Optimization of Fermentation Parameters in a Brewery: Modulation of Yeast Growth and Yeast Cell Viability

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Set-Up

2.2. Analytical Procedures

2.3. Statistical Analyses

Optimization of Growth and Viability of Yeast Cells

3. Results and Discussion

3.1. Yeast Growth (Multiplication) in the Fermentation Process

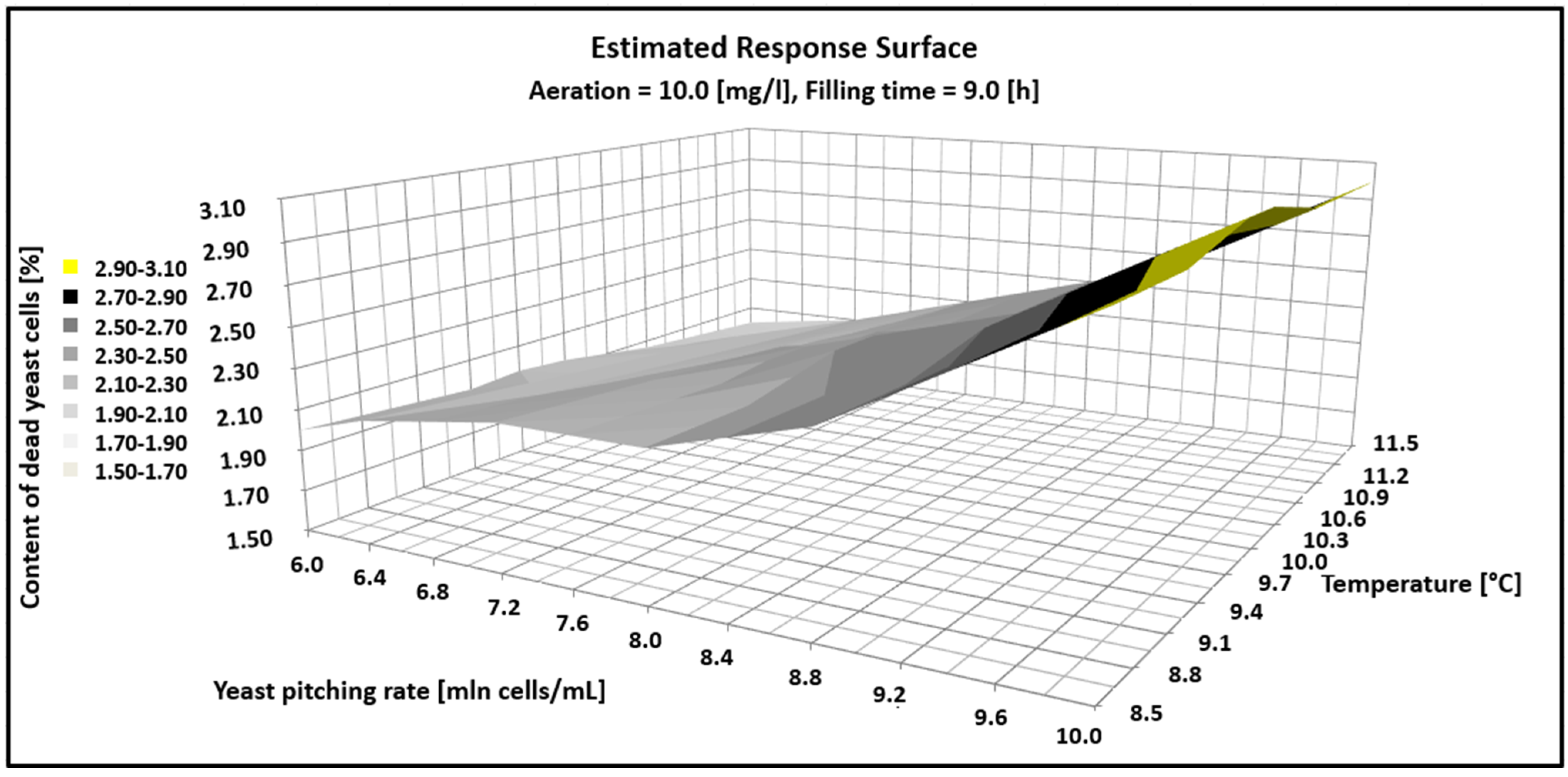

3.2. Yeast Viability in the Fermentation Process

3.3. Yeast Growth and Viability in the Industrial Fermentation Process—Validating Experiment

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Albergaria, H.; Arneborg, N. Dominance of Saccharomyces Cerevisiae in Alcoholic Fermentation Processes: Role of Physiological Fitness and Microbial Interactions. Appl. Microbiol. Biotechnol. 2016, 100, 2035–2046. [Google Scholar] [CrossRef] [PubMed]

