Optimization of Extrusion Cooking for Enhanced Physicochemical Properties in Jackfruit Seed (Artocarpus altilis) and Nixtamalized Maize (Zea mays L.) Flour Blend

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Chemical Composition, Total Energy, and pH

2.3. Degree of Gelatinization

2.4. Determination of Total Color Difference (ΔE) and Browning Index (BI)

2.5. Extrusion Process

2.6. Determination of Specific Mechanical Energy (SME)

2.7. Analysis of Physical Characteristics

2.8. Sensory Evaluation

2.9. Experimental Design and Statistical Analysis

3. Results and Discussion

3.1. Chemical Composition, Total Energy, Degree of Gelatinization, and Color Parameter

| Component (g/100 g) | JSF | NMF | Extruded Mixtures (JSF/NMF) 1 |

|---|---|---|---|

| Moisture | 8.58 ± 0.06 b | 7.25 ± 0.12 a | 7.66 ± 0.33 a |

| Protein | 13.20 ± 0.28 c | 10.85 ± 0.33 a | 12.10 ± 0.06 b |

| Fat | 6.87 ± 0.73 a | 3.69 ± 0.81 b | 2.18 ± 0.30 c |

| Fiber | 4.24 ± 0.36 b | 1.80 ± 0.04 a | 4.86 ± 0.37 c |

| Ash | 3.78 ± 0.19 a | 1.40 ± 0.01 b | 2.94 ± 0.02 c |

| Carbohydrates | 71.90 ± 1.26 a | 82.30 ± 0.66 b | 77.93 ± 0.42 c |

| Total energy (kJ/100 g) | 1680.00 ± 13.35 a | 1694.00 ± 17.49 a | 1585.49 ± 10.51 b |

| Degree of gelatinization (%) | 14.81 ± 0.17 a | 17.86 ± 0.06 b | 97.33 ± 0.79 c |

