1. Introduction

The chemical process industry (CPI) is characterized by complex operations that involve processing chemicals into a wide range of products and materials essential to various sectors, such as petrochemicals, pharmaceuticals, and agriculture. To manage the inherent risks in such operations, the CPI has historically prioritized safety through the implementation of rigorous process safety management (PSM) systems [

1,

2,

3]. Process safety focuses on identifying, assessing, and mitigating risks arising from unintentional incidents such as equipment failures, human errors, and operational disruptions, which could lead to catastrophic events, including large hazardous chemical releases, fires, and explosions [

4,

5]. Established methodologies such as Hazard and Operability studies (HAZOP), fault tree analysis (FTA), and layer of protection analysis (LOPA) have been instrumental in reducing such risks [

5,

6]. However, while effective, these methodologies often focus on individual hazards and reveal limitations in addressing systemic risks, necessitating more comprehensive frameworks for modern industrial operations [

7,

8,

9,

10].

On the other hand, process security focuses on protecting industrial facilities from intentional malicious acts, including sabotage, terrorism, and cyber-attacks [

11,

12]. Despite reports of 373 security-related incidents in industrial facilities [

13], process security has received comparatively less attention than process safety [

8]. Established methods, such as the vulnerability assessment methodology for chemical facilities (VAM-CF) and the security vulnerability assessment (SVA) method, have been developed to address these risks [

14,

15]. However, their application remains underutilized compared to process safety assessments, creating gaps in preparedness for intentional threats [

8,

16].

Traditionally, process safety and process security have been managed separately, creating silos that result in inefficiencies and gaps in addressing their interconnected risks [

17,

18,

19]. The evolving risk landscape in the CPI—marked by increasing complexity, interconnected systems, and emerging technologies—calls for a more integrated risk management approach that combines both process safety and process security considerations [

8,

17]. The growing complexity of CPI operations, driven by technological advancements and dynamic processes, introduces new and unforeseen risks that demand comprehensive strategies [

5]. Nevertheless, current risk management practices often overlook the interdependencies between safety and security risks, reducing the effectiveness of mitigation efforts [

8,

17].

The operations of CPI significantly impact both workers and surrounding communities, making societal values a critical factor in shaping risk management strategies. Societal values refer to the collective convictions that guide decisions in striving for a just and safe society [

20]. Examples include risk reduction, regulatory compliance, operational efficiency, and environmental stewardship [

21]. These values are central to decision-making processes, as they influence the priorities and trade-offs in managing process safety and process security risks. Aligning these values is essential for creating a cohesive and effective integrated risk management framework, yet the literature offers limited insight into how practitioners perceive and balance these values in practice. Addressing this gap is crucial for understanding the underlying drivers behind integrated risk management decisions in the CPI.

Moreover, resilience engineering has emerged as a promising paradigm to address the gaps in traditional risk management approaches [

22,

23]. Resilience engineering emphasizes the ability of systems to anticipate, adapt, and recover from both unintentional and intentional disruptions, including technical failures, terrorism, and natural hazards [

23,

24]. Key methodologies, such as the functional resonance analysis method (FRAM) and systems theoretic accident model and processes (STAMP), offer a more holistic perspective on risk management by focusing on system-wide interactions and adaptive capacity [

8,

24,

25]. Incorporating resilience principles enables organizations to enhance their ability to manage both process safety and process security risks within a unified framework.

While several studies have highlighted the importance of integrating safety and security risk assessments to improve system resilience [

8,

17,

24], there remain significant gaps in empirical research on how practitioners perceive, implement, and adapt to integrated frameworks within the CPI. This study seeks to address these gaps by examining industrial practices, engaging stakeholders in decision-making, gathering insights into practical implementation, and identifying challenges and opportunities for integrating process safety and process security risk management. To achieve this, the following research questions are addressed:

How do practitioners perceive the usefulness and benefits of integrating process safety and process security risk management?

What are practitioners’ awareness and perceptions regarding the resilience-based approach for integration?

How do practitioners perceive the importance of different societal values in process safety and process security risk management?

What barriers and enablers exist for integrating process safety and process security risk management, according to practitioners?

What strategies do practitioners propose for effective integration?

This research aims to explore the integration of process safety and process security risk management, leveraging resilience engineering principles to address both unintentional and intentional risks. By assessing the perceptions, awareness, and challenges faced by industrial practitioners, the research identifies critical barriers and enablers while proposing actionable strategies for effective integration. Although the development of a unified framework is beyond the scope of this paper, the findings contribute valuable insights and best practices from the domain of process safety, process security, and resilience engineering. These insights offer knowledge for industry practitioners to enhance their risk management practices and lay the groundwork for future efforts toward a cohesive and integrated framework.

The structure of this paper is as follows:

Section 2 presents the research methodology.

Section 3 presents the findings, followed by a discussion in

Section 4. The paper concludes with

Section 5.

2. Methodology

This study adopted a mixed-methods approach, integrating quantitative survey design with qualitative thematic analysis [

26,

27,

28]. The primary aim was to explore industry practitioners’ perceptions and experiences regarding the integration of process safety and process security risk management. The mixed-methods approach was selected to capture broad trends through quantitative data while also gathering contextual insights via qualitative responses, leveraging the strengths of both methods to support the study’s exploratory objectives. However, we acknowledge that survey-based qualitative data collection has inherent limitations, such as notably less depth and spontaneity. To address this, in-depth interviews with practitioners have been conducted as part of a broader research effort, focusing on follow-up research questions. These interviews will be presented in a separate publication to enrich the understanding of process safety and process security integration.

The survey instrument was developed based on a systematic literature review by the author [

8] and findings by Ylönen et al. (2022) [

17]. These studies provided insights into existing practices, challenges, and theoretical frameworks surrounding process safety, process security, and resilience in the CPI. This review informed the formulation of 31 multiple-choice questions designed to assess perceptions and levels of agreement (e.g., Likert scales) alongside six open-ended questions aimed at gathering qualitative insights into barriers, enablers, and strategies for integration.

Before finalizing the survey, a pilot test was conducted with six relevant practitioners and academics, who provided feedback on the clarity, structure, and content of the questions. Their input was incorporated to refine the final version, ensuring that the survey addressed key industry concerns and that respondents could understand the terminology and concepts. The refinements included simplifying definitions, rephrasing ambiguous questions, and restructuring sections for improved flow.

The survey provided definitions of key concepts, including process safety, process security, resilience, and relevant societal values, such as risk reduction and regulatory compliance, to enhance clarity. These definitions were included at the beginning of the related section to ensure that all participants shared a common understanding of the terms, reducing the risk of misinterpretation. The final survey comprised six sections covering respondent background, current practices, resilience awareness, societal values, barriers, enablers, and strategies for effective integration.

The survey was administered via the Microsoft Forms online platform. Participants were recruited using voluntary responses and snowball sampling methods. This approach was chosen to reach a specialized audience of practitioners within the CPI, leveraging the author’s professional network to identify individuals actively involved in process safety and security risk management. Although snowball sampling inherently limits representativeness, efforts were made to include a diverse range of perspectives by targeting professionals across different roles (e.g., regulatory staff, safety and security managers, operational personnel) and geographic locations. This approach aligns with the study’s exploratory objectives, prioritizing a breadth of qualitative insights over statistical representativeness. While not fully representative, the sample provided sufficient diversity to capture varied perspectives, supporting the qualitative dimension of the study. The survey was available from 1 February to 31 March 2024, and respondents could complete it anonymously with the option to withdraw at any time.

Quantitative data were analyzed using descriptive statistics to provide insights into respondent demographics and their perceptions of integrated risk management. Likert-scale responses assessed levels of agreement with statements on the perceived usefulness of resilience-based approaches, the integration of process safety and security, and strategies for effective integration. Data were reviewed for completeness, and inconsistent or incomplete responses were excluded. For example, Likert-scale responses were checked for anomalies, such as contradictory answers within the same response set, to ensure consistency. Results were summarized through descriptive statistics and visualized using tables and charts to highlight key trends and patterns.

Qualitative data from the open-ended questions were analyzed using the thematic analysis matrix (TAM) technique adapted from Mohd Zairul, 2021 [

26]. The TAM enables the systematic identification and organization of qualitative data through a combination of deductive and inductive coding approaches. Deductive codes are predefined categories based on the existing literature or research objectives, such as resilience capabilities. In contrast, inductive codes are derived directly from the data, representing new or unexpected insights that emerge during analysis.

The process began with open coding, where individual segments of text were labeled with initial codes to capture their meaning. These codes were then grouped into categories representing broader areas of interest, such as societal values or integration strategies. Finally, categories were synthesized into overarching themes that describe the key findings of the study. Emerging themes, specifically those identified through inductive coding, highlighted novel patterns or perspectives that were not initially anticipated.

The research team conducted iterative reviews of the codes and themes to ensure accuracy, consistency, and relevance. Qualitative data analysis software (ATLAS.ti) facilitated transparency and rigor by systematically organizing the data and maintaining traceability to the original responses. These findings were structured and presented using a thematic analysis matrix, visually illustrating the relationships between codes, categories, and themes.

To ensure transparency and replicability, the survey questionnaire and the anonymized dataset are available through the publicly accessible research repository 4TU.ResearchData at

https://data.4tu.nl/datasets/4522882f-0d76-46ad-b63f-5344964e1fb8, accessed on 2 January 2025. The anonymized data will be accessible under a CC-BY license, and readers may request additional information from the corresponding author if needed.

