Abstract

Harnessing the power of phase change materials (PCMs) in asphalt pavements proposes a sustainable solution for addressing temperature-related issues, affording more robust and energy-efficient infrastructure. PCMs hold enormous potential for reforming various industries due to their ability to store and release large amounts of thermal energy, offering noteworthy benefits in energy efficiency, thermal management, and sustainability. The integration of PCMs within pavements presents an increasingly exciting field of research. PCMs have the ability to efficiently manage the changes in and distribution of temperature in asphalt pavements via the release and absorption of latent heat that occurs during the phase shifts of PCMs. Asphalt pavements experience less severe temperatures and a slower rate of temperature fluctuation as a result of this, which in turn reduces the amount of stress caused by temperature. In addition, the function of temperature adjustment that PCMs provide is natural, intelligent, and in line with the direction in which the development of smart pavements is heading in the future. This study aims to explore the impact of organic, inorganic, and mixed organic–inorganic PCMs on diverse surface characteristics of asphalt. In addition, this review addresses current challenges associated with using PCMs in asphalt and explores potential advantages that could facilitate future research in addition to broadening the implementation of PCMs in construction.

1. Introduction

Asphalt mixes establish an energetic element in creating materials for road pavement construction. The primary drivers behind their use in road construction comprise simplified maintenance, reduced construction time, and improved ride quality and safety [1]. However, it may be challenging to get asphalt pavements to function well during their entire service lives, particularly when they are exposed to heavy vehicle traffic and tough weather situations (rain, for example). This challenge expands as the pavement ages, rendering it more exposed to adversative climatic circumstances as a result of prolonged exposure [2]. Amending the temperature distribution along the pavement is described as a prospective practice to lessen these effects and improve protection from extreme weather circumstances. This practice can delay freezing and temperature shock incidences within the pavement and, accordingly, diminish the occurrence of low-temperature cracking [3]. Furthermore, asphalt can rapidly expand or contract in reaction to sudden temperature deviations, such as those caused by hot days and cold nights. Over time, the asphalt structure becomes more brittle due to the continuous expansion and contraction, lessening its durability. It is therefore likely for gaps and cracks to form, dictating frequent maintenance and repairs [4].

Intensive research has been conducted to find solutions to the concerns related to pavement materials and construction and to improve their service life. To reduce the occurrence of high-temperature rutting in asphalt pavements, a number of pioneering methods have been executed. These comprise altered concrete gradations, heat-reflecting coatings, and polymer-improved asphalt binders. The popularity of rubber asphalt binders has increased recently as they enhance the pavement’s resilience to fatigue. To address the issue of pavement cracking, several solutions have been suggested, such as fiber-modified asphalt binders, slurry seals, and structural overlays. These measures contribute to mitigating thermal distress in asphalt pavements, albeit to varying degrees. However, even with these interventions, thermal distress can occur when the pavement is exposed to high-temperature conditions, exacerbated by the urban heat island effect. As a result, it is of the utmost importance to devise a technique for the active regulation of temperature in order to reduce the temperature peak and, as a consequence, avoid the thermal stress of asphalt pavements.

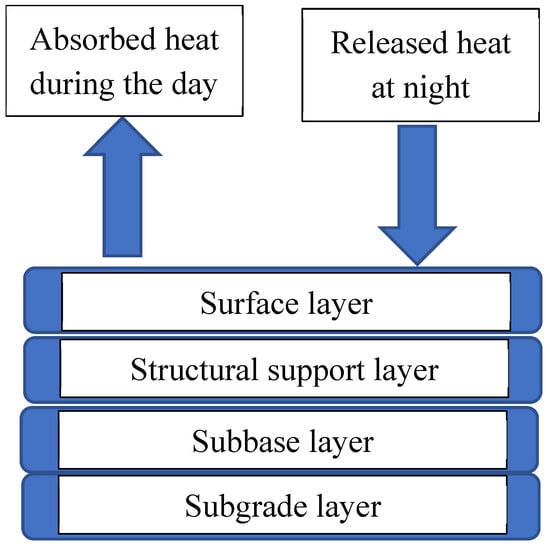

PCMs are an example of the functional materials included in numerous industrial applications. The temperatures of phase change are those at which changes in the phase state of PCMs can occur. These changes are followed by the release or absorption of enormous quantities of energy, which is frequently called the phase change latent heat. PCMs have many benefits, which include a high energy storage capacity, tiny volume, a wide range of temperatures at which phases transition, an approximate isothermal process, simple management, and a temperature that remains constant throughout the absorption or release of heat [5,6,7,8]. They are able to absorb or release heat as the state of their matter changes. Despite their relatively low thermal conductivity, PCMs exhibit great promise for addressing temperature-related challenges. Figure 1 shows a basic representation of the layers of asphalt pavement. These include the surface and base (structural support) layers, where PCMs are integrated, the subbase layer, which contains granular material, and finally the subgrade, which is the natural soil or rock layer below. Specifically tailored for asphalt mixtures, PCMs deliver a solution by absorbing excessive heat in warmer circumstances, thus avoiding asphalt softening and tearing. On the other hand, in colder climates, PCMs release stored heat, maintaining the asphalt’s flexibility and preventing cracking [9]. Consequently, it can be said that adding PCMs can decrease the thermal stress on asphalt, therefore extending the pavement’s lifespan.

Figure 1.

A schematic diagram of asphalt pavement layers with absorbed and released heat.

Polyethylene glycol (PEG) [10,11,12,13,14,15,16,17] and paraffin wax [18] are two specimens of the types of PCM that have been established to have an initial phase change temperature that is greater than 40 °C. PEG is a non-toxic material that is also cheap. It has a high enthalpy of phase change and is thermally stable [19]. Specifically, PEG that has a mean molecular weight of about 2000 is one of the PCMs that has been engaged in cooling asphalt pavement [12]. This is because the phase change temperature of PEG was appropriate for the asphalt pavement’s scorching heat. Zhang et al. [20] considered expandable graphite to be used as a medium to present PEG into the asphalt binder and performed research to understand if it could be utilized. Their study found that a composite containing PEG and expanded graphite could actually lower the asphalt binders’ thermal sensitivity by reducing the rate of temperature change. Jin et al. [21] established a temperature-adjusted asphalt mixture by substituting fine particles with a PEG/expanding perlite composite, permitting the mixture to preserve its original steadiness. The results showed that the asphalt mixture involving PCM reduced the surface temperature by up to 7 °C in comparison with the control asphalt mixture. Nevertheless, only a few investigations have thoroughly examined the effect of PEG on the asphalt binder and mixture. A study of the production and performance of PCMs used for asphalt pavements was published by Wang et al. [22]. Their review analyzed the efficiency and assessment techniques of asphalt mixes using various PCMs. The authors also summarized the mathematical simulation approaches of PCM-infused asphalt mixtures. In addition, they analyzed potential avenues for further research and proposed potential solutions to important technological difficulties.

Chen et al. [23] reviewed PCM categories and the various ways they can be included in asphalt mixtures. Additionally, the performances of PCM-modified asphalts and their thermal and mechanical characteristics were analyzed. They found that managing asphalt’s temperature-dependent performance with mixes can be accomplished effectively in the temperature range where phase change occurs. PEG and n-tetradecane have been traditionally applied on asphalt pavements to control low and high asphalt temperatures, respectively.

Considering the information listed above, it is reasonable to conclude that no specific study has been performed to look into all of the important aspects associated with using PCMs in asphalt pavements. In turn, the current review comes to fill this gap in the open literature. Specifically, this study aims to perform a comprehensive investigation on integrating organic, inorganic, and hybrid organic–inorganic PCMs into asphalt pavements, shedding a light on the significant challenges that require further investigation and then drawing essential conclusions based on the available research. Specifically, this introduces a complete understanding of the most effective options to enhance energy efficiency and thermal regulation, aimed towards developing more durable and sustainable infrastructure of asphalt pavements. Consequently, detailed explanations of various research, technical, and development methodologies regarding PCMs in asphalt pavements are outlined. This review focuses on analyzing studies published in the last five years, between 2019 and 2023. This review can therefore help scientists to better recognize the numerous challenges that should be addressed in future studies while using PCMs in asphalt pavements.

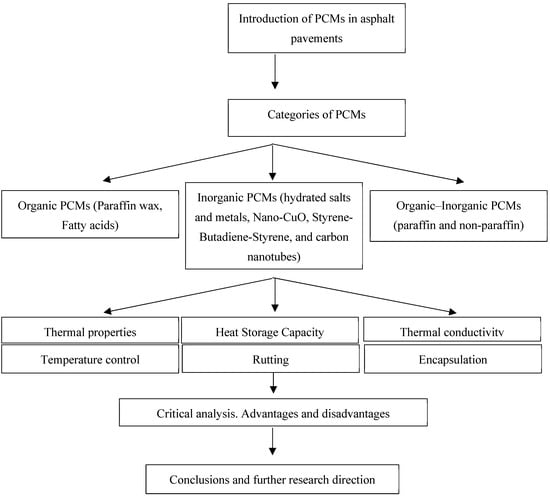

Figure 2 introduces the roadmap of the paper’s structure to elaborate the integration of PCMs in asphalt pavements. First, the introduction presents the importance of PCMs in improving thermal performance and energy efficiency. Details on the types of PCMs suitable for asphalt pavements are discussed in the subsequent sections, with investigation of their thermal characteristics and mechanisms. Additionally, the roadmap shows the discussion on the methodologies used to incorporate PCMs into asphalt mixes besides analyzing the effects on pavement performance. Lastly, the paper addresses the most challenges and potential solutions, recommending further research directions in this field.

Figure 2.

A roadmap of this paper’s structure for using PCMs in asphalt pavements.