| pH | 6.05 ± 0.00 a | 7.76 ± 0.03 b | 5.82 ± 0.06 c |

| L* | 61.60 ± 0.01 a | 79.80 ± 0.36 b | 53.78 ± 0.34 c |

| a* | 6.31 ± 0.01 a | 0.41 ± 0.01 b | 9.50 ± 0.44 c |

| b* | 22.93 ± 0.02 a | 15.45 ± 0.18 b | 26.88 ± 0.07 c |

| # Color | |||

| Color primer | #AE906D | #D2C5A9 | #9F7A53 |

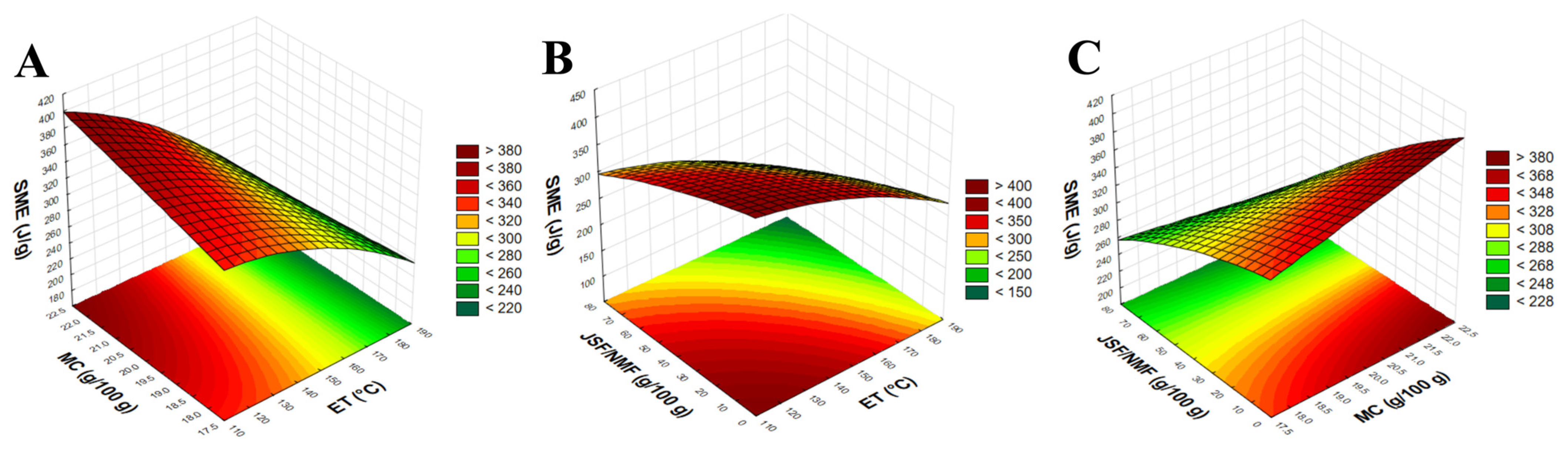

3.2. Specific Mechanical Energy (SME)

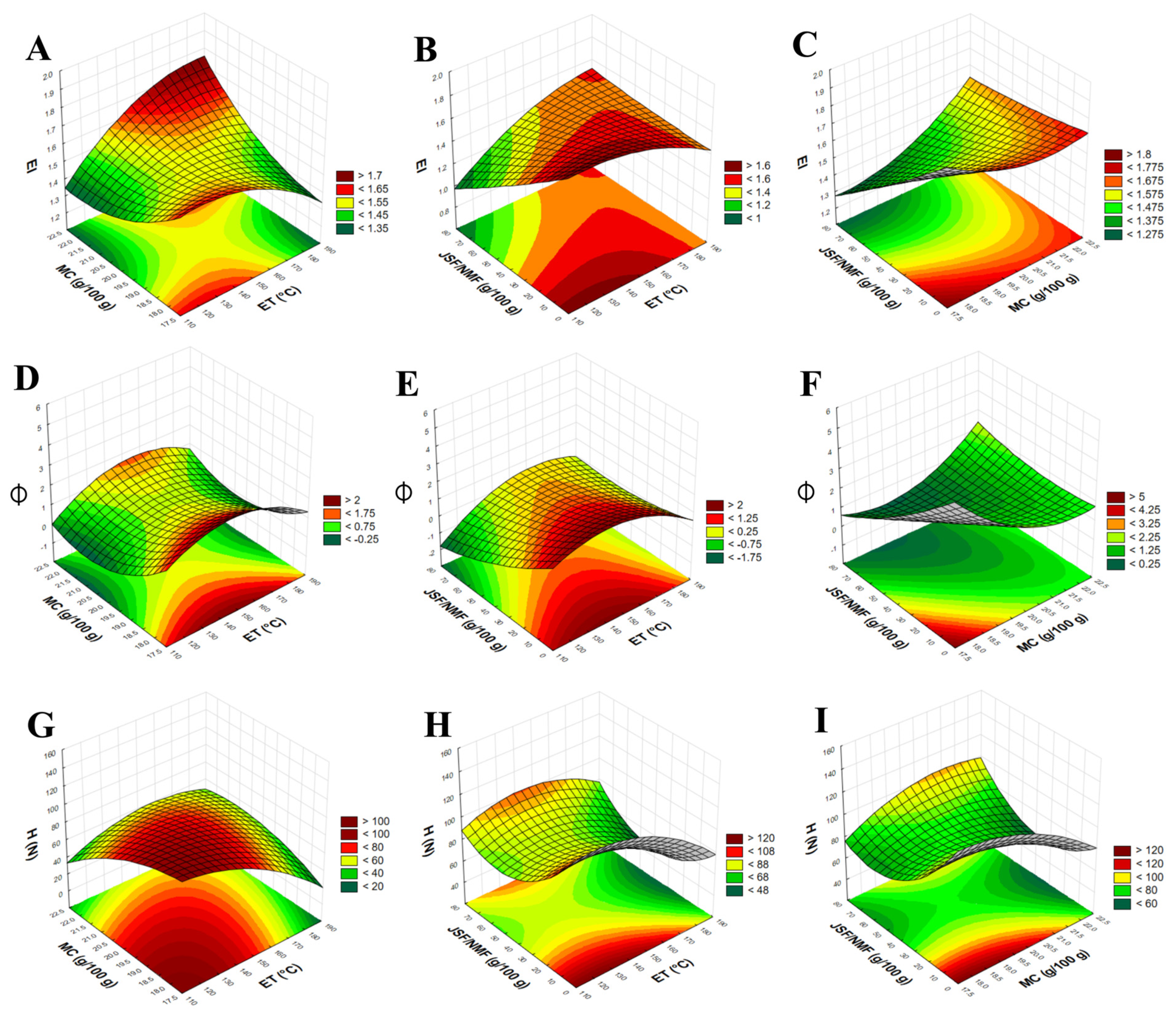

3.3. Expansion Index (EI) and Porosity (Φ)

| Run | Independent Variables | Response Variables | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ET (°C) | MC (g/100 g) | JSF/NMF (g/100 g) | SME (J/g) | EI | Φ | H (N) | WAI (g/g) | WSI (%) | pH | ΔE | BI | OA | |