- Lodolo, E.; Kocks, J.; Axcell, B.; Brooks, M. The yeast Saccharomyces cerevisiae the main character in beer brewing. FEMS Yeast Res. 2008, 8, 1018–1036. [Google Scholar] [CrossRef]

- Kucharczyk, K.; Tuszyński, T. The effect of wort aeration on fermentation, maturation and volatile components of beer produced on an industrial scale. J. Inst. Brew. 2017, 123, 31–38. [Google Scholar] [CrossRef]

- Alves, V.; Gonçalves, J.; Figueira, J.A.; Ornelas, L.P.; Branco, R.N.; Câmara, J.S.; Pereira, J.A.M. Beer volatile fingerprinting at different brewing steps. Food Chem. 2020, 326, 126856. [Google Scholar] [CrossRef]

- Hebbly, M.; Brickwedde, A.; Bolat, I.; Driessen, M.R.M.; de Hulster, E.A.F.; van den Broek, M.; Daran-Lapujade, P. S. cerevisiae × S. eubayanus interspecific hybrid, the best of both worlds and beyond. FEMS Yeast Res. 2015, 15, fov005. [Google Scholar] [CrossRef] [PubMed]

- Urbina, K.; Villarreal, P.; Nespolo, R.F.; Salazar, R.; Santander, R.; Cubillos, F.A. Volatile compound screening using HS-SPME-GC/MS on Saccharomyces eubayanus strains under low-temperature pilsner wort fermentation. Microorganisms 2020, 8, 755. [Google Scholar] [CrossRef]

- Goldammer, T. The Brewer’s Handbook, 3rd ed.; Apex Publishers: Haymarket, VA, USA, 2022; Chapter 4. [Google Scholar]

- Bogacka, E.; Diowksz, A. Physiological state of reused brewing yeast. Czech J. Food Sci. 2013, 3, 264–269. [Google Scholar] [CrossRef]

- Lorizzo, M.; Coppola, F.; Letizia, F.; Testa, B.; Sorrentiono, E. Role of yeasts in the brewing process: Tradition and innovation. Processes 2021, 9, 839. [Google Scholar] [CrossRef]

- Raihofer, L.; Zarnow, M.; Gastl, M.; Hutzler, M. A short history of beer brewing: Alcoholic fermentation and yeast technology over time. Embo Rep. 2022, 23, e56355. [Google Scholar] [CrossRef]

- Wang, J.; Diny, H.; Zheng, F.; Li, Y.; Liu, C.; Niu, C.; Li, Q. Physiological changes of beer brewer’s yeast during serial beer fermentation. J. Am. Soc. Brew. Chem. 2019, 1, 10–20. [Google Scholar] [CrossRef]

- Chen, H.; Fujita, M.; Feng, Q.; Clardy, J.; Fink, G.R. Tyrosol is a quorum-sensing molecule in Candida albicans. Proc. Natl. Acad. Sci. USA 2004, 101, 5048–5052. [Google Scholar] [CrossRef] [PubMed]

- Chen, A.; Si, Q.; Xu, Q.; Pan, C.; Qu, T.; Chen, J. Evaluation of stress tolerance and fermentation performance in commercial yeast strains for industrial applications. Foods 2025, 14, 142. [Google Scholar] [CrossRef] [PubMed]

- Guan, Y.; Xu, X.; Liu, C.; Wang, J.; Niu, C.; Zheng, F. Evaluating the physiology and fermentation performance of the lager yeast during very increased temperature. LWT 2023, 173, 114312. [Google Scholar] [CrossRef]

- Solgajová, M.; Francáková, H.; Dráb, S.; Tóth, Ž. Effect of temperature on the process of primary fermentation. J. Microb. Biotech. Food. Sci. 2013, 2, 1791–1799. [Google Scholar]

- Guadalupe-Daqui, M.; Chen, M.; Thompson-Witrick, K.; MacIntosh, A. Yeast morphology assessment through automated image analysis during fermentation. Fermentation 2021, 7, 44. [Google Scholar] [CrossRef]

