Abstract

Traditional multi-stage separated heat pipes (SHPs) face limitations in independently setting operation parameters for each stage. To address this issue, this paper presents a novel independent multi-stage microchannel Separated Gravity Heat Pipe (SGHP) for air compressor room cooling. The innovative structure and working principle of this novel multi-stage SGHP were introduced. Furthermore, numerical investigations on a single stage of the SGHP were then conducted to study the gas–liquid two-phase flow characteristics and phase-change heat transfer performance. Experimental research on a three-stage SGHP was carried out to further explore the impact of the filling ratio combinations and the temperature difference between the hot and cold ends on the heat transfer performance of the SGHP. The results show that the temperature difference between the hot and cold ends affects the flow pattern of the working fluid, which has a vital effect on the heat transfer performance of the SGHP. The optimum filling ratio combination of the three-stage SGHP depends on the temperature difference between the hot and cold ends. The optimum filling ratio combination is 37%/37%/30% at low temperature difference conditions and 43%/37%/37% at high temperature difference conditions, respectively. The highest heat transfer capacity of the three-stage SGHP reaches 15.3 kW, and the peak heat recovery efficiency is 74.0%. The findings provide a crucial foundation for developing novel independent multi-stage SGHP in compressor room cooling and similar industrial settings, promising high potential to reduce energy consumption and operational costs.

1. Introduction

As power plants continue to develop towards larger scales, the air compressor rooms of power plants exhibit high-temperature characteristics. This not only poses a potential safety threat to the workers but also accelerates equipment aging and thereby reduces its service life. In such high heat flux environments, developing a cooling device that is capable of efficiently dissipating the heat from air compressor rooms poses a formidable challenge. Among the cooling devices, heat pipes benefit from simple geometry, compact structure, excellent heat transfer performance, and no need for additional energy consumption [1]. For these reasons, heat pipes present considerable potential for cooling air compressor rooms of power plants.

Heat pipes were invented in the 1960s and have rapidly developed all over the world. Nowadays, they have been widely utilized in industrial sectors, such as fuel cells [2,3], aerospace [4,5], electronics [6], aluminum diecasting [7], the ceramic industry [8,9], the steel industry [10,11], air-conditioning systems [12,13], and the automobile sector [14,15]. Due to the phase change characteristics in the working process, the heat transfer capacity of heat pipes can be much higher than that of many other thermal conductors [16]. According to whether heat pipes have a wick structure or not, heat pipes are divided into wicked heat pipes and gravity heat pipes [17,18]. Based on the structural features, heat pipes can be classified into the classical heat pipe, rotating heat pipe, thermosiphon and loop thermosiphon, pulsating heat pipe, separated heat pipe (SHP), etc. [19]. Among them, the SHP has excellent heat transfer efficiency, outstanding thermal equilibrium, as well as a large heat transfer limit. Therefore, SHPs have been widely employed in applications with high heat flux.

The SHP is also called the loop heat pipe, which includes four parts: an evaporator, a condenser, a rising pipe, and a downward pipe. The evaporator and condenser are connected through the independent pipes. This configuration enables the SHP to meet the requirement of long-distance heat transfer, which helps to accomplish a flexible arrangement. Ling et al. [20] designed a novel SHP with a parallel arrangement of 13 vapor channels and conducted experimental tests on the start-up characteristics and steady-state performance under regular and random variable loads. They found that the SHP presented a rapid start-up feature and operated smoothly with the heat load from 30 to 180 W, thereby retaining the heat source temperature below 75 °C. Liu et al. [21] proposed and tested a novel integrated unit that couples a mechanically driven SHP system and a vapor compression system for cooling a data center. This integrated unit has a larger energy-saving potential in cold regions than in warm regions. Ding et al. [22] experimentally studied the influences of freon coolants and filling ratios on the heat transfer capacity of the SHP. With an increase in the filling ratio, the heat transfer capacity first increased, then almost remained unchanged, and finally decreased. Kuang and Wang [23] developed a numerical model to explore the effects of the filling ratio on the heat transfer capacity of a large SHP in the spent fuel pool. The influences of the filling ratio depended on the working fluids. The optimal filling ratio for water SHP was around 17%, while the optimal ratio for R134a or ammonia SHP ranged from 20% to 70%. Xia et al. [24] developed a quasi-three-dimensional distributed parameter model of microchannel SHPs to predict the influences of non-uniformly distributed refrigerant and air flows on the SHP performance. Wu et al. [25] manufactured an SHP radiator for the cooling of a spent fuel spool. The radiator dissipated around 4 kW under design working conditions, and the heat transfer capacity can be further increased in the inclined state. To enhance heat transfer performance, Kang et al. [26] proposed a new type of SHP with separating walls in flow channels that can change the flow pattern of the vapor and liquid plugs. Xiong et al. [27] designed a novel composite wick structure SHP, including sintered ceramic powder and sintered copper powder, leading to lower heat leakage into the compensation chamber and better heat transfer characteristics. Moreover, the application of microchannel structure on SHPs was a breakthrough in this scientific field. Yue et al. [28,29] explored the effects of refrigerant filling ratios on the heat transfer capacity of microchannel SHPs. Xia et al. [24] investigated the effect of refrigerant flow distribution and airflow on the performance of microchannel SHPs. Zhang et al. [30] studied the influences of the height difference between the condenser and evaporator on the two-phase length to obtain an optimal height difference parameter.

As modern cooling demands continue to grow, traditional single-stage SHPs are gradually showing limitations in terms of heat transfer capability, temperature uniformity, and heat flux density. Compared to single-stage SHPs, multi-stage SHPs, also called multi-row SHPs, have significant technological advantages of gradient heat transfer, leading to higher overall heat transfer capacity. However, the research on multi-stage SHPs remains relatively limited. Tong et al. [31] studied the effects of heating power distribution among different rows of evaporators on the heat transfer capacity of multi-row SHPs. Xia et al. [32] proposed a distributed parameter model of the multi-stage SHP for its efficient design and optimization. They found that the cooling capacity can be adjusted by increasing or decreasing the number of evaporators and condensers, demonstrating good scalability. And the heat transfer capacity no longer increased when the number of rows of tubes exceeded five. Wu et al. [33] proposed a multi-evaporator SHP system with three flat disk evaporators coupled with vapor lines, which helped to obviously decrease the adverse influence between evaporators. Wang et al. [34] proposed an innovative application of heat pipes by integrating micro-heat pipe arrays into bipolar plates for thermal management of proton exchange membrane fuel cells. The heat pipe array reached steady state in less than 900 s with changing heating power and presented good internal temperature uniformity.

To date, multi-stage microchannel SHPs exhibit significant technological advantages in terms of heat transfer performance, heat transfer distance, and engineering adaptability due to the unique structural features. However, in conventional multi-stage designs, the stages are interdependent, preventing individual optimization and limiting overall performance flexibility, which limits the usage flexibility of the multi-stage SHP and hinders the further improvement of its performance. This work aims to bridge this gap by proposing a novel independent multi-stage microchannel Separated Gravity Heat Pipe (SGHP), which enables setting the filling ratio and the operational pressure for each stage individually. Therefore, the novel independent multi-stage SGHP has better heat transfer performance than the traditional one. The structure and working principle of this novel SGHP were introduced. Numerical research on the internal flow characteristics of a single-stage SGHP was then carried out, and experimental investigations on a three-stage SGHP performance were finally conducted.

