Abstract

The transport sector’s impact on climate change and energy-related greenhouse gas (GHG) emissions has raised significant concerns, prompting the automotive industry to transition towards greener solutions. This includes producing lighter vehicles with sustainable materials, like recycled plastics. Understanding the behavior of these new recycled compounds is crucial, especially regarding their response to ageing and stress conditions throughout a vehicle’s lifecycle. This study aims to investigate the mechanical property variations of virgin and recycled talc-filled polypropylene (PP) compounds used in the automotive industry, emphasizing the effects of thermal ageing after recycling. Polypropylene samples with different talc concentrations and post-industrial recycled content percentages are examined. Thermal (TGA and DSC) and spectral (FT-IR) analysis reveal structural changes due to recycling-induced thermo-mechanical degradation. A multi-axial impact test shows varied ductile and brittle behaviors between virgin and recycled PP, influenced by filler content. Impact strength, tensile, and flexural properties are assessed, highlighting differences between virgin and recycled PP, but maintaining properties over ageing time. Despite thermo-oxidative degradation from recycling and thermal ageing, the mechanical performance of recycled polypropylene materials remains unaffected, making them a viable sustainable alternative for the automotive industry.

1. Introduction

The concept of sustainability has become a crucial issue in the general business world and even more critical and urgent in the automotive sector. The automotive industry is one of the largest industries worldwide, which significantly impacts various business sectors, society, and nature, bringing from one side economic and social advantages but also giving negative outputs like pollution and contribution to global warming [1]. The impact of the transport sector on climate change and energy-related greenhouse gas (GHG) emissions has become a major aspect of political discussion in recent years [2,3,4]. In line with these topics, the European Commission is tightening the regulatory framework to achieve the EU’s intermediate target of reducing net greenhouse gas emissions, including the ambitious 55 per cent CO2 reduction target for cars by 2030 (based on 2021 levels), moving to zero-emission vehicles in 2035 (European Commission, 2021), and pledging to reach climate neutrality by 2050 [5]. To align with these targets, the transition towards using recycled plastic for automotive application has become increasingly urgent [6]. The use of plastics in car parts has surged due to the pursuit of lighter vehicles in order to achieve better fuel economy and consequently carbon dioxide emission reduction during usage [7,8]. Recently, companies have started applying recycled plastic materials in both interior and exterior components, but this revolution in the automotive industry presents a complex challenge, involving various risk factors ranging from questions related to the quality of recycled materials, the reproducibility of the recycled matrix, the price, and the performance of the recycled material [9]. An important distinction between recycled material types is linked to the waste origin. Post-industrial recycling (PIR) materials are made of post-industrial waste (PIW), sometimes referred to as pre-consumer waste. PIR materials are by-products of manufacturing processes coming directly from production lines [10]. Indeed, PIW is often not referred to as waste but rather as a by-product of joint production; as the PI waste is generated inside an industrial production site, the composition, possible contamination, and homogeneity of these materials are well controlled, resulting in a high-quality recycled matrix [11]. Our interest in this research is focused on polypropylene pre-consumer recycled compounds filled with talc and carbon black. PP was chosen as it is the most commonly used type of plastic both for interior and exterior application [12,13] because of its excellent chemical resistance, ductility, good stiffness, and low price. In the automotive industry, one class of blends named thermoplastic olefines (TPOs) is extensively used for several applications such as bumpers, dashboards, and fender extensions. These are blends of a PP major component with ethylene–butene (EBR) or ethylene–propylene rubber, both of which act as impact modifiers in the relatively brittle PP matrix [14,15]. Moreover, we focused our attention on pre-consumer mechanical recycled PP. Nowadays, the majority of recycled plastic in new vehicles comes from mechanical recycling, of which 80% derives from pre-consumer disposal [16,17] since it is more homogeneous and easier to recycle compared to post-consumer waste [18]. One notable concern with using recycled materials in vehicles is the well-documented fact that mechanical recycling processes can alter the properties of polypropylene. Previous studies, such as J. Aurrekoetxea et al. [19], have demonstrated that the recycling process can influence the structure and the mechanical properties of PP. They observed a reduction in molecular weight and an increase in crystallinity, leading to lower elongation at break and fracture toughness and higher elastic modulus and yield stress. In addition to that, if we consider a vehicle environment, there are several factors such as temperature, moisture, and light that can influence the performances of polymers [20,21] and even cause degradation reactions with principal chain scission and consequential modification of morphological properties; mechanical properties can also be affected by this process [22,23,24]. Meides et al. [25] demonstrated that the simulated solar radiation can exponentially decrease molecular weight and particle size, accompanied by an increase in crystallinity and the formation of oxygen-containing functional groups. Thermal ageing can also lead to degradation effects, as indicated by Hedir et al. [26], who observed chain scission and oxidation phenomena with consequential changes in structural surfaces (damage, craters, and surface roughness) after 90 °C thermal ageing for 30 days. If we consider a vehicle, the mentioned stress acts deeply on both interior and exterior components [27]. Considering the green transition in the automotive industry, it is crucial to understand the behavior of these new compounds containing various percentages of recycled plastic, particularly regarding their response to ageing and stress conditions they may encounter during their life cycle in a vehicle. The selected polypropylene samples were chosen according to the type of recycled waste (PI) and because are both used for interior application. Considering the differences in terms of compound composition between the two sets of samples, our main goal was to investigate if and how the post-industrial content can influence the thermal and mechanical response of the PP compounds after thermal ageing. A mechanical and thermal evaluation has been performed on both virgin and corresponding recycled polypropylene types before and after thermal ageing, to quantify the degradation induced by the stress to which they were subjected. Although the literature reports a multitude of studies on the behavior of recycled polypropylene, the novelty of this study lies in analyzing how the mechanical and thermal properties of compounds specifically designed for the automotive sector vary with the incorporation of post-industrial recycled content. Additionally, it examines how such content further affects the degradation of mechanical and thermal properties after ageing. This information is of fundamental importance to understanding the behavior of these new plastics in the automotive sector, aiming to increase the use of these materials to enhance sustainability while maintaining aesthetics and safety.

2. Materials and Methods

2.1. Materials

Four commercial grades of polypropylene compounds applied in the automotive sector are studied in this paper. Samples 1 and 2 (Table 1) are TPO supplied by LyondellBasell. They have a high melt flow rate with good impact/stiffness balance polypropylene mineral filler, suitable for injection molding of large interior components such as the dashboard and door panel. Both samples are impact-modified with a percentage of elastomeric content between 10 and 20 wt.%. V-PP12 is the virgin version used as the standard reference, and R-PP12 is the recycled version containing 25 wt.% of mechanically recycled PP derived from the post-industrial (PI) waste stream, diverted from the manufacturing process of goods such as flexible packaging. The type of recycling employed by the supplier upgrades plastic waste into usable materials through mechanical processes, including sorting, washing, grinding, melting, and forming new pellets. Both PP compounds contain 12% talc, used for reinforcement purposes and carbon black. Samples 3 and 4 (Table 1) are polypropylene–ethylene copolymer supplied by Omikron. They have a low melt flow rate and high-stiffness polypropylene mineral filler, suitable for injection molding of hidden structural automotive parts. V-PP30 is the virgin version used as the standard reference, and R-PP30 is the recycled version containing 100 wt.% of mechanically recycled PP deriving from the post-industrial (PI) waste stream, which originates from the manufacturing process of goods processed by the textile and automotive industries. For this sample, the waste is also subjected to a sequence of processes including sorting, washing, grinding, melting, and reformation into new pellets. Both PP compounds contain 30% talc, used for reinforcement purposes and carbon black. Percentage of talc, recycled fraction, and MFR (melt flow rate) data are extrapolated from the Technical Data Sheet (TDS).

Table 1.

Sample summary information.

2.2. Thermal Ageing Test

Thermal ageing was performed on the test specimens according to Stellantis internal standard specification using the Challenge 600 climatic cell brand Angelantoni (Massa Martana, Italy). The samples were exposed to the following thermal cycle: 90 °C for 8 h; 40 °C for 8 h with 95% of humidity; −30 °C for 8 h. The cycle was repeated continuously and monitored over 4 days (step 1), 8 days (step 2), and 12 days (step 3).

2.3. Thermal Analysis

Thermal stability and content of fillers were measured through TGA analysis, performed with a TGA Q500 brand TA Instrument (New Castle, DE, USA). First, 10 mg of the sample was placed in the alumina pan and heated at a rate of 10 °C/min with an air flow of 60 mL/min. The assessment was conducted in a nitrogen atmosphere from 50 to 700 °C and then switched to oxygen until 800 °C. Differential scanning calorimetry (DSC) was carried out on TA Instrument DSC Q200 equipment (New Castle, DE, USA) with the aim to investigate melting and crystallization temperature. Next, 5 mg of the sample was placed in a hermetic aluminum pan and heated in an inert nitrogen atmosphere with a flow of 50 mL/min from 50 to 200 °C at a heating and cooling rate of 10 °C/min.

2.4. Fourier Transform Infrared (FT-IR) Analysis

Fourier transform infrared spectroscopy (FTIR) was run on a Perkin Elmer Spectrum 100 FT-IR spectrophotometer (Perkin Elmer, Waltham, MA, USA) with the aim of examining the presence of chemical reactions within the structure of samples. The test was carried out in attenuated total reflection (ATR) mode equipped with an internal diamond reflection element. All the spectra were acquired in absorbance, using 16 scans with a wavenumber range between 4000 cm−1 and 650 cm−1 and a resolution of 4 cm−1.

