The Effect of Chromium on the Microstructure and Transparency of Diamond-like Carbon Films

Abstract

1. Introduction

2. Materials and Methods

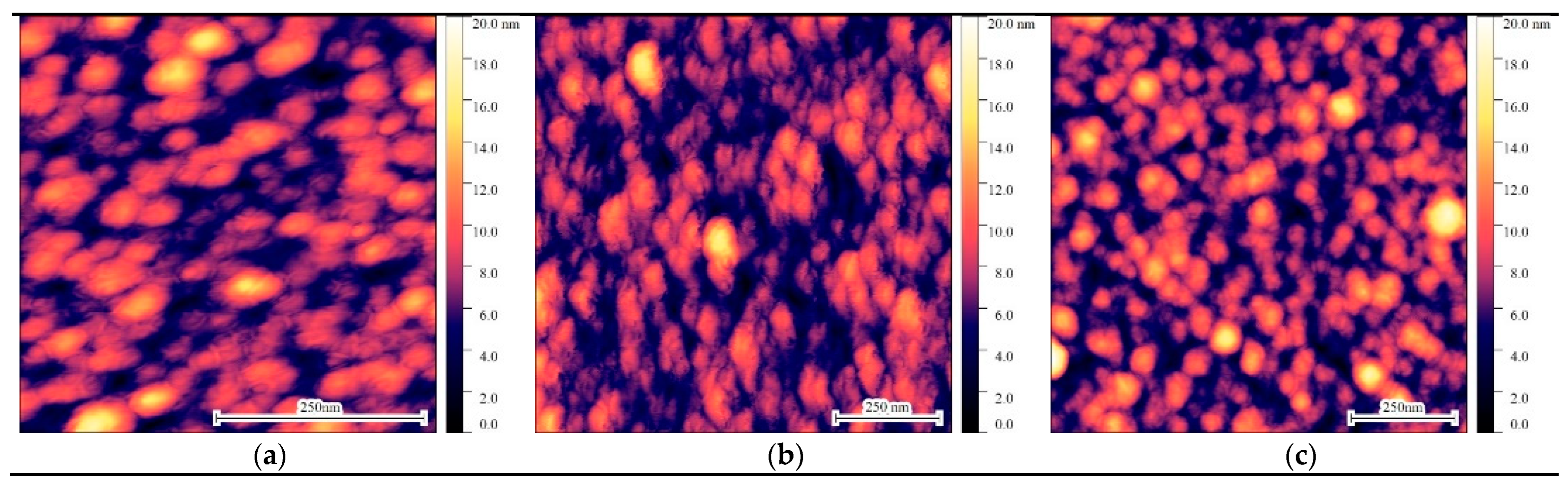

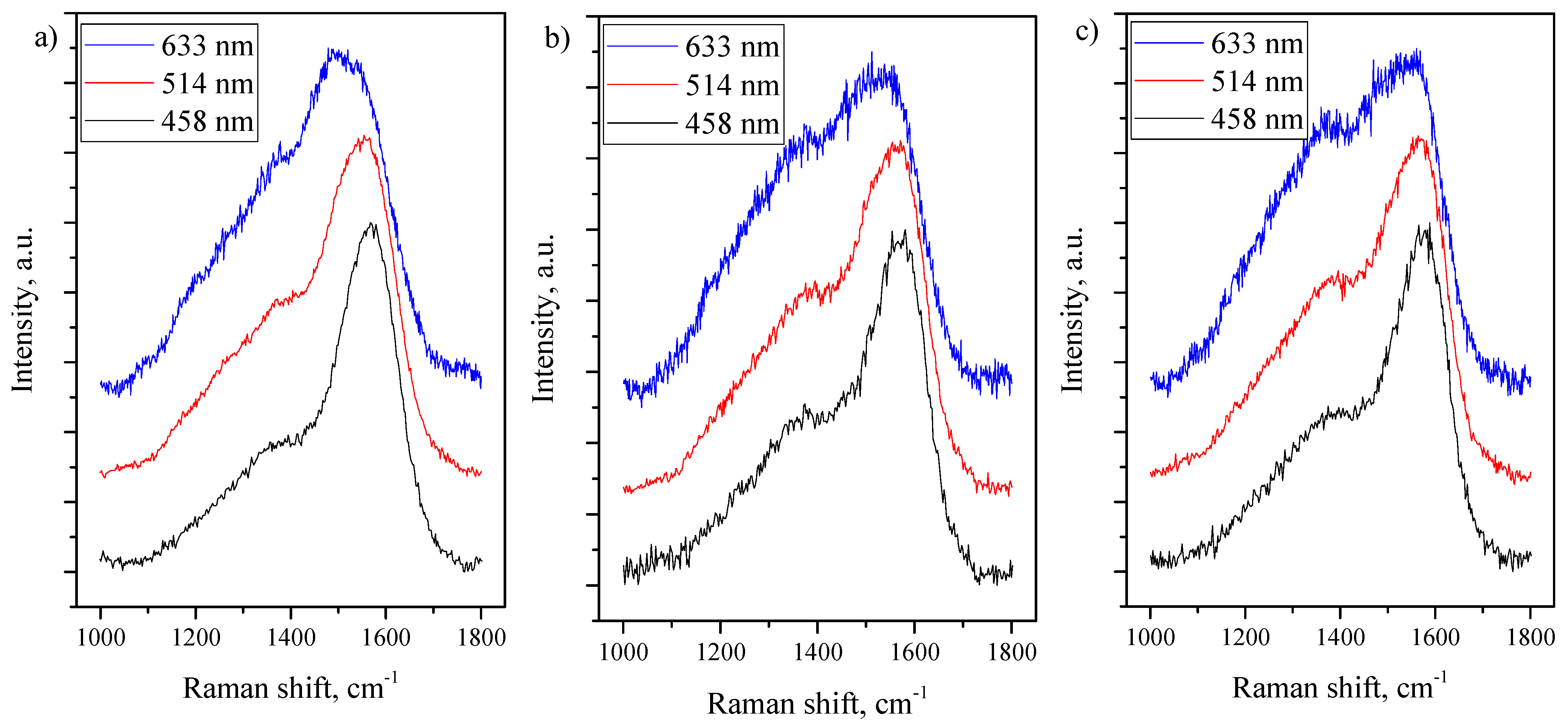

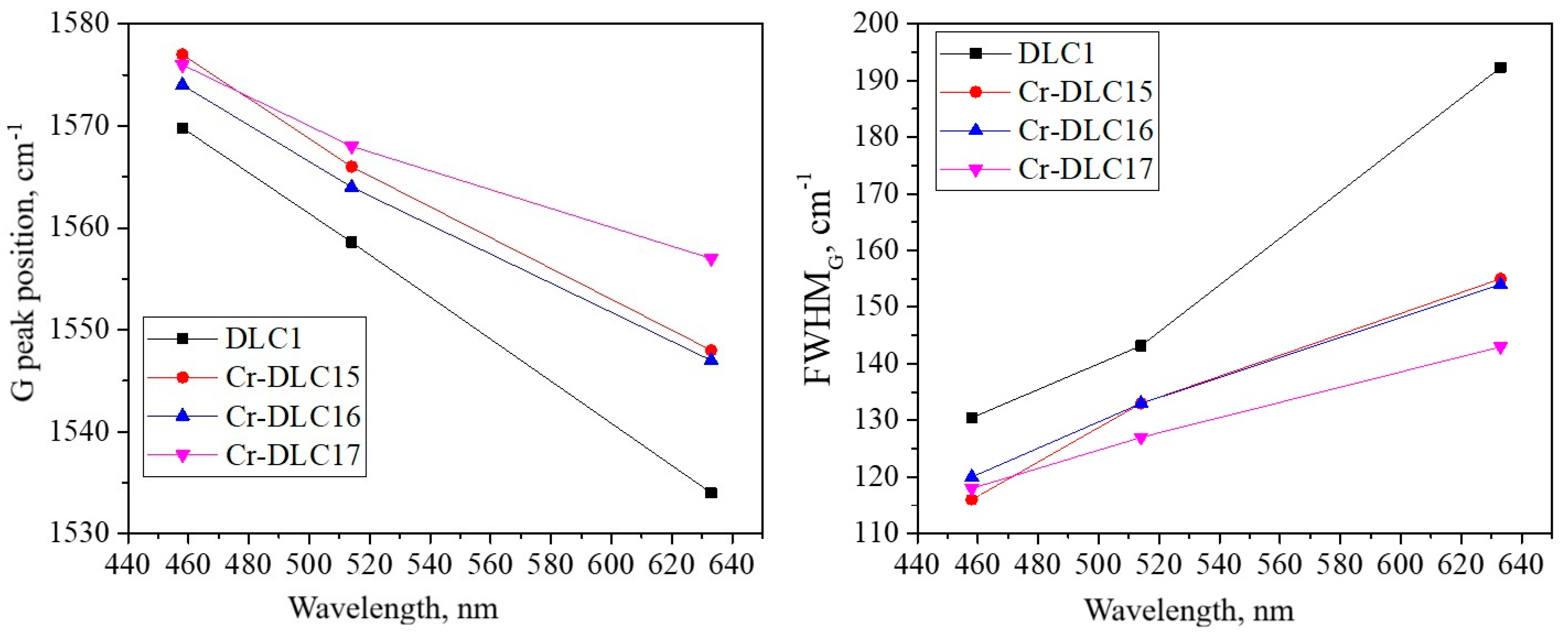

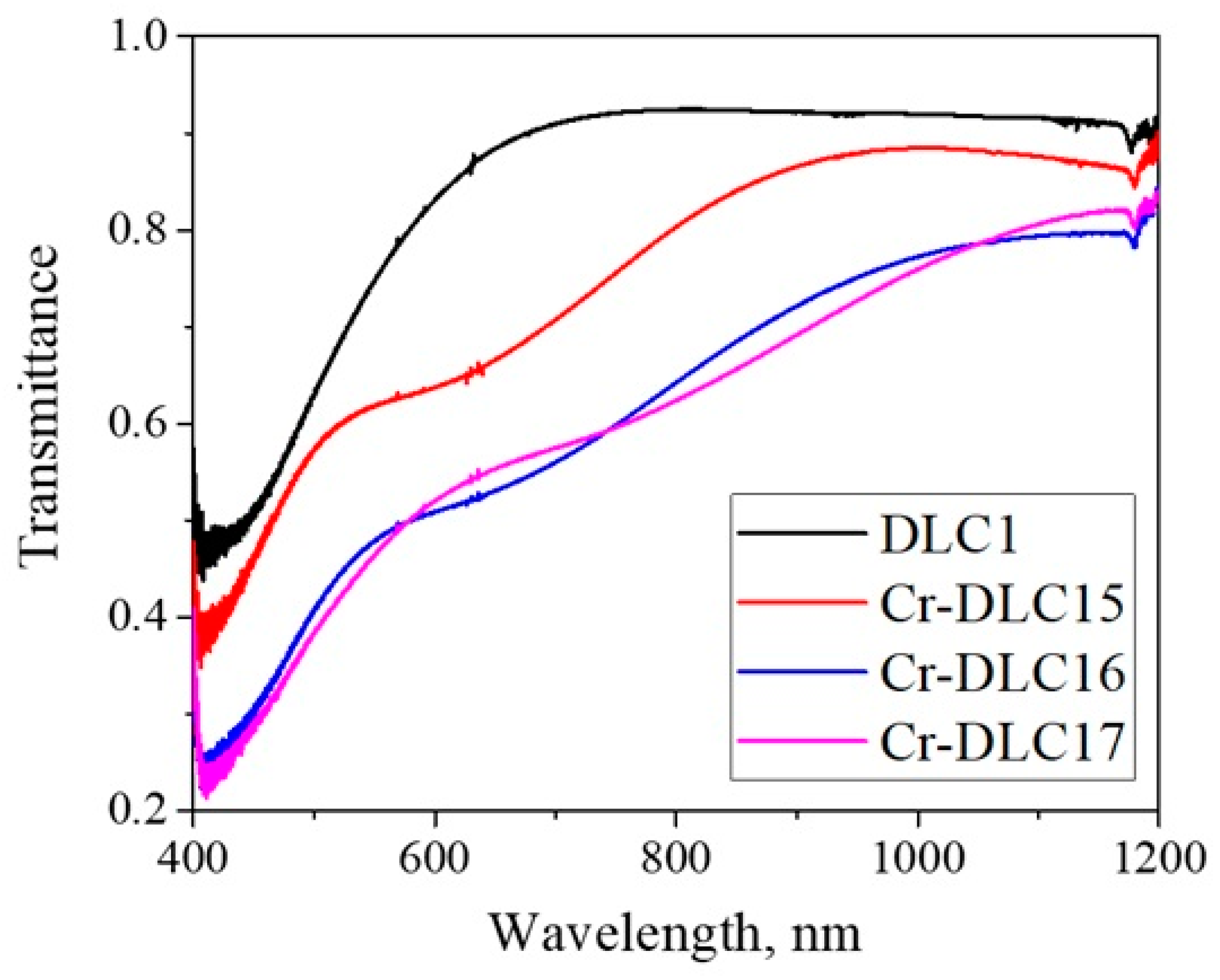

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ohtake, N.; Hiratsuka, M.; Kanda, K.; Akasaka, H.; Tsujioka, M.; Hirakuri, K.; Hirata, A.; Ohana, T.; Inaba, H.; Kano, M.; et al. Properties and Classification of Diamond-Like Carbon Films. Materials 2021, 14, 315. [Google Scholar] [CrossRef] [PubMed]

