Combined Cycle Gas Turbine System with Molten Salt Energy Storage: Peak Regulation and Flexibility

Abstract

1. Introduction

- (1)

- An F-class CCGT system and its coupled molten salt energy storage system were designed and established by using the power station thermal system calculation software EBSILON 16.0. At the same time, an integrated operation strategy for the CCGT system’s start-up, standstill operation, and load-following operation coupled with a molten salt energy storage device was proposed.

- (2)

- The performance of the coupled system was evaluated comprehensively by calculating the electrothermal characteristics, electrical output regulation capability, and thermal performance evaluation of systems. In addition, the advantages of the coupled system were determined through comparison with the F-class CCGT system.

- (3)

- The conclusions accelerate the performance improvement of the CCGT system, including the improvement of the generating capacity of the unit, the enhancement of the system peak load balancing capacity, and the improvement of the system heating capacity. Additionally, the economy of the system under different heat loads is analyzed.

2. Modeling of Systems

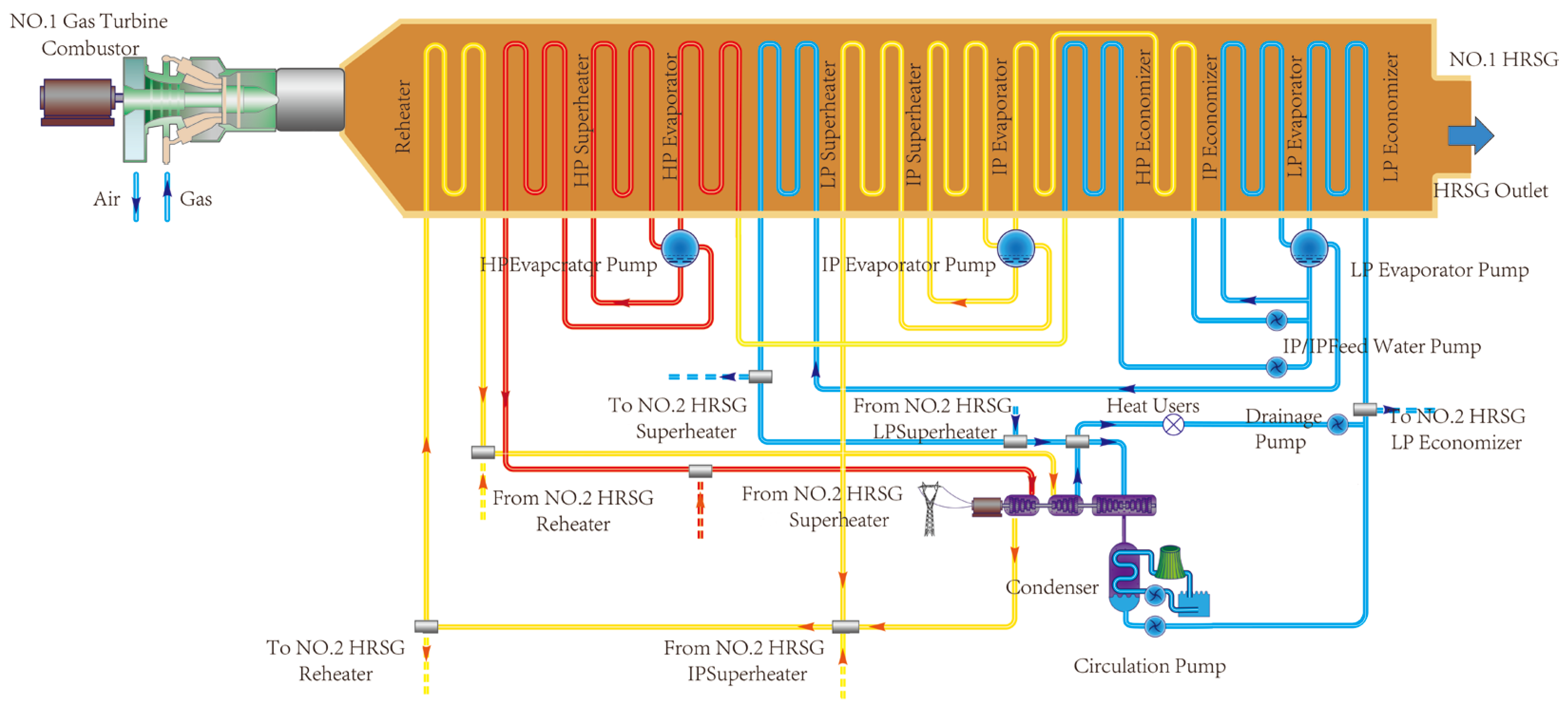

2.1. Description of CCGT System

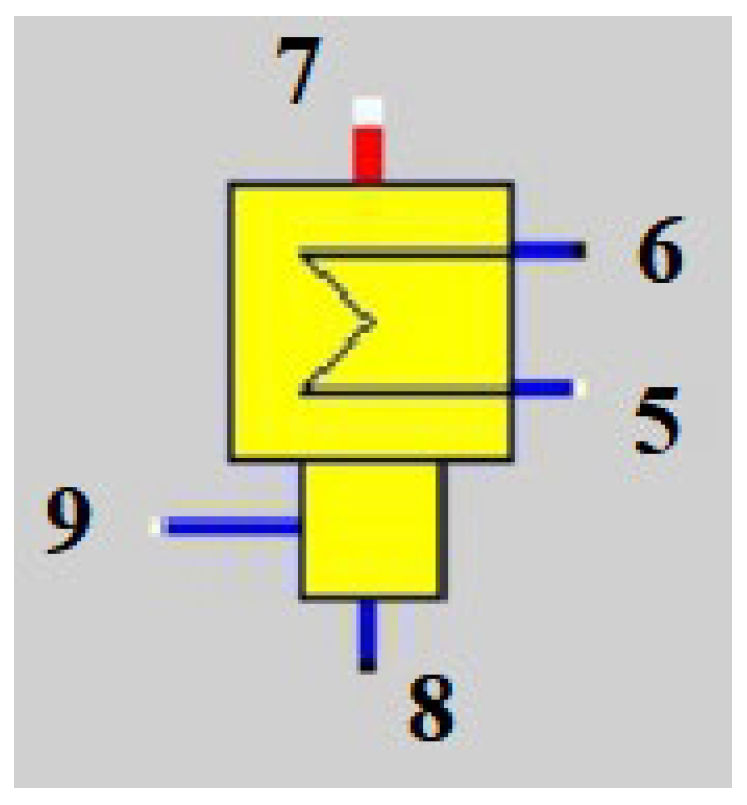

2.2. Description of Molten Salt Energy Storage Coupled with CCGT System

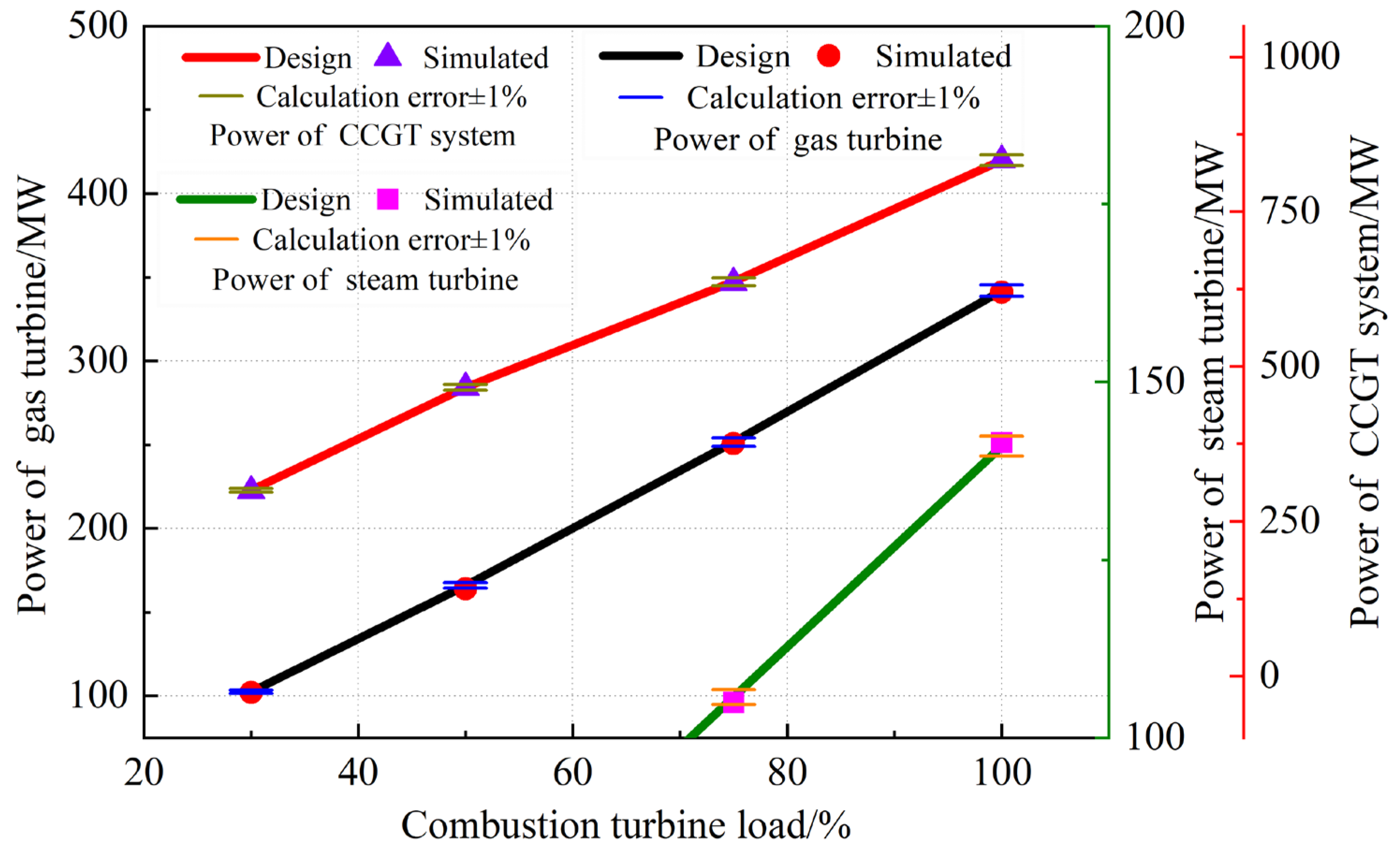

2.3. Modeling and Verification of the CCGT System

2.3.1. Modeling of Steam Turbine Subsystem

2.3.2. Modeling of Steam Turbine Condenser

2.3.3. Verification of the Model

3. Results and Discussion

3.1. Entropy Change and Thermal Efficiency of System

3.2. Electrothermal Characteristics of Systems

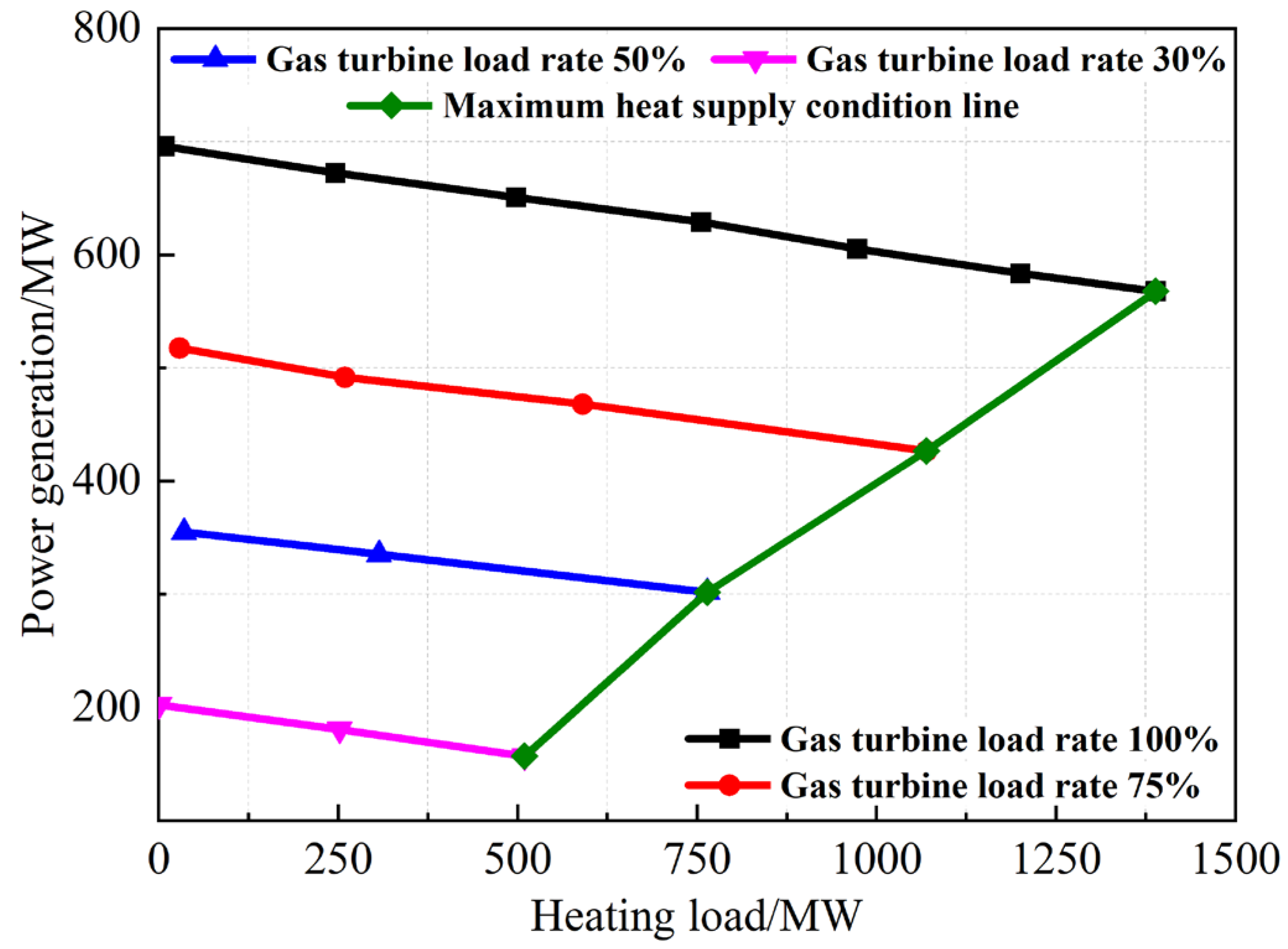

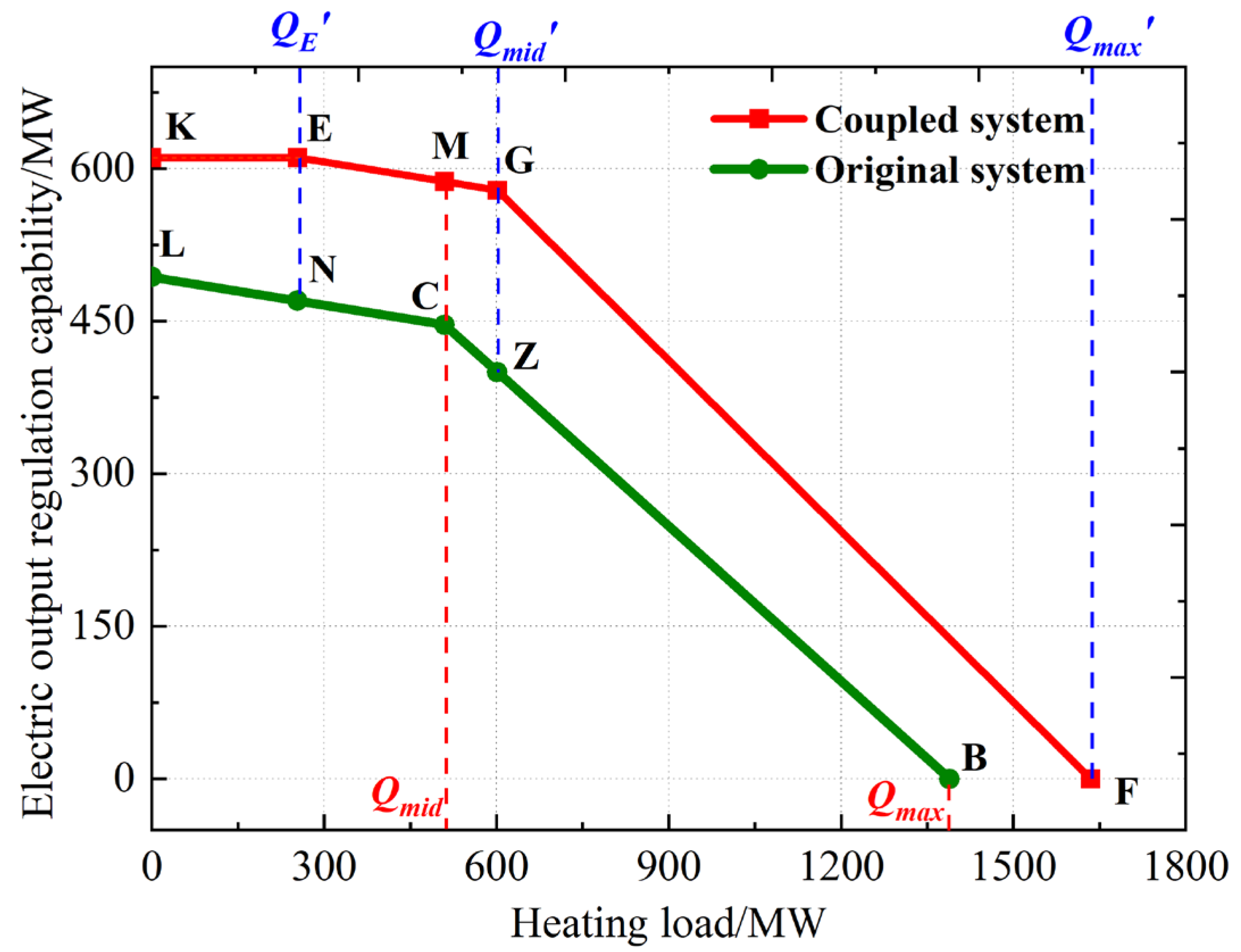

3.3. Electrical Output Regulation Capability of Systems

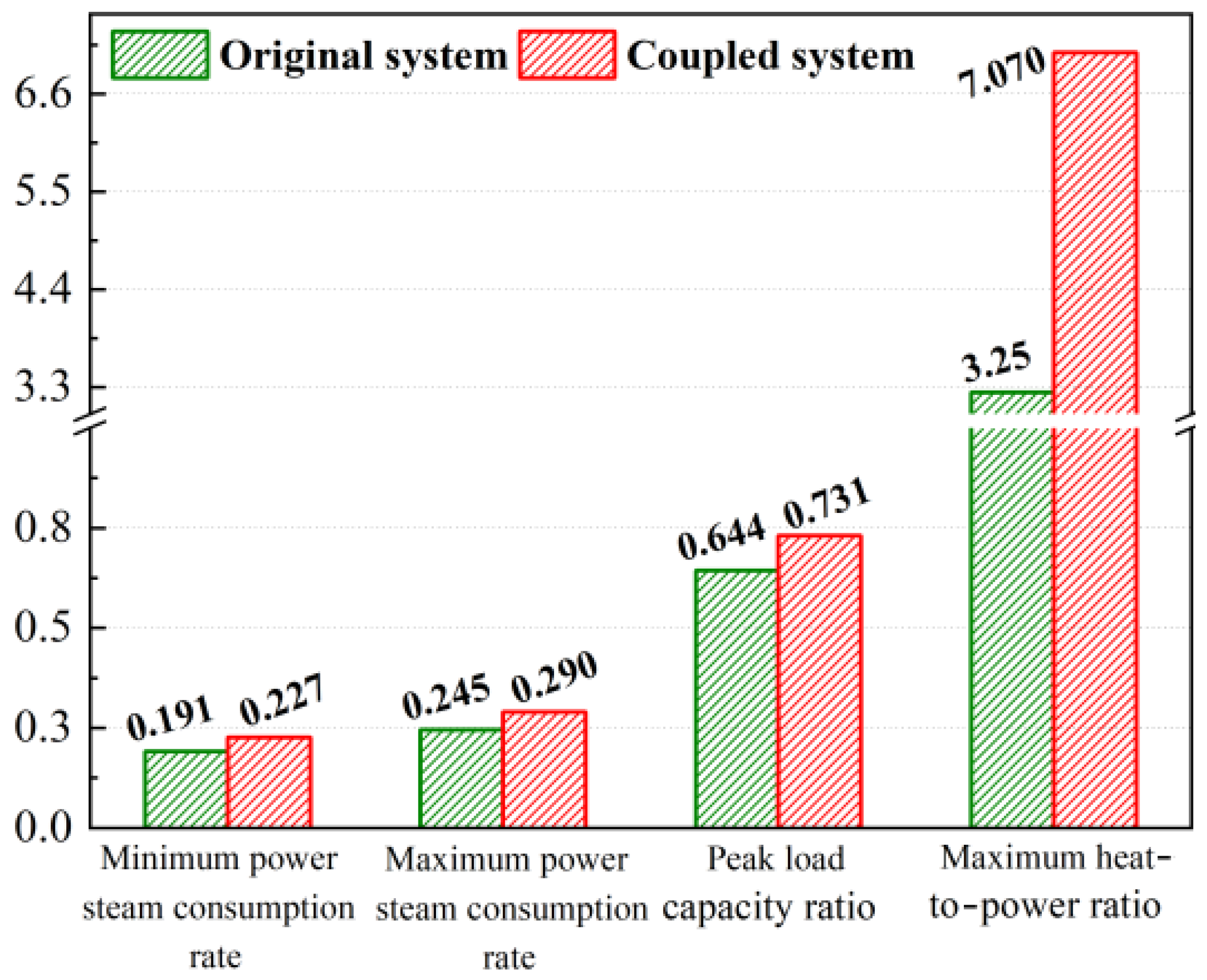

3.4. Thermal Performance Evaluation of Systems

4. Conclusions

- (1)

- A method of coupling a molten salt thermal energy storage device with a combined cycle gas turbine system is proposed. When the energy demand is reduced, the molten salt thermal energy storage device will adjust