Study on the Wellbore Instability Mechanism in the Longtan Formation with Soft/Hard Thin Interlayers in the South Sichuan Basin

Abstract

:1. Introduction

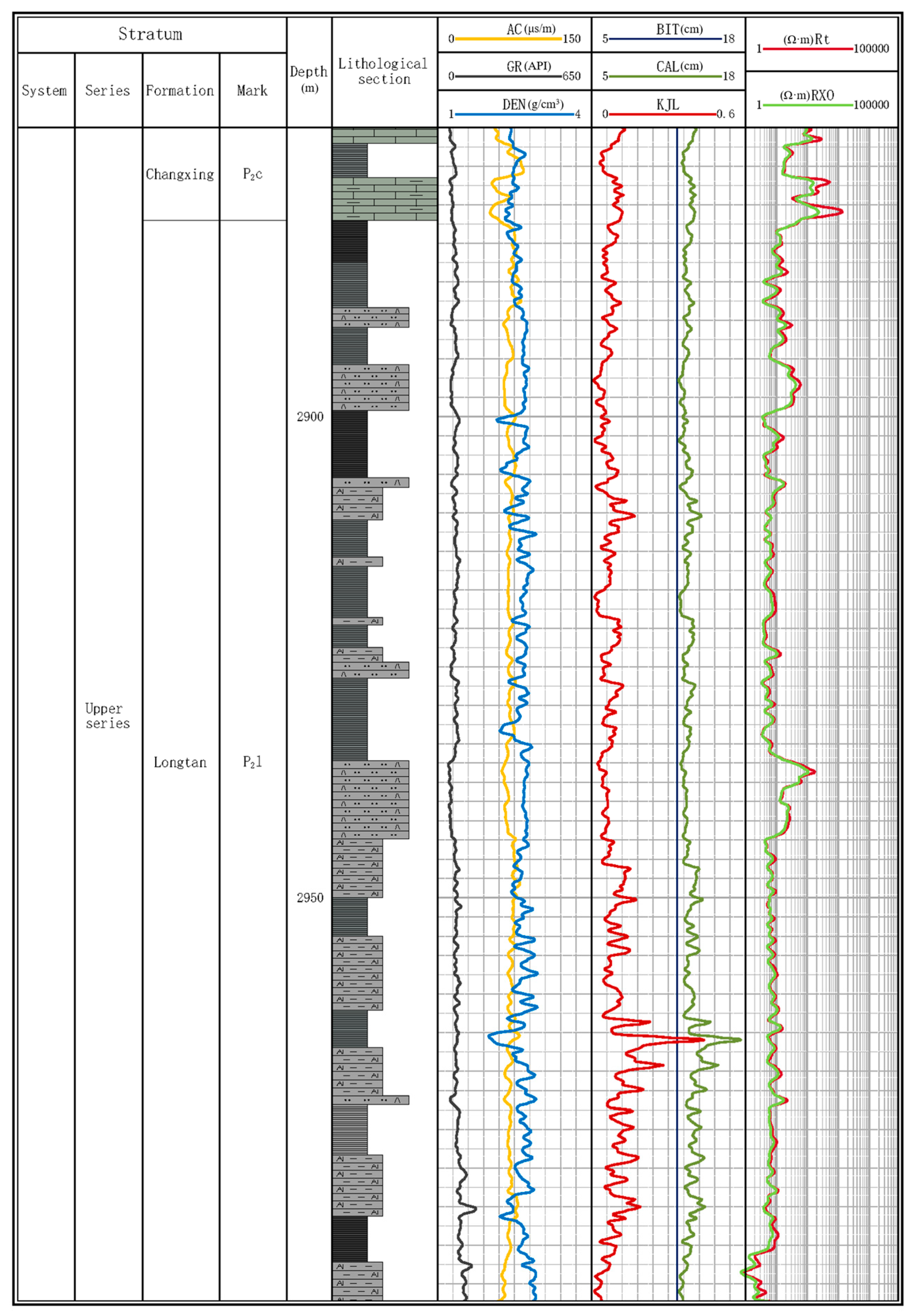

2. Basic Characteristics of Formation

3. Geomechanical Parameter Test and Analysis

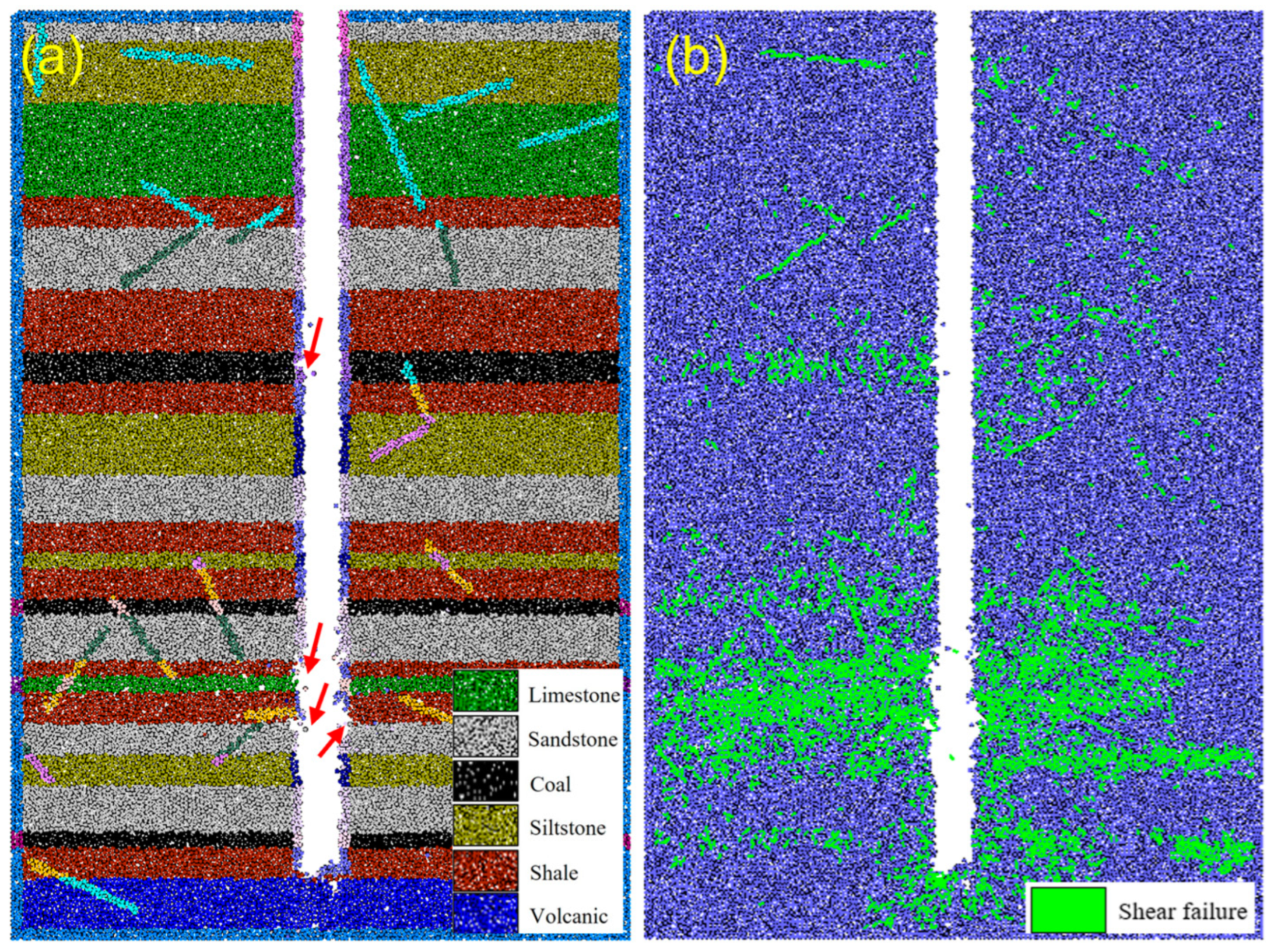

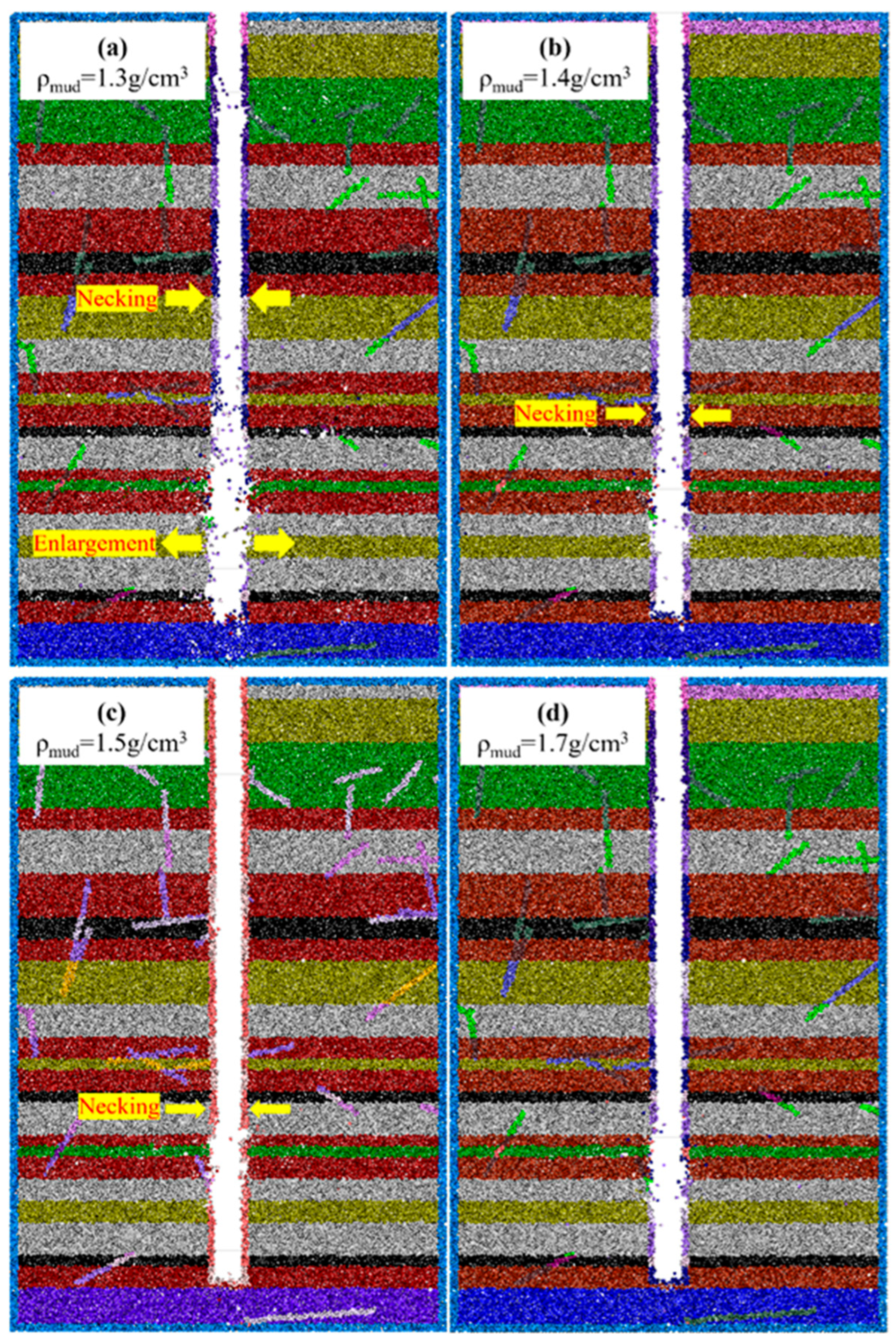

4. Discrete Element Simulation of Wellbore Instability in Thin Interlayer Formation

5. Conclusions

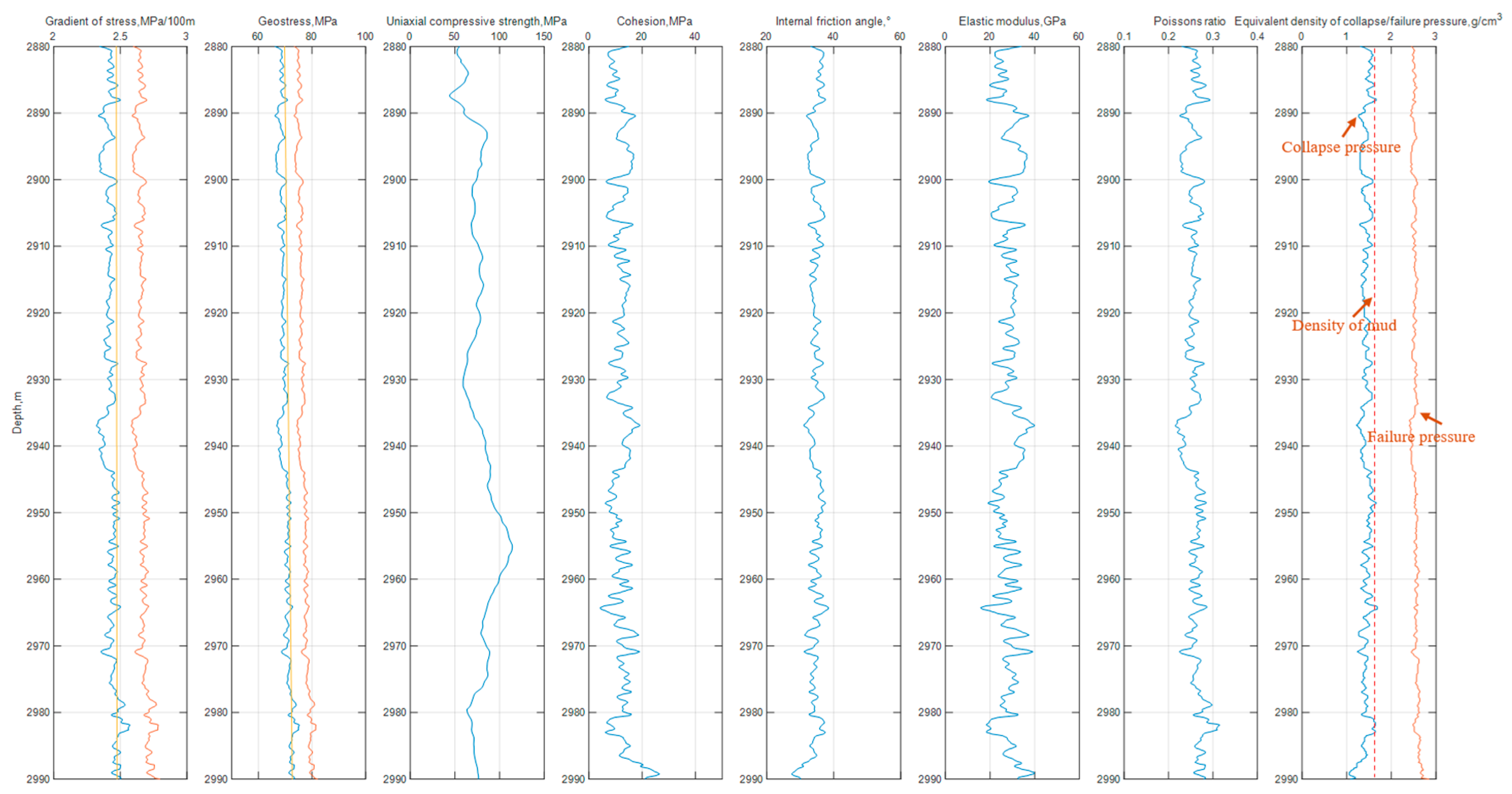

