Design and Performance Evaluation of an Automated Bud Grafting Machine for Cucurbitaceous Seedlings

Abstract

1. Introduction

- (1)

- To reveal the mechanism of seedling damage during the clamping, cutting, and bonding processes of Cucurbitaceae seedlings, and establish an integrated automatic grafting machine integrating “clamping-cutting-bonding-binding”;

- (2)

- To realize automatic grafting operations for Cucurbitaceae plug seedlings, with core technical indicators reaching: seedling damage rate less than 3%, grafting efficiency greater than 1400 plants per hour, interface fit degree greater than 95%, and grafting success rate greater than 90%;

- (3)

- To provide efficient and low-damage automatic equipment for large-scale grafting of Cucurbitaceae vegetables, promoting highly automated operations in the grafting link of protected agriculture.

2. Materials and Methods

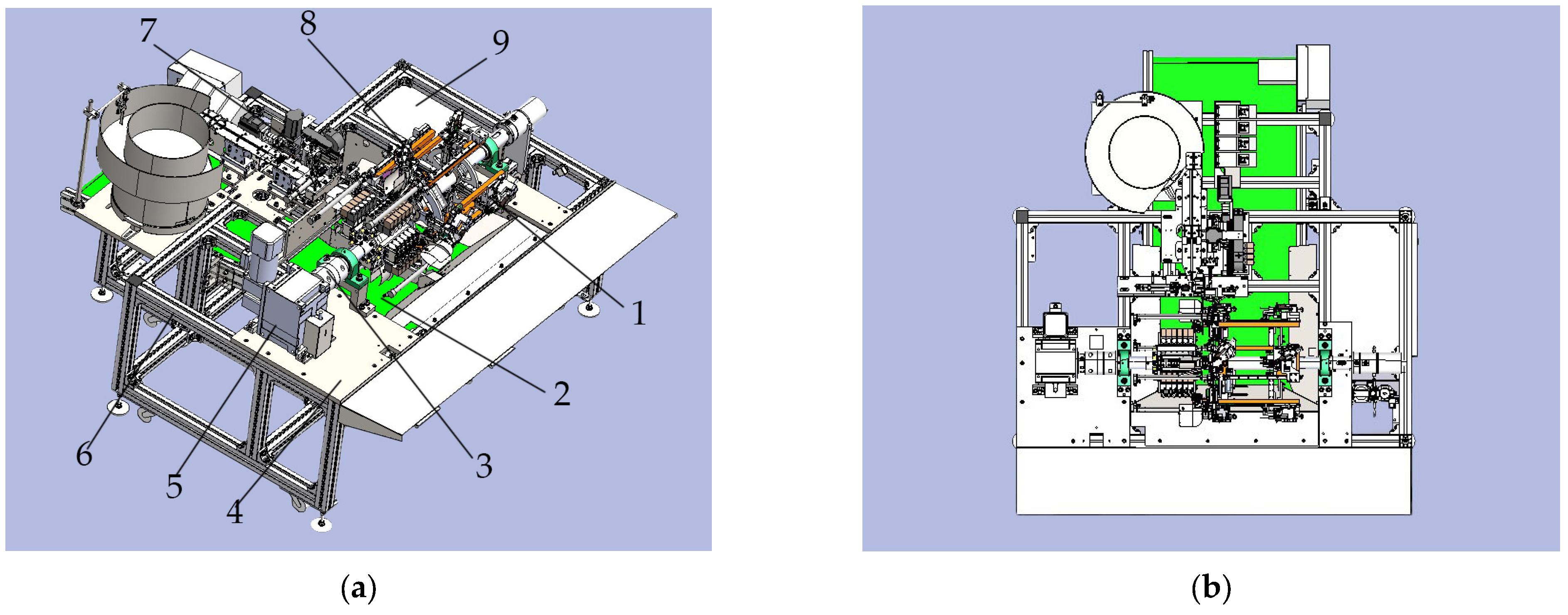

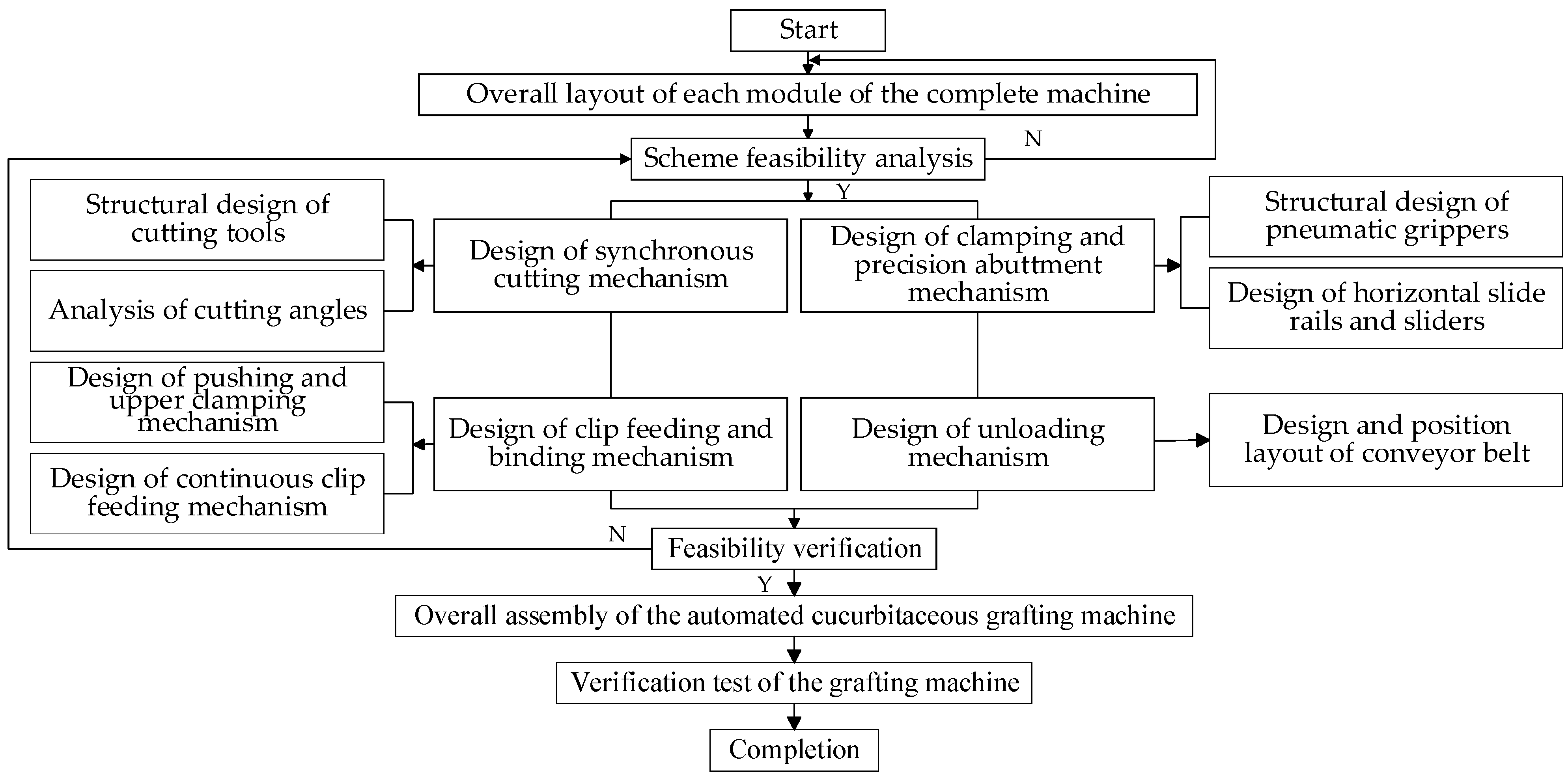

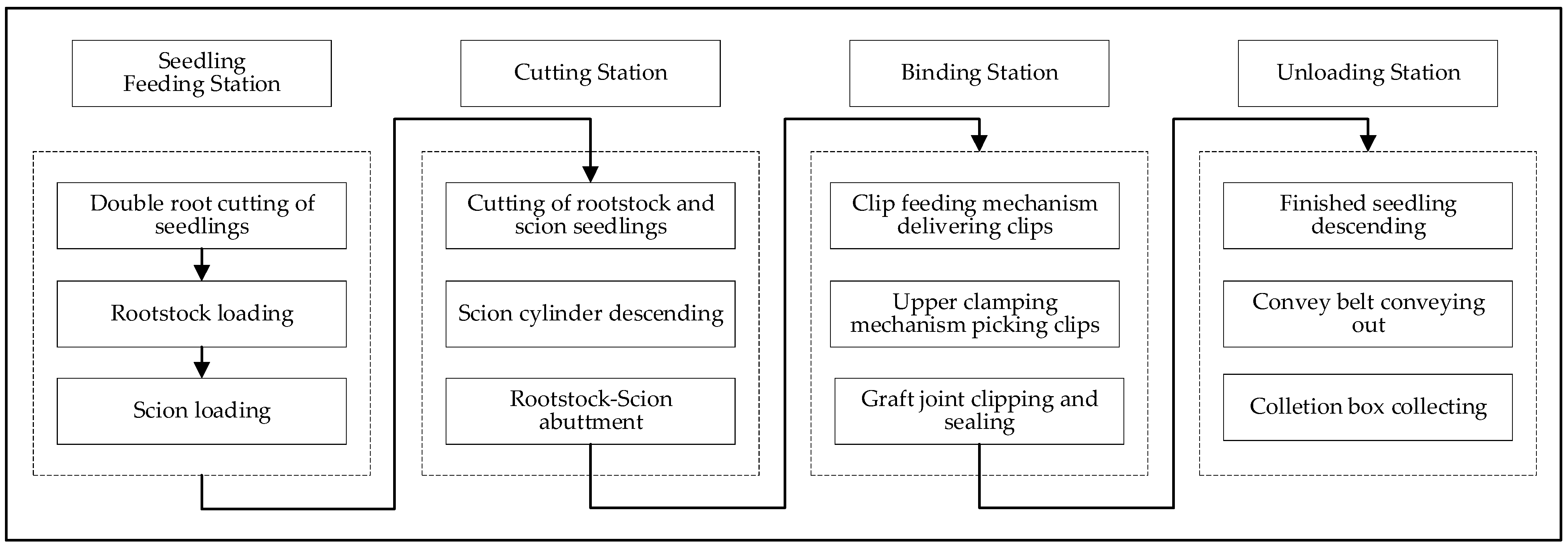