the plan. On the contrary, we can use the heat stored in high-temperature molten salt to release energy, improving the flexibility of unit operation and the energy configuration ability of the power system.

- (2)

- Before coupling the molten salt heat storage device in the extraction mode, the combined cycle gas turbine unit has the maximum and minimum generation power when the heat supply is constant. With the increase in heat supply, the difference between the total and minimum generation power becomes smaller and smaller, and the peaking capability of the combined cycle gas turbine unit becomes worse.

- (3)

- After coupling the molten salt heat storage device, the maximum generation power of the combined cycle gas turbine unit is increased while the minimum generation power decreases. The electrical output regulation capability is increased by 29.95–44.66%, and the heating capacity is increased by 17.69%. With the increase in heat supply, the difference between the maximum and minimum generation power increases, and the peaking capability of the coupled system increases. The peaking capacity ratio increases from 0.64 to 0.73, which is 13.5% higher than that of the original system.

- (4)

- When the heating load is high, the cold source loss of the coupling system and the gas consumption rate of power generation are reduced, resulting in the economy’s improvement. When the heating load is low, the efficiency loss of the gas turbine in the peak-shaving operation of the coupled system increases, the generation gas consumption rate of power generation increases, and the economy decreases. The maximum thermoelectric ratio of the coupled system can reach 7.07.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviations | |

| CCGT | combined cycle gas turbine |

| MEL | minimum environmental load |

| HPST | high-pressure steam turbine |

| IPST | intermediate-pressure steam turbine |

| LPST | low-pressure steam turbine |

| NGCC | natural gas combined cycle |

| CAES | compressed air energy storage |

| ORC | organic Rankine cycle |

| SNGCC | supercharged natural gas combined cycle |

| HRSG | heat recovery steam generator |

| IGV | inlet guide vane |

| EGR | exhaust gas recycle |

| IGVC | inlet guide vane control |

| EGRR | exhaust gas recirculation rate |

| CSP | concentrated solar power |

| MSEM | multistage steam expansion system |

| CLHS | cascaded latent heat storage |

| ACAES | adiabatic compressed air energy storage |

| GT | gas turbine |

| HPT | high-pressure turbine |

| HP | high pressure |

| IP | intermediate pressure |

| IPT | intermediate-pressure turbine |

| LP | low pressure |

| LPT | low-pressure turbine |

| THA | turbine heat acceptance |

| Symbols | |

| Qact,max | actual maximum energy supply, MW |

| Qthe,max | theoretical maximum energy storage, MW |

| η | efficiency of energy storage, % |

| △P | electrical output regulation capability of original system, MW |

| △P’ | electrical output regulation capability of coupled system, MW |

| Q | heating load, MW |

| Qmax | maximum generating heating load of original system, MW |

| PQmax | generating power corresponding to the maximum heating capacity of original system, MW |

| PQmin | generating power corresponding to the minimum heating capacity of original system, MW |