| 1 | 120 (−1) | 18 (−1) | 35 (0) | 355.41 | 1.59 | 1.18 | 99.73 | 7.87 | 5.79 | 6.96 | 35.42 | 39.20 | 2.57 |

| 2 | 180 (1) | 18 (−1) | 35 (0) | 235.27 | 1.57 | 1.36 | 38.30 | 7.30 | 5.34 | 7.08 | 37.63 | 43.36 | 3.13 |

| 3 | 120 (−1) | 22 (1) | 35 (0) | 404.38 | 1.29 | 0.42 | 59.37 | 5.66 | 3.84 | 7.07 | 37.33 | 43.81 | 3.27 |

| 4 | 180 (1) | 22 (1) | 35 (0) | 237.05 | 1.70 | 1.38 | 57.87 | 6.60 | 4.81 | 7.08 | 37.41 | 43.19 | 3.27 |

| 5 | 120 (−1) | 20 (0) | 0 (−1) | 388.52 | 1.74 | 1.57 | 118.00 | 7.89 | 5.51 | 7.99 | 30.23 | 32.01 | 2.80 |

| 6 | 180 (1) | 20 (0) | 0 (−1) | 321.48 | 1.33 | 0.17 | 83.04 | 7.62 | 5.39 | 8.05 | 32.21 | 35.44 | 2.97 |

| 7 | 120 (−1) | 20 (0) | 70 (1) | 284.35 | 1.36 | 0.17 | 94.93 | 5.30 | 5.92 | 6.82 | 41.17 | 51.35 | 2.40 |

| 8 | 180 (1) | 20 (0) | 70 (1) | 209.03 | 1.53 | 0.70 | 88.10 | 6.47 | 5.70 | 6.79 | 52.00 | 61.49 | 4.00 |

| 9 | 150 (0) | 18 (−1) | 0 (−1) | 343.50 | 1.89 | 5.55 | 151.12 | 6.00 | 9.85 | 8.11 | 30.84 | 31.25 | 3.53 |

| 10 | 150 (0) | 22 (0) | 0 (−1) | 378.79 | 1.88 | 2.10 | 99.69 | 7.54 | 4.98 | 8.04 | 32.35 | 32.74 | 3.37 |

| 11 | 150 (0) | 18 (−1) | 70 (1) | 277.60 | 1.16 | 0.24 | 67.76 | 5.77 | 7.55 | 6.64 | 42.72 | 55.40 | 2.93 |

| 12 | 150 (0) | 22 (1) | 70 (1) | 251.20 | 1.52 | 0.50 | 70.92 | 5.45 | 5.86 | 6.76 | 44.67 | 45.48 | 2.90 |

| 13 | 150 (0) | 20 (0) | 35 (0) | 331.96 | 1.52 | 0.99 | 89.56 | 6.91 | 5.50 | 7.22 | 40.47 | 50.18 | 4.87 |

| 14 | 150 (0) | 20 (0) | 35 (0) | 278.72 | 1.53 | 1.13 | 87.74 | 6.74 | 5.16 | 7.07 | 42.71 | 54.93 | 4.47 |

| 15 | 150 (0) | 20 (0) | 35 (0) | 315.26 | 1.57 | 1.23 | 71.85 | 6.56 | 6.48 | 6.88 | 48.12 | 63.91 | 4.30 |

| 16 | 150 (0) | 20 (0) | 35 (0) | 362.93 | 1.52 | 0.99 | 85.22 | 6.02 | 8.58 | 6.82 | 48.17 | 63.70 | 3.07 |

| 17 | 150 (0) | 20 (0) | 35 (0) | 315.27 | 1.56 | 0.90 | 79.28 | 6.47 | 5.02 | 6.73 | 40.43 | 51.42 | 4.10 |

3.4. Hardness (H)

3.5. Water Absorption Index (WAI) and Water Solubility Index (WSI)

| Coefficients | SME | IE | Φ | H | WAI | WSI | pH | ΔE | BI | OA |

|---|---|---|---|---|---|---|---|---|---|---|

| Intercept | 307.214 * | 1.553 * | 1.277 * | 85.736 * | 6.623 * | 5.878 * | 7.282 * | 37.831 * | 42.894 * | 3.094 * |

