Innovative Applications of Sugarcane Bagasse in the Global Sugarcane Industry

Abstract

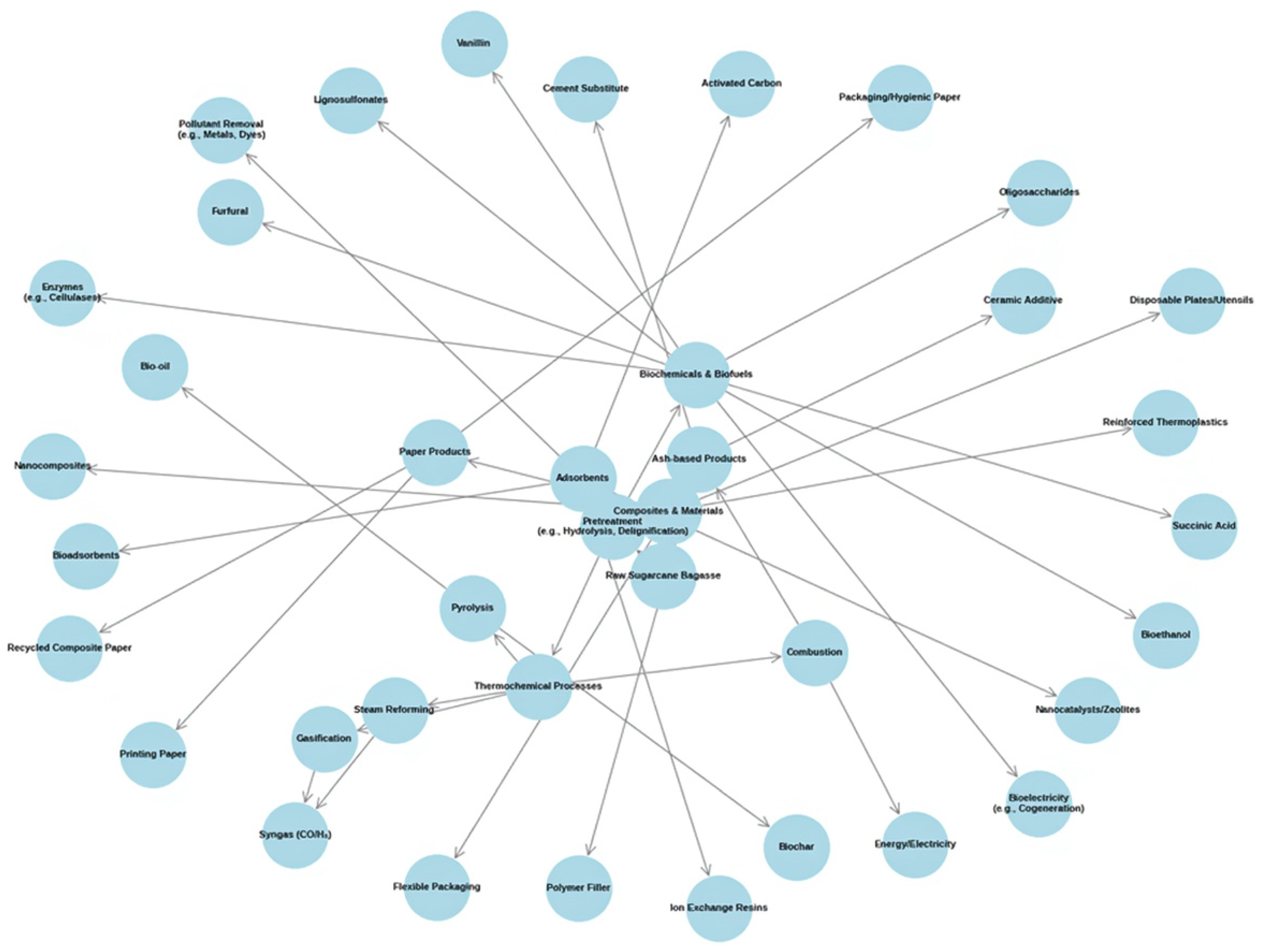

1. Introduction

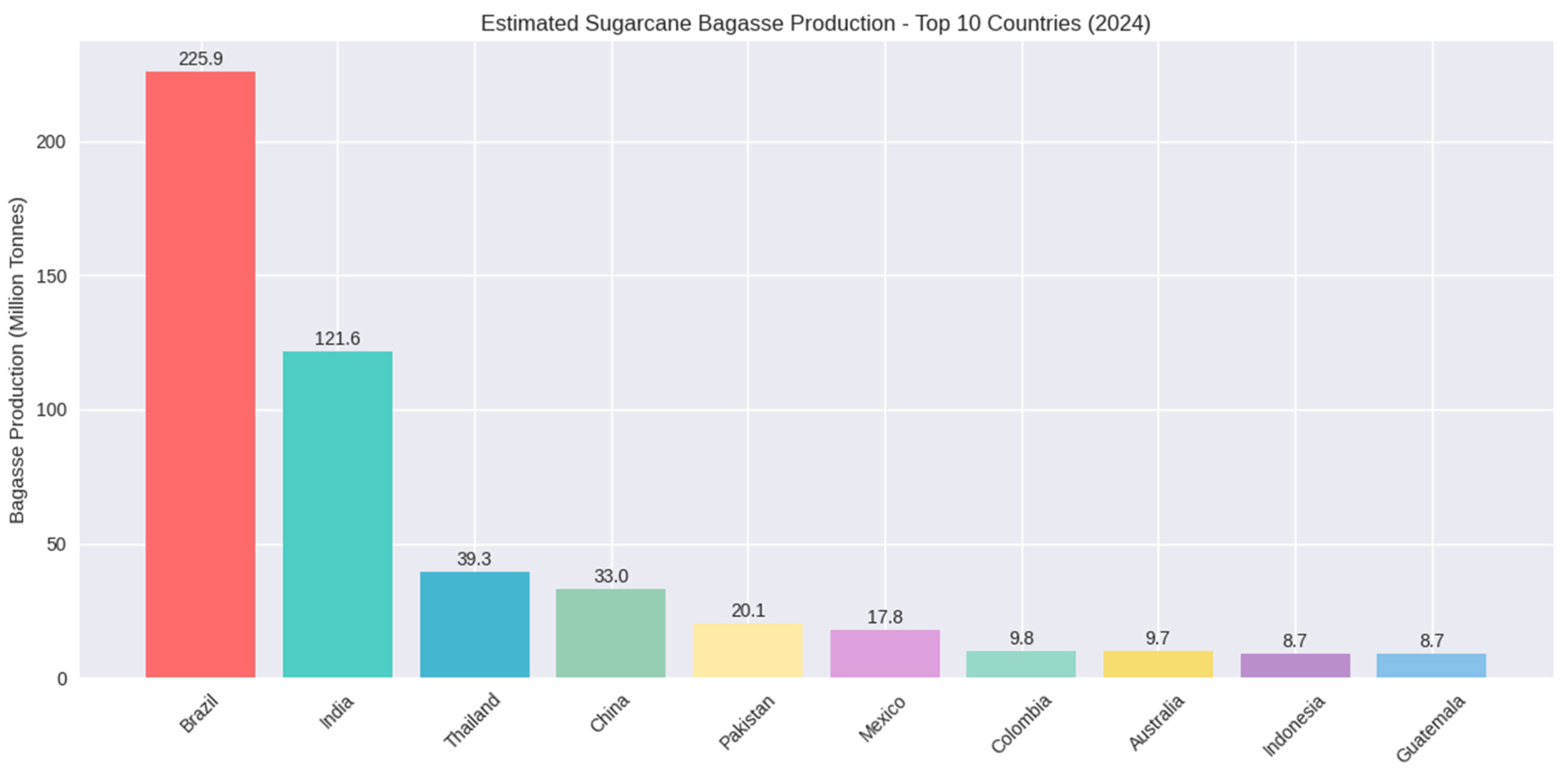

1.1. Context and Significance of the Topic

1.2. Problem Statement and Challenges

1.3. Objectives of the Review

1.4. Scope of the Study

- Justification and need for this review

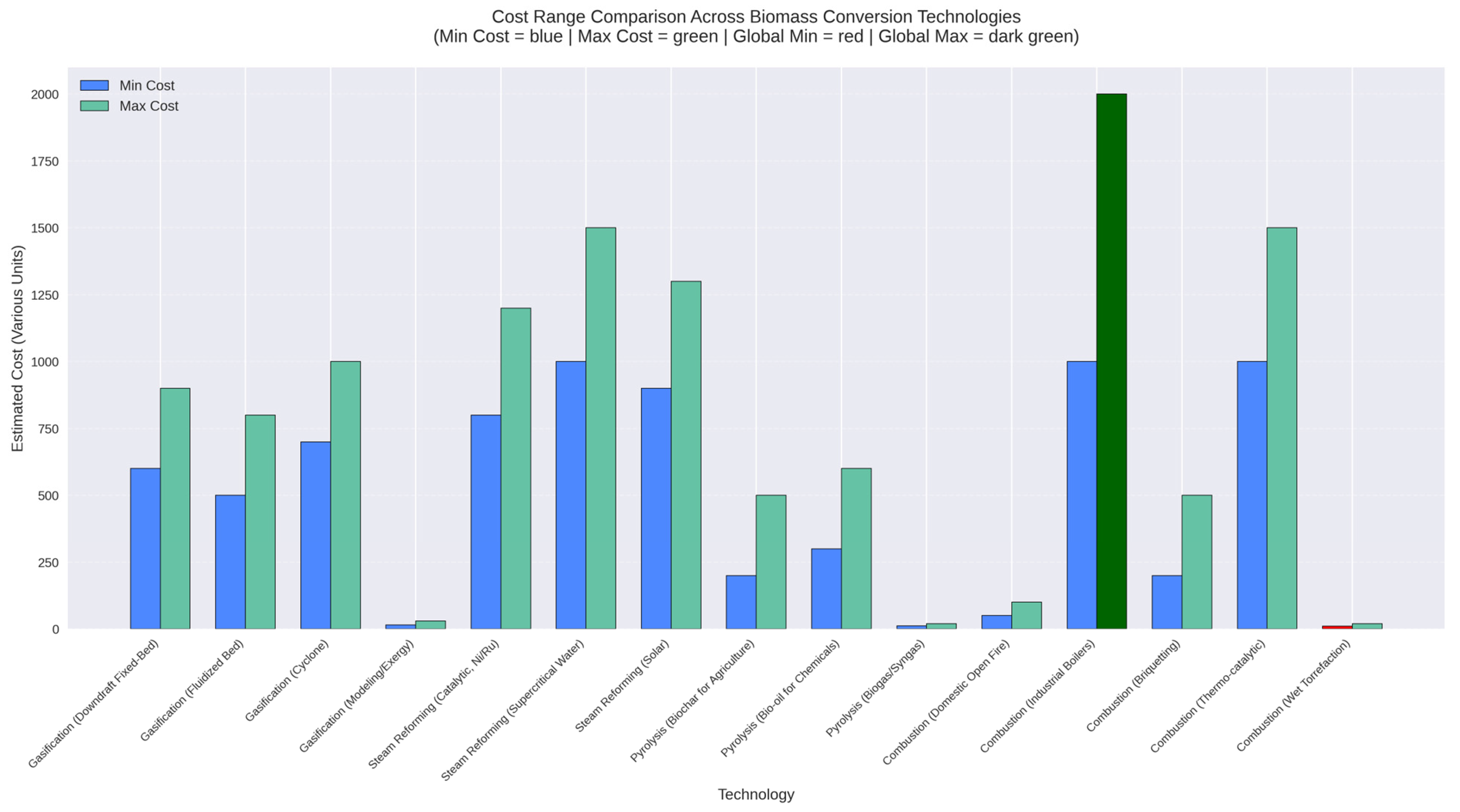

2. Products from Different Thermochemical Processes

2.1. Gasification (Air Gasification)

2.1.1. Process Optimization and Innovations for Efficient and Sustainable Gasification

2.1.2. Technical Challenges and Prospects for Industrial Development of SCB Gasification

2.2. Steam Reforming (Steam Gasification)

2.2.1. Current Challenges and Prospects for Improvement in Biomass Gasification

2.2.2. Innovative Approaches to Overcoming the Challenges of Biomass Gasification

2.2.3. Prospects and Challenges for Biomass Steam Reforming in the Field of Catalysis

2.3. Pyrolysis

2.3.1. Technical and Regulatory Challenges Related to the Production and Use of Biochar Through Pyrolysis

2.3.2. Research Prospects for Optimizing Biomass Pyrolysis and Integrated Recovery

2.3.3. Challenges and Prospects for Sustainable Industrial Development

2.4. Combustion

2.4.1. Environmental and Economic Challenges of Combustion: Pollution, Efficiency, and Regulatory Framework

2.4.2. Prospects for Optimizing Biomass Combustion Systems for Sustainable and Clean Use

2.4.3. Challenges and Prospects for the Large-Scale Deployment of LPG Combustion: Pollution, Reliability, and Technological Innovations

