Investigation of Microscopic Oil Flow Characteristics During Fracturing Fluid Invasion and Flowback in Shale Oil Reservoirs

Abstract

1. Introduction

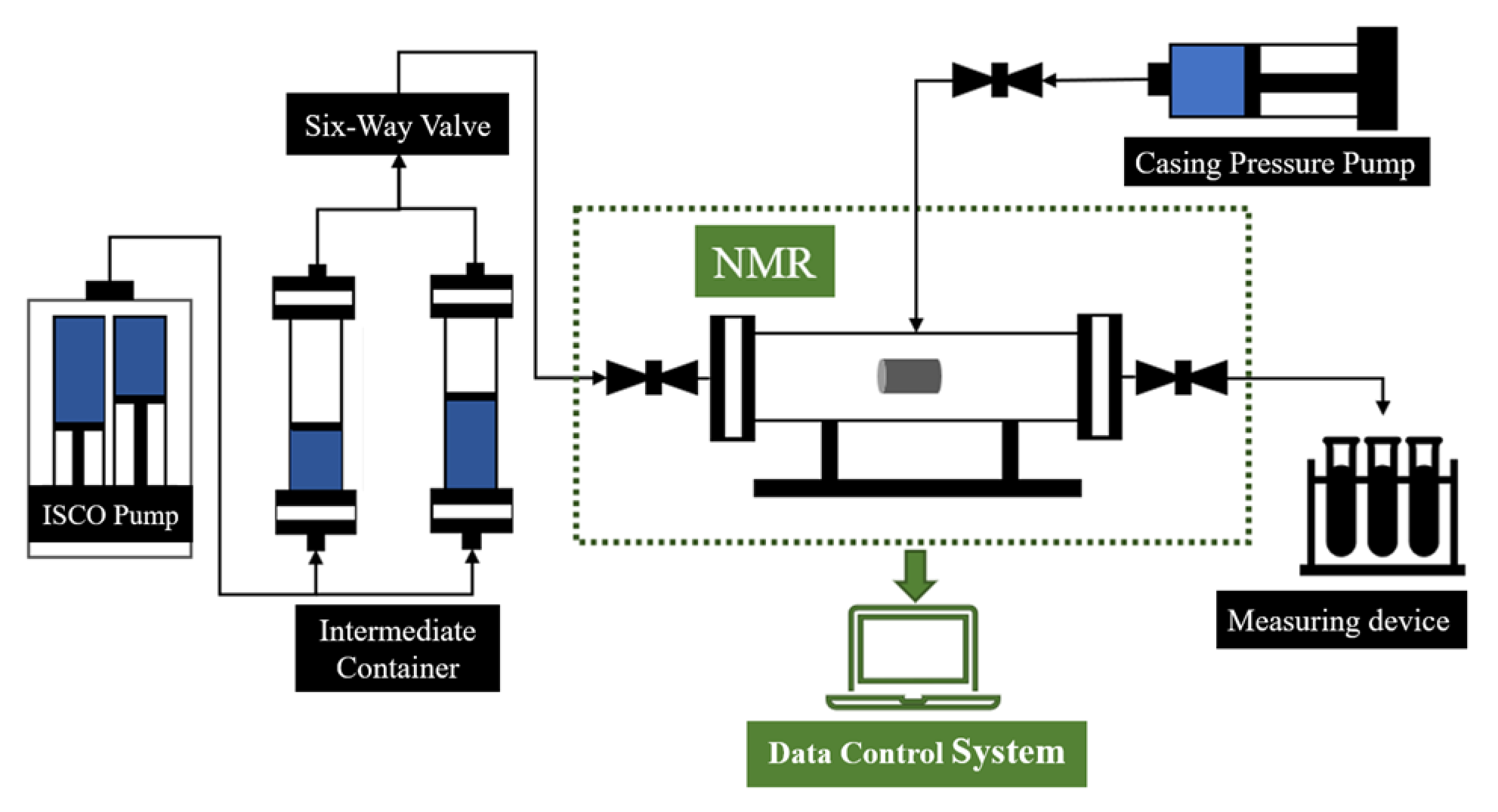

2. Experimental Equipment and Methods

2.1. Experimental Materials and Equipment

2.2. Experimental Procedure

2.2.1. Fracturing Fluid Invasion and Flowback

- ➀

- Cleaning and drying the cores. The thermotank is set to 50 °C;

- ➁

- Placing the core sample into the core holder, vacuuming it for 48 h, and then saturating oil into the core;

- ➂

- Closing the backpressure valve and continuing to inject oil until the pressure reaches 10 MPa and letting it stabilize. Taking NMR T2 spectrum and images;

- ➃

- Invasion: injecting fracturing fluid at 30 MPa and recording T2 spectrum when the pressure reaches 20 MPa and 30 MPa, respectively. Then the injection is stopped and the soaking is maintained for 5 h. The pressure difference of 10 MPa and 20 MPa is selected because it is reported that the pressure difference across the fracture face is reported to be 10~20 MPa;

- ➄

- Flowback: recording T2 spectrum when the production pressure drops to 20 MPa and 10 MPa, respectively.

2.2.2. Imbibition Test of Fracturing Fluid

- ➀

- Cleaning and drying the cores;

- ➁

- Vacuuming the core for 48 h and then saturating it with oil up to 25 MPa;

- ➂

- Weighing the core and taking the T2 spectrum;

- ➃

- Putting the core into a container at 80 °C and 10 MPa;

- ➄

- At different time intervals, depressurizing the system, taking the core out, weighing it, and taking the T2 spectrum.