2. Review Methodology

To deliver an overview of papers that have examined the integration of different types of PCMs in asphalt pavements, a systematic literature review is executed. Conducting this review is of importance as urban areas continue to encounter elevated temperatures and increased heat absorption as a result of extensive asphalt surfaces. In this aspect, the integration of PCMs grants a potential solution to improve thermal management and energy efficacy. This review is specifically conducted by critically analyzing the existing academic literature. Specifically, the steps of the PRISMA (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) were utilized. In this regard, different databases have been utilized to search peer-reviewed academic literature, including SpringerLink, ScienceDirect, Google Scholar, and Scopus. The inclusion criteria primarily consider the relevance of the topic, and therefore the studies that specifically explored the integration of PCMs in asphalt pavements were selected. In this aspect, the main focus is on selecting the experimental studies that contain experimental work to appraise the performance of PCMs in asphalt. More importantly, this review covers recent studies published between 2019 and 2023 to reflect the latest improvements in this field. On the other hand, irrelevant studies that do not directly correlate to PCMs in asphalt pavements, such as those targeting some other paving materials, are excluded. The keywords for the current review comprise phase change materials, asphalt, pavement, and recent advances. Thus, it is fair to admit that the outcomes of this review are necessary policymakers, engineers, and researchers who aim to optimize asphalt pavements’ performance.

3. Studies Related to Using Organic PCMs in Asphalt

The following section discusses the available investigations on using organic PCMs in asphalt mixtures.

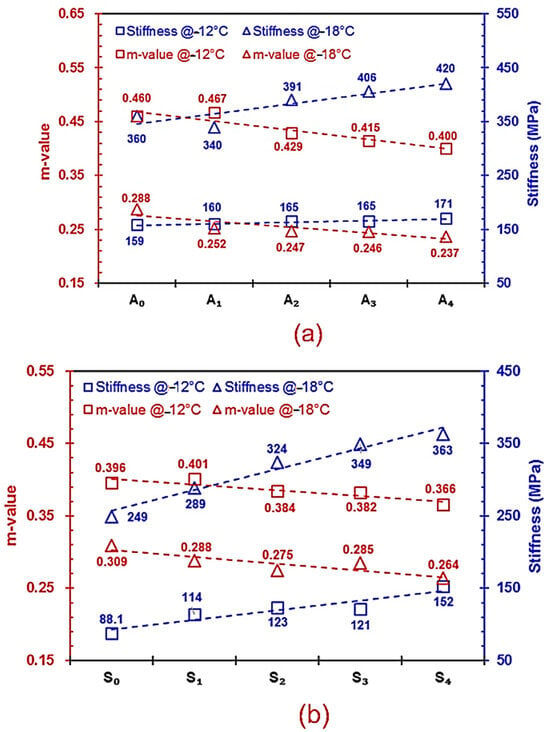

In 2019, Zhang et al. [24] conducted an investigation to discover the influence of an expanded graphite/polyethylene glycol composite phase change material (EP-CPCM) on the rheological and thermal performance of Styrene-Butadiene-Styrene (SBS)-modified binder and Pen 60/80 base binder. The researchers achieved a series of tests which exposed that the differences in thermal conductivity between the SBS asphalt binders and EP-CPCM enhanced base were below (8%), which specifies good compatibility between the binders and EP-CPCM. After EP-CPCM was added, the thermal diffusivity and thermal conductivity for both of the SBS binders doubled, creating a rapid and well-organized exchange of heat with the surrounding environment. The EP-CPCM experiences a phase change at temperatures between 40–50 °C and between 35–25 °C. This diminishes the rates of heating and cooling for the improved binders within these temperature ranges. The outcomes of BBR tests specified that the inclusion of EP-CPCM can lessen the modified binders’ creep rate, as well as upsurge their creep stiffness. Both of these parameters can be damaging to avoiding low-temperature cracking, as depicted in Figure 3.

Figure 3.

Assessment of EP-CPCM augmented base (a) and SBS (b) on asphalt binders for creep stiffness and m-value at low temperatures [24] (Reproduced with permission from Construction and Building Materials by Elsevier, 2024; Order Number: 5874491465554).

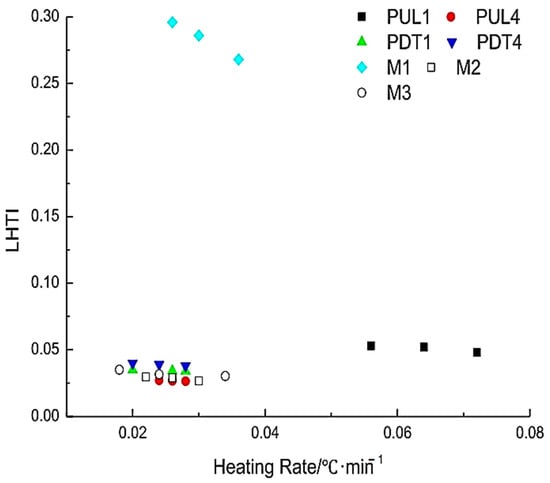

In 2019, Ma et al. [25] displayed two parameters to analyze the effect of micro-PCMs on temperature regulation. These factors are the latent heat accumulated temperature value (LHATV) and latent heat thermoregulation index (LHTI). They convoyed an outdoor cube model test using models of two cubes, each measuring 30 cm × 30 cm × 30 cm. Each model was made up of three asphalt samples which measured 30 cm × 30 cm × 10 cm. The experimental group was blended with micro-PCMs of 0.3 wt.%, while the control group did not comprise any micro-PCMs. The results showed that as the heating rates increased, the LHTI dropped when the LHATV was set at 60 ± 0.5 °C. This drop was substantial, since it was related to the conductivity capabilities of micro-PCMs. Figure 4 illustrates that for the micro-PCMs, the latent heat performance is unable to reach its full potential if the surrounding temperature rises quickly.

Figure 4.

Heat rate/LHIV diagram [25] (Reproduced with permission from Construction and Building Materials by Elsevier, 2024; Order Number: 5874500797041).

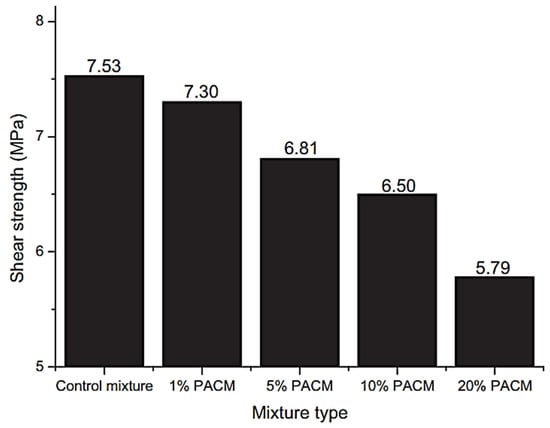

The association between asphalt and PEG was studied in 2019 by Du et al. [26]. Their study concentrated on its potential phase change impact, and a series of laboratory experiments were conducted. These comprised a rheometer test of dynamic shear, a microscopic test, a test of shear strength, and an indoor irradiation test. The tests allowed the analysis of the PCM’s impact on the asphalt/asphalt mixture’s efficiency. The researchers found that the calculated value of the phase transition enthalpy of the PEG/asphalt composite was bigger than what was predicted by the theoretical results. According to the Fourier Transform Infrared Spectroscopy (FTIR) spectra and fluorescence pictures that were analyzed, the PEG was found to be uniformly dispersed at a low concentration throughout the asphalt. Furthermore, the results obtained from the frequency and temperature sweep tests presented a suggestion, which was that the liquid condition of the PEG would be able to enhance the elastomeric quality of the PAC (the pure asphalt component). The PEG/asphalt combination that included 20% PEG had a peak temperature that was lesser than the control asphalt mixture’s by 3.3 °C. Figure 5 illustrates that the strength of the shear of the asphalt/PEG arrangement was 20.3% less than the shear strength of the control asphalt mixture.

Figure 5.

Estimated shear and split strengths [26] (Reproduced with permission from Construction and Building Materials by Elsevier, 2024; Order Number: 5874501113426).

In 2019, Tian et al. [27] perceived a latent heat thermoregulation effect of micro-PCM on mixtures of pavement asphalt. The researchers applied a cubic specimen in an outdoor environment which was made up of an asphalt/micro-PCM mixture. The specimen was 300 mm on one side and 300 mm on each of the other three sides. The micro-PCM’s latent heat thermoregulation performance was appraised using the LHATV and LHTI key parameters. These parameters were documented to measure the effectiveness of the micro-PCM during cooling and heating operations. It was exposed that air movement and solar radiation are the most essential contributors to the micro-PCM’s latent heat effect. The heat transfer reaction of the micro-PCM and the specimen’s latent heat storage effectiveness both change based on where you are in the specimen. The reaction of the phase change would be expressively delayed if the temperature rose and fell at an extremely quick rate.

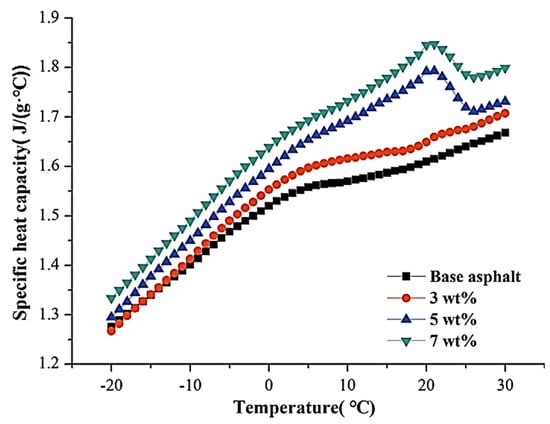

In 2019, Wei et al. [28] used the prepolymer approach to fabricate a polyurethane solid–solid PCM that has a low temperature of phase change. The deformation resistance at high temperatures of the improved asphalt steadily increased when the fraction of polyurethane solid–solid PCM grew with improving amounts. The performance of the asphalt at low temperatures was enhanced when using a polyurethane solid–solid PCM for temperatures below −18 °C. The enhanced asphalt’s specific heat capacity (Cp) steadily rose with the increase in the quantity of the polyurethane solid–solid PCM. As can be seen in Figure 6, the specific heat capacity of the modified asphalt reached its apparent high somewhere between 13 °C and 25 °C when the fraction of polyurethane solid–solid PCM was more than three percent by weight. As the PCM concentration increased across the fraction’s spectrum, the amended asphalt’s coefficient of heat conductivity progressively increased.