| Pmax | maximum generating power of original system, MW |

| Pmin | minimum generating power of original system, MW |

| Qmid | maximum heating load corresponding to the minimum generating power of original system, MW |

| Q’E | maximum heating load without load reduction in coupled system, MW |

| Q’max | maximum heating load of coupled system |

| Q’mid | maximum heating load corresponding to the minimum generating power of coupled system, MW |

| X | thermoelectric ratio |

| Q | heating load, MW |

| Pe | electric load, MW |

| be | gas consumption rate, m3/kW·h |

| Gg | natural gas mass flow rate, kg/s |

| Qar,net | natural gas net calorific value, MJ/Nm3 |

| qar,net | calorific value of natural gas, MJ/Nm3 |

| Rg | peak shaving capacity ratio, % |

| Pe,max | maximum generating power at a certain heating load, MW |

| Pe,min | minimum generating power at a certain heating load, MW |

| Pe,N | system rated power, MW |

References

- Ahmad, J.; Adeel, J.; Abdul, W.; Muhammad, O.Z.; Majid, A.; Asif, H.K.; Muhammad, I. Multiparametric optimization for reduced condenser cooling water consumption in a degraded combined cycle gas turbine power plant from a water-energy nexus perspective. Appl. Energy 2021, 304, 117764. [Google Scholar] [CrossRef]

- Zhi, W.; Qirun, S.; Yuping, L.; Wei, G.; Pengxiang, L.; Renjie, D.; Siming, W. Distributed chance-constrained based total energy supply capability evaluation method for integrated power and natural gas system. Int. J. Electr. Power Energy Syst. 2022, 141, 108193. [Google Scholar] [CrossRef]

- Mahmut, D. Prediction of NOx emissions from gas turbines of a combined cycle power plant using an ANFIS model optimized by GA. Fuel 2022, 321, 124037. [Google Scholar] [CrossRef]

- Na, W.; Hongbo, T.; Xiaoqiao, Q. Simulation and analysis of a peak regulation gas power plant with advanced energy storage and cryogenic CO2 capture. Energy Storage Sav. 2023, 2, 479–486. [Google Scholar] [CrossRef]

- Andrew, L.; Braden, C.; LaGrande, G.; Austin, B.; Logan, B.; Nick, R.; Matthew, M. Thermal design and analysis of a passive modular molten salt microreactor concept. Nucl. Eng. Des. 2023, 402, 112107. [Google Scholar] [CrossRef]

- Andreas, U.; Göran, A. Analyzing operational flexibility of electric power systems. Int. J. Electr. Power Energy Syst. 2015, 72, 155–164. [Google Scholar] [CrossRef]

- Chengxu, C.; Yichen, Z.; Zhihua, G.; Xiaoze, D.; ELSaeed, S.E. Comparative study on flexibility enhancement of combined heat and power for wind power accommodation. Appl. Therm. Eng. Des. Process. Equip. Econ. 2023, 235, 121287. [Google Scholar] [CrossRef]

- Kamal, A.; Uyioghosa, I.; Ioannis, R.; Richard, H. Impact of gas turbine flexibility improvements on combined cycle gas turbine performance. Appl. Therm. Eng. 2021, 189, 116703. [Google Scholar] [CrossRef]

- Polyzakis, A.L.; Koroneos, C.; Xydis, G. Optimum gas turbine cycle for combined cycle power plan. Energy Convers. Manag. 2008, 149, 551–563. [Google Scholar] [CrossRef]

- Zuming, L.; Karimi, I.A. Simulation of a combined cycle gas turbine power plant in Aspen HYSYS. Energy Procedia 2019, 158, 3620–3625. [Google Scholar] [CrossRef]

- Sylwia, K.G.; Paweł, Z.; Iliya, I.; Gabriel, P.N.; Janusz, B. Techno-economic evaluation of combined cycle gas turbine and a diabatic compressed air energy storage integration concept. Energy 2023, 266, 126345. [Google Scholar] [CrossRef]

- Yang, C.; Huanxin, L.; Ping, W.; Kunle, F.; Zhifeng, H.; Xiaoqian, M. Economic analysis on peak-regulation of GTCC cogeneration unit with extraction heating. Proc. CSEE 2020, 40, 592–600. [Google Scholar] [CrossRef]

- Bălănescu, D.T.; Homutescu, V.M. Performance analysis of a gas turbine combined cycle power plant with waste heat recovery in Organic Rankine Cycle. Procedia Manuf. 2019, 32, 520–528. [Google Scholar] [CrossRef]

- Linda, B.; Andrea, O. Supercharged gas turbine combined cycle: An improvement in plant flexibility and efficiency. Energy 2015, 81, 615–626. [Google Scholar] [CrossRef]

- Vahab, H.H.; Afef, F.; Concepción, A.M.; Ramin, F.A. H2, H∞, H2/H∞, and μ-synthesis controllers for the speed and temperature control of a real gas turbine unit in a combined cycle power plant. Energy Sci. Eng. 2019, 7, 2205–2222. [Google Scholar] [CrossRef]

