Study on the Evolution Law of Four-Dimensional In Situ Stress During Hydraulic Fracturing of Deep Shale Gas Reservoir

Abstract

1. Introduction

2. Theory

2.1. Theory of Multi-Physics Field Coupling for Fluid Flow and Geomechanics in Fractured Zones of Shale Reservoirs

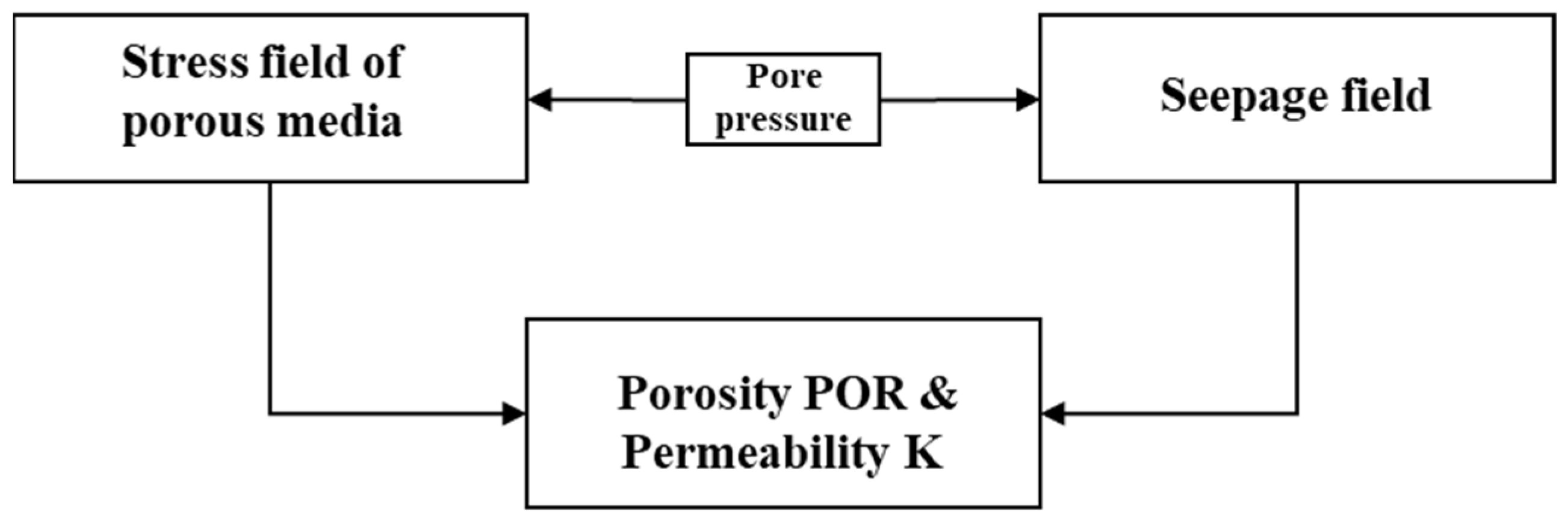

2.1.1. The Numerical Simulation Method for the Full Coupling of Fluid and Solid in the Evolution of In Situ Stress

2.1.2. Seepage-Geomechanics Fully Coupled Model

- (1)

- Reservoir rock mass control equation

- (2)

- Reservoir fluid flow control equation

- (3)

- Sensitivity control equation for reservoir fluid seepage stress

- (4)