Figure 6.

Temperature-dependent asphalt specific heat capacity curves [28] (Reproduced with permission from Solar Energy by Elsevier, 2024; Order Number: 5874510030623).

The Chemistry at Harvard macromolecular Mechanics (CHARMM) and OPLS-aa force fields are commonly used in molecular simulations. In 2020, a study was presented by Sonibare et al. [29] to compare the effectiveness of these two force fields in simulating the three main parts of a model asphalt mixture. The study found that the CHARMM force field accurately predicted the values for n-docosane, 1,7-dimethylnaphthalene, and a typical asphaltene molecule. However, at high temperatures of 300 K, 358 K, 400 K, and 443 K, the asphaltene molecule’s structure deviated from the energy-minimized structure, showing significant twisting of the alkane chains and a slight bending of the aromatic ring region. This deviation occurred from an initial temperature of 50 K. The n-C22 showed a noteworthy degree of chain twisting in the alkane system. On the other hand, the structure of 1,7-dimethylnaphthalene remained reliable, with the structure having the lowest possible amount of energy. To attain a suitable cooling effect, Yinfei et al. [30] estimated the influence of lightweight aggregate gradation on the latent heat storage capacity of the asphalt mixture in 2020. Using a vacuum adsorption method, PEG was mixed into three separate types of fly ash ceramsite (FACS). To make composite PCMs (PEG/FACS), diverse particle sizes were considered and designed within the measurements of (2.36–4.75 mm, 4.75–9.5 mm, and 9.5–13.2 mm). The use of C-PEG/FACS instead of an aggregate led to the development of two different kinds of asphalt mixtures: AC-13 and SMA-13. If compared to the control asphalt mixture, the AC-13 gradation shaped with C-PEG/FACS and particle size range between 2.36 mm and 4.75 mm had the optimal strength and greatest cooling contribution. This was due to the asphalt mixture retaining its distinctive strength. The research ascertained that the mixture made with the particle size range between 4.75 mm and 9.5 mm yielded an effective cooling effect, while the particle size range between 2.36 mm and 4.75 mm had the lowest loss in strength. These results were detected in the SMA-13 gradation.

In 2020, Ma et al. [31] developed an epoxy resin composite thermoregulation agent (ERCTA). They investigated the effects of this agent on an asphalt mixture’s temperature regulation. Characterizing the impacts of ERCTA thermoregulation requires the use of the latent heat-accumulated temperature value, a maximum temperature difference, and the latent heat thermoregulation index. Within specific parameters, a larger ERCTA dose resulted in improved thermoregulation effects. However, when the dose of ERCTA is increased, the transformation peak also increases in height. This is because ERCTA induces a sudden shift in the asphalt mixture’s specific heat capacity.

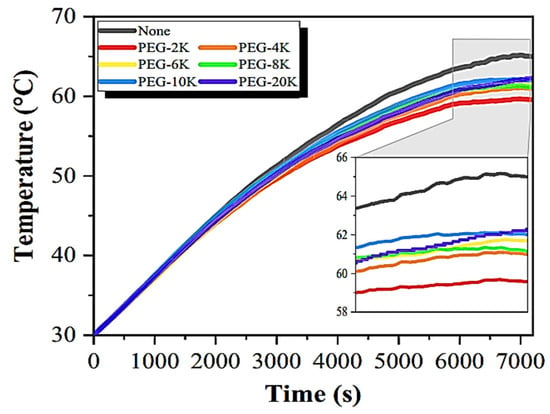

In 2021, Jia et al. [32] conducted research on PEG to investigate its phase change behaviors and its heat stability. It has been proven that PEG samples with a mean molecular weight in the range of 2000–20,000 (PEG-2K–20 K) have favorable phase transition temperatures in the range of 41.27 °C to 62.39 °C and moderately high latent heats in this range (184.8 to 211.9 calories per gm), with outstanding thermal stability at temperatures below 300 °C. Due to the detrimental effect that PEG has on the asphalt binder’s high- and low-temperature capabilities, as well as its temperature and stress sensitivity, it is imperative that PEG be encapsulated prior to its application. Figure 7 depicts the temperature–time curves of the basic binder as well as those of the PEG-modified binders, which may be used to verify the temperature regulation effects. At the beginning of the heating process, the thermal conductivity of all of the binders that have relatively few variances in their heating rates is comparable. PEG-modified binders, on the other hand, have temperatures that rise at a pace that is progressively slower than the base binders’ temperature after the temperature reaches roughly 52 °C and above.

Figure 7.

Binder temperature-time curves [32] (Reproduced with permission from Construction and Building Materials by Elsevier, 2024; Order Number: 5874510415321).

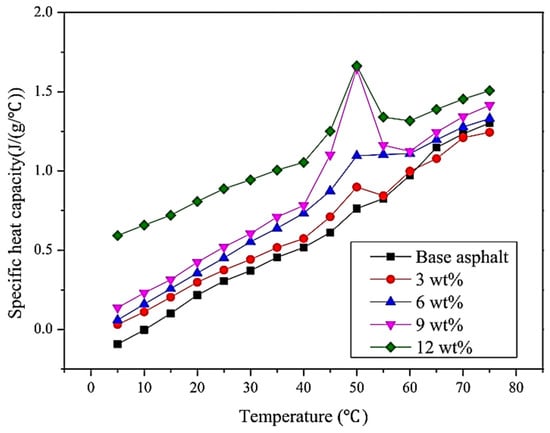

In 2021, Liu et al. [33] presented composite stereotyped phase change material (EPPCM) particles made of epoxy resin/polyethylene glycol 2000. These particles showed the ability to maintain their thermal storage capabilities even after being subjected to a heat treatment that raised their thermal breakdown starting temperature to 230 °C. The researchers then used high-speed shearing to create modified asphalt with an increasing amount of particle doping. It was discovered that an increase in the amount of EPPCM doping led to a progressive improvement in the rheological characteristics of the modified asphalt. Additionally, there was a tendency towards an increase in the temperature control effect. Figure 8 shows that the greatest temperature difference was 4.3 °C, and the specific heat of asphalt also rose over this time period.

Figure 8.

Asphalt sample heat capacity [33] (Reproduced with permission from Construction and Building Materials by Elsevier, 2024; Order Number: 5874510735397).

In 2022, Jimenez et al. [34] examined a new type of microcapsule that is expected to have tough walls and good thermal stability, making it suitable for managing pavement temperatures using PCMs. The researchers anticipate that this new microcapsule will be able to overcome some of the issues previously encountered with PCM use. However, there is a risk of low PCM content and PCM leakage using this approach. Experiments with thermal cycling demonstrated that when the PCM microcapsules were introduced to a hot mix asphalt (HMA), the samples with 10 and 20 vol.% PCM took 5 °C to 10 °C longer than the control mixture to reach the melting or freezing point of the PCM. This was seen in comparison to the temperature of the control mixture. These findings provided more evidence that microencapsulated PCMs are capable of controlling asphalt pavements’ temperature. However, the findings from experiments that were executed at a temperature of 40 °C and a frequency of one hertz indicated a drop of 75% in the dynamic modulus in specimens that included the PCM micro-capsules. This might suggest that the presence of these materials also affects the asphalt mixture’s toughness.

In 2022, Shi et al. [35] used the prepolymer technique to manufacture low-temperature polyurethane solid–solid phase change materials (LPSPCMs). The researchers established that LPSPCMs possess exceptional thermal stability and phase change heat storage capability, making them appropriate for use in hot mix asphalt mixes. However, the adding of LPSPCM particles to the asphalt mixture initially advances the high-temperature performance of the asphalt mixes, but as more particles are added, it leads to a reduction in abrasion resistance and embedding an influence between asphalt mixes, eventually deteriorating the road performance. The water stability of asphalt mixes also declines rapidly with an increasing content of LPSPCM particles in the mixture, as these particles do not attach well to asphalt compared to limestone aggregates. Furthermore, the phase change temperature control impact of the LPSPCM particles reasons the asphalt mixture’s cracking temperature to lessening gradually as the quantity of LPSPCM particles content increases, as detected from the thermal stress restrained specimen test (TSRST). This specifies that LPSPCM particles improve the asphalt mixtures’ low-temperature efficiency.

In 2022, Sha et al. [36] offered a study on the progress of solid–solid phase change materials (s-s PCMs) for use in cooling asphalt pavements. The emphasis was on creating polyurethanes (PUs) that can endure high temperatures without leaking. It was established that PUs with a higher isocyanate content have better thermal stability and performance. One of the produced PUs is M_PU5, which can store 93.5 J/g of latent heat and has phase change temperatures between 36 °C and 48.3 °C and is the best s-s PCM for use in asphalt pavements due to its ability to resist harsh conditions. 4,4′-diphenylmethane diisocyanate (MDI) was utilized as the isocyanate with a molar ratio of MDI to PEG of 5. The efficacy of M_PU5 in cooling asphalt pavements was recognized through external testing.

In 2022, a steel slag-based composite phase change aggregate (SS-CPCA) was developed by Xu et al. [37] for the determination of ice and snow melting on asphalt pavements. The researchers made a system of binary n-alkane eutectic that can express the PCM’s binary eutectic composite. Afterwards, an asphalt blend with a type designation of SMA-13 was designated to be the base material for the SS-CPCA asphalt mixture that was made. Both the pavement efficacy and the temperature regulation performance of an asphalt mixture that was based on the SS-CPCA were put to the test and compared to those of an asphalt mixture that was based on steel slag. The tests ascertained that the efficiency attributes of the pavement of the SS-CPCA asphalt mixture met the standards benchmarks, indicating that it is conceivable to use SS-CPCA for asphalt paving. Additionally, the results proved that the surface temperature rises up to 3.4 °C through the addition of SS-CPCA to the SMA-13 asphalt mixture. It also extended the cooling time, as soon as the asphalt mixture’s top temperature hits 0 °C, for 780 s.

