Experimental Investigation and Numerical Simulation of Freeze–Thaw Damage Behavior in Coal Gangue Concrete Used in High-Altitude Cold Western Mines

Abstract

1. Introduction

2. Experimental Study on Freeze–Thaw Degradation of Coal Gangue Concrete

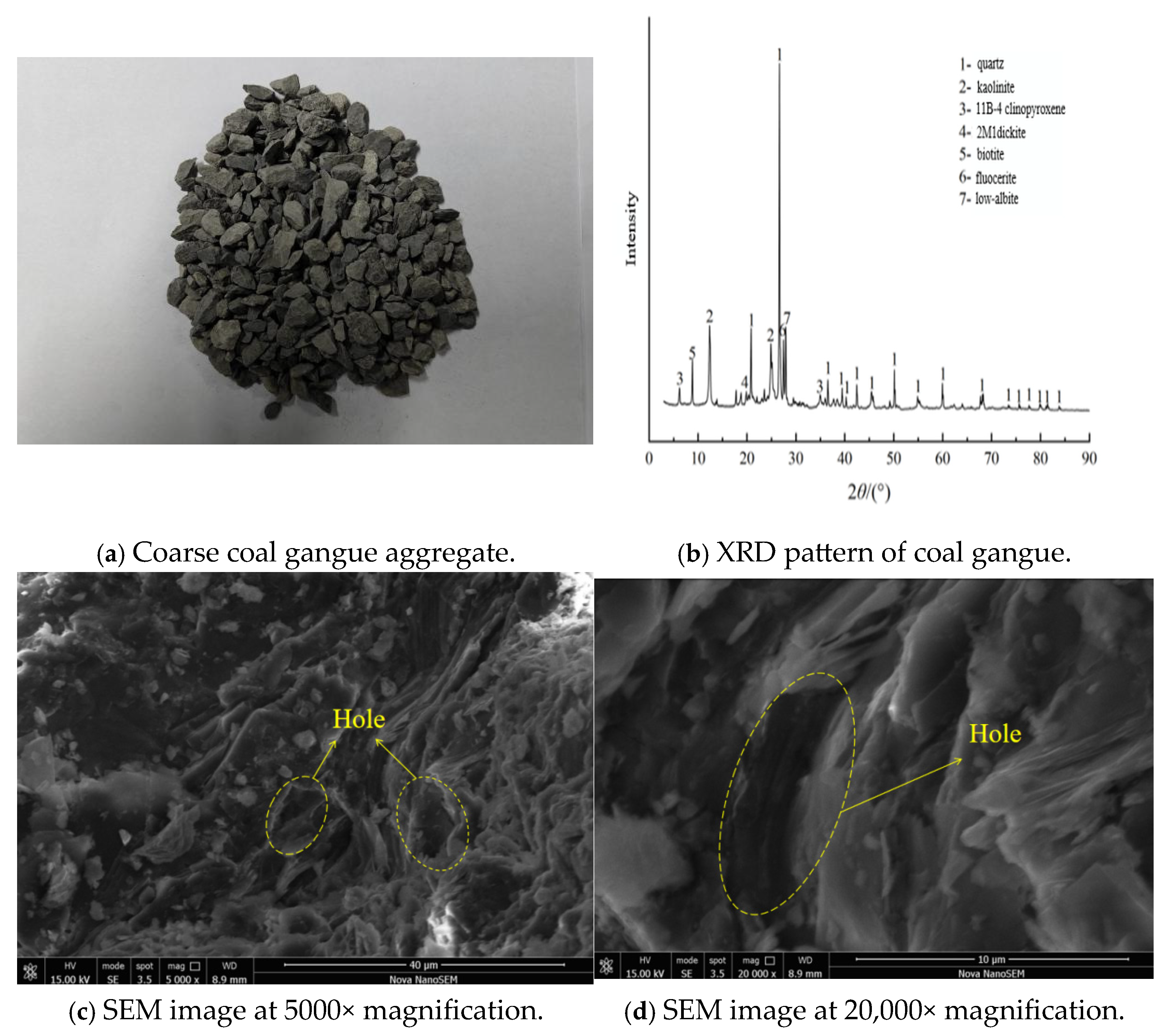

2.1. Raw Materials and Mix Proportions of Coal Gangue Concrete

2.2. Proportion Design of Coal Gangue Concrete

2.3. Freeze–Thaw Test

3. Results and Analysis

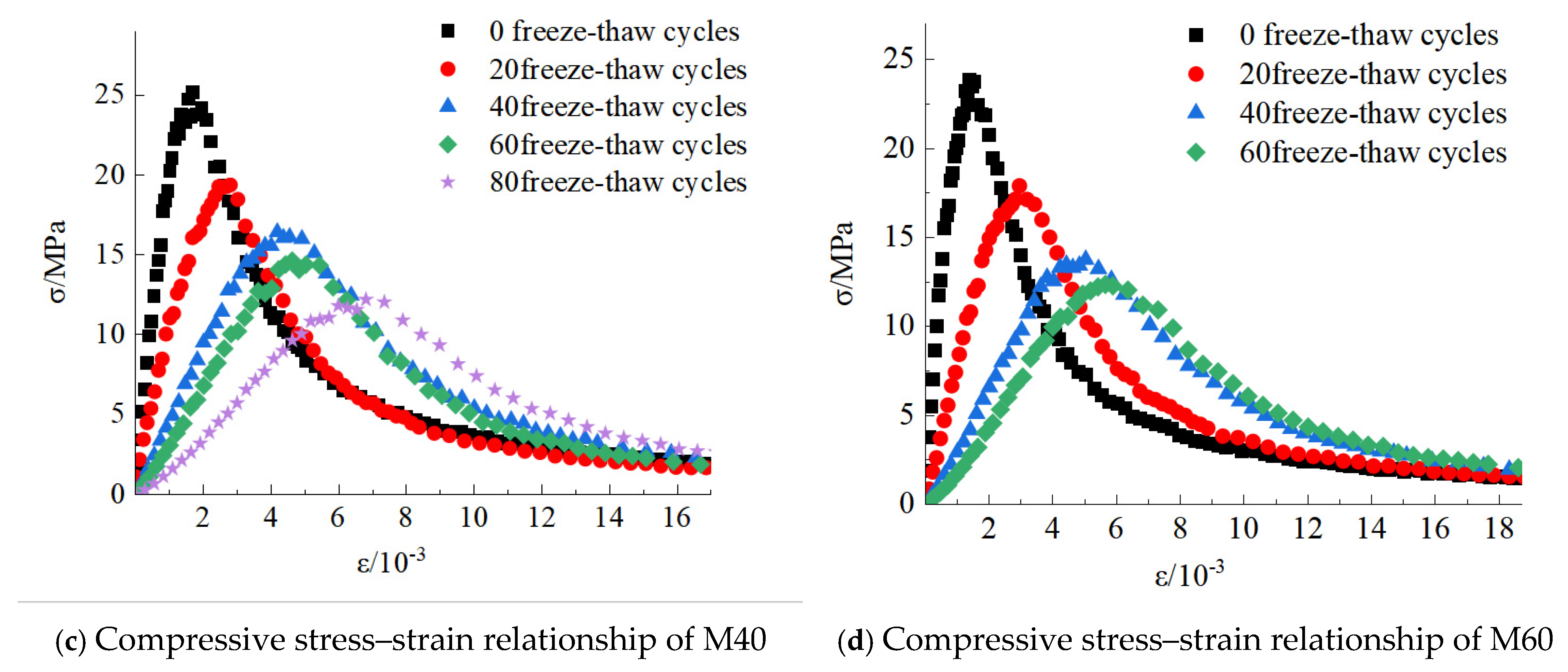

3.1. Compressive Stress–Strain Curves

3.2. Elastic Modulus

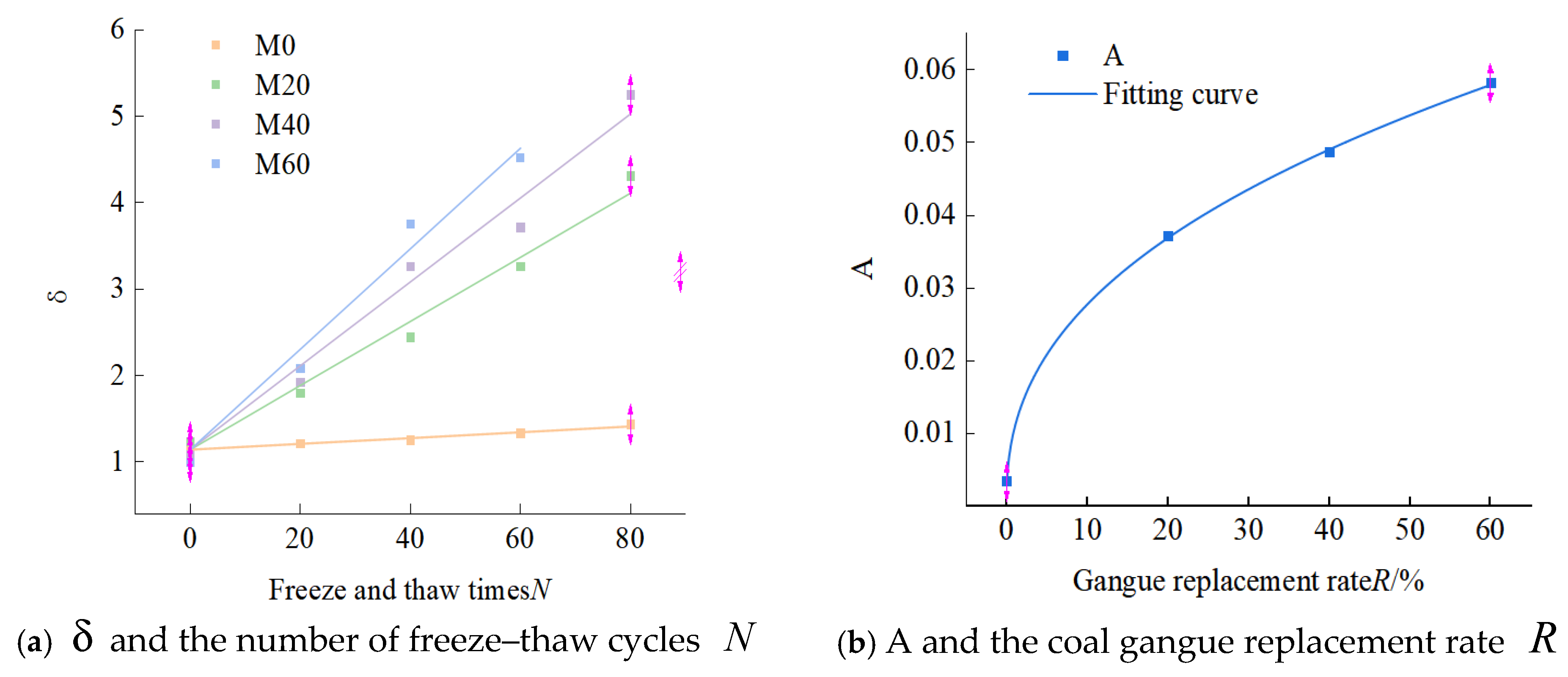

3.3. Peak Strain of Coal Gangue Concrete

3.4. Shape Parameter n of Coal Gangue Concrete in the Pre-Peak Elastoplastic Rising Stage

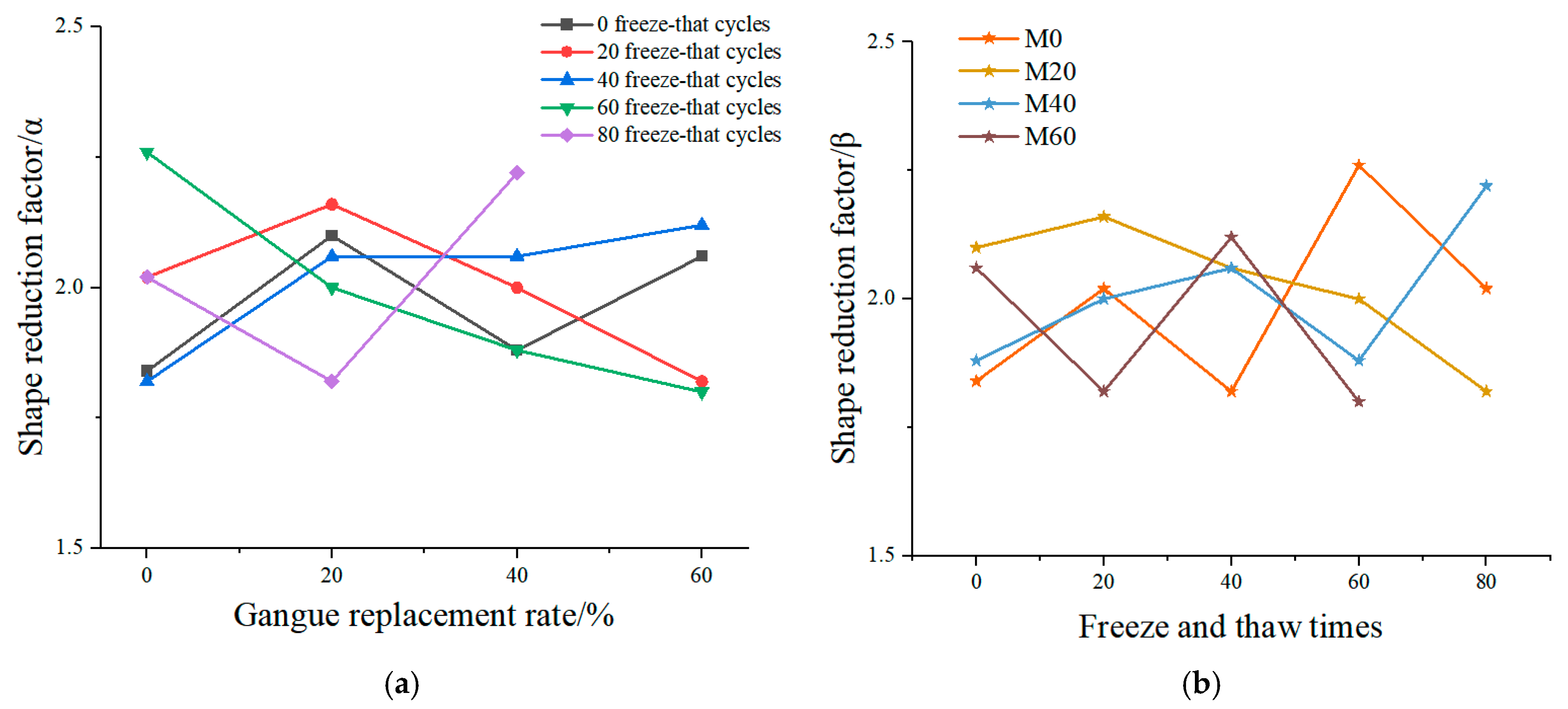

3.5. Parameters α and β of the Post-Peak Plastic Deformation Descent Section of Coal Gangue Concrete

4. Numerical Simulation Analysis