- Darcy Flow–Stress Coupling

3. Model-Construction of a Four-Dimensional Geostress Evolution Model Based on the Coupling of Seepage and Geomechanics

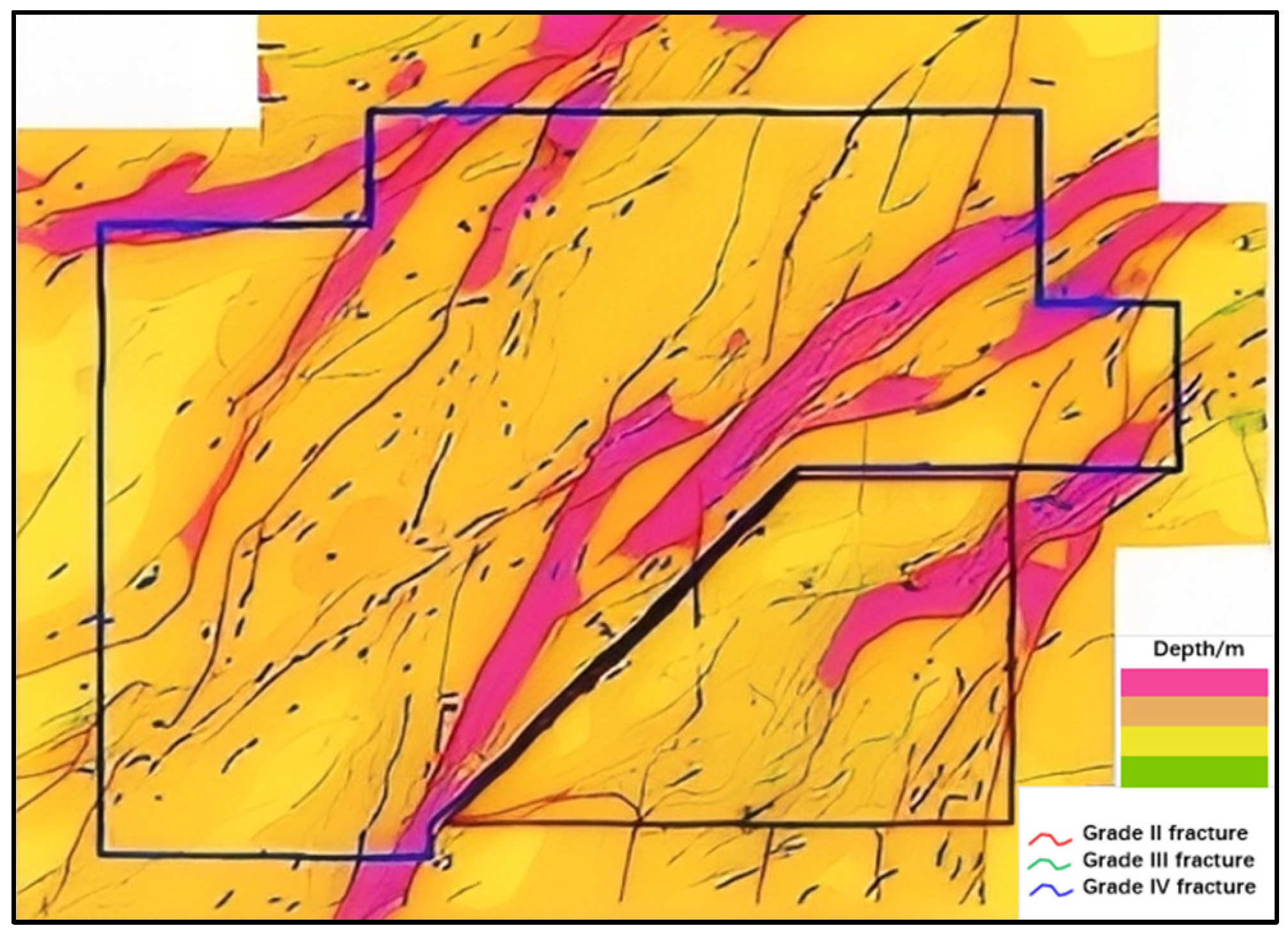

3.1. Establishment of a Fine-Scale Geomechanical Model in the Target Block

3.2. Establishment of the Finite Element Geomechanical Model

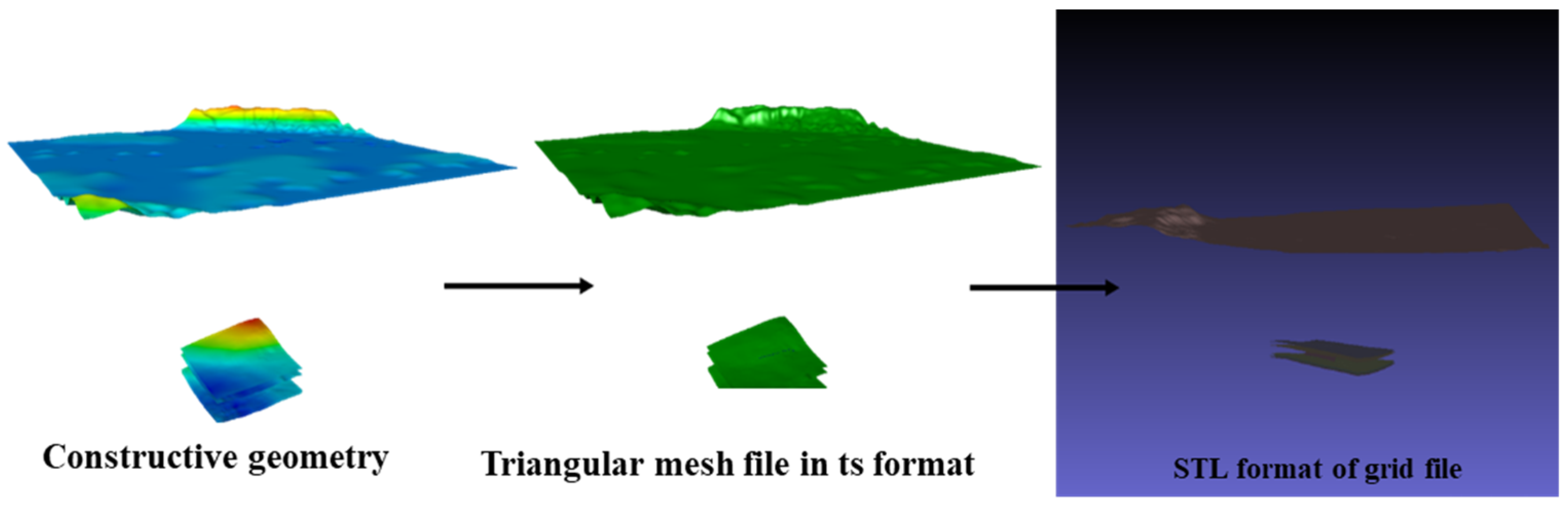