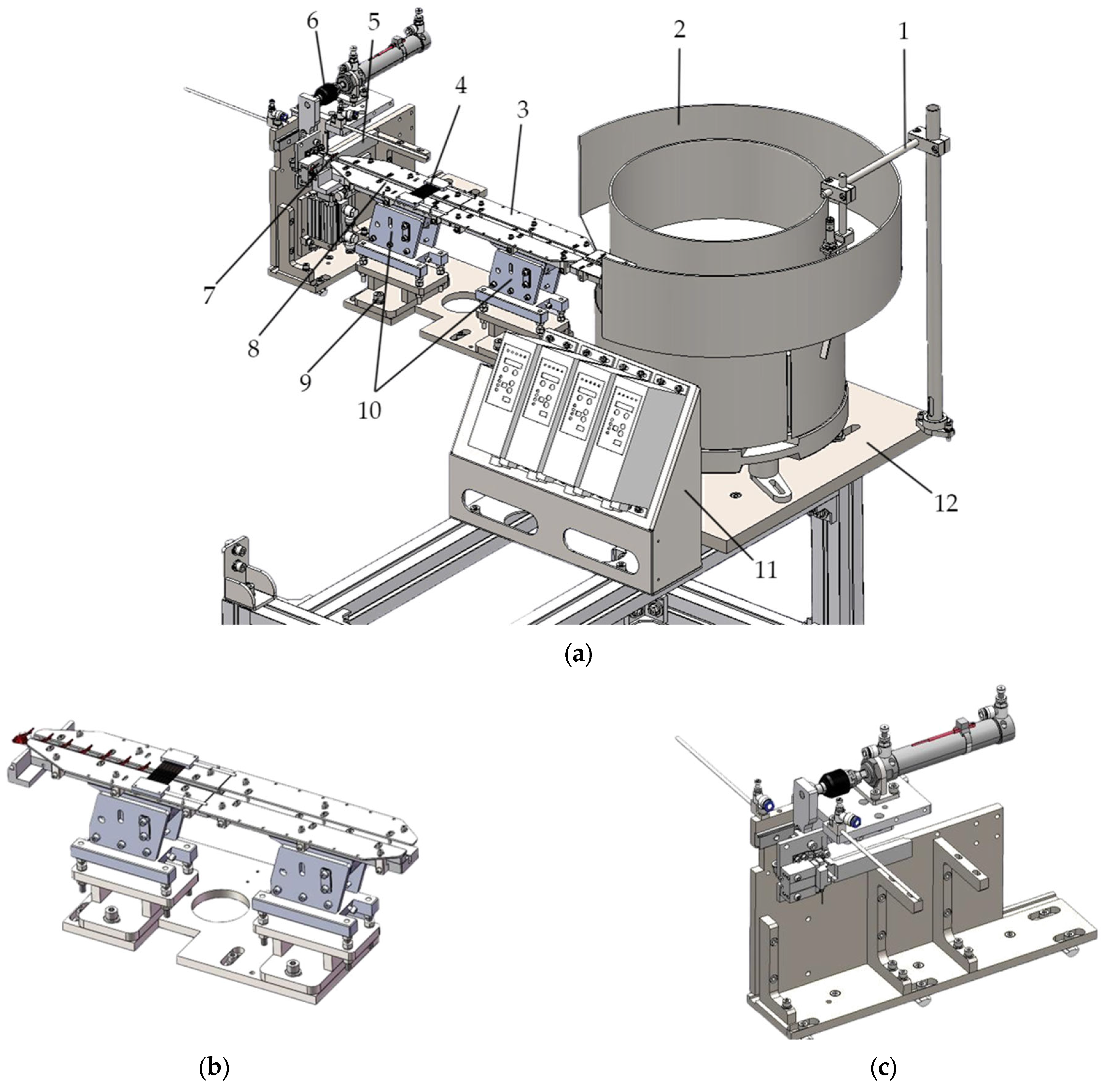

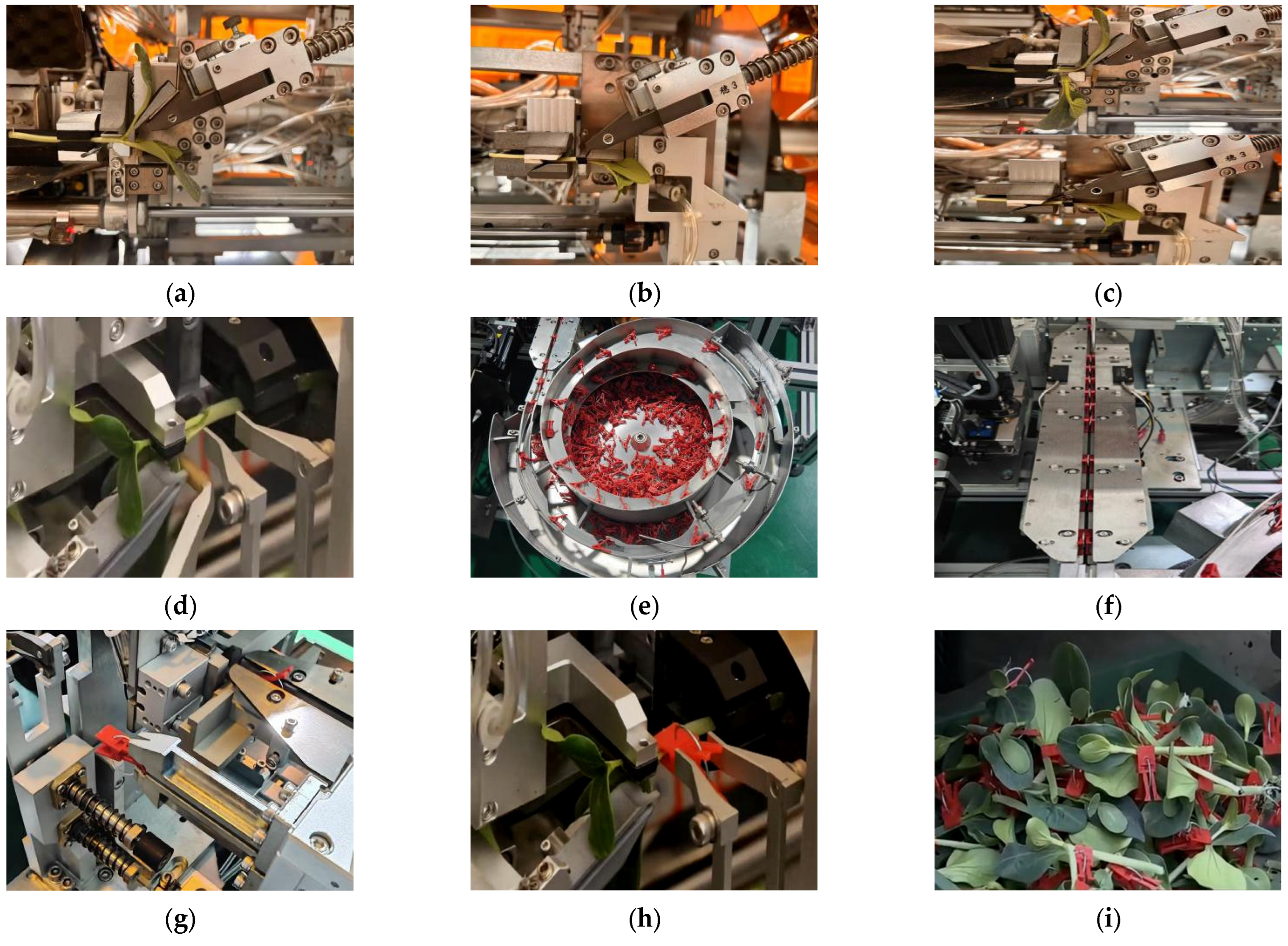

2.1. General Design of the Vegetable Grafting Machine

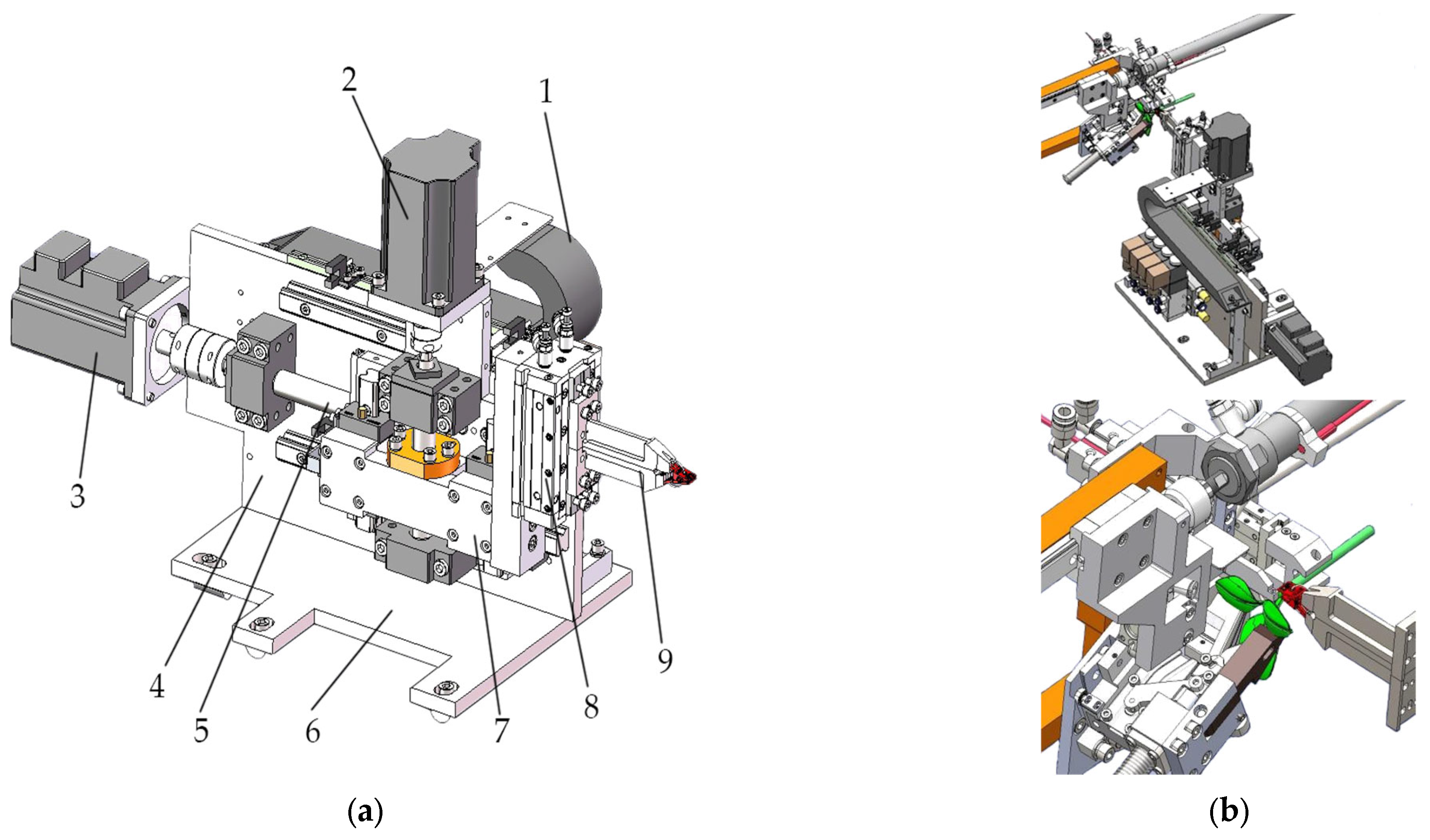

2.2. Design of the Cutting Mechanism Structure

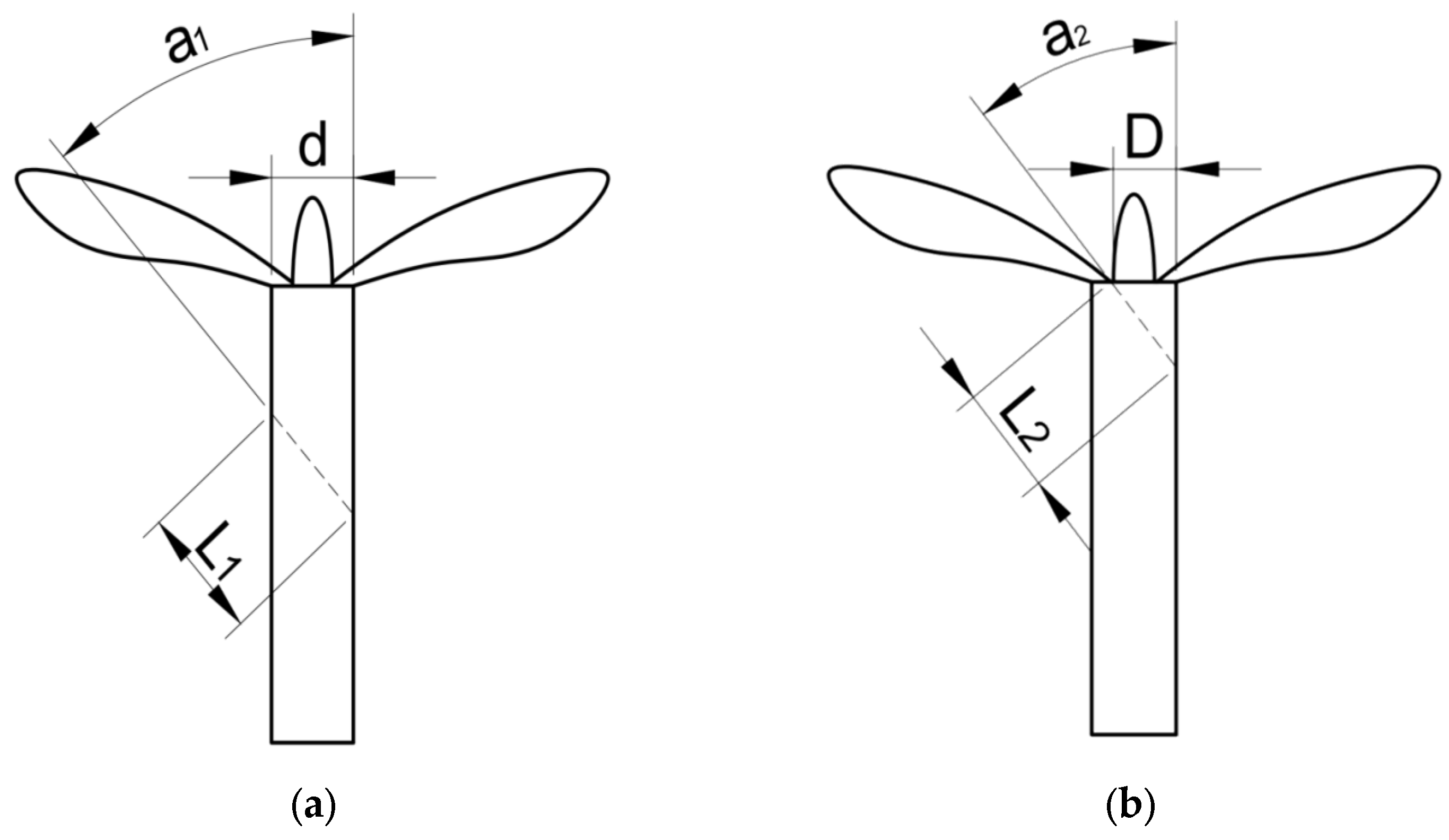

2.2.1. Theoretical Analysis of Cutting Operations

2.2.2. Selection of Cutting Angles

- (1)

- To prevent damage to the rootstock’s cotyledons during cutting and ensure complete removal of the growing point, an oblique cut must be made using the point immediately left of the growing point and the right edge of the stem as reference points.

- (2)

- During the cutting of the rootstock, caution should be exercised to prevent exposing the pith cavity. Should the pith cavity be incised, the rootstock and scion cuts will fail to fit closely, resulting in grafting failure. The scion seedling will then sprout new roots that penetrate the rootstock’s pith cavity and extend into the soil, thereby inviting disease infection. Consequently, the angle of the knife cut must be precisely controlled.