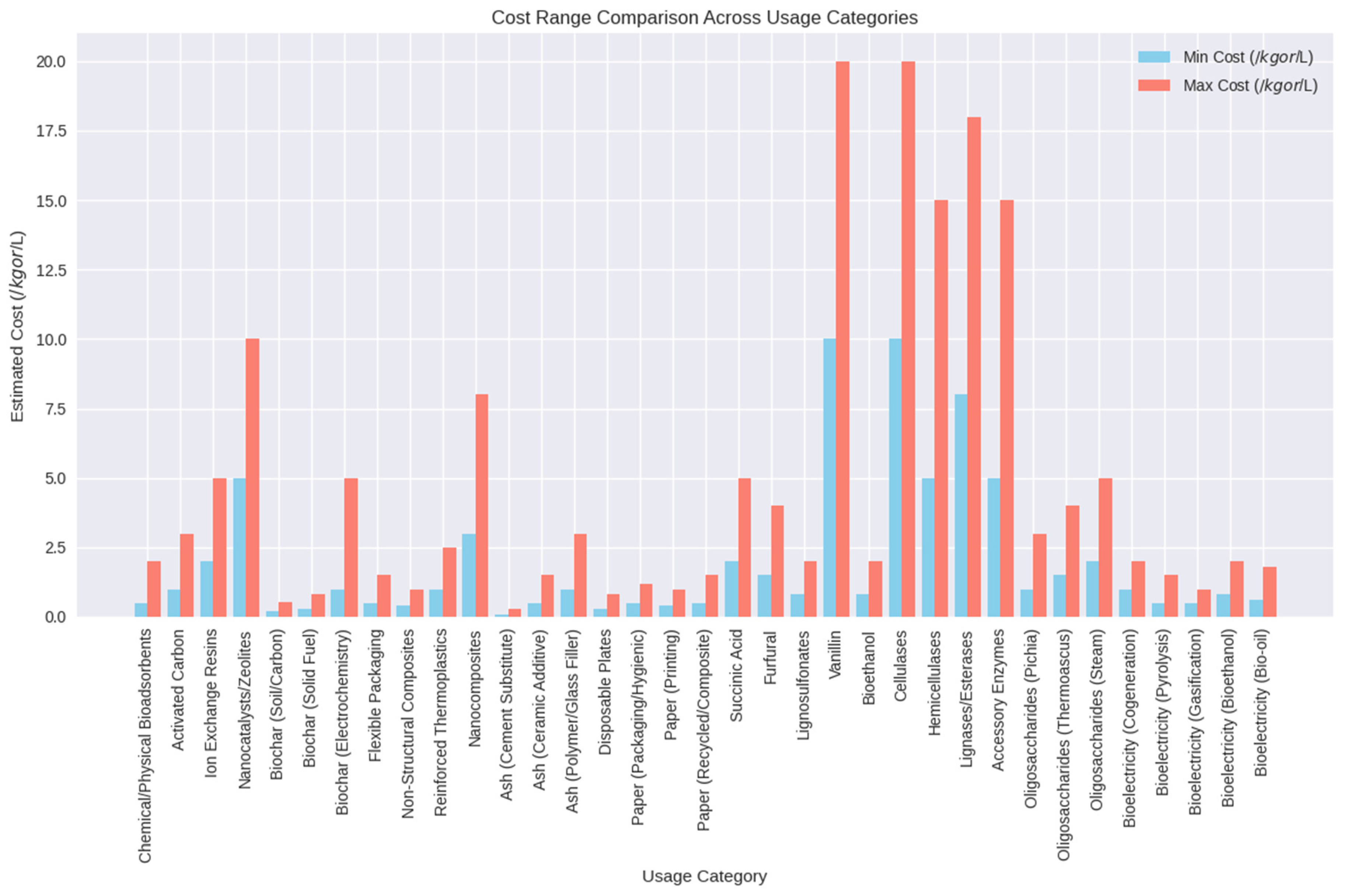

3. Adsorbents

3.1. Challenges and Prospects in the Sustainability and Commercialization of SCB-Based Bioadsorbents

3.2. Research Prospects for Improving the Performance and Sustainability of SCB-Based Adsorbents

3.3. Development Prospects for the Large-Scale Commercialization of SCB-Based Adsorbents: Technical, Environmental, and Economic Challenges

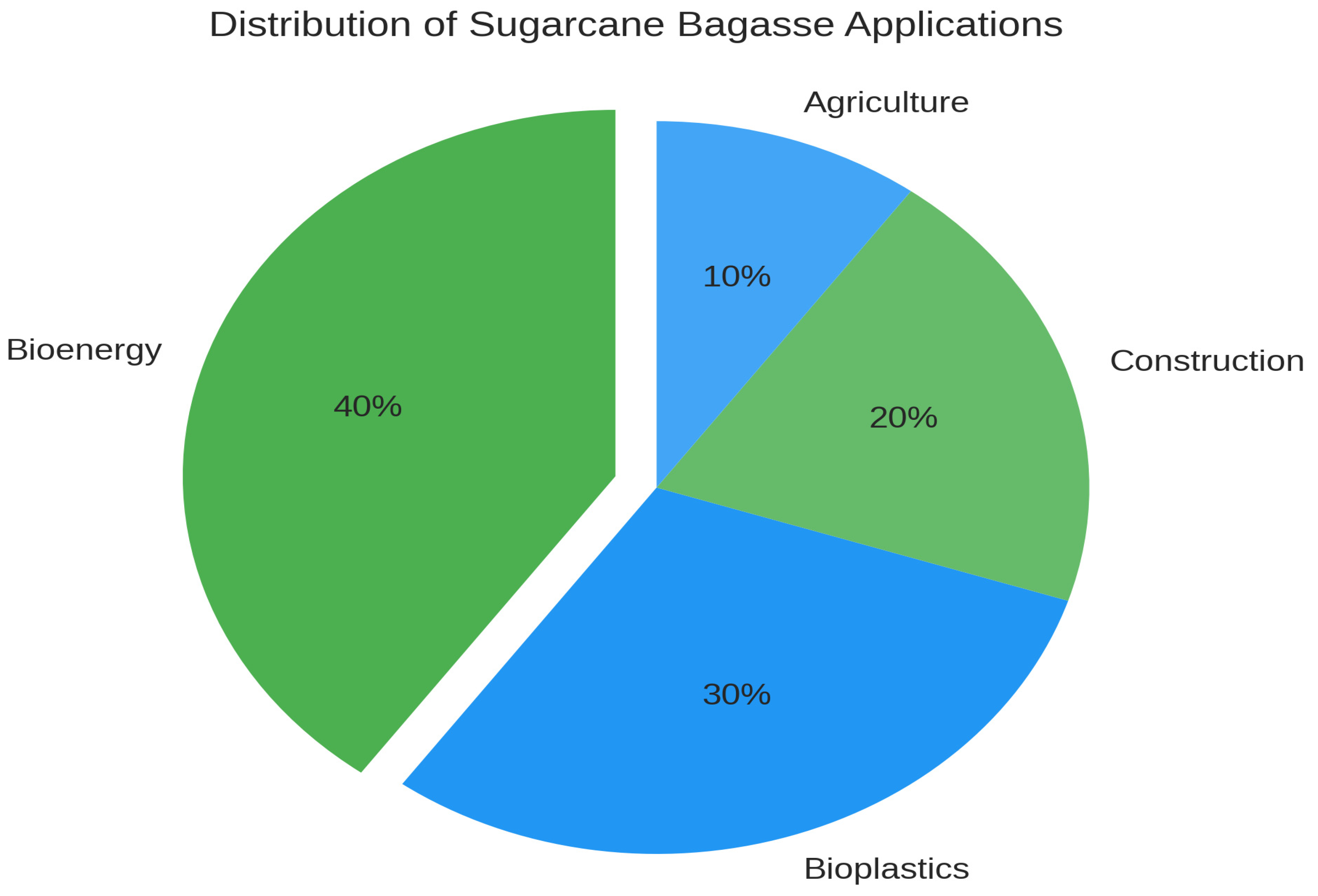

4. Commercial Products Made from Bagasse

4.1. Bagasse and Pectin-Based Composites for Food Packaging Applications

4.2. Technical and Regulatory Challenges in Integrating Bagasse Fiber into Polymer Matrices for Biodegradable Packaging

4.3. Research Prospects for Optimizing Bagasse Fiber-Based Composites in Biodegradable Packaging

Future Trends

4.4. Bagasse–Pectin Composites for Sustainable Packaging: Challenges and Prospects

5. Bagasse Ash as a Substitute for Cement

5.1. Bagasse Ash: Technical, Regulatory, and Sustainability Issues in Construction

5.2. Optimization and Sustainability of Bagasse Ash for Advanced Materials

5.3. Challenges and Prospects for Sustainable Use of Bagasse Ash in Cement and Ceramics

- Environmental benefits

- CO2 Emissions reduction

- Raw material savings

- Industrial prospects and steps for Large-Scale Production

- Challenges to overcome

- Variability in composition: SCBA’s chemical composition varies significantly due to differences in sugarcane origin, burning conditions (temperature and duration), and regional soil properties [166]. Silica content ranges from 59.2% to 87.7%, with some samples containing high levels of unburnt carbon or crystalline silica, reducing pozzolanic activity [167]. This variability complicates consistent performance in cement and ceramics.

- Processing requirements: Raw SCBA often contains fibrous particles and unburnt carbon, requiring sieving, grinding, and calcination to enhance pozzolanic properties [168]. For instance, grinding SCBA to a fineness comparable to cement (e.g., 45 min in a ball mill) increases its reactivity but adds processing costs.

- Lack of standardization: The absence of universal standards for SCBA use in cement and ceramics hinders industrial adoption. While ASTM C618 specifies requirements for pozzolanic materials, SCBA’s variable composition often fails to meet these criteria without preprocessing, limiting its acceptance compared to established SCMs like fly ash or slag [169,170].

- Long-Term Performance Data: Limited studies on the long-term durability of SCBA-blended materials, particularly under aggressive environments (e.g., chloride or sulfate exposure), create uncertainty for industrial applications.

- Steps for scaling up production

- Standardized processing protocols:

- Regional pilot projects:

- Development of industry standards:

- Investment in processing infrastructure:

- Long-term testing and certification:

- Supply chain integration:

6. Disposable Plates Made from Bagasse Pulp

6.1. Challenges and Prospects for Bagasse Pulp Plates: Strength, Safety, and Acceptability

6.2. Improvement of Bagasse Pulp Plates: Reinforcement, Treatment, and Certification

6.3. Bagasse Pulp Plates: Technical and Regulatory Challenges for Sustainable Production

7. Manufacturing Paper from Bagasse Pulp

7.1. Challenges of Bagasse Pulp: Strength, Recycling, and Standardization

7.2. Optimizing Bagasse Conversion Processes for Sustainable, High-Performance Paper

7.3. Bagasse-Based Paper: Eco-Design Challenges and Prospects

8. Nano-Cellulose from Bagasse

8.1. Nano-Cellulose: Technical Challenges and Industrial Issues

8.2. Sustainable Production and Integration of Nano-Cellulose in Composites

8.3. Bagasse Nanocellulose: Challenges and Prospects for the Industry

9. Biochemicals from Bagasse

9.1. Succinic Acid

9.2. Furfural

9.3. Lignosulfonates from Lignin

9.4. Vanillin from Lignin

9.5. Integrated Biomass Valorization: Challenges and Strategies for Sustainable Chemical Production

9.6. Bioethanol from Bagasse, Sugarcane Tops and Molasses

9.6.1. Optimizing the Valorization of Polysaccharides: Challenges and Industrial Prospects

9.6.2. Integrated Biotechnologies for the Sustainable Recovery of Lignocellulosic Biomass

9.6.3. Production of Bioethanol from Bagasse: Technological Challenges and Industrial Prospects

9.7. Enzymes Produced from Sugarcane Bagasse

9.7.1. Enzymatic and Biotechnological Optimization for the Industrial Production of Biocatalysts

9.7.2. Thermostable Enzymes and Co-Cultures: Innovations for Integrated Biomass Degradation

9.7.3. Enzyme Production from Bagasse: Challenges and Prospects for Industrialization

9.8. Oligosaccharides Produced

9.8.1. Pre-Treatment Methods and Experimental Results

9.8.2. Optimization of Bagasse Pre-Treatment and Enzymatic Degradation Processes: Strategies for Sustainable Industrial Valorization

10. Bioelectricity from Bagasse and Cane Residues

10.1. Mixed Thermochemical Technologies for the Sustainable Recovery of Bagasse

10.2. Bagasse Energy Optimization: Challenges and Industrial Prospects

11. Technical-Economic Analysis

11.1. Mixed Technologies for Sustainable Biomass Recovery: Optimization and Management of Co-Products

11.2. Technical and Economic Assessment of Bagasse Recovery: Industrial Opportunities and Challenges

12. Future Research and Policy Implications

12.1. Technical Research Gaps and Directions

12.2. Economic and Commercialization Gaps and Directions

12.3. Environmental and Policy Gaps and Directions

12.4. Integrated Strategies for Sustainable Bioeconomies

13. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

References

- Sheikhdavoodi, M.J.; Almassi, M.; Ebrahimi-Nik, M.; Kruse, A.; Bahrami, H. Gasification of sugarcane bagasse in supercritical water; evaluation of alkali catalysts for maximum hydrogen production. J. Energy Inst. 2015, 88, 450–458. [Google Scholar] [CrossRef]

- Ajala, E.O.; Ighalo, J.O.; Ajala, M.A.; Adeniyi, A.G.; Ayanshola, A.M. Sugarcane bagasse: A biomass sufficiently applied for improving global energy, environment and economic sustainability. Bioresour. Bioprocess. 2021, 8, 87. [Google Scholar] [CrossRef] [PubMed]

- Yin, C.-Y. Prediction of higher heating values of biomass from proximate and ultimate analyses. Fuel 2011, 90, 1128–1132. [Google Scholar] [CrossRef]

- Ajala, E.O.; Olonade, Y.O.; Ajala, M.A.; Akinpelu, G.S. Lactic Acid Production from Lignocellulose—A Review of Major Challenges and Selected Solutions. ChemBioEng Rev. 2020, 7, 38–49. [Google Scholar] [CrossRef]

- Lee, J.Y. Water-Food-Energy Challenges in the Face of a Growing Sugar Industry in Central India. Ph.D. Thesis, Stanford University, Stanford, CA, USA, 2024. [Google Scholar]

- Barbosa, F.d.S.; Coelho, R.D.; Barros, T.H.d.S.; Lizcano, J.V.; Fraga Júnior, E.F.; Santos, L.d.C.; Leal, D.P.V.; Ribeiro, N.L.; Costa, J.d.O. Sugarcane water productivity for bioethanol, sugar and biomass under deficit irrigation. AgriEngineering 2024, 6, 1117–1132. [Google Scholar] [CrossRef]

- Rizzioli, F. Recovery of Biofuels, Biobased Products and Nutrients in Agricultural Biogas Plants. Ph.D. Thesis, University of Verona, Verona, Italy, 2025. [Google Scholar]

- Pereira, L.G.; Ramos, N.P.; Pighinelli, A.L.M.; Novaes, R.M.; Seabra, J.E.; Debiasi, H.; Hirakuri, M.H.; Folegatti, M.I. State-Level Inventories and Life Cycle GHG Emissions of Corn, Soybean, and Sugarcane Produced in Brazil. Sustainability 2025, 17, 8482. [Google Scholar] [CrossRef]