2.5. Mechanical Characterization

Tensile properties were measured according to the ISO-527 standard [28] with an Alliance RF/100 dynamometer equipped with a load cell of 100 kN. The test was carried out applying a tensile force with a controlled speed of 1 mm/min during the first elastic section and 50 mm/min in the remaining plastic section. The test was performed in a controlled atmosphere at 23 °C and 55% humidity, recording the final value from an average of three ISO-527 (Type 1A) specimens. A flexural test was executed to recover the flexural elastic modulus, measured with an Instron 5554 dynamometer, equipped with a load cell of 2 kN. The test was performed according to the ISO 178 standard [29] using a strain rate of 1%/min, corresponding to a test speed of 2 mm/min, in a controlled atmosphere at 23 °C and 55% humidity. The final value was recorded from an average of five ISO 178 standard specimens obtained by injection molding.

2.6. Impact Behavior Test

The Izod impact test was achieved with an instrumented Ceast Resil Impact Junior pendulum brand Instron (Darmstadt, Germany) according to ISO 180/A [30]. The impact of the specimens occurred through a striker of 2 J energy, in a controlled atmosphere at 23 °C and 55% humidity. The final value was recorded from an average of five standard specimens obtained by injection molding. The ASTM D3763 standard [31], which regulates the investigation of high-speed puncture properties of plastic, was applied to evaluate the multi-axial impact properties of the PP specimens. The instrument setup is made by a clamp assembly constituted by two circular parallel plates with a 76 mm diameter hole in the center and a cylindrical 12.7 mm diameter steel striker with a hemispherical shape centered on the clamp hole. During impact, the striker moves down, and the polymer plaque, clamped by the circular plates, is totally penetrated. The objective is to evaluate the energy absorbed by the plate through a force transducer inside the dart and measuring its displacement over time. This energy is analogous to how the polymer deforms and fractures due to its strain-rate-dependent elastic and plastic behavior. The total energy absorbed is the sum of the spring-like elastic components and permanent plastic deformation [11]. The test was executed in a controlled atmosphere with 23 °C and 55% humidity using a Ceast 9350 drop tower brand Instron (Darmstadt, Germany) equipped with a TUP strain gauge of 22 kN. A speed of 6.6 m/s and a mass of 10 kg were used. The result was obtained from an average of 10 specimens with dimensions of 90 × 90 × 3.2 mm obtained by injection molding.

3. Results and Discussion

3.1. Thermal Analysis

A one-step decomposition process was observed in all samples. This can be attributed to the radical random scission mechanism of the PP after thermal degradation, which is typical for polyolefins [32]. Thermogravimetric data of the samples, including the extrapolated onset temperature, the percentage of polymer, carbon black, and talc, are reported in Table 2. A slight difference in degradation onset temperature has been registered between virgin and recycled samples, with a higher temperature for the recycled ones for both sets of samples.

Table 2.

TGA data of samples V-PP12, R-PP12, V-PP30, and R-PP30.

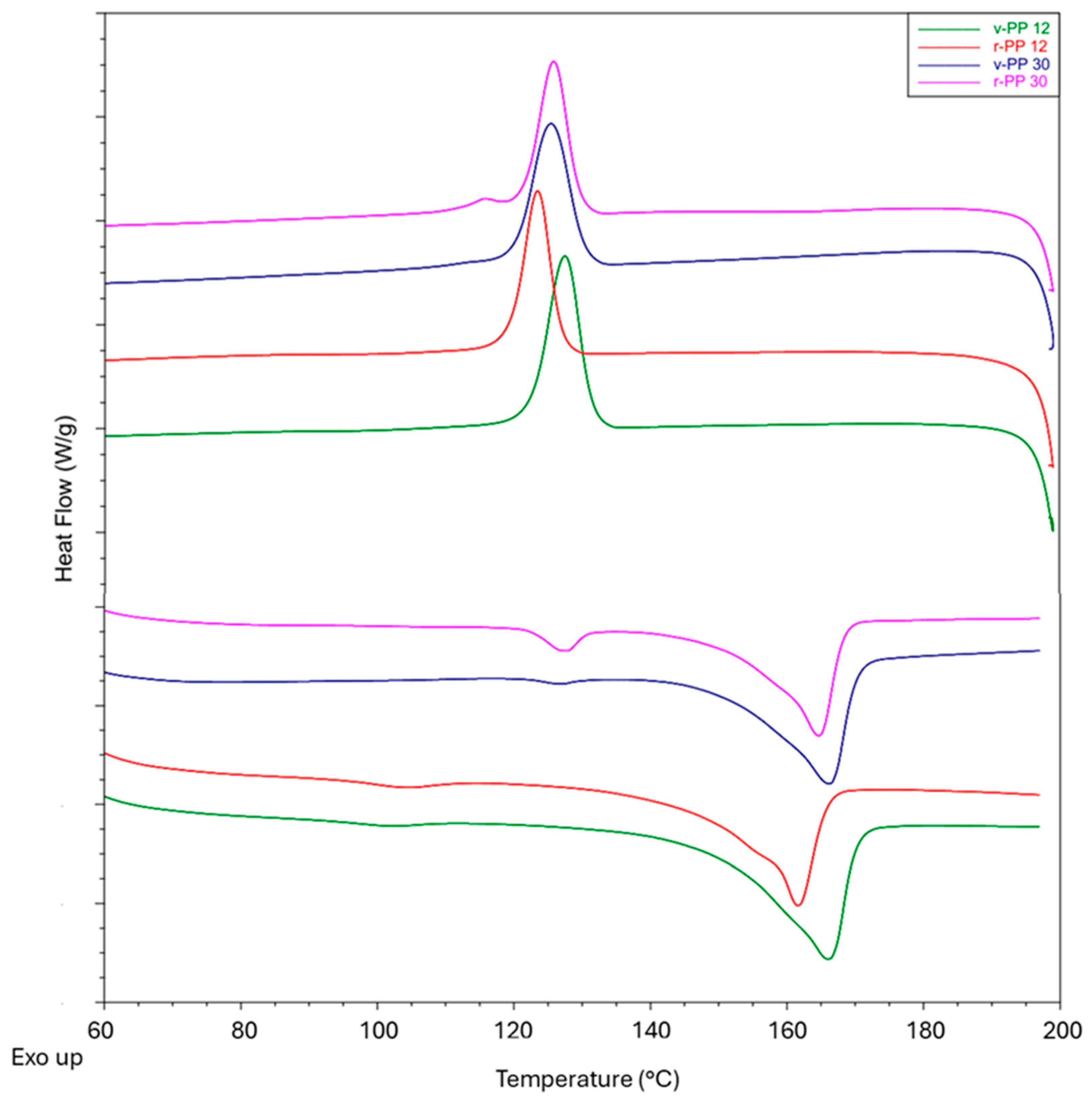

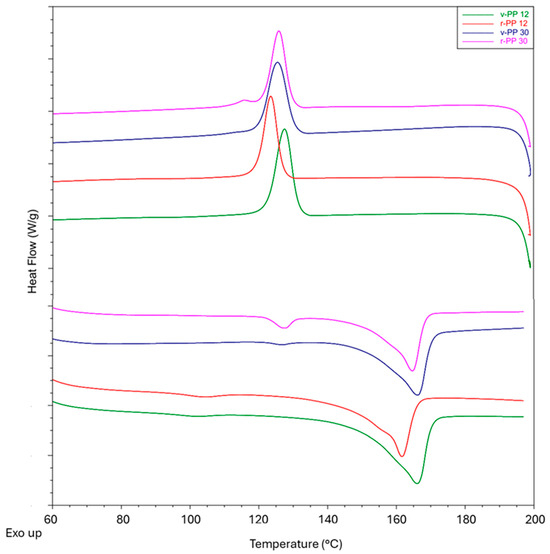

This result is the opposite of what is expected, since the recycled sample, having already undergone a mechanical process, would result in a higher degree of degradation than the virgin sample, which results in onset of degradation at lower temperatures [33]. However, this difference can be explained by the different stabilizing packs used for the formulation of the virgin and recycled PP compounds. The addition of various additives to recycled plastic helps to improve the properties of PP during recycling. It is well known that the addition of antioxidants protects polymers at their first processing cycle, especially polypropylene, which is more susceptible to attack by strong oxidizing agents [34]. Comparing V-PP12 and V-PP30, a higher degradation onset temperature in V-PP30 due to the high presence of talc has been recorded; indeed, the addition of talc filler is shown to increase the degradation temperature of PP/talc compound [35] because of the higher decomposition temperature of talc compared to PP [36]. In contrast, R-PP12 shows higher thermal stability than R-PP30; this phenomenon can be explained by both the presence of different stabilization packs and the source type of the PP recycled fraction. In general, these results demonstrate that the recycled PPs have an excellent thermal stability despite the re-extrusion-induced thermo-mechanical degradation by chain scission, which can occur during the recycling process [37,38]. The DSC thermograms are provided in Figure 1. In sample V-PP30, two noticeable melting peaks were observed: one within the range associated with polyethylene (125 °C) and another peak in the range normally associated with polypropylene (166 °C). Also, in sample R-PP30, the appearance of two distinguishable melting peaks is noticed: the first at 127 °C, related to PE, which is more pronounced compared to the V-PP30 one, and the second at 166 °C, attributable to PP. The presence of a higher amount of PE in the recycled sample could be explained by a contamination of PE in the recycled matrix used to formulate the compound [39]. Considering that R-PP30 is a 100% recycled compound, PE contamination could be blended mechanically during the recycling process and made immiscible with PP [40]. Polyethylene, indeed, often appears in PP waste because it is difficult to separate the two polyolefins during the recycling phase [41]. The V-PP12 and R-PP12 thermograms show only one melting peak, at 166 °C and 162 °C, respectively, related to PP. The reason why in V-PP30 we notice the appearance of the PE melting peak, unlike V-PP12, can be explained with a different polypropylene–ethylene copolymer structure of the two compounds. Feng et al. [42] demonstrated that block polypropylene–ethylene copolymer contains long ethylene sequences which are long enough to crystallize, while random copolymer has no long ethylene sequences. For this reason, in the DSC melting curve, the melting of polyethylene crystals can be observed for block copolymers, while no such melting peak is present for random copolymers. Comparing the differences between virgin and recycled, R-PP12 shows a lower melting (Tm) and crystallization (Tc) temperature compared to V-PP12. As is well known, the reprocessing can induce thermo-mechanical degradation of PP, resulting in molecular chain fragmentation with an average length lower than the initial one [43], explaining the reduction in melting temperature of the recycled PP. Looking at the differences between V-PP30 and R-PP30, both the Tm and the Tc do not change after the recycling process, these results, indeed, are well in agreement with Sarrionandia et al.’s study on the reprocessing effect on PP/EPDM/talc composites [44]. The higher content of talc can help to mitigate the effect of reprocessing, leading to the maintenance of the thermal properties. Observing the trend during the ageing steps (Table 3), the Tm values remain stable for all the samples, while the crystallization temperature remains constant for all PPs, except for R-PP12, in which it diminishes from step 0 to step 1 to the last ageing cycle. The thermograms of the samples after thermal cycles are not plotted here because of the similarity to those in Figure 1. However, they can be found in the Supplementary Materials.