| Linear | ||||||||||

| ET | −53.727 * | 0.004 | 0.033 | −13.093 * | 0.158 | 0.022 | 0.019 | 1.887 | 2.138 | 0.292 |

| MC | 7.454 | −0.059 | −0.490 | −8.633 | −0.215 | −1.129 * | 0.020 | 0.644 | −0.498 | 0.079 |

| JSF/NMF | −51.265 * | −0.220 * | −0.973 * | −16.267 * | −0.758 * | −0.088 | −0.647 * | 6.868 * | 10.284 * | −0.054 |

| Quadratic | ||||||||||

| ET2 | 6.182 | 0.017 | 0.352 | 5.068 | −0.237 | 0.560 * | −0.032 | 1.443 | 2.646 | 1.046 * |

| MC2 | 0.220 | −0.064 | −0.370 | 4.389 | 0.078 | −0.158 | −0.019 | 2.074 * | 4.573 * | 0.975 * |

| JSF/NMF2 | 3.809 | −0.034 | −0.154 | −11.710 * | 0.096 | −0.501 * | −0.203 * | 1.096 | 3.232 * | 0.983 * |

| Interactions | ||||||||||

| ET-MC | −11.799 | 0.088 | 0.196 | 14.983 | 0.378 | 0.355 | −0.026 | −0.533 | −1.196 | −0.142 |

| ET-JSF/NMF | −2.069 | 0.064 | 0.481 | 7.033 | 0.361 | −0.026 | −0.023 | 2.214 | 1.676 | 0.358 |

| MC-JSF/NMF | −15.421 | 0.110 | 0.926 | 13.649 | −0.466 | 0.794 | 0.048 | 0.110 | −2.851 | 0.033 |

| R2 | 0.876 | 0.799 | 0.759 | 0.858 | 0.742 | 0.823 | 0.960 | 0.876 | 0.884 | 0.821 |

| P of F (model) | 0.000 | 0.001 | 0.030 | 0.002 | 0.001 | 0.022 | 0.028 | 0.015 | 0.014 | 0.040 |

| p-value for lack of fit | 0.1215 | 0.7030 | 0.0884 | 0.1224 | 0.8862 | 0.2661 | 0.3854 | 0.3548 | 0.4652 | 0.9950 |

3.6. pH

3.7. Total Color Difference (ΔE) and Browning Index (BI)

3.8. Overall Acceptability (OA)

3.9. Optimization, Validation, and Characterization of the Optimal Product

| Process Parameter | Importance | Target | Experimental Value | Optimum Value | Experimental Value | |

|---|---|---|---|---|---|---|

| Min | Max | |||||

| ET (°C) | 5 | Range | 120.00 | 180 | 145.15 | 145.15 |

| MC (g/100 g) | 5 | Range | 18.00 | 22.00 | 22.00 | 22.00 |

| JSF/NMF (g/100 g) | 5 | Range | 0.00 | 70.00 | 70.00 | 70.00 |

| Responses | ||||||

| SME (J/g) | 4 | Minimize | 209.03 | 404.37 | 311.21 | 273.38 ± 24.02 ns |

| EI | 5 | Maximize | 1.16 | 1.74 | 1.62 | 1.12 ± 0.13 |

| Φ | 5 | Maximize | 0.17 | 5.55 | 1.21 | 0.84 ± 0.23 |

| H (N) | 4 | Minimize | 38.30 | 151.12 | 53.26 | 58.75 ± 8.20 ns |

| WAI (g/g) | 4 | Range | 5.30 | 7.89 | 7.06 | 6.14 ± 0.12 |

| WSI (%) | 4 | Range | 3.84 | 9.85 | 5.95 | 9.37 ± 0.11 |

| pH | 4 | Range | 6.64 | 8.11 | 6.89 | 6.82 ± 0.06 ns |

| ΔE | 4 | Range | 30.23 | 52.00 | 39.21 | 40.06 ± 0.24 |

| BI | 4 | Range | 31.25 | 63.91 | 62.46 | 61.68 ± 0.28 |

| OA | 4 | Maximize | 2.40 | 4.87 | 4.40 | 4.56 ± 1.06 ns |

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Acronyms | |

| BI | Browning index |

| EI | Expansion index |

| ET | Extrusion temperature |

| H | Hardness |

| JSF | Jackfruit seed flour |

| MC | Moisture content |

| NMF | Nixtamalized maize flour |

| OA | Overall acceptance |

| SME | Specific mechanical energy |

| WAI | Water absorption index |

| WSI | Water solubility index |

| Symbols | |

| Φ | Porosity |

| a* | Red–green chromaticity |

| b* | Yellow–blue chromaticity |

| L* | Luminosity |

| R2 | Coefficient of determination |

| ΔE | Total color difference |

References

- Pérez-Ramos, K.; Elías-Peñafiel, C.; Delgado-Soriano, V. Bocadito con Alto Contenido Proteico: Un Extruido a Partir de Quinua (Chenopodium quinoa Willd.), Tarwi (Lupinus mutabilis Sweet) y Camote (Ipomoea batatas L.). Sci. Agropecu. 2017, 8, 377–388. [Google Scholar] [CrossRef]