- Guadalupe-Daqui, M.; Chen, M.; Sarnoski, P.; Goodrich-Schneider, R.; MacIntosh, A. Impact of reduced (vacuum) pressure on yeast fermentation as assessed using standard methods and automated image analysis. Fermentation 2023, 9, 155. [Google Scholar] [CrossRef]

- Lara, J.; Dewasme, L.; Escoto, H.; Wouwer, A. Parameter estimation of dynamic beer fermentation models. Foods 2022, 11, 3602. [Google Scholar] [CrossRef]

- Verbelen, P.; Saerens, S.; Mulders, S.; Delvaux, F.; Delvaux, R. The role of oxygen in yeast metabolism during high cell density brewery fermentations. Appl. Microbiol. Cell Physiol. 2009, 82, 1143–1156. [Google Scholar] [CrossRef]

- Kalayu, G. Serial re-pitching: Its effect on yeast physiology, fermentation performance, and product quality. Ann. Microbiol. 2019, 69, 787–796. [Google Scholar] [CrossRef]

- Kucharczyk, K.; Tuszyński, T. Effect of wort filling time on fermentation, maturation and acetaldehyde content in beer. Czech J. Food Sci. 2016, 34, 265–270. [Google Scholar] [CrossRef]

- Yokoyama, A.; Ingledew, W. The effect of filling procedures on multi-fill fermentations. Tech. Q. Master Brew. Assoc. Am. 1997, 34, 320–327. [Google Scholar]

- Bellut, K.; Michel, M.; Zarnkow, M.; Hutzler, M.; Jacob, F.; Atzler, J.J.; Hoehnel, A.; Lynch, K.M.; Arendt, E.K. Screening and Application of Cyberlindnera Yeasts to Produce a Fruity, Non-Alcoholic Beer. Fermentation 2019, 5, 103. [Google Scholar] [CrossRef]

- Michel, M.; Meier-Dörnberg, T.; Jacob, F.; Schneiderbanger, H.; Haselbeck, K.; Zarnkow, M.; Hutzler, M. Optimization of Beer Fermentation with a Novel Brewing Strain Torulaspora delbrueckii Using Response Surface Methodology. Master Brew. Assoc. Am. Tech. Q. 2017, 54, 23–33. [Google Scholar]

- Puerari, C.; Strejc, J.; Souza, A.C.; Karabín, M.; Schwan, R.F.; Brányik, T. Optimization of alcohol-free beer production by lager and cachaça yeast strains using response surface methodology. J. Instig. Brew. 2016, 122, 69–75. [Google Scholar] [CrossRef]

- Kucharczyk, K.; Żyła, K.; Tuszyński, T. Simultaneous optimization of acetaldehyde and DMS concentration for better quality of beer fermented on an industrial scale. Foods 2020, 9, 1043. [Google Scholar] [CrossRef] [PubMed]

- Kwolek-Mirek, M.; Zadrag-Tęcza, R. Comparison of methods used for assessing the viability and vitality of yeast cells. FEMS Yeast Res. 2014, 14, 1068–1079. [Google Scholar] [CrossRef]

- Available online: https://chemometec.com/nucleocounters/nc-200/ (accessed on 6 January 2025).

- Nguyen, T.; Viet Man, L.V. Using high pitching rate for improvement of yeast fermentation performance in high gravity brewing. Food Res. Int. 2009, 16, 547–554. [Google Scholar]

- Verbelen, P.; Dekoninck, T.; Saerens, S.; Van Mulders, S.; Thevelein, M.; Delvaux, F. Impact of pitching rate on yeast fermentation performance and beer flavour. Appl. Microbiol. Biotechnol. 2009, 82, 155–167. [Google Scholar] [CrossRef]

- Olaniran, A.O.; Hiralal, L.; Mokoena, M.P.; Pillay, B. Flavour-active volatile compounds in beer: Production, regulation and control. J. Inst. Brew. 2017, 123, 13–23. [Google Scholar] [CrossRef]