- Karp, S.G.; Woiciechowski, A.L.; Soccol, V.T.; Soccol, C.R. Pretreatment strategies for delignification of sugarcane bagasse: A review. Braz. Arch. Biol. Technol. 2013, 56, 679–689. [Google Scholar] [CrossRef]

- Sun, J.-X.; Sun, X.-F.; Sun, R.-C.; Fowler, P.; Baird, M.S. Inhomogeneities in the chemical structure of sugarcane bagasse lignin. J. Agric. Food Chem. 2003, 51, 6719–6725. [Google Scholar] [CrossRef]

- Antunes, F.A.F.; Chandel, A.K.; Brumano, L.P.; Terán Hilares, R.; Peres, G.F.D.; Ayabe, L.E.S.; Sorato, V.S.; Santos, J.R.; Santos, J.C.; Da Silva, S.S. A novel process intensification strategy for second-generation ethanol production from sugarcane bagasse in fluidized bed reactor. Renew. Energy 2018, 124, 189–196. [Google Scholar] [CrossRef]

- Cao, S.; Aita, G.M. Enzymatic hydrolysis and ethanol yields of combined surfactant and dilute ammonia treated sugarcane bagasse. Bioresour. Technol. 2013, 131, 357–364. [Google Scholar] [CrossRef]

- Zhu, Z.; Rezende, C.A.; Simister, R.; McQueen-Mason, S.J.; Macquarrie, D.J.; Polikarpov, I.; Gomez, L.D. Efficient sugar production from sugarcane bagasse by microwave assisted acid and alkali pretreatment. Biomass Bioenergy 2016, 93, 269–278. [Google Scholar] [CrossRef]

- Nosratpour, M.J.; Karimi, K.; Sadeghi, M. Improvement of ethanol and biogas production from sugarcane bagasse using sodium alkaline pretreatments. J. Environ. Manag. 2018, 226, 329–339. [Google Scholar] [CrossRef] [PubMed]

- Canilha, L.; Carvalho, W.; Felipe, M.D.G.D.A.; Silva, J.B.d.A.e.; Giulietti, M. Ethanol Production from Sugarcane Bagasse Hydrolysate Using Pichia stipitis. Appl. Biochem. Biotechnol. 2010, 161, 84–92. [Google Scholar] [CrossRef] [PubMed]

- Velmurugan, R.; Muthukumar, K. Utilization of sugarcane bagasse for bioethanol production: Sono-assisted acid hydrolysis approach. Bioresour. Technol. 2011, 102, 7119–7123. [Google Scholar] [CrossRef]

- Veza, I.; Muhamad Said, M.F.; Latiff, Z.A. Recent advances in butanol production by acetone-butanol-ethanol (ABE) fermentation. Biomass Bioenergy 2021, 144, 105919. [Google Scholar] [CrossRef]

- Prasad, S.D. Butanol Production from Residues of Sugar and Timber and Estimation of Butanol Production Potential in Fiji. In School of Engineering and Physics; University of the South Pacific Suva: Suva, Fiji, 2020. [Google Scholar]

- Yue, T.; Jiang, D.; Zhang, Z.; Zhang, Y.; Li, Y.; Zhang, T.; Zhang, Q. Recycling of shrub landscaping waste: Exploration of bio-hydrogen production potential and optimization of photo-fermentation bio-hydrogen production process. Bioresour. Technol. 2021, 331, 125048. [Google Scholar] [CrossRef]

- Carvalho, W.; Santos, J.; Canilha, L.; Silva, S.; Perego, P.; Converti, A. Xylitol production from sugarcane bagasse hydrolysate: Metabolic behaviour of Candida guilliermondii cells entrapped in Ca-alginate. Biochem. Eng. J. 2005, 25, 25–31. [Google Scholar] [CrossRef]

- Borges, E.R.; Pereira, N., Jr. Succinic acid production from sugarcane bagasse hemicellulose hydrolysate by Actinobacillus succinogenes. J. Ind. Microbiol. Biotechnol. 2011, 38, 1001–1011. [Google Scholar] [CrossRef]

- Gómez, E.O.; Cortez, L.A.B.; Lora, E.S.; Sanchez, C.G.; Bauen, A. Preliminary tests with a sugarcane bagasse fueled fluidized-bed air gasifier. Energy Convers. Manag. 1999, 40, 205–214. [Google Scholar] [CrossRef]

- Pellegrini, L.F.; de Oliveira, S., Jr. Exergy analysis of sugarcane bagasse gasification. Energy 2007, 32, 314–327. [Google Scholar] [CrossRef]

- Gabra, M.; Pettersson, E.; Backman, R.; Kjellström, B. Evaluation of cyclone gasifier performance for gasification of sugar cane residue—Part 1: Gasification of bagasse. Biomass Bioenergy 2001, 21, 351–369. [Google Scholar] [CrossRef]

- Mavukwana, A.; Jalama, K.; Ntuli, F.; Harding, K. Simulation of Sugarcane Bagasse Gasification using Aspen Plus. In Proceedings of the International Conference on Chemical and Environmental Engineering (ICCEE), Johannesburg, South Africa, 15–16 April 2013; Volume 1516, pp. 70–74. [Google Scholar]

- Dellepiane, D.; Bosio, B.; Arato, E. Clean energy from sugarcane waste: Feasibility study of an innovative application of bagasse and barbojo. J. Power Sources 2003, 122, 47–56. [Google Scholar] [CrossRef]

- Zayer Kabeh, K.; Prussi, M.; Chiaramonti, D. Advances in Bio-Hydrogen Production: A Critical Review of Pyrolysis Gas Reforming. Appl. Sci. 2025, 15, 3995. [Google Scholar] [CrossRef]

- Rijo, B.; Nobre, C.; Brito, P.; Ferreira, P. An Overview of the Thermochemical Valorization of Sewage Sludge: Principles and Current Challenges. Energies 2024, 17, 2417. [Google Scholar] [CrossRef]

- Yabandeh, S.; Hajinezhad, A.; Moosavian, S.F.; Fattahi, R. Modeling and Simulation of Waste Tire-Based Power Generation System using Aspen Plus. Results Eng. 2025, 28, 107326. [Google Scholar] [CrossRef]

- Kumar, D.; Jain, V.; Shanker, G.; Srivastava, A. Citric acid production by solid state fermentation using sugarcane bagasse. Process Biochem. 2003, 38, 1731–1738. [Google Scholar] [CrossRef]

- Sengupta, P.; Manna, I. Advanced high-temperature structural materials in petrochemical, metallurgical, power, and aerospace sectors—An overview. Future Landsc. Struct. Mater. India 2022, 1, 79–131. [Google Scholar]

- Hiranobe, C.T.; Gomes, A.S.; Paiva, F.F.; Tolosa, G.R.; Paim, L.L.; Dognani, G.; Cardim, G.P.; Cardim, H.P.; dos Santos, R.J.; Cabrera, F.C. Sugarcane bagasse: Challenges and opportunities for waste recycling. Clean Technol. 2024, 6, 662–699. [Google Scholar] [CrossRef]

- Santana, H.E.; Jesus, M.; Santos, J.; Rodrigues, A.C.; Pires, P.; Ruzene, D.S.; Silva, I.P.; Silva, D.P. Lignocellulosic biomass gasification: Perspectives, challenges, and methods for tar elimination. Sustainability 2025, 17, 1888. [Google Scholar] [CrossRef]

- Makepa, D.C.; Chihobo, C.H. Barriers to commercial deployment of biorefineries: A multi-faceted review of obstacles across the innovation chain. Heliyon 2024, 10, e32649. [Google Scholar] [CrossRef]

- Shibukawa, V.P.; Ramos, L.; Cruz-Santos, M.M.; Prado, C.A.; Jofre, F.M.; de Arruda, G.L.; da Silva, S.S.; Mussatto, S.I.; dos Santos, J.C. Impact of product diversification on the economic sustainability of second-generation ethanol biorefineries: A critical review. Energies 2023, 16, 6384. [Google Scholar] [CrossRef]

- Mubarak Alqahtani, A. Sweet sorghum and bagasse: A comprehensive review of feedstock traits, conversion processes, and economic viability for bioethanol and biogas production. Biofuels 2024, 15, 575–585. [Google Scholar] [CrossRef]

- Pandey, A.; Sharma, Y.C. Advancements in biomass valorization in integrated biorefinery systems. Biofuels Bioprod. Biorefin. 2024, 18, 2078–2090. [Google Scholar] [CrossRef]

- Waheed, Q.M.K.; Williams, P.T. Hydrogen Production from High Temperature Pyrolysis/Steam Reforming of Waste Biomass: Rice Husk, Sugar Cane Bagasse, and Wheat Straw. Energy Fuels 2013, 27, 6695–6704. [Google Scholar] [CrossRef]

- Adeniyi, A.G.; Ighalo, J.O.; Abdulsalam, A. Modeling of integrated processes for the recovery of the energetic content of sugar cane bagasse. Biofuels Bioprod. Biorefin. 2019, 13, 1057–1067. [Google Scholar] [CrossRef]

- Osada, M.; Yamaguchi, A.; Hiyoshi, N.; Sato, O.; Shirai, M. Gasification of Sugarcane Bagasse over Supported Ruthenium Catalysts in Supercritical Water. Energy Fuels 2012, 26, 3179–3186. [Google Scholar] [CrossRef]

- Zhu, M.; Wang, Q.; Wang, S. Recent Advances and Future Perspectives in Catalyst Development for Efficient and Sustainable Biomass Gasification: A Comprehensive Review. Sustainability 2025, 17, 7370. [Google Scholar] [CrossRef]

- Małozięć, K. Modelling Hydrothermal Liquefaction Process. Master’s Thesis, School of Engineering Science, Kemiantekniikka, Finnish University of Applied Sciences, Tampere, Finland, 2025. [Google Scholar]

- Kumar, A.; Sharma, K.; Yadav, V.; Banerjee, D.K. Hydrogen Horizons: Tech, Trends, and Tomorrow; Book Saga Publications: Maharashtra, India, 2025. [Google Scholar]

- Gyandoh, E.S. Techno-Economic Analysis (TEA) and Life-Cycle Assessment (LCA) of Sustainable Aviation Fuel (SAF) Production Through Circular Economy (CE) Practices: A Focus on Supply Chain Optimization and Policy Implications. Ph.D. Thesis, The University of New Mexico, Albuquerque, NM, USA, 2025. [Google Scholar]

- Naquash, A.; Hameed, Z.; Qyyum, M.A.; Khan, Z.; Al-Muhtaseb, A.H.; Riaz, A.; Lee, M. Biohydrogen and biomethane production from biomass gasification: Compositional analysis, recent advancements, challenges, and prospects. Process Saf. Environ. Prot. 2025, 194, 1526–1537. [Google Scholar] [CrossRef]

- Akhtar, M.S.; Naseem, M.T.; Ali, S.; Zaman, W. Metal-Based Catalysts in Biomass Transformation: From Plant Feedstocks to Renewable Fuels and Chemicals. Catalysts 2025, 15, 40. [Google Scholar] [CrossRef]

- Ungureanu, N.; Vlăduț, N.-V.; Biriș, S.-Ș.; Ionescu, M.; Gheorghiță, N.-E. Municipal Solid Waste Gasification: Technologies, Process Parameters, and Sustainable Valorization of By-Products in a Circular Economy. Sustainability 2025, 17, 6704. [Google Scholar] [CrossRef]

- Yadav, A.; Mittal, R.; Bishnoi, N.R. Nanomaterial-Based Immobilization in Industrial Biocatalysis: Prospects, Gaps, and Challenges. In Enzyme Immobilization with Nanomaterials: Applications and Challenges; ACS Publications: Washington, DC, USA, 2025; pp. 81–103. ISBN 1947-5918. [Google Scholar]

- Khalil, M.I.; Jhanjhi, N.; Humayun, M.; Sivanesan, S.; Masud, M.; Hossain, M.S. Hybrid smart grid with sustainable energy efficient resources for smart cities. Sustain. Energy Technol. Assess. 2021, 46, 101211. [Google Scholar] [CrossRef]

- Borkertas, S.; Viskelis, J.; Viskelis, P.; Streimikyte, P.; Gasiunaite, U.; Urbonaviciene, D. Fungal biomass fermentation: Valorizing the food industry’s waste. Fermentation 2025, 11, 351. [Google Scholar] [CrossRef]

- Silva, J.; Rocha, C.; Soria, M.; Madeira, L.M. Catalytic steam reforming of biomass-derived oxygenates for H2 production: A review on Ni-based catalysts. Chem. Eng. 2022, 6, 39. [Google Scholar] [CrossRef]

- Mather, T.N.; Siva, N.; Jauregui, M.; Klatte, H.; Lambert, J.D.; Anderson, C.T. Preparation and compositional analysis of Lignocellulosic plant biomass as a precursor for food production during food crises. Curr. Protoc. 2024, 4, e1090. [Google Scholar] [CrossRef]

- Isahak, W.N.R.W.; Al-Amiery, A. Catalysts driving efficiency and innovation in thermal reactions: A comprehensive review. Green Technol. Sustain. 2024, 2, 100078. [Google Scholar] [CrossRef]

- Zafeer, M.K.; Menezes, R.A.; Venkatachalam, H.; Bhat, K.S. Sugarcane bagasse-based biochar and its potential applications: A review. Emergent Mater. 2024, 7, 133–161. [Google Scholar] [CrossRef]

- Tan, Z.; Li, Y.; Chen, F.; Liu, J.; Zhong, J.; Guo, L.; Zhang, R.; Chen, R. Challenges and perspectives of the conversion of lignin waste to high-value chemicals by pyrolysis. Processes 2024, 12, 589. [Google Scholar] [CrossRef]

- Al Arni, S.; Bosio, B.; Arato, E. Syngas from sugarcane pyrolysis: An experimental study for fuel cell applications. Renew. Energy 2010, 35, 29–35. [Google Scholar] [CrossRef]