2. Structural Design and Working Principle of an SGHP

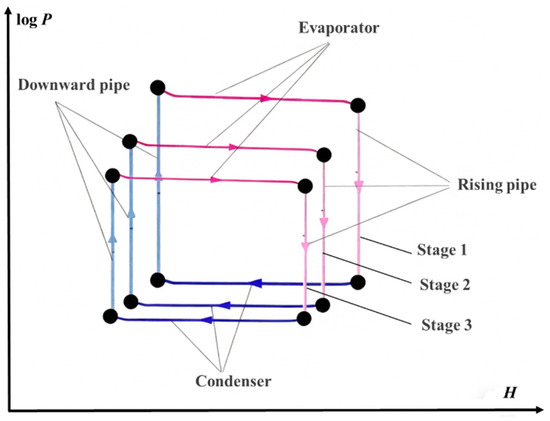

This paper presents a novel multi-stage SGHP, with the most distinctive feature being that each stage operates independently. This special configuration helps to adjust optimal parameters for each stage, respectively, which allows for better heat transfer performance for the novel SGHP than the conventional one. The pressure–enthalpy diagram of a three-stage SGHP is illustrated in Figure 1. Each stage can operate independently without affecting other stages. Different filling rates can be set for each stage independently, enabling each stage to achieve its best performance. The pressure and temperature inside the evaporator and condenser decrease from Stage 1 to Stage 3. The evaporator absorbs heat from the indoor air of compressor rooms, and thus it is called the hot end, while the condenser transfers heat to outdoor environments and is thus referred to as the cold end.

Figure 1.

Pressure–enthalpy diagram of a three-stage SGHP.

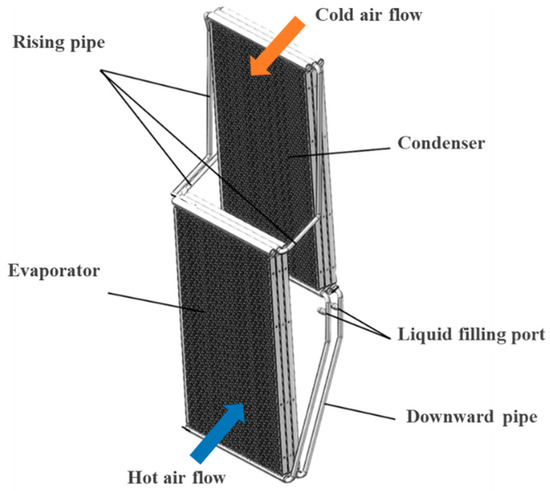

Figure 2 shows the three-dimensional structural model of a three-stage SGHP. In the present study, each stage of the SGHP has the same structure, which has an evaporator, a rising pipe, a condenser, and a downward pipe. The working fluid is R134a in this work. The selection of R134a as the working fluid almost depends on the operational temperature. The working fluid occurs at a suitable temperature and pressure, which helps to induce the phase change heat transfer process. The R134a evaporates inside the evaporator after absorbing the heat from the hot air. It then flows into the condenser through the rising pipe under a pressure difference. After that, the cooled airflow condenses the R134a in the condenser. At last, the R134a returns to the evaporator via the downward pipe due to gravity. Thus, a working cycle is formed, and it keeps repeating. Generally, fans are added at both hot and cold ends to increase the airflow rate, which helps to enhance heat transfer performance. The air flows from Stage 1 to Stage 3 at the hot end, while at the cold end, the air flows from Stage 3 to Stage 1.

Figure 2.

Three-dimensional structural model of a three-stage SGHP.

3. Numerical Investigations on an SGHP

3.1. Simulation Model

3.1.1. Geometrical Model

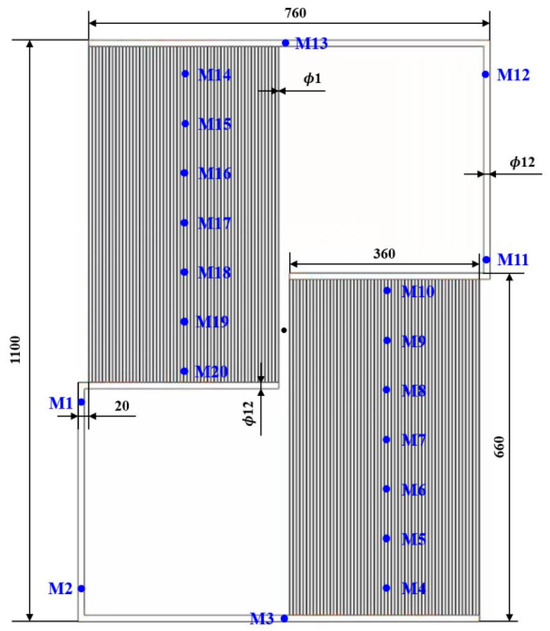

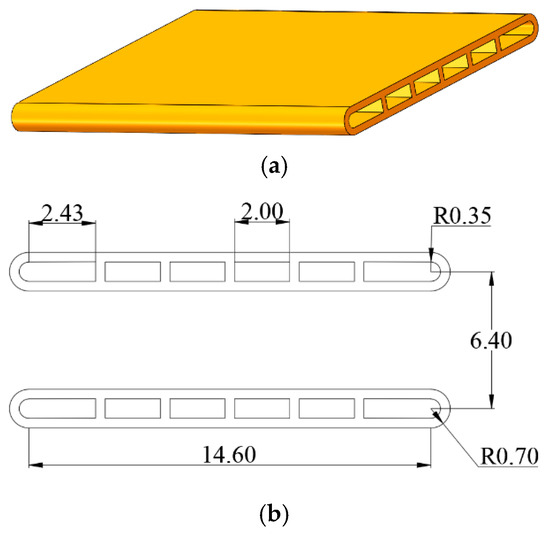

In this work, only one stage was simulated to reduce computational cost, as all stages have identical geometry and operational principles. Simulations with different operating conditions are able to reveal the working characteristics of the SGHP. Figure 3 displays the structural parameters of one stage. Both the evaporator and condenser have the same structural parameters in this work. The key structural parameters of the SGHP are detailed in Table 1. Among them, the total height and length of the SGHP were 1100 mm and 760 mm, respectively. The condenser had a higher vertical position than the evaporator, and the vertical position difference between them was 440 mm. A series of monitoring points were arranged along the circuit to monitor parameters such as pressure, temperature, and mass flow rate within the SGHP. In addition, both the evaporator and condenser had 57 finned microchannel flat tubes interconnected by straight fins, which helped to enhance heat transfer performance. The detailed geometrical parameters of flat tubes are illustrated in Figure 4. These flat tubes were made of aluminum and had a wall thickness of 0.35 mm. Each tube had six microchannels and slightly enlarged terminal channels.

Figure 3.