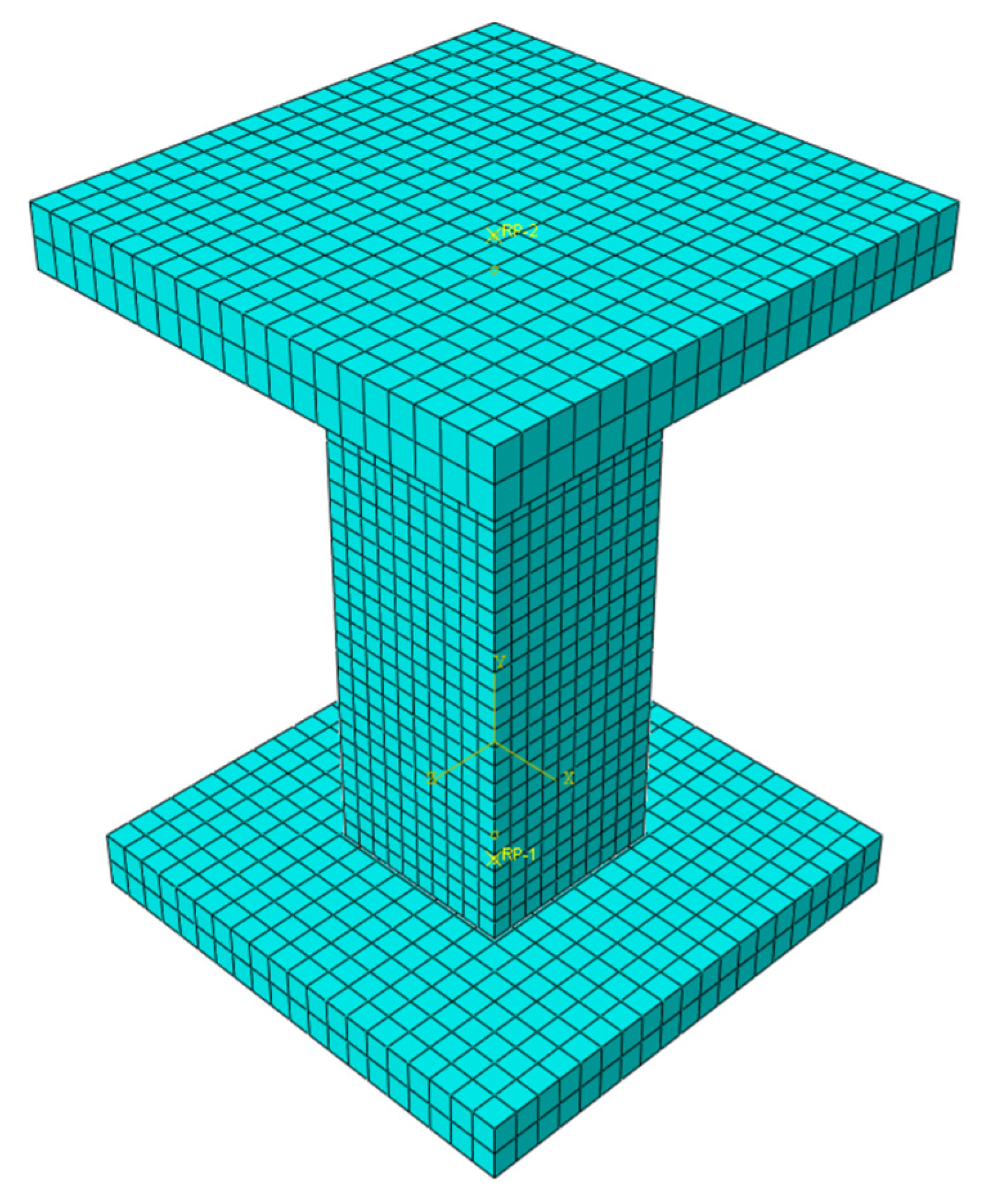

4.1. Model Establishment

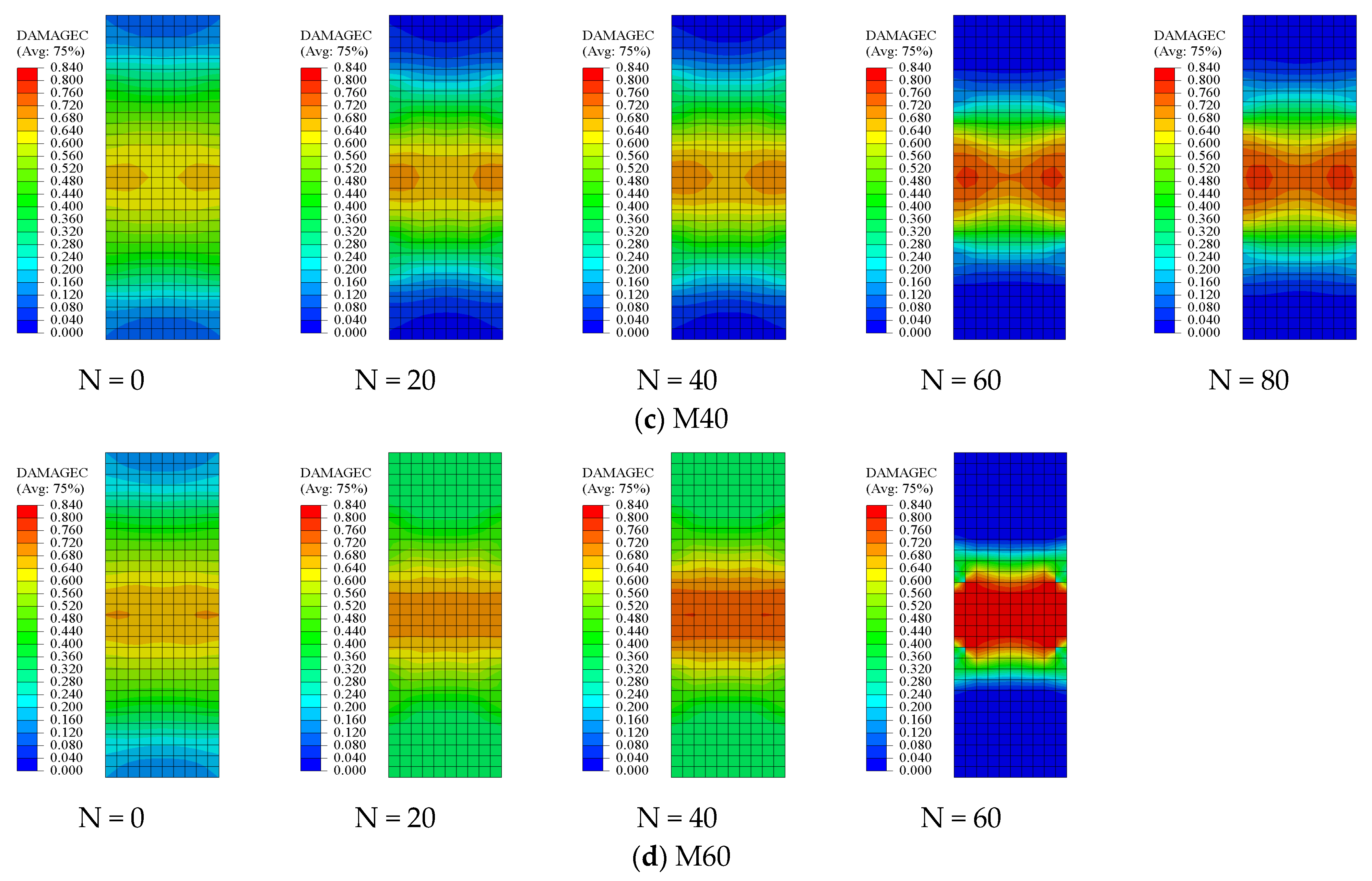

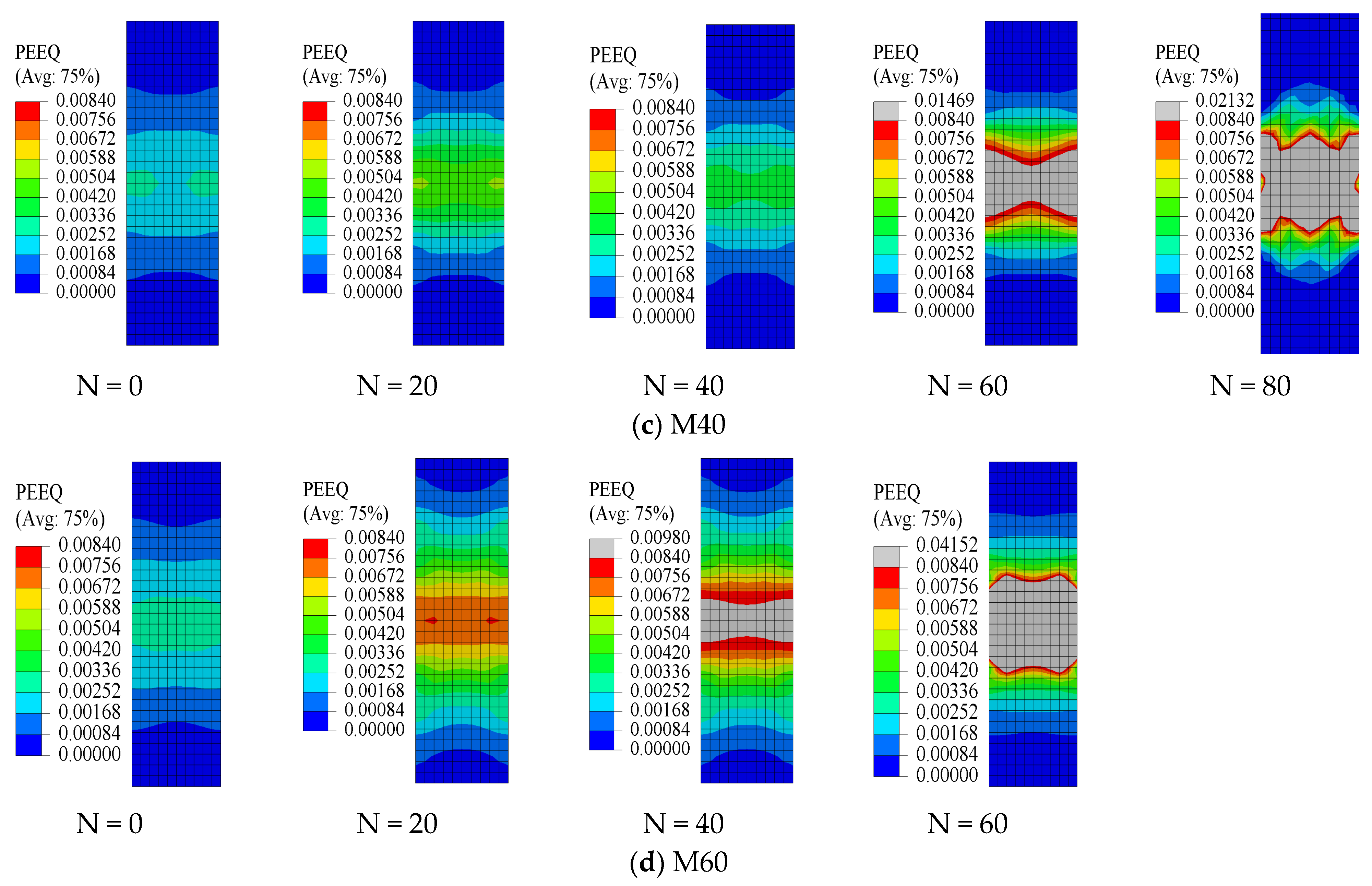

4.2. Analysis of Simulation Results

- (1)

- Aggravated overall plastic strain at the same number of freeze–thaw cycles N:

- (2)

- Shift in Strain Concentration Trends

- (3)

- Accelerated Strain Evolution During Freeze–Thaw Cycles

- (4)

- Implications for Material Performance

4.3. Fitting Analysis of Finite Element Model Data and Experimental Data

5. Conclusions

- (1)

- As the number of freeze–thaw cycles increased, the mechanical properties of all groups of coal gangue concrete deteriorated to varying degrees. When the number of freeze–thaw cycles increased from 0 to 80, the peak stress of mix M0 decreased by 35%, the peak strain increased by 10.8%, and the elastic modulus decreased by 49.2%. For mix M20, the peak stress decreased