- Hernández-Santos, B.; Juárez-Barrientos, J.M.; Torruco-Uco, J.G.; Ramírez-Figueroa, E.; Ramírez-Rivera, J.E.; Bautista-Viazcan, V.O.; Rodríguez-Miranda, J. Physicochemical Properties of Extruded Ready-to-eat Snack From Unripe Plantain Blends, Pineapple By-products and Stevia. Nova Sci. 2021, 13, 1–24. [Google Scholar] [CrossRef]

- Téllez-Morales, J.A.; Rodríguez-Miranda, J. Improved Extrusion Cooking Technology: A Mini Review of Starch Modification. J. Culin. Sci. Technol. 2025, 23, 1–10. [Google Scholar] [CrossRef]

- Awolu, O.O.; Magoh, A.O.; Ojewumi, M.E. Development and Evaluation of Extruded Ready-to-eat Snack from Optimized Rice, Kersting’s Groundnut and Lemon Pomace Composite Flours. J. Food Sci. Technol. 2020, 57, 86–95. [Google Scholar] [CrossRef]

- Téllez-Morales, J.A.; Hernández-Santos, B.; Navarro-Cortez, R.O.; Rodríguez-Miranda, J. Impact of the Addition of Cricket Flour (Sphenarium purpurascens) on the Physicochemical Properties, Optimization and Extrusion Conditions of Extruded Nixtamalized Corn Flour. Appl. Food Res. 2022, 2, 100149. [Google Scholar] [CrossRef]

- Pensamiento-Niño, C.A.; Hernández-Santos, B.; Herman-Lara, E.; Juárez-Barrientos, J.M.; Martínez-Sánchez, C.E.; Ramírez-Rivera, E.J.; Rodríguez-Miranda, J. Physical, Mechanical, Functional and Chemical Properties of Mexican Pink Pinion (Pinus pinea L.). J. Food Sci. Technol. 2019, 56, 763–774. [Google Scholar] [CrossRef]

- Rivera-Mirón, M.I.; Torruco-Uco, J.G.; Carmona-García, R.; Rodríguez-Miranda, J. Optimization of An Extrusion Process for the Development of a Fiber-rich, Ready-to-eat Snack from Pineapple By-products and Sweet Whey Protein Based on Corn Starch. J. Food Process Eng. 2020, 43, e13532. [Google Scholar] [CrossRef]

- Téllez-Morales, J.A.; Herman-Lara, E.; Gómez-Aldapa, C.A.; Rodríguez-Miranda, J. Techno-functional Properties of the Starch-Protein Interaction During Extrusion-cooking of a Model System (Corn Starch and Whey Protein Isolate). LWT-Food Sci. Technol. 2020, 132, 109789. [Google Scholar] [CrossRef]

- Delgado-Nieblas, C.I.; Ahumada-Aguilar, J.A.; Agramón-Velázquez, S.; Zazueta-Morales, J.J.; Jacobo-Valenzuela, N.; Ruiz-Armenta, X.A.; Carrillo-López, A.; Quintero-Ramos, A.; Barraza-Elenes, C. Physical, Phytochemical and Sensory Characteristics of Extruded High-fiber Breakfast Cereals Prepared by Combining Carrot By-products with Wheat and Oat Bran. Rev. Mex. Ing. Quím. 2021, 20, Alim2441-1. [Google Scholar] [CrossRef]

- Téllez-Morales, J.A.; Gómez-Aldapa, C.A.; Herman-Lara, E.; Carmona-García, R.; Rodríguez-Miranda, J. Effect of the Concentrations of Corn Starch and Whey Protein Isolate on the Processing Parameters and the Physicochemical Characteristics of the Extrudates. J. Food Process. Preserv. 2021, 45, e15395. [Google Scholar] [CrossRef]

- Rodríguez-Miranda, J.; Ruiz-López, I.I.; Herman-Lara, E.; Martínez-Sánchez, C.E.; Delgado-Licon, E.; Vivar-Vera, M.A. Development of Extruded Snacks Using Taro (Colocasia esculenta) and Nixtamalized Maize (Zea mays) Flour Blends. LWT-Food Sci. Technol. 2011, 44, 673–680. [Google Scholar] [CrossRef]