- Carrier, M.; Hugo, T.; Gorgens, J.; Knoetze, H. Comparison of slow and vacuum pyrolysis of sugar cane bagasse. J. Anal. Appl. Pyrolysis 2011, 90, 18–26. [Google Scholar] [CrossRef]

- Erlich, C.; Björnbom, E.; Bolado, D.; Giner, M.; Fransson, T.H. Pyrolysis and gasification of pellets from sugar cane bagasse and wood. Fuel 2006, 85, 1535–1540. [Google Scholar] [CrossRef]

- Garcáa-Pèrez, M.; Chaala, A.; Roy, C. Vacuum pyrolysis of sugarcane bagasse. J. Anal. Appl. Pyrolysis 2002, 65, 111–136. [Google Scholar] [CrossRef]

- Ounas, A.; Aboulkas, A.; Bacaoui, A.; Yaacoubi, A. Pyrolysis of olive residue and sugar cane bagasse: Non-isothermal thermogravimetric kinetic analysis. Bioresour. Technol. 2011, 102, 11234–11238. [Google Scholar] [CrossRef]

- Darmstadt, H.; Garcia-Perez, M.; Chaala, A.; Cao, N.-Z.; Roy, C. Co-pyrolysis under vacuum of sugar cane bagasse and petroleum residue: Properties of the char and activated char products. Carbon 2001, 39, 815–825. [Google Scholar] [CrossRef]

- Herath Bandara, S.J. Exploring the Potential of Biochar in Enhancing US Agriculture. Reg. Sci. Environ. Econ. 2025, 2, 23. [Google Scholar] [CrossRef]

- Peters, M.A.; Alves, C.T.; Onwudili, J.A. A review of current and emerging production technologies for biomass-derived sustainable aviation fuels. Energies 2023, 16, 6100. [Google Scholar] [CrossRef]

- El-Halwagi, M.M. Sustainable Design Through Process Integration: Fundamentals and Applications to Industrial Pollution Prevention, Resource Conservation, and Profitability Enhancement; Elsevier: Amsterdam, The Netherlands, 2025; ISBN 0-443-16040-6. [Google Scholar]

- Ayub, Y.; Zhou, J.; Shen, W.; Ren, J. Innovative valorization of biomass waste through integration of pyrolysis and gasification: Process design, optimization, and multi-scenario sustainability analysis. Energy 2023, 282, 128417. [Google Scholar] [CrossRef]

- Athira, G.; Bahurudeen, A.; Appari, S. Thermochemical Conversion of Sugarcane Bagasse: Composition, Reaction Kinetics, and Characterisation of By-Products. Sugar Tech 2021, 23, 433–452. [Google Scholar] [CrossRef]

- Hou, Y. A Comprehensive Review of Fuels Used in Combustion Processes. Bachelor’s Thesis, Hebei University of Technology, Tianjin, China, 2024. [Google Scholar]

- Ramajo-Escalera, B.; Espina, A.; García, J.; Sosa-Arnao, J.; Nebra, S. Model-free kinetics applied to sugarcane bagasse combustion. Thermochim. Acta 2006, 448, 111–116. [Google Scholar] [CrossRef]

- Ahmad, E.; Jäger, N.; Apfelbacher, A.; Daschner, R.; Hornung, A.; Pant, K.K. Integrated thermo-catalytic reforming of residual sugarcane bagasse in a laboratory scale reactor. Fuel Process. Technol. 2018, 171, 277–286. [Google Scholar] [CrossRef]

- Chen, W.-H.; Ye, S.-C.; Sheen, H.-K. Hydrothermal carbonization of sugarcane bagasse via wet torrefaction in association with microwave heating. Bioresour. Technol. 2012, 118, 195–203. [Google Scholar] [CrossRef]

- Munir, S.; Daood, S.S.; Nimmo, W.; Cunliffe, A.M.; Gibbs, B.M. Thermal analysis and devolatilization kinetics of cotton stalk, sugar cane bagasse and shea meal under nitrogen and air atmospheres. Bioresour. Technol. 2009, 100, 1413–1418. [Google Scholar] [CrossRef]

- Ryzhchenko, O. Environmental and Health Impacts of Agricultural Waste Combustion for Bioenergy: A Toxicity and Emission Review; National University of Civil Protection of Ukraine: Kharkiv, Ukraine, 2024; Volume 6, pp. 45–58. [Google Scholar] [CrossRef]

- Khobragade, D.S. Biomass–An Environmental Concern. In Plant Biomass Derived Materials: Sources, Extractions, and Applications; John Wiley and Sons: Hoboken, NJ, USA, 2024; pp. 1–22. [Google Scholar]

- Omwenga, S.C. An Evaluation of Renewable Energy Adoption in Kenya. A Case Study of Biomass Briquette Production and its Use in Industrial Boiler Operations. Ph.D. Thesis, University of Nairobi, Nairobi, Kenya, 2018. [Google Scholar]

- Nunes, L.J. Exploring the present and future of biomass recovery units: Technological innovation, policy incentives and economic challenges. Biofuels 2024, 15, 375–387. [Google Scholar] [CrossRef]

- Makepa, D.C.; Chihobo, C.H. Sustainable pathways for biomass production and utilization in carbon capture and storage—A review. Biomass Convers. Biorefin. 2025, 15, 11397–11419. [Google Scholar] [CrossRef]

- Perera, W.; Hosan, K.; Wijesekara, R.; Priyadarshana, H.; Abeysinghe, S.; Amarasinghe, A.; Koswattage, K. Biogas Purification Technologies: A Comparative Review of Methods and Accessibility for Sustainable Energy Applications. J. Agric. Value Addit. 2025, 8, 44–73. [Google Scholar] [CrossRef]

- Wu, M.; Wei, K.; Jiang, J.; Xu, B.B.; Ge, S. Advancing green sustainability: A comprehensive review of biomass briquette integration for coal-based energy frameworks. Int. J. Coal Sci. Technol. 2025, 12, 44. [Google Scholar] [CrossRef]

- Bharti, R.; Thakur, A.; Verma, M.; Sharma, R. Environmental and Health Impacts of Air Pollution: A State of Art Review on the Strategy to Control Air Pollution; AIP Publishing LLC: Melville, NY, USA, 2025; Volume 2807, p. 50006. [Google Scholar]

- Kim, C.; Park, K.; Lee, H.; Im, J.; Usosky, D.; Tak, K.; Park, D.; Chung, W.; Han, D.; Yoon, J. Accelerating the net-zero economy with CO2-hydrogenated formic acid production: Process development and pilot plant demonstration. Joule 2024, 8, 693–713. [Google Scholar] [CrossRef]

- Kpalo, S.Y.; Zainuddin, M.F.; Manaf, L.A.; Roslan, A.M. A review of technical and economic aspects of biomass briquetting. Sustainability 2020, 12, 4609. [Google Scholar] [CrossRef]

- Tawo, O.E.; Mbamalu, M.I. Advancing waste valorization techniques for sustainable industrial operations and improved environmental safety. Int. J. Sci. Res. Arch 2025, 14, 127–149. [Google Scholar] [CrossRef]

- Jorapur, R.; Rajvanshi, A.K. Sugarcane leaf-bagasse gasifiers for industrial heating applications. Biomass Bioenergy 1997, 13, 141–146. [Google Scholar] [CrossRef]

- Lourinho, G.; Alves, O.; Garcia, B.; Rijo, B.; Brito, P.; Nobre, C. Costs of gasification technologies for energy and fuel production: Overview, analysis, and numerical estimation. Recycling 2023, 8, 49. [Google Scholar] [CrossRef]

- Li, J.; Chen, H.; Cao, J.; Jin, Z.; Pan, P.; Xu, G.; Wang, X. Energy, Exergy, Economic, and Environmental (4E) Analysis of a Hybrid Sludge-Biomass Power System via Integrated Hydrocharization and Co-Gasification. Energy 2025, 335, 137945. [Google Scholar] [CrossRef]

- Gao, N.; Salisu, J.; Quan, C.; Williams, P. Modified nickel-based catalysts for improved steam reforming of biomass tar: A critical review. Renew. Sustain. Energy Rev. 2021, 145, 111023. [Google Scholar] [CrossRef]

- Khandelwal, K.; German, C.S.; Dalai, A.K. Technoeconomic analysis of supercritical water gasification of canola straw for hydrogen production. Int. J. Hydrog. Energy 2024, 96, 1067–1078. [Google Scholar] [CrossRef]

- Kruesi, M.; Jovanovic, Z.R.; dos Santos, E.C.; Yoon, H.C.; Steinfeld, A. Solar-driven steam-based gasification of sugarcane bagasse in a combined drop-tube and fixed-bed reactor—Thermodynamic, kinetic, and experimental analyses. Biomass Bioenergy 2013, 52, 173–183. [Google Scholar] [CrossRef]

- Boujjat, H.; Rodat, S.; Abanades, S. Techno-economic assessment of solar-driven steam gasification of biomass for large-scale hydrogen production. Processes 2021, 9, 462. [Google Scholar] [CrossRef]

- He, D.; Ma, H.; Hu, D.; Wang, X.; Dong, Z.; Zhu, B. Biochar for sustainable agriculture: Improved soil carbon storage and reduced emissions on cropland. J. Environ. Manag. 2024, 371, 123147. [Google Scholar] [CrossRef]

- Zandersons, J.; Gravitis, J.; Kokorevics, A.; Zhurinsh, A.; Bikovens, O.; Tardenaka, A.; Spince, B. Studies of the Brazilian sugarcane bagasse carbonisation process and products properties. Biomass Bioenergy 1999, 17, 209–219. [Google Scholar] [CrossRef]

- Humidity Sensor Market: Size Share & Trends Analysis Report by Type (Absolute Humidity Sensor, Relative Humidity Sensor), by End Use (Automotive, Industrial), by Region, and Segment Forecasts, 2025–2030. Grand View Research, Market Analysis Report. 2025. Available online: https://www.grandviewresearch.com/industry-analysis/humidity-sensor-market (accessed on 25 March 2025).

- Asadullah, M.; Rahman, M.A.; Ali, M.M.; Rahman, M.S.; Motin, M.A.; Sultan, M.B.; Alam, M.R. Production of bio-oil from fixed bed pyrolysis of bagasse. Fuel 2007, 86, 2514–2520. [Google Scholar] [CrossRef]

- Drugkar, K.; Rathod, W.; Sharma, T.; Sharma, A.; Joshi, J.; Pareek, V.K.; Ledwani, L.; Diwekar, U. Advanced separation strategies for up-gradation of bio-oil into value-added chemicals: A comprehensive review. Sep. Purif. Technol. 2022, 283, 120149. [Google Scholar] [CrossRef]

- Inayat, A.; Ahmed, A.; Tariq, R.; Waris, A.; Jamil, F.; Ahmed, S.F.; Ghenai, C.; Park, Y.-K. Techno-economical evaluation of bio-oil production via biomass fast pyrolysis process: A review. Front. Energy Res. 2022, 9, 770355. [Google Scholar] [CrossRef]

- Wills, V.C.; Rodriguez, J.K. Waste valorization: Harnessing biogas plant residues for fuel production. Sustain. Energy Fuels 2025, 9, 2045–2062. [Google Scholar] [CrossRef]

- Pratiti, R. Household air pollution related to biomass cook stove emissions and its interaction with improved cookstoves. AIMS Public Health 2021, 8, 309. [Google Scholar] [CrossRef]

- US EIA. Assumptions to the Annual Energy Outlook 2020: Electricity Market Module; US EIA: Washington, DC, USA, 2020; Volume 8. [Google Scholar]

- Zhang, J.; Li, G.; Borrion, A. Life cycle assessment of electricity generation from sugarcane bagasse hydrochar produced by microwave assisted hydrothermal carbonization. J. Clean. Prod. 2021, 291, 125980. [Google Scholar] [CrossRef]

- Valle, S.O.F.; López, D.M.M.; Plata, F.J.C.; Ángeles, E.L.; Camas, G.d.c.S. Catalytic Gasification of Biomass: Materials, Products and Other Considerations. In Gasification—Current Technologies and Future Prospect; De Gruyter: Berlin, Germany, 2025. [Google Scholar]

- Phang, F.J.F.; Chew, J.J.; Chakraborty, S.; Sunarso, J. Synthesis of Hydrochars via Wet Torrefaction of Biomass for Sustainable Energy Production: A Life Cycle Assessment Study. ACS Sustain. Chem. Eng. 2025, 13, 2884–2892. [Google Scholar] [CrossRef]

- Adelodun, B.; Ajibade, F.O.; Ighalo, J.O.; Odey, G.; Ibrahim, R.G.; Kareem, K.Y.; Bakare, H.O.; Tiamiyu, A.O.; Ajibade, T.F.; Abdulkadir, T.S.; et al. Assessment of socioeconomic inequality based on virus-contaminated water usage in developing countries: A review. Environ. Res. 2021, 192, 110309. [Google Scholar] [CrossRef] [PubMed]

- Eletta, O.A.A.; Adeniyi, A.G.; Ighalo, J.O.; Onifade, D.V.; Ayandele, F.O. Valorisation of Cocoa (Theobroma cacao) pod husk as precursors for the production of adsorbents for water treatment. Environ. Technol. Rev. 2020, 9, 20–36. [Google Scholar] [CrossRef]

- Xavier, A.L.P.; Adarme, O.F.H.; Furtado, L.M.; Ferreira, G.M.D.; da Silva, L.H.M.; Gil, L.F.; Gurgel, L.V.A. Modeling adsorption of copper(II), cobalt(II) and nickel(II) metal ions from aqueous solution onto a new carboxylated sugarcane bagasse. Part II: Optimization of monocomponent fixed-bed column adsorption. J. Colloid Interface Sci. 2018, 516, 431–445. [Google Scholar] [CrossRef]

- Wannahari, R.; Sannasi, P.; M Nordin, M.; Mukhtar, H. Sugarcane bagasse derived nano magnetic adsorbent composite (SCB-NMAC) for removal of Cu2+ from aqueous solution. ARPN J. Eng. Appl. Sci. 2018, 13, 1–9. [Google Scholar]