by 41.78%, the peak strain increased by 203.4%, and the elastic modulus decreased by 86.2%. Mix M40 exhibited a 51.1% reduction in peak stress, a 304.9% increase in peak strain, and a 92% decrease in elastic modulus. Mix M60 was severely damaged and could not be tested for axial compressive strength. Under the same number of freeze–thaw cycles, the concave effect in the stress–strain curves became more pronounced with higher coal gangue replacement ratios. This is primarily attributed to the higher water absorption of coal gangue, which leads to greater freeze–thaw stress compared to ordinary concrete, as well as the inferior mechanical properties and reduced resistance to freeze–thaw damage of coal gangue.

- (2)

- When using coal gangue from Halagou Gully for concrete preparation under freeze–thaw conditions, a 20% replacement ratio is identified as the optimal value. At this ratio, the strength loss rate due to freeze–thaw action is closest to that of ordinary concrete, meeting performance requirements while effectively utilizing gangue waste. This represents a viable pathway for the resource utilization of coal gangue.

- (3)

- As the coal gangue replacement ratio and the number of freeze–thaw cycles increase, the constitutive relationship for concrete specified in the Code for Design of Concrete Structures (GB 50010-2010) becomes increasingly inadequate. Therefore, the compressive damage evolution parameters in the code were modified, and a constitutive model for coal gangue concrete under freeze–thaw conditions was established. This model can be applied in the structural design of coal gangue concrete.

- (4)

- The constitutive relationship proposed in this study can be integrated with the Concrete Damaged Plasticity (CDP) model in Abaqus. It effectively simulates the uniaxial compressive behavior of coal gangue concrete after freeze–thaw action and accurately reflects the stress development and damage state of the concrete during loading.

- (5)

- Under freeze–thaw (F-T) cycles, the deterioration of coal gangue concrete (CGC) is governed by a synergistic mechanism involving highly absorbent coal gangue aggregates and the resulting low-temperature expansion. The inherent porosity of coal gangue introduces additional water reservoirs within the concrete matrix, which generate substantial internal expansive pressure during freezing. This process preferentially degrades the relatively weak interfacial transition zone (ITZ) between the coal gangue aggregates and the cement paste. Macroscopically, this degradation manifests as an accelerated reduction in compressive strength and elastic modulus, a notable increase in peak strain, and a more brittle post-peak response.

6. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liang, Y.; Liang, H.; Zhu, S. Mercury emission from spontaneously ignited coal gangue hill in Wuda coalfield, Inner Mongolia, China. Fuel 2016, 182, 525–530. [Google Scholar] [CrossRef]

- Liu, X.; Liang, C.; Qian, J.; Li, X.; Li, X.; Li, B.; Xu, G.; Zhou, B. Research on wireless monitoring system for internal temperature field of coal gangue mountain. Case Stud. Therm. Eng. 2025, 66, 105742. [Google Scholar] [CrossRef]

- Li, Y.; Liu, S.; Guan, X. Multitechnique investigation of concrete with coal gangue. Constr. Build. Mater. 2021, 301, 124114. [Google Scholar] [CrossRef]

- Cheng, L.; Zhao, L.; Cheng, L.; Gao, Y.; Guo, H.; Che, Y.; Fu, H. Research Progress of Concrete Preparation Based on Solid Waste Properties of Coal Gangue. Sustainability 2025, 17, 2007. [Google Scholar] [CrossRef]

- Jin, H.; Xu, G.; Han, W.; Gao, L.; Li, Z. Sustainable development of energy systems for western China. Energy 2009, 35, 4313–4318. [Google Scholar] [CrossRef]

- Liu, M.; Lu, J.; Ming, P.; Yu, J. Study on the fracture properties of concrete considering salt-freeze-thaw damage. Constr. Build. Mater. 2024, 448, 138147. [Google Scholar] [CrossRef]

- Luo, D.; Wang, Y.; Zhang, S.; Niu, D.; Song, Z. Frost Resistance of Coal Gangue Aggregate Concrete Modified by Steel Fiber and Slag Powder. Appl. Sci. 2020, 10, 3229. [Google Scholar] [CrossRef]

- Li, J.; Luo, J.; Chen, L.; Fan, X.; Zhu, Y.; Wang, X. Axial-compression performance and numerical-simulation analysis of steel tube coal gangue concrete column. J. Constr. Steel Res. 2024, 216, 108612. [Google Scholar] [CrossRef]

- Gao, S.; Zhao, G.; Guo, L.; Zhou, L.; Yuan, K. Utilization of coal gangue as coarse aggregates in structural concrete. Constr. Build. Mater. 2020, 268, 121212. [Google Scholar] [CrossRef]

- Cong, X.; Lu, S.; Yao, Y.; Wang, Z. Fabrication and characterization of self-ignition coal gangue autoclaved aerated concrete. Mater. Des. 2016, 97, 155–162. [Google Scholar] [CrossRef]

- Dong, Z.; Xia, J.; Fan, C.; Cao, J. Activity of calcined coal gangue fine aggregate and its effect on the mechanical behavior of cement mortar. Constr. Build. Mater. 2015, 100, 63–69. [Google Scholar] [CrossRef]

- Xiao, M.; Ju, F.; He, Z.-Q. Research on shotcrete in mine using non-activated waste coal gangue aggregate. J. Clean. Prod. 2020, 259, 120810. [Google Scholar] [CrossRef]

- Karimaei, M.; Dabbaghi, F.; Sadeghi-Nik, A.; Dehestani, M. Mechanical performance of green concrete produced with untreated coal waste aggregates. Constr. Build. Mater. 2020, 233, 117264. [Google Scholar] [CrossRef]

- Wu, C.; Zhang, C.; Li, J.; Wang, X.; Jiang, W.; Yang, S.; Wang, W. A sustainable low-carbon pervious concrete using modified coal gangue aggregates based on ITZ enhancement. J. Clean. Prod. 2022, 377, 134310. [Google Scholar] [CrossRef]

- Zhang, T.; Wen, Q.; Gao, S.; Tang, J. Comparative study on mechanical and environmental properties of coal gangue sand concrete. Constr. Build. Mater. 2023, 400, 132646. [Google Scholar] [CrossRef]

- Wang, J.; Chen, J.; Liu, M. Theoretical model for CFRP-confined spontaneous combustion gangue coarse aggregate concrete-filled steel tube stub columns under axial compression. Constr. Build. Mater. 2024, 415, 135113. [Google Scholar] [CrossRef]

- Xu, Z.; Wu, J.; Zhao, M.; Bai, Z.; Wang, K.; Miao, J.; Tan, Z. Mechanical and microscopic properties of fiber-reinforced coal gangue-based geopolymer concrete. Nanotechnol. Rev. 2022, 11, 526–543. [Google Scholar] [CrossRef]

- Qiu, J.; Zhang, R.; Guan, X.; Cheng, K.; Gao, Y.; Xiao, Z. Deterioration characteristics of coal gangue concrete under the combined action of cyclic loading and freeze-thaw cycles. J. Build. Eng. 2022, 60, 105165. [Google Scholar] [CrossRef]

- Wang, W.; Wang, Y.; Chen, Q.; Liu, Y.; Zhang, Y.; Ma, G.; Duan, P. Bond properties of basalt fiber reinforced polymer (BFRP) bars in recycled aggregate thermal insulation concrete under freeze–thaw cycles. Constr. Build. Mater. 2022, 329, 127197. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Z.; Wang, X.; Zhou, C. Dynamic and static interfacial bonding properties of CFRP-concrete subjected to freeze–thaw cycles. In Structures; Elsevier: Amsterdam, The Netherlands, 2022; Volume 37, pp. 947–959. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, C.; Liu, Q.; Shi, X.; Sun, Z. Investigation on frost heaving stress (FHS) of porous cement concrete exposed to freeze-thaw cycles. Cold Reg. Sci. Technol. 2023, 205, 103694. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Z.; Zhang, B.; Fu, K. A time-dependent diffusive model for the simulation of chloride penetration in concrete considering the effect of natural salt freeze-thaw cycles. Cold Reg. Sci. Technol. 2022, 201, 103622. [Google Scholar] [CrossRef]

- Scherer, G.W. Crystallization in pores. Cem. Concr. Res. 1999, 29, 1347–1358. [Google Scholar] [CrossRef]

- Zuber, B.; Marchand, J. Modeling the deterioration of hydrated cement systems exposed to frost action. Cem. Concr. Res. 2000, 30, 1929–1939. [Google Scholar] [CrossRef]

- JGJ 52-2006; Ministry of Construction of the People’s Republic of China. Standard for Quality and Testing Methods of Sand and Crushed Stone for Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2006. (In Chinese)

- GB/T 14685-2011; PRC National Standard. Specification of Pebble and Crushed Stone for Building. The National Cement Standardization Technical Committee (SAC/TC 184): Beijing, China, 2011.