- Navarro-Cortez, R.O.; Hernández-Santos, B.; Gómez-Aldapa, C.A.; Castro-Rosas, J.; Herman-Lara, E.; Martínez-Sánchez, C.E.; Júarez-Barrientos, J.M.; Antonio-Cisneros, C.M.; Rodríguez-Miranda, J. Development of Extruded Ready-to-eat Snacks Using Pumpkin Seed (Cucurbita pepo) and Nixtamalized Maize (Zea mays) Flour Blends. Rev. Mex. Ing. Quím. 2016, 15, 409–422. [Google Scholar] [CrossRef]

- Cuj-Laines, R.; Hernández-Santos, B.; Reyes-Jaquez, D.; Delgado-Licon, E.; Juárez-Barrientos, J.M.; Rodríguez-Miranda, J. Physicochemical Properties of Ready-to-eat Extruded Nixtamalized Maize-based Snacks Enriched with Grasshopper. Int. J. Food Sci. Technol. 2018, 53, 1889–1895. [Google Scholar] [CrossRef]

- Félix-Medina, J.V.; Montes-Ávila, J.; Reyes-Moreno, C.; Perales-Sánchez, J.X.K.; Gómez-Favela, M.A.; Aguilar-Palazuelos, E.; Gutiérrez-Dorado, R. Second-generation Snacks with High Nutritional and Antioxidant Value Produced by an Optimized extrusion Process from Corn/common Bean Flours Mixtures. LWT-Food Sci. Technol. 2020, 124, 109172. [Google Scholar] [CrossRef]

- Téllez-Morales, J.A.; Hernández-Santos, B.; Juárez-Barrientos, J.M.; Lerdo-Reyes, A.A.; Rodríguez-Miranda, J. The Use of Tubers in the Development of Extruded Snacks: A Review. J. Food Process. Preserv. 2022, 46, e16693. [Google Scholar] [CrossRef]

- Colbert, T.; Bothma, C.; Pretorius, W.; du Toit, A. Developing an Acceptable Nixtamalised Maize Product for South African Consumers: Sensory, Survey and Nutrient Analysis. Foods 2024, 13, 2896. [Google Scholar] [CrossRef]

- Oladunjoye, I.O.; Ologhobo, A.D.; Olaniyi, C.O. Nutrient Composition, Energy Value and Residual Antinutritional Factors in Differently Processed Breadfruit (Artocarpus altilis) Meal. Afr. J. Biotechnol. 2010, 9, 4259–4263. [Google Scholar]

- Ma, H.; Pan, Z.; Li, B.; Atungulu, G.G.; Olson, D.A.; Wall, M.M.; McHugh, T.H. Properties of Extruded Expandable BreadfruitProducts. LWT-Food Sci. Technol. 2012, 46, 326–334. [Google Scholar] [CrossRef]

- Juárez-Barrientos, J.M.; Hernández-Santos, B.; Herman-Lara, E.; Martínez-Sánchez, C.E.; Torruco-Uco, J.G.; de Jesús Ramírez-Rivera, E.; Rodríguez-Miranda, J. Effects of Boiling on the Functional, Thermal and Compositional Properties of the Mexican Jackfruit (Artocarpus heterophyllus) Seed Jackfruit Seed Meal properties. Emir. J. Food Agric. 2017, 29, 1–9. [Google Scholar] [CrossRef]

- Goh, S.X.; Mamat, H.; Aziz, A.H.A. Valorization of Agriculture By-product: Development of Gluten-free Biscuit Made from Blends of Okara and Jackfruit Seed Flour. Waste Manag. Bull. 2024, 2, 59–65. [Google Scholar] [CrossRef]

- Fabil, M.; Dubey, P.K.; Roy, S.; Sharma, M. Jackfruit Seed Valorization: A Comprehensive Review of Nutritional Potential, Value Addition, and Industrial Applications. Food Humanit. 2024, 3, 100406. [Google Scholar] [CrossRef]

- Kumari, A.; Gupta, A.; Chauhan, A.K. Optimization of the Iron-enriched Extruded Snack Containing Jackfruit Seed Flour, Mung Bean flour and Ferrous Ammonium Phosphate by Using Response Surface Methodology. Food Prod. Process. Nutr. 2022, 4, 31. [Google Scholar] [CrossRef]

- Chakraborty, P.; Bhattacharyya, D.K.; Ghosh, M. Study on Evaluation of Functional Properties of Blends of Soy and Jackfruit Seed Floor Based Extruded Products. Food Sci. Eng. 2022, 3, 170–183. [Google Scholar] [CrossRef]

- Gat, Y.; Ananthanarayan, L. Physicochemical, Phytochemical and Nutritional Impact of Fortified Cereal-based Extrudate Snacks: Effect of Underutilized Legume Flour Addition and Extrusion Cooking. Nutrafoods 2025, 14, 141–149. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC, 18th ed.; Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2005. [Google Scholar]