- In the Longtan Formation of the Zigong area in southern Sichuan, the vertical, maximum horizontal, and minimum horizontal principal stress gradients are 2.47 MPa/100 m, 2.72 MPa/100 m, and 2.34 MPa/100 m, respectively, indicating a strike-slip stress state. Vertically, the formation consists of thin interlayer structures of various lithologies, with significant differences in rock mechanical strength between layers, resulting in marked heterogeneity and a high risk of wellbore structural–mechanical instability.

- Based on the geomechanical parameter profile of the Longtan Formation, the Mohr–Coulomb failure criterion was used to calculate the critical collapse pressure equivalent density of the wellbore, which ranges from 1.05 to 1.69 g/cm3. At certain weak layers such as shale or lithological interfaces, the wellbore collapse pressure exceeds the actual drilling fluid density (1.53 g/cm3), making these points potential triggers for wellbore instability and falling blocks.

- A fluid–solid coupled discrete element model of wellbore instability was established for the multi-lithology thin interlayer structure of the Longtan Formation. The instability simulation results with varying drilling fluid densities show that under low-density conditions, both wellbore enlargement and necking coexist. Under high-density conditions, due to stress imbalance, localized block falls may still occur at the lithological interfaces of the soft and hard thin interlayer formations. These findings are significant for revealing the mechanical mechanisms of wellbore instability in thin interlayer formations during actual drilling and for guiding the prevention and control of wellbore instability and associated risks.