This study was approved by the Human Research Ethics Committee of TU Delft on 17 January 2024. Participation was voluntary, and no personally identifiable information was collected. The data were anonymized and analyzed in aggregate form to safeguard privacy. Respondents could optionally provide contact details for follow-up interviews, though this was not mandatory.

3. Results

3.1. Respondent Demographics

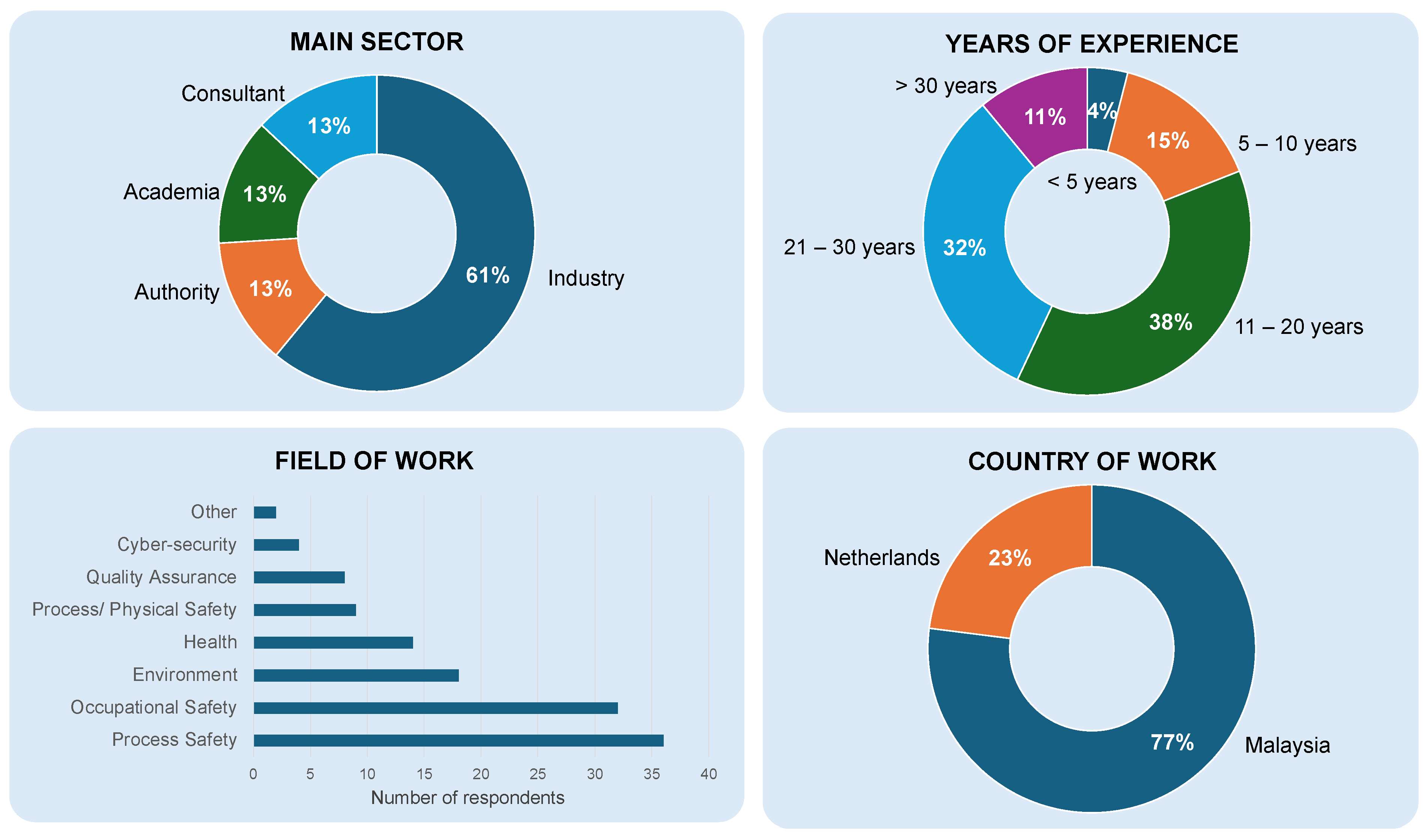

As shown in

Figure 1, a total of 47 participants responded to the survey, representing a diverse range of sectors, positions, and professional experiences within the chemical process industry (CPI). The respondents were predominantly based in Malaysia (61%,

n = 36) and the Netherlands (23%,

n = 11), reflecting the survey’s outreach and the authors’ networks.

Respondents were drawn from various sectors of the CPI. The majority were from industry (62%, n = 29), followed by consultancy (13%, n = 6), authority (13%, n = 6), and academia (13%, n = 6). This distribution reflects a broad cross-section of stakeholders involved in process safety and security management, offering a range of perspectives from both practical and academic settings.

The participants brought substantial professional experience to the survey, with 81% (n = 38) having over 10 years of experience in their respective fields. Specifically, 38% (n = 18) reported between 11 and 20 years of experience, 32% (n = 15) had 21–30 years of experience, and 11% (n = 5) had more than 30 years of experience. This high level of expertise among the respondents ensures that the insights gathered from the survey reflect a depth of knowledge in process safety and security risk management practices.

Furthermore, as summarized in

Table 1, a cross-tabulation of country vs. sector indicates that respondents from Malaysia are predominantly engaged in industry (58%,

n = 21), with smaller proportions involved in authority (17%,

n = 6), consultancy (14%,

n = 5), and academia (11%,

n = 4). Conversely, respondents from the Netherlands were also primarily from industry (73%,

n = 8) but with a notable presence in academia (18%,

n = 2), while only one respondent reported working in consultancy.

A cross-tabulation of country vs. years of experience reveals that respondents from Malaysia had a wider distribution across experience levels. The largest group (50%, n = 18) had between 11 and 20 years of experience, followed by 21–30 years (25%, n = 9). In contrast, respondents from the Netherlands showed a greater concentration of highly experienced professionals, with 55% (n = 6) having 21–30 years of experience and 35% (n = 5) having over 30 years.

Regarding sector vs. years of experience, the industry sector had the most significant representation of respondents, with 11–20 years of experience (45%, n = 13), followed by those with 21–30 years (24%, n = 7). A few participants in industry had over 30 years of experience (10%, n = 3), while some had less than 5 years (3%, n = 1). In academia, most respondents had between 21 and 30 years (n = 3) or more than 30 years of experience (n = 1), with very few in the lower experience categories. In authority, the respondents were spread evenly between five and thirty years of experience, while consultancy showed concentration distribution across 11 to 30 years of experience ranges.

3.2. Perception on Integration Usefulness

To assess how practitioners perceive the integration of process safety and process security risk management, respondents were asked whether they consider the integration to be useful.

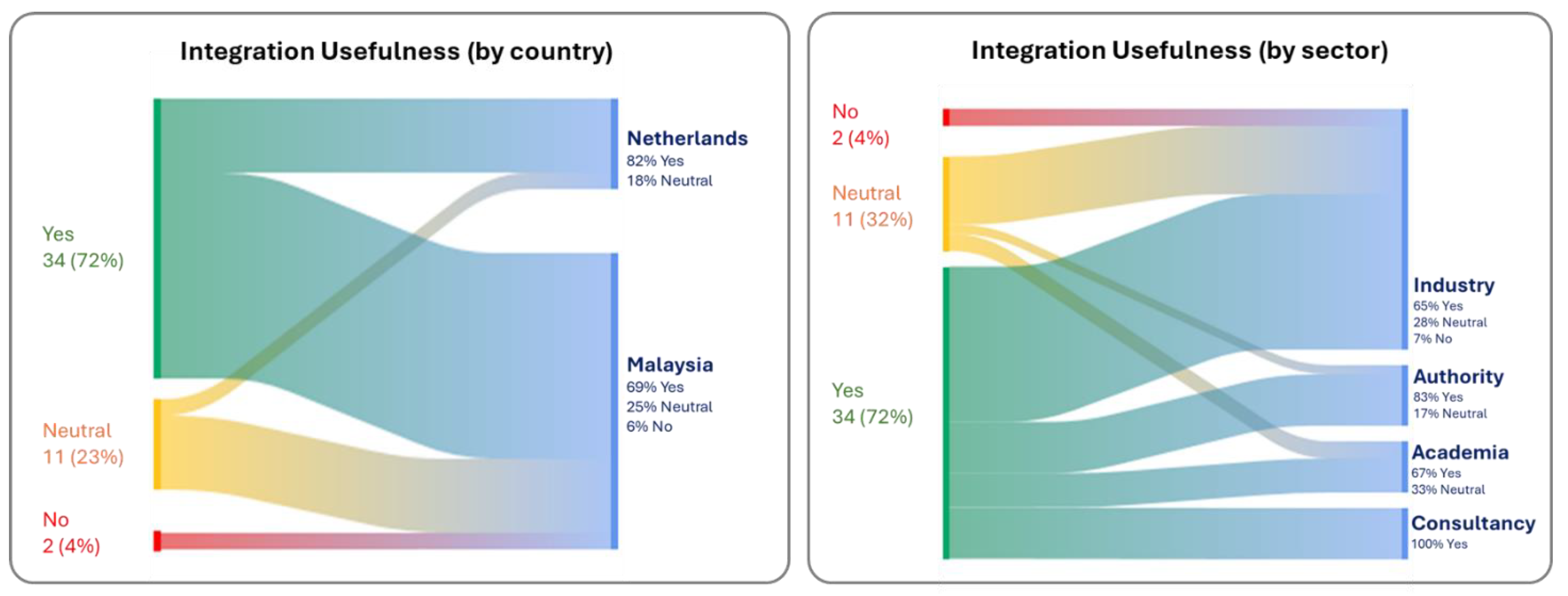

Figure 2 provides a visual representation of the perceived usefulness of integration among respondents by country and sector. The graph shows that 72% (

n = 34) of respondents found the integration useful, 23% (

n = 11) were neutral, and 4% (

n = 2) did not find it useful. The left side of the graph illustrates the overall responses, while the flow links to specific countries and sectors on the right side, helping readers understand the breakdown by group.