- Bewilogua, K.; Hofmann, D. History of diamond-like carbon films—From first experiments to worldwide applications. Surf. Coat. Technol. 2014, 242, 214–225. [Google Scholar] [CrossRef]

- Vetter, J. 60 years of DLC coatings: Historical highlights and technical review of cathodic arc processes to synthesize various DLC types, and their evolution for indus-trial applications. Surf. Coat. Technol. 2014, 257, 213–240. [Google Scholar]

- Sharifahmadian, O.; Pakseresht, A.; Mosas, K.K.A.; Galusek, D. Doping effects on the tribological performance of diamond-like carbon coatings: A review. J. Mater. Res. Technol. 2023, 27, 7748–7765. [Google Scholar] [CrossRef]

- Liu, J.; Yang, T.; Cao, H.; Deng, Q.; Pan, C.; Wen, F. Diamond-like Carbon Films for Tribological Modification of Rubber. Nanotechnol. Rev. 2022, 11, 2839–2856. [Google Scholar]

- Sánchez-López, J.C.; Fernández, A. Doping and Alloying Effects on DLC Coatings. In Tribology of Diamond-Like Carbon Films: Fundamentals and Applications; Donnet, C., Erdemir, A., Eds.; Springer: Berlin, Germany, 2008; pp. 311–338. [Google Scholar]

- Sun, H.; Yang, L.; Wu, H.; Zhao, L. Effects of Element Doping on the Structure and Properties of Diamond-like Carbon Films: A Review. Lubricants 2023, 11, 186. [Google Scholar] [CrossRef]

- Santiago, J.; Fernández-Martínez, I.; Sánchez-López, J.; Rojas, T.; Wennberg, A.; Bellido-González, V.; Molina-Aldareguia, J.; Monclús, M.; González-Arrabal, R. Tribomechanical properties of hard Cr-doped DLC coatings deposited by low-frequency HiPIMS. Surf. Coat. Technol. 2020, 382, 124899. [Google Scholar] [CrossRef]

- Li, L.; Song, W.; Liu, J.; Liu, Q.; Wang, S.; Zhang, G. Tribology International Nanomechanical and nanotribological behavior of ultra-thin silicon-doped diamond-like carbon films. Tribiol. Int. 2016, 94, 616–623. [Google Scholar] [CrossRef]

- Dai, W.; Wang, A. Synthesis, characterization and properties of the DLC films with low Cr concentration doping by a hybrid linear ion beam system. Surf. Coat. Technol. 2011, 205, 2882–2886. [Google Scholar] [CrossRef]