Structural parameters of each stage of the SGHP.

Table 1.

Key structural parameters of the SGHP.

Figure 4.

Schematic of flat tube: (a) microchannel structure; (b) geometrical parameters.

3.1.2. Mesh Model and Grid Independence Test

Grid generation of the SHP is a key step to carry out Computational Fluid Dynamics (CFD) investigations. To accurately resolve evaporation/condensation processes and near-wall viscous effects, localized mesh refinement was applied with 5 boundary layers (growth rate 1.15) near tube walls. The reliability of the simulated results has been verified by a grid independence test. The SGHP mesh at four different refinements and the corresponding mesh quality are shown in Table 2. All four cases were simulated under the same operational conditions with the same filling ratio of 43%, the evaporator inlet temperature of 56 °C, and the condenser inlet temperature of 30 °C. According to the simulated results of instantaneous mass flow rates at a monitoring plane where Point M17 was located for four different mesh sizes, the difference in the mass flow rates became negligible as the number of grids exceeded 4.49 × 106. Therefore, taking both computational cost and simulation accuracy into consideration, an SGHP mesh of 4.49 grids was utilized for all CFD simulations.

Table 2.

Four mesh configurations and mesh quality.

3.1.3. Model Simplifications

To address the complexity of fluid dynamics and heat transfer of SGHPs, the following simplifications were implemented while preserving the core circulation mechanism.

- (1)

- The interfacial shear stress between gas and liquid phases was neglected due to its minimal impact on the fluid flow and heat transfer. Neglecting the interfacial shear stress between vapor and liquid phases is an engineering simplification that improves numerical stability. It is reasonable in gravity-driven return flow regions, where buoyancy and pressure gradients dominate momentum exchange; however, in zones with high vapor velocity or thin liquid films, this neglect may alter local film dynamics and slightly affect the prediction of condensation behavior. Thus, while the assumption facilitates convergence, it reduces accuracy in capturing detailed interfacial phenomena.

- (2)

- The airflow distribution (such as air velocity, air capacity, and air temperature) was assumed to be uniform across the evaporator and condenser surfaces. Assuming a uniform airflow distribution over the evaporator and condenser surfaces simplifies the boundary conditions and ensures convergence of the coupled fluid–thermal field. This approximation is acceptable when the airflow is confined and well mixed, as the bulk flow largely determines convective heat transfer. Nevertheless, it suppresses local variations such as turbulence intensity, hot spots, and recirculation, which could smooth the temperature and velocity gradients, thereby limiting the precision of local heat transfer coefficient predictions.

- (3)

- The thermophysical properties (such as density, specific heat, viscosity, and thermal conductivity) of R134a remained unchanged within the operational temperature range from 25 to 100 °C. Treating the thermophysical properties of R134a as constant throughout the operating temperature range is a computationally convenient assumption but physically restrictive. Since the working fluid undergoes phase change under a wide temperature span, its density, viscosity, and thermal conductivity vary noticeably with temperature and pressure. Keeping them constant stabilizes the solver but sacrifices thermodynamic fidelity, potentially misrepresenting vapor–liquid distribution and overall heat transfer characteristics. This assumption is therefore more suitable for qualitative trend analysis than for accurate quantitative prediction.

- (4)

- Adiabatic conditions were applied to rising and downward pipes since the heat loss from the surfaces wrapped with insulating material can be neglected. The adiabatic boundary assumption on the rising and downward pipelines is commonly applied when external surfaces are insulated. It is practical when heat losses are relatively small compared with the total heat flow inside the system. In the present experimental setup, the rising and return pipes were wrapped with insulation material, and thermal imaging confirmed negligible surface heat loss. Therefore, this assumption is considered appropriate and does not introduce significant error into the numerical model.

In summary, these assumptions collectively enhance numerical stability and computational efficiency while preserving the major thermal–fluid mechanisms of the SGHP. However, they also constrain the model’s ability to reproduce fine-scale physical details and local heat transfer behavior. Consequently, the simulation results should be interpreted as indicative of overall performance trends and underlying mechanisms rather than as exact quantitative predictions.

3.1.4. Simulation Setup

The realizable k-ε turbulence model and the volume of fluid multiphase model were used in this work. This paper adopts the PISO pressure–velocity coupling algorithm and uses the cell-based Green–Gauss gradient algorithm and the second-order upwind discretization scheme for the momentum and energy equations. In addition, the initial temperature was set to 30 °C, and the time step was 0.0005 s. The evaporation and condensation phase change factors were set to 0.1 and 6000, respectively. The roughness thickness was set to 0 mm, and the roughness parameter was set to the default value of 0.5. When setting the boundary conditions, since the pressure inside the heat pipe remained at approximately 7 atm, to avoid the pressure variation being too small compared to 7 atm and being neglected, the ambient temperature was adjusted to 30 °C, and the operating pressure was set to the saturation pressure of R134a at the ambient temperature, which was 771.02 kPa.

3.2. Numerical Results and Discussions

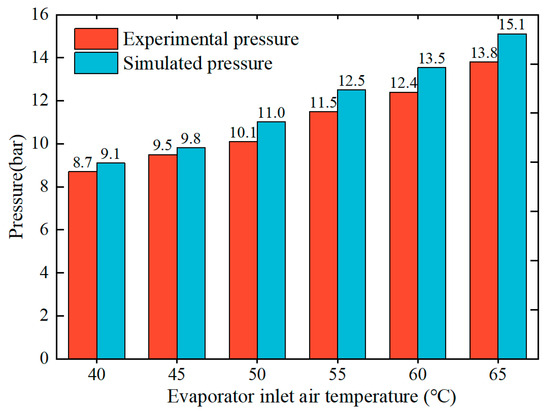

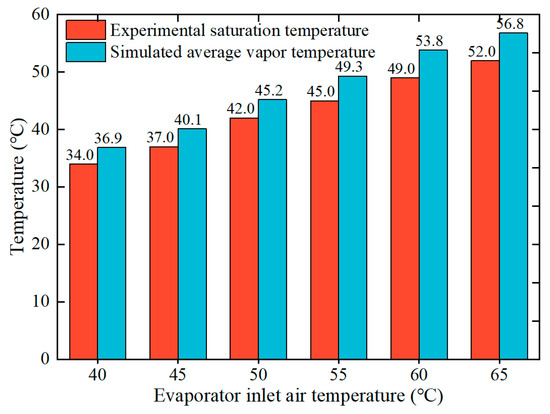

To validate the CFD simulation model of the SGHP, the simulated results have been compared to the corresponding experimental data carried out in the present work. The filling ratio was 43% for both simulations and experiments. The evaporator inlet air temperature ranged from 40 to 65 °C, while the condenser inlet temperature remained unchanged at 30 °C. Figure 5 displays experimental and simulated pressure varying with the evaporator inlet air temperature. The difference in simulated and experimental pressure values was less than 9.4%. Figure 6 shows the experimental and simulated saturation temperature varying with the evaporator inlet air temperature. By using experimental pressure data and referring to the saturation pressure–temperature relationship table for the refrigerant R134a, the measured pressure data could be mapped to the theoretical saturation temperature (i.e., the phase-change point temperature). This allowed the determination of the saturation temperature. The difference in experimental saturation temperature and simulated average vapor phase temperature was within 9.8%. The acceptable errors between simulated and experimental results could be the model simplifications mentioned above. Therefore, this comparison outcome allowed us to obtain the quantitative validation of the CFD simulation model of the SGHP developed in this work as satisfactory.