Making 4,4′-methylenebis-(2-chloroaniline), 4,4′-diphenyl methane diisocyanate, polytetramethylene ether glycol, and polyethylene glycol in two steps using condensation, Wang et al. [38] generated multiple samples of polyurethane solid–solid PCM (PUPCM) in 2022. For the asphalt modification, a PUPCM sample with an appropriate molar ratio was employed. This was done with both the temperature at which the phase shift occurs and the thermal stability in mind. The low- and high-temperature performances of the improved asphalt binder are not significantly impacted by the addition of PUPCM. Specifically, the viscosity and storage stability of the modified asphalt binder are good. The anti-aging performance of asphalt was enhanced by the addition of PUPCM, and the benefit becomes much more noticeable as the amount of PUPCM in the asphalt increases. Furthermore, it was discovered that the storage capabilities of the phase-change energy of the PUPCM in asphalt were adequate.

In 2022 and by using the vacuum adsorption approach, Wang et al. [39] was successfully created two distinct kinds of PCM particles that had outstanding resistance to heat. As a consequence of the material preparation, asphalt was mixed with PCM particles that had variable temperature intervals between phase changes. This caused in the formation of a composite-modified asphalt. The examination showed that the use of PCM particles in the composite adapted asphalt led to an upgrading in the rutting factor of the material. According to the findings of tests conducted, the incorporation of high/low-temperature PCM particles has not had a major impact on the low-temperature rheological capabilities. When the pace at which the temperature is changing is raised, three things happen: the maximum temperature difference becomes bigger, the LHATV gets smaller, and the LHTI gets higher.

In 2023, Jia et al. [40] produced a phase change heat storage asphalt pavement material and then designed phase change heat storage asphalt mixes with the potential to actively cool the environment. The polyurethane-based solid–solid PCMs (PUSSPCM) that was synthesized may satisfy the active cooling need of asphalt pavement due to its acceptable phase change temperatures, desired thermal energy storage capacity, and outstanding phase change cycle stability. In addition, it has an exceptional resistance to leakage, volume stability, and chemical stability, which permits it to handle the hard circumstances of asphalt pavement. An asphalt mixture’s low-temperature cracking resistance and high-temperature stability may both be improved by using replacements, but the mixture’s resistance to water will be reduced as a result. Phase change mixes are able to fulfil the criteria for pavement performance provided that the replacement quantity has not exceeded 40 percent by volume. As a result of the replacements, the asphalt mixture’s capability to absorb heat is increased, but the heat transfer pace is decreased. This results in a slower rate at which the mixture’s temperature increases when more PUSSPCM is used.

Polyurethane-based solid–solid phase change materials (PUSSPCMs) were synthesized by Jiao et al. [41] in 2023 using a two-step solution polymerization process. Then, asphalt mixes were created, with the PUSSPCMs functioning as fine aggregates. The viscoelastic features of asphalt mortars were used to decide the appropriate particle size of the PUSSPCMs. The efficiency of asphalt mixtures was used to decide the highest content of the PUSSPCMs. PUSSPCMs with a particle size ranging from 0.6 to 2.36 mm are suggested for use in asphalt mortar because they may absorb more light components in the asphalt and have a stronger interfering with the viscoelasticity of the asphalt. Increases of 26.2% and 14.2%, respectively, in low-temperature performance and high-temperature performance may be attributed to an increase in mixes containing 1–20% asphalt. PUSSPCM–asphalt mixes, on the other hand, had lower water stability, and the residual stability of a sample containing 1–30% asphalt did not fulfil the criteria. During the process of heating the samples, the heating rate of the PUSSPCM sample was constantly lesser than the control samples; moreover, the temperature difference between the control sample and the 1–20% and 1–10% samples was 4.6 °C and 3.3 °C, respectively.

In 2023, Zhang et al. [42] concentrated on analyzing the effects of two different types of PCMs, namely paraffin/expanded graphite/high-density polyethylene composite material (PHDP) and polyethylene glycol (PEG), on a variety of measures of effectiveness of high-viscosity modified asphalt (HVMA). The authors compared the effects of the PCMs on the HVMA. The findings showed that PHDP and PEG can be evenly dispersed in HVMA; nevertheless, the size and shape of their respective distributions were visibly distinct from one another. When compared to the HVMA that did not include PCM, the results of the physical tests demonstrated a growth in the penetration of PEG/HVMA and PHDP/HVMA. Due to the existence of a high amount of polymeric spatial reticulation, their softening points did not vary appreciably with growing PCM quantity. As indicated, the temperature regulating effect of PHDP/HVMA with 4% PHDP and PEG/HVMA with 15% PEG was 4 °C lower and 1240 s higher, respectively, as compared with HVMA without PCM. The delay time for these two mixtures was also 456 s and 1240 s, respectively.

In 2023 and in order to produce a thermo-regulating asphalt binder, Zhao et al. [43] built a unique type of capsule with a phase change heat storage function using waxy materials reclaimed from waste cooking oil (WCO) as the main element. This capsule has a function for heat storage using phase change technology. Modern studies have exposed that the waxy components treated with hydrolysis are the best choice for amending the temperature changes of asphalt binders due to their phase transition temperature, phase transition enthalpy, and thermal stability. The data were analyzed using a differential scanning calorimeter and a thermo-gravimetric instrument, which exposed that the ratio of wall material to core material in the phase change capsules (PCCs) was roughly 1:1, allowing for excellent heat storage properties (125 J/g), mechanical properties (greater than 13 N), and thermal stability (greater than 190 °C), all of which contributed to the capsule’s overall presentation. Additionally, it has been revealed that using a temperature sensor within PCCs can delay the pace at which asphalt’s temperature changes in reaction to the environment by going through a phase transition, thus dropping the amount of damage caused to asphalt pavement in hot districts.

In 2023, Wang et al. [44] created a paraffin/polymethyl methacrylate CPCM with a phase transition temperature of 55–56 °C using in situ polymerization and explored its use in asphalt binders. The CPCM has a spherical shape and may reach temperatures of 185.2 °C throughout the earliest stages of its disintegration. Thus, additional examination was done to research the thermoregulation efficacy of the CPCM for asphalt as well as the impact of the CPCM on the rheological performance and storage stability of the asphalt binder. Outcomes of the thermoregulation testing suggested that the highest temperature differential that may occur between the modified asphalt and matrix asphalt when the asphalt is being heated can reach 7.5 °C. Because the CPCM was going through a phase transition at temperatures between 47 °C and 55 °C, the heating rate of the improved asphalt dropped dramatically in this temperature range. In addition, the incorporation of the CPCM caused a reduction in the asphalt’s viscosity and low-temperature ductility, while also having a marginal impact on the point at which the asphalt began to soften and its level of penetrability. Table 1 summarizes the studies conducted on organic PCMs used in asphalt.

Table 1.

A summary of conducted research on organic PCMs used in asphalt.

4. Studies Related to the Use of Inorganic PCMs in Asphalt Pavements

Several studies can be found in the open literature that have investigated the utilization of inorganic PCMs in asphalt pavement. These studies are discussed in the following section.

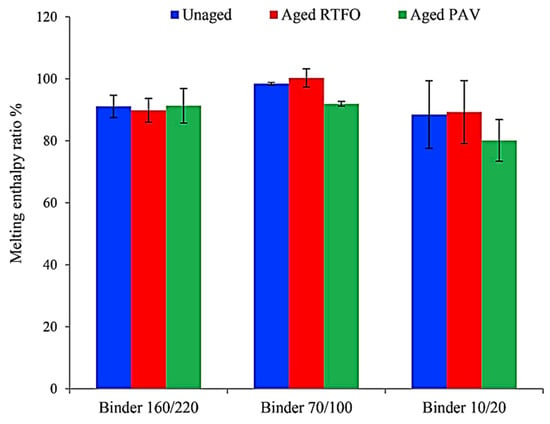

In 2019, Kakar et al. [45] investigated whether or not it would be possible to use microencapsulated PCMs in asphalt binders. As a result, many distinct penetration-grade binders that had been changed with microencapsulated PCMs were characterized, and their blends were artificially aged with the assistance of machines known as rolling thin film ovens (RTFOs) and PAV. Additionally, this research inspected a variety of size distributions of microcapsules. The rheological and thermal features of modified and unmodified asphalt binders that had been exposed to a diversity of ageing conditions were analyzed using techniques of Dynamic Scanning Calorimetry (DSC) and Dynamic Shear Rheometry (DSR). It was exposed that when improved asphalt binder ages, its melting enthalpy drops, and this decrease is dependent not only on the kind of binder but also on how long the binder has been aged, as depicted in Figure 9. Referring to the findings, the ability of microencapsulated PCMs to survive in asphalt binders is reliant on not only on the kind of binder but also on the microcapsules that are used. Furthermore, the thermal energy released by PCM crystallization throughout the cooling process has a contribution to improving the modified asphalt binder’s rheological parameters, which are assessed by DSR.

Figure 9.

Melting enthalpy ratio vs. ageing μPCM-21-modified binders [45] (Reproduced with permission from Composites Part B: Engineering by Elsevier, 2024; Order Number: 5874511107222).

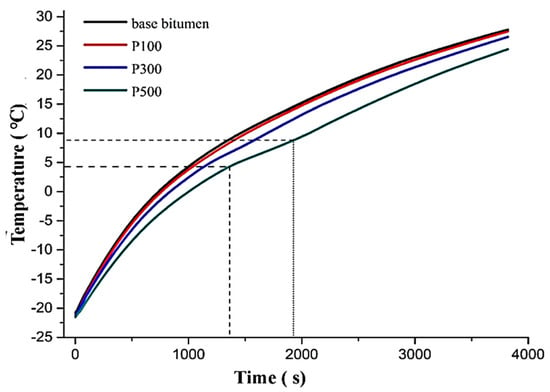

An asphalt binder that was modified using microencapsulated phase-change materials (micro-PCMs) was considered in 2019 by Wei et al. [46] to analyze its impact on the physical features of asphalt, storage stability, and temperature-adjustable performance. In situ, polymerization is used to produce micro-PCMs that have n-tetradecane cores and melamine–formaldehyde (MF) resin shells. Various quantities of micro-PCM modifiers have been added to a neat asphalt binder in order to modify its properties. For the micro-PCM-enhanced asphalt and with an increase in the amount of micro-PCMs present, the temperature change rate near the temperature at which the micro-PCM transition from one phase to another is slowed down. The temperature-rise curves of bitumen specimens that have been treated with micro-PCMs are presented in Figure 10. According to the data shown in this figure, there are no discernible changes between the curve of bitumen samples changed with less than 3 wt.% of micro-PCM concentration and that of the unmodified bitumen. The slope of the curve, however, undergoes a minor shift between 4 °C and 9 °C when the amount of micro-PCM in the sample approaches 3 wt.%.