Figure 1.

DSC heating and cooling curves of V-PP12, R-PP12, V-PP30, and R-PP30 before ageing.

Table 3.

DSC results of samples V-PP12, R-PP12, V-PP30, and R-PP30 before and after ageing.

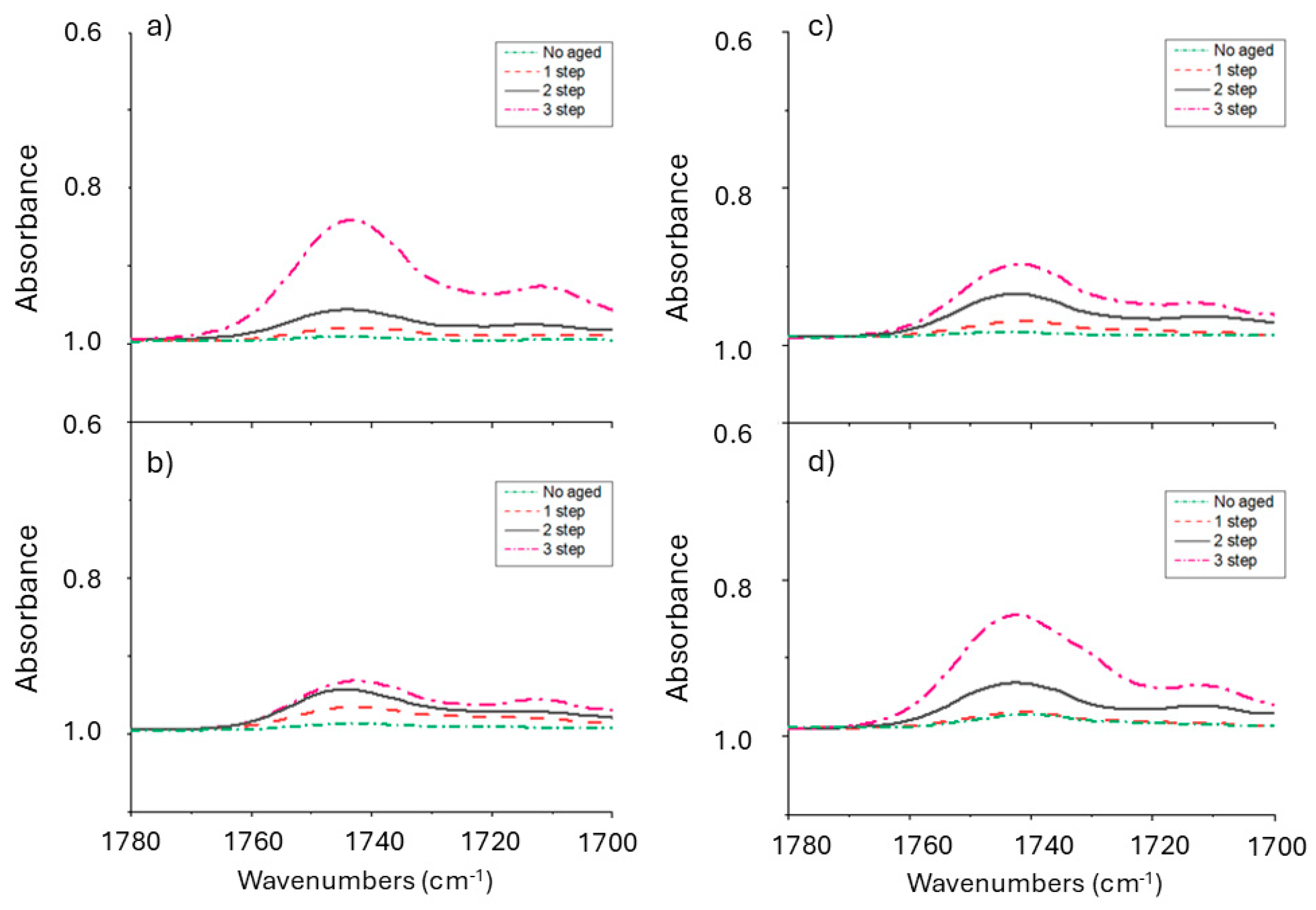

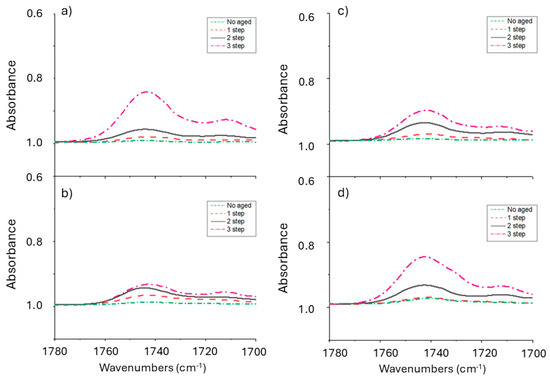

3.2. FT-IR

The FT-IR in ATR mode spectra of the samples are reported in Figure 2. Comparing the unaged and aged samples, no variations emerged regarding the typical vibrational bands of talc-filled polypropylene–ethylene copolymer; for this reason, only the area subject to variations is reported. Indeed, an increase in absorbance can be observed for the carbonyl bands in the region around 1780–1700 cm−1 in all samples. In samples after ageing, two vibrational bands are visible around 1740 cm−1 and 1710 cm−1, which indicate the presence of esters and carbonyl groups generated during the ageing [45]. Mylläri et al. [46] found the presence of the same functional groups during polypropylene photodegradation. They demonstrated that PP samples show a tendency for chain scission leading to a decrease in the molecular weight (MW) and to a degradation that grows exponentially with the ageing time. In all PP samples (Figure 2), the intensity of the bands increases gradually with ageing time, which indicates a growth in the degree of oxidative degradation due to the thermal stress action. A similar behavior was observed in Nasir et al.’s study [47], in which polypropylene copolymer samples were thermally aged at 130 °C and monitored over time. They investigated the carbonyl index (CI) to evaluate the degree of polypropylene degradation and demonstrated the oxidation of polypropylene copolymer over time by the increase in the peak at 1713 cm−1. Grigoriadi et al. [48] found the same trend for the carbonyl bands, and they also hypothesized that under thermal ageing conditions, the PE fraction degrades first and can act as a stabilizer for the PP fraction. There is a significant difference in absorbance between R-PP12 and V-PP12 regarding especially the third ageing step; V-PP12 shows a higher growth of the intensity of the band with respect to R-PP12, while the opposite trend is observed for PP30, in which the recycled sample shows a faster thermal oxidative degradation rate. This behavior of polypropylene 30% talc-filled is supported by Jubinville et al.’s study [49], where the concentration of carbonyl groups increases rapidly with the number of recycling processes. They showed that thermo-mechanical sequences already cause a decrease in the length of the polymer chains, decreasing the MW and consequently the viscosity of the samples. Instead, the mechanical properties do not undergo major changes, such as the results obtained from our research.

Figure 2.

FT-IR spectra of samples V-PP12 (a), R-PP12 (b), V-PP30 (c), and R-PP30 (d) before and after ageing.