Figure 5.

Comparison between experimental and simulated pressure.

Figure 6.

Comparison between experimental and simulated temperature.

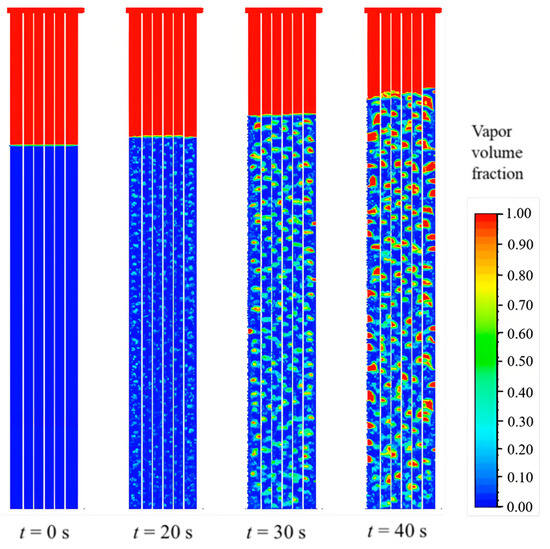

In this section, the gas–liquid two-phase flow characteristics and heat transfer performance of the SGHP have been studied with a constant filling ratio of 43%, a constant air inlet temperature at the hot end of 40 °C, and a constant air inlet temperature at the cold end of 30 °C. Figure 7 displays the transient gas–liquid two-phase distribution feature in the evaporator section from the initial state to the steady state. No phase change process occurs within the evaporator at 0 s, and the gas–liquid interface remains stable. From 0 s to 20 s, the evaporator is gradually heated to a state close to phase change. Fine bubbles occur inside the liquid phase and then flow into the gas phase at 20 s. As the evaporator is heated for 30 s, more bubbles form and become larger in size, indicating a more intense phase change process. It can be observed from Figure 7 that the heat pipe gradually reaches a stable state during the period from 30 s to 40 s. At the stable state of 40 s, larger bubbles form inside the evaporator, which shows that the SGHP has initiated the working cycle. However, the formed bubbles are not large in size within the evaporator, which indicates that the internal phase change process in the evaporator is not very intense under the present condition.

Figure 7.

Transient gas–liquid two-phase distribution in evaporator.

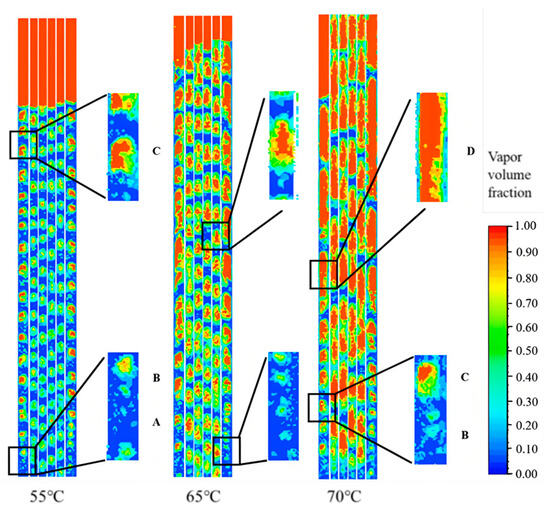

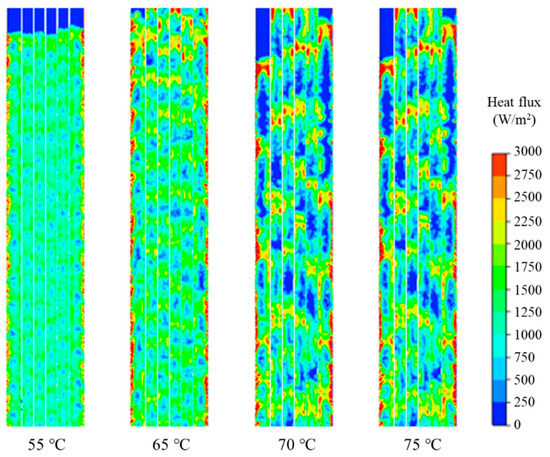

Figure 8 displays the flow regime of the R134a in the evaporator at steady-state conditions with different hot-end air inlet temperatures. The flow patterns are represented by the following letters: A for the bubble initiation point, B for the bubble growth point, C for slug flow, and D for annular flow. As shown in Figure 8, with a hot-end air inlet temperature of 55 °C, the slug flow begins to appear inside the evaporator. As the hot-end inlet temperature increases from 55 °C to 65 °C, the bubbles gradually grow and expand, which indicates that the internal flow transitions into the annular flow state. As the hot-end inlet temperature further increases to 70 °C, the annular flow transforms into intermittent annular flow, and bubble formation becomes more intense, corresponding to a highly intense phase change heat transfer process.

Figure 8.

Flow regime in the evaporator with different hot-end inlet temperatures.

As shown in Figure 8, bubbles form uniformly within the heat pipe with the hot-end inlet temperature from 55 to 65 °C. These bubbles detach and ascend faster than their nucleation rate, maintaining a homogeneous distribution. The ascending bubbles induce liquid-phase turbulence along the wall surface, enhancing heat transfer through intensified interfacial mixing. As the air inlet temperature increases, both bubble size and ascent velocity progressively rise, amplifying wall surface agitation and consequently improving heat flux density, as shown in Figure 9. However, as the hot-end air inlet temperature increases to 70 °C, the bubble nucleation rate accelerates beyond its ascent rate. New bubbles merge with retained bubbles, forming larger clusters that displace liquid R134a and create vapor cavities. These cavities reduce local heat transfer efficiency while impeding refrigerant circulation. The resultant decline in mass flow rate and heat flux density ultimately diminishes thermal performance. Furthermore, with the hot-end air inlet temperature of 75 °C, the intensified vaporization expands vapor cavities and reduces liquid phase content below 10%. This condition causes liquid entrainment into the rising pipe while depleting condensate in both the condenser and downward pipe sections. Consequently, only the evaporator base maintains effective two-phase heat transfer, with dry-out zones dominating most surfaces. The combined effects of reduced heat transfer efficiency and elevated internal pressure (exceeding design thresholds) ultimately compromise system reliability and operational lifespan.

Figure 9.

Heat flux density distribution under different hot-end inlet temperatures.