Figure 10.

Bitumen temperature change curve [46] (Reproduced with permission from Construction and Building Materials by Elsevier, 2024; Order Number: 5874510415321).

In 2019, Wei et al. [47] made a NiTi alloy phase change heat storage asphalt mixture (NiTi APCHAM) by using equal volume parts to replace some of the small asphalt chunks with NiTi APCEP. Due to the heat-storage impact caused by NiTi alloy phase change energy-storage particles (NiTi APCEP), the specific heat capacity of NiTi APCHAM first increases in reaction to an upsurge in temperature, but this increase is then followed by a decrease. The linear rise in the replacement rate of the NiTi APCEP is accompanied by an increase in the temperature at which the thermal conductivity coefficient of the NiTi APCHAM is measured. When added to the asphalt mixture, NiTi APCEP has the potential to lower the mixture’s daily maximum temperature. The ability of an asphalt mixture to phase shift heat store and regulate temperature may be improved by increasing the amount of NiTi APCEP that is added to the mixture as an additive. The latent heat thermoregulation effectiveness of NiTi APCEP, on the other hand, achieves its highest level when the replacement rate for the NiTi APCEP is set at 6 wt.%.

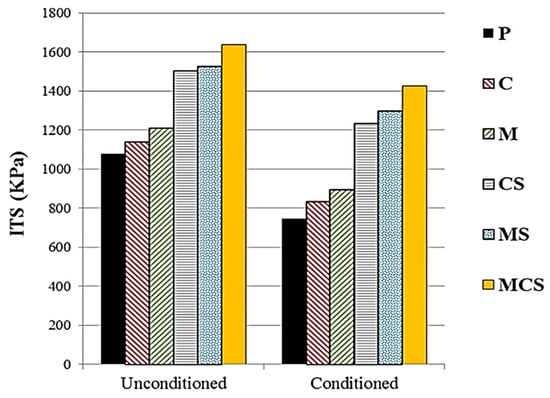

In 2020 and referring to HMA, Amini and Hayati [48] incorporated nano-CuO as a PCM, Styrene-Butadiene-Styrene (SBS), and carbon nanotubes (CNTs) as a conductive material, individually as well as composed in five different mixtures. The thermal energy storage (TES) in PCM-modified asphalt binders has been increased. Additionally, the melting peak temperature increased compared to the temperature of the pure asphalt binder, the transition temperature of glass was significantly increased, and the crystallization peak temperature decreased by 7 °C. Asphalt binders that were treated with nanoscale amounts of CuO showed a considerable improvement in their Cp, as well as a reduction in their sensitivity to temperature and moisture. Figure 11 shows the findings of the indirect tensile strength testing performed on materials that had not been conditioned and samples that had been conditioned. It was shown that the addition of the additives, in any combination, resulted in an increase in the tensile strength of the asphalt mixture in comparison to the standard asphalt mixture.

Figure 11.

Asphalt mixture indirect tensile strength [48] (Reproduced with permission from Renewable Energy by Elsevier, 2024; Order Number: 5874520023707).

In 2021 and for the purpose of developing innovative cooling asphalt pavement, Jin et al. [49] selected diatomite, expanded perlite, and stearic acid as primary ingredients for their compound phase change materials (CPCMs). CPCM micro-topography and characteristics were explained using X-ray diffraction, Fourier transform infrared spectroscopy, and scanning electronic microscopy. Thermo-gravimetric and differential scanning calorimetry confirmed the product’s thermal stability and performance. The cooling asphalt pavement was tested for thermal and pavement performance. The finite element method simulated heat transmission in standard and cooling asphalt pavements. CPCMs with diatomite carriers are chemically and thermally stable after 100 cycles.

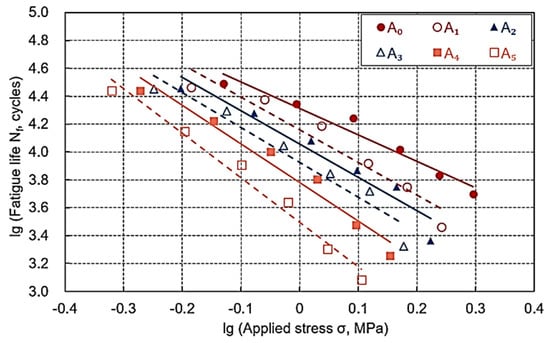

In 2021, an EP-CPCM was examined by Zhang et al. [50]. Its impacts on an asphalt mix’s thermal and pavement efficiency were studied. Different concentrations of EP-CPCM were applied to AC-13 asphalt. By lowering its heating and cooling rates and extending heating and cooling duration, EP-CPCM regulates asphalt pavement temperature. It reduces urban heat islands and pavement temperature extremes. According to the research, increasing EP-CPCM negatively affected moisture stability in hot water, freeze–thawing, fatigue life, and stress sensitivity. After measuring the temperature gradient at each step, the researchers determined that CPCMs can manage pavement temperatures. These impacts reduced fatigue resistance and enhanced stress sensitivity. Figure 12 shows the link between applied stress and fatigue life to compare the control and all combinations. When stressed equally, the EP-PCM-modified asphalt mixes had significantly shorter fatigue lives than the control asphalt mixture. As EP-CPCM grew, each combination’s loading cycle slowed.

Figure 12.

Control and EP-CPCM-modified asphalt mixture fatigue life under varied stress [50] (Reproduced with permission from Construction and Building Materials by Elsevier, 2024; Order Number: 5874520553705).

In 2021, Dai et al. [51] developed a PCM employing a binary eutectic combination of stearic acid (SA) and palmitic acid. This PCM was then tested in an asphalt binder. SA/PA-PCM enhanced crystallinity by 6%, micro-strain by 140%, and dislocation density by 432%, according to the research. The stearic acid/palmitic acid binary eutectic phase change material (SA/PA-PCM) had a stable crystal structure, resulting in a greater phase transition enthalpy (226.9 J/g) and superior temperature (54.8 °C) compared to traditional materials. Both the eutectic and enhanced asphalt binder methods demonstrated no chemical interactions. Crystalline SA/PA-PCM improved the binder’s anti-deforming capabilities, whereas the liquid form suppressed rheology. The breakdown temperature of the SA/PA-PCM material was over 200 °C, greater than that of the two separate fatty acids. These temperatures are still greater than those used to build hot-mix asphalt pavements.

In 2022, sol–gel synthesis was used by Gao et al. [52] to make silica composite phase transition materials. The asphalt mixture performed better with these SiO2-PCMs. The boundary conditions were measured to develop a finite element heat transfer model, and temperature modification was predicted and tested. SiO2-PCMs meet asphalt mixing temperature requirements and have excellent compatibility, thermal cycle stability, and leakage resistance. Asphalt mixtures with PEG/SiO2 exhibit significant temperature modification, lowering the top surface temperature by about 9 °C. PCMs store and convert energy to cool asphalt. This gives theoretical support and references for increasing asphalt pavement life and improving the near-surface thermal environment.

The prepolymer approach was used in 2022 by Wei et al. [53] in order to manufacture polyurethane solid–solid low-temperature phase change materials (PSLPCMs). The purpose of these materials was to slow down the cooling of the mixture and to prevent asphalt pavement’s low-temperature cracking in areas with substantial temperature difference zones. The production of particle asphalt required the addition of PSLPCMs to hot mix asphalt. Because of their increasing particle size, PSLPCM particles improve the performance of mixed roads. Due to the fact that particles are larger, when the amount of PSLPCM in the asphalt mixture grows, the specific heat capacity of the mixture increases, but the thermal conductivity of the mixture decreases. The asphalt mixture has an increasing influence on temperature control, despite the fact that cooling occurs at a slow pace. The combined temperature control is improved with PSLPCM particles with a size range of 1.18 to 2.36 mm. The combination has a maximum temperature control impact of 3.4 °C when it is present at a concentration of 7 wt.% of PSLPCM.

In 2022, Dai et al. [54] investigated the direct connection that asphalt has with SA/PA-PCM. Following the utilization of SA/PA-PCM, the binder required an approximately 20% higher specific heat to operate with improved efficiency. This enhanced binder effectively controlled temperature compared to its conventional counterpart.

In 2022, Jia et al. [55] verified that the presence of crystalline SA/PA-PCM content can lead to improvements in elastic recovery potential, elastic modulus, creep behavior, and complex modulus. According to the findings of the study, SA/PA-PCM led to an improvement in the resistance of asphalt to rutting at high temperatures and cracking at low temperatures. Adding stearic acid and palmitic acid in a SA/PA-PCM resulted in a 20% increase in the binder’s Cp. In a contrast to the basic binder, the adapted binder has a better temperature control, as shown by a temperature differential of 11.5 °C and a temperature hysteresis that remains constant for forty minutes. PUSSPCM was considered by Jia et al. [55] for its probable use as a filler for asphalt mastic that is cooling. Enhancements were made to the material to enhance the latent heat storage and thermal reaction rate capacity. Making graphite/PUSSPCM (GPCM) constructions with a variety of graphite compositions and mesh values was the technique. Thus, GPCMs have the greatest amount of graphite and the mesh has the highest heat conductivity. If compared to a PUSSPCM, the researchers developed GPCM-8000–1, which had a thermal conductivity which was 254.7% higher and a latent heat storage capacity which was 23.2% higher. GPCM-8000-1 proved to have extraordinary thermal stability at a temperature of 200 °C, permitting it to function admirably in asphalt pavement construction without demonstrating any liquid leakage or disintegration. An investigation of the cooling effects of phase change asphalt mastics was conducted. The largest cooling amplitude that was measured was 5.6 °C.