3. Experimental Results

3.1. Oil Flow Characteristics During Fracturing Fluid Invasion and Flowback

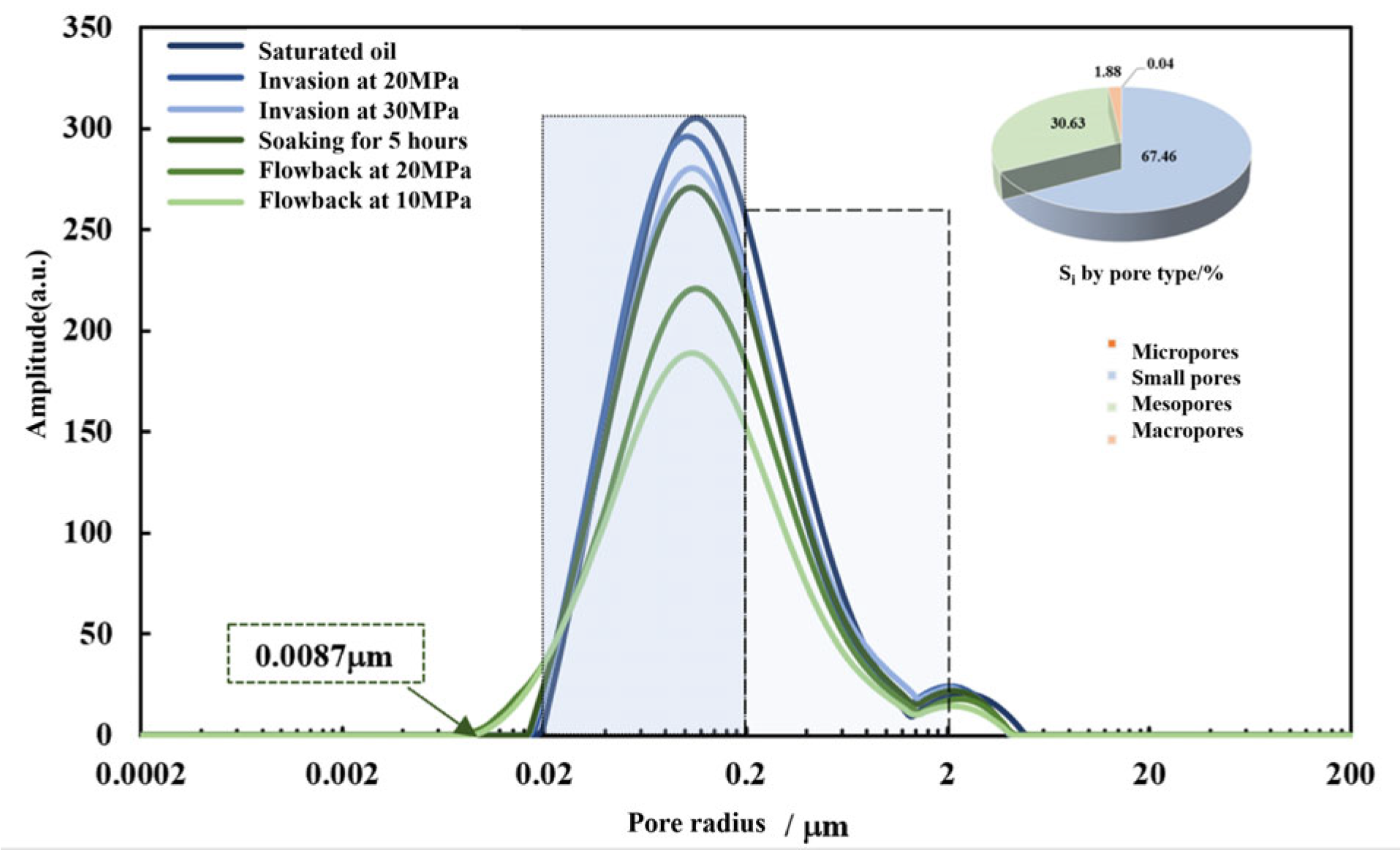

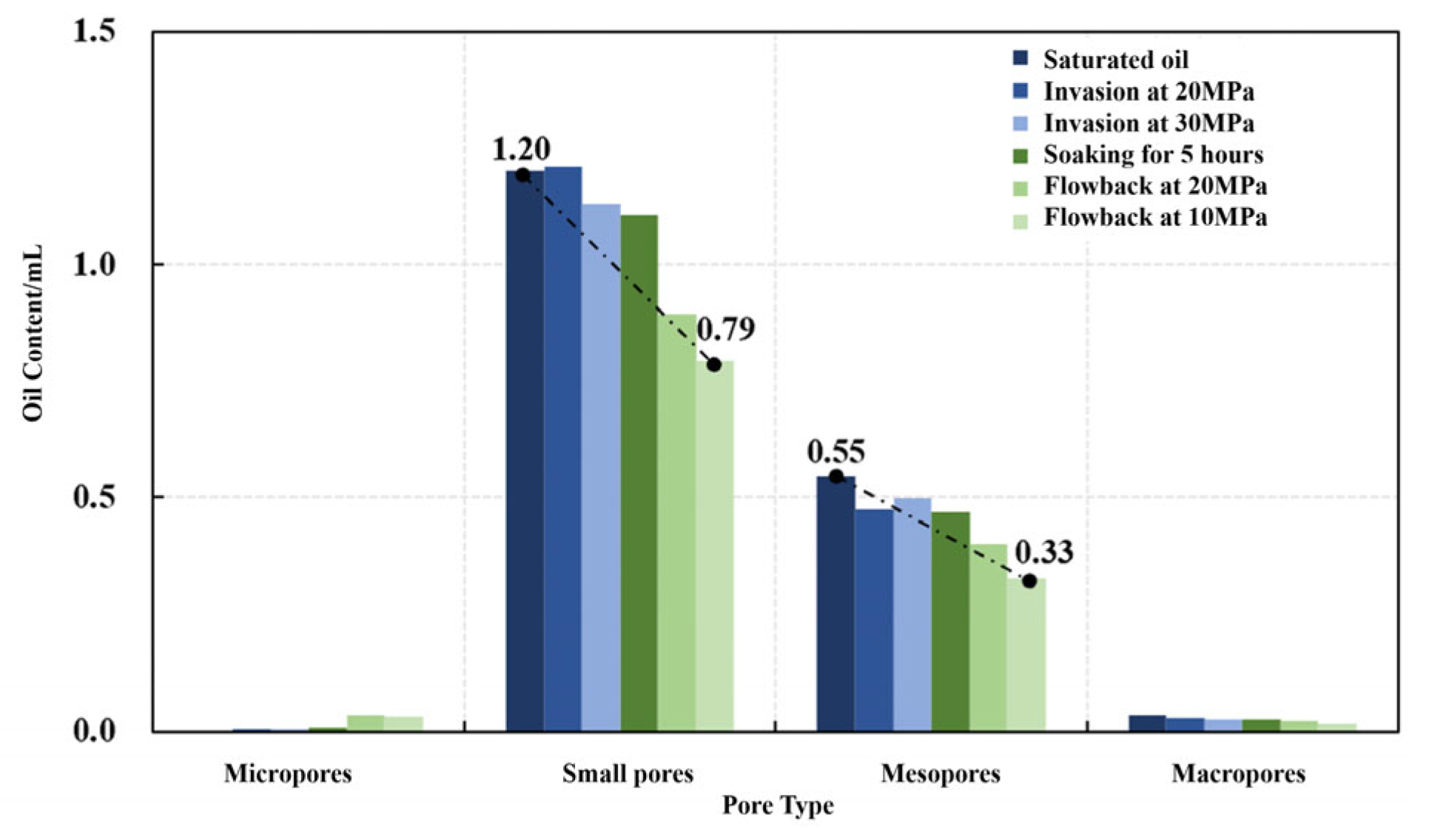

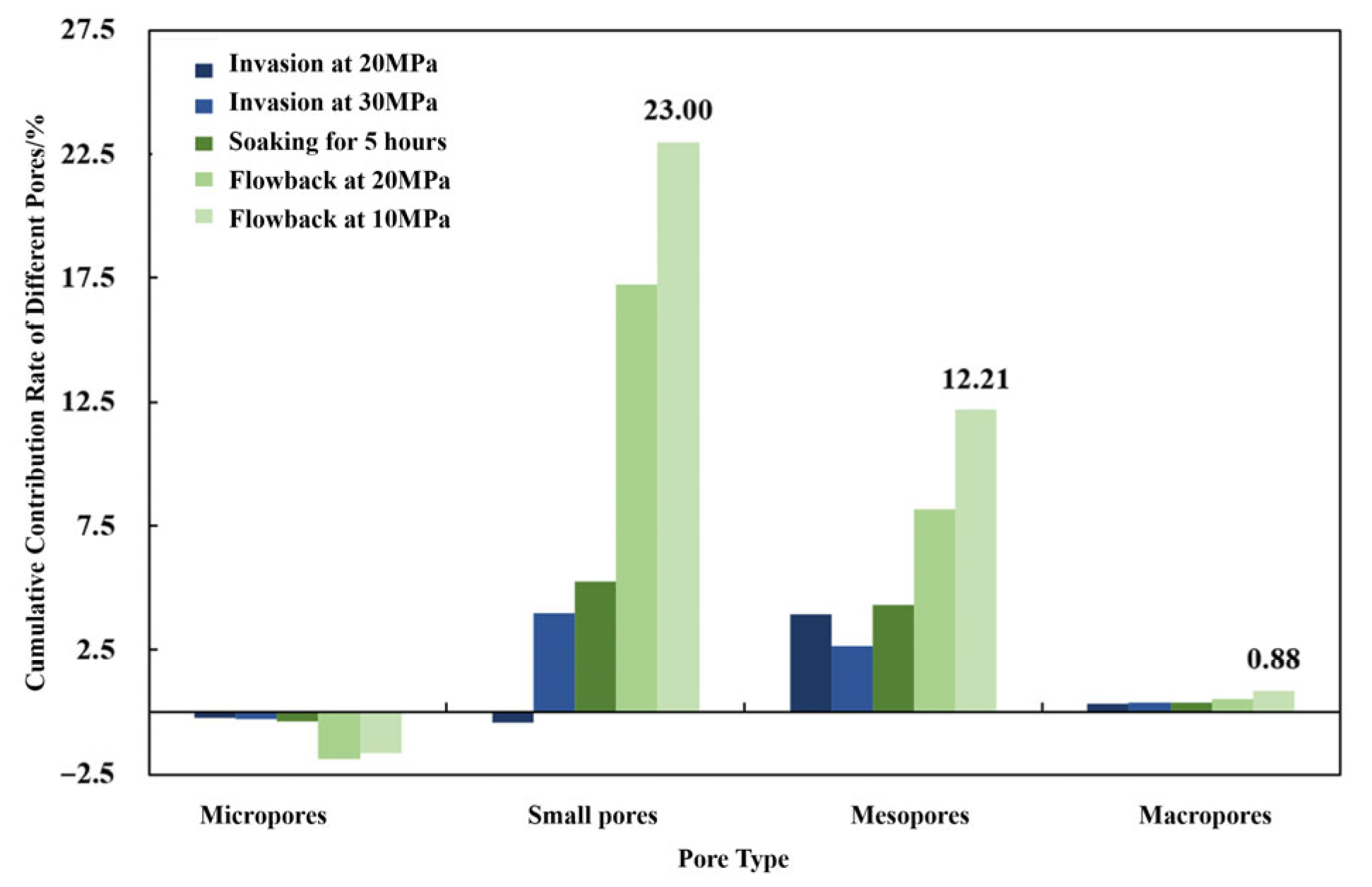

3.1.1. Study on Invasion and Flowback of Fracturing Fluids in Upper Sweet-Spot Core

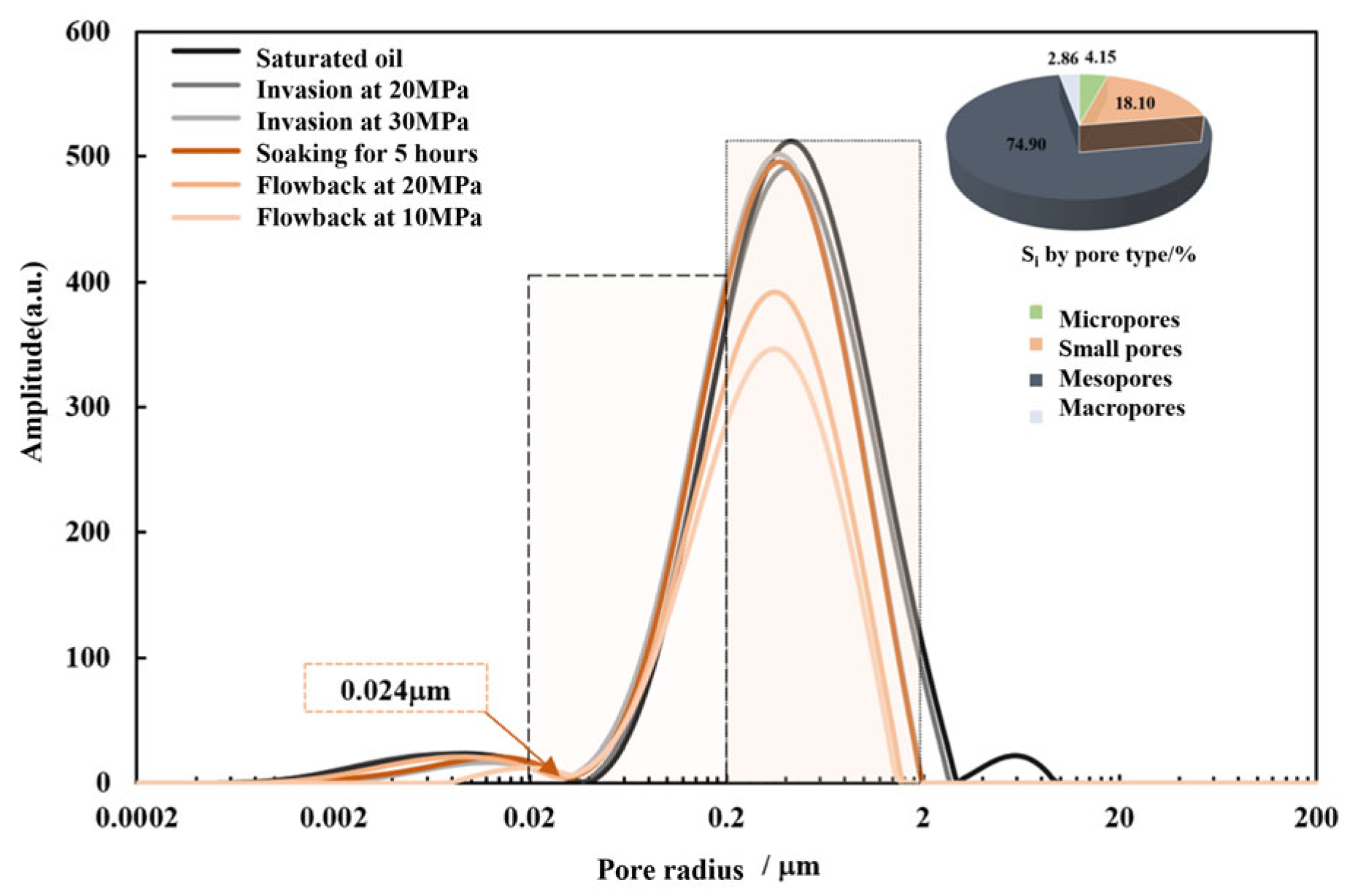

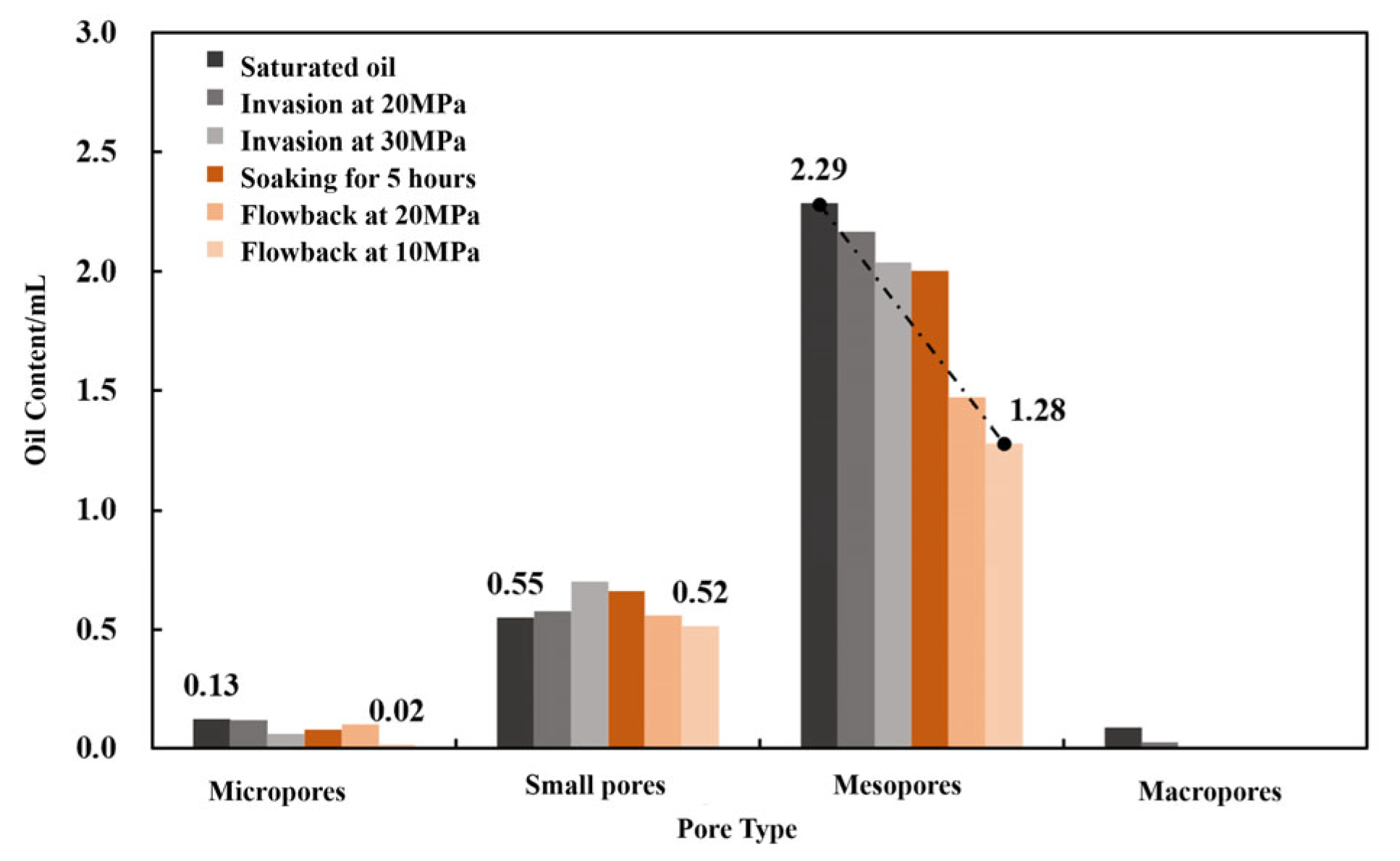

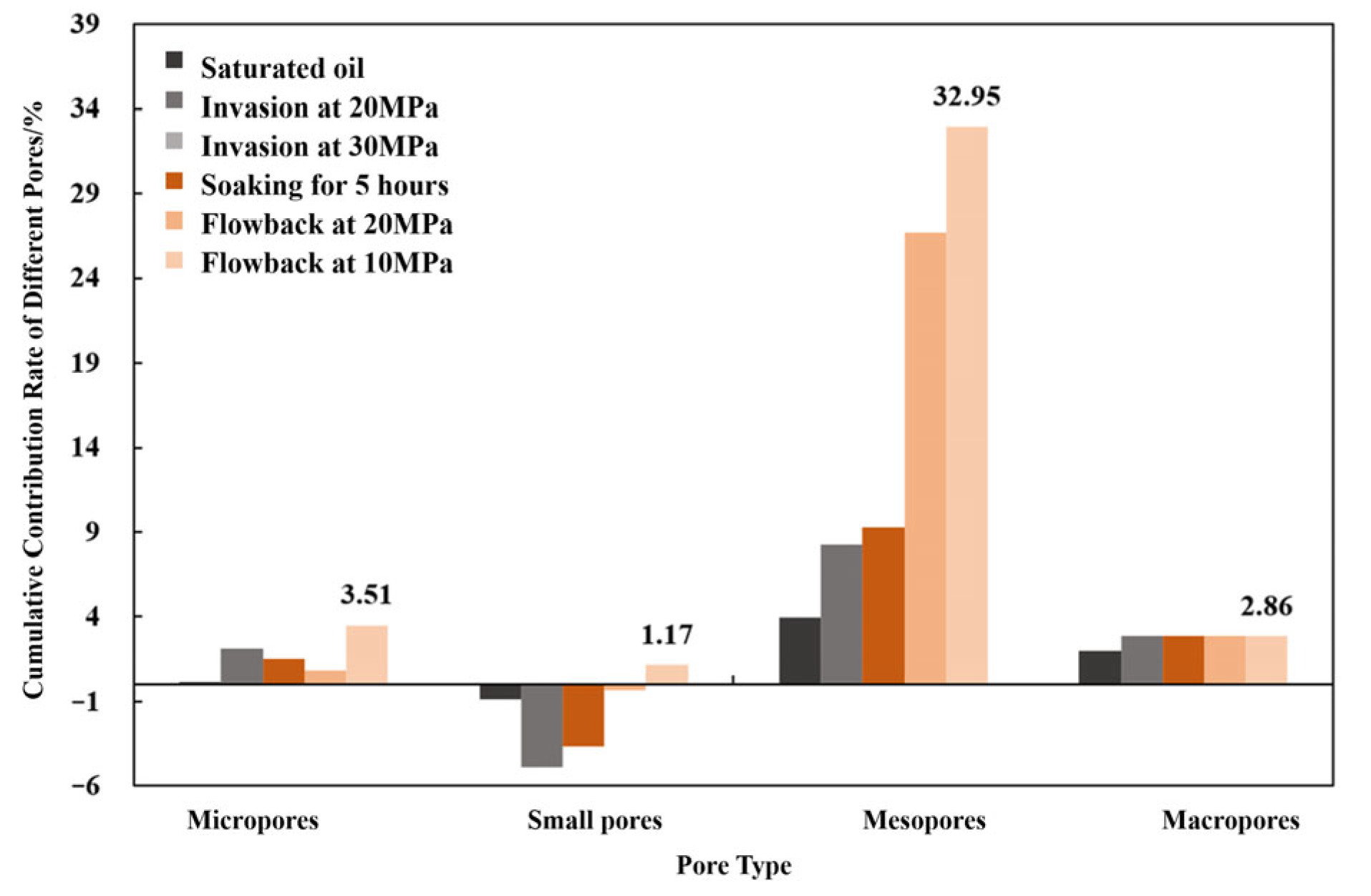

3.1.2. Study on the Invasion and Displacement of Fracturing Fluids in Lower Sweet-Spot Core

3.2. Fracturing Fluid Invasion Depth and Recovery Efficiency