4. Experimental Investigations on an SGHP

4.1. Experimental Setup

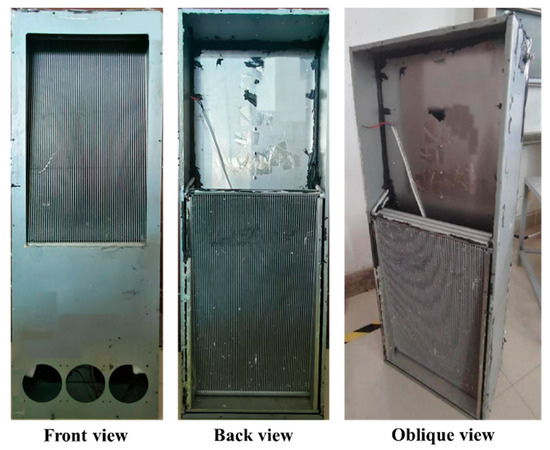

In this work, a three-stage SGHP was designed and manufactured based on the cooling demand of air compressor rooms in power plants, as shown in Figure 10. In the experimental investigations, the effects of the filling ratio combinations of refrigerant R134a and the temperature difference between hot and cold ends on the heat transfer performance have been studied.

Figure 10.

Three-stage SGHP used for the experimental test.

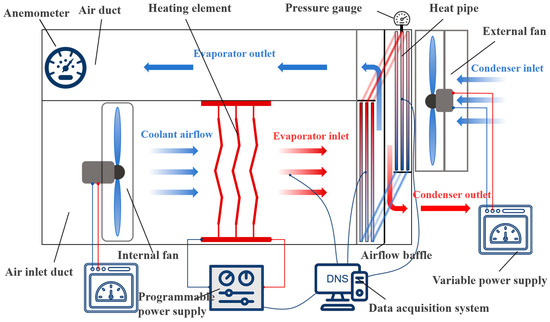

Figure 11 displays the schematic layout of the three-stage SGHP experimental platform. The test platform included four core parts: SGHP device, air duct system, thermal-power regulation device, and data acquisition system. The vertical three-stage SGHP maintained a specified height difference between the lower evaporator and upper condenser. Both the evaporator and condenser were perpendicular to the airflow. A transverse wind tunnel provides controlled vertical airflow via axial fans, with optimized duct geometry minimizing flow disturbances. To precisely control the evaporator inlet temperature, the electrical heating elements were installed between the internal fan and the evaporator. Also, a thermocouple-regulated feedback loop was set to adjust the heating power.

Figure 11.

Schematic layout of the three-stage SGHP experimental platform.

In the experimental platform, the custom air duct system was fabricated from cut and bent aluminum plates, with joints secured by bolts and nuts. Heating elements were installed on the evaporator inlet duct wall, which employed ceramic insulators for electrical isolation. Access ports on the duct sidewalls accommodated thermocouples and anemometers. High-performance insulation material enveloped the entire assembly, particularly the rising and downward pipes, to minimize thermal losses. In addition, an adjustable inline fan delivered air through 6 kW heating elements to achieve preset temperatures, while fans in the cold end supplied cooling airflow to dissipate heat from condensing R134a. A temperature control unit regulated heating power through closed-loop feedback from inlet air monitoring sensors, ensuring precise thermal input compliance. Specifically, the air temperature at the inlet and outlet of the condenser section was measured using calibrated K-type thermocouples, while the air velocity was measured using a hot-wire anemometer at multiple cross-sectional points to obtain an average value. The air-side temperature and velocity data were continuously recorded using a multi-channel data acquisition system.

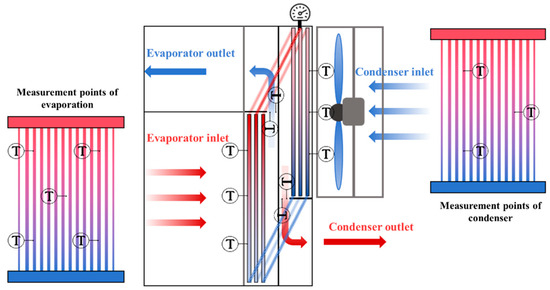

The data acquisition system comprised a series of thermocouples for temperature measurement and pressure gauges installed within the SGHP. Three pressure gauges were installed at the inlet header of the three-stage condenser section in the SGHP. These gauges were employed to measure the pressure of the rising pipe within the three-stage circuit. Subsequently, this pressure data was used to deduce the evaporation and condensation temperatures of the working fluid inside the heat pipe. The thermocouple arrangement positions in the three-stage SGHP were illustrated in Figure 12. A series of thermocouples was positioned at the inlet and outlet of the evaporator and condenser. This arrangement facilitates the acquisition of temperature data for both the hot and cold fluids entering and exiting the SGHP during normal operation.

Figure 12.

Schematic of thermocouple arrangement positions in the three-stage SGHP.

4.2. Performance Evaluation Index of the SGHP

In this work, the filling ratio (FR) of the SGHP is defined as the ratio of the volume of the filled working fluid to the total internal volume of the heat pipe, as displayed in Equation (1). The temperature difference between hot and cold ends (Δt) is calculated by Equation (2).

where Vwf is the volume of the filled working fluid, Vtot is the total internal volume of the SGHP, is the hot air temperature at the evaporator inlet, and is the cold air temperature at the condenser inlet.

The heat transfer capacity and heat recovery efficiency are used to evaluate the performance of the three-stage SGHP. The heat transfer capacity of the evaporator and condenser is calculated by Equations (3) and (4). The heat recovery efficiency is another critical performance evaluation index for the SGHP. This parameter is defined as the ratio of actual heat transfer capacity to the theoretically maximum one, which determines the performance of the heat transfer process where hot fluids transfer heat to cold fluids through the heat pipe. It can be calculated by Equation (5) if the volumetric flow rate at the hot end is equal to that at the cold end.

where Qevap and Qcond are the heat transfer capacities of evaporator and condenser ends, respectively, ca,p is the specific heat at constant pressure of air, and are the air densities at the evaporator and condenser ends, respectively, and are the air capacities at the evaporator and condenser ends, respectively, and are the inlet and outlet air temperature values at the evaporator end, respectively, and are the inlet and outlet air temperature values at the condenser end, respectively, is heat recovery efficiency.

4.3. Uncertainty and Error Analysis

Due to the inherent uncertainties in experimental conditions and measurement procedures, the obtained results may contain minor errors. To evaluate the reliability and accuracy of the measurements, an uncertainty analysis was conducted. The K-type thermocouples used for temperature measurement have an accuracy of ±0.1 °C, and the air velocity was measured by a hot-wire anemometer with an accuracy of ±2% (approximately ±0.1 m/s within the experimental range).

The combined uncertainty of the heat transfer rate, , was calculated using the root-sum-square method, as expressed in Equation (6):

where represents the uncertainty of the calculated heat transfer rate, denotes the uncertainty in temperature measurement, and represents the uncertainty in air velocity measurement. The terms and are the sensitivity coefficients of with respect to temperature and velocity, respectively. By substituting the measured parameters and instrument accuracies into Equation (6), the relative uncertainty of the heat transfer rate was determined to be 5.3%. This level of uncertainty is within the acceptable range (≤6%) for convective heat transfer experiments, confirming that the experimental data are reliable and the results are credible.