- Abdullah, A.L.; Salleh, M.M.; Mazlina, M.S.; Noor, M.; Osman, M.; Wagiran, R.; Sobri, S. Azo dye removal by adsorption using waste biomass: Sugarcane bagasse. Int. J. Eng. Technol. 2005, 2, 8–13. [Google Scholar]

- Brandão, P.C.; Souza, T.C.; Ferreira, C.A.; Hori, C.E.; Romanielo, L.L. Removal of petroleum hydrocarbons from aqueous solution using sugarcane bagasse as adsorbent. J. Hazard. Mater. 2010, 175, 1106–1112. [Google Scholar] [CrossRef]

- Moisés, M.P.; da Silva, C.T.P.; Meneguin, J.G.; Girotto, E.M.; Radovanovic, E. Synthesis of zeolite NaA from sugarcane bagasse ash. Mater. Lett. 2013, 108, 243–246. [Google Scholar] [CrossRef]

- Mathur, A.K.; Majumder, C.B.; Chatterjee, S. Combined removal of BTEX in air stream by using mixture of sugar cane bagasse, compost and GAC as biofilter media. J. Hazard. Mater. 2007, 148, 64–74. [Google Scholar] [CrossRef]

- Kamran, U.; Shezad, N.; Park, S.-J.; Rhee, K.Y.; You, S.; Akhtar, F. Solvent-free valorization of sugarcane bagasse fibers into nitrogen-doped microporous carbons: Efficient contenders for selective carbon dioxide capture. J. CO2 Util. 2025, 92, 103033. [Google Scholar] [CrossRef]

- Fei, Y.; Hu, Y.H. Design, synthesis, and performance of adsorbents for heavy metal removal from wastewater: A review. J. Mater. Chem. A 2022, 10, 1047–1085. [Google Scholar] [CrossRef]

- Akhtar, M.S.; Ali, S.; Zaman, W. Innovative adsorbents for pollutant removal: Exploring the latest research and applications. Molecules 2024, 29, 4317. [Google Scholar] [CrossRef] [PubMed]

- Al Ali, M. Advanced Techniques in Porous Structure Design for Additive Manufacturing; John Wiley & Sons: Hoboken, NJ, USA, 2025; ISBN 1-394-31268-7. [Google Scholar]

- Dey, N.; Bhardwaj, S.; Maji, P.K. Recent breakthroughs in the valorization of lignocellulosic biomass for advancements in the construction industry: A Review. RSC Sustain. 2025, 3, 3307–3357. [Google Scholar] [CrossRef]

- Singh, A.V.; Chandrasekar, V.; Prabhu, V.M.; Bhadra, J.; Laux, P.; Bhardwaj, P.; Al-Ansari, A.A.; Aboumarzouk, O.M.; Luch, A.; Dakua, S.P. Sustainable bioinspired materials for regenerative medicine: Balancing toxicology, environmental impact, and ethical considerations. Biomed. Mater. 2024, 19, 060501. [Google Scholar] [CrossRef]

- Almaraz-Sánchez, I.; Amaro-Reyes, A.; Acosta-Gallegos, J.A.; Mendoza-Sánchez, M. Processing agroindustry by-products for obtaining value-added products and reducing environmental impact. J. Chem. 2022, 2022, 3656932. [Google Scholar] [CrossRef]

- Henning, L.M.; Abdullayev, A.; Vakifahmetoglu, C.; Simon, U.; Bensalah, H.; Gurlo, A.; Bekheet, M.F. Review on polymeric, inorganic, and composite materials for air filters: From processing to properties. Adv. Energy Sustain. Res. 2021, 2, 2100005. [Google Scholar] [CrossRef]

- Mukesh, M.; Anwar, S.; Gulshan, A.; Ali, M.; Ali, K.M.; Guo, Y. Pilot-Scale Evaluation and Production Feasibility of Sustainable Antimicrobial Paper from Sugarcane Bagasse. Int. J. Environ. Agric. Biotechnol. 2025, 10, 595671. [Google Scholar] [CrossRef]

- Abegunde, S.M.; Idowu, K.S.; Adejuwon, O.M.; Adeyemi-Adejolu, T. A review on the influence of chemical modification on the performance of adsorbents. Resour. Environ. Sustain. 2020, 1, 100001. [Google Scholar] [CrossRef]

- Iwuozor, K.O.; Okoro, H.K.; Adeniyi, A.G.; Zvinowanda, C.; Ngila, J.C.; Emenike, E.C. Sugarcane bagasse adsorbents: Bibliometric insights and the influence of chemical treatment on adsorption performance in aqueous solution. Sugar Tech 2024, 26, 333–351. [Google Scholar] [CrossRef]

- Mahmud, M.A.; Anannya, F.R. Sugarcane bagasse—A source of cellulosic fiber for diverse applications. Heliyon 2021, 7, e07771. [Google Scholar] [CrossRef]

- Bantacut, T.; Romli, M.; Noor, E. Biomass by-product from crystal sugar production: A comparative study between Ngadirejo and Mauritius sugar mill. In Proceedings of the IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2018; Volume 141, p. 12009. [Google Scholar]

- Guerra, S.P.S.; Denadai, M.S.; Saad, A.L.M.; Spadim, E.R.; da Costa, M.X.R. Chapter 3—Sugarcane: Biorefinery, technology, and perspectives. In Sugarcane Biorefinery, Technology and Perspectives; Santos, F., Rabelo, S.C., De Matos, M., Eichler, P., Eds.; Academic Press: Oxford, UK, 2020; pp. 49–65. ISBN 978-0-12-814236-3. [Google Scholar]

- Shabbirahmed, A.M.; Haldar, D.; Dey, P.; Patel, A.K.; Singhania, R.R.; Dong, C.-D.; Purkait, M.K. Sugarcane bagasse into value-added products: A review. Environ. Sci. Pollut. Res. 2022, 29, 62785–62806. [Google Scholar] [CrossRef]

- Versino, F.; García, M.A. Particle Size Distribution Effect on Cassava Starch and Cassava Bagasse Biocomposites. ACS Sustain. Chem. Eng. 2019, 7, 1052–1060. [Google Scholar] [CrossRef]

- Stroescu, M.; Romina, A.; Mureșan, C.C. A Comprehensive Review on Sugarcane Bagasse in Food Packaging: Properties, Applications, and Future Prospects. Hop Med. Plants 2024, 32, 169–184. [Google Scholar] [CrossRef]

- López-Maldonado, E.A.; Solangi, A.R.; Granados-Chinchilla, F. Nanobiotechnology for Sustainable Food Management; CRC Press: Boca Raton, FL, USA, 2024; ISBN 1-040-13052-6. [Google Scholar]

- Edo, G.I.; Mafe, A.N.; Ali, A.; Akpoghelie, P.O.; Yousif, E.; Isoje, E.F.; Igbuku, U.A.; Zainulabdeen, K.; Owheruo, J.O.; Essaghah, A.E.A. Advancing sustainable food packaging: The role of green nanomaterials in enhancing barrier properties. Food Eng. Rev. 2025, 17, 573–607. [Google Scholar] [CrossRef]

- Huerta-Cardoso, O.; Durazo-Cardenas, I.; Longhurst, P.; Simms, N.J.; Encinas-Oropesa, A. Fabrication of agave tequilana bagasse/PLA composite and preliminary mechanical properties assessment. Ind. Crops Prod. 2020, 152, 112523. [Google Scholar] [CrossRef]

- Sekar, S.; Suresh Kumar, S.; Vigneshwaran, S.; Velmurugan, G. Evaluation of mechanical and water absorption behavior of natural fiber-reinforced hybrid biocomposites. J. Nat. Fibers 2022, 19, 1772–1782. [Google Scholar] [CrossRef]

- Antony Jose, S.; Cowan, N.; Davidson, M.; Godina, G.; Smith, I.; Xin, J.; Menezes, P.L. A comprehensive review on cellulose Nanofibers, nanomaterials, and composites: Manufacturing, properties, and applications. Nanomaterials 2025, 15, 356. [Google Scholar] [CrossRef]

- Guimarães, J.L.; Frollini, E.; da Silva, C.G.; Wypych, F.; Satyanarayana, K.G. Characterization of banana, sugarcane bagasse and sponge gourd fibers of Brazil. Ind. Crops Prod. 2009, 30, 407–415. [Google Scholar] [CrossRef]

- Chaharmahali, M.; Hamzeh, Y.; Ebrahimi, G.; Ashori, A.; Ghasemi, I. Effects of nano-graphene on the physico-mechanical properties of bagasse/polypropylene composites. Polym. Bull. 2014, 71, 337–349. [Google Scholar] [CrossRef]

- Kord, B.; Ravanfar, P.; Ayrilmis, N. Influence of Organically Modified Nanoclay on Thermal and Combustion Properties of Bagasse Reinforced HDPE Nanocomposites. J. Polym. Environ. 2017, 25, 1198–1207. [Google Scholar] [CrossRef]

- Barra, G.; Guadagno, L.; Raimondo, M.; Santonicola, M.G.; Toto, E.; Vecchio Ciprioti, S. A comprehensive review on the thermal stability assessment of polymers and composites for aeronautics and space applications. Polymers 2023, 15, 3786. [Google Scholar] [CrossRef]

- Jamwal, V.; Mittal, A. Recent progresses in nanocomposite films for food-packaging applications: Synthesis strategies, technological advancements, potential risks and challenges. Food Rev. Int. 2024, 40, 3634–3665. [Google Scholar] [CrossRef]

- Ferreira, P.S.; Scopel, E.; Pinto, L.O.; Rezende, C.A. Hydrophobic and Robust Sugarcane Bagasse-Based Biosorbents for Oil Spill Cleanup: Synergy of Hydrothermal Treatment and Cellulose Nanofibril Reinforcement. ACS Sustain. Resour. Manag. 2025, 2, 853–863. [Google Scholar] [CrossRef]

- Ashiwaju, B.I.; Orikpete, O.F.; Fawole, A.A.; Alade, E.Y.; Odogwu, C. A step toward sustainability: A review of biodegradable packaging in the pharmaceutical industry. Matrix Sci. Pharma 2023, 7, 73–84. [Google Scholar] [CrossRef]

- Rahman, M.M.; Khan, K.H.; Parvez, M.M.H.; Irizarry, N.; Uddin, M.N. Polymer nanocomposites with optimized nanoparticle dispersion and enhanced functionalities for industrial applications. Processes 2025, 13, 994. [Google Scholar] [CrossRef]

- Jayalath, S.U.; Alwis, A.P.D. PHA, the Greenest Plastic So Far: Advancing Microbial Synthesis, Recovery, and Sustainable Applications for Circularity. ACS Omega 2025, 10, 32564–32586. [Google Scholar] [CrossRef]

- Pandey, S.; Choudhry, S.; Singh, A. Multifunctional Biopolymers: Types, Preparation, and Industrial Applications. Multifunct. Mater. Eng. Biol. Appl. 2025, 1, 393–418. [Google Scholar]

- Silva, R.R.A.; Marques, C.S.; Arruda, T.R.; Teixeira, S.C.; de Oliveira, T.V. Biodegradation of polymers: Stages, measurement, standards and prospects. Macromol 2023, 3, 371–399. [Google Scholar] [CrossRef]

- Abdelhamid, H.N. Nanotechnology and Biopolymers: A Perfect Synergy for Modern Applications. Mater. Sci. 2024, preprint. [Google Scholar] [CrossRef]

- Singh, A.; Kaur, S.; Thakur, H.; Rashi; Kashyap, S.; Lyudmila, A.; Mudgal, G. Unveiling the transformative power of smart cellulosic nanomaterials: Revisiting potential promises to sustainable future. In Functionalized Cellulose Materials: Sustainable Manufacturing and Applications; Springer: Berlin/Heidelberg, Germany, 2025; pp. 1–42. [Google Scholar]

- Agrawal, K.M.; Barve, B.R.; Khan, S.S. Biogas from pressmud. IOSR J. Mech. Civ. Eng. 2013, 1, 37–41. [Google Scholar]

- Sholokhova, A.; Varžinskas, V.; Rutkaitė, R. Valorization of Agro-waste in Bio-based and Biodegradable Polymer Composites: A Comprehensive Review with Emphasis on Europe Perspective. Waste Biomass Valorization 2025, 16, 1537–1571. [Google Scholar] [CrossRef]

- da Silva, M.; Bastos, R.; Soares, M.; Cerri, B.; Bettani, S.; de Jesus, G.; Ragazzo, G.; Santos, N. Biopolymers in Sugarcane Vinasse Treatment and Valorization. In Agricultural Waste: Environmental Impact, Useful Metabolites and Energy Production; Springer: Berlin/Heidelberg, Germany, 2023; pp. 167–186. [Google Scholar]

- Rashid, A.B.; Haque, M.; Islam, S.M.; Labib, K.R.U. Nanotechnology-enhanced fiber-reinforced polymer composites: Recent advancements on processing techniques and applications. Heliyon 2024, 10, e24692. [Google Scholar] [CrossRef] [PubMed]

- Faheem, M.; Khan, K.A. Harnessing sustainable biocomposites: A review of advances in greener materials and manufacturing strategies. Polym. Bull. 2025, 82, 8827–8870. [Google Scholar] [CrossRef]

- Paiva, C.L.; Ugaya, C.M. Environmental impacts assessment in packaging and its contribution to reducing food waste. Clean. Circ. Bioecon. 2024, 8, 100083. [Google Scholar] [CrossRef]

- Villalba, V.; Kuiper, H.; Gill, E. Review on thermal and mechanical challenges in the development of deployable space optics. J. Astron. Telesc. Instrum. Syst. 2020, 6, 10902. [Google Scholar] [CrossRef]

- Hong, H.; Xiao, R.; Guo, Q.; Liu, H.; Zhang, H. Quantitively Characterizing the Chemical Composition of Tailored Bagasse Fiber and Its Effect on the Thermal and Mechanical Properties of Polylactic Acid-Based Composites. Polymers 2019, 11, 1567. [Google Scholar] [CrossRef]

- Kusuma, H.S.; Permatasari, D.; Umar, W.K.; Sharma, S.K. Sugarcane bagasse as an environmentally friendly composite material to face the sustainable development era. Biomass Convers. Biorefin. 2024, 14, 26693–26706. [Google Scholar] [CrossRef]