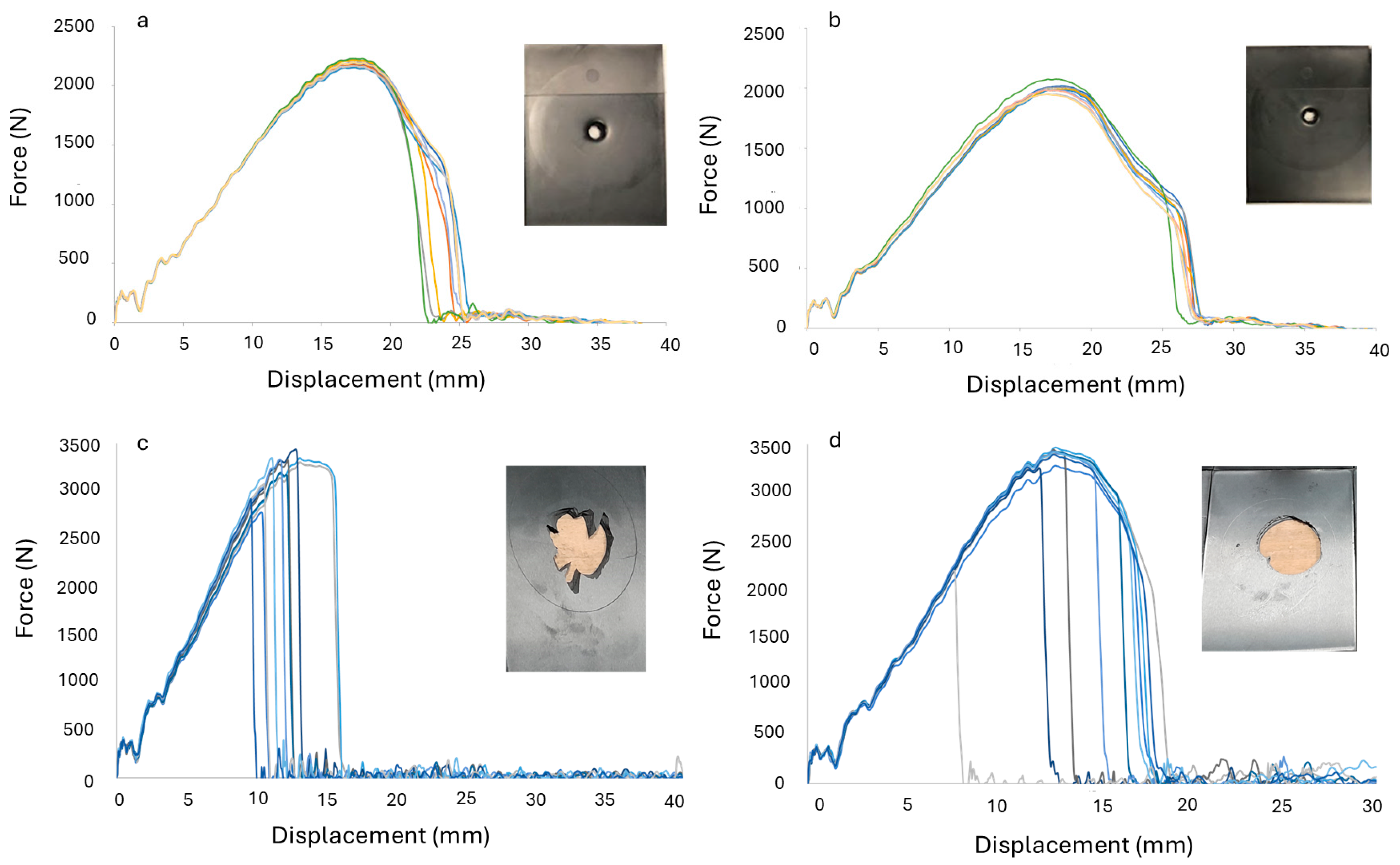

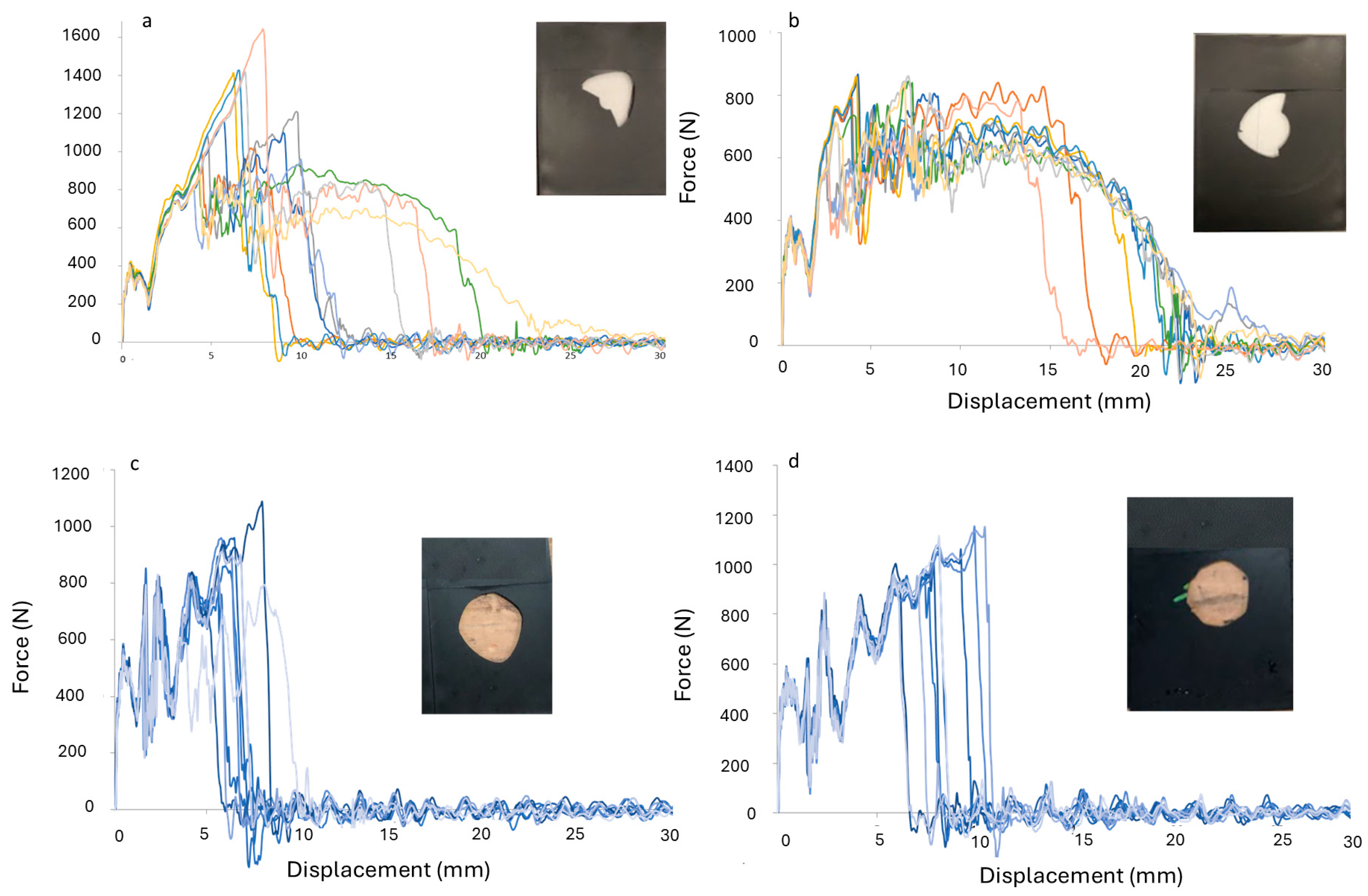

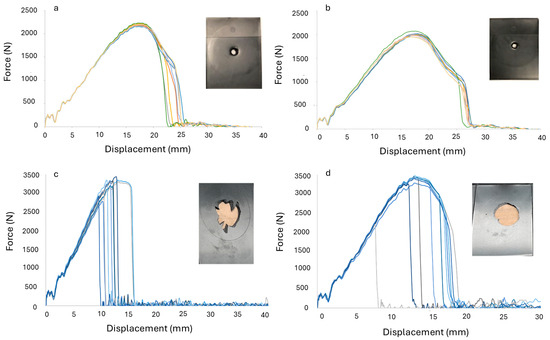

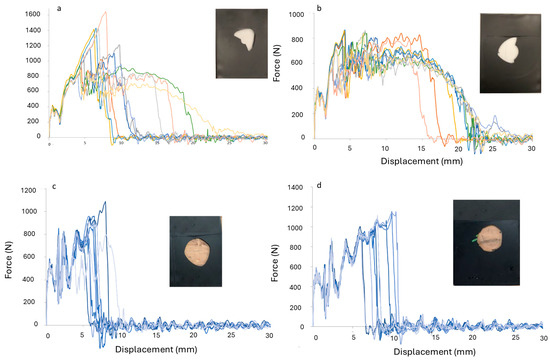

3.3. Impact Behavior

The multi-axial impact test in the automotive industry is crucial to determine the ductile and brittle behavior of the materials, especially for those that will be used for safety components both for interiors (dashboard and instrument panel) and exteriors (bumpers). The behavior of the sample is evaluated through the optical analysis of the material after breakage and the study of the curve force/deflection progression. In Figure 3, images of samples V-PP12 and R-PP12 tested at 23 °C and −30 °C are shown. At 23 °C, the materials show a ductile deformation characterized by a pronounced plastic deformation during crack propagation; also, the curve’s trend is characteristic of a ductile break as indicated by the ISO 6603-2 standard reference [50], and both samples correspond to case YD [51]. For the test conducted at −30 °C, the optical analysis suggests a brittle behavior for both V-PP12 and R-PP12 as the hole left by the striker is characterized by cracks and sharp edges [52]. According to the ISO 6603-2 standard [50], a difference can be noticed in the force–deflection diagram: V-PP12 falls within the NY case (Figure 3c), while R-PP12 can be associated with YU behavior (Figure 3d). Regardless, in both cases, the materials must be considered to be brittle. Considering samples V-PP30 and R-PP30 both at 23 °C and at −30 °C (Figure 4), they fall into the NY case exhibiting brittle behavior. From this preliminary test, PP30 can be considered a more brittle material compared to the PP12 samples. The differences can be attributed from one side to the different percentage of filler; a higher content of talc indeed helps to strengthen the composite but leads to a decrease in resilience and ductility. In addition, PP12 samples contain an elastomeric fraction that helps to enhance the impact resistance [53].

Figure 3.

PP12 multi-axial impact results. (a) V-PP12 at 23°C; (b) R-PP12 at 23°C; (c) V-PP12 at −30°C; (d) R-PP12 at −30°C.

Figure 4.

PP30 multi-axial impact results. (a) V-PP30 at 23°C; (b) R-PP30 at 23°C; (c) V-PP30 at −30°C; (d) R-PP30 at −30°C.