- Gandhi, N.; Singh, B.; Sharma, S.; Kapoor, S. Extrusion Process Optimization of Corn starch to Develop Instant Vegetable Soup Mix. Int. J. Curr. Microbiol. Appl. Sci. 2018, 7, 2886–2910. [Google Scholar] [CrossRef]

- Özer, E.A.; İbanoğlu, Ş.; Ainsworth, P.; Yağmur, C. Expansion Characteristics of a Nutritious Extruded Snack Food Using Response Surface Methodology. Eur. Food Res. Technol. 2004, 218, 474–479. [Google Scholar] [CrossRef]

- Rodríguez-Miranda, J.; Ramírez-Wong, B.; Vivar-Vera, M.A.; Solís-Soto, A.; Gómez-Aldapa, C.A.; Castro-Rosas, J.; Medrano-Roldan, H.; Delgado-Licon, E. Effect of Bean Flour Concentration (Phaseolus vulgaris L.), Moisture Content and Extrusion Temperature on the Functional Properties of Aquafeeds. Rev. Mex. Ing. Quím. 2014, 13, 649–663. [Google Scholar]

- Norma Oficial Mexicana NOM-147-SSA1-1996; Bienes y servicios. Cereales y sus Productos. Harinas de Cereales, Sémolas o Semolinas. Alimentos a Base de Cereales, de Semillas Comestibles, Harinas, Sémolas o Semolinas o sus Mezclas. Productos de Panificación. 1996. Available online: https://salud.gob.mx/unidades/cdi/nom/147ssa16.html#:~:text=1.1%20Esta%20Norma%20Oficial%20Mexicana,y%20los%20productos%20de%20panificaci%C3%B3n (accessed on 15 November 2024). (In Spanish).

- Yang, J.H.; Tran, T.T.T.; Le, V.V.M. Use of Corn Flour and Polydextrose in Fried Extrudate Making: Effects of Polydextrose Content in the Blend and Extrusion Temperature on the Product Quality. J. Food Process Eng. 2020, 43, e13438. [Google Scholar] [CrossRef]

- Lu, X.; Brennan, M.A.; Narciso, J.; Guan, W.; Zhang, J.; Yuan, L.; Serventi, L.; Brennan, C.S. Correlations Between the Phenolic and Fibre Composition of Mushrooms and the Glycaemic and Textural Characteristics of Mushroom Enriched Extruded Products. LWT-Food Sci. Technol. 2020, 118, 108730. [Google Scholar] [CrossRef]

- Menis-Henrique, M.E.C.; Janzantti, N.S.; Monteiro, M.; Conti-Silva, A.C. Physical and Sensory Characteristics of Cheese-flavored Expanded Snacks Obtained Using Butyric Acid and Cysteine as Aroma Precursors: Effects of Extrusion Temperature and Sunflower Oil Content. LWT-Food Sci. Technol. 2020, 122, 109001. [Google Scholar] [CrossRef]

- González, R.J.; Pastor-Cavada, E.; Vioque-Peña, J.; Torres, R.L.; De Greef, D.M.; Drago, S.R. Extrusion Conditions and Amylose Content Affect Physicochemical Properties of Extrudates Obtained from Brown Rice Grains. Int. J. Food Sci. 2013, 2013, 584148. [Google Scholar] [CrossRef]

- Meza, S.L.R.; Sinnecker, P.; Schmiele, M.; Massaretto, I.L.; Chang, Y.K.; Marquez, U.M.L. Production of Innovative Gluten-free Breakfast Cereals Based on Red and Black Rice by Extrusion Processing Technology. J. Food Sci. Technol. 2019, 56, 4855–4866. [Google Scholar] [CrossRef] [PubMed]

- Sriburi, P.; Hill, S.E. Extrusion of Cassava Starch with Either Variations in Ascorbic Acid Concentration or pH. Int. J. Food Sci. Technol. 2000, 35, 141–154. [Google Scholar] [CrossRef]

- Setiawan, B.; Sulaeman, A.; Giraud, D.W.; Driskell, J.A. Carotenoid Content of Selected Indonesian Fruits. J. Food Compos. Anal. 2021, 14, 169–176. [Google Scholar] [CrossRef]

- Shengbu, M.; Ai, L.; Shi, Q.; Zhao, Q.; Liu, X.; Lai, X. Research Progress of Maillard Reaction and its Application in Processing of Traditional Chinese Medicine. Nat. Prod. Commun. 2024, 19, 1–22. [Google Scholar] [CrossRef]