6. Discussion

- The current study is based on a single-well geomechanical profile and numerical simulations. To enhance its applicability, future work could extend this approach to multi-well case studies and field-scale analyses, incorporating real-time drilling data to validate the model’s predictive accuracy under varying geological conditions.

- This study primarily considers stress redistribution and lithological heterogeneity. However, the inclusion of anisotropy, thermal effects, and chemical interactions could further refine wellbore stability predictions. For instance, thermal expansion and hydration effects may significantly alter the mechanical behavior of rock, particularly in formations with high clay content.

- With advancements in big data analytics and artificial intelligence, future studies could integrate machine learning algorithms with geomechanical modeling to develop real-time, data-driven wellbore stability forecasting systems. By training models on large datasets from different well conditions, predictive accuracy and drilling risk mitigation strategies could be significantly improved.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, W.; Li, D.; Jin, J. Technical problems and measures of wellbore stability of broken formation in Shunbei oil and gas field. Sci. Technol. Eng. 2022, 22, 5205–5212. [Google Scholar]

- Liu, Z.; Chen, M.; Jin, Y.; Yang, X.; Lu, Y.; Xiong, Q. Calculation model for bore-hole collapse volume of a horizontal openhole in multiple-weak-plane formation. Pet. Explor. Dev. 2014, 41, 102–107. [Google Scholar] [CrossRef]

- Yang, Y.M.; Zhang, S.M.; Jin, T.; Ming, Y.; Guo, R.Y.; Wang, X.Z.; Han, L.Y. Characteristics and exploration potential of shale reservoirs of Permian Longtan Formation in southern Sichuan Basin. Lithol. Reserv. 2023, 35, 1–11. [Google Scholar]

- Yew, C.; Wang, O. Wellbore stress distribution produced by moisture adsorption. SPE Drill. Eng. 1990, 5, 311–316. [Google Scholar] [CrossRef]

- Huang, R.Z.; Chen, M.; Deng, J.G.; Wang, K.P.; Chen, Z.X. Study on shale stability of wellbore by mechanics coupling with chemistry method. Drill. Fluid Complet. Fluid 1995, 28, 18–24. [Google Scholar]

- Kang, Y.; Yang, B.; Li, X.; Jian, Y.; Lijun, Y.; Qiang, C. Quantitative characterization of micro forces in shale hydration and field applications. Pet. Explor. Dev. 2017, 44, 301–308. [Google Scholar] [CrossRef]

- Jin, Y.; Chen, M.; Chen, Z. Mechanics model of sidewall stability of straight wells drilled through weakly consolidated formations. Drill. Prod. Technol. 1999, 97, 13–14. [Google Scholar]

- Hubbert, M.K.; Willis, D.G. Mechanics of hydraulic fracturing. Trans. AIME 1957, 210, 153–168. [Google Scholar] [CrossRef]

- Westergaard, H.M. Plastic State of Stress Around a Deep Well; Harvard University: Cambridge, MA, USA, 1940. [Google Scholar]

- Gao, J.; Deng, J.; Lan, K.; Feng, Y.; Zhang, W.; Wang, H. Porothermoelastic effect on wellbore stability in transversely isotropic medium subjected to local thermal non-equilibrium. Int. J. Rock Mech. Min. Sci. 2017, 96, 66–84. [Google Scholar] [CrossRef]

- Yu, M.; Chenevert, M.E.; Sharma, M.M. Chemical–mechanical wellbore instability model for shales: Accounting for solute diffusion. J. Pet. Sci. Eng. 2003, 38, 131–143. [Google Scholar] [CrossRef]

- Aadnoy, B.S. Modeling of the stability of highly inclined boreholes in anisotropic rock formations. SPE Drill. Eng. 1988, 3, 259–268. [Google Scholar] [CrossRef]

- Ding, Y.I.; Luo, P.; Liu, X.; Liang, L. Wellbore stability model for horizontal wells in shale formations with multiple planes of weakness. J. Nat. Gas Sci. Eng. 2018, 52, 334–347. [Google Scholar] [CrossRef]

- AlBahrani, H.; Morita, N. Risk-controlled wellbore stability criterion based on a machine-learning-assisted finite-element model. SPE Drill. Complet. 2022, 37, 38–66. [Google Scholar] [CrossRef]