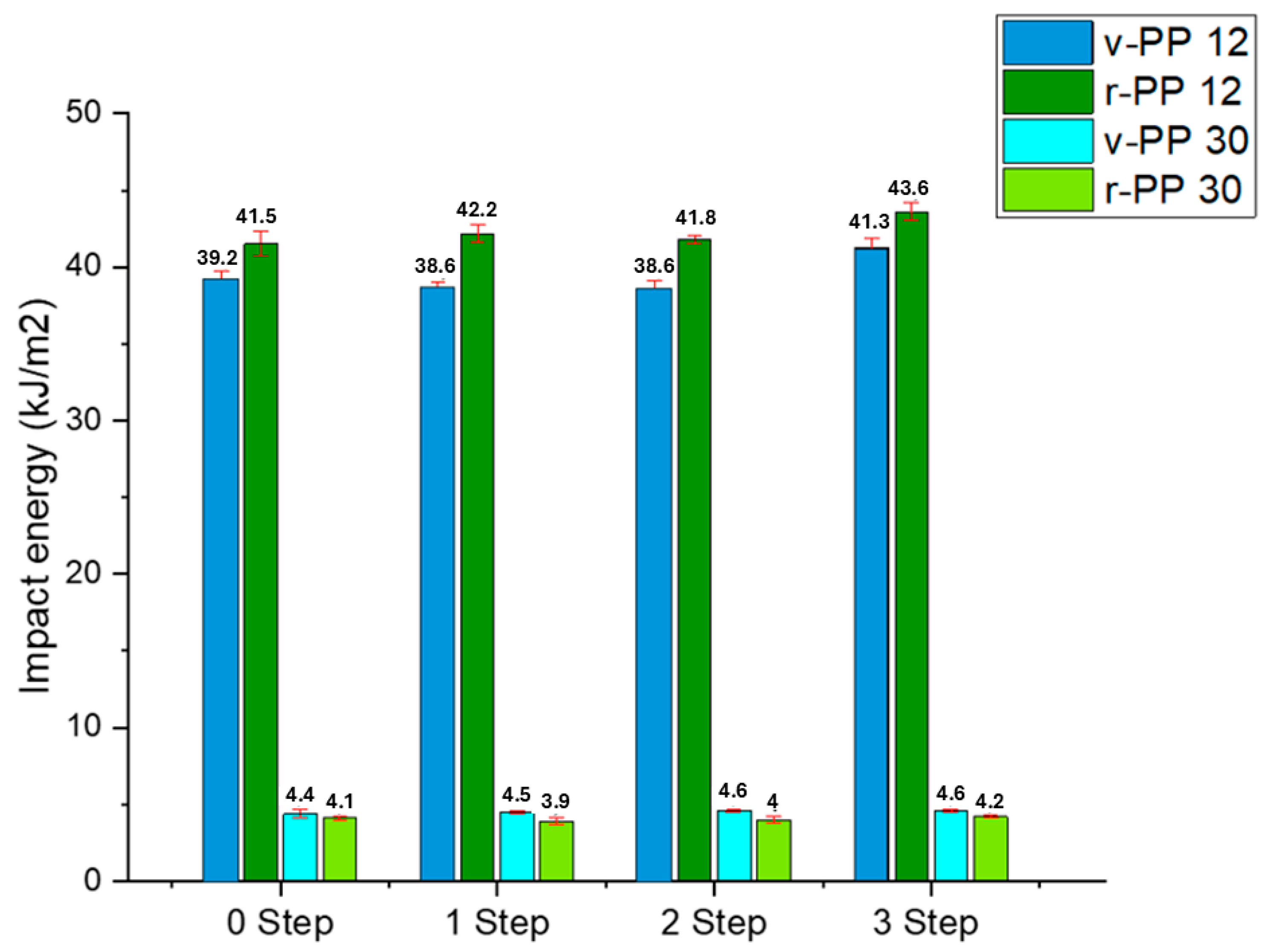

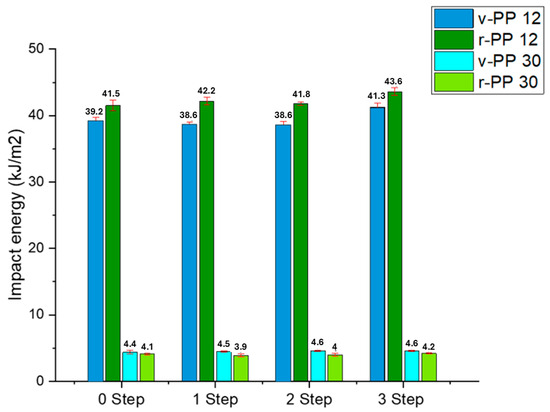

The values of the Izod impact strength are shown in Figure 5. Comparing PP12 and R-PP12, a major impact energy is recorded for the recycled PP, contrary to what we expected [54,55]. A slight increase in the value both for virgin and recycled PP during the ageing process has been noticed. This phenomenon has also been recorded by Morales and White’s study [56], in which it has been demonstrated that thermal treatment of talc-filled PP can lead to impact strength growth. Regarding the second set of samples, the same results are obtained for both V-PP30 and R-PP30 with a maintenance of the impact energy values during the three thermal cycle steps. The differences in terms of impact between PP12 and PP30 are coherent with the multi-axial impact test, for which we recorded ductile behavior for both V-PP12 and R-PP12 and brittle behavior for both V-PP30 and R-PP30. Likewise, the higher PP12 impact energy is due to the low amount of talc in the compound compared to PP30; indeed, a compound with a minor content of talc has lower tensile strength and Young’s modulus but a higher ductility and resistance to impact [57]. In addition, the presence of the elastomeric fraction in the compound plays a crucial role in increasing the impact toughness [58].

Figure 5.

Impact energy values before (0 step) and after ageing (1st step, 2nd step, and 3rd step) of V-PP12 (blue column), R-PP12 (green column), V-PP30 (light-blue column), and R-PP30 (light-green column).