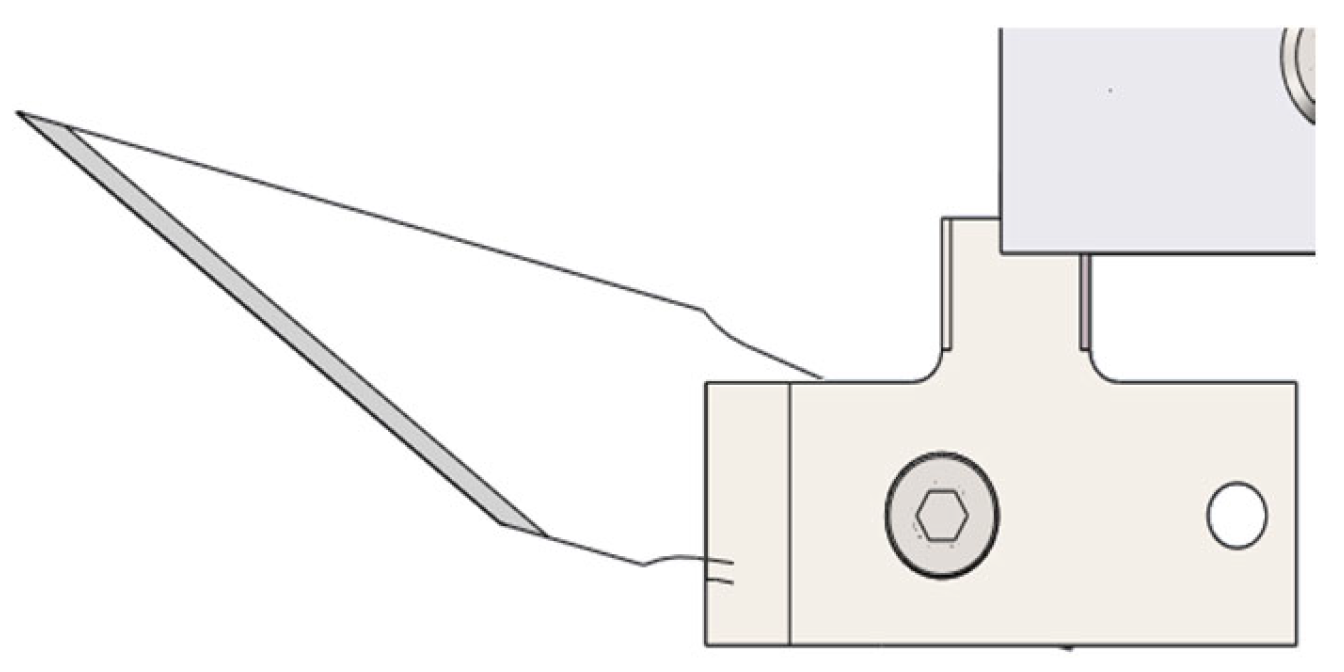

2.2.3. Cutting Mechanism Structural Design

- (1)

- Structure: Comprising a blade and a matching blade handle, the rear of the blade features a locking groove that engages precisely with the handle, facilitating swift assembly and disassembly.

- (2)

- Shape: It has an overall willow-leaf form with a curved cutting edge and an exceptionally sharp tip. The blade tapers narrowly at the front and widens slightly towards the rear, optimizing precision cutting applications.

- (3)

- Bevel Angle: The cutting edge is honed to an angle of approximately 15–20°. This angle ensures optimal sharpness and facilitates precise incisions.

- (4)

- Service Life: No specified service life; it is recommended to inspect the blade condition when grafting 2000 seedlings.

- (5)

- Material: Constructed from high-strength stainless steel, this material balances edge sharpness and hardness while providing excellent corrosion resistance.