- Ma, T.; Zhang, Y.; Qiu, Y.; Liu, Y.; Li, Z. Effect of parameter correlation on risk analysis of wellbore instability in deep igneous formations. J. Pet. Sci. Eng. 2022, 208, 109521. [Google Scholar] [CrossRef]

- Panchal, M.; Raghavendra, G.; Bhargav Alamgir, M.; Ojha, S.; Babu, V.S.; Ben, B.S. Spectroscopic analysis of natural fiber/epoxy composites. In Handbook of Epoxy/Fiber Composites; Springer: Singapore, 2022; pp. 1–36. [Google Scholar]

- Ma, Y.; Yu, R. New analytical methods to evaluate uncertainty of wellbore stability. J. Pet. Sci. Eng. 2019, 180, 268–277. [Google Scholar] [CrossRef]

- Khatibi, S.; Aghajanpour, A.; Ostadhassan, M.; Farzay, O. Evaluating single-parameter parabolic failure criterion in wellbore stability analysis. J. Nat. Gas Sci. Eng. 2018, 50, 166–180. [Google Scholar] [CrossRef]

- Aslannezhad, M.; Keshavarz, A.; Kalantariasl, A. Evaluation of mechanical, chemical, and thermal effects on wellbore stability using different rock failure criteria. J. Nat. Gas Sci. Eng. 2020, 78, 103276. [Google Scholar] [CrossRef]

- Liu, C.; Han, Y.; Liu, H.; Abousleiman, Y.N. Wellbore-stability analysis by integrating a modified hoek-brown failure criterion with dual-porochemoelectroelastic theory (includes associated erratum). SPE J. 2019, 24, 1957–1981. [Google Scholar] [CrossRef]

- Darvishpour, A.; Seifabad, M.C.; Wood, D.A.; Ghorbani, H. Wellbore stability analysis to determine the safe mud weight window for sandstone layers. Pet. Explor. Dev. 2019, 46, 1031–1038. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Q.; An, X. Characteristics of sedimentary environment and evolution of Permian in southern Sichuan Basin: An example from the profile of Gulin Bajiaocun in Sichuan province. Sediment. Geol. Tethyan Geol. 2022, 42, 398–412. [Google Scholar]

- Zoback, M.D. Reservoir Geomechanics; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- Fan, Y.; Wang, J.; Liu, H.; Wu, P.C. Formation mechanical properties and wellbore stability of the whole well section in Luzhou block. Sci. Technol. Eng. 2020, 20, 6433–6439. [Google Scholar]

- Zhao, Y.; Luo, Y.; Li, L.; Zhou, Y.; Li, L.; Wang, X. In-situ stress simulation and integrity evaluation of underground gas storage: A case study of the Xiangguosi underground gas storage, Sichuan, SW China. J. Geomech. 2022, 28, 523–536. [Google Scholar]

- Deng, J.; Huang, R.; Tian, X. A New Method for Measuring in-situ Stress in Deep Formation. J. Univ. Pet. China 1997, 34–37, 115–116. [Google Scholar]

- Cundall, P.A. A computer model for simulating progressive large-scale movements in blocky rock systems. In Proceedings of the Symposium of the International Society for Rock Mechanics, Nancy, France, 4–6 October 1971. [Google Scholar]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Géotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Jeoungseok, Y. Application of experimental design and optimization to PFC model calibration in uniaxial compression simulation. Int. J. Rock Mech. Min. Sci. 2007, 44, 871–889. [Google Scholar]

- Potyondy, D.O. Simulating stress corrosion with a bonded-particle model for rock. Int. J. Rock Mech. Min. Sci. 2007, 44, 677–691. [Google Scholar] [CrossRef]

- Hou, B.; Jin, Y.; Song, L.; Chao, Z. Failure mechanisms of borehole wall rocks in gravel beds with different grain sizes. Nat. Gas Ind. 2015, 35, 66–70. [Google Scholar]

- Karatela, E.; Taheri, A. Three-dimensional hydro-mechanical model of borehole in fractured rock mass using discrete element method. J. Nat. Gas Sci. Eng. 2018, 53, 263–275. [Google Scholar] [CrossRef]

- Park, N.; Olson, J.E.; Holder, J. Stress-corrosion cracking as an alternative time-dependent shale-stability model. SPE Drill. Complet. 2010, 25, 168–176. [Google Scholar] [CrossRef]