- Zheng, J.; Shang, J.; Zhuang, W.; Ding, J.C.; Mei, H.; Yang, Y.; Ran, S. Structural and tribomechanical properties of Cr-DLC films deposited by reactive high power impulse magnetron sputtering. Vacuum 2024, 230, 113611. [Google Scholar] [CrossRef]

- Khodayari, A.; Elmkhah, H.; Alizadeh, M.; Maghsoudipour, A. Modified dia-mond-like carbon (Cr-DLC) coating applied by PACVD-CAPVD hybrid method: Characterization and evaluation of tribological and corrosion behavior. Diam. Relat. Mater. 2023, 136, 109968. [Google Scholar] [CrossRef]

- Wang, L.; Wu, Y.; Yu, S.; Liu, Y.; Shi, B.; Hu, E.; Hei, H. Investigation of hydrophobic and anti-corrosive behavior of Cr-DLC film on stainless steel bipolar plate. Diam. Relat. Mater. 2022, 129, 109352. [Google Scholar] [CrossRef]

- Zou, C.; Wang, H.; Feng, L.; Xue, S. Effects of Cr concentrations on the microstructure, hardness, and temperature-dependent tribological properties of Cr-DLC coatings. Appl. Surf. Sci. 2013, 286, 137–141. [Google Scholar] [CrossRef]

- Dai, W.; Ke, P.; Wang, A. Microstructure and property evolution of Cr-DLC films with different Cr content deposited by a hybrid beam technique. Vacuum 2011, 85, 792–797. [Google Scholar] [CrossRef]

- Viswanathan, S.; Mohan, L.; Bera, P.; Kumar, V.P.; Barshilia, H.C.; Anandan, C. Corrosion and Wear Behaviors of Cr-Doped Diamond-Like Carbon Coatings. J. Mater. Eng. Perform. 2017, 26, 3633–3647. [Google Scholar] [CrossRef]

- Zhuang, Y.; Jiang, X.; Rogachev, A.; Piliptsou, D.; Ye, B.; Liu, G.; Zhou, T.; Rudenkov, A. Influences of pulse frequency on the structure and anti-corrosion properties of the a-C:Cr films. Appl. Surf. Sci. 2015, 351, 1197–1203. [Google Scholar] [CrossRef]

- Gayathri, S.; Kumar, N.; Krishnan, R.; Ravindran, T.; Dash, S.; Tyagi, A.; Sridharan, M. Influence of Cr content on the micro-structural and tribological properties of PLD grown nanocomposite DLC-Cr thin films. Mater. Chem. Phys. 2015, 167, 194–200. [Google Scholar] [CrossRef]

- Liu, S.; Zhuang, W.; Ding, J.; Liu, Y.; Yu, W.; Yang, Y.; Liu, X.; Yuan, J.; Zheng, J. Fabrication and Tribological Properties of Diamond-like Carbon Film with Cr Doping by High-Power Impulse Magnetron Sputtering. Coatings 2024, 14, 916. [Google Scholar] [CrossRef]

- Li, G.; Xu, Y.; Xia, Y. Effect of Cr Atom Plasma Emission Intensity on the Characteristics of Cr-DLC Films Deposited by Pulsed-DC Magnetron Sputtering. Coatings 2020, 10, 608. [Google Scholar] [CrossRef]

- Mohammadinia, E.; Elahia, S.M.; Shahid, S. Structural and optical properties of Ni-embedded hydrogenated diamondlike carbon (Ni-DLC) prepared by co-deposition of RF-Sputtering and RF-PECVD method. Mater. Sci. Semicond. Process. 2018, 74, 7–12. [Google Scholar] [CrossRef]

- Zhou, B.; Liu, Z.; Piliptsou, D.; Yu, S.; Wang, Z.; Rogachev, A.; Rudenkov, A.; Balmakou, A. Structure and optical properties of Cu-DLC composite films deposited by cathode arc with double-excitation source. Diam. Relat. Mater. 2016, 69, 191–197. [Google Scholar] [CrossRef]

