source Rocks Theory. In Theory and Practice of Hydrocarbon Generation within Space-Limited Source Rocks; Springer: Berlin/Heidelberg, Germany, 2017; pp. 19–68. [Google Scholar]

- Zhen, Q.I.; Zhensheng, S.H.; Dazhong, D.O.; Bin, L.; Zhang, C.; Jie, Z.H.; Hongyan, W.A.; Xiong, B.; Zhenglian, P.A.; Hekun, G.U. Geological characteristics of source rock and reservoir of tight oil and its accumulation mechanism: A case study of Permian Lucaogou Formation in Jimusar sag, Junggar Basin. Pet. Explor. Dev. 2016, 43, 1013–1024. [Google Scholar]

- Zou, C.; Zhang, G.; Yang, Z.; Tao, S.; Hou, L.; Zhu, R.; Yuan, X.; Ran, Q.; Li, D.; Wang, Z. Concepts, characteristics, potential and technology of unconventional hydrocarbons: On unconventional petroleum geology. Pet. Explor. Dev. 2013, 40, 413–428. [Google Scholar] [CrossRef]

- Zhao, S.; Ding, R.; Tian, W.; Ye, J. Multiscale fine characterization of a coal pore-fracture system based on SEM, CT, and NMR in the Jingbian Block, Ordos Basin. Energies 2023, 16, 5315. [Google Scholar] [CrossRef]

- Zhang, Z.; Liao, J.; Li, Z. Prediction of oil production in a tight sandstone reservoir: Triassic Chang 9 Member, Jiyuan Area, Ordos Basin, NW China. Processes 2024, 12, 382. [Google Scholar] [CrossRef]

- Wang, K.; Guo, L.; Xu, C.; Wang, W.; Yang, T.; Lin, S.; Cai, Y. Multiscale characteristics of pore-fracture structures in coal reservoirs and their influence on coalbed methane (CBM) transport: A review. Geoenergy Sci. Eng. 2024, 242, 213181. [Google Scholar] [CrossRef]

- Tohidi, E.; Hesan, M.; Azad, A.; Abbasi, M.; Sadeghnejad, S. Implementing pore size distribution into saturation height function modelling of reservoir rock types: A case study on a carbonate gas reservoir. Gas Sci. Eng. 2024, 121, 205188. [Google Scholar] [CrossRef]

- Guo, T.; Li, X.; Ye, S.; Dong, X.; Wei, L.; Yang, Y. Theory and practice of unconventional gas exploration in carrier beds: Insight from the breakthrough of new type of shale gas and tight gas in Sichuan Basin, SW China. Pet. Explor. Dev. 2023, 50, 27–42. [Google Scholar]

- Li, H.; Black, J.R.; Hao, Y.; Hao, P.; Mishra, A.; Haese, R.R. Modelling diagenetic reactions and secondary porosity generation in sandstones controlled by the advection of low-molecular-weight organic acids. Basin Res. 2024, 36, e12860. [Google Scholar]

- Fu, J.; Li, S.; Liu, X.; Yang, S.; Luo, A.; Hui, X. Multi-layer composite accumulation mechanism and exploration significance of Jiyuan Oilfield, Ordos Basin. China Pet. Explor. 2013, 18, 1–9. [Google Scholar]

- Liu, W.; Zhou, L.; Gao, S. Fracture characteristics of the Triassic Yanchang formation in the midwest of Ordos Basin. Lithol. Reserv. 2012, 24, 66–71. [Google Scholar]

- Li, W.; Zhang, X.; Zhong, Y. Formation mechanism of secondary dissolved pores in arcose. Oil Gas Geol. 2005, 26, 220–223. [Google Scholar]

- Huang, X.; Gao, H.; Dou, L. Mircro pore structure and water-flooding characteristics on tight sandstone reservoir. J. China Univ. Pet. 2020, 44, 80–88. [Google Scholar]

- Yang, L.; Cheng, D.; Liu, B.; Bai, S. Reservoir classification and application based on mercury injection coefficient. Sci. Technol. Rev. 2014, 32, 46–50. [Google Scholar]

- Li, Y.; Zhang, Z.; Zhang, C. Application of mercury injection data to Chang 6 reservoir classification in Changqing area. Lithol. Reserv. 2009, 21, 91–93. [Google Scholar]

- Hu, M.; Shen, J.; Hu, D. Reservoir characteristics and its main controlling factors of the Pinghu Formation in Pinghu structural belt, Xihu Depression. Oil Gas Geol. 2013, 34, 185–191. [Google Scholar]