3.4. Mechanical Characterization

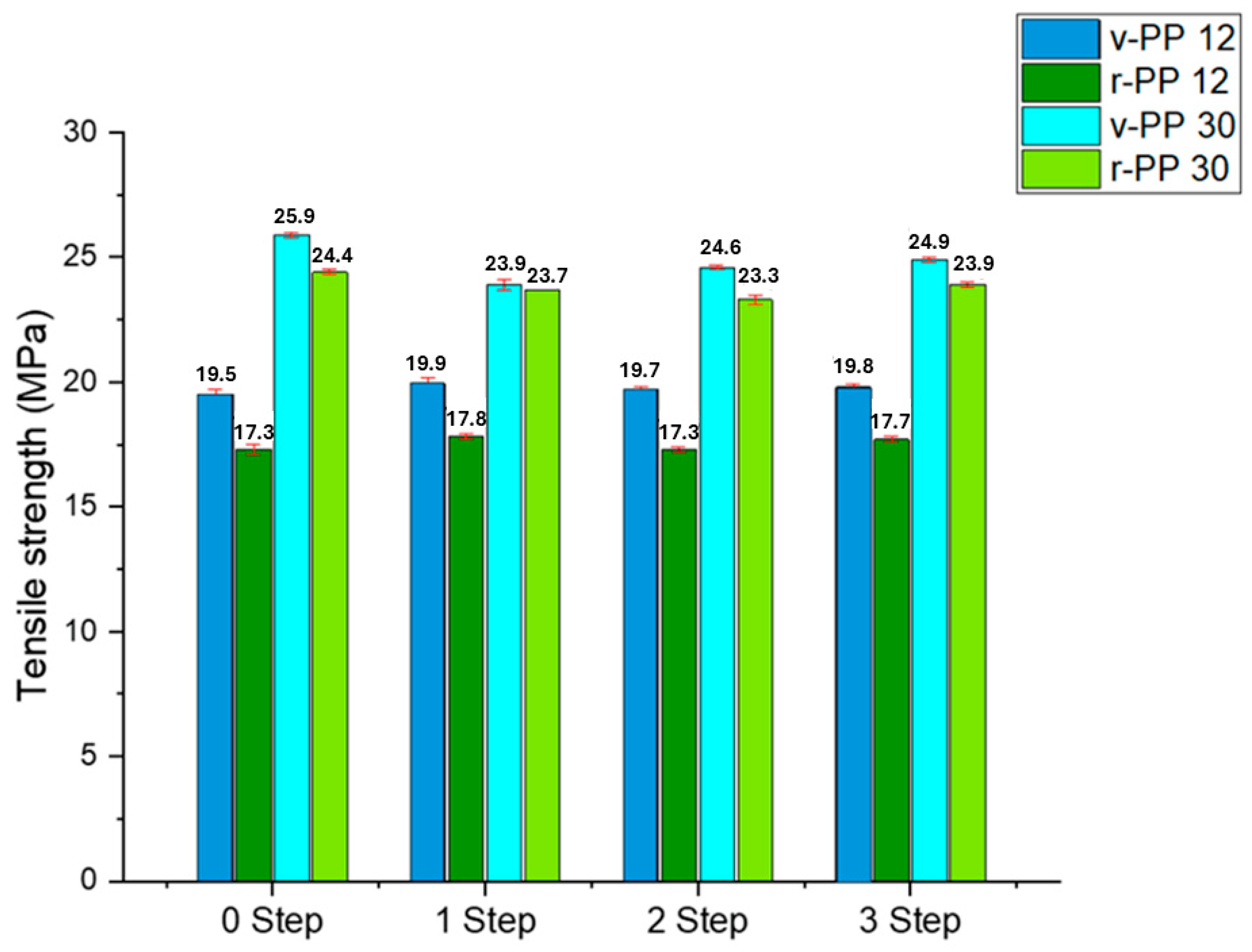

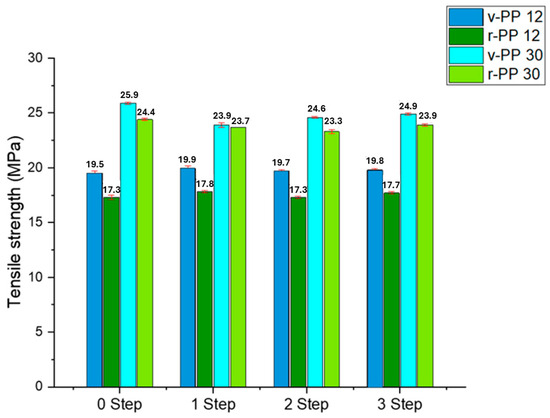

In Figure 6, the tensile strength values of all four PP samples, before and after thermal cycles, are presented. Analyzing the first set of samples, V-PP12 shows a higher tensile strength value compared to R-PP12. This difference may be addressed to the thermo-mechanical degradation of PP polymeric chains induced by the recycling process, resulting in a diminishing of toughness [41,59]. The graph further illustrates that the tensile strength of both samples remains stable during the ageing steps. For PP30 samples, the tensile strength is slightly higher for virgin PP. The lower differences between V-PP30 and R-PP30 are attributed to the higher content of talc compared to PP12, which helps to stabilize the mechanical performance during the reprocessing cycle [60]. For both virgin and recycled versions, the mechanical property remains stable during thermal cycles. These results find support in Deshmukh et al.’s study [61], where they demonstrated that the mechanical performances of PP talc-filled composites can be improved by cryo-ageing treatment followed by thermal annealing. This can further explain the stability of the tensile strength value for both virgin and recycled after thermal cycles.

Figure 6.

Tensile strength values before and after ageing of V-PP12 (blue column), R-PP12 (green column), V-PP30 (light-blue column), and R-PP30 (light-green column).

PP30 samples exhibit a higher tensile strength compared to PP12 due to the higher content of talc in the compound. The increased amount of talc leads to a stiffer and more robust compound, enhancing tensile strength and Young’s modulus.

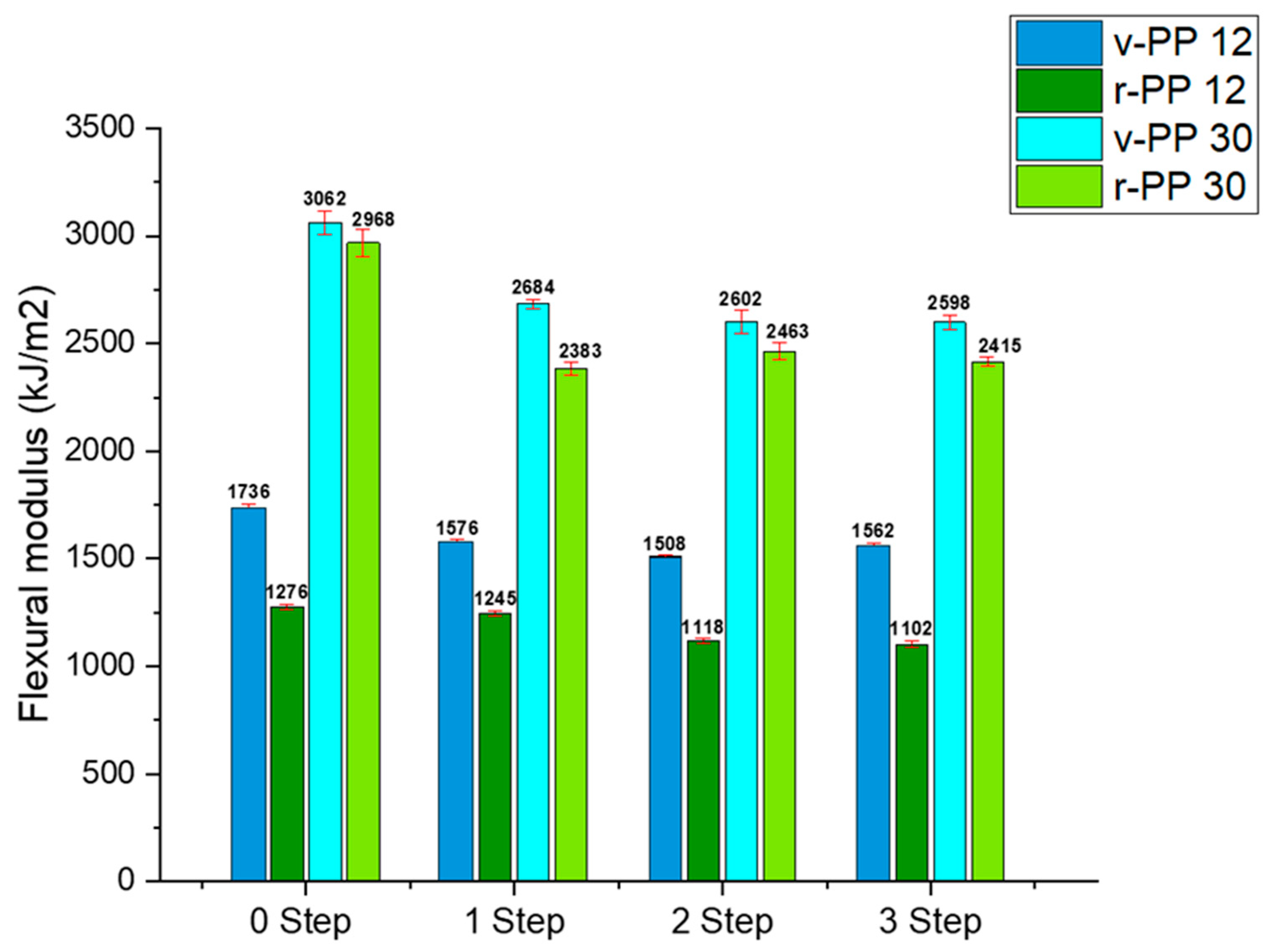

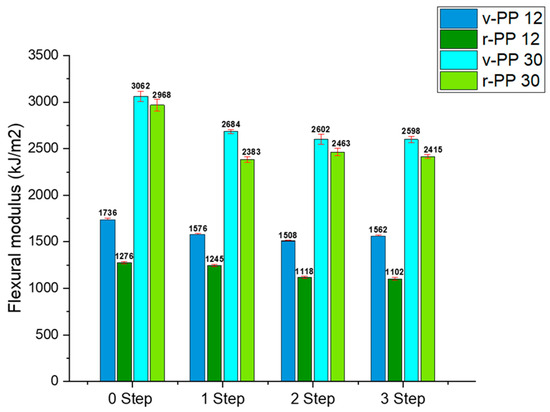

The results of the flexural test are reported in Figure 7 where it can be noticed that R-PP12 lost 460 MPa compared to V-PP12. These results confirm the thermo-mechanical degradation suffered by the recycled PP matrix. This effect seems to be more evident in flexural modulus than in tensile strength, in accordance with the work Hyie et al. [51] conducted on the tensile and flexural investigation of recycled polypropylene. It can also be noted that PP12 samples have lower flexural modulus values compared to PP30; this result can be attributed to the presence of elastomeric content in PP12 compounds. Teodorescu et al. found in their research that the introduction of elastomer leads to 25–39% higher impact strength; meanwhile, the values for stiffness are reduced by approximately 30% [62].

Figure 7.

Flexural modulus values before and after ageing of V-PP12 (blue column), R-PP12 (green column), V-PP30 (light-blue column), and R-PP30 (light-green column).

Analyzing the results trend over time, it can be noted that the V-PP12 flexural modulus diminishes by 200 MPa from step 0 to step 1, then the values tend to stabilize during the following ageing steps. R-PP12 shows, instead, a gradual decrease over time, probably due to the already degraded recycled PP matrix. The decrease in the R-PP30 flexural modulus with respect to V-PP30 before ageing is lower compared to PP12 thanks to the stabilizing effect of talc. The gap starts increasing after the first step of ageing. V-PP30 loses 378 MPa going from step 0 to step 1, maintaining a slight decrease until step 3. For R-PP30, an important decrease is recorded after the first four days of ageing, then the value increases in step 2 before decreasing again in step 3.

4. Conclusions

This study investigates the thermal and mechanical behavior of virgin and post-industrial recycled polypropylene samples, focusing on the effects of the recycled matrix combined with the ageing processes. Both recycled materials demonstrated thermal stability, comparable to that of their virgin PP counterparts. A superior performance was particularly observed for the R-PP30 sample, due to the stabilizing effect of talc (30 wt.%), present in a higher percentage compared to R-PP12 (12 wt.%). IR spectroscopy did not reveal significant differences between virgin and recycled samples, indicating chemical structure preservation despite the thermo-oxidative stress induced by the recycling process. This finding is further supported by mechanical tests, which show that the materials retained their properties under various mechanical stresses. Based on the results obtained, it can be concluded that for compounds with a low talc content, represented in our study by the R-PP12 sample, a 25% content of post-industrial recycled PP does not significantly affect the mechanical and thermal performance of the material, supporting the potential for an increased percentage of recycled material. Furthermore, by increasing the talc content, it is possible to produce a compound entirely composed of recycled material with properties comparable to its virgin counterpart, as demonstrated by the results collected for the R-PP30 sample. Considering the results obtained after the thermal ageing process, the thermal properties were excellently preserved. However, an increase in the absorbance of the carbonyl band was observed, suggesting partial thermo-oxidative degradation. Despite this, no significant reduction in mechanical properties was detected. Consequently, it can be concluded that the ageing process did not lead to substantial structural changes within the material. Overall, the findings suggest that post-industrial recycled PP, especially when supplemented with appropriate stabilizers and fillers like talc, can maintain excellent thermal and mechanical properties even after ageing. This supports the potential for using post-industrial recycled PP in applications requiring high performance, such as automotive components. Future research should continue to explore the optimization of additive combinations to further increase the percentage of recycled material, leading to more and more sustainable vehicles.