- Wang, C.; Tannant, D.D.; Lilly, P.A. Numerical analysis of the stability of heavily jointed rock slopes using PFC2D. Int. J. Rock Mech. Min. Sci. 2003, 40, 415–424. [Google Scholar] [CrossRef]

- Wu, S.; Xu, X. A study of three intrinsic problems of the classic discrete element method using flat-joint model. Rock Mech. Rock Eng. 2016, 49, 1813–1830. [Google Scholar] [CrossRef]

- Yang, F. Stability Analysis of End Soil of Tunnel in Sand Layer Based on PFC Fluid-Solid Coupling; Changsha University of Science & Technology: Changsha, China, 2020. [Google Scholar]

- Hu, J.X.; Bian, K.; Liu, J.; Xie, Z.Y.; Chen, M.; Li, B.Y.; Cen, Y.; Liu, Z.P. Discrete element simulation of shale softening based on parallel-bonded water-weakening model. Chin. J. Geotech. Eng. 2021, 43, 725–733. [Google Scholar]

| Formation | Depth /m | Vertical Stress /MPa | Minimum Horizontal Principal Stress/MPa | Maximum Horizontal Principal Stress/MPa | Gradient of Vertical Stress /MPa | Gradient of Minimum Horizontal Principal Stress/MPa | Gradient of Maximum Horizontal Principal Stress/MPa |

|---|---|---|---|---|---|---|---|

| Longtan | 3190 | 78.31 | 74.13 | 85.56 | 2.45 | 2.32 | 2.71 |

| Longtan | 3193 | 79.05 | 75.40 | 87.2 | 2.48 | 2.36 | 2.73 |

| Ave. | \ | 78.68 | 74.77 | 86.88 | 2.47 | 2.34 | 2.72 |

| Parameter | Value | ||||

|---|---|---|---|---|---|

| Shale | Siltstone | Sandstone | Limestone | Coal | |

| Density of particle (g/cm3) | 2.7 | 2.7 | 2.7 | 2.7 | 1.8 |

| Mean particle radius of particle (mm) | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

| Contact modulus of particle (MPa) | 20,000 | 30,000 | 35,500 | 40,000 | 8000 |

| Stiffness ratio of particle | 2.6 | 2.0 | 1.5 | 1.5 | 2.0 |

| Friction coefficient of particle | 0.45 | 0.55 | 0.6 | 0.52 | 0.35 |

| Effective modulus of parallel bond (MPa) | 20,000 | 30,000 | 35,500 | 10,000 | 8000 |

| Stiffness ratio of parallel bond | 2.6 | 2.0 | 1.5 | 1.5 | 2.0 |

| Tensile strength of parallel bond (MPa) | 2.0 | 5.0 | 6.0 | 6.0 | 1.0 |

| Cohesion strength of parallel bond (MPa) | 10 | 20 | 30 | 25 | 4 |

| Friction angle of parallel bond (°) | 30 | 35 | 40 | 38 | 25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, J.; Sang, Y.; Meng, B.; Xia, L.; Wang, Y.; Ma, C.; Tan, T.; Yang, B. Study on the Wellbore Instability Mechanism in the Longtan Formation with Soft/Hard Thin Interlayers in the South Sichuan Basin. Processes 2025, 13, 727. https://doi.org/10.3390/pr13030727

Guo J, Sang Y, Meng B, Xia L, Wang Y, Ma C, Tan T, Yang B. Study on the Wellbore Instability Mechanism in the Longtan Formation with Soft/Hard Thin Interlayers in the South Sichuan Basin. Processes. 2025; 13(3):727. https://doi.org/10.3390/pr13030727

Chicago/Turabian StyleGuo, Jianhua, Yu Sang, Beiqiao Meng, Lianbin Xia, Yangsong Wang, Chengyu Ma, Tianyi Tan, and Bin Yang. 2025. "Study on the Wellbore Instability Mechanism in the Longtan Formation with Soft/Hard Thin Interlayers in the South Sichuan Basin" Processes 13, no. 3: 727. https://doi.org/10.3390/pr13030727

APA StyleGuo, J., Sang, Y., Meng, B., Xia, L., Wang, Y., Ma, C., Tan, T., & Yang, B. (2025). Study on the Wellbore Instability Mechanism in the Longtan Formation with Soft/Hard Thin Interlayers in the South Sichuan Basin. Processes, 13(3), 727. https://doi.org/10.3390/pr13030727