- Zhao, J.; Liu, Z.; Xie, Q.; Zhou, J. Micro pore throat structural classification of Chang-7 tight oil reservoir of Jiyuan Oilfield in Ordos Basin. China Pet. Explor. 2014, 19, 73–79. [Google Scholar]

| Area | Quartz (%) | Feldspar (%) | Debris (%) | Components of Interstitial Material (%) | Others (%) | Sample Quantity | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Igneous Debris | Metamorphic Rock Debris | Sedimentary Debris | Kaolinite | Hydromica | Chlorite | Network Clay | Calcite | Iron Calcite | Dolomite | Siliceous | |||||

| Wuqi | 25.30 | 45.14 | 2.50 | 6.18 | 1.21 | 1.55 | 2.32 | 3.54 | 0.27 | 0.69 | 2.25 | 0.64 | 1.31 | 7.10 | 385 |

| Dingbian | 31.53 | 35.49 | 2.50 | 6.54 | 1.71 | 3.26 | 1.95 | 2.92 | 0.17 | 0.32 | 3.77 | 0.67 | 1.25 | 7.93 | 450 |

| Average | 30.04 | 37.81 | 2.50 | 6.45 | 1.59 | 2.40 | 2.14 | 3.23 | 0.22 | 0.50 | 3.01 | 0.65 | 1.28 | 7.73 | 835 |

| Area | Intergranular Pore (%) | Emposieu (%) | Intercrystal Pore (%) | Microfracture (%) | Sample Quantity | |||

|---|---|---|---|---|---|---|---|---|

| Feldspar Dissolutio | Rock Fragment | Intergranular Dissolution Pore | Zeolite Dissolution Pore | |||||

| Wuqi | 57.98 | 30.96 | 3.94 | 0.66 | 0.34 | 3.09 | 3.03 | 386 |

| Dingbian | 55.14 | 34.01 | 5.75 | 1.11 | 0.1 | 2.32 | 1.57 | 453 |

| Reservoir Classification | Sample Quantity | Porosity (%) | Permeability (mD) | Displacement Pressure (MPa) | Maximum Connected Throat Radius (μm) | Median Pressure (MPa) | Median Radius (μm) | Sorting Coefficient | Ratio of Pore Throat Volume | Maximum SHg (%) | Mercury Removal Efficiency (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| I | 33 | 13.8 | 2.049 | 0.46 | 2.31 | 3.51 | 0.28 | 2.41 | 0.64 | 80.92 | 38.30 |

| II | 62 | 12.9 | 0.584 | 1.08 | 0.82 | 7.46 | 0.15 | 1.76 | 2.11 | 73.11 | 29.97 |

| III | 42 | 11.5 | 0.213 | 1.68 | 0.58 | 10.65 | 0.11 | 1.47 | 2.76 | 69.15 | 23.45 |

| IV | 14 | 8.2 | 0.081 | 4.43 | 0.30 | 19.30 | 0.06 | 1.21 | 3.58 | 59.60 | 17.46 |

| Average | 12.9 | 0.686 | 1.42 | 1.03 | 8.58 | 0.16 | 1.77 | 2.11 | 72.46 | 28.82 | |

| Block | Porosity (%) | Permeability (mD) | Proportion of Type I + Type II Reservoirs | Proportion of Type III + Type IV Reservoirs |

|---|---|---|---|---|

| Northeast provenance (W area) | 12.85 | 0.642 | 0.64 | 80.92 |

| Northwest provenance (D area) | 12.34 | 0.415 | 2.11 | 73.11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Wang, M.; Li, Y.; Yuan, K.; Liu, L.; Meng, L. Comparative Analysis of Microscopic Pore Throat Heterogeneity in the Chang 6 Tight Sandstone Reservoir: Implications for Production Dynamics and Development Strategies in the Wuqi-Dingbian Region, Ordos Basin. Processes 2025, 13, 1109. https://doi.org/10.3390/pr13041109

Li J, Wang M, Li Y, Yuan K, Liu L, Meng L. Comparative Analysis of Microscopic Pore Throat Heterogeneity in the Chang 6 Tight Sandstone Reservoir: Implications for Production Dynamics and Development Strategies in the Wuqi-Dingbian Region, Ordos Basin. Processes. 2025; 13(4):1109. https://doi.org/10.3390/pr13041109

Chicago/Turabian StyleLi, Jun, Mingwei Wang, Yan Li, Kaitao Yuan, Liang Liu, and Lingdong Meng. 2025. "Comparative Analysis of Microscopic Pore Throat Heterogeneity in the Chang 6 Tight Sandstone Reservoir: Implications for Production Dynamics and Development Strategies in the Wuqi-Dingbian Region, Ordos Basin" Processes 13, no. 4: 1109. https://doi.org/10.3390/pr13041109

APA StyleLi, J., Wang, M., Li, Y., Yuan, K., Liu, L., & Meng, L. (2025). Comparative Analysis of Microscopic Pore Throat Heterogeneity in the Chang 6 Tight Sandstone Reservoir: Implications for Production Dynamics and Development Strategies in the Wuqi-Dingbian Region, Ordos Basin. Processes, 13(4), 1109. https://doi.org/10.3390/pr13041109