In 2022, Ren and Hao [56] assessed the gains from using commercial graphene (CG) in the coating of adapted phase change microcapsules (MFPCMs) and asphalt walls. They developed graphene-modified phase-change microcapsules (CGMFPCMs) by using varying amounts of melamine formaldehyde (MF) resin and cyclohexanone (CG) as wall materials for the microcapsules, and n-tetradecane as the core material. The thermal performance of the MFPCMs was improved by 0.45% CG, and this improvement did not affect the thermal stability. It has been shown that PCMs are only capable of physically altering basal asphalt structures. There did not seem to be any chemical reactions taking place, and it appeared that the PCMs were spread uniformly throughout the base asphalt. The results of tests conducted at both the microscopic and macroscopic levels demonstrated that the CGMFPCM enhanced the low-temperature performance of the asphalt.

In 2022 and by using latent heat fusion during the phase transition of micro-encapsulated PCM, Phan et al. [57] were able to increase the performance of the material at low temperatures and prevent the production of black ice. The purpose of this experiment was to investigate the impact that the PCM has on temperature control by subjecting asphalt slabs that included additives to winter conditions. A comparison was made between freshly cut PCM slabs and slabs that had been aged for six months in order to assess the latent heat release. By reducing the stiffness and increasing the phase angle, the incorporation of PCM into the asphalt mixture has the potential to lessen the occurrence of cracking at low temperatures. In addition to this, the temperature of the PCM-modified mixture was 2 °C higher than the temperature of the traditional combination. Because of the freeze delay of one hour and ten minutes, the creation of black ice may have been delayed. Last but not least, PCM has the potential to enhance low-temperature breaking resistance and postpone the production of black ice. Inorganic PCM research pertaining to asphalt is detailed in Table 2.

Table 2.

A summary of conducted research on inorganic PCMs used in asphalt.

5. Studies Related to the Use of Mixture (Organic–Inorganic) PCMs in Asphalt Pavements

Organic PCMs (for example, paraffin and non-paraffin) and inorganic PCMs (for example, hydrated salts and metals) are the two principal categories of particulate carbon materials (PCMs). PCMs find prevalent use in a variety of applications, one of the most imperative of which is the insulation of building walls. The use of PCMs for effectual temperature regulation in buildings may significantly save energy usage by diminishing the variation in interior temperature. Further, PCMs have been examined for their potential to alter the thermal features of paving materials. The next section discusses the most relevant studies of organic and inorganic PCMs in asphalt pavements.

In 2019 and during the process of developing a form-stable composite phase change material (CPCM), Jin et al. [58] directed an examination to determine whether or not the use of diatomite (DI) as the load matrix and palmitic acid (PA) and stearic acid (SA) as the eutectic binary fatty acids was beneficial. In this regard, experiments on thermal storage and release exposed that the impact was highly effective in delaying the material’s temperature increase. The results of these experiments were indicated to be quite effective. After a total of one hundred thermal cycling tests, the DSC analysis came to the decision that the (SA + PA)/DI has extreme thermal dependability. This result was reached after the DSC study. Moreover, the findings of the thermal performance tests exposed that temperature-adjusting asphalt pavements with (SA + PA)/DI had the ability to decrease the highest temperature of the top surface by as much as 8.11 °C and the lowest temperature by as much as 6.36 °C on a normal temperature day throughout the summer. In addition, the testing of pavement performance specified that the temperature-adjusting asphalt mixes’ high-temperature performance and water stability intensely worsened, although their low-temperature performance was scarcely altered at all.

In 2020 and using the finite element technique (FEM), Si et al. [59] generated a model of asphalt pavement with and without PCM and then compared the two patterns’ capacities for temperature regulation in great detail. The constituents that had an effect on the temperature field of the asphalt pavement were split into two groups: internal and exterior. The authors examined how the presence of PCM affected the temperature of the asphalt surface. To define the extent of the latent heat effect, LHATV and LHTI were applied. The researchers indicated that when only the upper surface course was built using variable doses of PCM, the temperature increased as the amount of PCM decreased. However, the time domain of the PCM remained fixed on both the surface and the bottom of the upper surface course. This was true despite the pavement’s surface and the lower portion of the top surface course’s time domains for PCM. The levels of LHATV and LHTI increased when the dose of PCM was enlarged.

In 2020 and to achieve temperature control in porous asphalt concrete, Chen et al. [60] evaluated whether or not it would be practicable to use a phase change composite in place of aggregate on the surface of concrete. As a probable substitute for the fine aggregate in porous asphalt concrete, the researchers studied the opportunity of using a phase change composite material called SiO2 as the shell and PEG as the PCM. Simultaneously, the influences of the size and dosage of the PEG/SiO2 composite were evaluated and the inner temperature of the asphalt concrete was tested. A PEG/SiO2 composite with a mass content of 70% PEG was recognized to be a good option for usage in porous asphalt concrete. Additionally, the researchers found that the ideal replacement level was 1.4% of the total aggregate weight and that the appropriate range for the size of phase change composite particles was between 0.6 and 1.18 mm.

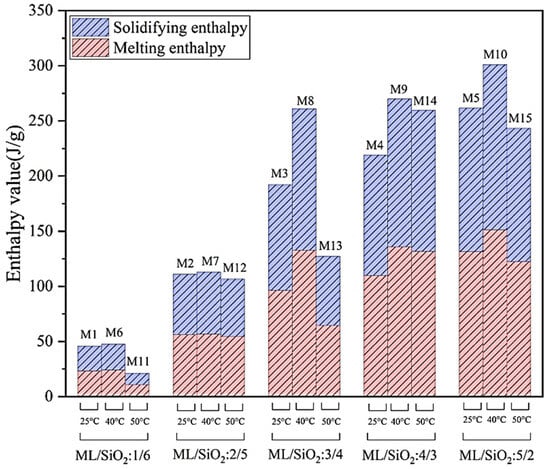

In 2022, Wan et al. [61] developed a novel composite material that can be utilized for the storage of cold energy. A PCM known as methyl laurate (ML) and silica are the components that work together to construct the composite. A good phase transition temperature of 3.96 °C and a high latent heat of 210.1 J/g make the ML a proper medium for cold energy since it has both of these features. The ML is shielded from the harsh environment by the silica. Because of its one-of-a-kind structure, which resembles a net, the composite material is able to efficiently retain cold energy. Both the temperature at which the composite was manufactured and the quantity of ML that was present in the composite were shown to have a significant impact on the phase change enthalpies of the composite. The ratio of ML to SiO2 in mass expanded from 1/6 to 5/2, which resulted in an increase in the enthalpies. For each fixed mass ratio of ML/SiO2, however, the enthalpies should, in theory, stay constant all the time. Figure 13 illustrates that in actual fact, the enthalpies first climbed and subsequently fell when the temperature of the preparation were raised. As a potentially useful material for the storage of cold energy, the ML/SiO2 composite has a great deal of promise.

Figure 13.

Comparison graphs of PCM composite enthalpies at various reaction temperatures and ML/SiO2 ratios: 1/6, 2/5, 3/4, 4/3, 5/2 [61] (Reproduced with permission from Journal of Energy Storage by Elsevier, 2024; Order Number: 5874520830145).

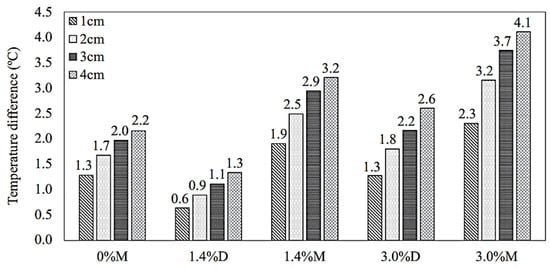

After conducting their research in 2021, Kuai et al. [62] addressed the issue of the open-graded friction course (OGFC) being subject to clogging during the summer months as a result of high temperatures inside the system. In order to solve this problem, they updated it by including a phase change composite material known as PEG/SiO2. This material was made up of plate number 1 as its core and SiO2 as its shell. Using slab specimens that varied in PEG/SiO2 dosages and moisture conditions, the research proved that PEG/SiO2-modified OGFC is successful in maintaining the temperature of the pavement. This was accomplished using laboratory-scale indoor heating testing. In addition, a three-dimensional heat transfer modeling technique was used in order to provide a description of the temperature field of the slab as it was being heated. A comparison is shown in Figure 14 between the reference slab and the moisture or (and) PEG/SiO2-modified OGFC slabs at a variety of depths. The comparison also includes the greatest temperature drop that was obtained by the reference slab. There is a direct correlation between the depth of the slab and the temperature drop that it experiences. It is possible that the temperature of the slab might decrease by a maximum of 4.1 °C at a depth of 4 cm in the situation when M is 3.0% and there is both moisture and the maximum dosage of PEG/SiO2.

Figure 14.

Maximum temperature decreases of moisture or PEG/SiO2 treated OGFC slabs compared to the control slab [62] (Reproduced with permission from Construction and Building Materials by Elsevier, 2024; Order Number: 5874521085550).