- Goyal, A.; Anwar, A.; Kunio, H.; Hidehiko, O. Properties of Sugarcane Bagasse Ash and Its Potential as Cement-Pozzolana Binder. In Proceedings of the 12th International Conference on Structural and Geotechnical Engineering; Ain Shams University, Faculty of Engineering: Cairo, Egypt, 2007; pp. 10–12. [Google Scholar]

- Natarajan, S.; Subramaniyam, S.T.; Kumaravel, V. Fabrication of hydrophobic coatings using sugarcane bagasse waste ash as silica source. Appl. Sci. 2019, 9, 190. [Google Scholar] [CrossRef]

- Souza, A.; Teixeira, S.; Santos, G.; Costa, F.; Longo, E. Reuse of sugarcane bagasse ash (SCBA) to produce ceramic materials. J. Environ. Manag. 2011, 92, 2774–2780. [Google Scholar] [CrossRef] [PubMed]

- Guna, V.; Ilangovan, M.; Hu, C.; Venkatesh, K.; Reddy, N. Valorization of sugarcane bagasse by developing completely biodegradable composites for industrial applications. Ind. Crops Prod. 2019, 131, 25–31. [Google Scholar] [CrossRef]

- Jang, J.K.; Kalina, R.D.; Al-Shmaisani, S.; Ferron, R.D.; Juenger, M.C. Assessing Pozzolanicity of supplementary cementitious materials using ASTM standard test methods. Adv. Civ. Eng. Mater. 2022, 11, 485–499. [Google Scholar] [CrossRef]

- Mahmudul Hasan, M. Investigation of Bagasse Ash as a Partial Supplementary Cementitious Material. Master’s Thesis, Bangladesh University of Engineering and Technology, Dhaka, Bangladesh, 2018. [Google Scholar]

- Assumptor, O.M.; Masika, E.; Thiong’o, K. Probing Optimal Blends of Pozzolans to Develop Supplementary Cementing Material Within Busia County, Kenya. Ph.D. Thesis, Kenyatta University, Nairobi, Kenya, 2024. [Google Scholar]

- Nassiri, S.; Butt, A.A.; Mateos, A.; Roy, S.; Filani, I.; Zarei, A.; Pandit, G.; Haider, M.M.; Harvey, J. Identification of Likely Alternative Supplementary Cementitious Materials in California: A Review of Supplies, Technical Performance in Concrete, Economic, and Climatic Considerations; University of California: Davis, CA, USA, 2024. [Google Scholar]

- Capuano, R. Mechanochemistry: Versatile and Functional Strategy for the Realization and the Recycling of Multi-Phase Materials. Ph.D. Thesis, University of Brescia, Brescia, Italy, 2023. [Google Scholar]

- Keskin, T.; Yilmaz, E.; Kasap, T.; Sari, M.; Cao, S. Toward viable industrial solid residual waste recycling: A review of its innovative applications and future perspectives. Minerals 2024, 14, 943. [Google Scholar] [CrossRef]

- Qamar, S.Z.; Al-Hinai, N.; Márquez, F.P.G. Quality Control and Quality Assurance: Techniques and Applications; BoD–Books on Demand: Norderstedt, Germany, 2024; ISBN 0-85014-024-2. [Google Scholar]

- Onsongo, S.K.; Olukuru, J.; Munyao, O.M.; Mwabonje, O. The role of agricultural ashes (rice husk ash, coffee husk ash, sugarcane bagasse ash, palm oil fuel ash) in cement production for sustainable development in Africa. Discov. Sustain. 2025, 6, 62. [Google Scholar] [CrossRef]

- Singh, A.B.; Khandelwal, C.; Dangayach, G.S. Advancements in healthcare materials: Unraveling the impact of processing techniques on biocompatibility and performance. Polym.-Plast. Technol. Mater. 2024, 63, 1608–1644. [Google Scholar] [CrossRef]

- Chen, S. Thermomechanical Pulp Fines as Additives for 3D Printing Filaments. Master’s Thesis, University of British Columbia, Vancouver, BC, Canada, 2024. [Google Scholar]

- Yaseen, N. Exploring the potential of sugarcane bagasse ash as a sustainable supplementary cementitious material: Experimental investigation and statistical analysis. Results Chem. 2024, 10, 101723. [Google Scholar] [CrossRef]

- Ullah, M.F.; Tang, H.; Ullah, A.; Toth, Z.; Ahmad, M.; Alzlfawi, A. Mechanical and environmental performance of sugarcane Bagasse Ash from Khyber Pakhtunkhwa in sustainable concrete. Sci. Rep. 2025, 15, 24571. [Google Scholar] [CrossRef]

- Gudia, S.E.L.; Go, A.W.; Giduquio, M.B.; Juanir, R.G.; Jamora, J.B.; Gunarto, C.; Tabañag, I.D.F. Sugarcane bagasse ash as a partial replacement for cement in paste and mortar formulation–A case in the Philippines. J. Build. Eng. 2023, 76, 107221. [Google Scholar] [CrossRef]

- Patil, P.P.; Katare, V.D. Development of sustainable alkali-activated binder for building products using sugarcane bagasse ash: A review. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Hauser, P.D.; Fonseca, R.T. Global cooperation and challenges of sustainable development: CDM results and lessons learned for the design of new financial mechanisms. In Environment and Natural Resources; Institute of Applied Economic Research: Rio de Janeiro, Brazil, 2019. [Google Scholar]

- Gbadeyan, O.J.; Sibiya, L.; Mpongwana, N.; Linganiso, L.Z.; Linganiso, E.C.; Deenadayalu, N. Manufacturing of building materials using agricultural waste (sugarcane bagasse ash) for sustainable construction: Towards a low carbon economy. A review. Int. J. Sustain. Eng. 2023, 16, 368–382. [Google Scholar] [CrossRef]

- Chop, H.; Arnold, B.J. Utilization of Coal Wastes for the Production of Ceramic Materials: A Review. Min. Metall. Explor. 2025, 42, 1001–1023. [Google Scholar] [CrossRef]

- Francioso, V.; Lemos-Micolta, E.D.; Elgaali, H.H.; Moro, C.; Rojas-Manzano, M.A.; Velay-Lizancos, M. Valorization of sugarcane bagasse ash as an alternative SCM: Effect of particle size, temperature-crossover effect mitigation & cost analysis. Sustainability 2024, 16, 9370. [Google Scholar] [CrossRef]

- Zaheer, M.M.; Tabish, M. The durability of concrete made up of sugar cane bagasse ash (SCBA) as a partial replacement of cement: A review. Arab. J. Sci. Eng. 2023, 48, 4195–4225. [Google Scholar] [CrossRef]

- Aziz, A.A.; Nassar, H.F.; Al-Shemy, M.T.; Mohamed, O. Boosting the mechanical performance and fire resistivity of white ordinary portland cement pastes via biogenic mesoporous silica nanoparticles. Sci. Rep. 2025, 15, 2909. [Google Scholar] [CrossRef]

- Moraes, J.d.; Cordeiro, G.; Akasaki, J.; Vieira, A.; Payá, J. Improving the reactivity of a former ground sugarcane bagasse ash produced by autogenous combustion through employment of two different additional grinding procedures. Constr. Build. Mater. 2021, 270, 121471. [Google Scholar] [CrossRef]

- Suraneni, P.; Burris, L.; Shearer, C.R.; Hooton, R.D. ASTM C618 fly ash specification: Comparison with other specifications, shortcomings, and solutions. ACI Mater. J. 2021, 118, 157–167. [Google Scholar] [CrossRef]

- Sadoon, A.; Bassuoni, M.; Ghazy, A. Assessment of Oat Husk Ash from Cold Climates as a Supplementary Cementitious Material. J. Mater. Civ. Eng. 2025, 37, 04025371. [Google Scholar] [CrossRef]

- Kalkan, Ö.F. Effect of Grinding Chemicals and Aids on the Grinding Efficiency and the Performance of Portland Cement. Master’s Thesis, Middle East Technical University, Ankara, Turkiye, 2023. [Google Scholar]

- Matias, D.R.M.R.d.A. Optimization of Energy Consumption in the Ceramics Industry: A Techno-Economic Analysis. Master’s Thesis, Politecnico di Milano, Milan, Italy, 2023. [Google Scholar]

- Singh, N.; Sharma, R.; Yadav, K. Sustainable solutions: Exploring Supplementary Cementitious Materials in Construction. Iran. J. Sci. Technol. Trans. Civ. Eng. 2025, 49, 2191–2224. [Google Scholar] [CrossRef]

- Ferraro, C.C.; Paris, J.M.; Riding, K.A.; Townsend, T.G.; Bueno, E.T. Evaluation of Silica-Based Materials for Use in Portland Cement Concrete; Florida Department of Transportation: Tallahassee, FL, USA, 2021. [Google Scholar]

- Caibin, W. Ball Grinding Process. In The ECPH Encyclopedia of Mining and Metallurgy; Springer: Berlin/Heidelberg, Germany, 2024; pp. 117–118. [Google Scholar]

- Alaneme, G.U.; Olonade, K.A.; Esenogho, E.; Lawan, M.M.; Dintwa, E. Artificial intelligence prediction of the mechanical properties of banana peel-ash and bagasse blended geopolymer concrete. Sci. Rep. 2024, 14, 26151. [Google Scholar] [CrossRef] [PubMed]

- Alsarhan, H.; Al-Fakih, A. Performance and sustainability of industrial by-products-based alkali-activated concrete: A review. Multiscale Multidiscip. Model. Exp. Des. 2025, 8, 1–25. [Google Scholar] [CrossRef]

- Paul, A.; Nair, R. Carbon Emission Trading—A Critical Analysis. J. Environ. Law Policy 2024, 12, 145–162. [Google Scholar]

- Murugesan, T.; Athira, G.; Vidjeapriya, R.; Bahurudeen, A. Sustainable opportunities for sugar industries through potential reuse of sugarcane bagasse ash in blended cement production. Sugar Tech 2021, 23, 949–963. [Google Scholar] [CrossRef]

- Yarra, A.; Nakkeeran, G.; Roy, D.; Alaneme, G.U. Evaluation of SCBA-replaced cement for carbon credits and reduction in CO2 emissions. Discov. Appl. Sci. 2025, 7, 114. [Google Scholar] [CrossRef]

- Mohammadi, A.; Ramezanianpour, A.M. Investigating the environmental and economic impacts of using supplementary cementitious materials (SCMs) using the life cycle approach. J. Build. Eng. 2023, 79, 107934. [Google Scholar] [CrossRef]

- Dybka-Stępień, K.; Antolak, H.; Kmiotek, M.; Piechota, D.; Koziróg, A. Disposable food packaging and serving materials—Trends and biodegradability. Polymers 2021, 13, 3606. [Google Scholar] [CrossRef]

- Konde, K.S.; Nagarajan, S.; Kumar, V.; Patil, S.V.; Ranade, V.V. Sugarcane bagasse based biorefineries in India: Potential and challenges. Sustain. Energy Fuels 2021, 5, 52–78. [Google Scholar] [CrossRef]

- Singh, S.P.; Jawaid, M.; Chandrasekar, M.; Senthilkumar, K.; Yadav, B.; Saba, N.; Siengchin, S. Sugarcane wastes into commercial products: Processing methods, production optimization and challenges. J. Clean. Prod. 2021, 328, 129453. [Google Scholar] [CrossRef]

- Global Strategy for Food Safety 2022–2030: Towards Stronger Food Safety Systems and Global Cooperation; World Health Organization: Geneva, Switzerland, 2022; ISBN 92-4-005768-4.

- Karim, A.; Raji, Z.; Habibi, Y.; Khalloufi, S. A review on the hydration properties of dietary fibers derived from food waste and their interactions with other ingredients: Opportunities and challenges for their application in the food industry. Crit. Rev. Food Sci. Nutr. 2024, 64, 11722–11756. [Google Scholar] [CrossRef]

- Kumar, B.; Pimentel, J.; Cano-Londoño, N.A.; Ruiz-Mercado, G.J.; Deak, C.T.; Cabezas, H. Designing cost-effective supply chains for plastics at the end-of-life. J. Clean. Prod. 2025, 501, 145227. [Google Scholar] [CrossRef]

- Moshood, T.D.; Mahmud, F.; Nawanir, G.; Ahmad, M.H.; Mohamad, F.; AbdulGhani, A. Sustainable adoption of biodegradable plastics: A quantitative analysis of determinants and consumer behaviour in developing economies. Manag. Environ. Qual. Int. J. 2025, 36, 706–740. [Google Scholar] [CrossRef]

- Etuk, S.E.; Robert, U.W.; Agbasi, O.E.; Inyang, N.J. Evaluation of thermophysical and strength properties of composite panels produced from sugarcane bagasse and waste newspapers. Adv. Mater. Sci. 2023, 23, 19–31. [Google Scholar] [CrossRef]

- Barthwal, S.; Uniyal, S.; Barthwal, S. Nature-inspired superhydrophobic coating materials: Drawing inspiration from nature for enhanced functionality. Micromachines 2024, 15, 391. [Google Scholar] [CrossRef]

- Czepiel, M.; Bańkosz, M.; Sobczak-Kupiec, A. Advanced injection molding methods. Materials 2023, 16, 5802. [Google Scholar] [CrossRef]

- Haile, A.; Gelebo, G.G.; Tesfaye, T.; Mengie, W.; Mebrate, M.A.; Abuhay, A.; Limeneh, D.Y. Pulp and paper mill wastes: Utilizations and prospects for high value-added biomaterials. Bioresour. Bioprocess. 2021, 8, 35. [Google Scholar] [CrossRef]

- Hielm, A.; Sampson, G.; Pampin, M.P.; Treweek, J.; McCord, M.; Newsom, M.D.; Thorning, A.; Monaghan, J.; De Olde, E.; Heilandt, T. Improving Standards and Certification in Agri-Food Supply Chains: Ensuring Safety, Sustainability and Social Responsibility; Burleigh Dodds Science Publishing: Cambridge, UK, 2024; Volume 148, ISBN 1-80146-452-9. [Google Scholar]

- Hossam, Y.; Fahim, I.S. Towards a circular economy: Fabrication and characterization of biodegradable plates from sugarcane waste. Front. Sustain. Food Syst. 2023, 7, 1220324. [Google Scholar] [CrossRef]

