Carbonate formations constitute a major component of global unconventional hydrocarbon resources, representing approximately 60% of worldwide oil and gas reserves [

1,

2]. In China, such reservoirs are predominantly distributed across the Tarim, Sichuan, and Ordos Basins, as well as the North China area, among which the Tarim fractured-vuggy carbonate system is globally recognized as the area’s largest accumulation of carbonate oil and gas [

3,

4].The development of such reservoirs is crucial for the replacement of China’s oil and gas resources. The storage framework of fractured-vuggy carbonate reservoirs mainly consists of interconnected pores, vugs, and fractures that exhibit pronounced heterogeneity [

1]. Considerable variations exist in both the scale of the fractured-vuggy systems and the regularity of their interconnections. The pronounced spatial heterogeneity of fractured-vuggy carbonate reservoirs leads to substantial challenges in their development, often resulting in inefficient recovery from fracture–cave systems [

5].

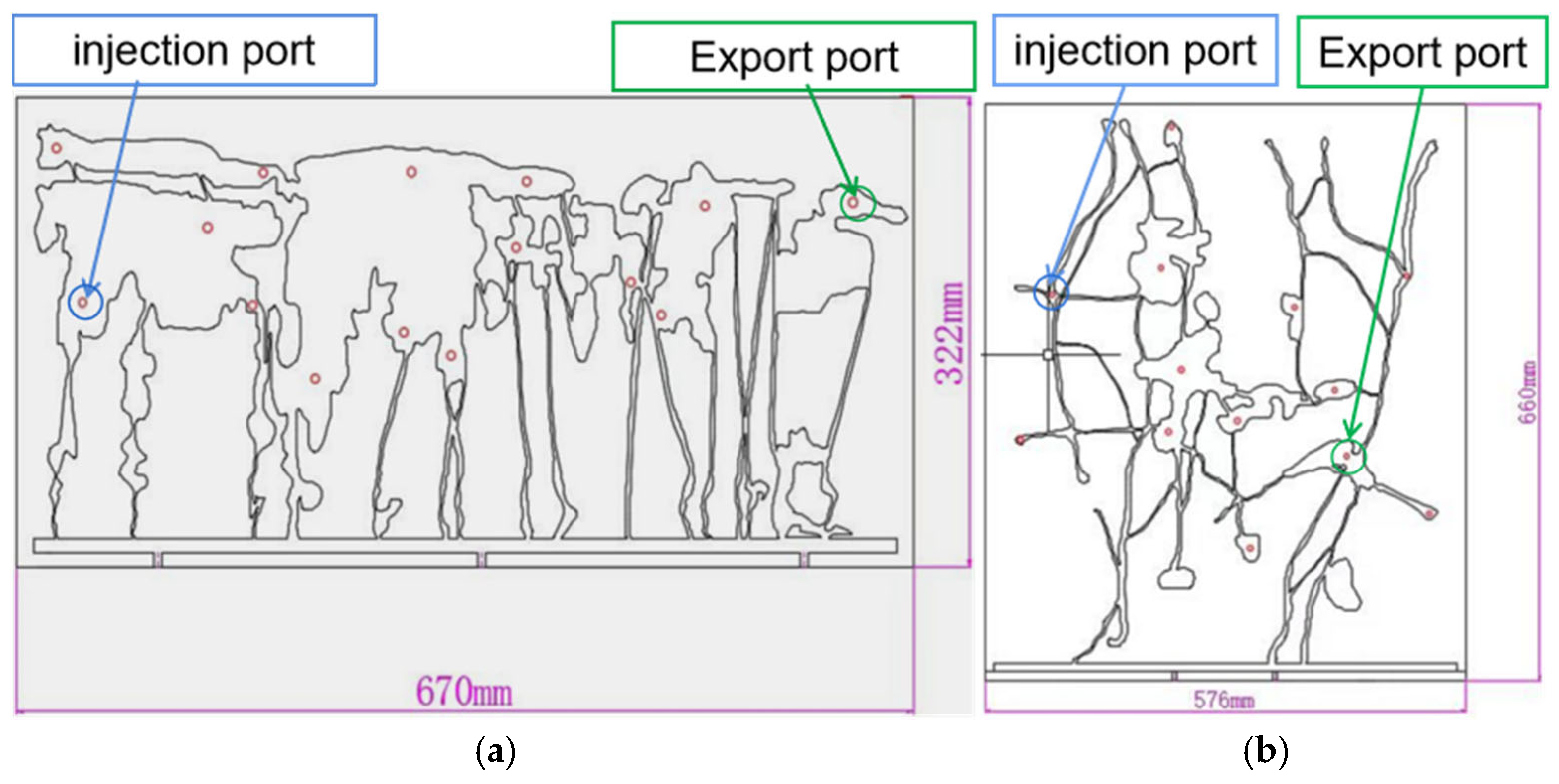