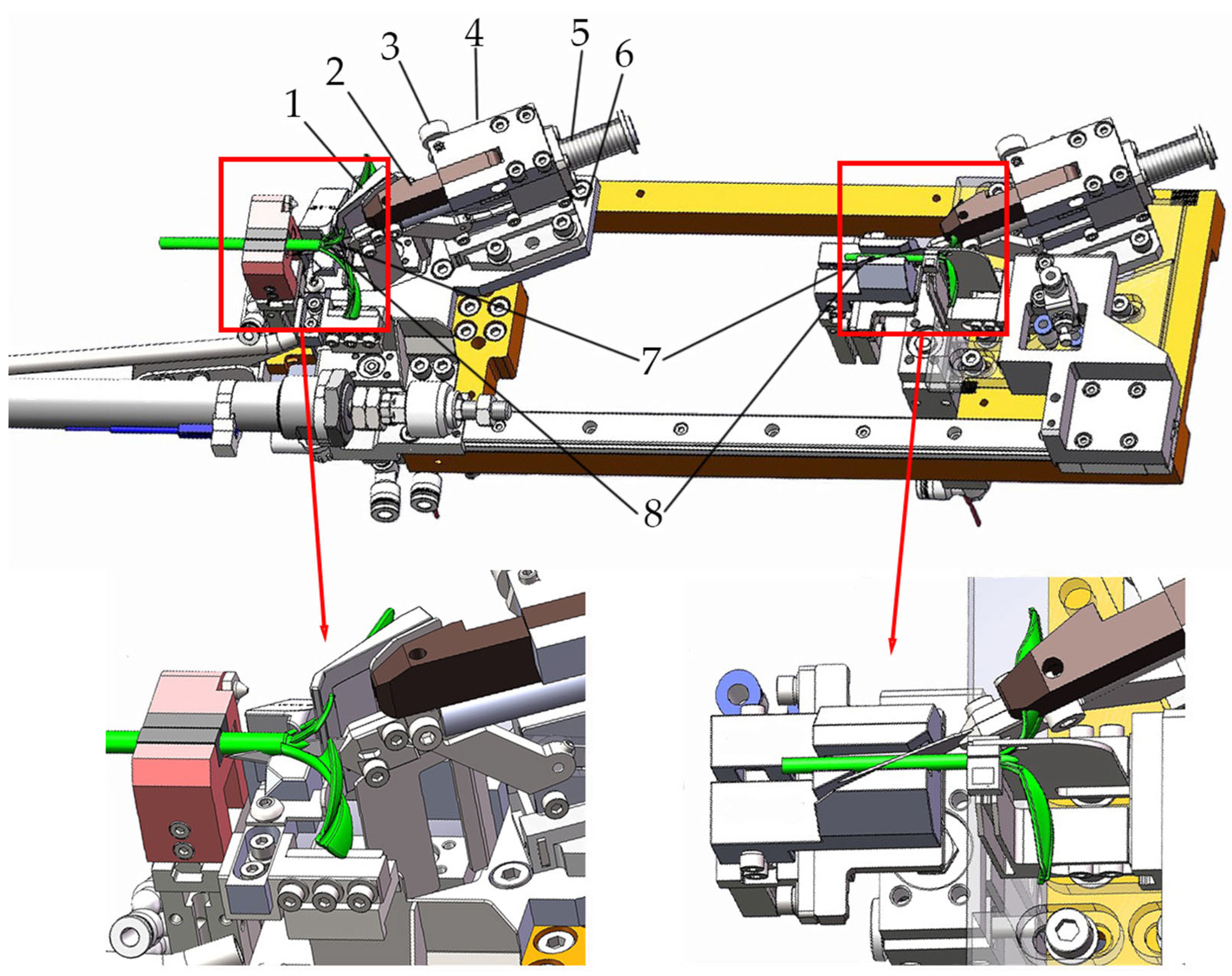

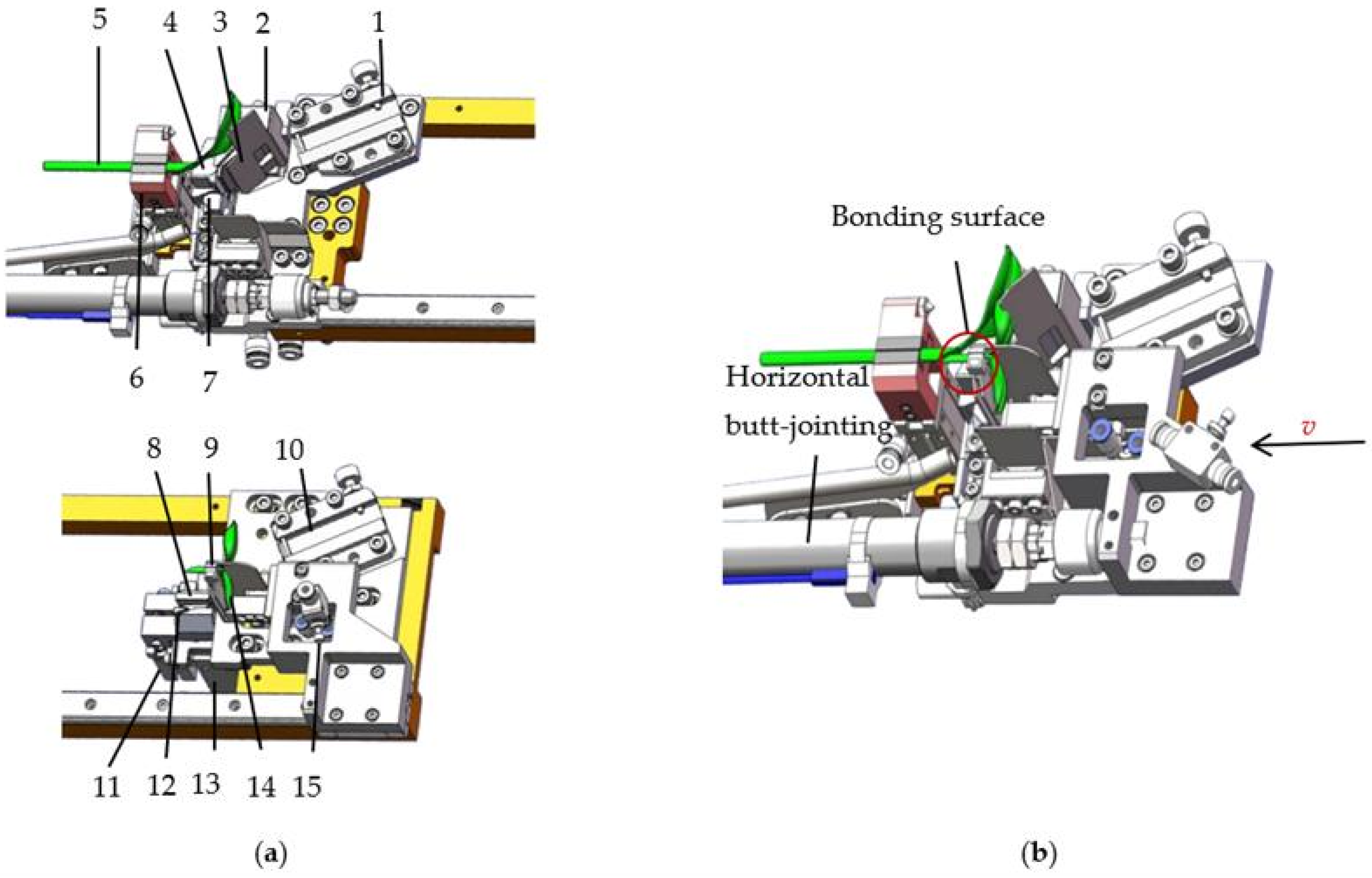

2.3. Design of an Integrated Clamping and Bonding Mechanism

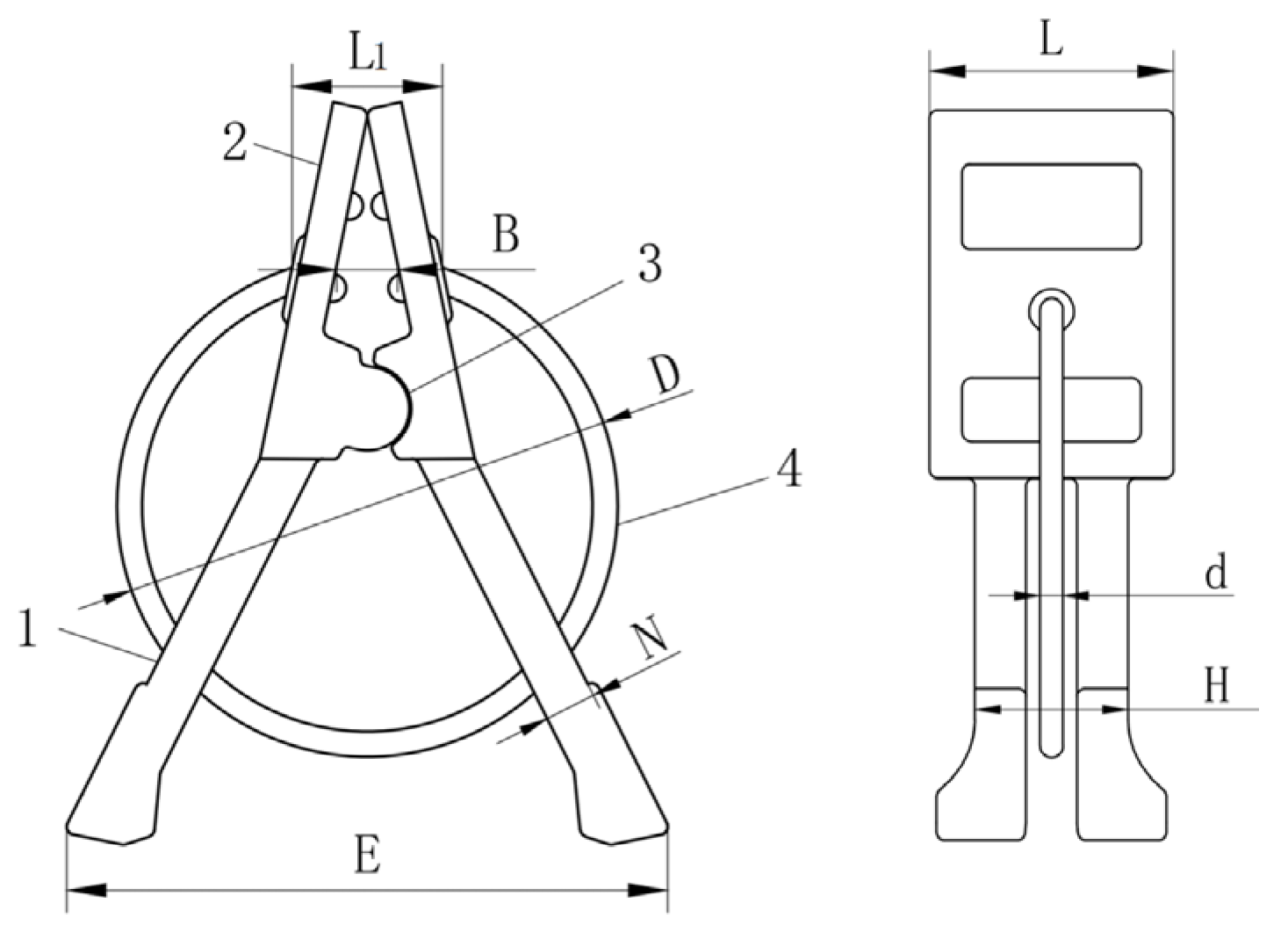

2.3.1. Structural Design of the Gripping Claw

2.3.2. Design of Grafting Seedling Cleft Grafting Mechanism

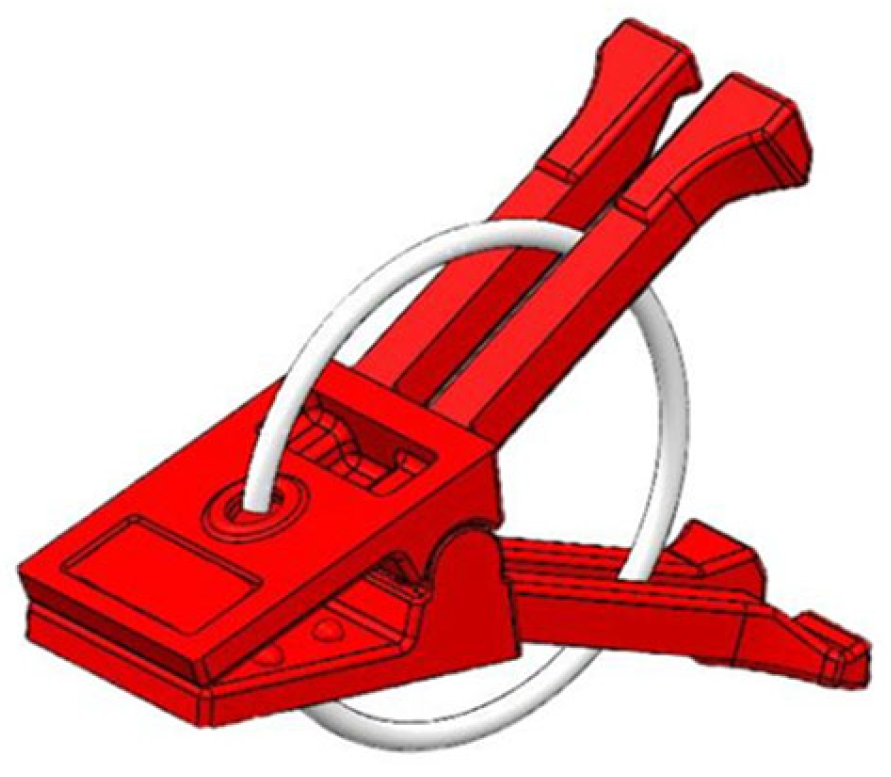

2.4. Design of the Clamping and Strapping Mechanism

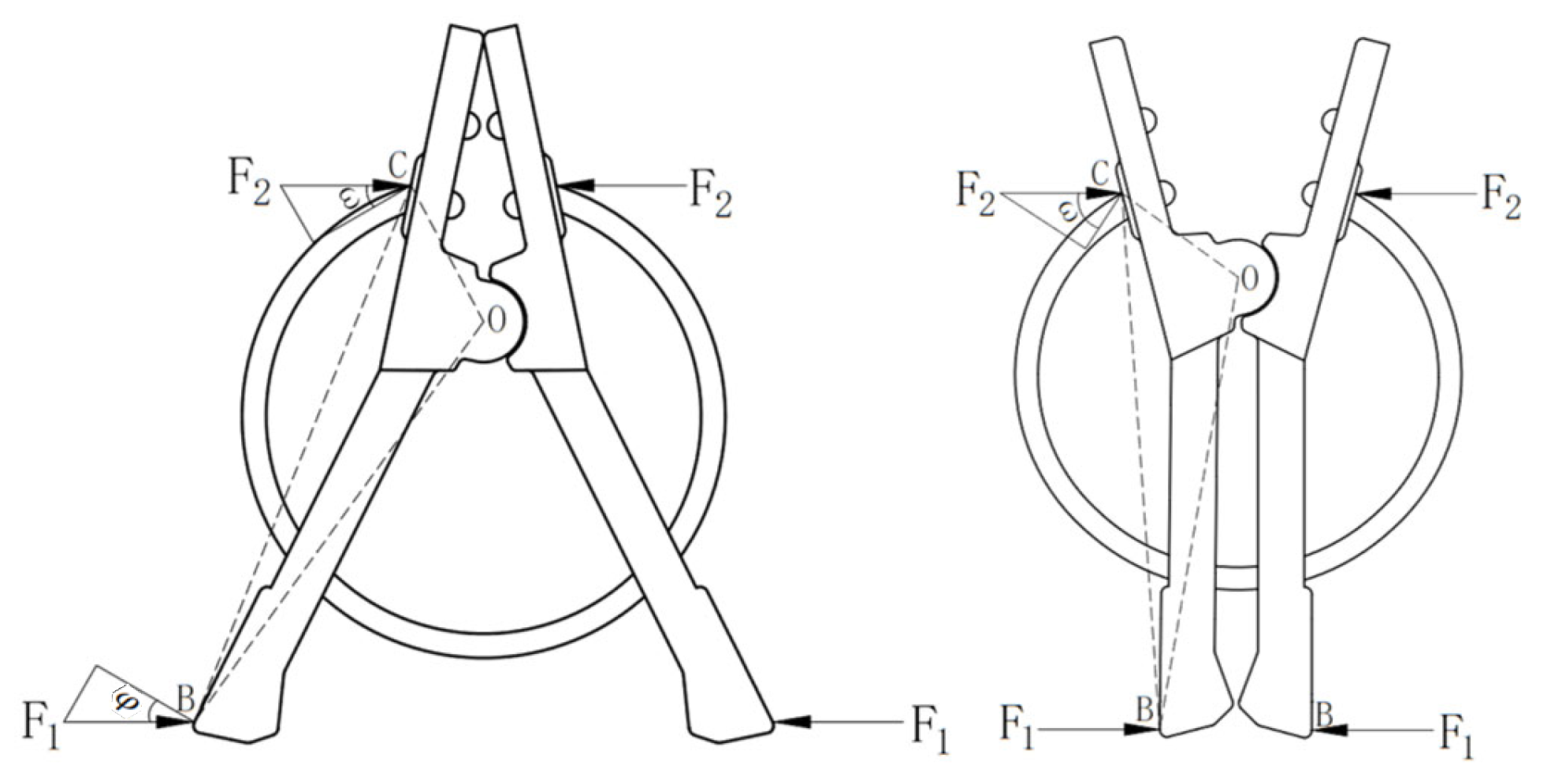

2.4.1. Study on the Mechanism of Grafting Clips

- Grafting clamp selection

- 2.

- Safety validation of grafting clamps

2.4.2. Continuous Clamp Feeding Mechanism

2.4.3. Push-Up Clamping Mechanism

3. Results

3.1. Results of Experiments

3.1.1. Evaluation of Automated Grafting Machinery for Cucurbit Seedling Propagation

- (1)

- Prior to operation: Wipe cutting blades, locating jaws, and other relevant components with 75% alcohol. Clean equipment casings using chlorine-based disinfectant.

- (2)

- During operation: Wipe blades and fixtures with alcohol swabs every two hours. Promptly remove seedling juices and residues to prevent bacterial proliferation due to accumulation.

- (3)

- After operation: Dismantle removable components (e.g., fixtures, blades). Rinse with clean water, then soak in disinfectant for 15 min before rinsing with clean water and air-drying. Clean internal equipment with a high-pressure air gun to remove dust. Apply sterile lubricant to transmission components.

3.1.2. A Study on Cutting Parameter Evaluation for Successful Grafting of Cucurbit Seedling

3.1.3. Comprehensive Outcomes of Grafting Success Rate Testing

4. Discussion

- (1)

- A clamp-on bandaging mechanism has been designed, comprising a clamp feeder and a clamp-pushing unit. While employing a conventional disc-type clamp feeder, this design incorporates a two-stage linear vibratory clamp-feeding mechanism equipped with photoelectric distance sensors. Compared to traditional clamp feeders, this design achieves significantly enhanced stability in both clamp feeding and bandaging operations. The primary improvements are manifested in the following aspects: (a) The Japanese ISEKI GRF803-U grafting machine adopts traditional single-stage vibratory bowl feeding. As