Cross-tabulation by country showed similar levels of support between Malaysia and the Netherlands. Among Malaysian respondents, 69% (n = 25) indicated that the integration of process safety and process security was beneficial, while 25% (n = 9) held neutral views and 6% (n = 2) did not find the integration useful. Conversely, respondents from the Netherlands showed a slightly higher level of support, with 82% (n = 9) finding the integration useful. In comparison, a smaller proportion (18%, n = 2) were neutral, and none of the respondents from the Netherlands indicated that the integration was not useful.

Sectoral analysis revealed further differences. Industry respondents showed strong support, with 66% (n = 19) finding integration useful, 28% (n = 8) neutral, and 7% (n = 2) not finding it useful. In the consultancy sector, all respondents (n = 6) found integration useful, while in authority roles, 83% (n = 5) found it useful and 17% (n = 1) were neutral. Academia showed a more divided view, with 67% (n = 4) finding integration useful and 33% (n = 2) expressing neutral opinions.

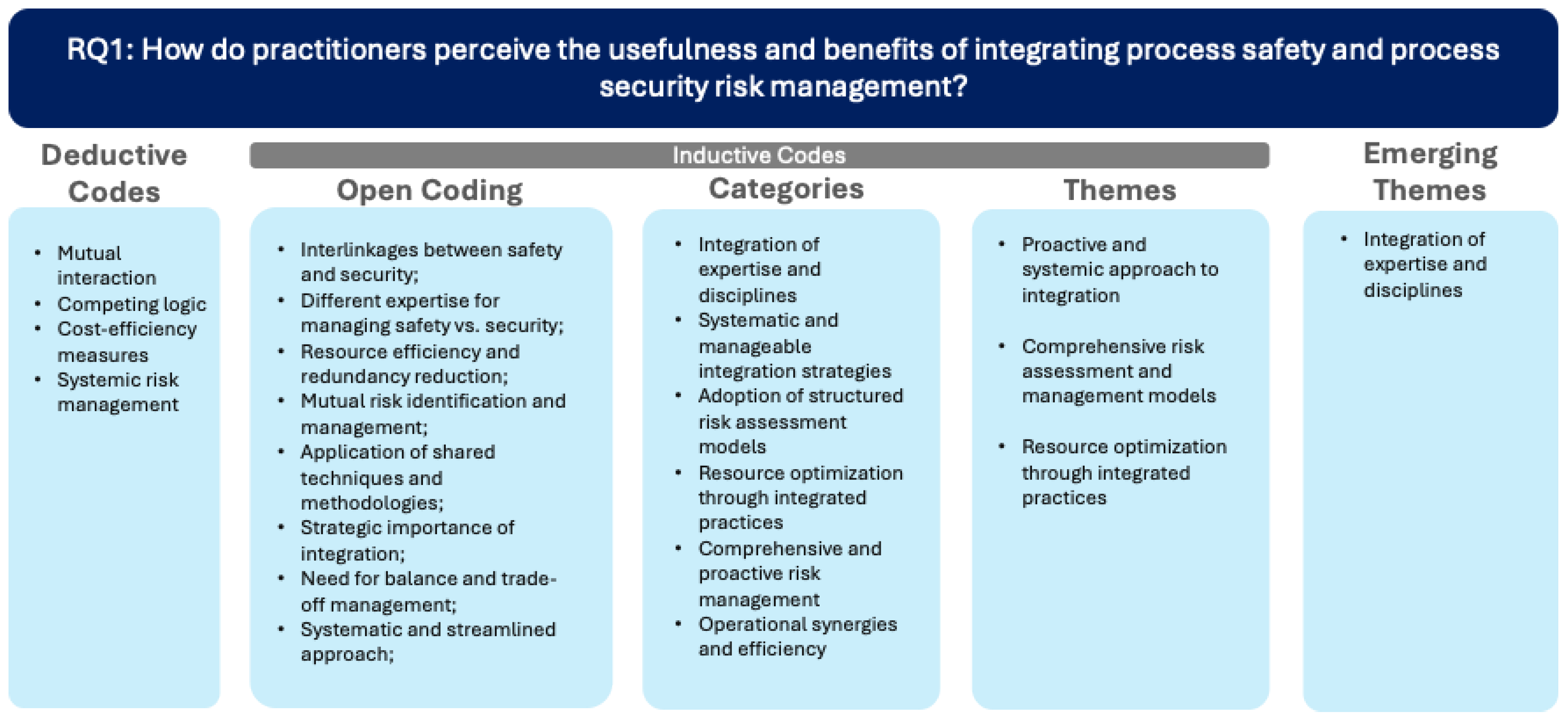

The qualitative responses provided further depth to these quantitative findings, highlighting why respondents found the integration of process safety and process security useful, as summarized in the thematic analysis matrix (

Figure 3). Several key themes emerged from the open-ended responses, reflecting a consensus on the interconnectedness of safety and security risks and the importance of a proactive, systematic approach to managing them.

Respondents emphasized the shared nature of risks between process safety and process security. One Malaysian authority figure commented the following: “In most cases, safety and security risk share the same hazard and effect. The differences would be in terms of caused (intentional vs. unintentional). Therefore, the convergence of these two aspects can strengthen the facility readiness in managing the safety and security threat”. This view was mirrored by a consultant from Malaysia, who remarked the following: “Either domain may pose risks to one another. Hence, integrating both domains may eliminate risks between them”.

In addition to risk mitigation, several respondents discussed the potential for resource optimization through integration. A respondent from the Netherlands in the industry sector emphasized the operational benefits: “Process safety and process security risk are important to make sure no one gets hurt. Integrating them in our daily operations reduces the risk of incidents or minimizes the impact when incidents do occur”. This perspective highlights the practical benefits of integration, particularly in minimizing the severity of incidents.

Moreover, respondents identified the commonality of methodologies between process safety and process security. An academic respondent from the Netherlands noted the following: “Same risk assessment principles and process steps, e.g., identify, assess, minimize, control”. This underscores that existing risk management frameworks could be leveraged for both process safety and process security, streamlining the integration efforts.

The combination of the quantitative and qualitative analyses demonstrates a strong shared belief among practitioners in the value of integrating process safety and process security risk management. Quantitatively, most respondents across countries and sectors found integration useful, and these perceptions were enriched by qualitative insights that emphasized the interrelated nature of risks and the efficiency gains from integrated approaches.

The numerical data and the thematic analysis point toward a consensus on the practical and strategic benefits of integration, with respondents calling for systematic approaches, resource optimization, and cross-disciplinary collaboration. These findings suggest that integration is not only viewed as beneficial but also necessary for enhancing overall risk management effectiveness.

3.3. Awareness and Perception on Resilience Concept

To explore how practitioners perceive the resilience-based approach in managing process safety and security risks, respondents were asked to rate their familiarity with the concept and their perceptions of its usefulness (