- Jones, H.; Margaritis, A.; Stewart, R. The combined effect of oxygen supply strategy, inoculum size and temperature profile on Very-High-Gravity beer fermentations by Saccharomyces cerevisiae. J. Inst. Brew. 2007, 113, 168–184. [Google Scholar] [CrossRef]

| Independent Variables | Units | Symbol | Coded Levels | ||

|---|---|---|---|---|---|

| −1 | 0 | +1 | |||

| Pitching rate | mln cells/mL | x1 | 6 | 8 | 10 |

| Fermentation temperature | °C | x2 | 8.5 | 10 | 11.5 |

| Aeration level | mg/L | x3 | 8 | 10 | 12 |

| Total CCT filling time | h | x4 | 4.5 | 9 | 13.5 |

| Source | Sum of Squares | Df | Mean Square | F-Ratio | p-Value |

|---|---|---|---|---|---|

| x1 | 2.1915 | 1 | 2.1962 | 132.83 | 0.0003 |

| x2 | 0.5704 | 1 | 0.5704 | 34.50 | 0.0042 |

| x3 | 1.9380 | 1 | 1.9380 | 117.22 | 0.0004 |

| x4 | 0.2128 | 1 | 0.2128 | 12.87 | 0.0230 |

| x1 x2 | 2.1841 | 1 | 2.1841 | 132.10 | 0.0003 |

| x1 x3 | 0.8978 | 1 | 0.8978 | 54.30 | 0.0018 |

| x1 x4 | 0.1458 | 1 | 0.1458 | 8.82 | 0.0412 |

| x2 x3 | 0.3362 | 1 | 0.3362 | 20.33 | 0.0107 |

| x2 x4 | 1.5488 | 1 | 1.5488 | 93.68 | 0.0006 |

| x3 x4 | 6.0205 | 1 | 6.0205 | 364.1 | 0.0001 |

| Blocks | 0.0012 | 1 | 0.0012 | 0.080 | 0.7968 |

| Lack-of-fit | 26.294 | 34 | 0.7734 | 46.77 | 0.0009 |

| Pure error | 0.0661 | 4 | 0.0165 | ||

| Total (correlation) | 45.636 | 53 |

| Source | Sum of Squares | Df | Mean Square | F-Ratio | p-Value |

|---|---|---|---|---|---|

| x1 | 5.9004 | 1 | 5.9004 | 8.90 | 0.0406 |

| x2 | 0.2604 | 1 | 0.2604 | 0.39 | 0.5649 |

| x3 | 4.6817 | 1 | 4.6817 | 7.06 | 0.0466 |

| x4 | 16.007 | 1 | 16.007 | 24.13 | 0.0080 |

| x1 x3 | 5.1200 | 1 | 5.1200 | 7.72 | 0.0499 |

| Blocks | 0.0012 | 1 | 0.0012 | 0.080 | 0.7968 |

| Lack-of-fit | 26.294 | 1 | 0.7734 | 46.77 | 0.0009 |

| Pure error | 0.0661 | 4 | 0.0165 | ||

| Total (correlation) | 45.636 | 53 |

| Factor | Units | Values | ||

|---|---|---|---|---|

| Low | High | Optimum | ||

| Pitching rate | mln cells/mL | 6 | 10 | 6.19 |

| Fermentation temperature | °C | 8.5 | 11.5 | 11.5 |

| Aeration level | mg/L | 8 | 12 | 8 |

| Total time of CCT filling | h | 4.5 | 13.5 | 4.5 |

| Response | Calculated Values | Values from the Validating Industrial Experiment |

|---|---|---|

| Yeast growth [M] | 5.09 | 5.34 |

| Dead cells [%] | 1.47 | 1.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kucharczyk, K.; Żyła, K.; Tuszyński, T. Optimization of Fermentation Parameters in a Brewery: Modulation of Yeast Growth and Yeast Cell Viability. Processes 2025, 13, 906. https://doi.org/10.3390/pr13030906

Kucharczyk K, Żyła K, Tuszyński T. Optimization of Fermentation Parameters in a Brewery: Modulation of Yeast Growth and Yeast Cell Viability. Processes. 2025; 13(3):906. https://doi.org/10.3390/pr13030906

Chicago/Turabian StyleKucharczyk, Krzysztof, Krzysztof Żyła, and Tadeusz Tuszyński. 2025. "Optimization of Fermentation Parameters in a Brewery: Modulation of Yeast Growth and Yeast Cell Viability" Processes 13, no. 3: 906. https://doi.org/10.3390/pr13030906

APA StyleKucharczyk, K., Żyła, K., & Tuszyński, T. (2025). Optimization of Fermentation Parameters in a Brewery: Modulation of Yeast Growth and Yeast Cell Viability. Processes, 13(3), 906. https://doi.org/10.3390/pr13030906