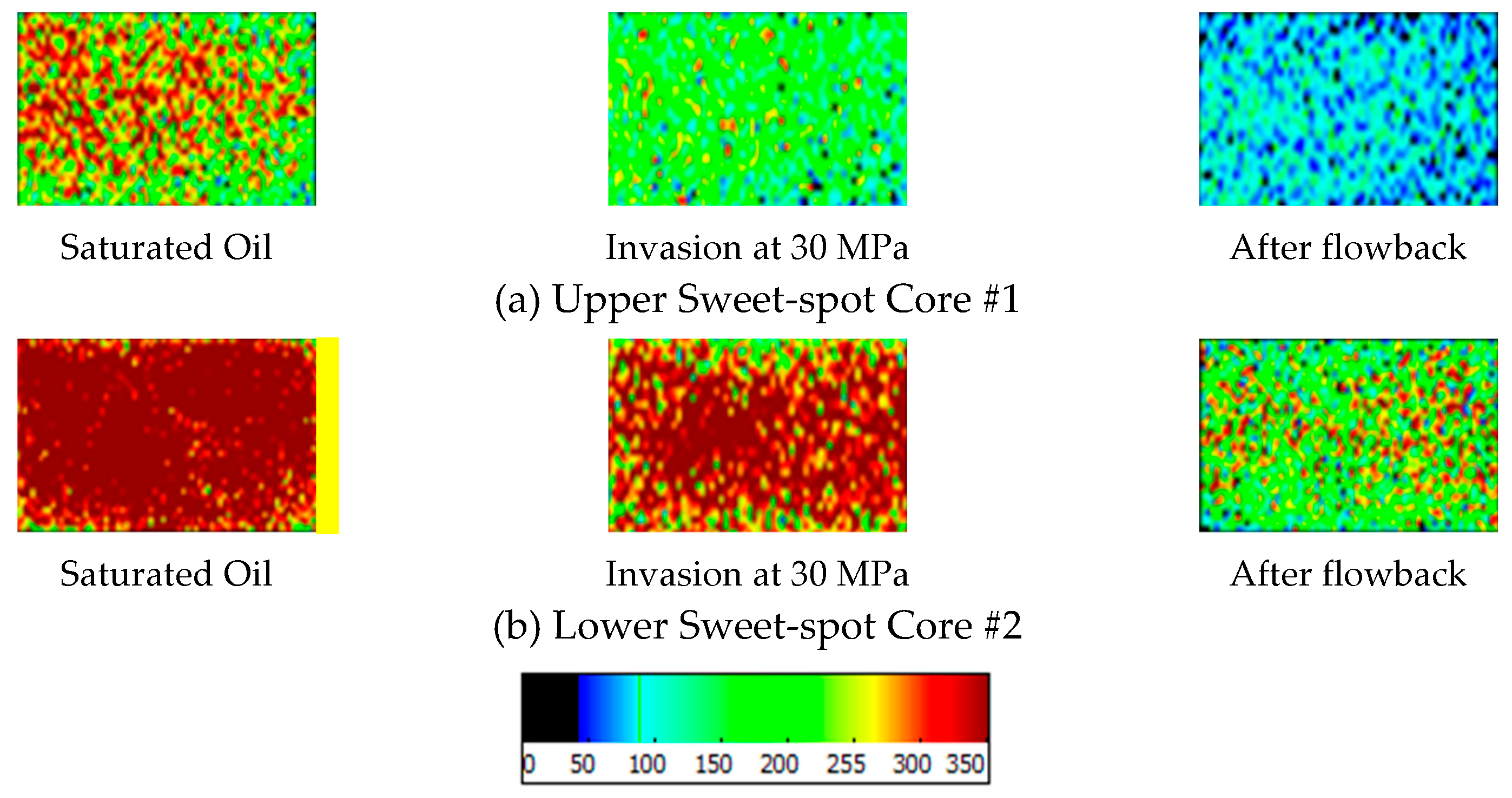

3.2.1. Fracturing Fluid Invasion and Flowback Nuclear Magnetic Resonance Imaging

3.2.2. Fracturing Fluid Invasion Depth

3.2.3. Flowback Behavior of Fracturing Fluid

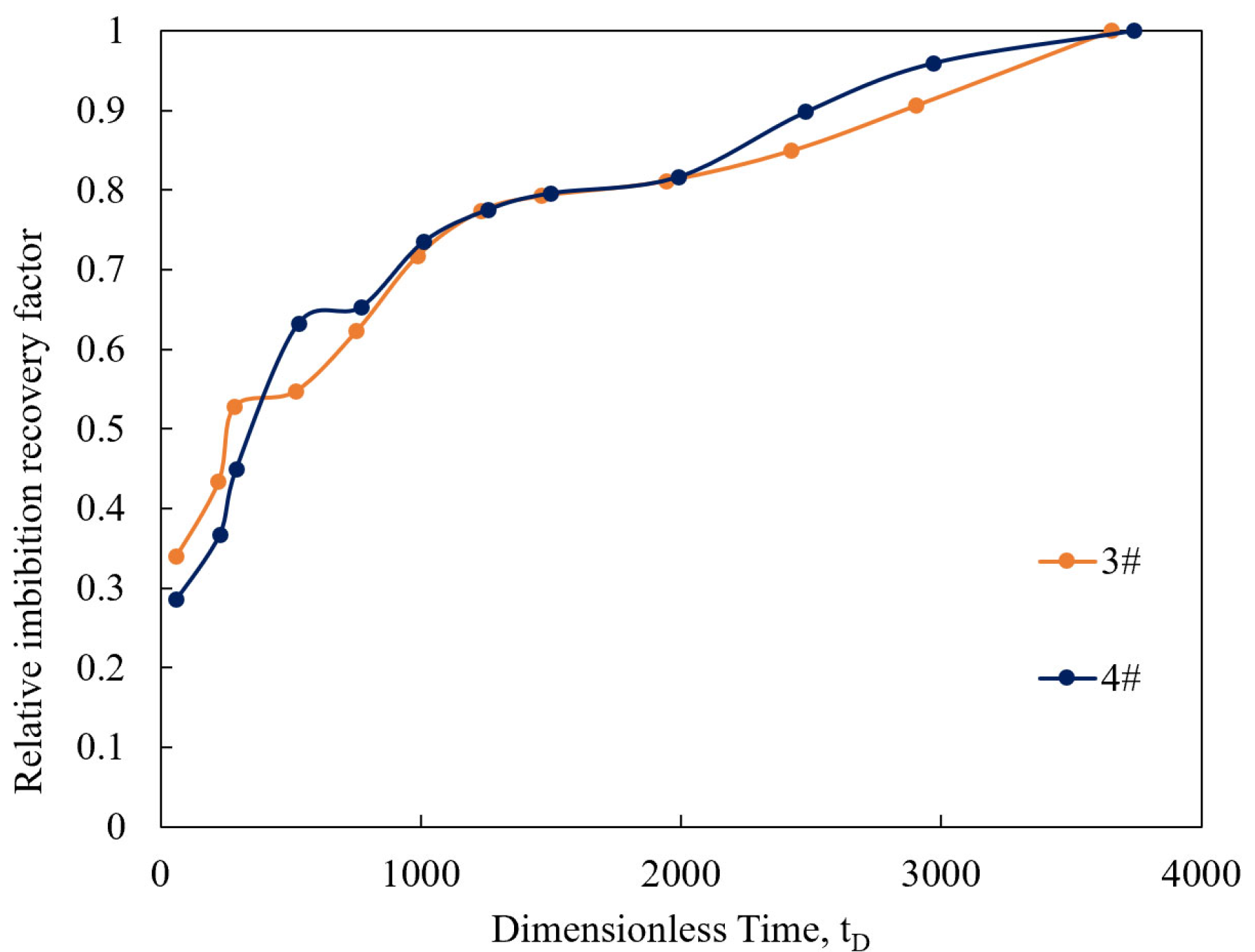

3.3. HTHP Imbibition Characteristics of Fracturing Fluid

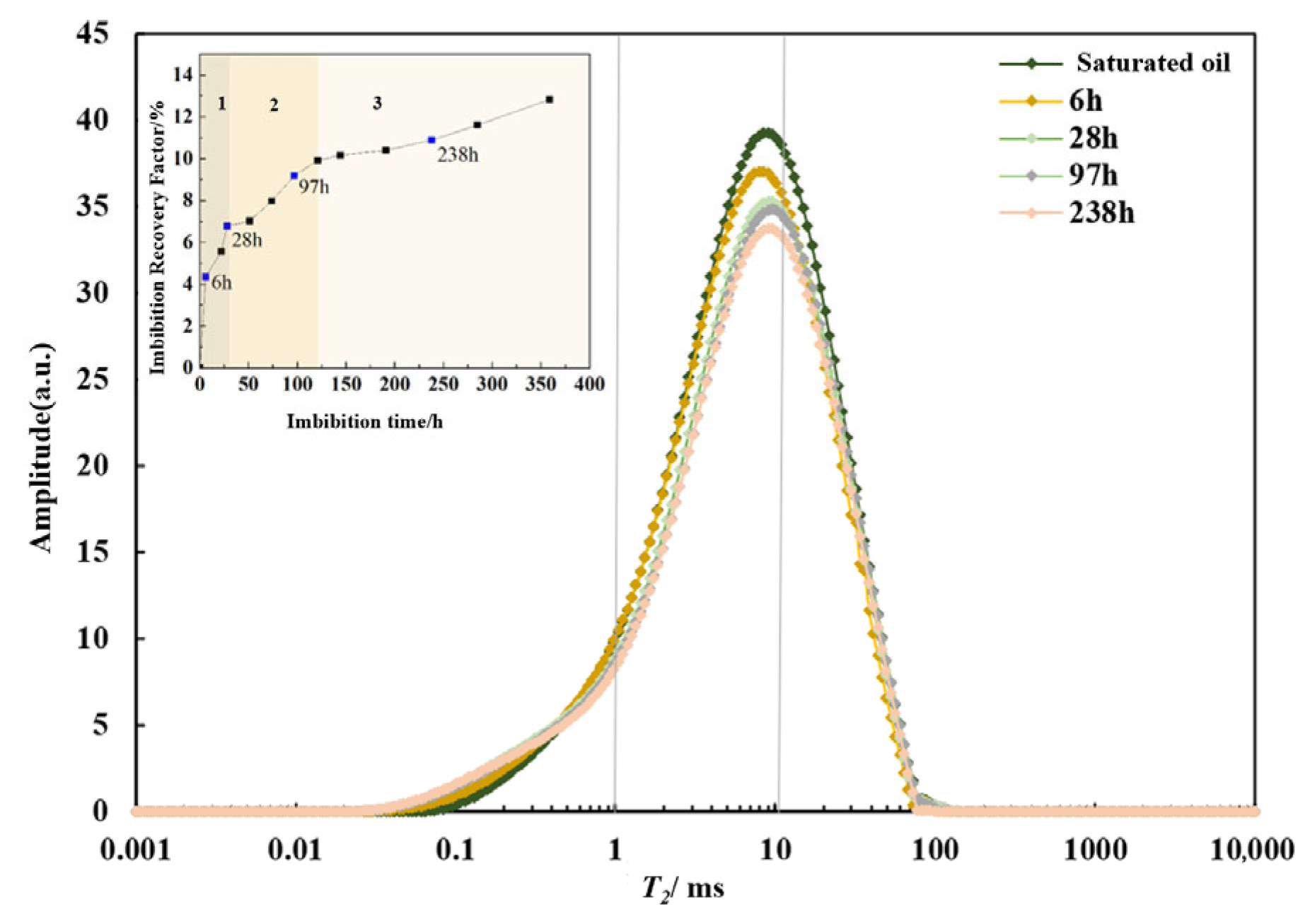

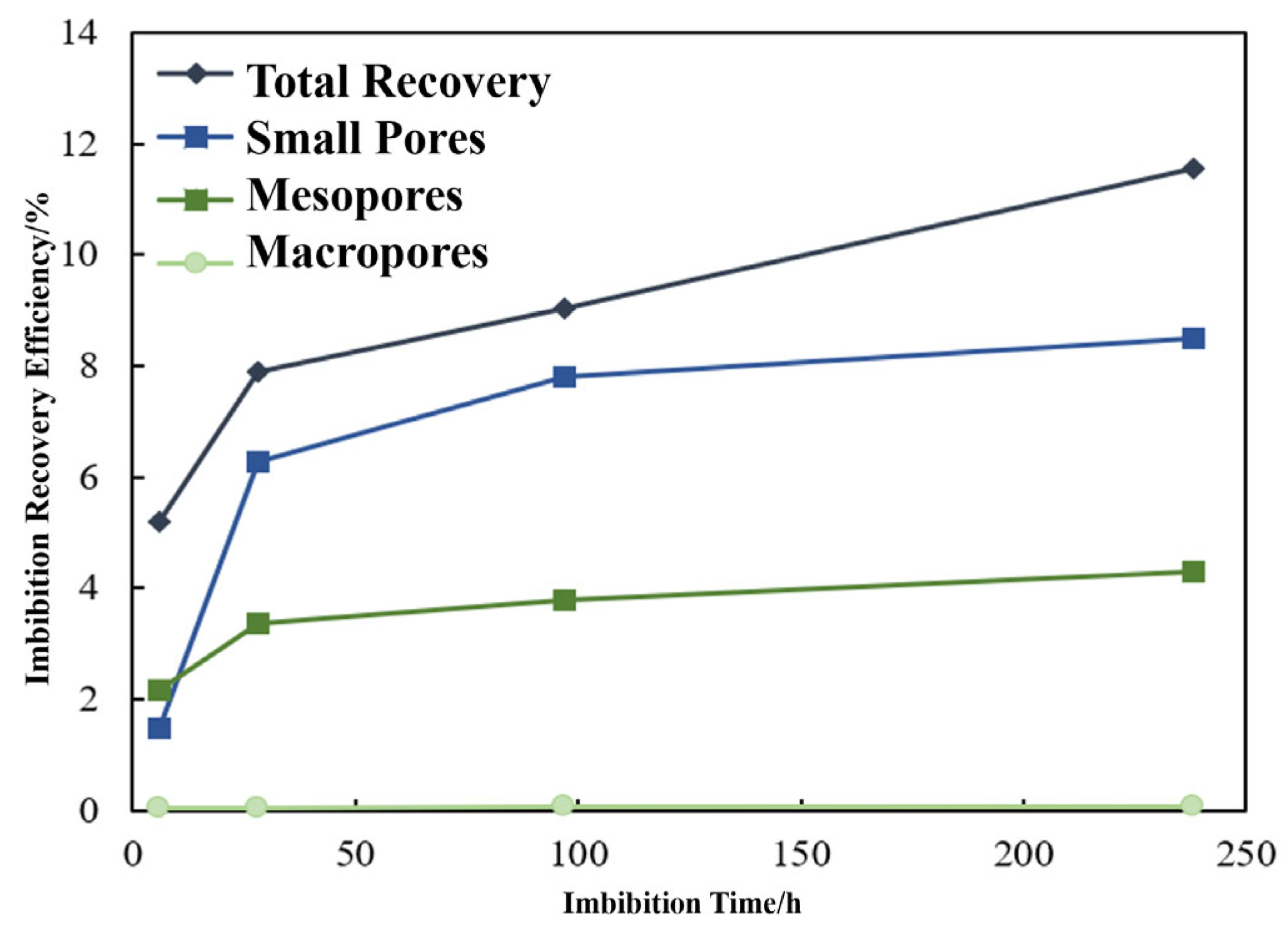

3.3.1. Imbibition of Fracturing Fluid in Upper Sweet-Spot Cores

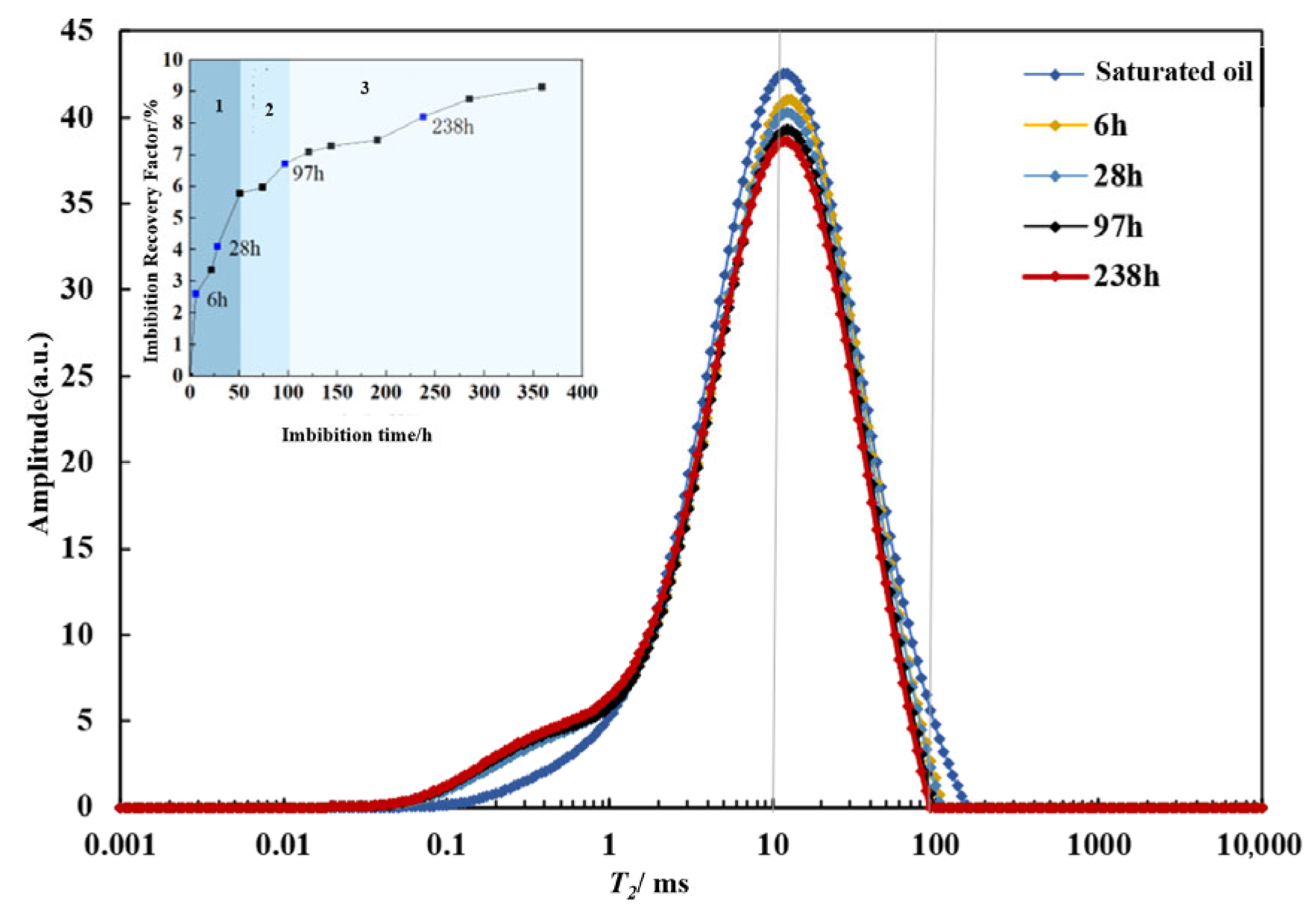

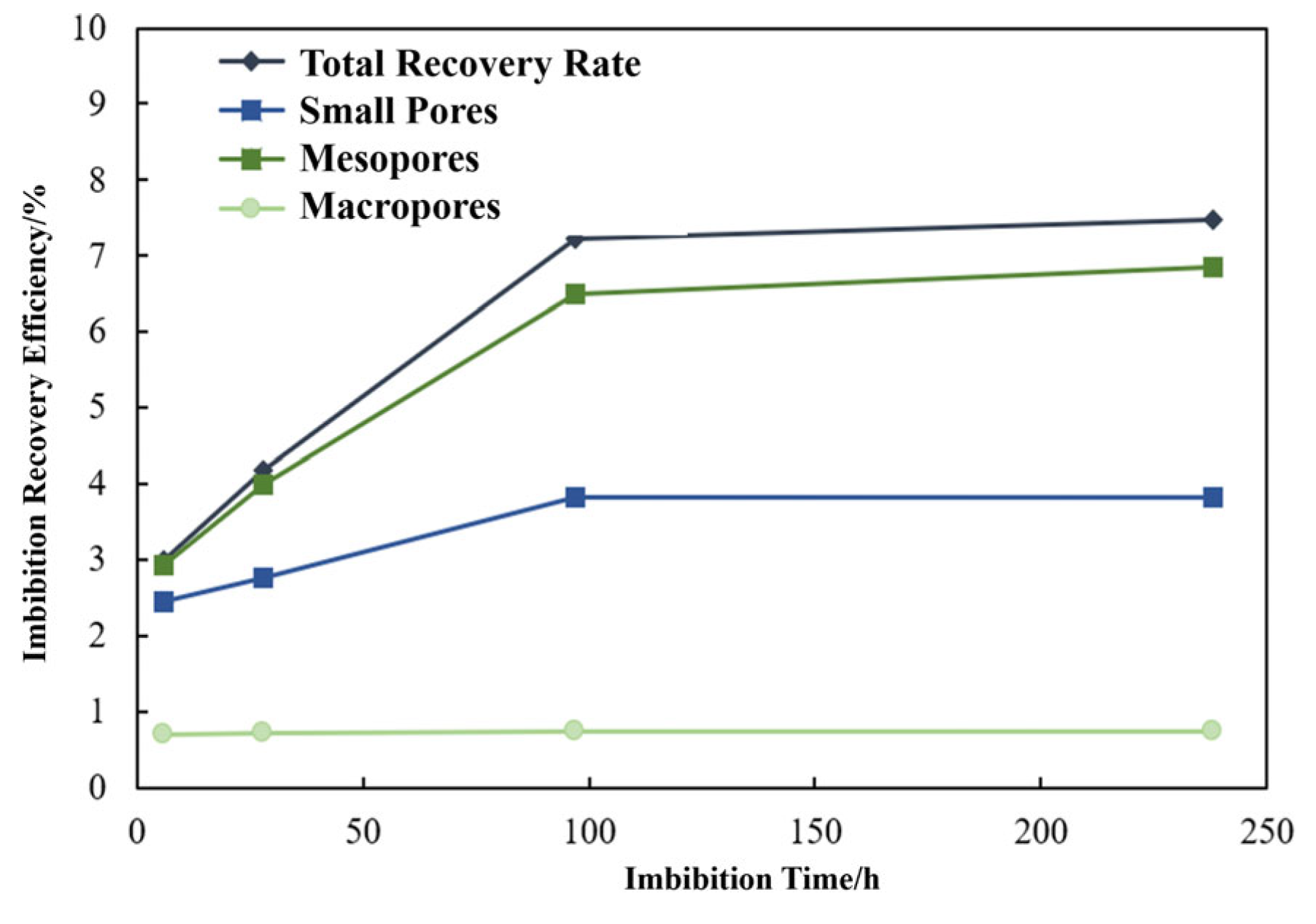

3.3.2. Imbibition of Fracturing Fluid in Lower Sweet-Spot Cores