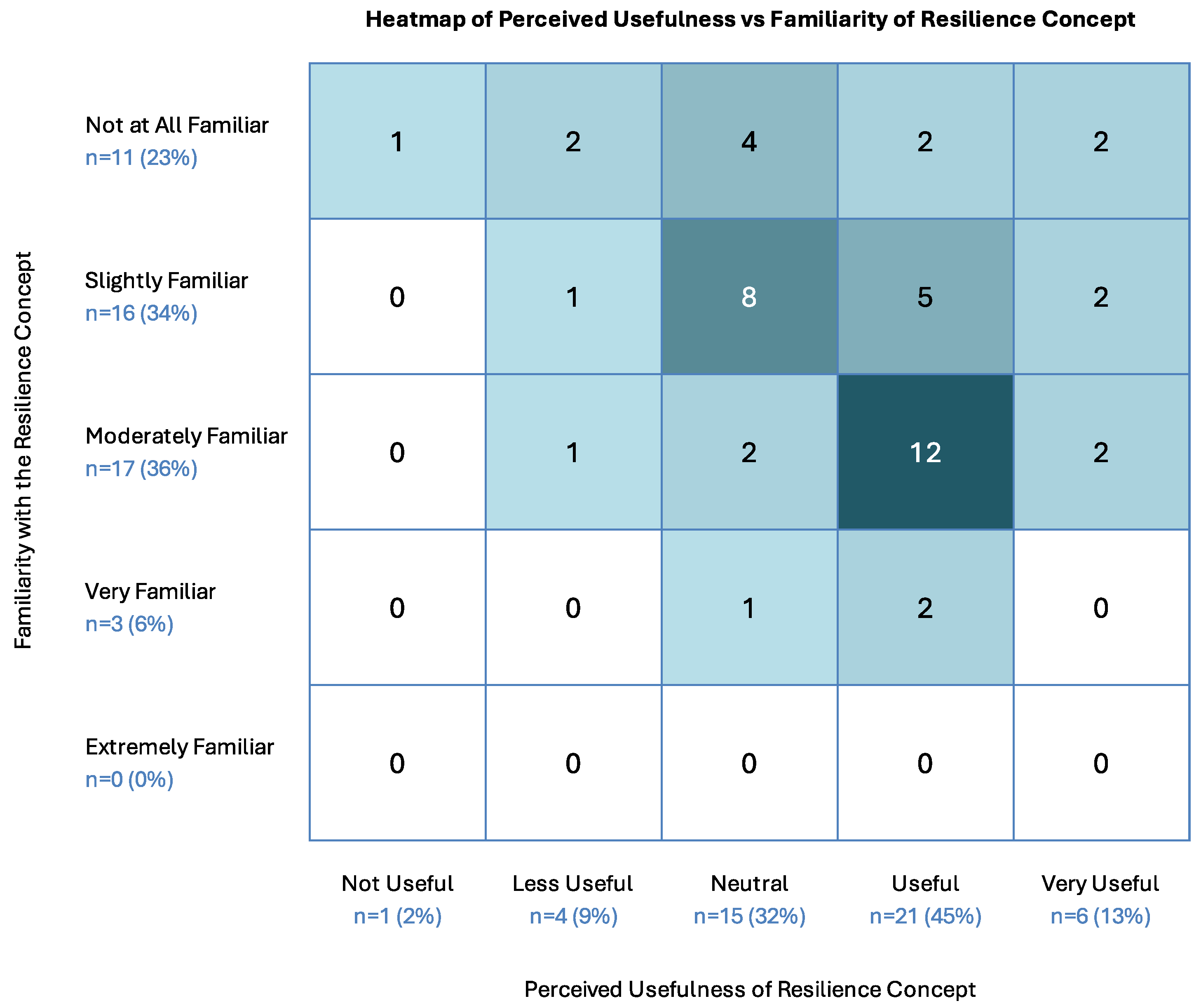

Table 2). The analysis revealed important insights regarding both familiarity and usefulness, as well as how these perceptions vary by country and experience level.

As shown in

Table 2, most respondents (70%,

n = 33) reported being either slightly or moderately familiar with resilience concepts. In comparison, only a tiny portion (6%,

n = 3) considered themselves very familiar, and none indicated they were extremely familiar. Familiarity varied notably between countries and across different levels of professional experience. Among Malaysian respondents, familiarity levels were more diverse, particularly within the 11–20 years of experience group, where responses ranged from not at all familiar to very familiar. In contrast, Dutch respondents with more than 21 years of experience mostly (91%) described themselves as slightly or moderately familiar, with none reporting very or extremely familiar. These findings suggest that while moderate familiarity is common, a more profound understanding of resilience concepts is limited, particularly in the Netherlands, where even highly experienced practitioners tend to lack advanced familiarity.

In terms of perceived usefulness (

Table 3), the majority of respondents (45%,

n = 21) found resilience concepts to be useful, while 13% (

n = 6) considered them very useful. Notably, there was variation in how practitioners from different countries and experience levels rated the usefulness of resilience concepts. Among Malaysian respondents, 16 out of 36 participants (61%) rated resilience as either useful or very useful, indicating more substantial overall support for resilience-based approaches. In contrast, among Dutch respondents, only five out of eleven participants (45%) rated resilience concepts as either useful or very useful, reflecting a more mixed perception.

Moreover, Malaysian respondents with less than five years of experience unanimously found resilience concepts useful. However, those with 11–20 years of experience were more divided, with seven respondents finding resilience useful and three rating it as very useful, while six remained neutral. Among Dutch practitioners with more than 21 years of experience, perceptions were also mixed, with four respondents rating resilience as useful and one rating it as very useful. These findings suggest that perceptions of resilience-based approaches vary by experience and national context, with stronger support observed among Malaysian respondents.

Furthermore, the heatmap analysis in

Figure 4 provided additional insights into the relationship between familiarity and perceived usefulness. Respondents who were moderately familiar with resilience concepts were the most likely to find them useful or very useful, whereas those with only slight familiarity tended to remain neutral. This suggests that moderate familiarity is sufficient for practitioners to recognize the value of resilience-based approaches. However, the lack of respondents in the “extremely familiar” category and the relatively high number of neutral responses across all familiarity levels indicate that deeper understanding or practical exposure may be needed to appreciate the benefits of resilience-based approaches fully.

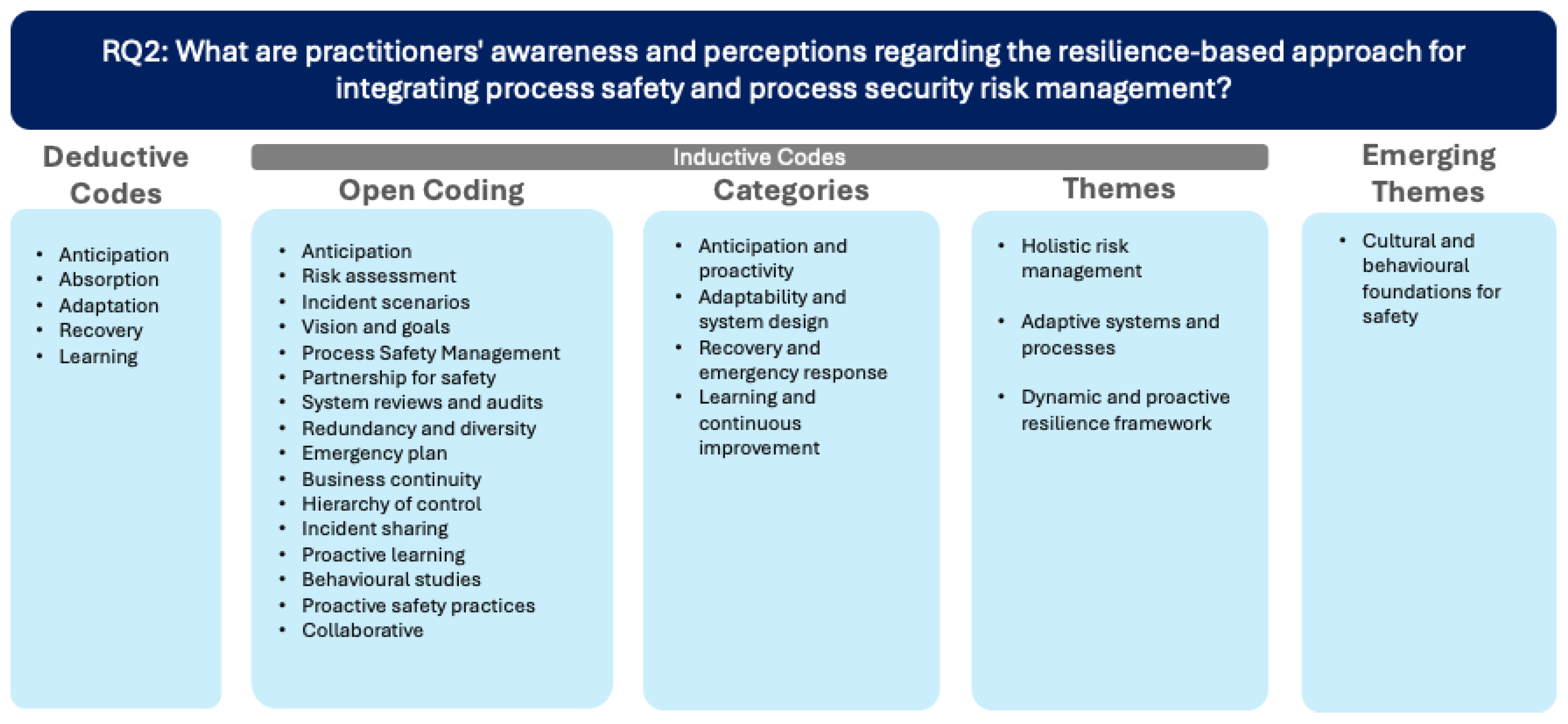

We also asked the respondent in an open-ended question to list any resilience-based practices or principles they are aware of. The qualitative responses supported these quantitative findings, revealing several key categories and themes that align with broader resilience frameworks (

Figure 5). One key category that emerged was anticipation and proactivity. Respondents emphasized the importance of anticipating risks and taking proactive measures to mitigate them before they escalate. For instance, a consultant from Malaysia highlighted anticipation as a key practice in resilience, stressing the need for the early identification of potential threats. This reflects the proactive stance central to resilience-based approaches, which aim to address risks before they become critical issues.

Another important category was adaptability and system design. Respondents discussed the need for adaptable systems that are capable of handling disruptions and ensuring safety under varying conditions. Practices such as redundancy, diversity, and system reviews were mentioned as vital components of resilience. An academic from the Netherlands cited specific resilience practices such as “tiered risk assessment, Process Hazard Analyses, and Inherently Safe by Design”, which underscore the structured and adaptive nature of resilience approaches. These systems are designed to be flexible and able to respond to changes in the operational environment while maintaining safety and security.

Respondents also mentioned the categories of recovery and emergency response. Respondents emphasized the importance of having effective recovery and emergency response mechanisms in place to ensure that operations can continue or recover quickly in the event of an incident. A consultant from Malaysia pointed to business contingency plans as a key resilience practice that allows organizations to bounce back from disruptions. This category also includes practices like emergency response planning and incident sharing, which enable organizations to learn from incidents and enhance their resilience over time.