- Afshar, S.V.; Boldrin, A.; Christensen, T.H.; Corami, F.; Daugaard, A.E.; Rosso, B.; Hartmann, N.B. Disintegration of commercial biodegradable plastic products under simulated industrial composting conditions. Sci. Rep. 2025, 15, 8569. [Google Scholar] [CrossRef]

- Domínguez-Solera, E.; Gadaleta, G.; Ferrero-Aguar, P.; Navarro-Calderón, Á.; Escrig-Rondán, C. The biodegradability of plastic products for agricultural application: European regulations and technical criteria. Clean Technol. 2025, 7, 11. [Google Scholar] [CrossRef]

- Santos, T.J.C.d. Organization and Management of Maintenance Indexed to Risk Factors in Healthcare Environment. Master’s Thesis, Polytechnic Institute of Coimbra, Coimbra, Portugal, 2017. [Google Scholar]

- Thapliyal, D.; Karale, M.; Diwan, V.; Kumra, S.; Arya, R.K.; Verros, G.D. Current status of sustainable food packaging regulations: Global perspective. Sustainability 2024, 16, 5554. [Google Scholar] [CrossRef]

- Bijimol, B.I.; Elias, L.; Sreelekshmy, B.R.; Shibli, S.M.A. Effective Exploitation of Sugarcane Byproducts and Industrial Effluents for Strategic Energy Applications: A Review on Recent Developments and Approaches with Special Reference to Microbial Fuel Cells. ACS Appl. Bio Mater. 2025, 8, 3657–3690. [Google Scholar] [CrossRef]

- Ding, Z.; Grundmann, P. Understanding system interdependencies in sustainable paper production from residue grass biomass: Insights from fuzzy cognitive mapping. Sci. Rep. 2025, 15, 1398. [Google Scholar] [CrossRef] [PubMed]

- Rainey, T.J.; Covey, G. Pulp and paper production from sugarcane bagasse. In Sugarcane-Based Biofuels and Bioproducts; John Wiley and Sons: Hoboken, NJ, USA, 2016; pp. 259–280. [Google Scholar]

- Andrade, M.F.; Colodette, J.L. Dissolving pulp production from sugar cane bagasse. Ind. Crops Prod. 2014, 52, 58–64. [Google Scholar] [CrossRef]

- Ashori, A.; Marashi, M.; Ghasemian, A.; Afra, E. Utilization of sugarcane molasses as a dry-strength additive for old corrugated container recycled paper. Compos. Part B Eng. 2013, 45, 1595–1600. [Google Scholar] [CrossRef]

- Sharma, M.; Durães, L.; Soares, B.; Alves, J.L.; Ferreira, P.J. Strengthening of sustainable packaging: Impact of microfibrillated cellulose in the presence of industrial white-water. Cellulose 2025, 32, 4387–4401. [Google Scholar] [CrossRef]

- Sathish, M.; Radhika, N.; Venuvanka, N.; Rajeshkumar, L. A review on sustainable properties of plant fiber-reinforced polymer composites: Characteristics and properties. Polym. Int. 2024, 73, 887–943. [Google Scholar] [CrossRef]

- Rajan, K.; Berton, P.; Rogers, R.D.; Shamshina, J.L. Is Kraft Pulping the Future of Biorefineries? A Perspective on the Sustainability of Lignocellulosic Product Development. Polymers 2024, 16, 3438. [Google Scholar] [CrossRef]

- Li, J.; Wei, X.; Wang, Q.; Chen, J.; Chang, G.; Kong, L.; Su, J.; Liu, Y. Homogeneous isolation of nanocellulose from sugarcane bagasse by high pressure homogenization. Carbohydr. Polym. 2012, 90, 1609–1613. [Google Scholar] [CrossRef]

- Zhong, Z.-W. Processes for environmentally friendly and/or cost-effective manufacturing. Mater. Manuf. Process. 2021, 36, 987–1009. [Google Scholar] [CrossRef]

- Barbosa, L.d.S.N.S.; Hytönen, E.; Vainikka, P. Carbon mass balance in sugarcane biorefineries in Brazil for evaluating carbon capture and utilization opportunities. Biomass Bioenergy 2017, 105, 351–363. [Google Scholar] [CrossRef]

- Khan, M.F. Recent advances in microbial enzyme applications for sustainable textile processing and waste management. Sci 2025, 7, 46. [Google Scholar] [CrossRef]

- El-Feky, M.; Badawy, A.H.; Helal, Y. Nanotechnology-Enabled Innovations in Cement: Enhancing Durability, and Impact Load Resistance with Nanocellulose, Nano Silica, and Nano Clay Additives. Egypt. J. Chem. 2025, 68, 223–231. [Google Scholar] [CrossRef]

- Shen, D.; Chen, L.; Wu, S.; Chen, K.; Qi, D.; Zhu, S. Fibrillation in cellulose-based Lyocell: Chemical insights, engineering solutions and emerging challenges. Carbohydr. Polym. 2025, 363, 123722. [Google Scholar] [CrossRef]

- Kichonge, B.; Kivevele, T. Viability of non-edible oilseed plants and agricultural wastes as feedstock for biofuels production: A techno-economic review from an African perspective. Biofuels Bioprod. Biorefin. 2023, 17, 1382–1410. [Google Scholar] [CrossRef]

- Markevičiūtė, Z. Creation of a Biodegradable Paper-Based Packaging Material with Additives Enhancing Biodegradability in the Context of the Circular Economy. Ph.D. Thesis, Kaunas University of Technology, Kaunas, Lithuania, 2025. [Google Scholar]

- Kumar, B. A Comprehensive Analysis of Sugarcane Bagasse as a Sustainable Solution for Environmentally Friendly Paper Manufacturing. In The Economics of Learning: Shaping Student Welfare and Society; Board of Editors, Ed.; Bharti Publications: New Delhi, India, 2024; pp. 24–35. ISBN 978-81-976277-2-9. [Google Scholar]

- Yadav, M.; Maurya, A.K.; Chaurasia, S.K. Eco-friendly polymer composites for green packaging: Environmental policy, governance and legislation. In Sustainable Packaging Strengthened by Biomass; Elsevier: Amsterdam, The Netherlands, 2025; pp. 317–346. [Google Scholar]

- Moutinho, L.G.; Soares, E.; Oliveira, M. Bio-based thermoplastic composites reinforced with natural fillers for sustainable packaging: A comprehensive review. Polym. Compos. 2025, 46, 9703–9727. [Google Scholar] [CrossRef]

- Priya, A.; Alagumalai, A.; Balaji, D.; Song, H. Bio-based agricultural products: A sustainable alternative to agrochemicals for promoting a circular economy. RSC Sustain. 2023, 1, 746–762. [Google Scholar] [CrossRef]

- Chandel, S.; Shaji, A.; Chutturi, M. Life Cycle Assessment of Biocomposites: Environmental Impacts and Sustainability Perspectives. In Innovations and Applications of Advanced Biomaterials in Healthcare and Engineering; IGI Global Scientific Publishing: Hershey, PA, USA, 2025; pp. 439–502. [Google Scholar]

- Omran, A.A.B.; Mohammed, A.A.; Sapuan, S.; Ilyas, R.; Asyraf, M.; Rahimian Koloor, S.S.; Petrů, M. Micro-and nanocellulose in polymer composite materials: A review. Polymers 2021, 13, 231. [Google Scholar] [CrossRef]

- Mandal, A.; Chakrabarty, D. Isolation of nanocellulose from waste sugarcane bagasse (SCB) and its characterization. Carbohydr. Polym. 2011, 86, 1291–1299. [Google Scholar] [CrossRef]

- Lee, W.; Kim, J.; Lee, T.G. Certifications and testing methods for biodegradable plastics. Rev. Chem. Eng. 2025, 41, 125–146. [Google Scholar] [CrossRef]

- Trache, D.; Tarchoun, A.F.; Derradji, M.; Hamidon, T.S.; Masruchin, N.; Brosse, N.; Hussin, M.H. Nanocellulose: From fundamentals to advanced applications. Front. Chem. 2020, 8, 392. [Google Scholar] [CrossRef]

- Catarino, M.L.; Sampaio, F.; Gonçalves, A.L. Sustainable Wet Processing Technologies for the Textile Industry: A Comprehensive Review. Sustainability 2025, 17, 3041. [Google Scholar] [CrossRef]

- Rao, H.J.; Singh, S.; Ramulu, P.J.; Singh, N.; Santos, T.F.; Santos, C.M.; Nadar, N.R.; Kumar, G.D. Nature-inspired nano cellulose materials, advancements in nano cellulose preparation and versatile applications. In Nanocellulose-Sources, Preparations, and Applications; IntechOpen: London, UK, 2024; ISBN 1-83769-259-9. [Google Scholar]

- Pascoli, D.U. Nanocellulose Production from Low-Cost Agricultural Residues: Process Development, Economic Assessment, and Process Robustness; University of Washington: Washington, DC, USA, 2022; ISBN 979-8-3514-3969-3. [Google Scholar]

- Afolalu, S.A.; Ikumapayi, O.M.; Ogedengbe, T.S.; Kazeem, R.A.; Ogundipe, A.T. Waste pollution, wastewater and effluent treatment methods—An overview. Mater. Today Proc. 2022, 62, 3282–3288. [Google Scholar] [CrossRef]

- Krexner, T.; Bauer, A.; Zollitsch, W.; Weiland, K.; Bismarck, A.; Mautner, A.; Medel-Jiménez, F.; Gronauer, A.; Kral, I. Environmental life cycle assessment of nano-cellulose and biogas production from manure. J. Environ. Manag. 2022, 314, 115093. [Google Scholar] [CrossRef] [PubMed]

- Fekiač, J.J.; Krbata, M.; Kohutiar, M.; Janík, R.; Kakošová, L.; Breznická, A.; Eckert, M.; Mikuš, P. Comprehensive Review: Optimization of Epoxy Composites, Mechanical Properties, & Technological Trends. Polymers 2025, 17, 271. [Google Scholar] [CrossRef]

- Silva, F.A.; Dourado, F.; Gama, M.; Poças, F. Nanocellulose bio-based composites for food packaging. Nanomaterials 2020, 10, 2041. [Google Scholar] [CrossRef]

- Tofanica, B.-M.; Mikhailidi, A.; Fortună, M.E.; Rotaru, R.; Ungureanu, O.C.; Ungureanu, E. Cellulose Nanomaterials: Characterization Methods, Isolation Techniques, and Strategies. Crystals 2025, 15, 352. [Google Scholar] [CrossRef]

- Castellanos, H.G.; Aryanfar, Y.; Mohtaram, S.; Keçebaş, A.; Karaca-Dolgun, G.; Ahmad, S.; Asiri, A.N.M.; Islam, S. The efficacy of nano-cellulose-based composites in heavy metal removal from wastewater: A comprehensive review. J. Chem. Technol. Biotechnol. 2025, 100, 291–312. [Google Scholar] [CrossRef]

- Yazdizadeh, M.; Nasr, M.J.; Safekordi, A. A new catalyst for the production of furfural from bagasse. RSC Adv. 2016, 6, 55778–55785. [Google Scholar] [CrossRef]

- Franca-Oliveira, G.; Fornari, T.; Hernández-Ledesma, B. A review on the extraction and processing of natural source-derived proteins through eco-innovative approaches. Processes 2021, 9, 1626. [Google Scholar] [CrossRef]

- Abdel-Hakim, A.; Mouradb, R.M. Nanocellulose and its polymer composites: Preparation, characterization, and applications. Russ. Chem. Rev 2023, 92, 5076. [Google Scholar] [CrossRef]

- Ramnani, P.; Singh, R.; Gupta, R. Keratinolytic potential of Bacillus licheniformis RG1: Structural and biochemical mechanism of feather degradation. Can. J. Microbiol. 2005, 51, 191–196. [Google Scholar] [CrossRef] [PubMed]

- Qi, X.; Wei, W.; Shen, J.; Dong, W. Salecan polysaccharide-based hydrogels and their applications: A review. J. Mater. Chem. B 2019, 7, 2577–2587. [Google Scholar] [CrossRef]

- Harrats, C.; Groeninckx, G. Reactive Processing of Polymer Blend Using Reactive Compatibilization and Dynamic Crosslinking: Phase Morphology Control and Microstructure–Property Relations. Modif. Blending Synth. Nat. Macromol. 2004, 175, 155–199. [Google Scholar]

- Chen, S.; Ding, L.; Hou, J.; Wang, J. Glucose-Based Surfactants for the Oil and Gas Industry: A Review. Energy Fuels 2025, 47, 16100–16131. [Google Scholar] [CrossRef]

- Singh, S.; Johri, P.; Trivedi, M.; Lopez-Sanchez, P. Green Biotechnology for Herbal and Medicinal Plant Metabolites; CRC Press: Boca Raton, FL, USA, 2025; ISBN 1-040-34011-3. [Google Scholar]

- Sharmile, N.; Chowdhury, R.R.; Desai, S. A comprehensive review of quality control and reliability research in micro–nano technology. Technologies 2025, 13, 94. [Google Scholar] [CrossRef]

- Bechthold, I.; Bretz, K.; Kabasci, S.; Kopitzky, R.; Springer, A. Succinic acid: A new platform chemical for biobased polymers from renewable resources. Chem. Eng. Technol. 2008, 31, 647–654. [Google Scholar] [CrossRef]

- Corona-González, R.I.; Varela-Almanza, K.M.; Arriola-Guevara, E.; Martínez-Gómez, Á.d.J.; Pelayo-Ortiz, C.; Toriz, G. Bagasse hydrolyzates from Agave tequilana as substrates for succinic acid production by Actinobacillus succinogenes in batch and repeated batch reactor. Bioresour. Technol. 2016, 205, 15–23. [Google Scholar] [CrossRef]

- Chen, J.; Yang, S.; Alam, M.d.A.; Wang, Z.; Zhang, J.; Huang, S.; Zhuang, W.; Xu, C.; Xu, J. Novel biorefining method for succinic acid processed from sugarcane bagasse. Bioresour. Technol. 2021, 324, 124615. [Google Scholar] [CrossRef]