4. Conclusions

- (1)

- In the upper sweet-spot core, small pores are the primary oil-bearing pores, while they are mesopores in the lower sweet-spot core. During fracturing fluid invasion and flowback, small pores in the upper sweet-spot core are the main oil-producing pores, followed by mesopores, with a Minimum Pore Production Radius (MPPR) of 0.0087 µm. While in the lower sweet-spot core, mesopores are the primary oil-producing pores, followed by micropores, with a MPPR of 0.024 µm.

- (2)

- As the invasion pressure increases, the maximum invasion depth increases. The upper sweet-spot core exhibits a maximum invasion depth of 1.46 cm and a final recovery rate of 34.45%, whereas the value is 1.77 cm and 40.49% for the lower sweet-spot core, respectively. With larger pore throats, the lower sweet-spot core achieves a maximum invasion depth and recovery rate approximately 1.2 times greater than those of the upper sweet-spot.

- (3)

- The total volume of fracturing fluid injected into the upper and lower sweet-spot core was 0.80 mL and 1.50 mL, with a flowback efficiency of 23.60% and 17.66%, respectively. Due to differences in the dominant oil-producing pore systems between the two cores, the upper sweet-spot exhibited lower total fracturing fluid invasion but a higher flowback efficiency than the lower sweet spot.

- (4)

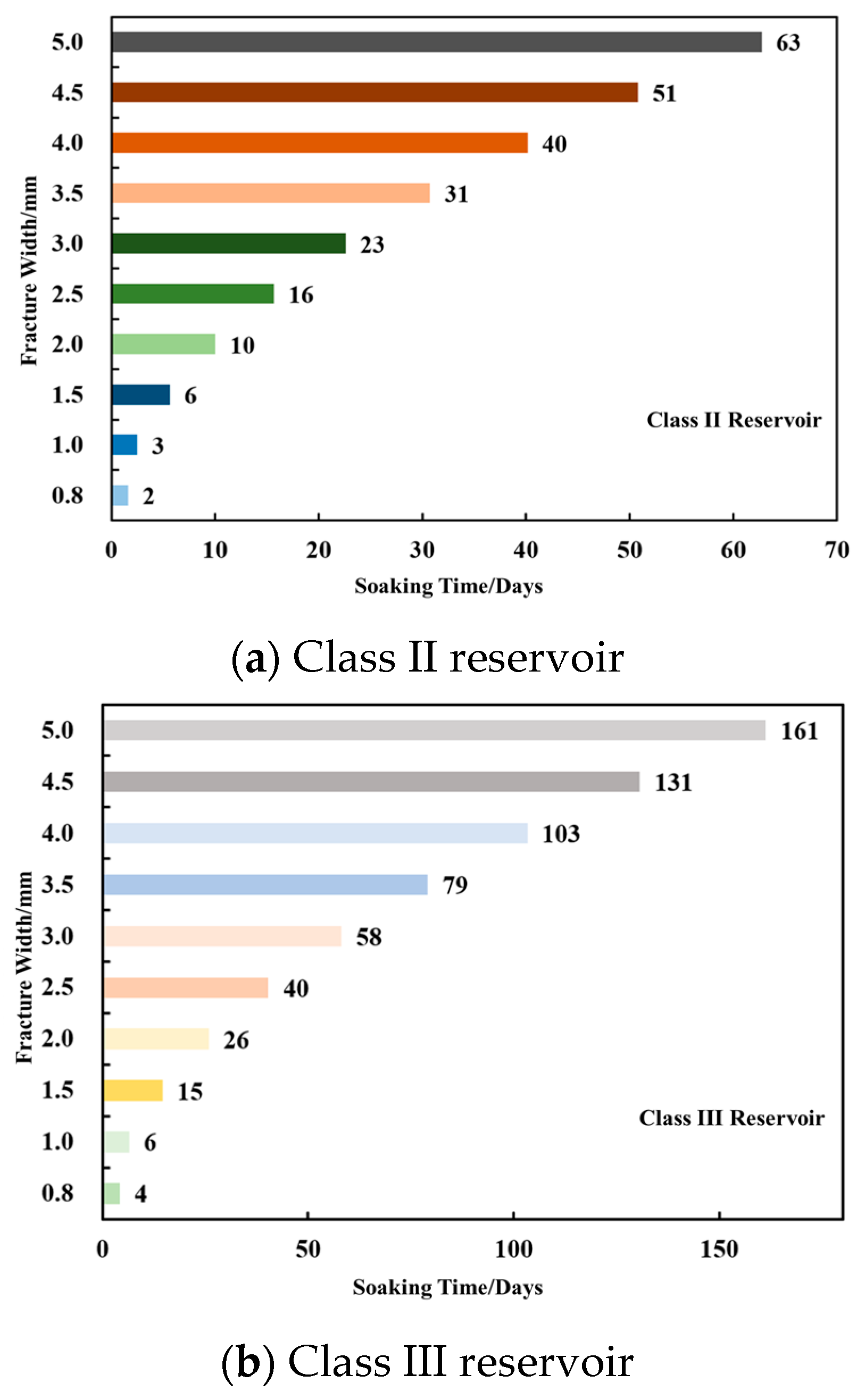

- Due to lower permeability in the upper sweet-spot core, the imbibition recovery factor under high temperature and high pressure was higher than that in the upper sweet-spot. Ma’s model provided a good fit to the imbibition results. By equating Ma’s dimensionless time for core scale and reservoir scale, the optimized well-soaking time for different fracture widths was proposed.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, X.; Hasheti, Y.; Yan, X.; Zheng, B.; Liu, B.; Zhang, J. Geological Characteristics and Distribution of Promising Areas for Tight Oil in the Luchaogou Formation of the Jimsar Depression. Sci. Technol. Eng. 2022, 22, 5134–5145. [Google Scholar] [CrossRef]

- Liu, Z.; Zeng, Z.; Tian, J.; Li, J.; Li, W.; Zhang, W.; Zhang, Z. Genesis and Distribution Prediction of the “Sweet-spot” in the Luchaogou Formation of the Permian System, Jimusar Depression. Lithol. Reserv. 2022, 34, 15–28. [Google Scholar] [CrossRef]