Respondents also highlighted the significance of learning and continuous improvement. Several emphasized the need to learn from both successful and unsuccessful events to improve safety practices continually. A Malaysian academic mentioned proactive learning from successful tasks, demonstrating how organizations can enhance their resilience through reflection and adaptation. Continuous learning is an integral part of resilience, as it allows organizations to evolve and better manage risks in the future.

Finally, the category of cultural and behavioral foundations for safety emerged as a critical component of resilience-based approaches. Many respondents noted the importance of organizational culture and human behavior in building resilience. An authority figure from Malaysia mentioned behavioral-based studies as essential for understanding and improving human factors in resilience. This highlights that resilience goes beyond technical systems and requires a cultural commitment to safety, collaboration, and proactive behavior within the organization.

From these categories, several broader themes emerged that offer deeper insights into how resilience-based approaches are understood and applied in practice. One key theme is holistic risk management, which draws from the categories of anticipation, adaptability, and learning. Practitioners see resilience as an integral part of a comprehensive risk management framework rather than an isolated strategy. This theme reflects the understanding that resilience-based approaches are embedded within broader efforts to manage risks across the organization.

Another emerging theme is the concept of a dynamic and proactive resilience framework. This theme combines insights from the categories of adaptability and continuous improvement, highlighting that resilience is not a static attribute but rather a dynamic and evolving framework. Organizations must continuously adjust their systems and processes to maintain resilience in response to new challenges and changing circumstances. This emphasizes the need for ongoing flexibility and proactive adjustments in resilience management.

Lastly, the cultural and behavioral foundations theme highlights that resilience is supported by organizational leadership, teamwork, and a proactive safety culture. This theme emerged from the category focused on organizational culture, where respondents recognized that resilience is not only about systems but also about the people who operate within those systems. Leadership, collaboration, and a commitment to proactive safety behaviors are seen as critical components of a resilient organization, reinforcing the idea that resilience is as much about people and culture as it is about technical systems.

The quantitative and qualitative findings comprehensively show how practitioners perceive resilience-based approaches. While the quantitative data suggest that familiarity is generally moderate, the qualitative responses reveal that those with moderate familiarity often have a deeper understanding of resilience practices, such as anticipation, adaptability, and learning. This suggests that increased exposure and hands-on experience with resilience concepts could enhance their perceived usefulness among practitioners. The findings point to opportunities for training and capacity-building in resilience-based approaches, potentially improving the plant’s overall safety and security.

3.4. Importance of Different Societal Values

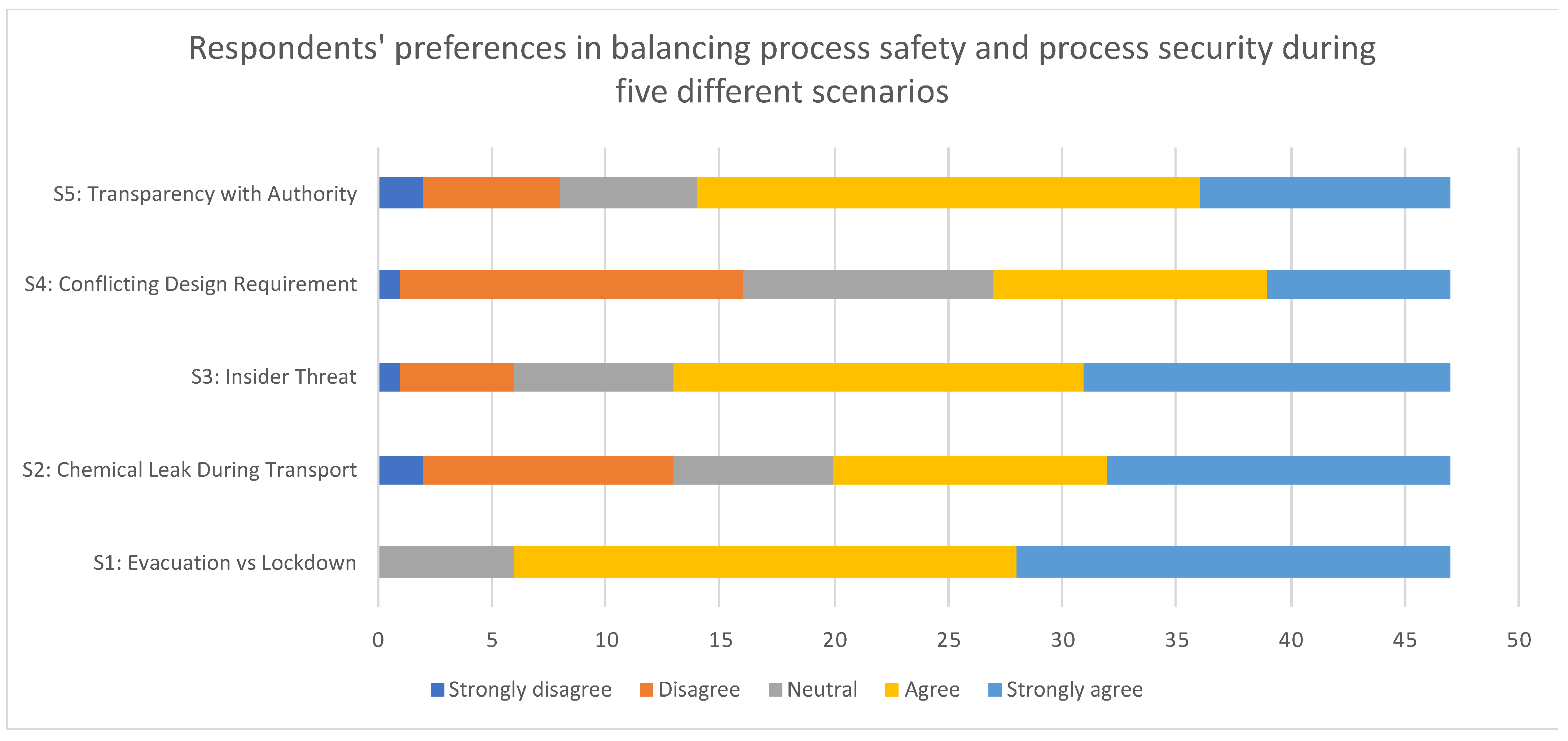

In industrial settings, professionals frequently face challenging decisions that involve balancing the sometimes conflicting values of process safety and process security. This section examines how practitioners prioritize these values across five hypothetical risk scenarios, each presenting a trade-off between process safety and process security (

Figure 6). The scenarios are briefly mentioned below, and full descriptions can be found in

Appendix A.

In Scenario 1 (evacuation vs. lockdown), participants were asked to choose between executing an evacuation for process and personnel safety, even at the risk of exposing the site to security threats or opting for a lockdown to secure the site. An overwhelming majority (87%) agreed or strongly agreed that prioritizing evacuation for safety is the appropriate course of action. This reflects the strong preference for prioritizing life safety over site security in situations where personnel are at risk.

In Scenario 2 (chemical leak during transport), respondents considered whether to immediately inform the public about a chemical leak, prioritize safety, or secure the transport from potential threats before making any disclosures. A majority (57%) supported prioritizing public safety, but a notable proportion (28%) disagreed, showing concern for securing hazardous materials first. This finding illustrates the complexity of balancing safety with security in scenarios involving hazardous substances.

In Scenario 3 (insider threat), respondents were asked to prioritize restricting access to chemicals to prevent potential misuse by an insider at the cost of disrupting regular operations. A strong majority (72%) agreed or strongly agreed with prioritizing security by restricting access. This demonstrates an apparent inclination toward process security measures when facing malicious threats, even if they compromise operational continuity.

In Scenario 4 (conflicting design requirements), respondents considered the importance of an open workspace design needed for safety audits versus security recommendations to limit access points. Responses were more divided, with 43% supporting the safety audit requirement, while 34% favored the security recommendation. This split indicates the difficulty practitioners face when operational safety and security requirements conflict, particularly in design-related decisions.

In Scenario 5 (transparency with regulatory bodies), participants were asked whether they would opt for full transparency with regulatory bodies, even if it exposed security vulnerabilities or limit the information to protect process security. A clear majority (70%) supported full transparency, reflecting the importance practitioners place on regulatory compliance and safety. However, 17% preferred limiting information to safeguard security, showing that security concerns remain significant, even in the face of regulatory transparency.

The analysis reveals a distinct pattern; in scenarios directly involving process and personnel safety, respondents tend to prioritize process safety over security concerns. This is evident in the strong support for evacuation (Scenario 1) and public communication during chemical leaks (Scenario 2). However, in scenarios emphasizing security threats, such as insider threats (Scenario 3) or design-related security vulnerabilities (Scenario 4), practitioners strongly prefer security measures, even at the expense of operational safety.

The responses to Scenario 5 reinforce this tendency. Although most respondents favored full transparency, suggesting that regulatory compliance and safety-driven transparency are critical, the notable portion of respondents who prioritized security indicates that security concerns are not entirely secondary. This demonstrates the nuanced balancing act practitioners must navigate when dealing with competing safety and security priorities.

These findings suggest that practitioners’ values shift depending on the nature of the scenario. When personnel safety is at immediate risk, there is a clear preference for prioritizing safety, as seen in the evacuation and chemical leak scenarios. However, when security vulnerabilities or malicious actions are involved, practitioners lean toward security measures, such as restricting access or prioritizing security recommendations in design considerations. The divided responses in these scenarios highlight the complexity of these trade-offs and the need for careful decision-making in real-world situations.