- Gottardo, S.; Mech, A.; Drbohlavová, J.; Małyska, A.; Bøwadt, S.; Sintes, J.R.; Rauscher, H. Towards safe and sustainable innovation in nanotechnology: State-of-play for smart nanomaterials. NanoImpact 2021, 21, 100297. [Google Scholar] [CrossRef]

- Dulie, N.W.; Woldeyes, B.; Demsash, H.D. Synthesis of lignin-carbohydrate complex-based catalyst from Eragrostis tef straw and its catalytic performance in xylose dehydration to furfural. Int. J. Biol. Macromol. 2021, 171, 10–16. [Google Scholar] [CrossRef]

- Trung, T.Q.; Thinh, D.B.; Anh, T.N.M.; Nguyet, D.M.; Quan, T.H.; Viet, N.Q.; Tuan, T.T.; Dat, N.M.; Nam, H.M.; Hieu, N.H. Synthesis of furfural from sugarcane bagasse by hydrolysis method using magnetic sulfonated graphene oxide catalyst. Vietnam J. Chem. 2020, 58, 245–250. [Google Scholar] [CrossRef]

- Yu, S.-B.; Lin, F.; Tian, J.; Yu, J.; Zhang, D.-W.; Li, Z.-T. Water-soluble and dispersible porous organic polymers: Preparation, functions and applications. Chem. Soc. Rev. 2022, 51, 434–449. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, A.T. Design and Investment of High Voltage Nanodielectrics; IGI Global: Hershey, PA, USA, 2020; ISBN 1-7998-3830-7. [Google Scholar]

- Zhang, Y.; Luan, H.; Qiu, W.; Zhang, X.; Wang, H.; Liu, M.; Song, P. Advances in vanillin synthesis: Focusing on microbial synthesis pathways and prospects. World J. Microbiol. Biotechnol. 2025, 41, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Buchner, G.A.; Stepputat, K.J.; Zimmermann, A.W.; Schomäcker, R. Specifying technology readiness levels for the chemical industry. Ind. Eng. Chem. Res. 2019, 58, 6957–6969. [Google Scholar] [CrossRef]

- Kumar, V.; Yadav, S.K.; Kumar, J.; Ahluwalia, V. A critical review on current strategies and trends employed for removal of inhibitors and toxic materials generated during biomass pretreatment. Bioresour. Technol. 2020, 299, 122633. [Google Scholar] [CrossRef]

- D’Arrigo, P.; Rossato, L.A.; Strini, A.; Serra, S. From waste to value: Recent insights into producing vanillin from lignin. Molecules 2024, 29, 442. [Google Scholar] [CrossRef]

- Yılbaşı, Z. Biofuels, E-Fuels, and Waste-Derived Fuels: Advances, Challenges, and Future Directions. Sustainability 2025, 17, 6145. [Google Scholar] [CrossRef]

- Dulie, N.W.; Woldeyes, B.; Demsash, H.D. Xylose Release from Sugarcane Bagasse via Acid-Catalyzed Hydrothermal Reaction and Its Conversion into Furfural Using Teff (Eragrostis tef) Straw-Based Catalyst. Waste Biomass Valorization 2022, 13, 955–965. [Google Scholar] [CrossRef]

- Banerjee, G.; Chattopadhyay, P. Vanillin biotechnology: The perspectives and future. J. Sci. Food Agric. 2019, 99, 499–506. [Google Scholar] [CrossRef]

- Singh, M.; Kumar, S.; Ali, H.; Singh, S.; Kansal, S.K. Valorization of lignocellulosic biomass into high-value chemicals: Forging a route towards the circular economy. In Energy Materials; CRC Press: Boca Raton, FL, USA, 2024; pp. 98–133. ISBN 1-003-26977-X. [Google Scholar]

- Alemde, V. Innovative process technologies: Advancing efficiency and sustainability through optimization and control. Int. J. Res. Publ. Rev. 2025, 6, 1941–1955. [Google Scholar] [CrossRef]

- Formann, S.; Hahn, A.; Janke, L.; Stinner, W.; Sträuber, H.; Logroño, W.; Nikolausz, M. Beyond sugar and ethanol production: Value generation opportunities through sugarcane residues. Front. Energy Res. 2020, 8, 579577. [Google Scholar] [CrossRef]

- Qi, B.; Chen, X.; Shen, F.; Su, Y.; Wan, Y. Optimization of enzymatic hydrolysis of wheat straw pretreated by alkaline peroxide using response surface methodology. Ind. Eng. Chem. Res. 2009, 48, 7346–7353. [Google Scholar] [CrossRef]

- Sindhu, R.; Kuttiraja, M.; Binod, P.; Janu, K.U.; Sukumaran, R.K.; Pandey, A. Dilute acid pretreatment and enzymatic saccharification of sugarcane tops for bioethanol production. Bioresour. Technol. 2011, 102, 10915–10921. [Google Scholar] [CrossRef] [PubMed]

- Sadik, M.W.; Halema, A.A. Production of ethanol from molasses and whey permeate using yeasts and bacterial strains. Int. J. Curr. Microbiol. App. Sci 2014, 3, 804–818. [Google Scholar]

- Domingues, R.; Bondar, M.; Palolo, I.; Queirós, O.; de Almeida, C.D.; Cesário, M.T. Xylose metabolism in bacteria—Opportunities and challenges towards efficient lignocellulosic biomass-based biorefineries. Appl. Sci. 2021, 11, 8112. [Google Scholar] [CrossRef]

- Sobti, R.; Sharma, A.; Soni, S.K. Applications of Biotechnological Techniques in Mitigating Environmental Concerns. In Genomic, Proteomics, and Biotechnology; CRC Press: Boca Raton, FL, USA, 2022; pp. 249–312. [Google Scholar]

- Paschoa, J.L.; Avila, P.F.; Ramalho, E.X.; Silva, M.F.; Bueno, D.; Goldbeck, R. Production and purification of xylooligossaccharides from sugarcane bagasse and antioxidant potential assessment for functional ingredient application in the food industry. Ind. Crops Prod. 2024, 208, 117844. [Google Scholar] [CrossRef]

- Bloch, P.-Y. Industrialisation of the Production of a Technological Innovation with a Significant Environmental Gain Potential: Application to Bio-Enzymatic Cells. Ph.D. Thesis, University of Grenoble Alpes, Saint-Martin-d’Hères, France, 2024. [Google Scholar]

- Arshad, M.; Ahmed, S. Cogeneration through bagasse: A renewable strategy to meet the future energy needs. Renew. Sustain. Energy Rev. 2016, 54, 732–737. [Google Scholar] [CrossRef]

- Su, G.; Jiang, P.; Zhou, H.; Zulkifli, N.W.M.; Ong, H.C.; Ibrahim, S. Integrated production of methanol and biochar from bagasse and plastic waste: A three-in-one solution for carbon sequestration, bioenergy production, and waste valorization. Energy Convers. Manag. 2024, 307, 118344. [Google Scholar] [CrossRef]

- Lynd, L.R.; Beckham, G.T.; Guss, A.M.; Jayakody, L.N.; Karp, E.M.; Maranas, C.; McCormick, R.L.; Amador-Noguez, D.; Bomble, Y.J.; Davison, B.H. Toward low-cost biological and hybrid biological/catalytic conversion of cellulosic biomass to fuels. Energy Environ. Sci. 2022, 15, 938–990. [Google Scholar] [CrossRef]

- Osaki, M.R. An energy optimization model comparing the use of sugarcane bagasse for power or ethanol production. Ind. Crops Prod. 2022, 187, 115284. [Google Scholar] [CrossRef]

- Laszlo, J.A. Preparing an Ion Exchange Resin from Sugarcane Bagasse to Remove Reactive Dye from Wastewater. EBSCOhost. Available online: https://openurl.ebsco.com/contentitem/gcd:31830969?sid=ebsco:plink:crawler&id=ebsco:gcd:31830969 (accessed on 19 August 2025).

- Rodier, L.; Bilba, K.; Onésippe, C.; Arsène, M.-A. Utilization of bio-chars from sugarcane bagasse pyrolysis in cement-based composites. Ind. Crops Prod. 2019, 141, 111731. [Google Scholar] [CrossRef]

- Okonkwo, C.A.; Menkiti, M.C.; Obiora-Okafo, I.A.; Ezenwa, O.N. Controlled pyrolysis of sugarcane bagasse enhanced mesoporous carbon for improving capacitance of supercapacitor electrode. Biomass Bioenergy 2021, 146, 105996. [Google Scholar] [CrossRef]

- Ramaraj, B. Mechanical and thermal properties of polypropylene/sugarcane bagasse composites. J. Appl. Polym. Sci. 2007, 103, 3827–3832. [Google Scholar] [CrossRef]

- Janjaturaphan, S.; Wansom, S. Pozzolanic activity of industrial sugar cane bagasse ash. Suranaree J. Sci. Technol. 2010, 17, 487–498. [Google Scholar]

- Jaturapiree, A.; Saowapark, T.; Sukrat, K.; Chaichana, E. Hydrothermal Extraction of Cellulose from Sugarcane Bagasse for Production of Biodegradable Food Containers. Recycling 2025, 10, 110. [Google Scholar] [CrossRef]

- Jackson de Moraes Rocha, G.; Martin, C.; Soares, I.B.; Souto Maior, A.M.; Baudel, H.M.; Moraes de Abreu, C.A. Dilute mixed-acid pretreatment of sugarcane bagasse for ethanol production. Biomass Bioenergy 2011, 35, 663–670. [Google Scholar] [CrossRef]

- Wanderley, M.C.d.A.; Martín, C.; Rocha, G.J.d.M.; Gouveia, E.R. Increase in ethanol production from sugarcane bagasse based on combined pretreatments and fed-batch enzymatic hydrolysis. Bioresour. Technol. 2013, 128, 448–453. [Google Scholar] [CrossRef]

- Gottschalk, L.M.F.; Oliveira, R.A.; Bon, E.P.d.S. Cellulases, xylanases, β-glucosidase and ferulic acid esterase produced by Trichoderma and Aspergillus act synergistically in the hydrolysis of sugarcane bagasse. Biochem. Eng. J. 2010, 51, 72–78. [Google Scholar] [CrossRef]

- Manavalan, T.; Manavalan, A.; Thangavelu, K.P.; Heese, K. Secretome analysis of Ganoderma lucidum cultivated in sugarcane bagasse. J. Proteom. 2012, 77, 298–309. [Google Scholar] [CrossRef]

- Lamounier, K.F.R.; Rodrigues, P.O.; Pasquini, D.; Baffi, M.A. Saccharification of Sugarcane Bagasse Using an Enzymatic Extract Produced by Aspergillus fumigatus. J. Renew. Mater. 2018, 6, 169–175. [Google Scholar] [CrossRef]

- Mohammadi, A.; Nasernejad, B. Enzymatic degradation of anthracene by the white rot fungus Phanerochaete chrysosporium immobilized on sugarcane bagasse. J. Hazard. Mater. 2009, 161, 534–537. [Google Scholar] [CrossRef] [PubMed]

- Mazutti, M.; Bender, J.P.; Treichel, H.; Luccio, M.D. Optimization of inulinase production by solid-state fermentation using sugarcane bagasse as substrate. Enzym. Microb. Technol. 2006, 39, 56–59. [Google Scholar] [CrossRef]

- Rajagopalan, G.; Krishnan, C. α-Amylase production from catabolite derepressed Bacillus subtilis KCC103 utilizing sugarcane bagasse hydrolysate. Bioresour. Technol. 2008, 99, 3044–3050. [Google Scholar] [CrossRef] [PubMed]

- Bian, J.; Peng, F.; Peng, X.-P.; Peng, P.; Xu, F.; Sun, R.-C. Structural features and antioxidant activity of xylooligosaccharides enzymatically produced from sugarcane bagasse. Bioresour. Technol. 2013, 127, 236–241. [Google Scholar] [CrossRef]

- Brienzo, M.; Carvalho, W.; Milagres, A.M.F. Xylooligosaccharides Production from Alkali-Pretreated Sugarcane Bagasse Using Xylanases from Thermoascus aurantiacus. Appl. Biochem. Biotechnol. 2010, 162, 1195–1205. [Google Scholar] [CrossRef]

- Acosta Fernandez, R.A.; Viviescas, P.; Sandoval, M.; Nabarlatz, D. Autohydrolysis of sugar cane bagasse and empty fruit bunch: Kinetics model and analysis of xylo-oligosaccharides yield. Chem. Eng. Trans. 2018, 65, 307–312. [Google Scholar] [CrossRef]

- Silalertruksa, T.; Gheewala, S.H.; Pongpat, P. Sustainability assessment of sugarcane biorefinery and molasses ethanol production in Thailand using eco-efficiency indicator. Appl. Energy 2015, 160, 603–609. [Google Scholar] [CrossRef]

- Adeniyi, A.G.; Ighalo, J.O. Biosorption of pollutants by plant leaves: An empirical review. J. Environ. Chem. Eng. 2019, 7, 103100. [Google Scholar] [CrossRef]

- Xiong, W. Bagasse composites: A review of material preparation, attributes, and affecting factors. J. Thermoplast. Compos. Mater. 2018, 31, 1112–1146. [Google Scholar] [CrossRef]

- Thaha, A.N.; Ghamari, M.; Jothiprakash, G.; Velusamy, S.; Karthikeyan, S.; Ramesh, D.; Sundaram, S. High Impact Biomass Valorization for Second Generation Biorefineries in India: Recent Developments and Future Strategies for Sustainable Circular Economy. Biomass 2025, 5, 16. [Google Scholar] [CrossRef]

- Chandel, A.K.; Da Silva, S.S.; Carvalho, W.; Singh, O.V. Sugarcane bagasse and leaves: Foreseeable biomass of biofuel and bio-products. J. Chem. Technol. Biotechnol. 2012, 87, 11–20. [Google Scholar] [CrossRef]

- Khoo, R.; Chow, W.; Ismail, H. Sugarcane bagasse fiber and its cellulose nanocrystals for polymer reinforcement and heavy metal adsorbent: A review. Cellulose 2018, 25, 4303–4330. [Google Scholar] [CrossRef]