Supplementary Materials

The following supporting information can be downloaded at: www.mdpi.com/article/10.3390/pr13020315/s1. Figure S1. DSC thermograms before and after ageing. (a) Melting peaks V-PP12; (b) melting peaks R-PP12; (c) crystallization peaks V-PP12; (d) crystallization peaks R-PP12. Figure S2. DSC thermograms before and after ageing. (a) Melting peaks V-PP12; (b) melting peaks R-PP12; (c) crystallization peaks V-PP12; (d) crystallization peaks R-PP12.

Author Contributions

Methodology, validation, resources, investigation, project administration, writing—original draft preparation, and writing—review and editing, M.A.; writing—original draft preparation, formal analysis, and data curation, I.B.; supervision, project administration, and funding acquisition, G.C.; validation, writing—review and editing, visualization, supervision, project administration, and funding acquisition, V.B. All authors have read and agreed to the published version of the manuscript.

Funding

This work is part of the project NODES, which has received funding from the MUR-M4C2 1.5 of PNRR with grant agreement no. ECS00000036.

Data Availability Statement

The original contributions presented in the study are included in the article and Supplementary Materials; further inquiries can be directed to the corresponding authors.

Acknowledgments

The authors thank LyondellBasell and Omikron for providing the polypropylene samples characterized in the study. The authors acknowledge support from the Project CH4.0 under the MUR program “Dipartimenti di Eccellenza 2023–2027” (CUP: D13C22003520001).

Conflicts of Interest

Authors Matilde Arese, Ilaria Bolliri and Gabriele Ciaccio was employed by the Fiat Research center SCPA (CRF), Stellantis. The remaining author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. The company had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Lenort, R.; Wicher, P.; Zapletal, F. On Influencing Factors for Sustainable Development Goal Prioritisation in the Automotive Industry. J. Clean. Prod. 2023, 387, 135718. [Google Scholar] [CrossRef]

- Reimers, P. The Subsidized Green Revolution: The Impact of Public Incentives on the Automotive Industry to Promote Alternative Fuel Vehicles (AFVs) in the Period from 2010 to 2018. Energies 2021, 14, 5765. [Google Scholar] [CrossRef]

- Poschmann, J.; Bach, V.; Finkbeiner, M. Deriving Decarbonization Targets and Pathways—A Case Study for the Automotive Industry. J. Clean. Prod. 2023, 409, 137256. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Bach, V. Life Cycle Assessment of Decarbonization Options—Towards Scientifically Robust Carbon Neutrality. Int. J. Life Cycle Assess. 2021, 26, 635–639. [Google Scholar] [CrossRef]

- Pulignano, V.; Hauptmeier, M.; Frans, D. Determinants of Union Strategies towards the Twin Digital and Green Transitions in the German and Belgian Automotive Industry. Transf. Eur. Rev. Labour Res. 2023, 29, 121–138. [Google Scholar] [CrossRef]

- Hallack, E.; Peris, N.M.; Lindahl, M.; Sundin, E. Systematic Design for Recycling Approach—Automotive Exterior Plastics. Procedia CIRP 2022, 105, 204–209. [Google Scholar] [CrossRef]

- Stoycheva, S.; Marchese, D.; Paul, C.; Padoan, S.; Juhmani, A.; Linkov, I. Multi-Criteria Decision Analysis Framework for Sustainable Manufacturing in Automotive Industry. J. Clean. Prod. 2018, 187, 257–272. [Google Scholar] [CrossRef]

- Ruffino, B.; Panepinto, D.; Zanetti, M. A Circular Approach for Recovery and Recycling of Automobile Shredder Residues (ASRs): Material and Thermal Valorization. Waste Biomass Valorization 2021, 12, 3109–3123. [Google Scholar] [CrossRef]

- Albini, G.; Brunella, V.; Placenza, B.; Martorana, B.; Guido Lambertini, V. Comparative Study of Mechanical Characteristics of Recycled PET Fibres for Automobile Seat Cover Application. J. Ind. Text. 2019, 48, 992–1008. [Google Scholar] [CrossRef]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics Recycling: Challenges and Opportunities. Phil. Trans. R. Soc. B 2009, 364, 2115–2126. [Google Scholar] [CrossRef]

- Hubo, S.; Ragaert, K.; Leite, L.; Martins, C. Evaluation of Post-Industrial and Post-Consumer Polyolefin-Based Polymer Waste Streams for Injection Moulding. In Proceedings of the 6th Polymers & Mould Innovations International Conference, Guimaraes, Portugal, 10–12 September 2014. [Google Scholar]

- Emilsson, E.; Dahllöf, L.; Söderman, M.L. Plastics in Passenger Cars A Comparison over Types and Time; IVL Swedish Environmental Research Institute: Stockholm, Sweden, 2019. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, M. Current Recycling Regulations and Technologies for the Typical Plastic Components of End-of-Life Passenger Vehicles: A Meaningful Lesson for China. J. Mater. Cycles Waste Manag. 2014, 16, 187–200. [Google Scholar] [CrossRef]

- Moffitt, M.; Rharbi, Y.; Chen, W.; Tong, J.; Winnik, M.A.; Thurman, D.W.; Oberhauser, J.P.; Kornfield, J.A.; Ryntz, R.A. Stratified Morphology of a Polypropylene/Elastomer Blend Following Channel Flow. J. Polym. Sci. B Polym. Phys. 2002, 40, 2842–2859. [Google Scholar] [CrossRef]

- Brunella, V.; Aresti, V.; Romagnolli, U.; Muscato, B.; Girotto, M.; Rizzi, P.; Luda, M.P. Recycling of EPDM via Continuous Thermo-Mechanical Devulcanization with Co-Rotating Twin-Screw Extruder. Polymers 2022, 14, 4853. [Google Scholar] [CrossRef]

- Matos, J.; Santos, S.; Simões, C.L.; Martins, C.I.; Simoes, R. Practical Application of Circularity Micro-Indicators to Automotive Plastic Parts in an Industrial Context. Sustain. Prod. Consum. 2023, 43, 155–167. [Google Scholar] [CrossRef]

- Baldassarre, B.; Maury, T.; Mathieux, F.; Garbarino, E.; Antonopoulos, I.; Sala, S. Drivers and Barriers to the Circular Economy Transition: The Case of Recycled Plastics in the Automotive Sector in the European Union. Procedia CIRP 2022, 105, 37–42. [Google Scholar] [CrossRef]

- Schulte, A.; Kampmann, B.; Galafton, C. Measuring the Circularity and Impact Reduction Potential of Post-Industrial and Post-Consumer Recycled Plastics. Sustainability 2023, 15, 12242. [Google Scholar] [CrossRef]

- Aurrekoetxea, J.; Sarrionandia, M.A.; Urrutibeascoa, I.; Maspoch, M.L. Effects of Recycling on the Microstructure and the Mechanical Properties of Isotactic Polypropylene. J. Mater. Sci. 2001, 36, 2607–2613. [Google Scholar] [CrossRef]

- Tokiwa, Y.; Calabia, B.; Ugwu, C.; Aiba, S. Biodegradability of Plastics. Int. J. Mol. Sci. 2009, 10, 3722–3742. [Google Scholar] [CrossRef]

- Ito, M.; Nagai, K. Degradation Issues of Polymer Materials Used in Railway Field. Polym. Degrad. Stab. 2008, 93, 1723–1735. [Google Scholar] [CrossRef]

- Brebu, M. Environmental Degradation of Plastic Composites with Natural Fillers—A Review. Polymers 2020, 12, 166. [Google Scholar] [CrossRef]

- Kiersnowska, A.; Fabianowski, W.; Koda, E. The Influence of the Accelerated Aging Conditions on the Properties of Polyolefin Geogrids Used for Landfill Slope Reinforcement. Polymers 2020, 12, 1874. [Google Scholar] [CrossRef]

- Grigoriadou, I.; Pavlidou, E.; Paraskevopoulos, K.M.; Terzopoulou, Z.; Bikiaris, D.N. Comparative Study of the Photochemical Stability of HDPE/Ag Composites. Polym. Degrad. Stab. 2018, 153, 23–36. [Google Scholar] [CrossRef]

- Meides, N.; Mauel, A.; Menzel, T.; Altstädt, V.; Ruckdäschel, H.; Senker, J.; Strohriegl, P. Quantifying the Fragmentation of Polypropylene upon Exposure to Accelerated Weathering. Micropl. Nanopl. 2022, 2, 23. [Google Scholar] [CrossRef]

- Hedir, A.; Slimani, F.; Moudoud, M.; Lamrous, O.; Diaham, S. Thermal Ageing Effects on Polypropylene Properties. In Proceedings of the 2019 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Richland, WA, USA, 20–23 October 2019; pp. 130–133. [Google Scholar]

- Lajunen, A.; Yang, Y.; Emadi, A. Review of Cabin Thermal Management for Electrified Passenger Vehicles. IEEE Trans. Veh. Technol. 2020, 69, 6025–6040. [Google Scholar] [CrossRef]

- ISO 527:2019; Plastics—Determination of tensile properties. ISO: Geneva, Switzerland, 2019.

- ISO 178:2019; Plastics—Determination of flexural properties. ISO: Geneva, Switzerland, 2019.

- ISO 180:2023; Plastics—Determination of Izod impact strength. ISO: Geneva, Switzerland, 2023.

- ASTM D3763-18; Standard Test Method for High Speed Puncture Properties of Plastics Using Load and Displacement Sensors. ASTM: West Conshohocken, PA, USA, 2018.