The results from Scenario 5 suggest that while process security is important, regulatory compliance and safety-driven transparency take precedence. The tension between safety and security underscores the need for integrated frameworks that balance safety and security without compromising one for the other. Practitioners could benefit from tools and approaches that help them make informed decisions when process safety and process security come into conflict, ensuring that neither aspect is neglected in critical situations.

In addition to evaluating specific safety and security scenarios, respondents were asked to rank various societal values based on their importance in process safety and process security contexts [

21]. The ranking, shown in

Table 4, highlights key priorities in both domains and reveals some significant differences.

The two highest-ranked values across both process safety and process security were risk reduction potential and risk creation, but their order differs between the two domains. In process safety, risk reduction potential emerged as the top priority, indicating that practitioners prioritize actions that can prevent incidents and reduce losses. This reflects the core objective of process safety, which is minimizing harm and preventing accidents. Conversely, in process security, risk creation was ranked as the most important value, emphasizing that practitioners are more concerned with preventing the introduction of new risks or vulnerabilities, especially those related to malicious actions, such as theft or sabotage. This difference highlights the distinction between unintentional risks in safety and intentional risks in security. The focus on minimizing new risks in security suggests that the primary goal is not just to reduce existing risks but also to prevent any additional threats from emerging.

Jurisdictional authority ranked third in process safety but dropped to fifth in process security, suggesting that regulatory support and compliance are seen as slightly more critical in safety contexts. This could be due to the direct oversight that safety regulations often have on industrial operations, where ensuring compliance with safety standards is a top priority. In security, while still important, jurisdictional authority takes a backseat to other factors, such as cost and timing, reflecting the need for more immediate tactical responses to security threats.

Similarly, effects on the environment ranked fourth in process safety but seventh in process security, suggesting that practitioners see environmental impacts as more closely tied to safety incidents, where accidents like spills or fires can have immediate and direct effects on the environment. In process security, environmental concerns are less prominent, possibly due to the more focused goal of protecting assets and preventing malicious actions.

Cost was ranked higher in process security (third) than in process safety (seventh), reflecting the larger role that economic considerations play in security decisions. In the context of security, managing risks often involves strategic investments in protective measures, making cost a significant factor in decision-making. In contrast, in process safety, other values such as risk reduction potential and jurisdictional authority are seen as more pressing concerns, pushing cost lower on the list of priorities.

Timing, ranked fifth in process safety and fourth in process security, was consistently valued in both domains. This indicates that how quickly risk mitigation measures can be implemented is critical across both safety and security contexts. However, the slightly higher ranking in security suggests that there is a greater emphasis on responding swiftly to security threats, where delays and inaction could lead to serious consequences.

Values such as equity, fairness, and administrative efficiency were ranked lower in both process safety and process security. Fairness ranked last in both domains, indicating that concerns about the fair distribution of costs or responsibilities are often secondary to more immediate considerations such as risk reduction or cost-effectiveness.

Administrative efficiency was also ranked relatively low, eighth in process safety and ninth in process security. This suggests that while the ease of implementing risk management measures is considered, it is not a primary driver of decision-making in either domain. Practitioners appear more focused on achieving effective risk reduction than on whether the process is easy to administer.

In summary, the ranking shown in

Table 4 highlights key priorities in both domains and reveals some important differences. These differences highlight the need for integrated risk management frameworks that can accommodate these varying priorities. Practitioners must be able to balance economic, environmental, and regulatory concerns while addressing both intentional risks in security and unintentional risks in safety. In conclusion, while many values are shared between process safety and process security, the differences in prioritization suggest that a holistic approach is needed to manage risks in both domains effectively.

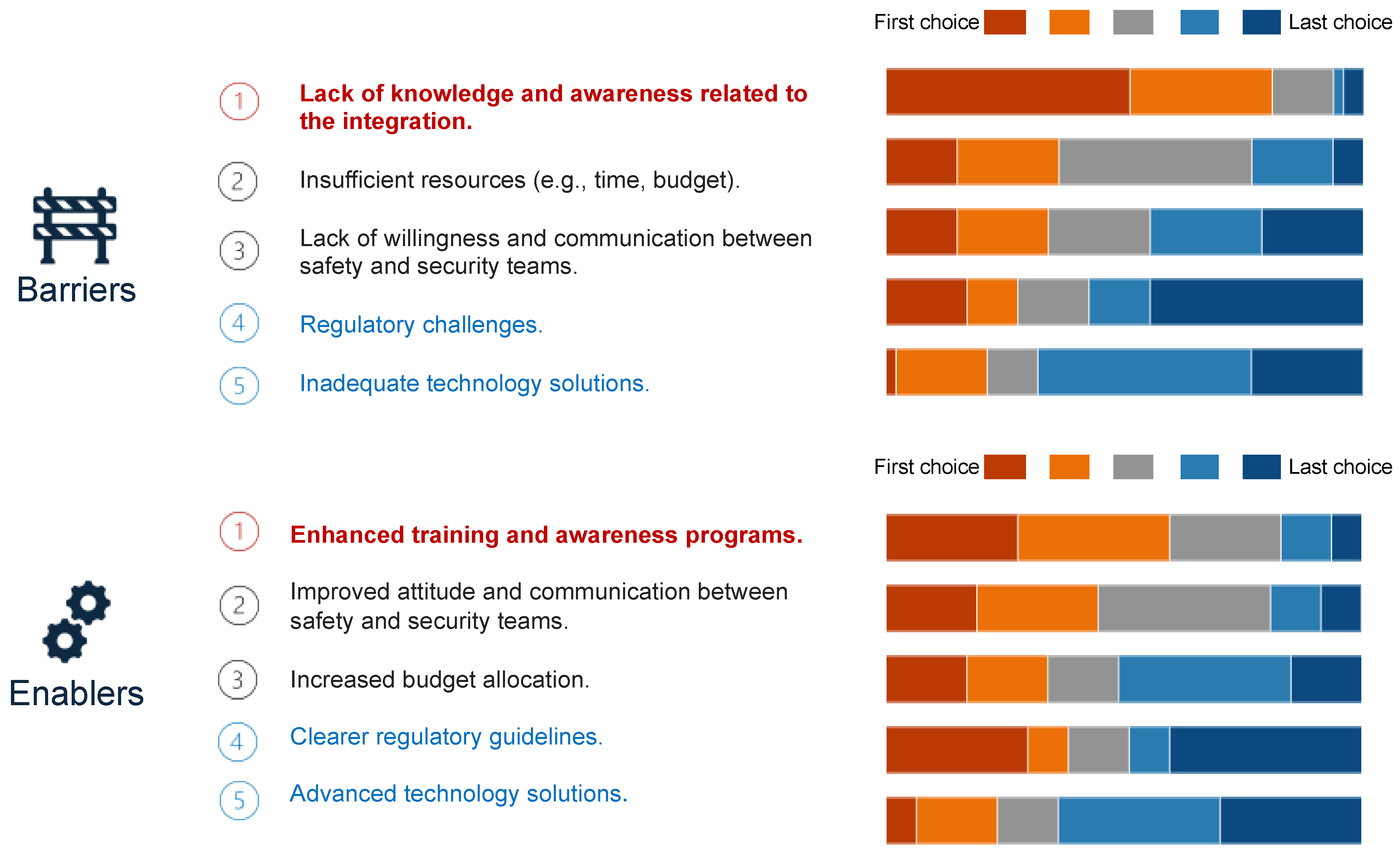

3.5. Barriers and Enablers for Integration

In the survey, practitioners were asked to rank the main barriers to integrating process safety and process security risk management [

17]. Lack of knowledge and awareness emerged as the most significant barrier (

Figure 7). This highlights that many practitioners still lack a foundational understanding of how safety and security processes can be effectively integrated, representing a critical obstacle.

The second-highest barrier was insufficient resources such as time, budget, and personnel. This may indicate that organizations struggle with resource constraints, which limits their ability to implement comprehensive integration strategies. For instance, budgetary limitations may prevent cross-disciplinary training, while time pressures may lead to short-term measures over integrated, long-term solutions. Lack of willingness and communication between safety and security teams emerged as the third major barrier. Respondents cited in an open-ended response that poor communication and organizational silos are key challenges that prevent safety and security professionals from collaborating effectively. Regulatory challenges and inadequate technology solutions were ranked lower but remained relevant. Unclear or conflicting regulatory requirements and the need for better technological tools were noted by respondents, who emphasized the importance of aligning regulatory frameworks to support integration.

On the enabler side, enhanced training and awareness programs were identified as the top factor promoting successful integration. A respondent from the Netherlands stressed the need for “knowledge on how to implement integration”, highlighting the importance of targeted training. Improved communication and collaboration were the second most critical enabler, reflecting the need for coordinated efforts between safety and security teams. Increased budget allocation was the third-ranked enabler, which respondents saw as vital for supporting training, technology upgrades, and dedicated personnel. Lower-ranked enablers included clearer regulatory guidelines and advanced technology solutions, which respondents acknowledged could assist integration but were not seen as immediate priorities.