indicated in its technical manual, when the feeding speed exceeds 1.5 times the consumption speed, the jamming rate of the linear feeder reaches 18%, requiring manual intervention for cleaning. Although the South Korean AFGR-800CS has been improved to dual-track feeding, it is not equipped with a real-time monitoring device, resulting in a remaining 12% jamming risk in actual operation. The “two-stage linear vibration + photoelectric distance measurement” design in this study controls the jamming rate below 2% by dynamically adjusting the feeding gap, achieving an 89% reduction compared to the GR803-U and outperforming the improvement effect of the AFGR-800CS. (b) As cucurbit grafted seedlings possess relatively smooth surfaces and hollow stems, this grafting clamp features anti-slip granules within its jaws. Constructed from polyethylene, its gripping surfaces ensure the grafted seedlings are held securely in place, significantly reducing damage to the young plants. (c) The push-up clamping mechanism, controlled by two stepper motors, enables both vertical and horizontal movement, markedly enhancing grafting efficiency.

- (2)

- A high-precision cutting and alignment assembly has been developed. Compared to conventional cucurbit grafting equipment, earlier models required transferring the scion seedling from the initial workstation to the rootstock’s grafting surface during cutting and alignment operations. This process was prone to misalignment of the grafting surfaces, leading to a significant reduction in grafting success rates. This equipment innovatively employs synchronous cutting technology, whereby the scion need only slide horizontally onto the rootstock’s cutting surface. This effectively prevents lateral displacement of the seedlings, markedly enhancing grafting success rates. This design achieves a breakthrough in performance over earlier equipment in both bonding precision and operational success rates. The Chinese TJ-800 grafting machine employs a three-step operation of “scion grasping-transferring-bonding”. High-speed camera footage reveals that the lateral displacement of the scion reaches 0.3–0.5 mm, resulting in an incision misalignment rate of 25%.