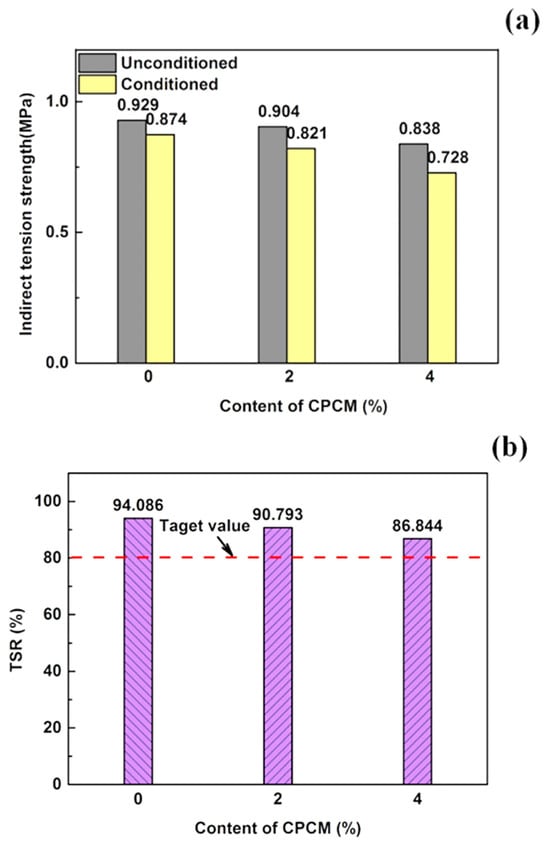

In 2021, Wang et al. [63] utilized a diatomite-supported PEG composite as a filler to achieve a self-regulating temperature characteristic in asphalt mixtures. At a composite percentage of approximately 4% in the material, the self-regulating temperature fluctuation could reach up to 7.3 °C. The influence of composite PCMs on road performance was negligible and could be overlooked, although there was a possibility of affecting mechanical characteristics, high-temperature stability, water stability, and microstructures. Despite a decrease in water stability with increased composite material, all specified parameters in the specification were met. Figure 15 illustrates a modest reduction in indirect tension strengths for the CPCM-treated asphalt mixture. The indirect tension strength ratio (TSR) values remained relatively stable at around 90%, with minimal shifts even after undergoing freeze–thaw cycles. Despite the apparent lower water stability in the CPCM-modified asphalt mixture, it still met the required criteria.

Figure 15.

Split-test freeze–thaw findings, (a) indirect tension strength against content of CPCM, and (b) TSR% against content of CPCM [63] (Reproduced with permission from Case Studies in Construction Materials by Elsevier, 2024; Order Number: 5874521323918).

In 2021, Cheng et al. [64] investigated how the performance of an asphalt mixture was affected by the use of a recently developed solid–solid PCM known as PPGC-PCM. Mixtures of AC-13 asphalt were given to the control group besides PPGC-PCM at one of six distinct concentrations. The mechanical, moisture, high-temperature, and low-temperature cracking resistance merits of asphalt mixture were investigated, along with the impact that PPGC-PCM had on those features. The thermal conductivity test was utilized to examine how much of an impact the PPC-PCM had on the asphalt mixture’s thermal characteristics. The inclusion of PPGC-PCM in asphalt mixes was found to expressively lower the mixture’s thermal conductivity, improve the mixture’s resilience to cracking at low temperatures and moisture, and improce the mixture’s resistance to cracking at high temperatures. By using a PPGC-PCM addition ratio of 7.5%, it was conceivable to get the best potential application. In addition, the results of the cooling test certified that the incorporation of PPGC-PCM into the asphalt mixture had the possibility to considerably improve its ability to maintain heat.

In 2022, Deng et al. [65] analyzed the impacts of PCMs on asphalt concrete pavements’ temperature and rutting effectiveness. The researchers focused on the types, quantities, and placements of PCMs and developed a model to measure their influence on the accumulation of rut depth. The findings showed that replacing 10% of the aggregate in the top sublayer of asphalt with polyethylene glycol encapsulated by silicon dioxide as the PCM caused in the most effective anti-rutting performance. The study expected a 14% reduction in rut depth in a typical Texas summer scenario within one month of pavement construction. Nevertheless, the research also found that the addition of PCMs to AC did not improve pavement rutting performance. This is because PCMs require a specific pavement temperature range to participate in phase transitions, and they cannot function properly if installed in pavement layers with temperatures that are too low or too high.

A novel kind of temperature-adaptive pavement coating was considered by Wu et al. [66] in 2022. The temperature of the pavement was successfully lowered by the coating that was devised. To create two-dimensional Mt nano-sheets (2DMts), the mineral montmorillonite (Mt) was exfoliated to a size smaller than 19.78 nanometers on a massive scale using a freezing and thawing process. After being fashioned into a unique card house structure, the 2DMts were further encapsulated in stearic acid (SA). Both the thermal stability and heat storage performance of the produced 2DMt/SA nanocomposite are very high. The heat storage performance is 221.6 J/g. Also, the temperature ranges of the composite material’s phase transition grew between 40 °C and 80 °C, and the temperature ranges is flexible enough to accommodate a wide range of environmental circumstances. Moreover, the self-regulating temperature pavement coating’s real cooling impact was evaluated. When compared to an uncoated asphalt block, the temperature will be lowered by roughly 5 °C in one hour when the volume percentage of the composite material is 12%.

In 2023, Zhang et al. [67] came up with the idea for a revolutionary PCM-integrated cooling asphalt pavement. A binary eutectic combination of fatty acid PCMs was used in the construction of this pavement. In order to do this, the palmitic acid and stearic acid (PA-SA) PCM composite was to be eliminated, and a composite phase change steel slag aggregate, also referred to as CPC-SSA, was to be developed. Additionally, the TCE-based CPC-SSA asphalt mixture was to be developed utilizing three distinct kinds of TCEs. According to the findings, the insertion of the PCM composite consisting of PA-SA and nano-Al2O3 into the asphalt pavement has the potential to effectively cool the pavement and prevent rutting distress on the asphalt from occurring at high temperatures.

In 2023, Cheng et al. [68] considered the effects of a shape-stabilized phase change material (PPGC-PCM) on the mechanical properties, moisture resistance, high temperature stability, and low temperature fracture resistance of several layouts of asphalt mixture (AC-13 and SMA-13). The researchers signposted that an inclusion of PPGC into an asphalt mixture has the possibility to expand its thermal insulation and heat storage effectiveness. Nevertheless, as the amount of PPGC-PCM increased, the mixture’s mechanical properties and resistance to moisture initially upgraded but then began to worsen. The inclusion of PPGC-PCM can boost the asphalt mixture’s performance as an insulator and its capacity to store heat within the temperature range of PPGC and PCM phase shift.

In 2023, Ma et al. [69] applied octanoic acid (OA) and tetradecane (TD) to manufacture a micro-encapsulated phase change material (MPCM) with nano-TiO2 as the wall material and polyvinyl alcohol-strengthened melamine formaldehyde resin as the wrapping material. The MPCM successfully reduced the pace at which asphalt cooled and lowered its peak temperature. The incorporation of MPCM into asphalt causes a reduction in its penetrability as well as its ductility but also causes a growth in its softening point. Because of the effects of MPCM on asphalt at high temperatures, the material’s viscosity, composite modulus, and rutting parameters were all improved, which led to an increase in the material’s resilience to high-temperature deformation.

In 2023 and through an in situ dehydration and condensation process, Wang et al. [70] assured the possibility of creating a micro-encapsulated phase change material (MPCM) made of paraffin and SiO2 with a phase transition temperature of 53.64 °C. When mixed with asphalt binder, this material had a cooling effect. The MPCM particles were very small, with an average size of around 94.8 nm, and were almost spherical in shape. The paraffin was completely surrounded by a SiO2 shell. The differential scanning calorimeter (DSC) results showed that the solidifying and melting enthalpies of the MPCM were 108.7 J/g and 110.5 J/g, respectively. When added to asphalt binders, the solidifying and melting enthalpies were maximized at 11.04 J/g and 13.76 J/g, respectively. The MPCM-enhanced asphalt binders had a higher Cp than basic asphalt binders, especially in the temperature range of 20–60 °C, which indicates that they had a significant impact on thermal regulation. Table 3 summarizes the research conducted on the use of mixture (organic–inorganic) phase change materials in asphalt.

Table 3.

A summary of conducted research on the mixture (organic–inorganic) of PCMs used in asphalt.

6. A Summary of Advantages and Disadvantages of Using Organic and Inorganic PCMs in Asphalt Pavements

According to the research that was stated the utilization of organic PCMs in asphalt pavements, the incorporation of expanded graphite/polyethylene glycol composite phase change material had a marginal impact on the temperature at which asphalt softened and its ability to penetrate, while simultaneously decreasing its low-temperature ductility and viscosity. In very hot areas, phase change capsules may delay the pace at which asphalt’s temperature varies in response to the surrounding environment by experiencing a phase transition. This helps to lessen the impairment that is caused to asphalt pavement by severe heat. Additionally, when compared to high-viscosity modified asphalt without PCM, paraffin/expanded graphite/high-density polyethylene composite material/high-viscosity modified asphalt containing 4% paraffin/expanded graphite/high-density polyethylene composite material and polyethylene glycol/high-viscosity modified asphalt containing 15% polyethylene glycol had a temperature-regulating effect that was 4 °C less effective during heating and had a delay time of 456 s and 1240 s, respectively. This was the case even though both formulations had the same amount of PCM.

In the analysis of the numerous studies that have covered the use of inorganic PCMs in asphalt pavements, the performance of asphalt at low temperatures was found to be enhanced significantly after the addition of graphene-modified phase-change microcapsules. When added to the asphalt mixture, NiTi alloy phase change energy-storage particles have the potential to lower the mixture’s daily maximum temperature. The ability of an asphalt mixture to phase shift heat storage and regulate temperature can be improved by increasing the amount of NiTi alloy phase change energy-storage particles that are added to the mixture as an additive.

In the same context, the appraisal of those studies related to the combination of organic–inorganic mixtures into asphalt pavements and the associated results, one can ascertain that the micro-encapsulated phase change material-enhanced asphalt binders have a larger Cp than basic asphalt binders, particularly in the temperature range of phase transitions (20–60 °C), which shows that the main impacts of thermal regulation are evident. Additionally, asphalt pavement that has been coupled with a PCM composite comprised of the palmitic acid and stearic acid and nano-Al2O3 can cool asphalt pavement effectively and lessen the strain that high-temperature rutting causes.

Referring to the findings of this review, a number of advantages of utilizing organic, inorganic and mixtures of organic–inorganic PCMs in asphalt pavements can be summarized as follows:

- Both organic and inorganic PCMs can store a considerable amount of thermal energy, which lead to enhanced thermal management of asphalt pavements.