4.4. Experimental Results and Discussions

4.4.1. Effects of Temperature Difference Between Hot and Cold Ends on SGHP Performance

In this section, the effects of the temperature difference between hot and cold ends on the SGHP performance were experimentally studied with a constant filling ratio of 30% across all three stages. The temperature difference ranged from 30 °C to 65 °C in 5 °C increments in the present experiments, which can be controlled by adjusting heating elements.

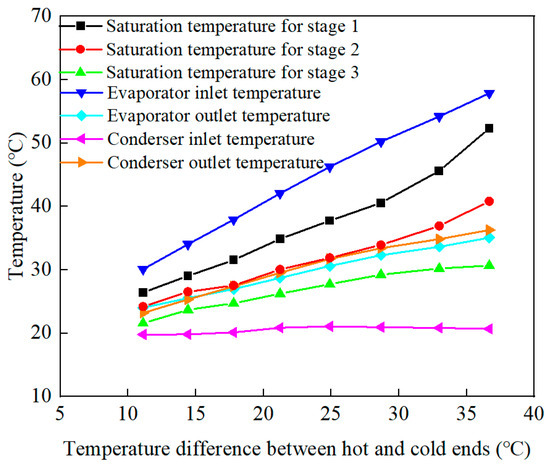

Figure 13 displays the inlet/outlet air temperature of the evaporator and condenser and the saturation temperature at each stage with different temperature differences between hot and cold ends. The saturation temperature was calculated by correlating the pressure values in the rising pipe with R134a thermophysical property tables and the phase-change equations. Since each measured pressure data point was the data when the SGHP reached stability under this working condition, it can be determined that the interior of the heat pipe was in a saturated state where evaporation and condensation coexist at this pressure. Therefore, this saturation temperature can roughly represent the working temperature inside the heat pipe. As shown in Figure 13, the saturation temperature steadily increases with the temperature difference between the hot and cold ends across all three stages. All values remained bounded between the hot-end inlet temperature and cold-end inlet temperature, which indicates that all three stages of the SGHP are in a normal start-up state. In addition, in the first stage of the SGHP, the saturation temperature of the rising pipe begins to increase at a faster rate when the temperature difference between the hot and cold ends is higher than 30 °C, and the temperature value gradually approaches the hot end temperature. This could be the reason that at high temperatures between hot and cold end conditions, most of the R134a working fluid has transformed into a gaseous state. The proportion of the liquid phase of the working fluid is too low, resulting in a decline in the heat transfer performance of the first-stage heat pipe. At this point, the first-stage heat pipe has reached its limit. At the same time, the saturation temperature corresponding to the second-stage heat pipe also shows a rapid increase as the temperature difference between the hot and cold ends exceeds 30 °C, and the heat transfer performance of the second-stage SGHP gradually improves. While for the third stage, the saturation temperature slightly increases with the temperature difference between the hot and cold ends.

Figure 13.

Inlet/outlet air temperature of evaporator and condenser, and saturation temperature at each stage with different temperature differences between hot and cold ends.

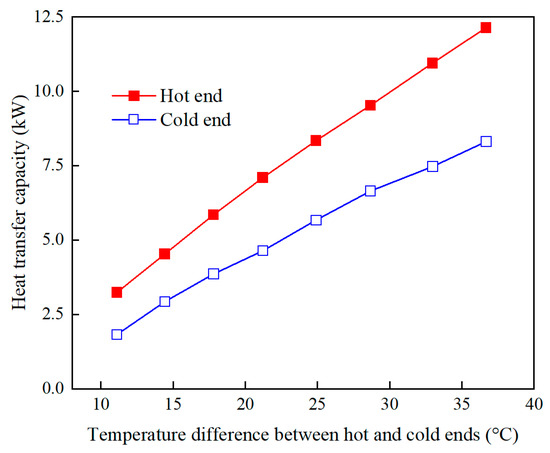

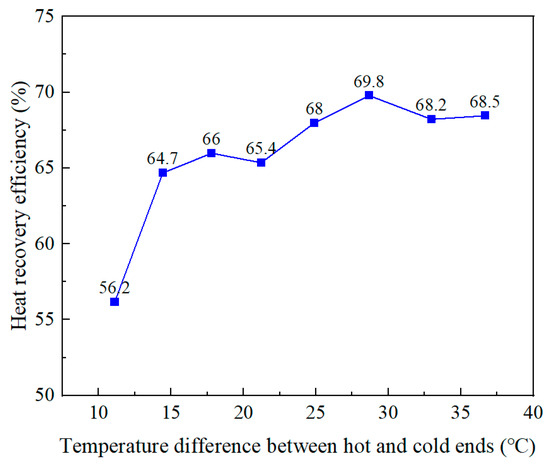

The heat transfer capacity and heat recovery efficiency were used to evaluate the performance of the three-stage SGHP, which were obtained by Equations (3) and (4). Figure 14 displays the heat transfer capacity with different temperature differences between hot and cold ends. Both the heat transfer capacities of the hot end and the cold end almost linearly increase with the temperature difference between the hot and cold ends. And the former is greater than the latter, which is attributed to the heat losses. As shown in Figure 15, the heat recovery efficiency sharply increases from 56.2% to 64.7% with the temperature difference from 9.6 °C to 14.4 °C. This efficiency then increases overall in a fluctuating manner with the temperature difference from 14.4 °C to 36.4 °C, with the value ranging between 64% and 70%. It might be because with a low temperature difference between the hot and cold ends (less than 15 °C), the heat pipes of the last two stages mainly transfer heat by sensible heat, which keeps the heat recovery efficiency at a relatively low level. As the temperature difference between the hot and cold ends increases beyond 15 °C, all three stages operate normally, leading to an increase in the heat recovery efficiency. With a further increase in the temperature difference between the hot and cold ends, the heat recovery efficiency reaches its limit and stabilizes gradually.

Figure 14.

Heat transfer capacity with different temperature differences between the hot and cold ends.

Figure 15.

Heat recovery efficiency with different temperature differences between the hot and cold ends.