- JGJ 63-2006; Ministry of Construction of the People’s Republic of China. Standard of Water for Concrete. China Architecture & Building Press: Beijing, China, 2006. (In Chinese)

- GB 175-2007; PRC National Standard. Common Portland Cement. The National Cement Standardization Technical Committee (SAC/TC 184): Beijing, China, 2007.

- GB/T 1596-2017; General Administration of Quality Supervision; Inspection and Quarantine of the People’s Republic of China and National Standardization Administration. Fly Ash Used for Cement and Concrete. Standards Press of China: Beijing, China, 2017. (In Chinese)

- GB 8076-2008; General Administration of Quality Supervision; Inspection and Quarantine of the People’s Republic of China and National Standardization Administration. Concrete Admixtures. Standards Press of China: Beijing, China, 2009. (In Chinese)

- GB/T 50081-2019; Ministry of Housing and Urban-Rural Development of the People’s Republic of China; State Administration for Market Regulation. Standard for Test Methods of Concrete Physical and Mechanical Properties. China Architecture & Building Press: Beijing, China, 2019. (In Chinese)

- GB/T 50080-2016; Standard for Test Methods of Performance of Ordinary Concrete Mixtures. China Architecture & Building Press: Beijing, China, 2016.

- GB/T 50082-2024; Ministry of Housing and Urban-Rural Development of the People’s Republic of China; State Administration for Market Regulation. Standard for Test Methods of Long-Term Performance and Durability of Concrete. China Architecture & Building Press: Beijing, China, 2024. (In Chinese)

- Qian, Z.K. Experimental Study on Mechanical Properties of Coal Gangue Concrete after Freeze-Thaw in Northern Shaanxi Mining Area. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2023. [Google Scholar]

- GB/T 50010-2010; Ministry of Construction of the People’s Republic of China. Code for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2011. (In Chinese)

- Wang, X.; Zhang, K.; Guo, J.; Wei, R.; Zhang, Z. Study on the Performance Degradation of Concrete Under Freeze-thaw Cycles Based on Mesoscopic Mechanical Models. Mod. Tunn. Technol. 2024, 61, 209–218. [Google Scholar] [CrossRef]

- Zhang, Z.; Feng, C.; Jiang, T.; Zhang, Y. Numerical simulation study on the freeze-thaw performance of recycled concrete based on ABAQUS. J. Chang. Inst. Technol. 2020, 21, 5–11. [Google Scholar] [CrossRef]

- Zhao, W.P.; Zhong, L.; Zhang, K.; Su, Z.; Xu, Y.; Chen, J. Experimental study and numerical simulation on bond performance of reinforced coal gangue concrete. J. Harbin Inst. Technol. 2025, 1–16. [Google Scholar]

| Type of Coarse Aggregate | Bulk Density | Apparent Density | Water Absorption | Crushing Index | Clay Content |

|---|---|---|---|---|---|

| Coal gangue | 1350 kg/m3 | 2440 kg/m3 | 5.47% | 23.04% | 0.88% |

| Natural crushed stone | 1382 kg/m3 | 2687 kg/m3 | 0.46% | 7.2% | 0.32% |

| Sample Number | Water | Cement | Fly Ash kg/m3 | Sand kg/m3 | Coal Gangue | Natural Crushed Stone | Water Reducer |

|---|---|---|---|---|---|---|---|

| M0 | 216 kg/m3 | 384 kg/m3 | 96 kg/m3 | 735 kg/m3 | 0 kg/m3 | 1045 kg/m3 | 5.76 kg/m3 |

| M20 | 216 kg/m3 | 384 kg/m3 | 96 kg/m3 | 735 kg/m3 | 209 kg/m3 | 836 kg/m3 | 5.76 kg/m3 |

| M40 | 216 kg/m3 | 384 kg/m3 | 96 kg/m3 | 735 kg/m3 | 418 kg/m3 | 627 kg/m3 | 5.76 kg/m3 |

| M60 | 216 kg/m3 | 384 kg/m3 | 96 kg/m3 | 735 kg/m3 | 627 kg/m3 | 418 kg/m3 | 5.76 kg/m3 |