- Moghadam, R.Z.; Dizaji, H.R.; Ehsani, M.H.; Kameli, P.; Jannesari, M. Correlation study of structural, optical, and hydrophobicity properties of diamond-like carbon films prepared by an anode layer source. Mater. Res. Express. 2019, 6, 055601. [Google Scholar] [CrossRef]

- Meškinis, Š.; Vasiliauskas, A.; Andrulevičius, M.; Peckus, D.; Tamulevičius, S.; Viskontas, K. Diamond Like Carbon Films Containing Si: Structure and Nonlinear Optical Properties. Materials 2020, 13, 1003. [Google Scholar] [CrossRef] [PubMed]

- Qi, M.; Xiao, J.; Cheng, Y.; Wang, Z.; Jiang, A.; Guo, Y.; Tao, Z. Effect of various nitrogen flow ratios on the optical properties of (Hf:N)-DLC films prepared by reactive magnetron sputtering. AIP Adv. 2017, 7, 085012. [Google Scholar] [CrossRef]

- Kijaszek, W.; Wiatrowski, A.; Mazur, M.; Wojcieszak, D.; Paszkiewicz, R.; Kovac, J., Jr. Study on properties of diamond-like carbon films deposited by RF ICP PECVD method for micro- and optoelectronic applications. Mater. Sci. Eng. B 2023, 296, 116691. [Google Scholar] [CrossRef]

- Boubiche, N.; El Hamouchi, J.; Hulik, J.; Abdesslam, M.; Speisser, C.; Djeffal, F.; Le Normand, F. Kinetics of graphitization of thin diamond-like carbon (DLC) films catalyzed by transition metal. Diam. Relat. Mater. 2019, 91, 190–198. [Google Scholar] [CrossRef]

- Dovydaitis, V.; Marcinauskas, L.; Ayala, P.; Gnecco, E.; Chimborazo, J.; Zhairabany, H.; Zabels, R. The Influence of Cr and Ni Doping on the Microstructure of Oxygen Containing Diamond-like Carbon Films. Vacuum 2021, 191, 110351. [Google Scholar] [CrossRef]

- Zhairabany, H.; Khaksar, H.; Vanags, E.; Marcinauskas, L. Effect of Molybdenum Concentration and Deposition Temperature on the Structure and Tribological Properties of the Diamond-like Carbon Films. Crystals 2024, 14, 962. [Google Scholar] [CrossRef]

- Park, Y.S.; Jung, T.H.; Lim, D.G.; Park, Y.; Kim, H.; Choi, W.S. Tribological properties of metal doped a-C film by RF magnetron sputtering method. Mater. Res. Bull. 2012, 47, 2784–2787. [Google Scholar] [CrossRef]

- Wu, Z.; Tian, X.; Gui, G.; Gong, C.; Yang, S.; Chu, P.K. Microstructure and surface properties of chromium-doped diamond-like carbon thin films fabricated by high power pulsed magnetron sputtering. Appl. Surf. Sci. 2013, 276, 31–36. [Google Scholar] [CrossRef]

- Jastrzębski, K.; Grabarczyk, J.; Niedzielski, P.; Jędrzejczak, A.; Sobczyk-Guzenda, A.; Szymański, W.; Kamińska, M.; Skibska, B. The Doping of a Carbon Coating with Phosphorus as a Potential Way of Improving the Biological Properties of Diamond-like Carbon. Materials 2024, 17, 5859. [Google Scholar] [CrossRef]

- Dong, H.; He, S.; Wang, X.; Zhang, C.; Sun, D. Study on conductivity and corrosion resistance of N-doped and Cr/N co-doped DLC films on bipolar plates for PEMFC. Diam. Relat. Mater. 2020, 110, 108156. [Google Scholar] [CrossRef]

- Li, Z.; Ma, G.; Zhang, Z.; Shi, J.; He, T.; Han, C.; Xing, Z.; Wang, H. Vacuum tribological properties in Cr-doped H-DLC self-lubricating radial spherical plain bearings. Diam. Relat. Mater. 2024, 141, 110694. [Google Scholar] [CrossRef]