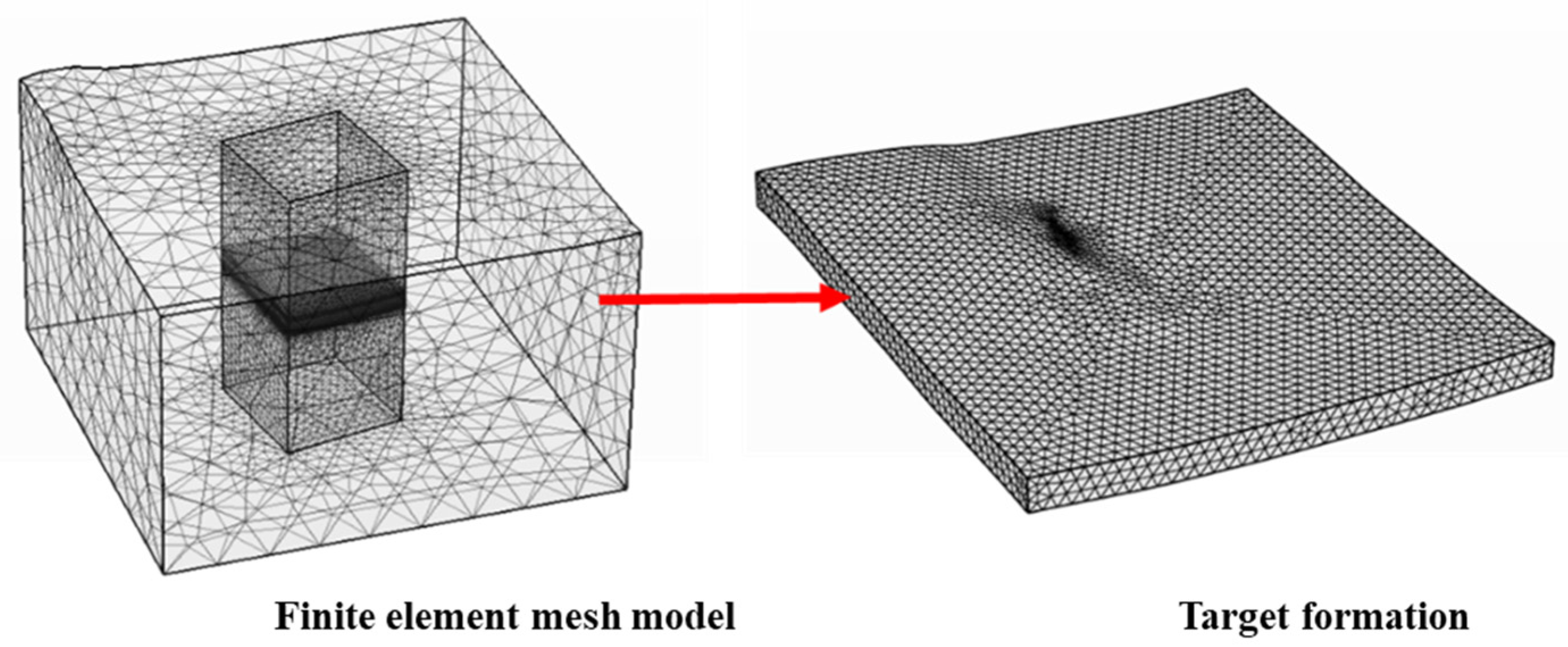

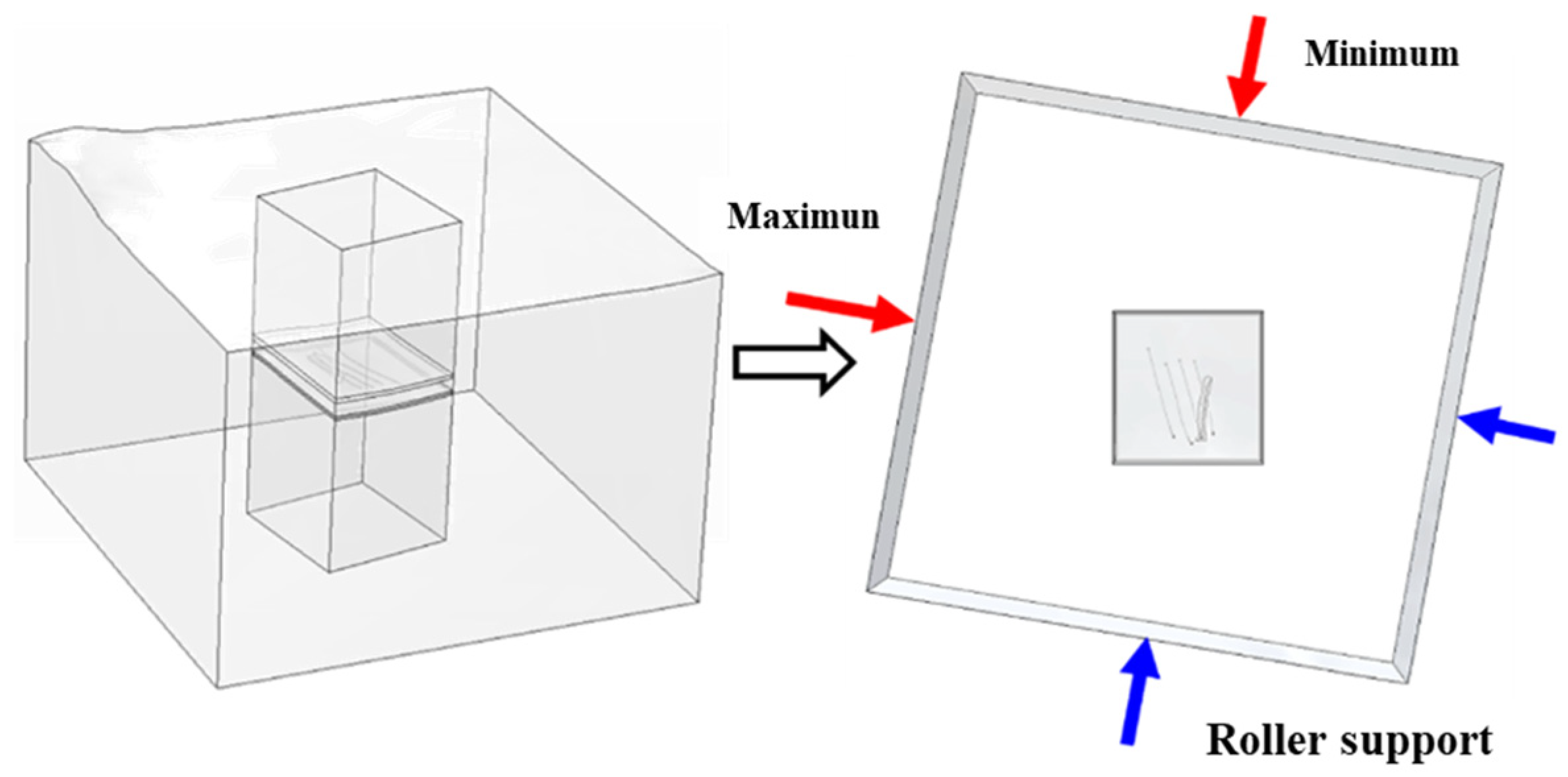

3.2.1. Geometric Conversion of Geological Structures and Grid Construction

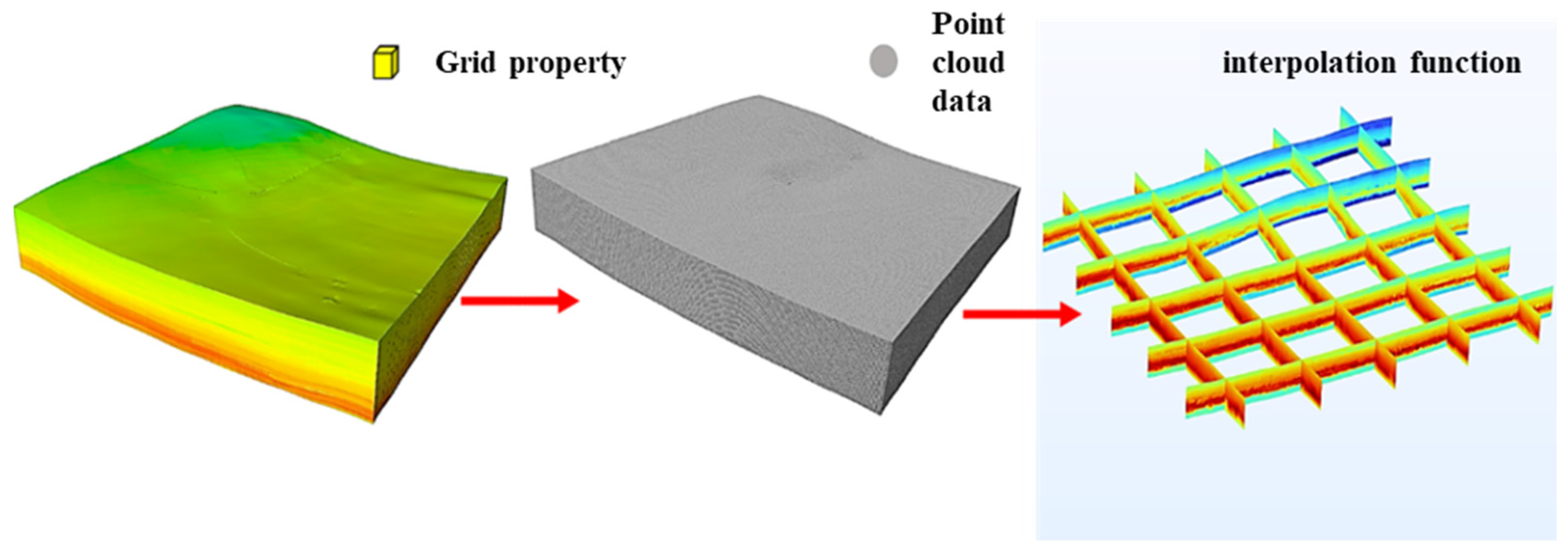

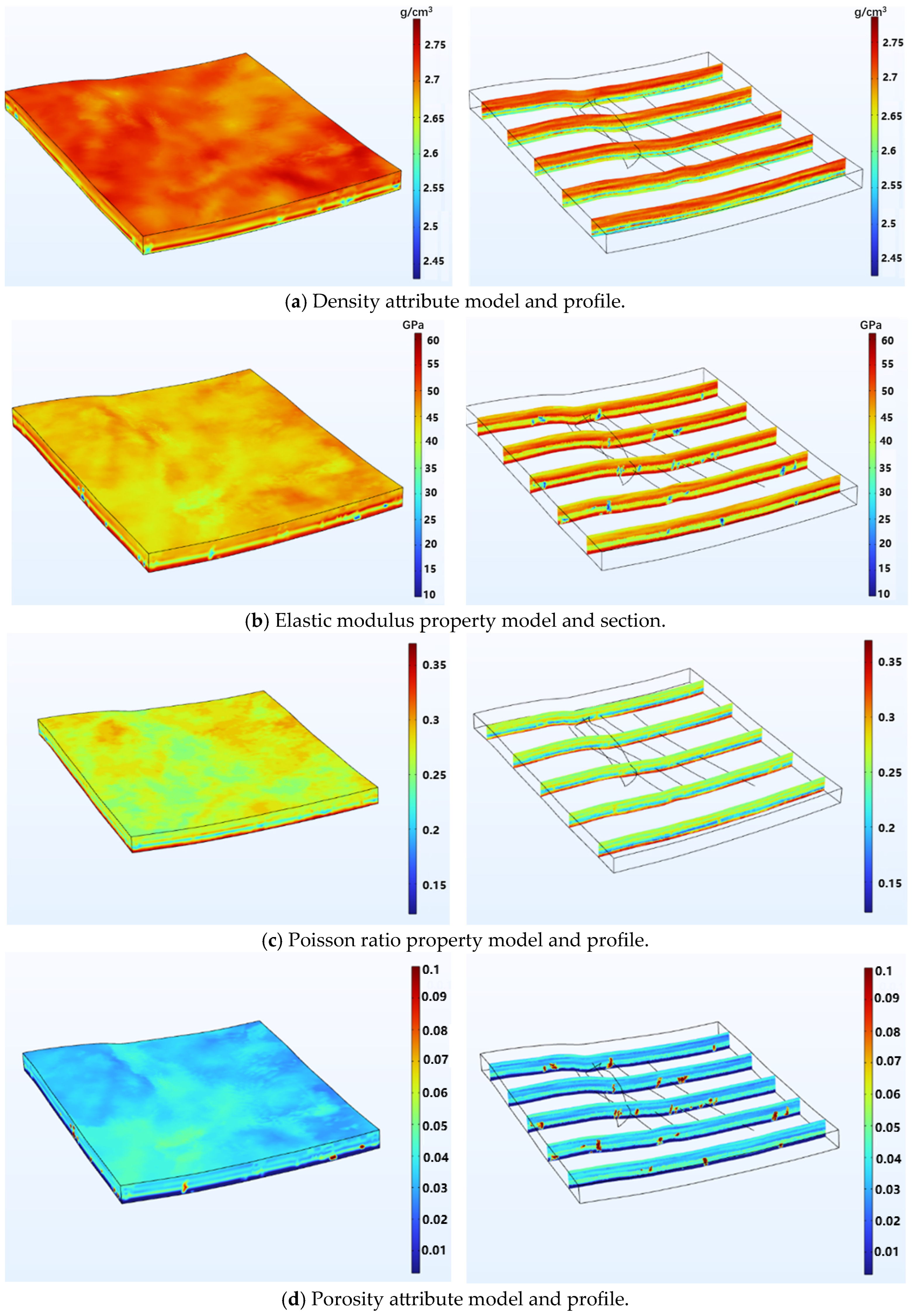

3.2.2. Construction of Finite Element Attribute Parameter Fields for Mechanical Properties and Fluid Flow Characteristics in the Fracturing Zone