- (3)

- This study conducted tests on grafting angle for grafted seedlings and verified the safety of domestically produced specialised grafting clamps. Through experimentation, mechanical properties and geometric dimensions were obtained for commonly used cucurbit rootstocks and scions. These foundational data ensure optimal fit between cut surfaces, thereby enhancing grafting precision and final product quality. For seedlings with varying stem diameters, these parameters will support adaptive adjustment of cutting specifications. They also provide a reference basis for developers undertaking clamping mechanism design and material selection.

- (4)

- The automated cucurbit grafting equipment developed herein possesses high operational efficiency, significantly reducing labour costs throughout the entire process from seedling retrieval by operators to the transplantation of finished seedlings. However, the equipment has certain limitations: as its core components are predominantly custom-designed, they require adaptation based on the stem characteristics and varietal traits of batch-produced seedlings. Furthermore, the extended maintenance and debugging cycles result in relatively high manufacturing costs. Compared to conventional models, this equipment offers superior adjustability, enabling rapid adaptation to diverse grafting requirements. Grafting failure also occurred in the experiments, and the main causes of grafting failure include precision degradation of the mechanical system, sensor and algorithm errors, defects in executive components, and improper maintenance and debugging. Specifically, tool wear or angular deviation may cause the incision surfaces to fail to make close contact; sensor malfunction may lead to system shutdown; and issues such as material aging or insufficient elasticity of the polyethylene clip body may also contribute to failure.

- (5)

- The long-term stable operation of grafting machines relies on the durability of core components, with key elements including the cutting, grafting, and clamp-feeding or wrapping mechanisms. During operation, cutting precision degradation stems from blade wear, cylinder seal ageing, or increased push rod transmission clearance. Under prolonged stress, sliding clearance between sleeve rods and limit rods readily develops, causing positioning deviation. Frequent clamp feeding by upper and lower stepper motors increases contact surface roughness, compromising conveyance stability. Spring clamp performance directly impacts grafting precision and efficiency. However, optimisations were implemented during research: cutting blades were upgraded to high-speed steel or cemented carbide with edge coatings extending wear life by 3–5 times; load-bearing components like connecting rods and sleeve rods underwent tempering to reduce deformation; and increased stockpiles of springs and blades were maintained. These comprehensive measures ensure continuous operation, meeting the demands of large-scale nursery operations.

5. Conclusions

- (1)

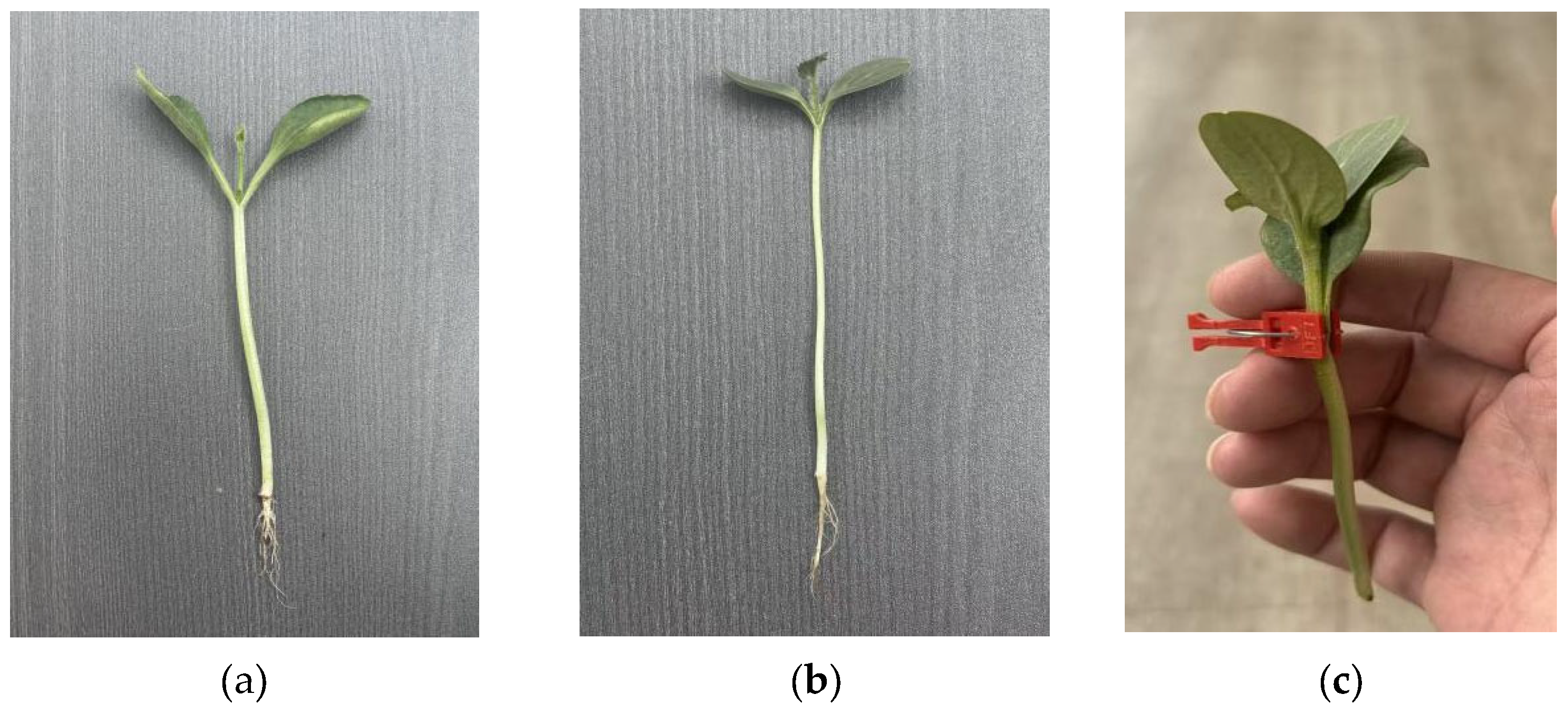

- To enhance the grafting survival rate of cucurbit seedlings, the grafting equipment design must accomplish the removal of both the rootstock’s growing point and one cotyledon. Furthermore, considering the presence of a pith cavity within the cucurbit seedling stem, it is essential to ensure that the pith cavity remains concealed after the growing point is excised. To this end, this paper proposes an automated cucurbit grafting equipment solution. Through conducting cutting angle tests and safety validation of grafting clamps, in addition to designing the cutting, positioning and clamp supply mechanisms, this solution realizes multiple key functions. Specifically, these encompass grafted seedling synchronized cutting, precise seedling localization, grafting clamp sustained supply, automatic wrapping and bonding of grafting clamps, and transplanting of finished seedlings.

- (2)

- To identify the optimal cutting angle, the study conducted tests on the mechanical properties and geometric dimensions of rootstocks and scions. These foundational data provided crucial reference for establishing cutting surface parameters in grafted seedlings. Through measurement and analysis of seedling geometry, the optimal matching angle for the cut was identified, upon which grafting validation trials were conducted. The findings from cutting angle testing hold significant practical value for the research, development, design, debugging optimisation, and technological upgrading of grafting equipment for cucurbit crops.

- (3)

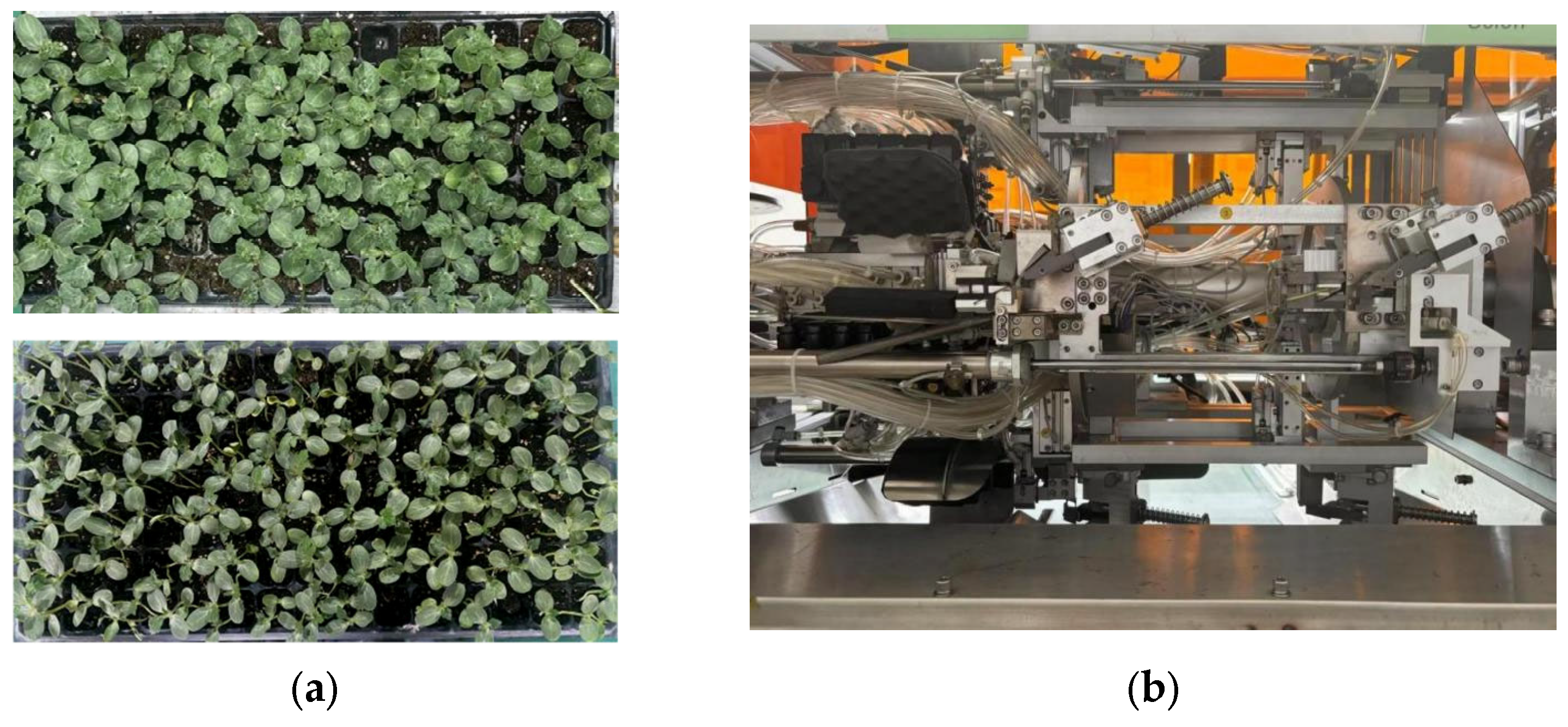

- During the optimal seedling cultivation period, Qingyan rootstock No. 1 tray seedlings and Yongtian No. 5 scion tray seedlings were selected as experimental materials. Systematic grafting trials and incision quality assessments were conducted using automated synchronous grafting equipment for cucurbit crops. Experimental data indicated a cut formation success rate exceeding 98%, with over 95% of grafted seedlings achieving satisfactory adhesion. Concurrently, the clamp attachment success rate surpassed 98%, yielding an overall grafting success rate of no less than 90%. When operated by skilled personnel, the equipment achieved an hourly throughput of 1400 plants, with an exceptionally low damage rate to finished seedlings.