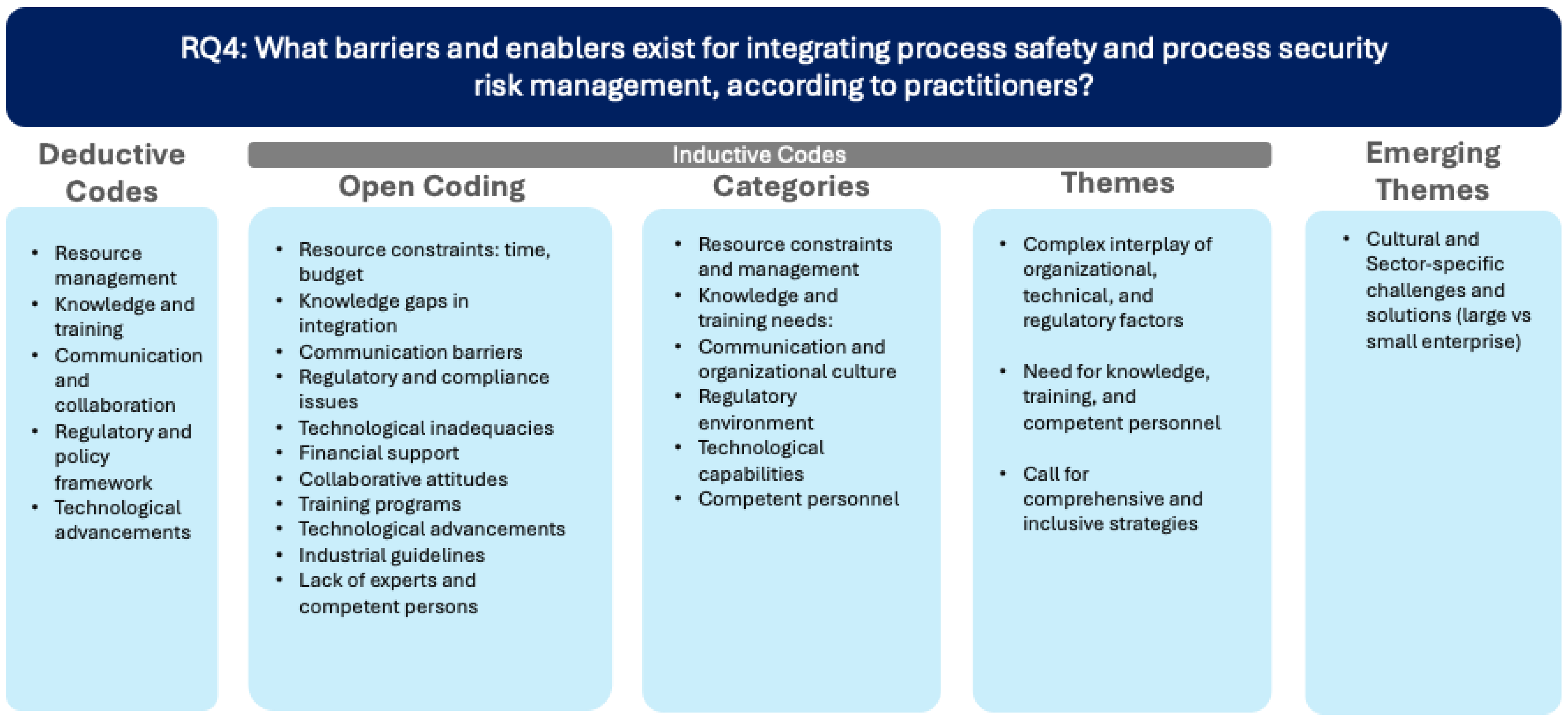

The qualitative analysis revealed key themes that further illuminate the complexity of integrating process safety and security (

Figure 8). The intertwined nature of barriers was a prominent theme, where respondents identified a mix of organizational, technical, and regulatory challenges. For instance, a respondent from Malaysia noted the “

lack of communication and commitment” between departments, while a respondent from the Netherlands highlighted inadequate regulatory enforcement as a barrier.

Another key theme was the need for training and the development of competent personnel. Respondents pointed to knowledge gaps, with a respondent from Malaysia’s authority sector emphasizing the importance of “management support” in providing resources for training. Other respondents from the Netherlands emphasized the need for “knowledge on how to implement integration” and the development of “common tools and language” to address these gaps. Since the integration of process safety and security is relatively new, the lack of professionals trained in both domains creates a significant barrier.

Respondents also called for comprehensive strategies involving multiple stakeholders. A respondent from Malaysia emphasized the importance of regulatory support, stating the need to “enhance regulation and enforcement”. Ensuring top-down support and cross-departmental communication was viewed as essential for successful integration.

An emerging theme in the responses was the influence of cultural and sector-specific factors on the integration of process safety and security. Respondents from different regions and sectors highlighted distinct challenges. For instance, one participant remarked, “they are two different worlds in our organization”, pointing to the organizational silos between safety and security teams. Similarly, a respondent from Malaysia noted the “lack of security risk awareness”, suggesting that cultural attitudes toward security may lag behind those for safety, further complicating integration efforts.

This theme also underscores the importance of tailoring integration strategies to fit the specific context of each organization, including its size, resources, and operational complexity. Smaller enterprises commonly face resource constraints, with one respondent identifying “budget and skilled personnel” as key barriers. These organizations may benefit from solutions that focus on securing financial support and affordable technological tools. In contrast, larger organizations often struggle with communication inefficiencies and internal misalignment, requiring strategies to enhance interdepartmental communication and ensure unified safety and security policies.

In essence, lack of knowledge, resources, and communication were the primary barriers identified, while training, collaboration, and increased budget allocation were the key enablers. Integration strategies must be tailored to the specific organizational context, with smaller firms needing resource support and larger firms focusing on communication and policy alignment. Holistic strategies, including enhanced training, communication, and financial investment, are essential for effective integration across the process safety and security domains.

3.6. Proposed Strategies for Integrating Process Safety and Process Security

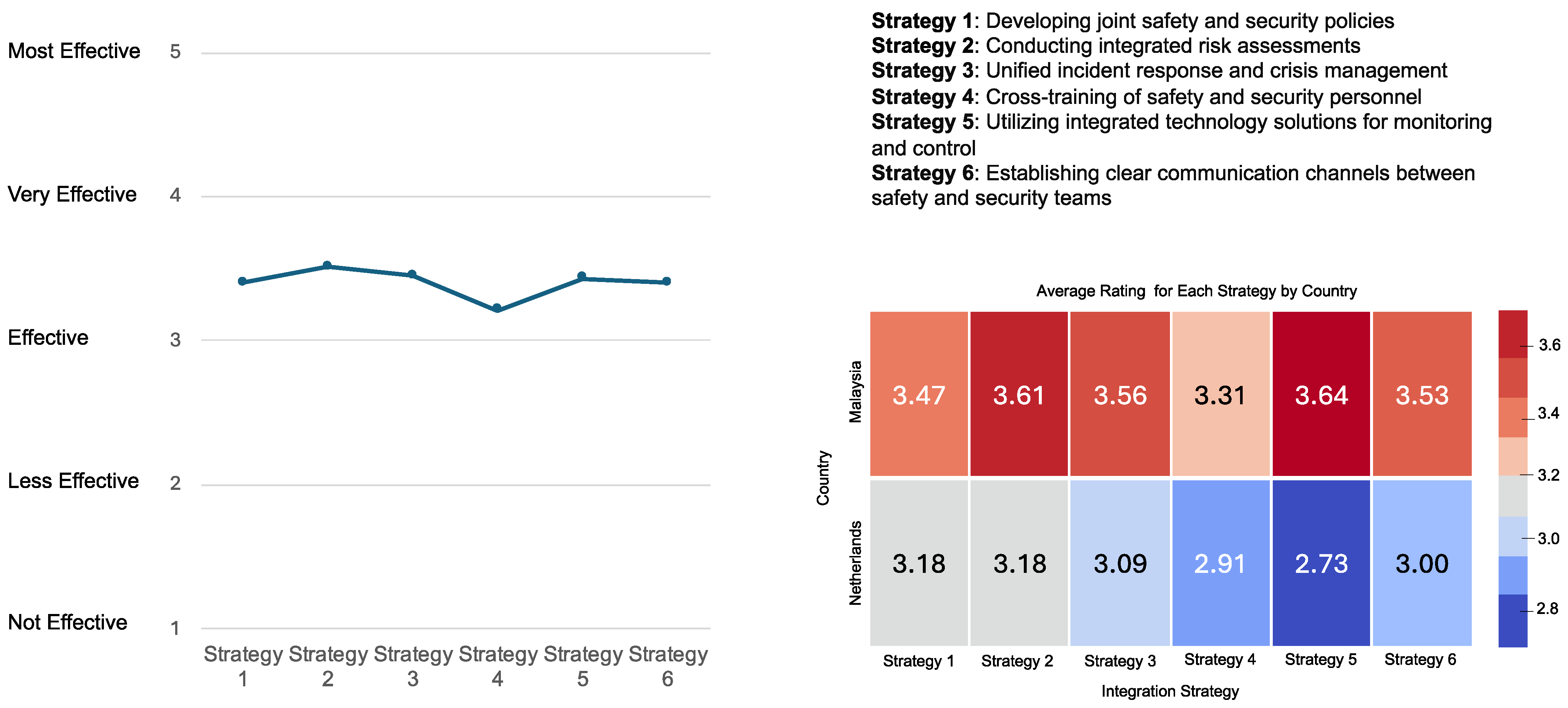

Respondents were asked to rate six proposed strategies for integrating process safety and security risk management [

8,

17]. These strategies included developing joint policies, conducting integrated risk assessments, and fostering clear communication channels. The quantitative data (

Figure 9) provided insights into the perceived effectiveness of these strategies, with notable differences in ratings between respondents from Malaysia and the Netherlands.