- Palisch, T.T.; Vincent, M.; Handren, P.J. Slickwater Fracturing: Food for Thought. In Proceedings of the Society of Petroleum Engineers Annual Technical Conference and Exhibition, Denver, CO, USA, 21 September 2008. [Google Scholar] [CrossRef]

- King, G.E. Thirty years of gas shale fracturing: What have we learned. In Proceedings of the SPE Annual Technical Conference and Exhibition, Florence, Italy, 19 September 2010. [Google Scholar] [CrossRef]

- Hou, X.; Zhang, X.; Zhou, J. Study on the effect of surfactant functions on invasion–flowback and interaction depth based on online computed tomography and numerical simulation. Phys. Fluids 2025, 37, 076617. [Google Scholar] [CrossRef]

- Agrawal, S.; Sharma, M.M. Liquid Loading Within Hydraulic Fractures And Its Impact on Unconventional Reservoir Productivity. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Denver, CO, USA, 12–14 August 2013. [Google Scholar] [CrossRef]

- Liu, N.; Liu, M.; Zhang, S. Post-Pressurization Backflow Patterns in Shale Gas Wells. Nat. Gas Ind. 2015, 35, 50–54. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, S.; Guan, H.; Liu, Y.; Hui, G. Relationship between Characteristics of Tight Oil Reservoirs and Fracturing Fluid Damage: A Case Study of the Chang 7 Member of the Triassic Yanchang Formation in the Ordos Basin. Pet. Nat. Gas Geol. 2015, 36, 848–854. [Google Scholar] [CrossRef]

- Xia, H.; Han, K.; Song, W.; Yang, C.; Luo, F.; Yao, J. Study on the Micro-Scale Mechanism of Fracturing Fluid Retention in Multi-Scale Pores and Fractures of Shale Gas Reservoirs. Reserv. Eval. Dev. 2023, 13, 627–635+685. [Google Scholar] [CrossRef]

- Ren, K.; Ge, H.; Yang, L.; Wu, S.; Shen, Y. Shale Self-Suction Experiment and Its Application in Flow Reversal Analysis. Sci. Technol. Eng. 2015, 15, 106–109. [Google Scholar]

- Zhang, T.; Li, X.; Wang, Y.; Shi, J.; Yang, L.; Sun, Z.; Yang, J.; Zhang, Z. Influence of Shale Reservoir Properties on Fracturing Fluid Flowback Rate and Production Capacity. Nat. Gas Geosci. 2017, 28, 828–838. [Google Scholar]

- Ding, Y.; Lei, W.; Liu, X.; Qin, Z.; Liang, L.; Zhou, J.; Xiong, J. Experimental Study on the Correlation Among Self-Suction, Hydration Damage, and Ion Diffusion in Shale Gas Reservoirs. Pet. Drill. Technol. 2023, 51, 88–95. [Google Scholar]

- Yuan, X.; Xu, D.; Chen, S.; He, X.; Cheng, N.; Chen, J. Damage to Flow Conductivity in Shale Reservoirs Caused by Fracturing Fluid Invasion. Sci. Technol. Eng. 2020, 20, 3591–3597. [Google Scholar] [CrossRef]

- Shao, J.; You, L.; Jia, N.; Kang, Y.; Chen, M. Investigation of induced change in pore structure by the reaction of shale with fracturing fluid. Gas Sci. Eng. 2023, 110, 204860. [Google Scholar] [CrossRef]

- Jing, J.; Guo, B.; Wang, X.; Li, X. Improvement and Application of Pressure Drop Analysis Method for Small-Scale Fracturing in Tight Reservoirs. Xinjiang Pet. Geol. 2019, 40, 371–375. [Google Scholar]

- Qin, T. Practical Reservoir Engineering Methods; Petroleum Industry Press: Beijing, China, 1989. [Google Scholar]

- Ma, S.; Morrow, N.R.; Zhang, X. Generalized scaling of spontaneous imbibition data forstrongly water-wet systems. J. Pet. Sci. Eng. 1997, 18, 165–178. [Google Scholar]

- Pu, Y. Experimental Study on Static Suction Patterns in Dense Reservoirs. Master’s Thesis, China University of Petroleum, Beijing, China, 2017. Available online: https://kns.cnki.net/kcms2/article/abstract?v=ldCk9GscAdAQRUSKSCQyktGufRGbBV8CHmB9uWH8yDOALR4rPaT1IGOLTtlNBHFNDB1kFBfP9a1RPSBQFx-7fBVk7sxwMbpCjpjG8mn8QClCezBq9NtezLRY9fYtDkw06iTG8CPW2JN6H0XN_CRJaZvSJcdKRB1e3wLzFtV01lY=&uniplatform=NZKPT (accessed on 20 October 2025).

- An, X.; Wang, D.; Xiang, L.; Wang, Z.; Zhang, G. Cluster Analysis of Rock Pore Structure Characteristics in Tight Oil Reservoirs: A Case Study of the Luchaogou Formation Reservoir in the Jimsar Depression. Reserv. Eval. Dev. 2016, 6, 7–13. [Google Scholar] [CrossRef]

- Wang, F.; Ruan, Y.; Chen, Q.; Zhang, S. A Pressure Decline Model for Fracturing and Steaming Wells Considering Fluid Seepage and Oil Replacement Effects. Pet. Explor. Dev. 2021, 48, 1250–1257. [Google Scholar] [CrossRef]

| Core | Diameter/cm | Length/cm | Porosity/% | Permeability/(10−3 μm2) | Experimental Protocol |

|---|---|---|---|---|---|

| 1# (Upper sweet spot) | 2.457 | 4.265 | 9.35 | 0.018 | Fracturing Fluid Invasion and Flowback |

| 2# (Lower sweet spot) | 2.586 | 4.367 | 14.26 | 0.032 | |

| 3# (Upper sweet spot) | 2.427 | 4.749 | 7.47 | 0.015 | 10 Mpa, 80 °C Imbibition |

| 4# (Lower sweet spot) | 2.507 | 4.913 | 10.44 | 0.025 |

| Different Stages | Invasion 20 MPa | Invasion 30 MPa | Soaking 5 h | Flow Back 20 MPa | Flow Back 10 MPa |

|---|---|---|---|---|---|

| Recovery Rate/% | 3.64 | 6.76 | 9.65 | 24.08 | 34.45 |

| Depth of Deployment/cm | 0.15 | 0.29 | 0.41 | 1.02 | 1.46 |

| Different Stages | Invasion 20 MPa | Invasion 30 MPa | Soaking 5 h | Flow Back 20 MPa | Flow Back 10 MPa |

|---|---|---|---|---|---|

| Recovery Rate/% | 5.28 | 8.27 | 10.03 | 30.06 | 40.49 |

| Depth of Deployment/cm | 0.23 | 0.36 | 0.44 | 1.31 | 1.77 |

| Core | Invasion Volume/mL | Oil Production Volume/mL | Flowback Volume/mL | Flowback Efficiency/% |

|---|---|---|---|---|

| 1# | 0.80 | 0.61 | 0.19 | 23.60 |

| 2# | 1.50 | 1.24 | 0.27 | 17.66 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Fan, W.; Yang, C.; Lu, Y.; Gao, Y.; Wang, X.; Li, M. Investigation of Microscopic Oil Flow Characteristics During Fracturing Fluid Invasion and Flowback in Shale Oil Reservoirs. Processes 2025, 13, 3780. https://doi.org/10.3390/pr13123780

Zhang Y, Fan W, Yang C, Lu Y, Gao Y, Wang X, Li M. Investigation of Microscopic Oil Flow Characteristics During Fracturing Fluid Invasion and Flowback in Shale Oil Reservoirs. Processes. 2025; 13(12):3780. https://doi.org/10.3390/pr13123780

Chicago/Turabian StyleZhang, Yongqiang, Wei Fan, Chengwei Yang, Yao Lu, Yuanyuan Gao, Xiuyu Wang, and Mei Li. 2025. "Investigation of Microscopic Oil Flow Characteristics During Fracturing Fluid Invasion and Flowback in Shale Oil Reservoirs" Processes 13, no. 12: 3780. https://doi.org/10.3390/pr13123780

APA StyleZhang, Y., Fan, W., Yang, C., Lu, Y., Gao, Y., Wang, X., & Li, M. (2025). Investigation of Microscopic Oil Flow Characteristics During Fracturing Fluid Invasion and Flowback in Shale Oil Reservoirs. Processes, 13(12), 3780. https://doi.org/10.3390/pr13123780