- (4)

- This automated grafting apparatus enables fully automated grafting of cucurbit seedlings, substantially reducing labour requirements. However, constrained by cost considerations and design limitations, the equipment retains scope for improvement: its core drive relies on rotary cylinders and necessitates motor integration. Subsequent research may employ miniaturised clamping systems to achieve highly integrated equipment architecture. During grafting operations, morphological variations in rootstock apical meristems may lead to incomplete grafting, while dimensional mismatches between rootstock and scion also impact efficacy. Consequently, standardised regulation of seedling growth conditions is essential during the nursery stage. Furthermore, apical meristems and cotyledons removed during cutting may remain adhered to stem surfaces. It is recommended to incorporate a waste tissue removal mechanism, with its application to be validated in subsequent research.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Azam, A.; Shafique, M. An overview of fruits and vegetables trade of China. Int. J. u- e- Serv. Sci. Technol. 2018, 11, 33–44. [Google Scholar] [CrossRef]

- Gu, S. The emergence and development of the vegetable sector in China. Ind. Innov. 2009, 16, 499–524. [Google Scholar] [CrossRef]

- Chartres, C.J.; Noble, A. Sustainable intensification: Overcoming land and water constraints on food production. Food Secur. 2015, 7, 235–245. [Google Scholar] [CrossRef]

- Kartini, N.L.; Saifulloh, M.; Trigunasih, N.M.; Sukmawati, N.M.S.; Mega, I. Impact of long-term continuous cropping on soil nutrient depletion. Ecol. Eng. Environ. Technol. 2024, 25, 18–29. [Google Scholar] [CrossRef]

- Pervaiz, Z.H.; Iqbal, J.; Zhang, Q.; Chen, D.; Wei, H.; Saleem, M. Continuous cropping alters multiple biotic and abiotic indicators of soil health. Soil Syst. 2020, 4, 59. [Google Scholar] [CrossRef]

- Chaudhary, S.; Devi, P.; HanumanthaRao, B.; Jha, U.C.; Sharma, K.D.; Prasad, P.V.; Kumar, S.; Siddique, K.H.M.; Nayyar, H. Physiological and molecular approaches for developing thermotolerance in vegetable crops: A growth, yield and sustenance perspective. Front. Plant Sci. 2022, 13, 878498. [Google Scholar] [CrossRef]

- Parmar, N.; Singh, K.H.; Sharma, D.; Singh, L.; Kumar, P.; Nanjundan, J.; Khan, Y.J.; Chauhan, D.K.; Thakur, A.K. Genetic engineering strategies for biotic and abiotic stress tolerance and quality enhancement in horticultural crops: A comprehensive review. 3 Biotech 2017, 7, 239. [Google Scholar] [CrossRef]

- Ahmed, N.; Zhang, B.; Bozdar, B.; Chachar, S.; Rai, M.; Li, Y.; Hayat, F.; Chachar, Z.; Tu, P. The power of magnesium: Unlocking the potential for increased yield, quality, and stress tolerance of horticultural crops. Front. Plant Sci. 2023, 14, 1285512. [Google Scholar] [CrossRef]

- Singh, L.; Kumari, M.S.; Mounika, K.; Bhrihavasi, G. Grafting and Budding Techniques. In Plant Propogation in Horticulture Crops; A K International Publication: Ambala, India, 2025; p. 56. [Google Scholar]

- Awazade, A.S.; Verma, D. Advancing Vegetable Grafting: A comprehensive review of techniques, challenges, and the future of automated solutions. J. Sci. Res. Rep. 2024, 30, 517–530. [Google Scholar] [CrossRef]

- Pingali, P. Agricultural mechanization: Adoption patterns and economic impact. Handb. Agric. Econ. 2007, 3, 2779–2805. [Google Scholar]

- Diao, X.; Silver, J.; Takeshima, H. Agricultural Mechanization and Agricultural Transformation; International Food Policy Research Institute: Washington, DC, USA, 2016. [Google Scholar]

- Lee, J.M.; Kubota, C.; Tsao, S.J.; Bie, Z.; Echevarria, P.H.; Morra, L.; Oda, M. Current status of vegetable grafting: Diffusion, grafting techniques, automation. Sci. Hortic. 2010, 127, 93–105. [Google Scholar] [CrossRef]

- Lee, J.M.; Bang, H.J.; Ham, H.S. Grafting of vegetables (grafting and raising of seedlings, for further development of horticulture in East Asia). J. Jpn. Soc. Hortic. Sci. 1998, 67, 1098–1104. [Google Scholar] [CrossRef]

- Liu, Z.; Zhou, W.; Wang, F.; Li, J.; Jiang, L.; Wang, G.; Zhang, C. Advanced Design and Performance Evaluation of an Automatic Synchronized Grafting Machine for Solanum Vulgare. Processes 2025, 13, 131. [Google Scholar] [CrossRef]

- Unadi, A.; Budiharti, U.; Parikesit, A.; Tjahohutomo, R.; Rosmeika; Asari, A.; Hoesen, Y.A.; Widodo, T.W.; Samudiantono, A. Design and development of a semi-automatic grafting machine for cocoa. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2024; Volume 2957, p. 050007. [Google Scholar]

- Chang, Y.C.; Chen, S.; Chiu, Y.C.; Lin, L.H.; Chang, Y.S. Growth and union acclimation process of sweet pepper grafted by a tubing-grafting robotic system. Hortic. Environ. Biotechnol. 2012, 53, 93–101. [Google Scholar] [CrossRef]

- Huang, Y.; Kong, Q.S.; Chen, F.; Bie, Z.L. The history, current status and future prospects of vegetable grafting in China. In Proceedings of the I International Symposium on Vegetable Grafting 1086, Wuhan, China, 17–21 March 2014; pp. 31–39. [Google Scholar]

- Kailiang, Z.H.A.N.G.; Jia, C.H.U.; Tiezhong, Z.H.A.N.G.; Quan, Y.I.N.; Yanshan, K.O.N.G.; Zhan, L.I.U. Development status and analysis of automatic grafting technology for vegetables. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2017, 48, 1–13. [Google Scholar]

- Comba, L.; Gay, P.; Aimonino, D.R. Robot ensembles for grafting herbaceous crops. Biosyst. Eng. 2016, 146, 227–239. [Google Scholar] [CrossRef]

- Pardo-Alonso, J.L.; Carreño-Ortega, Á.; Martínez-Gaitán, C.C.; Fatnassi, H. Behavior of different grafting strategies using automated technology for splice grafting technique. Appl. Sci. 2020, 10, 2745. [Google Scholar] [CrossRef]

- Belforte, G.; Raparelli, T.; Eula, G.; Sirolli, S. An Innovative Automatic Tomato Grafting Machine Prototype. J. Eng. Sci. Technol. 2022, 17, 2272–2286. [Google Scholar]

- Kubota, C.; McClure, M.A.; Kokalis-Burelle, N.; Bausher, M.G.; Rosskopf, E.N. Vegetable grafting: History, use, and current technology status in North America. HortScience 2008, 43, 1664–1669. [Google Scholar] [CrossRef]

- Bhat, R.R.; Tomlinson, M.R.; Wu, T.; Genzer, J. Surface-grafted polymer gradients: Formation, characterization, and applications. In Surface-Initiated Polymerization II; Springer: Berlin/Heidelberg, Germany, 2005; pp. 51–124. [Google Scholar]

- Murugan, R.; Ramakrishna, S. Development of nanocomposites for bone grafting. Compos. Sci. Technol. 2005, 65, 2385–2406. [Google Scholar] [CrossRef]

- Liang, H.; Zhu, J.; Ge, M.; Wang, D.H.; Liu, K.; Zhou, M.B.; Sun, Y.H.; Zhang, Q.; Jiang, K.; Shi, X.F. A comparative analysis of the grafting efficiency of watermelon with a grafting machine. Horticulturae 2023, 9, 600. [Google Scholar] [CrossRef]

- Xie, Z.; Gu, S.; Chu, Q.; Li, B.; Fan, K.J.; Yang, Y.L.; Yang, Y.; Liu, X.G. Development of a high-productivity grafting robot for Solanaceae. Int. J. Agric. Biol. Eng. 2020, 13, 82–90. [Google Scholar] [CrossRef]

- Tian, S.; Yang, J.; Wang, R.; Xu, D.; Li, T. Optimization experiment of operating parameters on vibration sorting-clip device for vegetable grafting machine. Trans. Chin. Soc. Agric. Eng. 2014, 30, 9–16. [Google Scholar]

- Chen, S.; Liang, H.; Zhang, Q.; Feng, Q.; Li, T.; Chen, L.; Jiang, K. Melon robotic grafting: A study on the precision cutting mechanism and experimental validation. Agriculture 2023, 13, 2139. [Google Scholar] [CrossRef]

- Junhua, T.O.N.G.; Yuhua, D.I.N.G.; Chuanyu, W.U.; Qingcang, Y.U.; Jinhui, P.A.N.; Liang, S.U.N. Design and experiment of key mechanism for semi-automatic vegetable grafting machine. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2018, 49, 65–72. [Google Scholar]