- Navarro, R.; Torre, L.; Kenny, J.M.; Jiménez, A. Thermal Degradation of Recycled Polypropylene Toughened with Elastomers. Polym. Degrad. Stab. 2003, 82, 279–290. [Google Scholar] [CrossRef]

- Gaxiola-Cockburn, R.; Martínez-Romero, O.; Elías-Zúñiga, A.; Olvera-Trejo, D.; Reséndiz-Hernández, J.; Soria-Hernández, C. Investigation of the Mechanical Properties of Parts Fabricated with Ultrasonic Micro Injection Molding Process Using Polypropylene Recycled Material. Polymers 2020, 12, 2033. [Google Scholar] [CrossRef]

- Mihelčič, M.; Oseli, A.; Huskić, M.; Slemenik Perše, L. Influence of Stabilization Additive on Rheological, Thermal and Mechanical Properties of Recycled Polypropylene. Polymers 2022, 14, 5438. [Google Scholar] [CrossRef]

- Zhou, Y.; Rangari, V.; Mahfuz, H.; Jeelani, S.; Mallick, P.K. Experimental Study on Thermal and Mechanical Behavior of Polypropylene, Talc/Polypropylene and Polypropylene/Clay Nanocomposites. Mater. Sci. Eng. A 2005, 402, 109–117. [Google Scholar] [CrossRef]

- Wang, K.; Bahlouli, N.; Addiego, F.; Ahzi, S.; Rémond, Y.; Ruch, D.; Muller, R. Effect of Talc Content on the Degradation of Re-Extruded Polypropylene/Talc Composites. Polym. Degrad. Stab. 2013, 98, 1275–1286. [Google Scholar] [CrossRef]

- Wang, K.; Addiego, F.; Bahlouli, N.; Ahzi, S.; Rémond, Y.; Toniazzo, V.; Muller, R. Analysis of Thermomechanical Reprocessing Effects on Polypropylene/Ethylene Octene Copolymer Blends. Polym. Degrad. Stab. 2012, 97, 1475–1484. [Google Scholar] [CrossRef]

- Camacho, W.; Karlsson, S. Assessment of Thermal and Thermo-Oxidative Stability of Multi-Extruded Recycled PP, HDPE and a Blend Thereof. Polym. Degrad. Stab. 2002, 78, 385–391. [Google Scholar] [CrossRef]

- Baltes, L.; Costiuc, L.; Patachia, S.; Tierean, M. Differential Scanning Calorimetry—A Powerful Tool for the Determination of Morphological Features of the Recycled Polypropylene. J. Therm. Anal. Calorim. 2019, 138, 2399–2408. [Google Scholar] [CrossRef]

- Ajorloo, M.; Ghodrat, M.; Kang, W.-H. Incorporation of Recycled Polypropylene and Fly Ash in Polypropylene-Based Composites for Automotive Applications. J. Polym. Environ. 2021, 29, 1298–1309. [Google Scholar] [CrossRef]

- Stoian, S.A.; Gabor, A.R.; Albu, A.-M.; Nicolae, C.A.; Raditoiu, V.; Panaitescu, D.M. Recycled Polypropylene with Improved Thermal Stability and Melt Processability. J. Therm. Anal. Calorim. 2019, 138, 2469–2480. [Google Scholar] [CrossRef]

- Feng, Y.; Jin, X.; Hay, J.N. Evaluation of Multiple Melting Peaks of Propylene-Ethylene Copolymers. Polym. J. 1998, 30, 215–221. [Google Scholar] [CrossRef]

- Da Costa, H.M.; Ramos, V.D.; De Oliveira, M.G. Degradation of Polypropylene (PP) during Multiple Extrusions: Thermal Analysis, Mechanical Properties and Analysis of Variance. Polym. Test. 2007, 26, 676–684. [Google Scholar] [CrossRef]

- Sarrionandia, M.; Lopez-Arraiza, A.; Aurrekoetxea, J.; Arostegui, A. Structure and mechanical properties of a talc-filled polypropylene/ethylene-propylene-diene composite after reprocessing in the melt state. J. Appl. Polym. Sci. 2009, 114, 1195–1201. [Google Scholar] [CrossRef]

- Wu, X.; Liu, P.; Wang, H.; Huang, H.; Shi, Y.; Yang, C.; Gao, S. Photo Aging of Polypropylene Microplastics in Estuary Water and Coastal Seawater: Important Role of Chlorine Ion. Water Res. 2021, 202, 117396. [Google Scholar] [CrossRef]

- Mylläri, V.; Ruoko, T.; Syrjälä, S. A Comparison of Rheology and FTIR in the Study of Polypropylene and Polystyrene Photodegradation. J. Appl. Polym. Sci. 2015, 132, 42246. [Google Scholar] [CrossRef]

- Nasir, A.; Yasin, T.; Islam, A. Thermo-oxidative Degradation Behavior of Recycled Polypropylene. J. Appl. Polym. Sci. 2011, 119, 3315–3320. [Google Scholar] [CrossRef]

- Grigoriadi, K.; Nooijens, M.; Vanhouttem, M.M.C.; Barthelemy, V.; Klemm, B.; Boersma, A. The Role of Recycling in UV and Thermal Ageing of Polypropylene Block Copolymer. Polym. Degrad. Stab. 2024, 222, 110693. [Google Scholar] [CrossRef]

- Jubinville, D.; Esmizadeh, E.; Tzoganakis, C.; Mekonnen, T. Thermo-Mechanical Recycling of Polypropylene for the Facile and Scalable Fabrication of Highly Loaded Wood Plastic Composites. Compos. Part B Eng. 2021, 219, 108873. [Google Scholar] [CrossRef]

- ISO 6603-2:2003; Plastics—Determination of Puncture Impact Behaviour of Rigid Plastics. Part 2: Instrumented Impact Testing. ISO: Geneva, Switzerland, 2003.

- Hyie, K.M.; Budin, S.; Martinus, N.; Salleh, Z.; Mohd Masdek, N.R.N. Tensile and Flexural Investigation on Polypropylene Recycling. J. Phys. Conf. Ser. 2019, 1174, 012005. [Google Scholar] [CrossRef]

- Mizera, A.; Mizera, M.; Navratil, M.; Sanda, S.; Opocensky, M. The Multiaxial Behavior of Filled Polypropylene Parts by Drop-Weight Impact Test. MATEC Web Conf. 2018, 210, 05013. [Google Scholar] [CrossRef]

- Ma, L.-F.; Wang, W.-K.; Bao, R.-Y.; Yang, W.; Xie, B.-H.; Yang, M.-B. Toughening of Polypropylene with β-Nucleated Thermoplastic Vulcanizates Based on Polypropylene/Ethylene–Propylene–Diene Rubber Blends. Mater. Des. 2013, 51, 536–543. [Google Scholar] [CrossRef]

- Aurrekoetxea, J.; Sarrionandia, M.A.; Urrutibeascoa, I.; Maspoch, M.L. Fracture Behaviour of Virgin and Recycled Isotactic Polypropylene. J. Mater. Sci. 2001, 36, 5073–5078. [Google Scholar] [CrossRef]

- Gustavo Barbosa, L.; Piaia, M.; Henrique Ceni, G. Analysis of Impact and Tensile Properties of Recycled Polypropylene. Int. J. Mater. Eng. 2017, 7, 117–120. [Google Scholar] [CrossRef]

- Morales, E.; White, J.R. Effect of Ageing on the Mechanical Properties and the Residual Stress Distribution of Hybrid Clay–Glass Fibre–Polypropylene Injection Mouldings. J. Mater. Sci. 2009, 44, 4734–4742. [Google Scholar] [CrossRef]

- Bouakkaz, A.; Albedah, A.; Bouiadjra, B.B.; Khan, S.M.; Benyahia, F.; Elmeguenni, M. Effect of Temperature on the Mechanical Properties of Polypropylene–Talc Composites. J. Thermoplast. Compos. Mater. 2018, 31, 896–912. [Google Scholar] [CrossRef]

- Jose, J.; Nag, A.; Nando, G.B. Environmental Ageing Studies of Impact Modified Waste Polypropylene. Iran. Polym. J. 2014, 23, 619–636. [Google Scholar] [CrossRef]

- Satya, S.K.; Sreekanth, P.S.R. An Experimental Study on Recycled Polypropylene and High-Density Polyethylene and Evaluation of Their Mechanical Properties. Mater. Today Proc. 2020, 27, 920–924. [Google Scholar] [CrossRef]

- Gu, F.; Hall, P.; Miles, N.J. Experimental Investigating Effect of Reprocessing on Properties of Composites Based on Recycled Polypropylene. In Proceedings of the 2015 International Conference on Power Electronics and Energy Engineering, Hong Kong, China, 19–20 April 2015. [Google Scholar]

- Deshmukh, K.A.; Pode, G.R.; Roy, S.R.; Gupte, B.K.; Deshmukh, A.D.; Chopra, S.; Peshwe, D.R. Effect of Cryo-Ageing at Liquid Nitrogen Temperature and Subsequent Thermal-Annealing on the Interface of Talc Filled Polypropylene with Different Particle Size. Trans. Indian Inst. Met. 2018, 71, 403–409. [Google Scholar] [CrossRef]

- Teodorescu, G.M.; Vuluga, Z.; Ion, R.M.; Fistoș, T.; Ioniță, A.; Slămnoiu-Teodorescu, S.; Paceagiu, J.; Nicolae, C.A.; Gabor, A.R.; Ghiurea, M. The Effect of Thermoplastic Elastomer and Fly Ash on the Properties of Polypropylene Composites with Long Glass Fibers. Polymers 2024, 16, 1238. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).