4.4.2. Effects of Filling Ratio Combinations on SGHP Performance

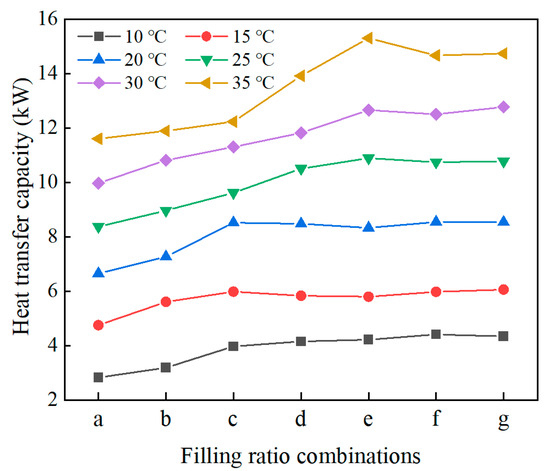

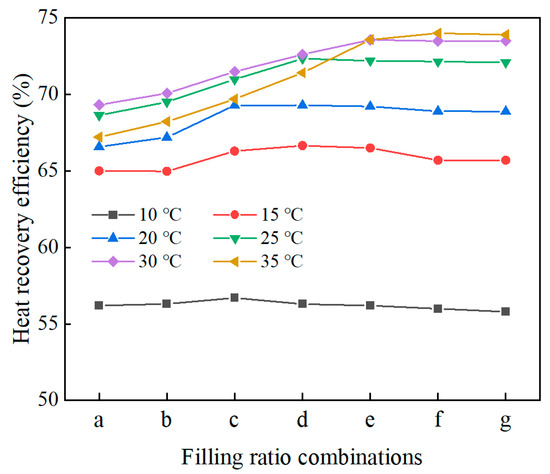

The filling ratio configuration significantly impacts the working performance of the three-stage SGHP. This experimental investigation employed R134a refrigerant to evaluate the hot-end heat transfer capacity and heat recovery efficiency under varying filling ratio combinations. As all three stages of the SGHP operated simultaneously, the temperature difference between the hot and cold ends of the first stage was the greatest, while that of the third stage was the smallest. Based on the simulation results, it can be concluded that a higher filling ratio had a more significant advantage for larger temperature difference conditions. Therefore, the first stage should prioritize a larger filling ratio. According to Ref. [22], the optimal filling ratio ranged from 30% to 50% for SGHPs. Numerical simulations identified stage-specific optimal ratios of 43% (first stage), 37% (second stage), and 30% (third stage) under standard operating conditions, which helped to set filling ratio values in the experiments. A higher filling ratio in the first stage (highest heat load) helps to prevent dry-out, and the lower ratio in the last stage helps to avoid liquid flooding. Detailed filling ratio combinations across three stages in the experimental test are denoted by Group (a) to Group (g): (a) 30%/30%/30%, (b) 37%/30%/30%, (c) 37%/37%/30%, (d) 37%/37%/37%, (e) 43%/37%/37%, (f) 43%/43%/37%, and (g) 43%/43%/43%. The cold-end inlet temperature was equal to room temperature, and the temperature differences between the hot and cold ends were set to be from 10 °C to 35 °C.

Figure 16 shows the hot-end heat transfer capacity with different filling ratio combinations under different temperature differences between the hot and cold ends. For a low temperature difference between the hot and cold ends (from 10 to 20 °C), the heat transfer capacity of the hot end increases as the filling ratio combination changes from Group (a) to Group (c), and then it almost remains unchanged as the filling ratio combination changes from Group (c) to Group (g). However, when the temperature difference between the hot end and cold end increases to higher values (from 25 to 35 °C), the heat transfer capacity at the hot end steadily increases as the filling ratio combination changes from Group (a) to Group (e). After that, a further increase in the filling ratio has little effect on the heat transfer capacity with the temperature difference between the hot and cold ends of 25 °C and 30 °C. While with the temperature difference of 35 °C, a further increase in the filling ratio even leads to a lower hot-end heat transfer capacity. And at this point, the heat transfer capacity reaches its peak value of approximately 15.3 kW with the filling ratio combination of Group (e), which is 43%/37%/37%. Ding et al. [35] has demonstrated that the filling ratio significantly influences the heat transfer capacity of SHPs. When the filling ratio is too low, there is insufficient liquid to cover the entire heat transfer surface in the evaporator, causing localized dry-out and a sharp decline in heat transfer efficiency, which severely restricts the system’s overall thermal performance. Conversely, an excessively high filling ratio leads to the accumulation of excess liquid in the lower part of the condenser, occupying space that should be reserved for vapor condensation. This diminishes the condenser’s effectiveness and similarly results in a degradation of the system’s total heat transfer capability. Due to different working conditions for different stages, the optimal filling ratios are different for each stage. As a result, the optimal filling ratio combination is 37%/37%/30% for low temperature difference between hot and cold ends (from 10 to 20 °C) and 43%/37%/37% for high temperature difference between hot and cold ends (from 25 to 35 °C).

Figure 16.

Variation in hot-end heat transfer capacity with different filling ratio combinations under different temperature differences between the hot and cold ends.

The heat recovery efficiency is another representative index to evaluate the SGHP performance. Figure 17 illustrates the variation in the heat recovery efficiency with different filling ratio combinations under different temperature differences between hot and cold ends. For low temperature differences between the hot and cold ends (from 10 to 25 °C), the heat recovery efficiency increases with the filling ratio combination from Group (a) to Group (c) and then slightly decreases from Group (c) to Group (g) due to the uneven temperature distribution inside the heat pipe, reaching its peak at the filling ratio combination of Group (c), which is 37%/37%/30%. At high filling ratios, the liquid occupies a larger portion of the condenser and adiabatic sections, leading to increased hydraulic resistance during condensate return. The excessive liquid inventory restricts the vapor passage and reduces the effective vapor flow area, resulting in partial vapor entrapment and local flow blockage in the rising pipe. Consequently, the vapor–liquid circulation becomes unstable, and the working fluid distribution along the flow path becomes uneven. The accumulation of liquid also thickens the condensate film and weakens the interfacial momentum exchange, further reducing phase-change efficiency and overall heat transfer performance. While for high temperature differences between the hot and cold ends (from 30 °C to 35 °C), the optimal filling ratio combination is Group (e), which is 43%/37%/37%. It should be noted that the heat recovery efficiency decreases as the temperature difference between the hot and cold ends increases from 30 °C to 35 °C for low filling ratio combinations from Group (a) to Group (e). This is because the temperature distribution within the SGHP becomes uneven under a high temperature difference between the hot and cold ends. While under a high temperature difference (35 °C), the heat recovery efficiency of Groups (f) and (g) surpassed that of Group (e), indicating a performance reversal induced by increased temperature difference. This result was not only related to the increase in filling ratio at the second stage but also closely linked to the overall phase-change behavior and thermal coupling characteristics of the system under high-temperature difference conditions.

Figure 17.

Variation in heat transfer efficiency with different filling ratio combinations under different temperature differences between the hot and cold ends.

From the above results, with a relatively low temperature difference between the hot and cold ends (10~20 °C), the optimal filling ratio combination for the three-stage SGHP is 37%/37%/30%; while for a relatively high temperature difference between the hot and cold ends (25~35 °C), the optimal filling ratio combination is 43%/37%/37%.

5. Conclusions

This work has proposed a novel independent multi-stage Separated Gravity Heat Pipe (SGHP) for the cooling demand of air compressor rooms in power plants. The internal flow characteristics of the SGHP have been numerically studied, and the heat transfer performance of a three-stage SGHP has been experimentally investigated. The numerical results show that the slug flow initiates at a temperature difference between the hot and cold ends of 25 °C with a filling ratio of 43%. Annular flow with uniform liquid film develops as the temperature difference increases, leading to the enhancement of heat transfer. However, an excessively high temperature difference (>30 °C) results in intermittent flow due to the vapor accumulation, which increases gas-wall contact and reduces heat transfer efficiency. According to experimental results, the overall heat recovery efficiency generally fluctuates and increases with the temperature difference between hot and cold ends, reaching its peak at a temperature difference of 30 °C. In addition, the filling ratio combination of 37%/37%/30% helps to achieve better heat transfer performance of the three-stage SGHP at low temperature difference conditions, while the filling ratio combinations of 43%/37%/37% excel at high temperature difference conditions. The decoupled design of the proposed SGHP, which allows for independent parameter control, presents a significant advancement over conventional interdependent systems. Future work will focus on exploring alternative working fluids, conducting long-term reliability tests, and implementing a full-scale prototype in a real-world power plant setting to further validate its industrial application potential.