- do Carmo, C.S.; Varela, P.; Poudroux, C.; Dessev, T.; Myhrer, K.; Rieder, A.; Zobel, H.; Sahlstrøm, S.; Knutsen, S.H. The Impact of Extrusion Parameters on Physicochemical, Nutritional and Sensorial Properties of Expanded Snacks from Pea and Oat Fractions. LWT-Food Sci. Technol. 2019, 112, 108252. [Google Scholar] [CrossRef]

- Raleng, A.; Singh, A.; Chavan, P.; Attkan, A.; Singh, B. Standardization of Deep-frying Process and Their effects on Storage Stability of Pineapple Pomace Powder-incorporated Rice-based Extruded Product. J. Food Process. Preserv. 2019, 43, e13950. [Google Scholar] [CrossRef]

- Toledo, V.C.; Carvalho, C.W.; Vargas-Solórzano, J.W.; Ascheri, J.L.; Comettant-Rabanal, R. Extrusion Cooking of Gluten-free Whole Grain Flour Blends. J. Food Process Eng. 2020, 43, e13303. [Google Scholar] [CrossRef]

- Borah, A.; Mahanta, C.L.; Kalita, D. Optimization of Process Parameters for Extrusion Cooking of Low Amylose Rice Flour Blended with Seeded Banana and Carambola Pomace for Development of Minerals and Fiber Rich Breakfast Cereal. J. Food Sci. Technol. 2016, 53, 221–232. [Google Scholar] [CrossRef]

- Nascimento, T.A.; Calado, V.; Carvalho, C.W. Effect of Brewer’s Spent Grain and Temperature on Physical Properties of Expanded Extrudates from Rice. LWT-Food Sci. Technol. 2017, 79, 145–151. [Google Scholar] [CrossRef]

- Basilio-Atencio, J.; Condezo-Hoyos, L.; Repo-Carrasco-Valencia, R. Effect of Extrusion Cooking on the Physical-chemical Properties of Whole kiwicha (Amaranthus caudatus L) Flour Variety Centenario: Process Optimization. LWT-Food Sci. Technol. 2020, 128, 109426. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Juárez-Barrientos, J.M.; Hernández-Santos, B.; Torruco-Uco, J.G.; Martínez-Sánchez, C.E.; Herman-Lara, E.; Ramírez-Rivera, E.J.; Ramírez-Figueroa, E.; Avendaño-Apolinar, A.V.; Cabal-Prieto, A.; Rodríguez-Miranda, J. Optimization of Extrusion Cooking for Enhanced Physicochemical Properties in Jackfruit Seed (Artocarpus altilis) and Nixtamalized Maize (Zea mays L.) Flour Blend. Processes 2025, 13, 772. https://doi.org/10.3390/pr13030772

Juárez-Barrientos JM, Hernández-Santos B, Torruco-Uco JG, Martínez-Sánchez CE, Herman-Lara E, Ramírez-Rivera EJ, Ramírez-Figueroa E, Avendaño-Apolinar AV, Cabal-Prieto A, Rodríguez-Miranda J. Optimization of Extrusion Cooking for Enhanced Physicochemical Properties in Jackfruit Seed (Artocarpus altilis) and Nixtamalized Maize (Zea mays L.) Flour Blend. Processes. 2025; 13(3):772. https://doi.org/10.3390/pr13030772

Chicago/Turabian StyleJuárez-Barrientos, José M., Betsabé Hernández-Santos, Juan G. Torruco-Uco, Cecilia E. Martínez-Sánchez, Erasmo Herman-Lara, Emmanuel J. Ramírez-Rivera, Enrique Ramírez-Figueroa, América V. Avendaño-Apolinar, Adán Cabal-Prieto, and Jesús Rodríguez-Miranda. 2025. "Optimization of Extrusion Cooking for Enhanced Physicochemical Properties in Jackfruit Seed (Artocarpus altilis) and Nixtamalized Maize (Zea mays L.) Flour Blend" Processes 13, no. 3: 772. https://doi.org/10.3390/pr13030772

APA StyleJuárez-Barrientos, J. M., Hernández-Santos, B., Torruco-Uco, J. G., Martínez-Sánchez, C. E., Herman-Lara, E., Ramírez-Rivera, E. J., Ramírez-Figueroa, E., Avendaño-Apolinar, A. V., Cabal-Prieto, A., & Rodríguez-Miranda, J. (2025). Optimization of Extrusion Cooking for Enhanced Physicochemical Properties in Jackfruit Seed (Artocarpus altilis) and Nixtamalized Maize (Zea mays L.) Flour Blend. Processes, 13(3), 772. https://doi.org/10.3390/pr13030772