- The thermal and structural stability can be ascertained via incorporating inorganic PCMs into asphalt pavements besides preventing the degrading of pavement at high-temperatures.

- The existence of organic and inorganic compounds can demonstrate better resistance to aging and fatigue when compared to pure PCMs.

However, the most challenges of utilizing organic, inorganic, and mixtures of organic–inorganic PCMs in asphalt pavements can be addressed as follows:

- The reduced thermal conductivity of organic and inorganic PCMs is a well-known challenge. This in turn would reduce the absorption and release of heat.

- The possible leaching of organic PCMs can hinder their effectiveness.

7. Conclusions

In this research, the impacts of employing organic, inorganic, and mixtures of organic–inorganic PCMs on the thermal and mechanical characteristics of asphalt pavements were examined. Recent advancements, innovations, and consequences were discussed. The following observations can be made as conclusions:

- A micro-encapsulated PCM-enhanced asphalt binder exhibited higher specific heat capacities than basic asphalt binders within their phase transition temperature range (20–60 °C), indicating its significance in thermal regulation.

- The incorporation of a micro-PCM into asphalt resulted in a modification of its characteristics, namely a reduction in ductility and penetrability, as well as an increase in the softening point. The visible viscosity, composite modulus, and rutting factor were all improved as a result, which strengthened the material’s resistance to deformation at high temperatures.

- Phase change capsules can mitigate asphalt pavement damage from excessive heat by undergoing phase transition, slowing down temperature variations in response to the environment.

- The impact of 4% paraffin/expanded graphite/high-density polyethylene composite material/high-viscosity modified asphalt and 15% polyethylene glycol/high-viscosity modified asphalt on temperature regulation during heating was 4 °C lower when compared to high-viscosity modified asphalt without PCM, and the delay durations for these two mixtures were 456 and 1240 s, respectively, despite the fact that the exact same quantity of PCM was included in both compositions.

- It has been observed that the rate of heating of polyurethane-based solid–solid PCM samples is consistently lower than the rate of heating of the control samples while the samples are being heated.

- A PCM composite comprised of palmitic acid and stearic acid and nano-Al2O3 effectively cools asphalt pavement, reducing stress caused by high-temperature rutting.

- When compared to an asphalt block that is not coated, the temperature will drop by about 5 °C in one hour due to the fact that the volume percentage of the composite material is exactly 12%.

- Increasing the amount of polyurethane solid–solid PCM in asphalt can make it more resistant to aging, and this benefit becomes more pronounced as the polyurethane solid–solid PCM content increases.

- The top surface temperature of an asphalt mixture including polyethylene glycol/SiO2 can be lowered by around 9 °C, thanks to the asphalt mixture’s remarkable temperature adjustment performance.

- Adding polyethylene glycol with a 4000 molar mass that was encapsulated in SiO2 as a replacement for 10% of the aggregate in the top sublayer was determined to be the most effective method for improving rutting performance in asphalt. For a period of one month after the construction of the pavement, this replacement led to a decrease in rut depth of fourteen percent.

- Asphalt binders that were given treatments with CuO at the nanoscale had much higher specific heat capacities and less reactivity to moisture and temperature.

- A polyethylene glycol/SiO2 composite is a great option for porous asphalt concrete, with a bulk polyethylene glycol content of 70%. It has been determined that the optimal replacement level should be 1.4%, based on the total weight of the aggregate. Additionally, the ideal particle size range for the PCM is between 0.6 mm and 1.18 mm.

- The inclusion of expanded graphite/polyethylene glycol composite PCM causes the enhanced binders’ creep rate to drop and their creep stiffness to increase, both of which are counterproductive to the goal of preventing low-temperature cracking.

Referring to the above concussions, it is fair to admit that the utilization of PCMs in asphalt pavements can offer an encouraging solution for modifying temperature-related issues, improving thermal management, and facilitating sustainable infrastructure development. This practice would therefore contribute to enhanced energy efficiency, mitigated environmental impact, and elevated pavement durability, which in turn would afford the maintaining of more resilient and sustainable transportation systems. However, it should be noted that this review focused on studies published between 2019 and 2023 and this might lead to the omission of some earlier studies that are still relevant to the studied field.

8. Recommendations and Challenges for Future Directions

Recent studies have provided visual indicators regarding the thermal performance and composition of PCM–asphalt mixtures. The associated results are summarized in Table 1, Table 2 and Table 3. Accordingly, a set of recommendations for further research can be made as follows:

- Various asphalt binders need to have their thermal and rheological characteristics assessed, and it is necessary to determine the influence of variable temperatures on the quality of PCMs.

- Future research should explore methods to increase PCM content in pavements without significantly compromising their mechanical strength.

- Exploring the use of porous coarse aggregates as carriers for PCMs is an intriguing strategy to augment PCM quantities in asphalt mixtures. However, this approach requires identifying aggregates capable of efficiently absorbing PCMs while ensuring the asphalt’s structural integrity under pressure.

- Collaborative efforts among physicists, chemists, and civil engineers will likely be essential to develop durable PCMs capable of effective heat regulation among the pressures encountered during asphalt pavement production.

- It is essential to horizon the research of incorporating high-conductivity nanoparticles into PCMs to improve their heat transfer capabilities.

- It is mandatory to explore innovative composite PCMs with optimal thermal conductivity by merging organic and inorganic materials with high-conductivity fillers.

- Researching the impact of PCMs’ shape and geometry on thermal conductivity within the asphalt pavement matrix is essential.

- A specific trend of research should focus on improving the chemical structure of organic PCMs to mitigate their solubility in water.

- Modelling and optimization are vital tools for deploying sustainable asphalt pavement solutions that support a sustainable transportation system [71]. Indeed, optimizing energy efficiency based on reduced environmental impact would permit the introduction of groundbreaking PCM technologies with a high potential to perfectly design and construct our roads and sustain excellent transportation systems.

- Despite this review covering several types of organic, inorganic, and mixtures of organic and inorganic PCMs in asphalt pavements, there is still a necessity to examine the integration of other PCMs to asphalt. These would include the biodegradable organic fatty acids of capric acid and lauric acid and the inorganic PCM of calcium chloride hexahydrate.

Author Contributions

F.L.R.: Conceptualization, Methodology, Investigation, Writing—original draft. M.A.A.-O.: Conceptualization, Investigation, Writing—review and editing. W.A.H.: Project administration. R.R.A.A.: Conceptualization, Resources. Z.A.A.R.: Methodology, Investigation. N.M.L.A.M.: Investigation, resources. A.D.: Investigation, resources, Project administration. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Athukorallage, B.; Dissanayaka, T.; Senadheera, S.; James, D. Performance analysis of incorporating phase change materials in asphalt concrete pavements. Constr. Build. Mater. 2018, 164, 419–432. [Google Scholar] [CrossRef]

- Nobakht, M.; Sakhaeifar, M.S. Dynamic modulus and phase angle prediction of laboratory aged asphalt mixtures. Constr. Build. Mater. 2018, 190, 740–751. [Google Scholar] [CrossRef]

- Manning, B.J.; Bender, P.R.; Cote, S.A.; Lewis, R.A.; Sakulich, A.R.; Mallick, R.B. Assessing the feasibility of incorporating phase change material in hot mix asphalt. Sustain. Cities Soc. 2015, 19, 11–16. [Google Scholar] [CrossRef]

- Mohod, M.V.; Kadam, K.N. A comparative study on rigid and flexible pavement: A review. IOSR J. Mech. Civ. Eng. (IOSR-JMCE) 2016, 13, 84–88. [Google Scholar]

- Dave, E.V.; Buttlar, W.G. Thermal reflective cracking of asphalt concrete overlays. Int. J. Pavement Eng. 2010, 11, 477–488. [Google Scholar] [CrossRef]

- Brown, N.R. Solution for distressed pavements and crack reflection. Transp. Res. Rec. 2003, 1819, 313–317. [Google Scholar] [CrossRef]

- Tapkin, S.; Uuml Usar, N.; Tuncan, A.; Tuncan, M. Repeated creep behavior of polypropylene fiber-reinforced bituminous mixtures. J. Transp. Eng. 2009, 135, 240–249. [Google Scholar] [CrossRef]

- Ihnayyish, I.L.; Ahmed, A.Q.; Mohammad, A.T.; Al-Syyab, A.K.S. Numerical Study to Investigate the Performance of U-shaped Flat Plate Solar Collector Using Phase Change Materials (PCMs). J. Tech. 2023, 5, 74–80. [Google Scholar] [CrossRef]

- Shamsaei, M.; Carter, A.; Vaillancourt, M. A review on the heat transfer in asphalt pavements and urban heat island mitigation methods. Constr. Build. Mater. 2022, 359, 129350. [Google Scholar] [CrossRef]

- Zhao, Y.; Min, X.; Huang, Z.; Liu, Y.; Wu, X.; Fang, M. Honeycomb-like structured biological porous carbon encapsulating PEG: A shape-stable phase change material with enhanced thermal conductivity for thermal energy storage. Energy Build. 2017, 158, 1049–1062. [Google Scholar] [CrossRef]

- Mu, S.Y.; Guo, J.; Yu, Y.; An, Q.D.; Zhang, S.; Wang, D.; Chen, S.; Huang, X.L.; Li, S.L. Synthesis and thermal properties of cross-linked poly(acrylonitrile-coitaconate)/polyethylene glycol as novel form-stable change material. Energy Convers. Manag. 2016, 110, 176–183. [Google Scholar] [CrossRef]

- He, L.; Li, J.; Zhou, C.; Zhu, H.; Cao, X.; Tang, B. Phase change characteristics of shape-stabilized PEG/SiO2 composites using calcium chloride-assisted and temperature-assisted sol gel methods. Sol. Energy 2014, 103, 448–455. [Google Scholar] [CrossRef]

- Rashid, F.L.; Al-Obaidi, M.A.; Dulaimi, A.; Mahmood, D.M.N.; Sopian, K. A Review of Recent Improvements, Developments, and Effects of Using Phase-Change Materials in Buildings to Store Thermal Energy. Designs 2023, 7, 90. [Google Scholar] [CrossRef]