- Zuming, L.; Iftekhar, A.K. New operating strategy for a combined cycle gas turbine power plant. Energy Convers. Manag. 2018, 171, 1675–1684. [Google Scholar] [CrossRef]

- Yufei, Z.; Hanfei, Z.; Shuo, L.; Ziyi, L.; Xingqi, D.; Liqiang, D.; Umberto, D. Experimental study on heat transfer characteristics between high-pressure air and molten salt used in solar-aided compressed air energy storage systems. Energy 2024, 313, 134127. [Google Scholar] [CrossRef]

- Xue, X.; Yifan, Z.; Xiang, L.; Ao, Z.; Hao, Z. 1.05 MW molten salt furnace experimental investigation of full-conditional thermal energy storage for the transfer and storage of waste heat from blast furnace gas. Renew. Energy 2024, 231, 120955. [Google Scholar] [CrossRef]

- Burcu, K.; Marc, M.; Camila, B.; Ana, I.F.; Halime, P. Performance analysis of a molten salt packed-bed thermal energy storage system using three different waste materials. Sol. Energy Mater. Sol. Cells 2024, 278, 113199. [Google Scholar] [CrossRef]

- Shuai, Z.; Ziyuan, L.; Yuanpeng, Y.; Limei, T.; Yuying, Y. Heat transfer characteristics and compatibility of molten salt/ceramic porous composite phase change material. Appl. Therm. Eng. 2022, 100, 107476. [Google Scholar]

- Appasaheb, R.; Sandip, K.S.; Mohit, J. Transient performance analysis of concentrating solar thermal power plant with finned latent heat thermal energy storage. Renew. Energy 2020, 145, 1957–1971. [Google Scholar] [CrossRef]

- Qijun, Z.; Jianning, D.; Heng, C.; Fuyuan, F.; Gang, X.; Xiuyan, W.; Tong, L. Dynamic characteristics and economic analysis of a coal-fired power plant integrated with molten salt thermal energy storage for improving peaking capacity. Energy 2024, 290, 130132. [Google Scholar] [CrossRef]

- Soto, G.J.; Wagner, M.J.; Neises, T.W.; Lindley, B.A. Performance analysis of integrated Nuclear-Solar Energy system sharing same molten salt thermal energy storage. Prog. Nucl. Energy 2024, 171, 105166. [Google Scholar] [CrossRef]

- Ehsanolah, A.; Mehdi, P.; Siamak, H.; Moonyong, L. A new analysis for a concentrated solar power-based cogeneration system with molten salt energy storage and heat recovery steam generator-Case study(USA, France, Canada). Renew. Energy Focus 2023, 46, 256–280. [Google Scholar] [CrossRef]

- Decai, L.; Yukun, H.; Dacheng, L.; Jihong, W. Combined-cycle gas turbine power plant integration with cascaded latent heat thermal storage for fast dynamic responses. Energy Convers. Manag. 2019, 183, 1–13. [Google Scholar] [CrossRef]

- Jacek, D.W.; Jihong, W. Feasibility study of Combined Cycle Gas Turbine (CCGT) power plant integration with Adiabatic Compressed Air Energy Storage (ACAES). Appl. Energy 2018, 221, 477–489. [Google Scholar] [CrossRef]

- ISO 18888:2017; Gas Turbine Combined Cycle Power Plants—Thermal Performance Tests. ISO: Geneva, Switzerland, 2017.

- EBSILON Professional 16.0 (Simulation Software). STEAG Energy Services-System Technologies. 2024. Available online: https://www.ebsilon.com/en/ (accessed on 18 February 2025).

- Muhammad, F.; Ahmed, K.A.; Binjian, N.; Imran, A. Thermal energy storage integration with nuclear power: A critical review. J. Energy Storage 2024, 96, 112577. [Google Scholar] [CrossRef]

- Nianci, L.; Lei, P.; Simon, P.; Deli, Z.; Ahmad, A. A complete dynamic modeling of two-by-one gas-steam combined cycle unit for coordinated control design. Appl. Therm. Eng. 2024, 253, 123766. [Google Scholar] [CrossRef]

- Adams, T.; Dowell, N.M. Off-design point modelling of a 420 MW CCGT power plant integrated with an amine-based post-combustion CO2 capture and compression process. Appl. Energy 2016, 178, 681–702. [Google Scholar] [CrossRef]

- Xin, H.; Chengchen, L.; Huanran, W. Thermodynamics analysis of a combined cooling, heating and power system integrating compressed air energy storage and gas-steam combined cycle. Energy 2022, 260, 125105. [Google Scholar] [CrossRef]

- Tengfei, Z.; Sayed, F.A.; Manoj, K.A.; Ahmad, Y.A.B.A.; Ayman, A.G.; Prajoona, V.; Nehad, A.S.; Xiaomin, G. Design and thermo-enviro-economic analyses of a novel thermal design process for a CCHP-desalination application using LNG regasification integrated with a gas turbine power plant. Energy 2024, 295, 131003. [Google Scholar] [CrossRef]