- Písařík, P.; Jelínek, M.; Kocourek, T.; Zezulová, M.; Remsa, J.; Jurek, K. Chromium-doped diamond-like carbon films deposited by dual-pulsed laser deposition. Appl. Phys. A 2014, 117, 83–88. [Google Scholar] [CrossRef]

- Mi, B.; Wang, H.; Wang, Q.; Cai, J.; Qin, Z.; Chen, Z. Corrosion resistance and contact resistance properties of Cr-doped amorphous carbon films deposited under different carbon target current on the 316L stainless steel bipolar plate for PEMFC. Vacuum 2022, 203, 111263. [Google Scholar] [CrossRef]

- Savchenko, D.; Vorlíček, V.; Prokhorov, A.; Kalabukhova, E.; Lančok, J.; Jelínek, M. Raman and EPR spectroscopic studies of chromium-doped diamond-like carbon films. Diam. Relat. Mater. 2018, 83, 30–37. [Google Scholar] [CrossRef]

- Assembayeva, A.; Ryaguzov, A.; Nemkayeva, R.; Guseinov, N.; Myrzabekova, M. Research of the structure of a-C films by the Raman spectroscopy method. Mater. Today Proc. 2019, 25, 58–63. [Google Scholar] [CrossRef]

- Evaristo, M.; Azevedo, R.; Palacio, C.; Cavaleiro, A. Influence of the silicon and oxygen content on the properties of non-hydrogenated amorphous carbon coatings. Diam. Relat. Mater. 2016, 70, 201–210. [Google Scholar] [CrossRef]

- Mi, B.; Wang, Q.; Xu, Y.; Qin, Z.; Chen, Z.; Wang, H. Improvement in Corrosion Resistance and Interfacial Contact Resistance Properties of 316L Stainless Steel by Coating with Cr, Ti Co-Doped Amorphous Carbon Films in the Environment of the PEMFCs. Molecules 2023, 28, 2821. [Google Scholar] [CrossRef]

- Braca, E.; Saraceni, G.; Kenny, J.M.; Lozzi, L.; Santucci, S. Structural and optical properties of nitrogen and oxygen doped a-C:H coatings. Thin Solid Films 2002, 415, 195–200. [Google Scholar] [CrossRef]

- Mikhchin, A.; Hosseini, S.I.; Abadi, S.K.N.; Mohammadhosseini, B.; Mehrabian, S. Tuning the optical, electrical, and structural properties of Cu-DLC thin films via simultaneous DC-RF unbalanced magnetron sputtering. Heliyon 2024, 10, e40171. [Google Scholar] [CrossRef] [PubMed]

- Kundoo, S.; Kar, S. Nitrogen and Boron Doped Diamond Like Carbon Thin Films Synthesis by Electrodeposition from Organic Liquids and Their Characterization. Adv. Mater. Phys. Chem. 2013, 3, 25–32. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dovydaitis, V.; Milieška, M.; Chimborazo, J.; Gnecco, E.; Marcinauskas, L. The Effect of Chromium on the Microstructure and Transparency of Diamond-like Carbon Films. Processes 2025, 13, 1098. https://doi.org/10.3390/pr13041098

Dovydaitis V, Milieška M, Chimborazo J, Gnecco E, Marcinauskas L. The Effect of Chromium on the Microstructure and Transparency of Diamond-like Carbon Films. Processes. 2025; 13(4):1098. https://doi.org/10.3390/pr13041098

Chicago/Turabian StyleDovydaitis, Vilius, Mindaugas Milieška, Johnny Chimborazo, Enrico Gnecco, and Liutauras Marcinauskas. 2025. "The Effect of Chromium on the Microstructure and Transparency of Diamond-like Carbon Films" Processes 13, no. 4: 1098. https://doi.org/10.3390/pr13041098

APA StyleDovydaitis, V., Milieška, M., Chimborazo, J., Gnecco, E., & Marcinauskas, L. (2025). The Effect of Chromium on the Microstructure and Transparency of Diamond-like Carbon Films. Processes, 13(4), 1098. https://doi.org/10.3390/pr13041098