3.3. Construction of Fluid-Solid Coupling Seepage and Geostress Field

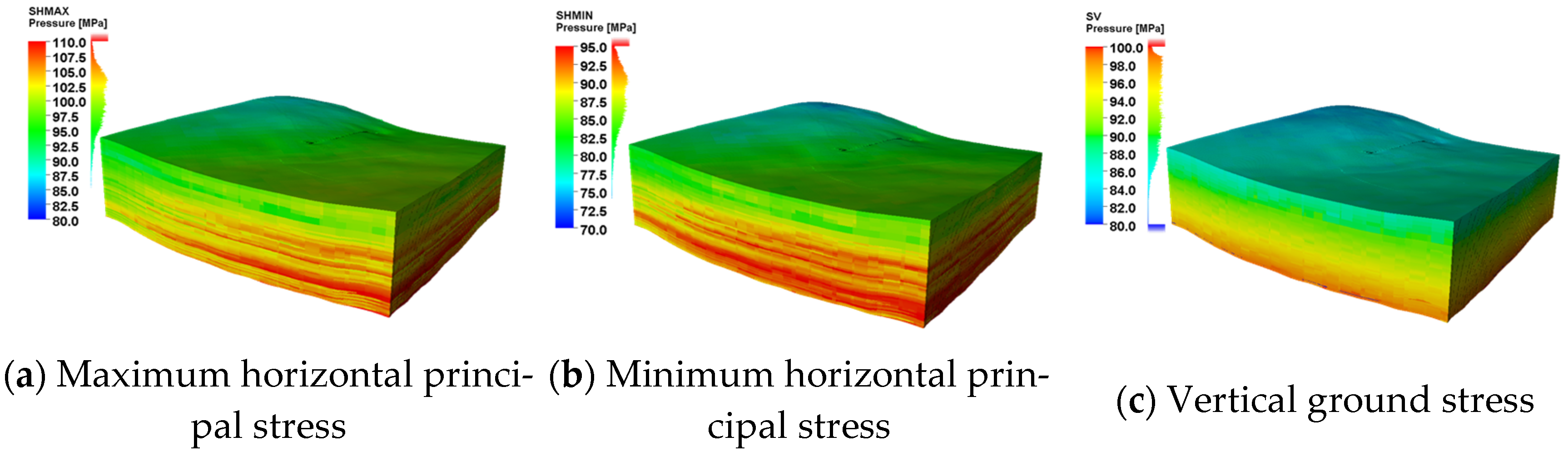

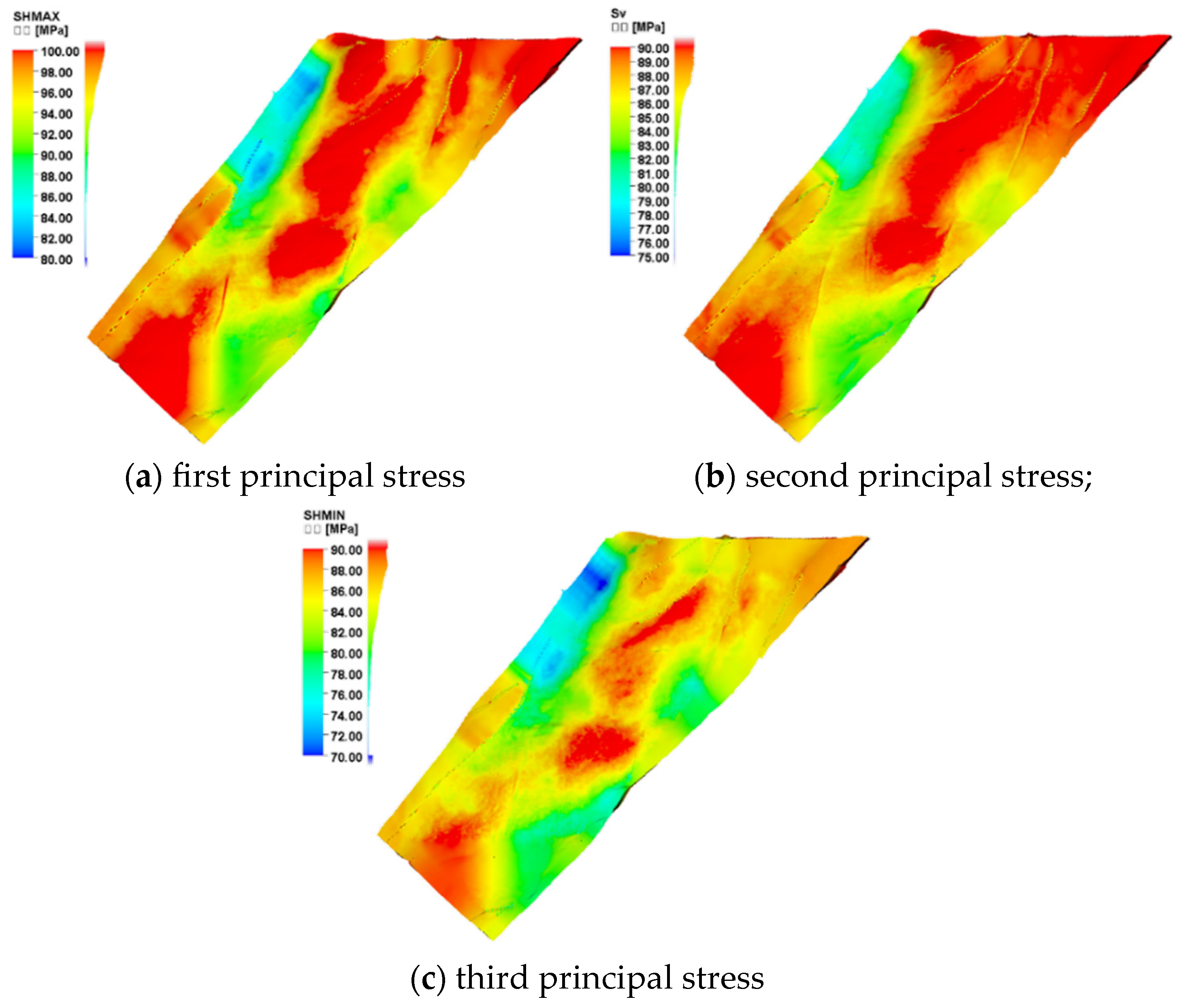

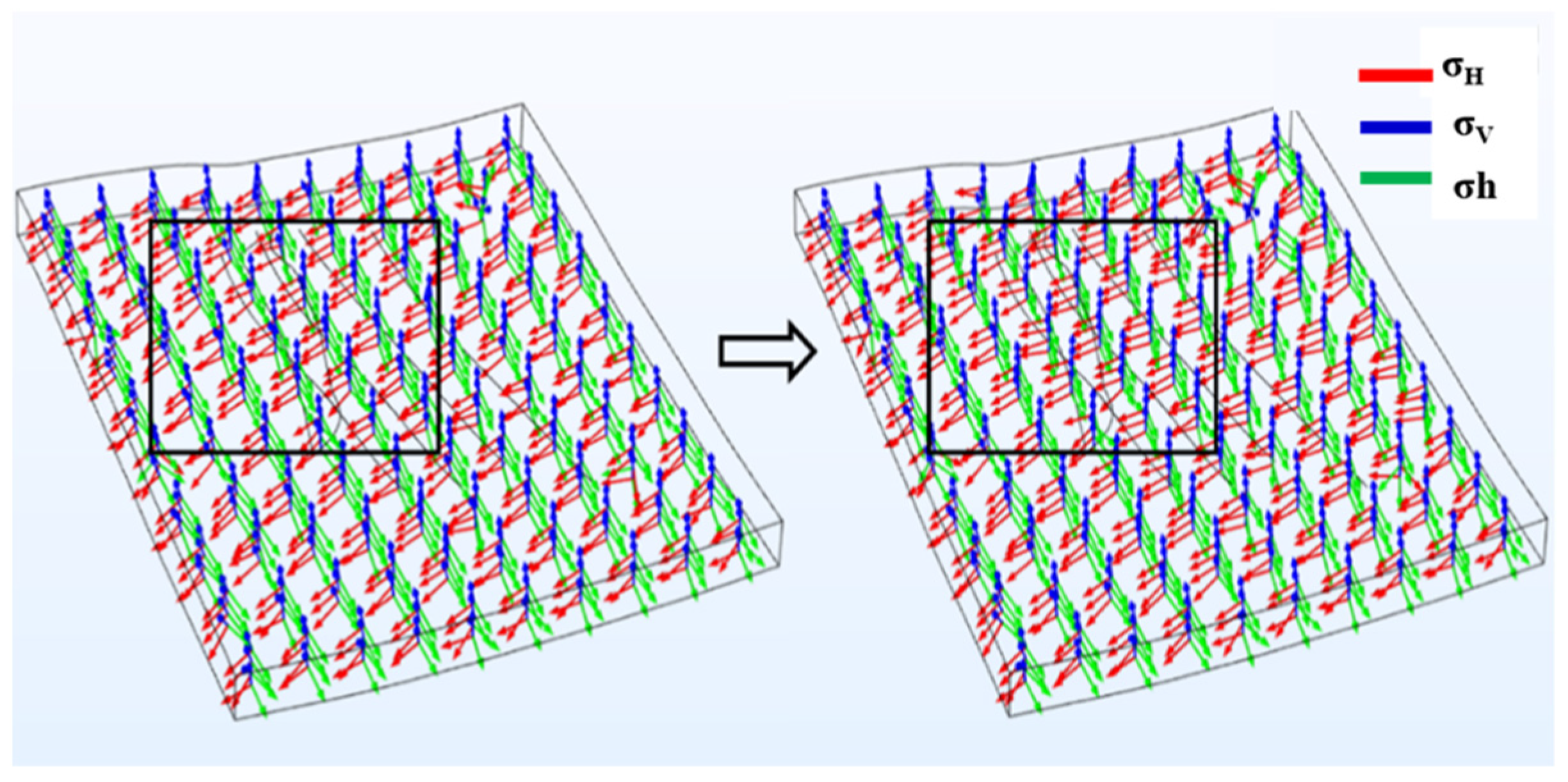

3.3.1. Simulation of the Original In Situ Stress Field

3.3.2. The Seepage Physical Field and Boundary Conditions

3.4. Construction and Simulation of the Four-Dimensional Seepage-Stress Coupling Model

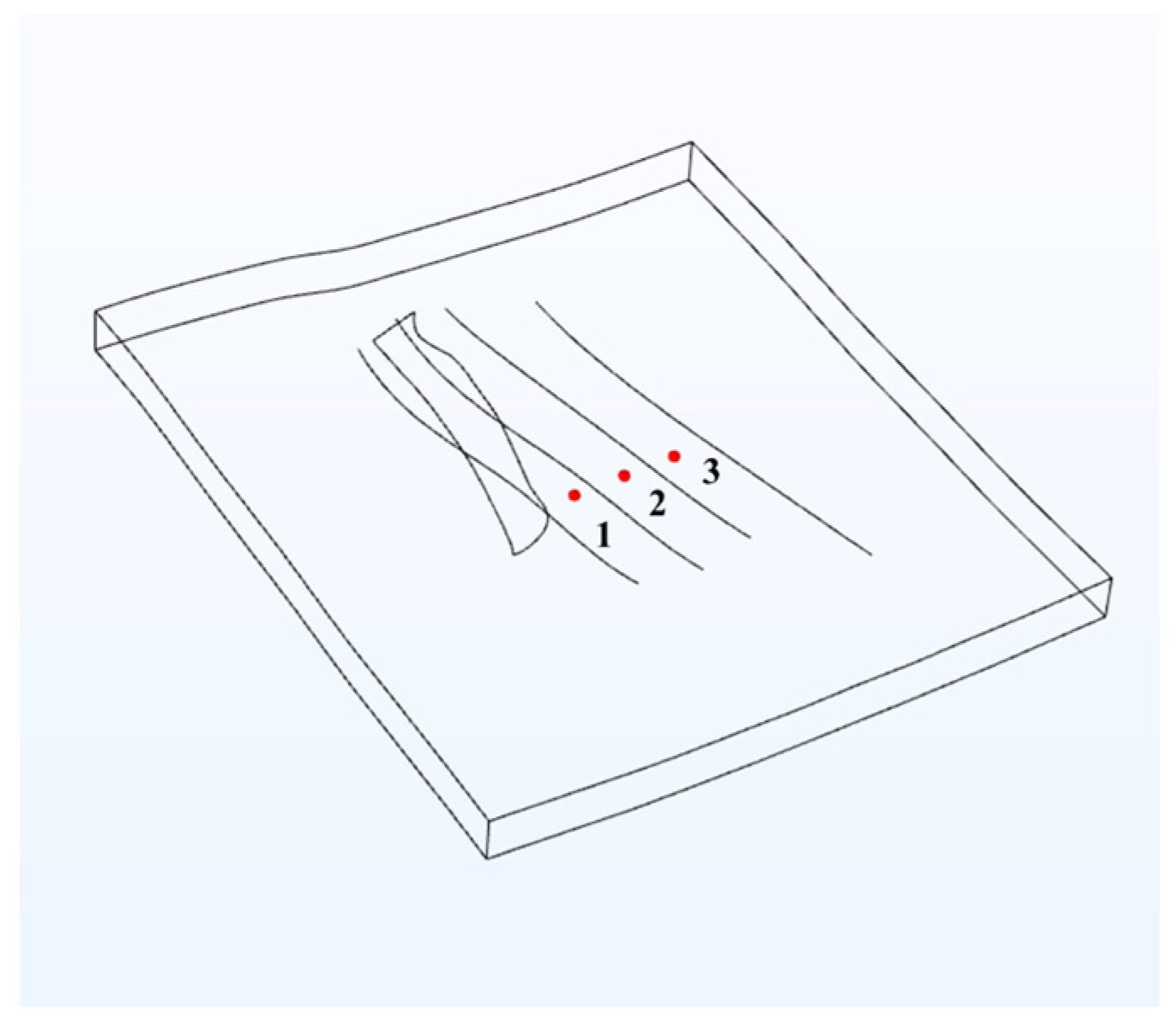

4. Results and Discussion

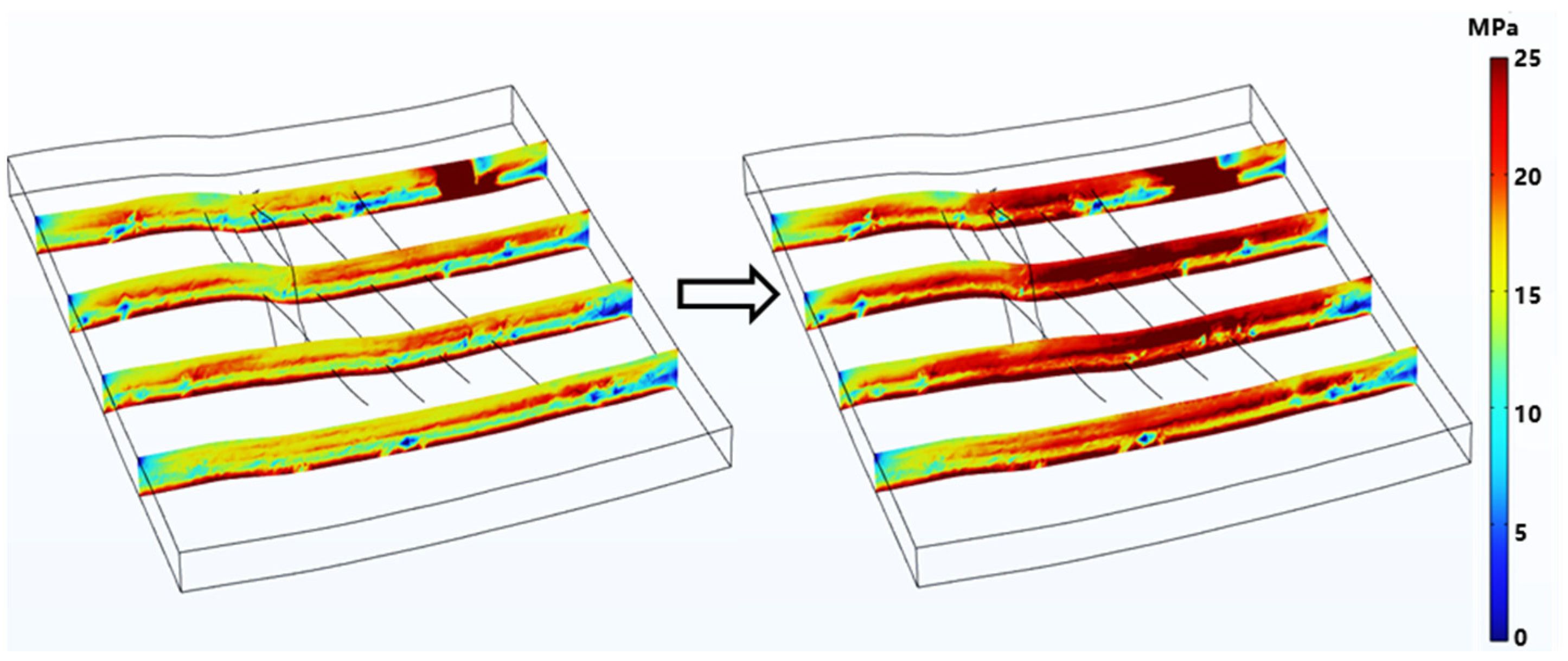

4.1. Characteristics of Pore Pressure Changes in the Surrounding Strata of the Fracturing Area Wells