Across all six strategies, respondents generally rated the approaches as either “Effective” or “Very Effective”. Conducting integrated risk assessments was the highest-rated strategy, with an average effectiveness score of 3.51 (3.61 in Malaysia and 3.18 in the Netherlands), emphasizing the importance of aligning risk assessment methodologies across both domains. Unified incident response and crisis management followed closely, with an overall score of 3.44, highlighting the need for coordinated responses to ensure swift resolution during both safety and security incidents.

Developing joint safety and security policies was rated 3.40 overall (3.47 in Malaysia and 3.18 in the Netherlands), underscoring the importance of having a structured framework for integration. Similarly, establishing clear communication channels between teams scored 3.40, with Malaysia rating it 3.53 compared to 3.00 in the Netherlands. Effective communication is critical for breaking down organizational silos.

However, strategies like cross-training safety and security personnel (3.21 overall) and utilizing integrated technology solutions (3.42 overall) received lower ratings, especially from Dutch respondents. These differences suggest regional or organizational variations in the perceived feasibility of such measures, with Malaysian respondents being more favorable toward the use of technology and cross-training.

A noticeable trend emerged when comparing responses from Malaysia and the Netherlands. Malaysian respondents consistently rated the proposed strategies higher than their Dutch counterparts. This may reflect cultural or organizational differences in how integration is approached in the two countries, with Malaysian practitioners potentially placing greater support on structured and proactive strategies.

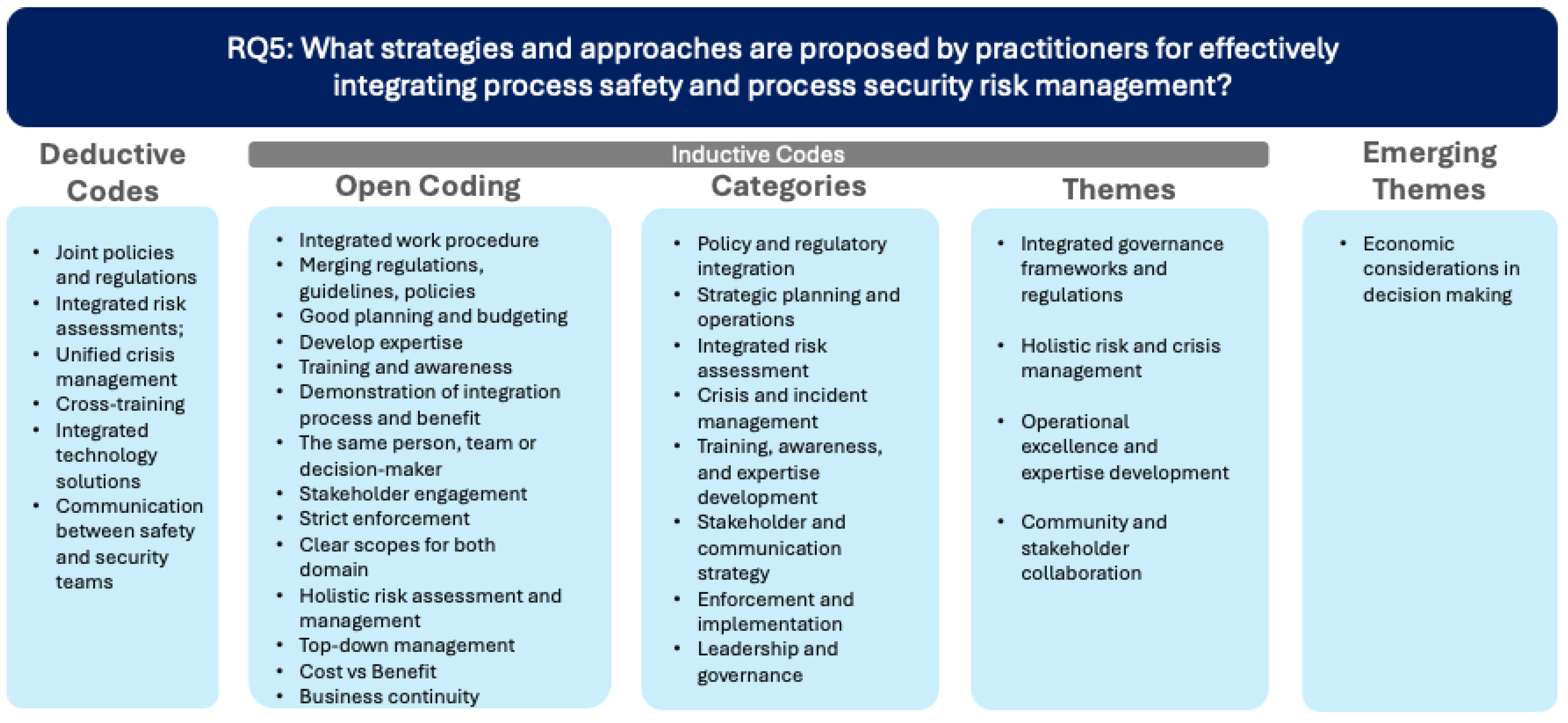

A thematic analysis of open-ended responses revealed deeper insights into these strategies (

Figure 10). Resilience-oriented risk management emerged as a key theme, with respondents emphasizing the need for proactive, adaptive strategies that balance safety and security. While not always explicitly rated as a standalone strategy, several respondents indirectly supported resilience principles through their emphasis on holistic risk and crisis management. One respondent suggested the creation of “

specific expert teams” to focus on integrated risk assessments, while another stressed the importance of having clear guidelines for managing safety and security during crises. This highlights the importance of having a well-defined crisis management plan that integrates both safety and security considerations and supports resilience by ensuring that core functions are maintained even in the face of disruption.

Respondents also highlighted the need for integrated governance frameworks. Several called for “merging regulations or guidelines” to support alignment between safety and security. The role of top management was frequently mentioned, with one respondent noting that “top management or the executor for safety and security should be the same person”, stressing the need for unified leadership.

Training and awareness programs were consistently identified as critical enablers. Respondents advocated for “awareness programs and training” to equip practitioners with cross-disciplinary skills, bridging the knowledge gap between safety and security practices. Operational excellence, driven by strategic “planning and budgeting”, was also seen as crucial for successful integration.

Collaboration between stakeholders was another recurring theme. Respondents called for stronger communication between safety and security teams and with external stakeholders, such as regulators. One respondent suggested “forums and feedback between all related parties” to foster collaboration.

Finally, economic considerations played a key role in shaping integration strategies. Several respondents noted that financial investment is necessary for successful integration, with one respondent stating that “business is willing to invest for such integration”, indicating that organizations are likely to prioritize integration if it offers clear value.

In summary, both the quantitative and qualitative findings suggest the need for a comprehensive, resilience-oriented approach to integrating process safety and security. Key strategies include policy alignment, risk assessment, stakeholder collaboration, and tailored training programs supported by strong leadership and governance. By embedding resilience principles into these efforts, organizations can enhance their capacity to respond to and recover from both process safety and security threats, ultimately improving overall risk management.

5. Conclusions

Integrating process safety and security risk management is essential for enhancing resilience in the chemical process industry, particularly in increasingly complex and interconnected operational environments. This study highlights the intertwined nature of safety and security risks, with 72% of respondents agreeing that integration is beneficial. Organizations can optimize resource utilization, improve risk mitigation, and enhance operational efficiency by addressing these interdependencies.

While this study employs a mixed-methods approach, the findings primarily aim to explore practitioner perspectives and generate qualitative insights into the integration of process safety and security rather than achieving broad generalizability. Based on a diverse sample of 47 practitioners, the findings reveal significant barriers to integration, including knowledge gaps, resource constraints, and communication challenges. Addressing these barriers requires targeted interventions such as enhanced training programs, management support, and regulatory alignment. Critical enablers identified in this study, such as leadership commitment, cross-functional collaboration, and the adoption of advanced technologies, are pivotal for fostering organizational change and resilience.

To support integration, this study proposes actionable strategies such as establishing robust performance indicators to monitor and evaluate progress. Metrics like leadership engagement, incident response times, and system resilience provide measurable insights into integration effectiveness. Advanced technologies such as digital twins and machine learning offer further opportunities by enabling proactive risk management through scenario simulation and predictive analytics. These technologies can help organizations identify vulnerabilities, optimize mitigation strategies, and enhance overall resilience.

Though this study provides valuable insights, several limitations must be acknowledged. The sample size limits the generalizability of findings, and reliance on self-reported data introduces potential biases. Future research could address these limitations by expanding the scope to other high-risk sectors, such as healthcare, transportation, and energy and by employing longitudinal designs to assess the long-term effectiveness of integration efforts. Additionally, in-depth qualitative methods, such as interviews and case studies, could provide richer narratives and deeper insights into organizational dynamics and the practical applications of integration strategies.

The role of advanced technologies in supporting integration is another promising avenue for future research. Exploring the adoption and impact of real-time monitoring, data analytics, and AI-driven tools across industries could provide critical insights for developing more sophisticated integrated frameworks.

In conclusion, this study provides both theoretical and practical contributions to the integration of process safety and security risk management. It lays the groundwork for developing a unified, resilience-oriented framework to address integration challenges and enhance risk management practices. By tackling identified barriers, implementing proposed strategies, and exploring the outlined research directions, organizations can advance toward a cohesive and adaptive approach to risk management. These findings serve as a call to action for practitioners, policymakers, and researchers to collaboratively foster resilience and create safer, more secure industrial environments.