- Jun, L.I.; Tiezhong, Z.H.A.N.G.; Jia, C.H.U.; Libo, Z.H.A.N.G.; Wenbo, Z.H.A.N.G.; Quan, Y.I.N. Design and Experiment of Grafting-clip Transporting Mechanism of Full Automatic Grafting Machine for Whole-row Vegetable Seedlings. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2017, 48, 14–20. [Google Scholar]

- Li, Y.; Wang, C.; Wu, H.; Zhao, Y.; Song, J. Simulation and experimental study of flexible adsorption and localization mechanism for vegetable grafting machines. Sci. Rep. 2024, 14, 17616. [Google Scholar] [CrossRef]

- Khadatkar, A.; Sawant, C.P.; Magar, A.P.; Kumar, V. Agricultural robots and automated machinery for handling of nursery seedlings with special reference to the transplanting devices. Discov. Appl. Sci. 2025, 7, 916. [Google Scholar] [CrossRef]

- Fu, X.; Shi, J.; Huang, Y.; Zhu, E.; Bie, Z.; Lin, W. Design and experiment of full-tray grafting device for grafted melon seedling production. Agriculture 2022, 12, 861. [Google Scholar] [CrossRef]

- Rasool, A.; Mansoor, S.; Bhat, K.M.; Hassan, G.I.; Baba, T.R.; Alyemeni, M.N.; Alsahi, A.A.; El-Serehy, H.A.; Paray, B.A.; Ahmad, P. Mechanisms underlying graft union formation and rootstock scion interaction in horticultural plants. Front. Plant Sci. 2020, 11, 590847. [Google Scholar] [CrossRef]

- Shivran, M.; Sharma, N.; Dubey, A.K.; Singh, S.K.; Sharma, N.; Sharma, R.M.; Singh, N.; Singh, R. Scion–rootstock relationship: Molecular mechanism and quality fruit production. Agriculture 2022, 12, 2036. [Google Scholar] [CrossRef]

- Islam, M.N.; Iqbal, M.Z.; Ali, M.; Chowdhury, M.; Kabir, M.S.N.; Park, T.; Kim, Y.-J.; Chung, S.-O. Kinematic analysis of a clamp-type picking device for an automatic pepper transplanter. Agriculture 2020, 10, 627. [Google Scholar] [CrossRef]

- Yue, R.; Hu, J.; Liu, Y.; Yao, M.; Zhang, T.; Shi, J. Design and working parameter optimization of pneumatic reciprocating seedling-picking device of automatic transplanter. Agriculture 2022, 12, 1989. [Google Scholar] [CrossRef]

- Mekeel, K.L.; Halldorson, J.B.; Berumen, J.A.; Hemming, A.W. Kidney clamp, perfuse, re-implant: A useful technique for graft salvage after vascular complications during kidney transplantation. Clin. Transplant. 2015, 29, 373–378. [Google Scholar] [CrossRef]

- Huerta, E.; Corona, J.E.; Oliva, A.I.; Avilés, F.; González-Hernández, J. Universal testing machine for mechanical properties of thin materials. Rev. Mex. Física 2010, 56, 317–322. [Google Scholar]

- Kai, L.; Qi, C.; Song, G. Research development of solanaceae vegetables automatic grafting machines. J. Agric. Mech. Res. 2011, 33, 230–233. [Google Scholar]

| Comparison Items | Automated Cucurbitaceae Grafting Machine | Manual Grafting |

|---|---|---|

| Grafting efficiency (plants/hour) | 1200–1500 | 200 |

| Operating cost (RMB/hour) | 15–20 | 50 (per person) |

| Cost per plant (RMB/plant) | 0.2–0.3 | 0.5–0.6 |

| Main cost components | Equipment depreciation, energy consumption | Labor wages |

| Cutting Angle α (°) | Rootstock: Yongzhen No. 2 | Scion: Yongtian No. 5 | ||

|---|---|---|---|---|

| Average Value D (mm) | Bevel Length L2 (mm) | Mean Stem Diameter d (mm) | Bevel Length L1 (mm) | |

| 20 | 3.17 ± 0.12 | 9.27 ± 0.12 | 2.66 ± 0.15 | 7.78 ± 0.21 |

| 25 | 7.50 ± 0.16 | 6.29 ± 0.14 | ||

| 30 | 6.34 ± 0.18 | 5.32 ± 0.20 | ||

| 35 | 5.53 ± 0.19 | 4.63 ± 0.17 | ||

| 40 | 4.93 ± 0.15 | 4.14 ± 0.15 | ||

| 45 | 4.48 ± 0.13 | 3.76 ± 0.13 | ||

| Clamp Types | Figure Number | Internal Diameter (mm) | Materials | Suitable Crops | Characteristics |

|---|---|---|---|---|---|

| Polyethylene butterfly clip | 1 | 2.0~2.5 | Polyethylene | Solanaceae | Moderately resilient, suitable for seedlings with slender stems of uniform diameter |

| Sleeve grafting clamp | 2 | 2.5~3.5 | Transparent elastic plastic | Solanaceae | No dismantling required; adapts to different stem thicknesses of Solanaceae seedlings. |

| Handmade grafting clamp(red) | 3 | 1.2~2.5 | Rigid plastic | Solanaceae | The stems possess moderate rigidity, with some featuring support holes to aid in securing them. |

| Handmade grafting clamp(green) | 4 | 1.5~3 | Flexible plastic and metal spring | Solanaceae | The stems possess high rigidity, and the spring exhibits substantial compressive force. |

| Domestic-Specific grafting clamp | 5 | 3~15 | Polyethylene and metal spring | Cucurbitaceae | Capable of securing sturdy rootstocks, providing sufficient clamping force. |

| Clamp Body Material | Clamp Width | External Fix Action Point Distance | Clamp Tail Distance | Spring Steel Ring Diameter | Wire Diameter | Quality of Grafting Clamps |

|---|---|---|---|---|---|---|

| L (mm) | B (mm) | E (mm) | D (mm) | d (mm) | m (g) | |

| pe polyethylene | 9.5 | 1.5 | 20 | 17 | 10 | 1 |

| Test Subject | Stem Diameter (mm) | Elasticity Limit of Seedlings (N) | Jaw Opening (mm) | Clamp Tail Compression (mm) | Average Clamping Force (N) | Maximum Clamping Force (N) |

|---|---|---|---|---|---|---|

| Sheng Zhen No. 1 | 4.22 ± 0.42 | 6.29 | 4.92 ± 0.22 | 8.21 ± 0.29 | 0.85 | 0.80 |

| Guazhen No. 15 | 4.14 ± 0.39 | 6.97 | 4.69 ± 0.25 | 8.01 ± 0.34 | 0.79 | 0.76 |

| Yongzhen No. 2 | 3.66 ± 0.30 | 6.83 | 4.18 ± 0.27 | 7.69 ± 0.42 | 0.75 | 0.71 |

| Xi Yu No. 1 | 2.76 ± 0.44 | 5.74 | 3.36 ± 0.22 | 6.87 ± 0.37 | 0.64 | 0.61 |

| Yao Long 25 | 2.73 ± 0.46 | 5.35 | 3.28 ± 0.30 | 6.69 ± 0.40 | 0.62 | 0.58 |

| Yongtian No. 5 | 2.69 ± 0.32 | 5.17 | 3.16 ± 0.23 | 6.58 ± 0.25 | 0.59 | 0.54 |

| Test Number | Rootstock: Yongzhen No. 2 | Scion: Yongtian No. 5 | Bevel Fit Rate (%) | ||||

|---|---|---|---|---|---|---|---|

| Sample Size (plants) | D Value (mm) | Bevel Length (mm) | Sample Size (plants) | Shaft Length (mm) | Bevel Length (mm) | ||

| 1 | 50 | 3.17 | 6.34 | 50 | 2.64 | 6.24 | 98.4 |

| 2 | 50 | 3.12 | 6.24 | 50 | 2.67 | 6.31 | 98.9 |

| 3 | 50 | 3.21 | 6.42 | 50 | 2.62 | 6.19 | 96.4 |

| 4 | 50 | 3.06 | 6.12 | 50 | 2.57 | 6.08 | 99.3 |

| 5 | 50 | 3.23 | 6.46 | 50 | 2.72 | 6.43 | 99.5 |

| Average | 50 | 3.17 | 6.32 | 50 | 2.64 | 6.24 | 98.7 |

| Test Number | Sample Size | Seedling Loading Rate (%) | Cutting Success Rate (%) | Upper Clamp Success Rate (%) | Grafting Success Rate (%) | Grafting Productivity (plants/h) | ||

|---|---|---|---|---|---|---|---|---|

| S | R | S | R | |||||

| 1 | 100 | 98 | 99 | 97 | 98 | 98 | 91.30 | 1432 |

| 2 | 100 | 100 | 98 | 98 | 97 | 99 | 92.22 | 1456 |

| 3 | 100 | 99 | 98 | 98 | 96 | 99 | 90.36 | 1475 |

| 4 | 100 | 97 | 100 | 95 | 99 | 100 | 91.22 | 1463 |

| 5 | 100 | 98 | 99 | 98 | 98 | 98 | 93.19 | 1472 |

| Average | 100 | 98.40 | 98.8 | 97.20 | 97.6 | 98.8 | 91.67 | 1460 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Wang, G.; Zhang, C.; Liu, Z.; Jiang, L.; Hu, X.; Zhang, X. Design and Performance Evaluation of an Automated Bud Grafting Machine for Cucurbitaceous Seedlings. Processes 2025, 13, 3788. https://doi.org/10.3390/pr13123788

Li J, Wang G, Zhang C, Liu Z, Jiang L, Hu X, Zhang X. Design and Performance Evaluation of an Automated Bud Grafting Machine for Cucurbitaceous Seedlings. Processes. 2025; 13(12):3788. https://doi.org/10.3390/pr13123788

Chicago/Turabian StyleLi, Jiawei, Guoqiang Wang, Caihong Zhang, Zhenya Liu, Luyan Jiang, Xinmei Hu, and Xiaohui Zhang. 2025. "Design and Performance Evaluation of an Automated Bud Grafting Machine for Cucurbitaceous Seedlings" Processes 13, no. 12: 3788. https://doi.org/10.3390/pr13123788

APA StyleLi, J., Wang, G., Zhang, C., Liu, Z., Jiang, L., Hu, X., & Zhang, X. (2025). Design and Performance Evaluation of an Automated Bud Grafting Machine for Cucurbitaceous Seedlings. Processes, 13(12), 3788. https://doi.org/10.3390/pr13123788