| Sample Number | Number of Freeze–Thaw Cycles | |||

|---|---|---|---|---|

| M0 | 0 | 24,000.46 MPa | 32,958.33 MPa | 0.73 |

| 20 | 18,934.57 MPa | 31,657.84 MPa | 0.60 | |

| 40 | 17,583.37 MPa | 31,433.35 MPa | 0.56 | |

| 60 | 14,472.83 MPa | 30,137.34 MPa | 0.48 | |

| 80 | 12,186.84 MPa | 28,708.54 MPa | 0.42 | |

| M20 | 0 | 24,424.46 MPa | 32,714.05 MPa | 0.75 |

| 20 | 13,433.69 MPa | 31,496.13 MPa | 0.43 | |

| 40 | 12,556.08 MPa | 30,895.19 MPa | 0.41 | |

| 60 | 5787.21 MPa | 29,398.59 MPa | 0.20 | |

| 80 | 3372.33 MPa | 27,236.19 MPa | 0.12 | |

| M40 | 0 | 23,438.18 MPa | 31,739.13 MPa | 0.74 |

| 20 | 9075.74 MPa | 29,260.78 MPa | 0.31 | |

| 40 | 7596.59 MPa | 27,572.45 MPa | 0.28 | |

| 60 | 3360.03 MPa | 26,219.51 MPa | 0.13 | |

| 80 | 1884.09 MPa | 24,150.41 MPa | 0.08 | |

| M60 | 0 | 28,064.74 MPa | 31,278.09 MPa | 0.90 |

| 20 | 7838.10 MPa | 28,375.19 MPa | 0.28 | |

| 40 | 5438.73 MPa | 25,819.57 MPa | 0.21 | |

| 60 | 2207.29 MPa | 24,437.45 MPa | 0.09 |

| Sample Number | Number of Freeze–Thaw Cycles | /10−3 | /10−3 | |

|---|---|---|---|---|

| M0 | 0 | 1.845 | 1.608 | 1.15 |

| 20 | 1.877 | 1.547 | 1.21 | |

| 40 | 1.921 | 1.537 | 1.25 | |

| 60 | 1.977 | 1.484 | 1.33 | |

| 80 | 2.045 | 1.432 | 1.43 | |

| M20 | 0 | 1.965 | 1.596 | 1.23 |

| 20 | 2.761 | 1.540 | 1.79 | |

| 40 | 3.699 | 1.515 | 2.44 | |

| 60 | 4.752 | 1.457 | 3.26 | |

| 80 | 5.962 | 1.384 | 4.31 | |

| M40 | 0 | 1.679 | 1.551 | 1.08 |

| 20 | 2.789 | 1.452 | 1.92 | |

| 40 | 4.544 | 1.394 | 3.26 | |

| 60 | 5.024 | 1.353 | 3.71 | |

| 80 | 6.798 | 1.295 | 5.25 | |

| M60 | 0 | 1.522 | 1.531 | 0.99 |

| 20 | 2.955 | 1.421 | 2.08 | |

| 40 | 5.035 | 1.341 | 3.75 | |

| 60 | 5.890 | 1.303 | 4.52 |

| Sample Number | Number of Freeze–Thaw Cycles | |||

|---|---|---|---|---|

| M0 | 0 | 2.67 | 2.70 | 0.99 |

| 20 | 2.92 | 3.15 | 0.93 | |

| 40 | 3.10 | 3.35 | 0.93 | |

| 60 | 3.16 | 3.66 | 0.86 | |

| 80 | 3.20 | 3.66 | 0.87 | |

| M20 | 0 | 2.32 | 2.30 | 1.01 |

| 20 | 2.97 | 2.80 | 1.06 | |

| 40 | 2.24 | 1.93 | 1.16 | |

| 60 | 3.45 | 3.37 | 1.02 | |

| 80 | 4.48 | 4.67 | 0.96 | |

| M40 | 0 | 2.63 | 2.64 | 1.00 |

| 20 | 3.34 | 4.07 | 0.82 | |

| 40 | 2.34 | 1.89 | 1.24 | |

| 60 | 5.67 | 6.82 | 0.83 | |

| 80 | 13.32 | 15.46 | 0.86 | |

| M60 | 0 | 2.23 | 2.20 | 1.01 |

| 20 | 4.08 | 4.13 | 0.99 | |

| 40 | 2.41 | 2.03 | 1.19 | |

| 60 | 16.37 | 18.25 | 0.90 | |

| Mean Value | — | — | — | 0.98 |

| Coefficient of Variation | — | — | — | 0.12 |

| Parameter Name | Dilation Angle | Eccentricity c | Viscosity Parameter | ||

|---|---|---|---|---|---|

| Value | 30 | 0.1 | 1.15 | 0.667 | 0.0005 |

| Sample Number | Number of Freeze–Thaw Cycles | Compressive Peak Stress/MPa | Compressive Peak Strain/10−3 | ||

|---|---|---|---|---|---|

| Experimental Results | Numerical Simulation | Experimental Results | Numerical Simulation | ||

| M0 | 0 | 27.87 | 28.2 | 1.845 | 1.846 |

| 20 | 24.25 | 24.41 | 1.877 | 1.903 | |

| 40 | 23.69 | 23.72 | 1.921 | 2.047 | |

| 60 | 20.79 | 20.82 | 1.977 | 2.124 | |

| 80 | 18.12 | 18.33 | 2.045 | 2.195 | |

| M20 | 0 | 27.14 | 27.66 | 1.965 | 2.014 |

| 20 | 23.85 | 23.95 | 2.761 | 2.968 | |

| 40 | 22.42 | 22.78 | 3.699 | 3.727 | |

| 60 | 19.35 | 19.69 | 4.752 | 4.896 | |

| 80 | 15.80 | 16.23 | 5.962 | 6.048 | |

| M40 | 0 | 24.46 | 24.71 | 1.679 | 1.727 |

| 20 | 19.10 | 19.47 | 2.789 | 2.834 | |

| 40 | 16.29 | 16.53 | 4.544 | 4.684 | |

| 60 | 14.41 | 14.57 | 5.024 | 5.153 | |

| 80 | 11.98 | 12.24 | 6.798 | 6.914 | |

| M60 | 0 | 23.32 | 23.56 | 1.522 | 1.675 |

| 20 | 17.56 | 17.81 | 2.955 | 3.053 | |

| 40 | 13.90 | 14.12 | 5.035 | 5.452 | |

| 60 | 12.29 | 12.51 | 5.890 | 6.094 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, G.; Cui, J.; Gao, M.; Hu, Z.; Guo, C.; Fan, D.; Li, M.; Guo, Z. Experimental Investigation and Numerical Simulation of Freeze–Thaw Damage Behavior in Coal Gangue Concrete Used in High-Altitude Cold Western Mines. Processes 2025, 13, 3654. https://doi.org/10.3390/pr13113654

Gao G, Cui J, Gao M, Hu Z, Guo C, Fan D, Li M, Guo Z. Experimental Investigation and Numerical Simulation of Freeze–Thaw Damage Behavior in Coal Gangue Concrete Used in High-Altitude Cold Western Mines. Processes. 2025; 13(11):3654. https://doi.org/10.3390/pr13113654

Chicago/Turabian StyleGao, Guojun, Jiaxin Cui, Mingtao Gao, Zhenhua Hu, Chengyang Guo, Donglin Fan, Minhui Li, and Zihao Guo. 2025. "Experimental Investigation and Numerical Simulation of Freeze–Thaw Damage Behavior in Coal Gangue Concrete Used in High-Altitude Cold Western Mines" Processes 13, no. 11: 3654. https://doi.org/10.3390/pr13113654

APA StyleGao, G., Cui, J., Gao, M., Hu, Z., Guo, C., Fan, D., Li, M., & Guo, Z. (2025). Experimental Investigation and Numerical Simulation of Freeze–Thaw Damage Behavior in Coal Gangue Concrete Used in High-Altitude Cold Western Mines. Processes, 13(11), 3654. https://doi.org/10.3390/pr13113654