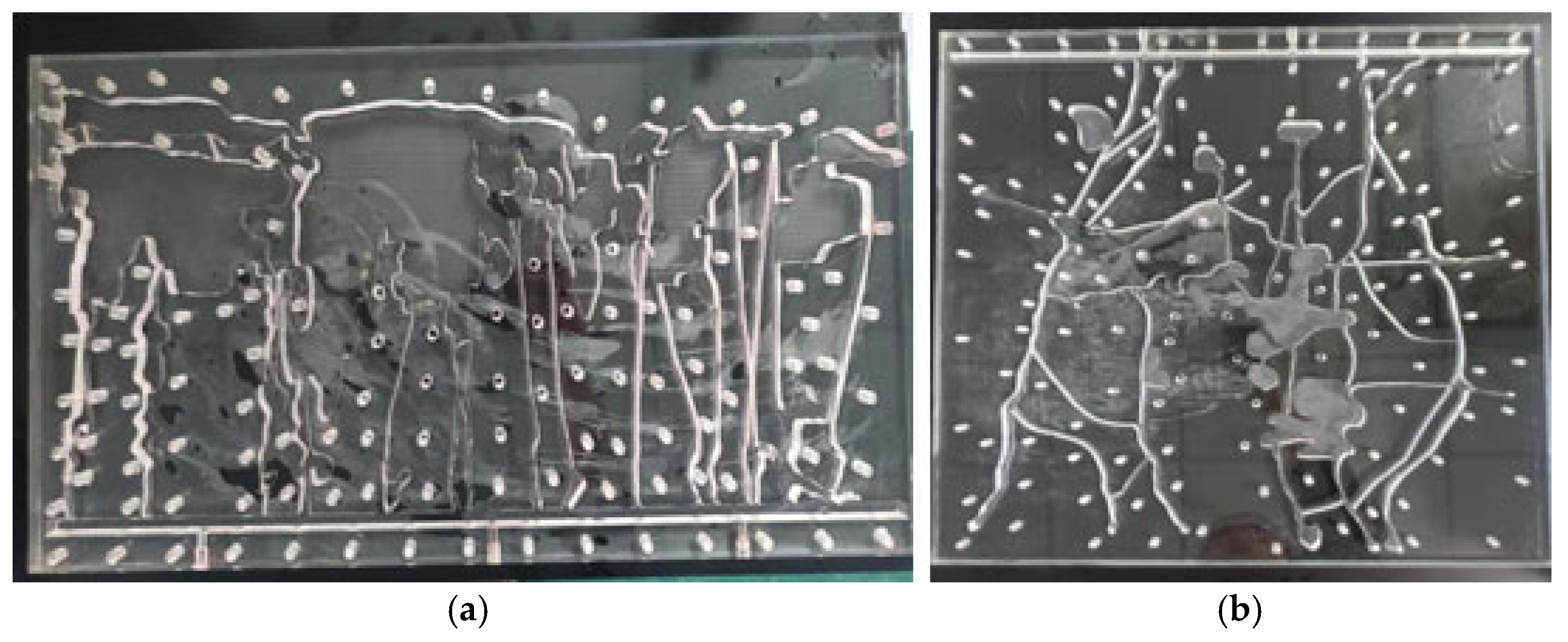

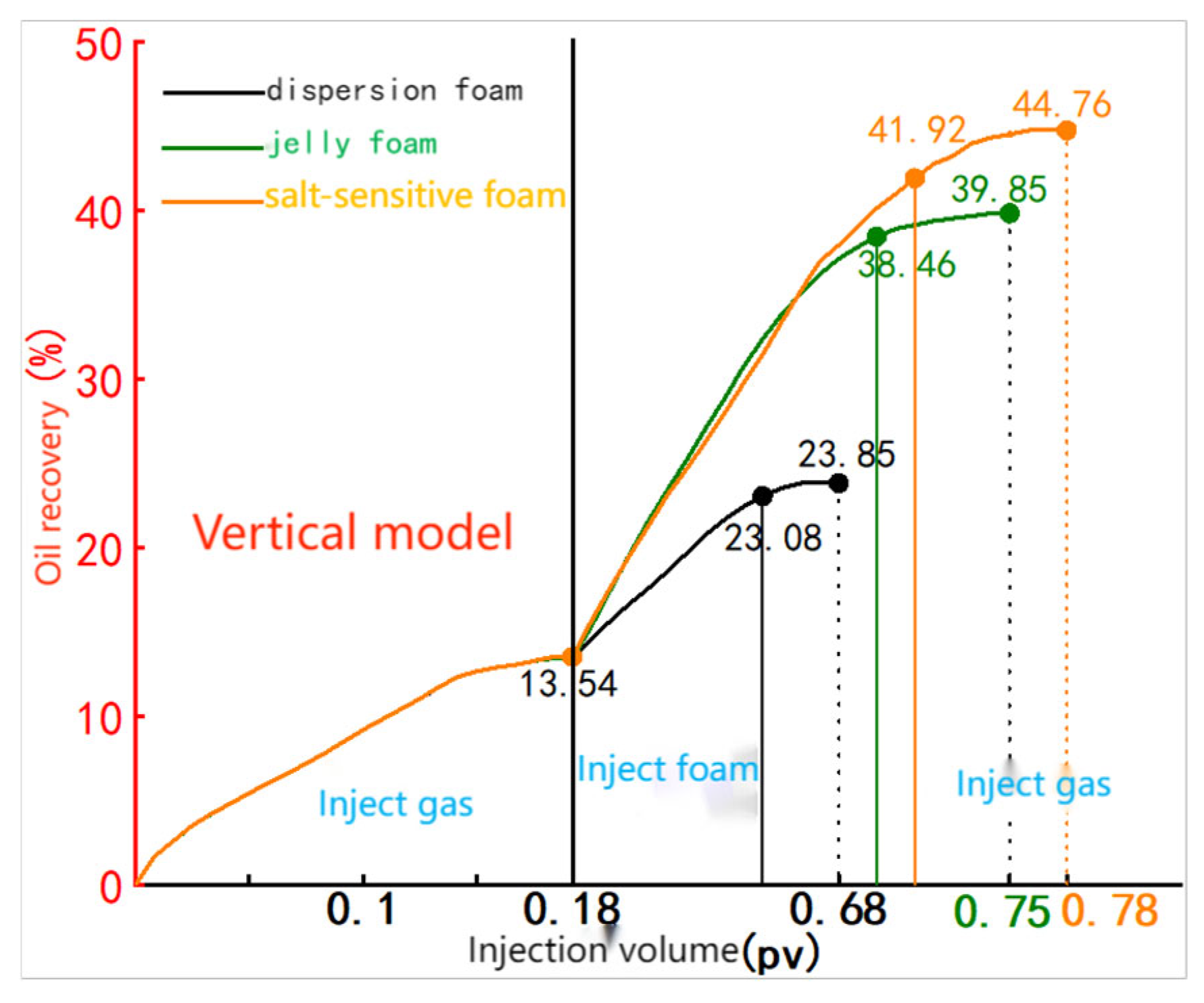

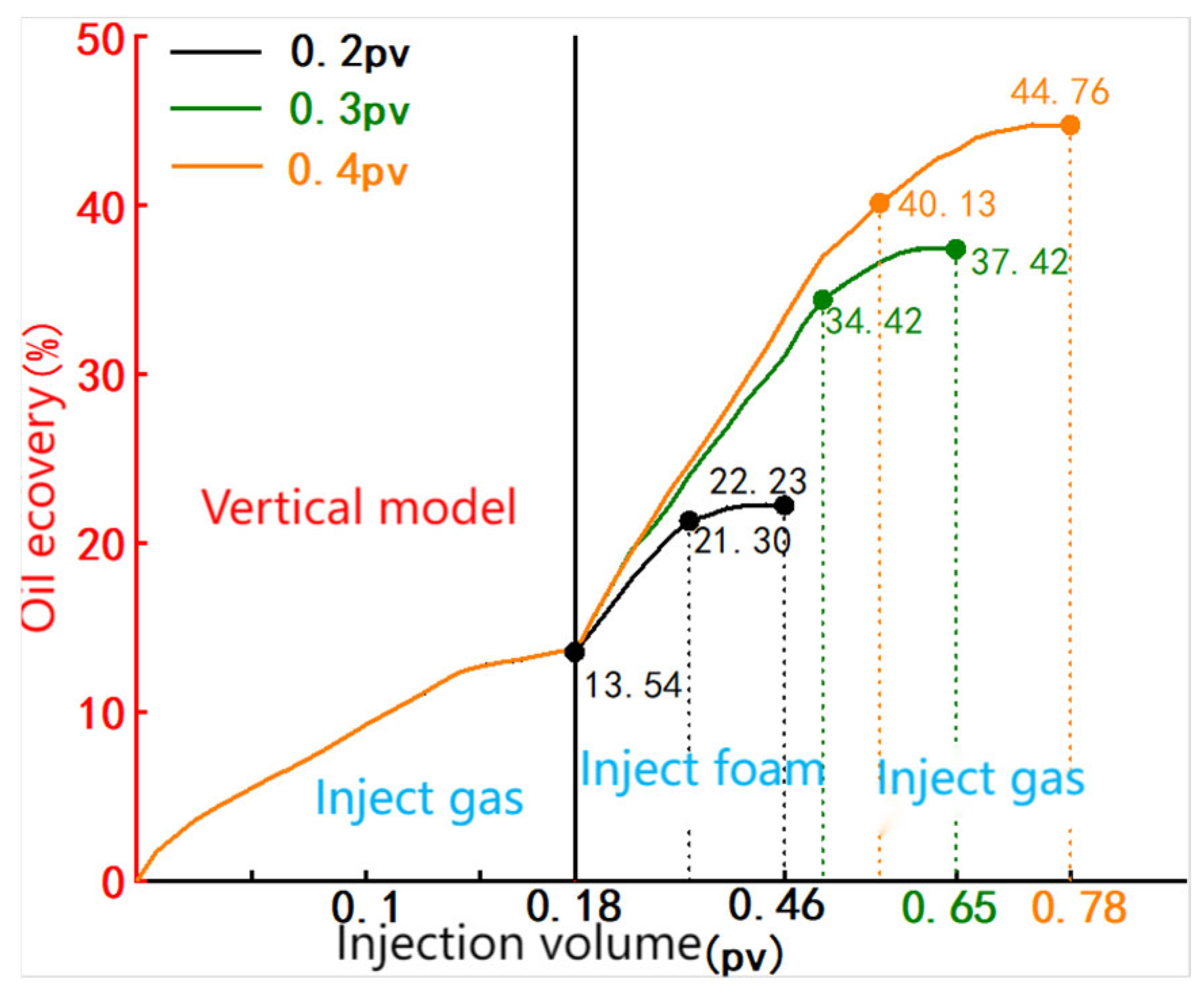

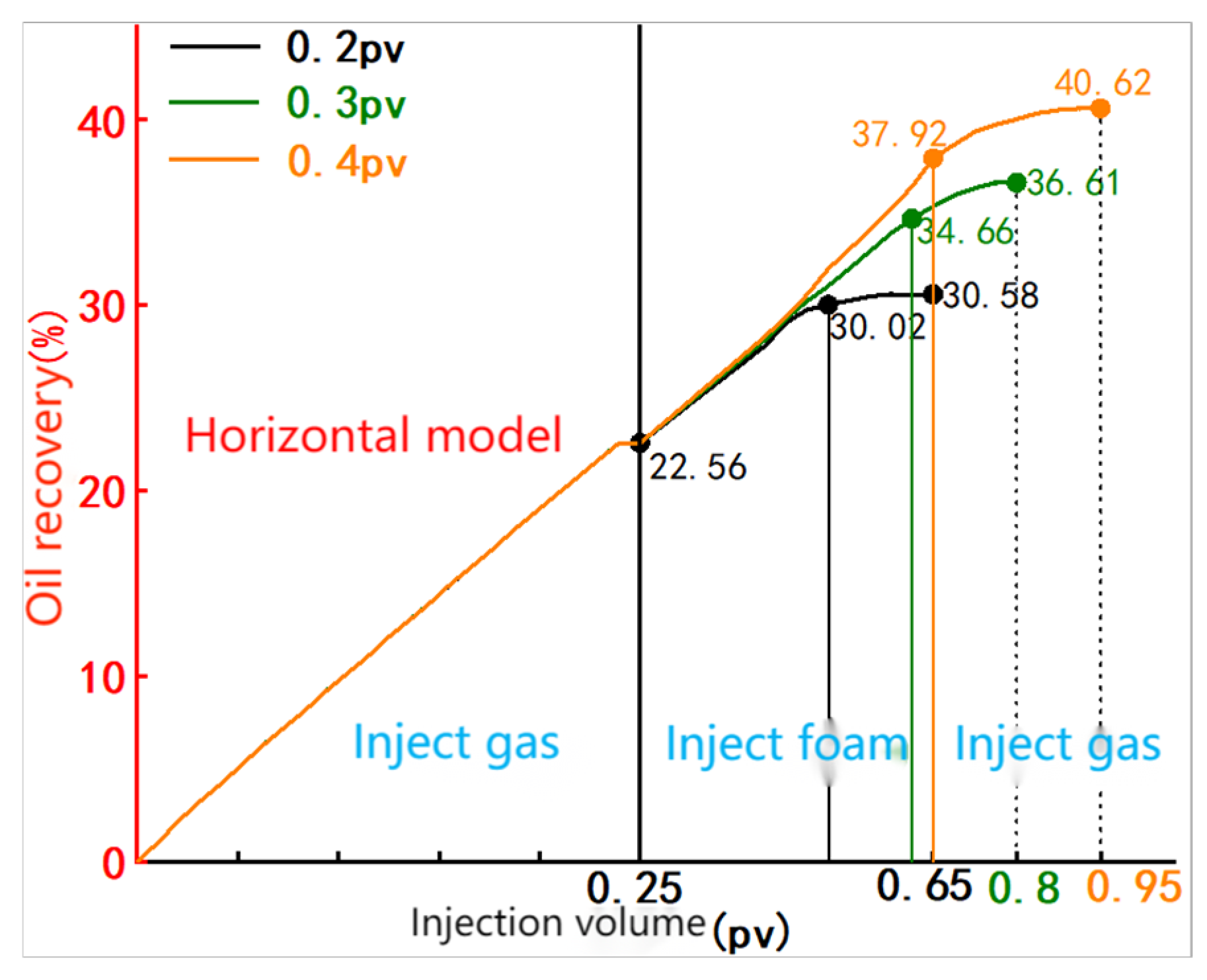

In the early stages of the Tarim oilfield’s development, water flooding was the primary method used; however, as the water injection period increased, the water cut rose, and oil production declined. Subsequently, nitrogen injection was implemented to recover the remaining oil, but owing to pronounced reservoir heterogeneity and large fluid mobility contrast, injected gas easily established preferential flow pathways, causing gas coning and resulting in only a marginal enhancement of recovery. The gas injection production curve is shown in

Figure 1.