- Serhat, K.; Mustafa, I. Experimental and numerical analysis of turbulent premixed combustion of low calorific value coal gases in a generated premixed burner. Fuel 2018, 220, 586–598. [Google Scholar] [CrossRef]

| Gas Turbine | |||

|---|---|---|---|

| Type | M701F4, heavy-duty, axial-flow | Stage of gas turbine | 4 |

| Rated speed (rpm) | 3000 | Efficiency (%) | 39.9 |

| Exhaust temperature (°C) | 576 | Single power (MW) | 346.32 |

| Single displacement (t/h) | 2808.60 | Exhaust pressure (kPa) | 3.93 |

| Gas turbo-compressor | Blade number | 17 | |

| Type | axial-flow | ||

| Pressure ratio | 18 (ISO 18888:2017) [27] | ||

| Adjustable blade | 1 | ||

| Gas turbine combustor | Type | dry, low NOx | |

| Burner number | 20 | ||

| Steam turbine | |||

| Model | TC2F-40.5inch | Type | three-pressure reheat/double-cylinder operation |

| Length of last stage blade (mm) | 1029 | Power (MW) | 143.6 |

| Steam pressure (MPa) | Main steam of high-pressure cylinder | 12.59 | |

| Reheat steam | 3.36 | ||

| Steam temperature (°C) | Main steam of high-pressure cylinder | 523.90 | |

| Reheat steam | 549.20 | ||

| Steam flow rate (t/h) | Main steam of high-pressure cylinder | 584.10 | |

| Reheat steam | 730.90 | ||

| HRSG | |||

| Type | Non-supplementary combustion, horizontal, three-pressure reheat, natural circulation boiler | Maximum pressure drop of gas side (kPa) | 3.93 |

| High-pressure section | Mass flow rate of steam (t/h) | 292.10 | |

| Outlet steam pressure (MPa) | 12.97 | ||

| Outlet steam temperature (°C) | 525.90 | ||

| Reheat section | Mass flow rate of steam (t/h) | 365.40 | |

| Outlet steam pressure (MPa) | 3.45 | ||

| Outlet steam temperature (°C) | 551.20 | ||

| Intermediate-pressure section | Mass flow rate of steam (t/h) | 82.30 | |

| Outlet steam pressure (MPa) | 3.66 | ||

| Outlet steam temperature (°C) | 292.90 | ||

| Low-pressure section | Mass flow rate of steam (t/h) | 44.20 | |

| Outlet steam pressure (MPa) | 0.70 | ||

| Outlet steam temperature (°C) | 246.60 | ||

| Name | Value | Name | Value |

|---|---|---|---|

| Heating load (MW) | 695.40 | Power (MW) | 836.24 |

| Single fuel quality (t/h) | 67.49 | Extraction flow for heat supply (t/h) | 834.60 |

| Fuel gas density (kg/m3) | 0.72 | Efficiency of HRSG (%) | 82.60 |

| Name | Value | Name | Value |

|---|---|---|---|

| Type | KCl(54)-46ZnCl2 | Heat storage efficiency (%) | 78 |

| Ρ (kg/m3) | 2410 | Capacity of heat storage tank (m3) | 700–20,000 |

| , PCM (J/kg·K) | 670 | Energy storage time (h) | 1.28 |

| , PCM (J/kg·K) | 880 | λPCM (W/m·K) | 0.83 |

| Tm (K) | 705 | L (kJ/kg) | 218 |

| Gas Turbine | Steam Turbine | HRSG | |

|---|---|---|---|

| Entropy change (kJ/kg) | 1.36 | 1.28 | 1.55 |

| Project | Before | After | ||

|---|---|---|---|---|

| Corridor | ||||

| Thermal Load (MW) | 0–509.66 | 509.66–1388.94 | 0–601.22 | 601.22–1634.64 |

| Electrical Load (MW) | 157.03–696.00 | 157.03–649.42 | 85.03–696.00 | 85.03–589.98 |

| Thermoelectric Ratio | 0–3.25 | 0.78–2.45 | 0–7.07 | 1.02–2.77 |

| Generation Gas Consumption Rate/m3 (kW·h) | 0.19–0.24 | 0.22–0.25 | 0.23–0.29 | 0.23–0.27 |

| Peaking Capacity Ratio/% | 0.64 | 0.73 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, L.; Yu, J.; Wang, L.; Xu, X. Combined Cycle Gas Turbine System with Molten Salt Energy Storage: Peak Regulation and Flexibility. Processes 2025, 13, 604. https://doi.org/10.3390/pr13030604

Cao L, Yu J, Wang L, Xu X. Combined Cycle Gas Turbine System with Molten Salt Energy Storage: Peak Regulation and Flexibility. Processes. 2025; 13(3):604. https://doi.org/10.3390/pr13030604

Chicago/Turabian StyleCao, Lihua, Jingwen Yu, Lei Wang, and Xin Xu. 2025. "Combined Cycle Gas Turbine System with Molten Salt Energy Storage: Peak Regulation and Flexibility" Processes 13, no. 3: 604. https://doi.org/10.3390/pr13030604

APA StyleCao, L., Yu, J., Wang, L., & Xu, X. (2025). Combined Cycle Gas Turbine System with Molten Salt Energy Storage: Peak Regulation and Flexibility. Processes, 13(3), 604. https://doi.org/10.3390/pr13030604