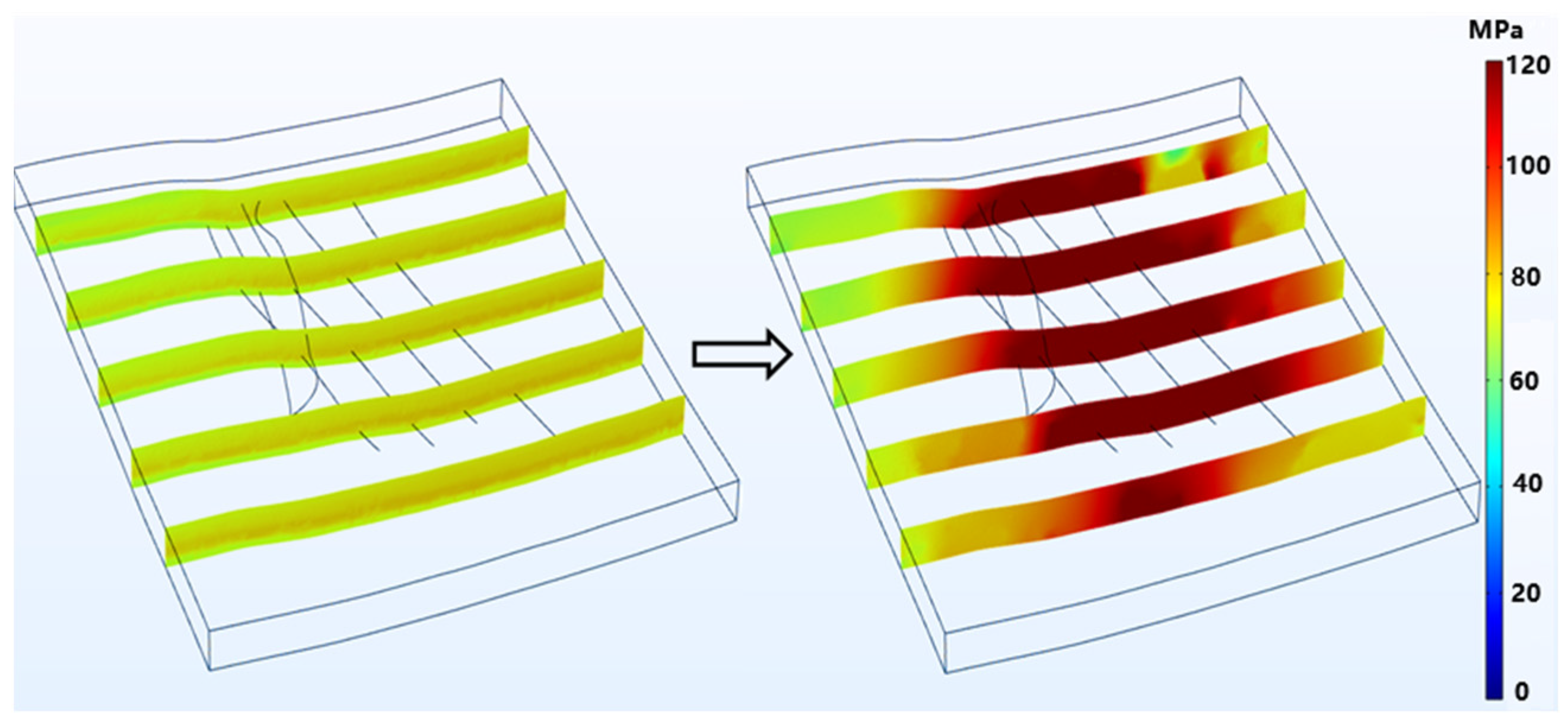

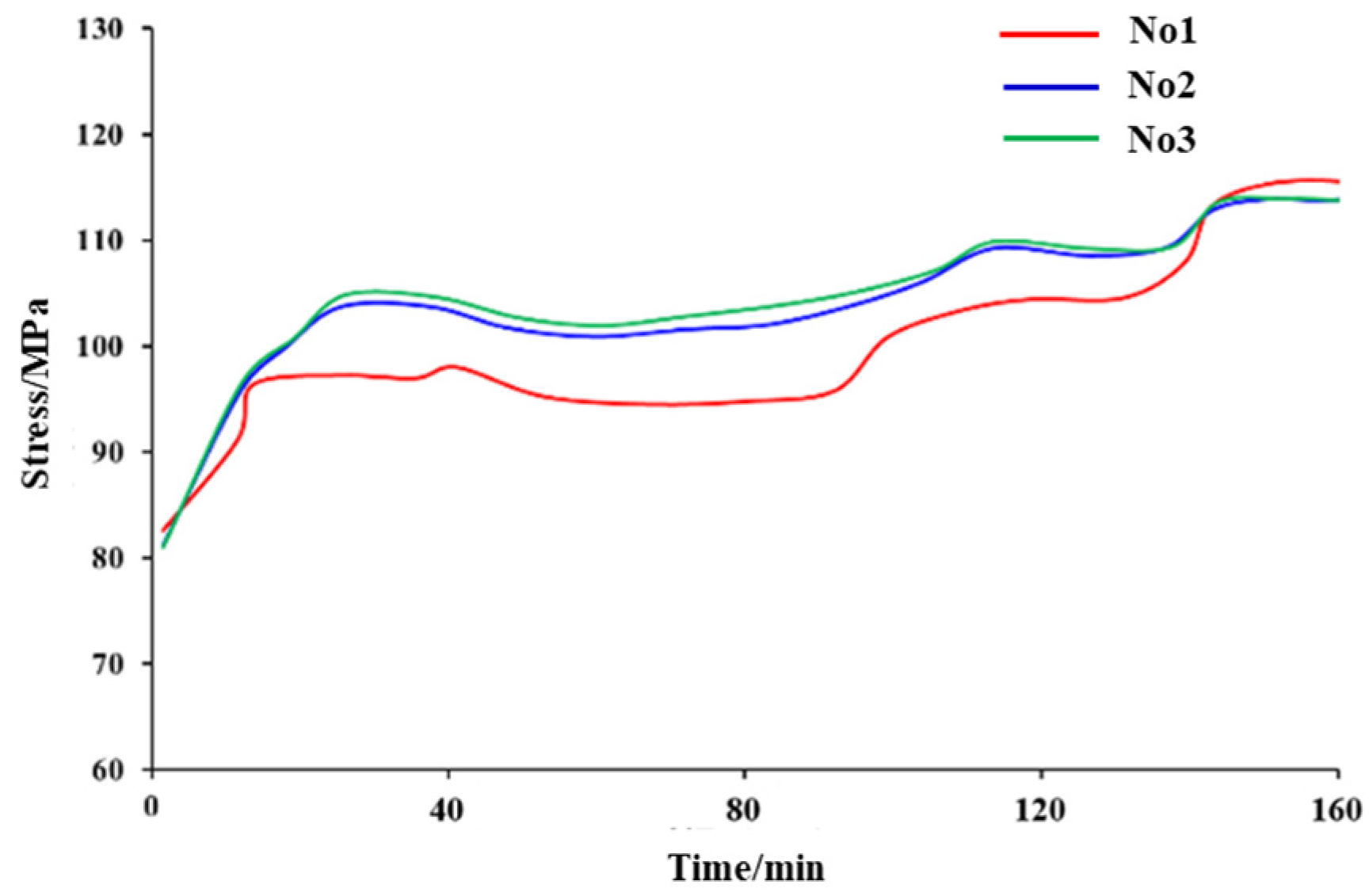

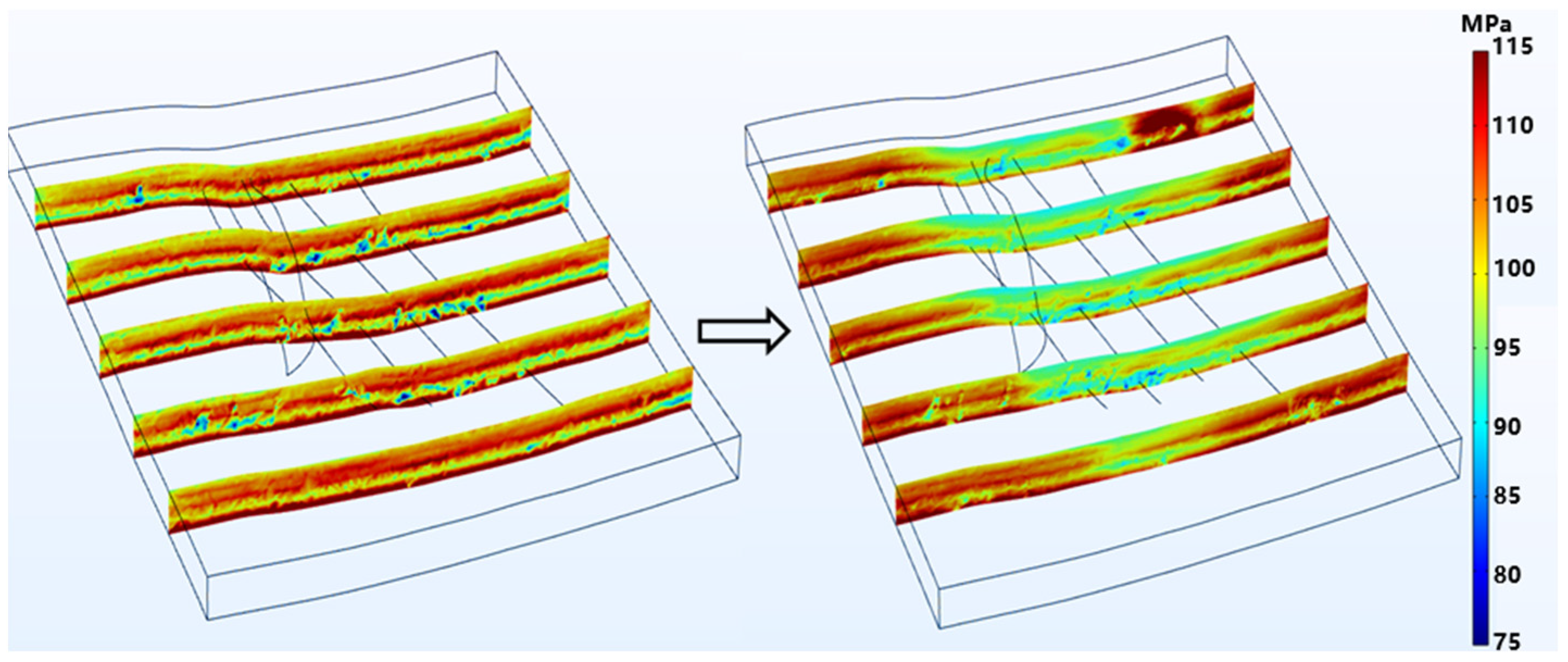

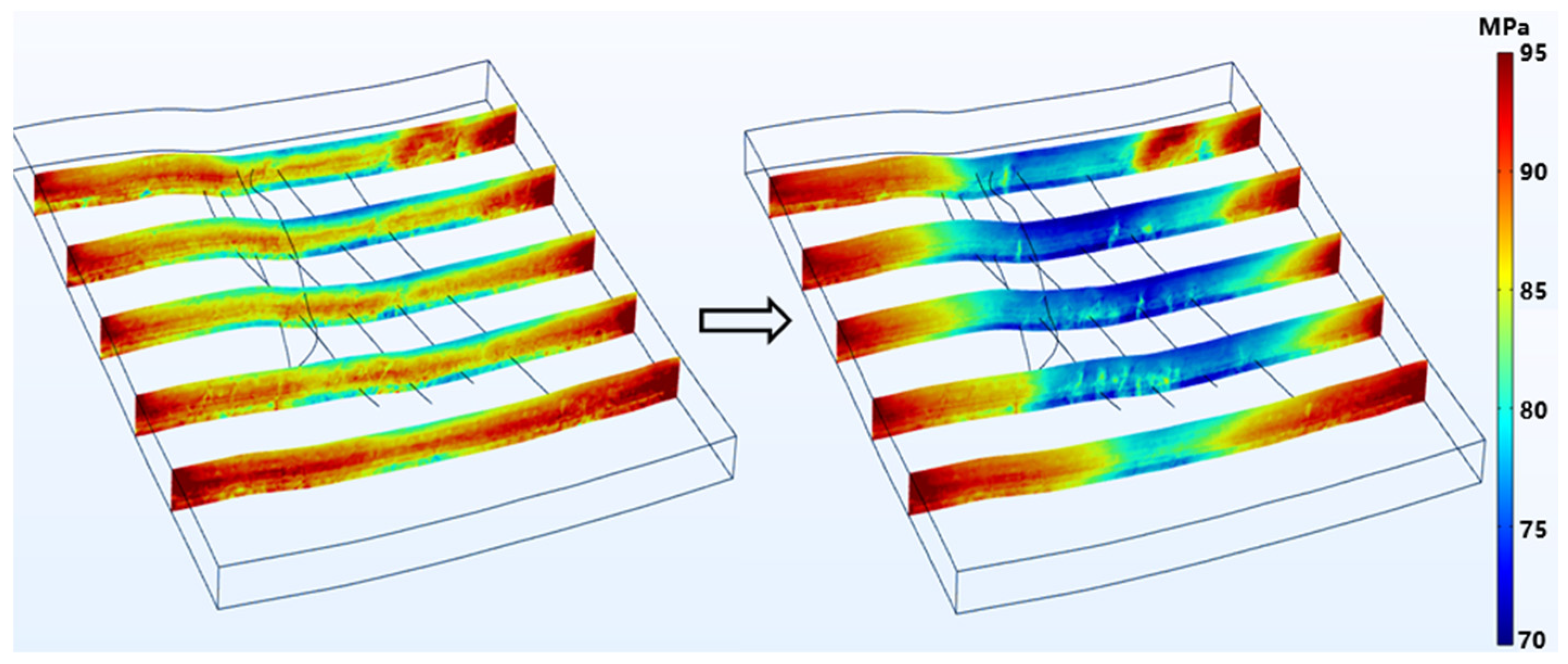

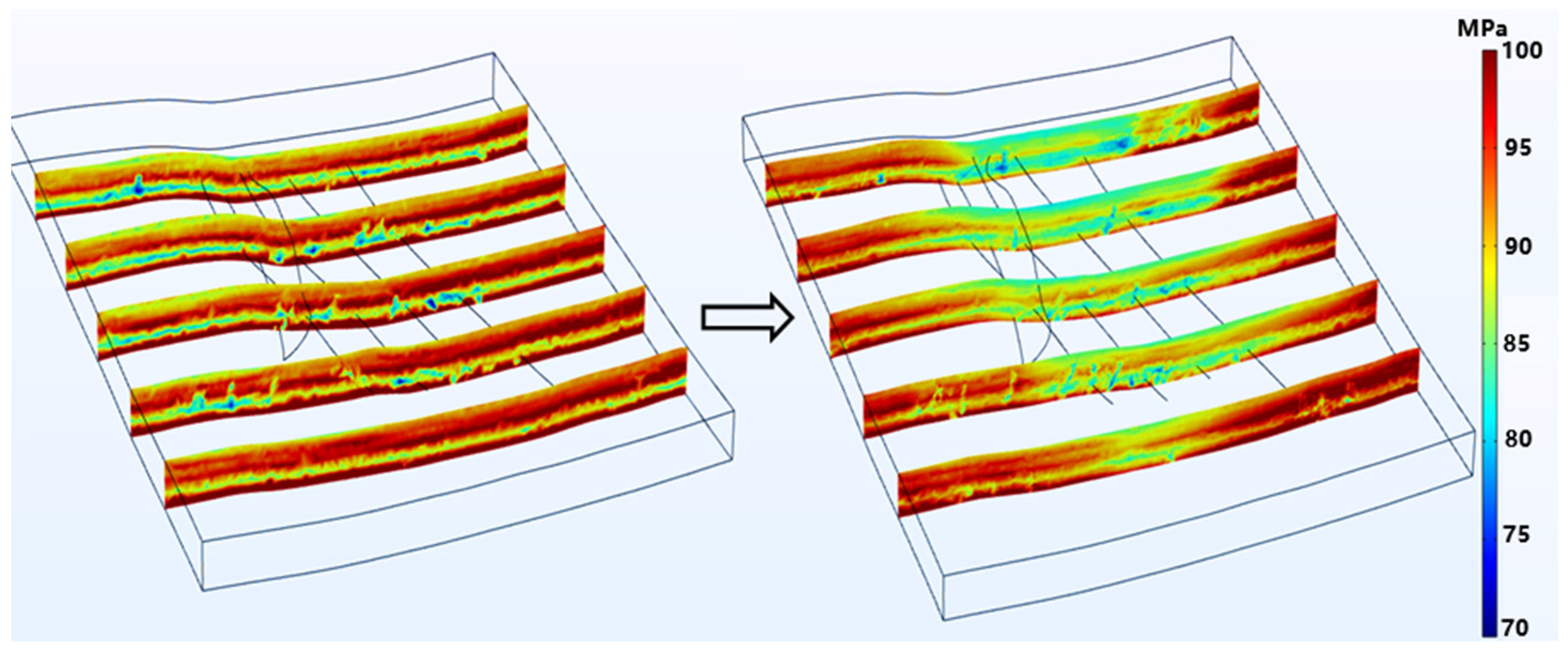

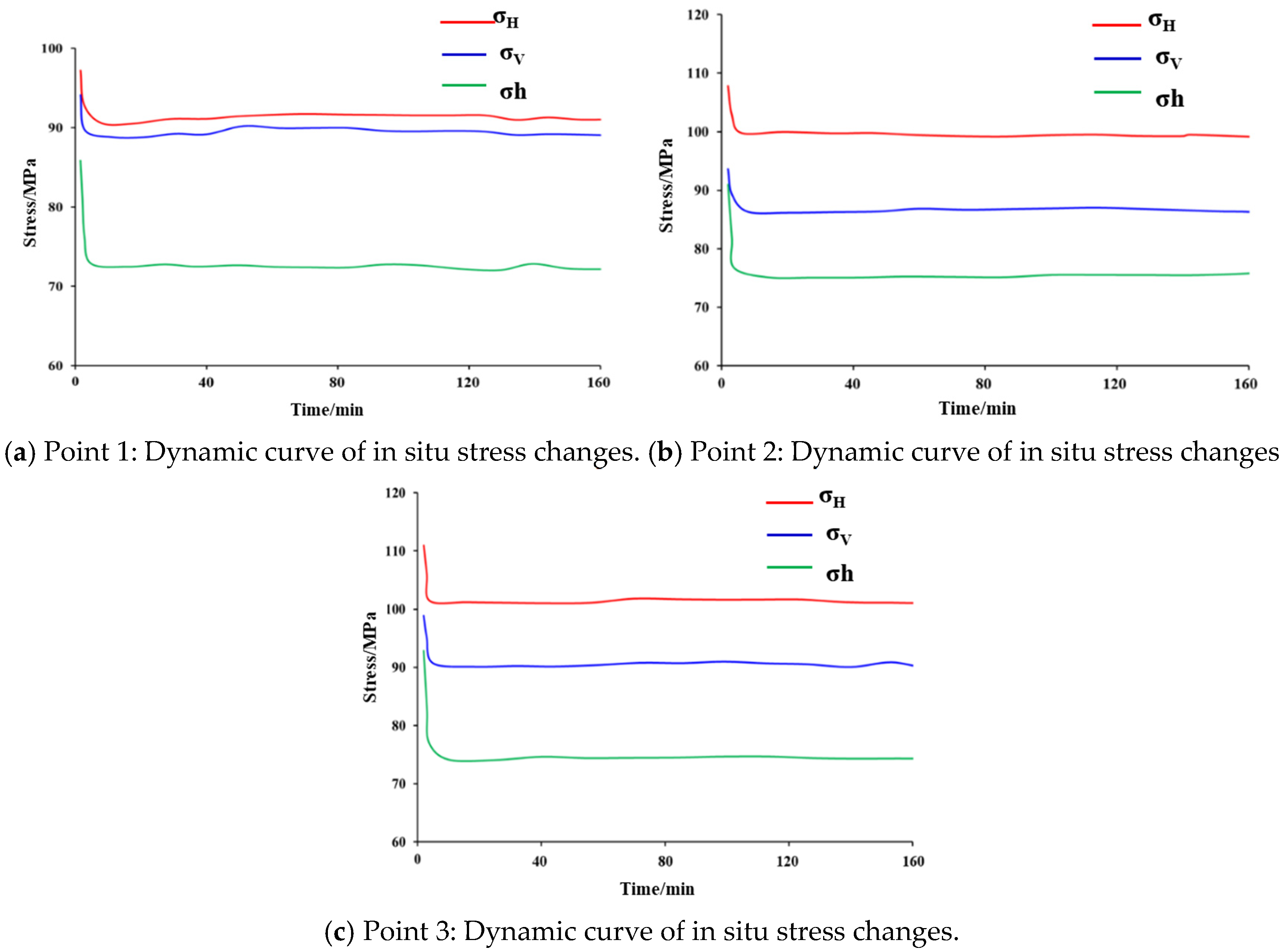

4.2. The Variation Characteristics of the In Situ Stress Field of the Surrounding Strata in the Fracturing Area Wells

4.3. Implications of the Risk of Casing Deformation

5. Conclusions

- (1)

- The dynamic changes in pore pressure are the main controlling factor for the redistribution of regional ground stress. The non-uniformity near the well and the distribution of geomechanical parameters also affect its accuracy. The injection of fracturing fluid forms a high-pressure gradient, driving the non-steady diffusion of pore pressure and fluids along artificial or natural fracture networks. The spatial heterogeneity is strong: the pressure increase is the greatest in the near-wellbore area, and it decays with distance, forming a stress concentration funnel effect. Its influence range expands with the extension of fracturing time.

- (2)

- Elevated pore pressure redistributes in situ stress: all three principal stresses are negatively correlated with pore pressure and decrease accordingly; the minimum horizontal stress exhibits the greatest reduction, whereas the vertical stress shows the least variation. A pressure-drop funnel forms near the wellbore corresponding to the stress-concentration zone. Fracturing increases horizontal stress anisotropy; rapid pore-pressure changes together with fault or fracture distributions trigger stress reorientation, and stronger pore-pressure fluctuations lead to larger rotations.