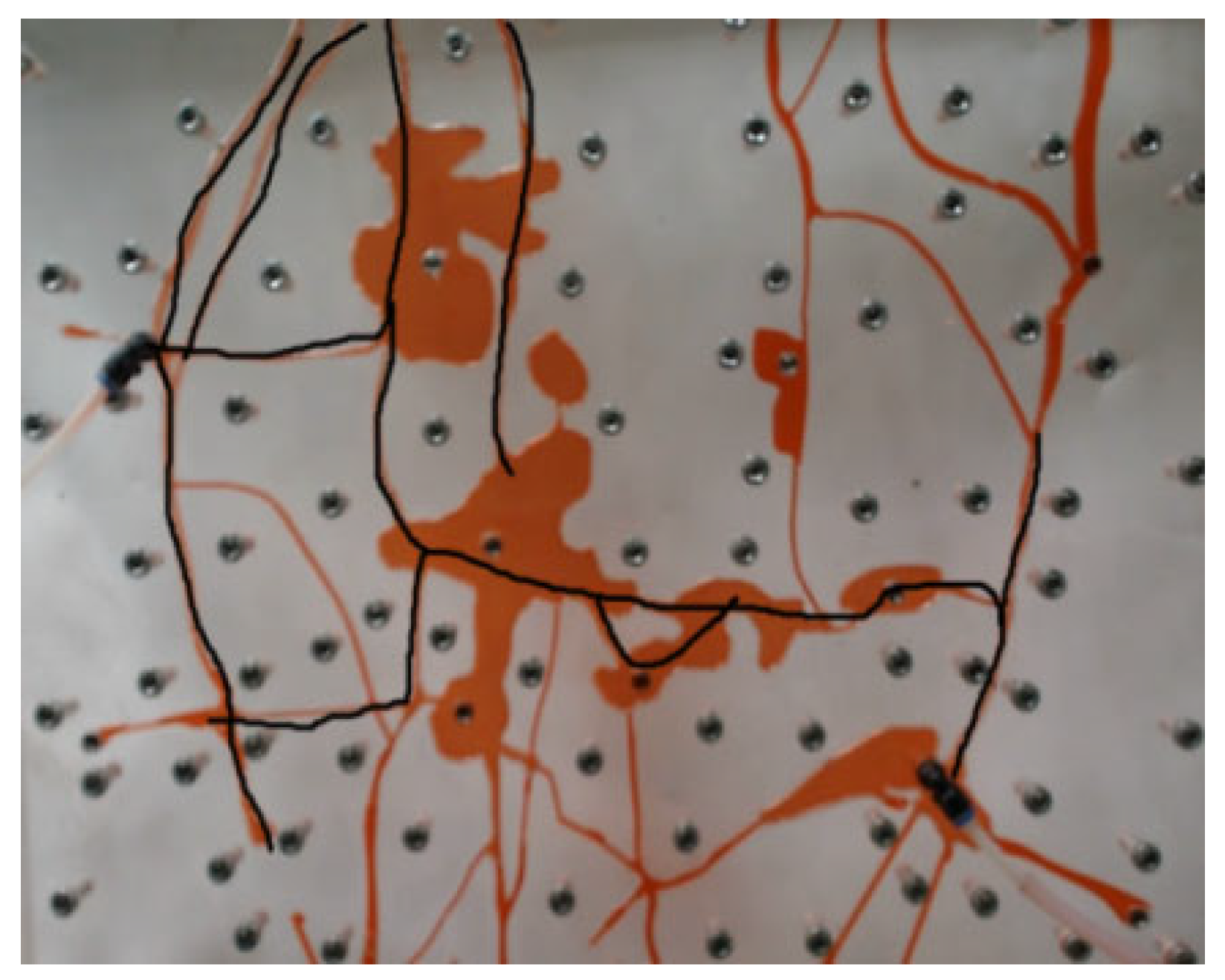

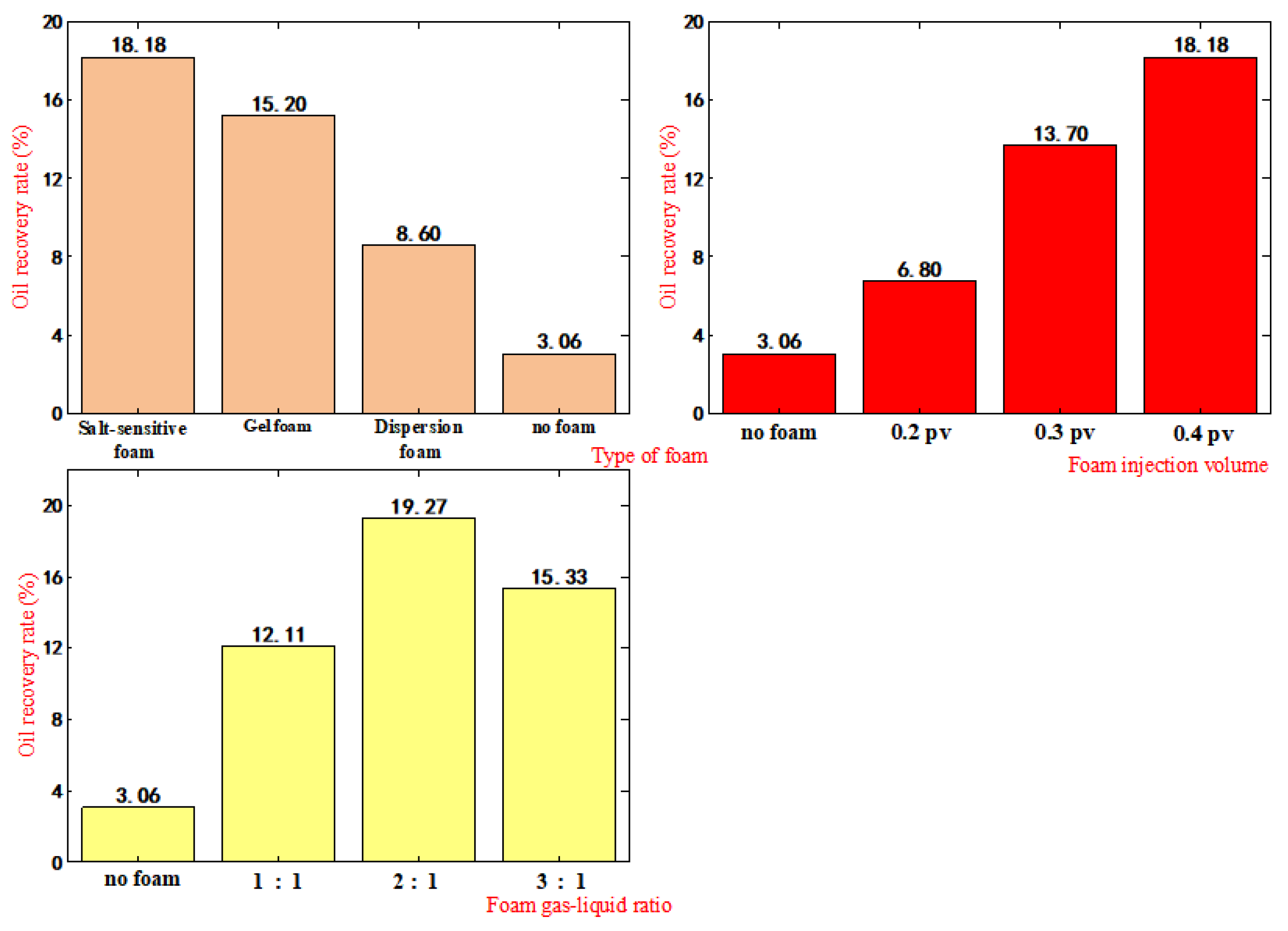

Foam has excellent channel-blocking capabilities and can block dominant flow channels during the displacement process, thereby expanding the sweep volume and effectively increasing the recovery factor. Yang et al. [

6] revealed that within a regular slit-hole network, gel foam adheres to and seals the openings, thereby guiding the upward migration of gas and enhancing the co-driving recovery of residual oil. In systems containing both fractures and irregular cavities, the foam—owing to its density and mobility—propagates downward and laterally along the fracture paths, facilitating the displacement of crude oil and formation water toward production wells. Youssif et al. [

7] noted that foam-assisted gas injection technology can significantly enhance oil sweep efficiency in fractured carbonate reservoirs by improving gas mobility and controlling fluid flow direction. Fu et al. [

8] demonstrated that a novel ultra-low interfacial tension DES-CTAB composite foam system performs excellently in heavy oil recovery, and its nitrogen foam-assisted steam flooding can substantially increase the overall recovery rate by 44.9% by altering the occurrence state of residual oil. Tuoliang et al. [

9] reported that fluctuations at the oil–water and gas–oil interfaces positively influence recovery in fractured–porous reservoirs. The addition of foam during the nitrogen injection process stabilizes gas flow, intensifies interfacial fluctuation behavior, and consequently raises the recovery efficiency. Wen et al. [