- (3)

- In the early stage of fracturing, the fluids preferentially enter the high-porosity and high-permeability fault or suture networks. The pore pressure rises sharply, and the in situ stress rapidly decreases from the wellbore to the periphery. As the fracturing progresses, the fractures are filled and the pressure is transmitted to the bedrock. In the middle and later stages, the pore pressure rises and the trend of in situ stress decrease becomes stable. The system gradually reaches a dynamic equilibrium.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, S.B.; Zhu, Y.M.; Wang, H.Y.; Liu, H.; Wei, W.; Luo, Y.; Li, W.; Fang, J. Research status and trends of shale gas in China. Acta Pet. Sin. 2010, 31, 689–694. [Google Scholar] [CrossRef]

- Zhao, W.Z.; Jia, A.L.; Wei, Y.S.; Wang, J.; Zhu, H. Progress in shale gas exploration in China and prospects for future development. China Pet. Explor. 2020, 25, 31–44. [Google Scholar] [CrossRef]

- Li, G.X.; Lei, Z.D.; Dong, W.H.; Wang, H.; Zheng, X.; Tan, J. Progress, challenges and prospects of unconventional oil and gas development of CNPC. China Pet. Explor. 2022, 27, 1–11. [Google Scholar]

- Guo, M.; Lu, X.; Nielsen, C.P.; McElroy, M.B.; Shi, W.; Chen, Y.; Xu, Y. Prospects for shale gas production in China: Implications for water demand. Renew. Sustain. Energy Rev. 2016, 66, 742–750. [Google Scholar] [CrossRef]

- Dong, D.Z.; Gao, S.K.; Huang, J.L.; Guan, Q.; Wang, S.; Wang, Y. A discussion on the shale gas exploration & development prospect in the Sichuan Basin. Nat. Gas Ind. 2014, 34, 1–15. [Google Scholar]

- Dong, D.Z.; Wang, Y.M.; Li, X.J.; Zou, C.; Guan, Q.; Zhang, C.; Huang, J.; Wang, S.; Wang, H.; Liu, H.; et al. Breakthrough and prospect of shale gas exploration and development in China. Nat. Gas Ind. 2016, 36, 19–32. [Google Scholar] [CrossRef]

- Gao, D.L.; Liu, K. Progresses in shale gas well integrity research. Oil Gas Geol. 2019, 40, 602–615. [Google Scholar] [CrossRef]

- Gao, D.L.; Liu, K.; Wang, Y.B.; Liu, J.; Li, X. Some research advances in the failure mechanism and design & control technologies of shale gas well integrity. Acta Pet. Sin. 2022, 43, 1798–1812. [Google Scholar] [CrossRef]

- Xi, Y.; Li, J.; Liu, G.H.; Zeng, Y.; Li, J. Overview of Casing Deformation in Multistage Fracturing of Shale Gas Horizontal Wells. Spec. Oil Gas Reserv. 2019, 26, 1–6. [Google Scholar]

- Dean, R.H.; Gai, X.; Stone, C.M.; Minkoff, S.E. A comparison of techniques for coupling porous flow and geomechanics. SPE J. 2006, 11, 132–140. [Google Scholar] [CrossRef]

- Hatchell, P.; Bourne, S. Rocks under strain: Strain-induced time-lapse time shifts are observed for depleting reservoirs. Lead. Edge 2005, 24, 1222–1225. [Google Scholar] [CrossRef]

- Herwanger, J.; Koutsabeloulis, N. Seismic Geomechanics: How to Build and Calibrate Geomechanical Models Using 3D and 4D Seismic Data; European Association of Geoscientists & Engineers: Houten, The Netherlands, 2011. [Google Scholar]

- Onaisi, A.; Fiore, J.; Rodriguez, H.A.; Koutsabeloulis, N.; Selva, F. Matching stress-induced 4D seismic time-shifts with coupled geomechanical models. In Proceedings of the 49th US Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 28 June–1 July 2015. [Google Scholar]

- Zhang, F.S.; Damjanac, B.; Maxwell, S. Investigating hydraulic fracturing complexity in naturally fractured rock masses using fully coupled multiscale numerical modeling. Rock Mech. Rock Eng. 2019, 52, 5137–5160. [Google Scholar] [CrossRef]

- Marongiu, P.M.; Lee, D.; Shan, D.; Morales, A. Advanced modeling of interwell fracturing interference: An Eagle Ford Shale oil study. SPE J. 2016, 21, 1567–1582. [Google Scholar] [CrossRef]

- Yang, D.; Moridis, G.J.; Blasingame, T.A. A fully coupled multiphase flow and geomechanics solver for highly heterogeneous porous media. J. Comput. Appl. Math. 2014, 270, 417–432. [Google Scholar] [CrossRef]

- Guo, X.Y.; Song, H.Q.; Wu, K.; Killough, J. Pressure characteristics and performance of multi-stage fractured horizontal well in shale gas reservoirs with coupled flow and geomechan-ics. J. Pet. Sci. Eng. 2018, 163, 1–15. [Google Scholar] [CrossRef]

- Li, Y.M.; Wang, Y.C.; Zhao, J.Z.; Shen, F.; Qiao, H. Calculation Model of Kink Angle in Shale Gas Reservoirs with Consideration of Stress Interference. Nat. Gas Geosci. 2015, 26, 1979–1983. [Google Scholar]

- Li, Y.M.; Chen, X.Y.; Zhao, J.Z.; Shen, F. The Effects of Crack Interaction in Multi-stage Horizontal Fracturing. J. Southwest Pet. Univ. (Sci. Technol. Ed.) 2016, 38, 76–83. [Google Scholar]

- Zhao, J.Z.; Chen, X.Y.; Liu, C.Y.; Li, H.; Cao, X.J. The Analysis of Crack Interaction in Multi-Stage Horizontal Fracturing. Nat. Gas Geosci. 2015, 26, 533–538. [Google Scholar]

- Furui, K.; Fuh, G.; Abdelmalek, N.; Morita, N. A comprehensive modeling analysis of borehole stability and production-liner deformation for inclined/horizontal wells completed in a highly compacting chalk formation. SPE Drill. Complet. 2010, 25, 530–543. [Google Scholar] [CrossRef]

- Zhang, X.; Jeffrey, R.G. Fluid-driven nucleation and propagation of splay fractures from a permeable fault. J. Geophys. Res. Solid Earth 2016, 121, 5257–5277. [Google Scholar] [CrossRef]

- Zhu, H.Y.; Song, Y.J.; Tang, X.H.; Li, K.; Xiao, J. Optimization of fracturing timing of infill wells in shale gas reservoirs: A case study on Well Group X1 of Fuling Shale Gas Field in the Sichuan Basin. Nat. Gas Ind. 2021, 41, 154–168. [Google Scholar]

- Zhu, H.Y.; Song, Y.J.; Xu, Y.; Li, K.; Tang, X. Four-dimensional in-situ stress evolution of shale gas reservoirs and its impact on infill well complex fractures propagation. Acta Pet. Sin. 2021, 42, 1224–1236. [Google Scholar]

- Chugunova, T.; Corpel, V.; Gomez, J.P. Explicit fracture network modelling: From multiple point statistics to dynamic simulation. Math. Geosci. 2017, 49, 541–553. [Google Scholar] [CrossRef]

- Ren, X.Q.; Gao, X.R.; Wang, H.L.; Liu, J.; Sun, C.; Lu, X.; Sun, Z. Research on multi-scale diserete fracture 3D refined geological modeling and geothermal resource evaluation: A case study of Xianxian County geothermal field, Bohai Bay Basin. Pet. Reserv. Eval. Dev. 2025, 15, 1104–1111. [Google Scholar]

- Zhao, C.S.; Lei, S.; Hang, Y.; Yan, L.; Luo, Y.; Luo, S.; Qiu, P.; Hu, Y. Study on the Four-Dimensional Variations of In Situ Stress in Stress-Sensitive Ultra-High-Pressure Tight Gas Reservoirs. Processes 2025, 13, 1508. [Google Scholar] [CrossRef]

- Wu, Y.; Zhu, Z.; Shen, Y.; Yu, X.; Liu, G.; Liu, P. Study on the Evolution Law of Four-Dimensional Dynamic Stress Fields in Fracturing of Deep Shale Gas Platform Wells. Processes 2025, 13, 2709. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, S.; Wu, J.; Zeng, B.; Huang, H.; Wang, S.; Liu, H.; Gui, J. Study on the Evolution Law of Four-Dimensional In Situ Stress During Hydraulic Fracturing of Deep Shale Gas Reservoir. Processes 2025, 13, 3772. https://doi.org/10.3390/pr13123772

Cui S, Wu J, Zeng B, Huang H, Wang S, Liu H, Gui J. Study on the Evolution Law of Four-Dimensional In Situ Stress During Hydraulic Fracturing of Deep Shale Gas Reservoir. Processes. 2025; 13(12):3772. https://doi.org/10.3390/pr13123772

Chicago/Turabian StyleCui, Shuai, Jianfa Wu, Bo Zeng, Haoyong Huang, Shouyi Wang, Houbin Liu, and Junchuan Gui. 2025. "Study on the Evolution Law of Four-Dimensional In Situ Stress During Hydraulic Fracturing of Deep Shale Gas Reservoir" Processes 13, no. 12: 3772. https://doi.org/10.3390/pr13123772

APA StyleCui, S., Wu, J., Zeng, B., Huang, H., Wang, S., Liu, H., & Gui, J. (2025). Study on the Evolution Law of Four-Dimensional In Situ Stress During Hydraulic Fracturing of Deep Shale Gas Reservoir. Processes, 13(12), 3772. https://doi.org/10.3390/pr13123772