10] found that gel foam demonstrates superior flow control and high microscopic displacement efficiency, enabling multidirectional sweeping at nearly uniform velocities. The principal enhanced oil recovery mechanisms of gel foam in crevice–porosity reservoirs include lowering interfacial tension, improving fluid mobility, selectively blocking high-permeability channels, and inducing discontinuous flow behavior. Wen et al. [

11] reviewed the performance of micro-dispersed gel foam in fractured carbonate systems, concluding that its application intensifies gas drive efficiency and expands the area of effective oil displacement. Feng Yao et al. [

12] conducted a numerical simulation study on CO

2 foam-assisted gas flooding in tight reservoirs. The results demonstrate that CO

2 foam flooding significantly enhances oil recovery and gas control under various reservoir conditions. Compared to Water-Alternating Gas (WAG) and continuous gas injections, Surfactant-Alternating Gas (SAG) more effectively delays gas breakthrough, reduces the gas–oil ratio (GOR), and improves the mobilization of residual oil. It performs well in tight, vertically and laterally heterogeneous, and fractured reservoirs, particularly those dominated by vertical fractures.

Therefore, based on the selective plugging performance of foam, this study focuses on addressing the gas channeling issue in the Tarim Basin by conducting research on foam-assisted gas flooding. The aim of the study is to extend the effective duration of gas injection, enhance the overall recovery efficiency of the oilfield, and increase the economic benefits of gas injection.