Author Contributions

Conceptualization, Y.Z.; Formal analysis, J.Z., D.S., F.Y., Z.L., G.L., R.K., W.J. and H.W.; Funding acquisition, Y.Z. and F.Y.; Investigation, J.Z., D.S., F.Y., Z.L., G.L., R.K., W.J. and H.W.; Methodology, J.Z. and D.S.; Project administration, Y.Z.; Writing—original draft, J.Z. and D.S.; Writing—review and editing, Z.L., Y.Z. and F.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (No. 52166009, No. 52206088, No. 12372246), Jiangxi Provincial Natural Science Foundation (No. 20232BAB204057, No. 20242BAB26072, No. 20242BAB20213, No. 20252BAC240054), and Jiangxi Province Key Laboratory of Light Alloy (No. 2024SSY05031).

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

Author Zhihua Li was employed by the CHN Energy Jiangxi Power Co., Ltd. Authors Juan Zi and Deji Sun were employed by the CHN Energy Shenhua Jiujiang Power Generation Co., Ltd. Author Guanglie Liu was employed by the CHN Energy Fengcheng Power Generation Co., Ltd. Authors Renqin Kuang, Weiguo Jiang and Hualiang Wu were employed by the Jiangxi Ganneng Fengcheng Power Generation Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Hota, S.K.; Lee, K.-L.; Leitherer, B.; Elias, G.; Hoeschele, G.; Rokkam, S. Pulsating heat pipe and embedded heat pipe heat spreaders for modular electronics cooling. Case Stud. Therm. Eng. 2023, 49, 103256. [Google Scholar] [CrossRef]

- Zhao, J.; Han, J.; Zhou, C.; Cheng, X.; Jian, Q.; Chen, C. Design and experimental study of a novel vapor chamber for proton exchange membrane fuel cell cooling. Int. J. Heat Mass Transf. 2024, 220, 124949. [Google Scholar] [CrossRef]

- Huang, Z.; Jian, Q.; Zhao, J. Thermal management of open-cathode proton exchange membrane fuel cell stack with thin vapor chambers. J. Power Sources 2021, 485, 229314. [Google Scholar] [CrossRef]

- Zhao, X.; Su, L.; Jiang, J.; Deng, W.; Zhao, D. A review of working fluids and flow state effects on thermal performance of micro-channel oscillating heat pipe for aerospace heat dissipation. Aerospace 2023, 10, 179. [Google Scholar] [CrossRef]

- Wang, W.-W.; Song, Y.-J.; Li, B.; Liu, D.; Zhao, F.-Y.; Cai, Y. A novel flat heat pipe for anti-gravity orientations: Leaf fractal evaporator and bi-directional transport capillary channel. Appl. Therm. Eng. 2023, 232, 120954. [Google Scholar] [CrossRef]

- Cai, B.; Deng, W.; Wu, T.; Wang, T.; Ma, Z.; Liu, W.; Ma, L.; Liu, Z. Experimental Study of a Loop Heat Pipe with Direct Pouring Porous Wick for Cooling Electronics. Processes 2021, 9, 1332. [Google Scholar] [CrossRef]

- Jouhara, H.; Nieto, N.; Egilegor, B.; Zuazua, J.; González, E.; Yebra, I.; Igesias, A.; Delpech, B.; Almahmoud, S.; Brough, D.; et al. Waste heat recovery solution based on a heat pipe heat exchanger for the aluminium die casting industry. Energy 2023, 266, 126459. [Google Scholar] [CrossRef]

- Delpech, B.; Milani, M.; Montorsi, L.; Boscardin, D.; Chauhan, A.; Almahmoud, S.; Axcell, B.; Jouhara, H. Energy efficiency enhancement and waste heat recovery in industrial processes by means of the heat pipe technology: Case of the ceramic industry. Energy 2018, 158, 656–665. [Google Scholar] [CrossRef]

- Jouhara, H.; Bertrand, D.; Axcell, B.; Montorsi, L.; Venturelli, M.; Almahmoud, S.; Milani, M.; Ahmad, L.; Chauhan, A. Investigation on a full-scale heat pipe heat exchanger in the ceramics industry for waste heat recovery. Energy 2021, 223, 120037. [Google Scholar] [CrossRef]

- Jouhara, H.; Almahmoud, S.; Chauhan, A.; Delpech, B.; Bianchi, G.; Tassou, S.A.; Llera, R.; Lago, F.; Arribas, J.J. Experimental and theoretical investigation of a flat heat pipe heat exchanger for waste heat recovery in the steel industry. Energy 2017, 141, 1928–1939. [Google Scholar] [CrossRef]

- Ma, H.; Du, N.; Zhang, Z.; Lyu, F.; Deng, N.; Li, C.; Yu, S. Assessment of the optimum operation conditions on a heat pipe heat exchanger for waste heat recovery in steel industry. Renew. Sustain. Energy Rev. 2017, 79, 50–60. [Google Scholar] [CrossRef]

- Abd El-Baky, M.A.; Mohamed, M.M. Heat pipe heat exchanger for heat recovery in air conditioning. Appl. Therm. Eng. 2007, 27, 795–801. [Google Scholar] [CrossRef]

- Abdelaziz, G.B.; Abdelbaky, M.A.; Halim, M.A.; Omara, M.E.; Elkhaldy, I.A.; Abdullah, A.S.; Omara, Z.M.; Essa, F.A.; Ali, A.; Sharshir, S.W.; et al. Energy saving via Heat Pipe Heat Exchanger in air conditioning applications “experimental study and economic analysis”. J. Build. Eng. 2021, 35, 102053. [Google Scholar] [CrossRef]

- Yang, F.; Yuan, X.; Lin, G. Waste heat recovery using heat pipe heat exchanger for heating automobile using exhaust gas. Appl. Therm. Eng. 2003, 23, 367–372. [Google Scholar] [CrossRef]

- Wang, S.; Rong, B.; Ma, S.; Ma, D.; Wu, L.; Ma, H.; Ma, Y.; Wang, R.; Hu, H. Investigation of the cooling and purification effect of automobile exhaust using heat pipe heat exchanger. Appl. Therm. Eng. 2024, 236, 121675. [Google Scholar] [CrossRef]

- Ling, L.; Zhang, Q.; Yu, Y.; Liao, S.; Sha, Z. Experimental study on the thermal characteristics of micro channel separate heat pipe respect to different filling ratio. Appl. Therm. Eng. 2016, 102, 375–382. [Google Scholar] [CrossRef]

- Srimuang, W.; Amatachaya, P. A review of the applications of heat pipe heat exchangers for heat recovery. Renew. Sustain. Energy Rev. 2012, 16, 4303–4315. [Google Scholar] [CrossRef]

- Zhang, B.; Fang, S.; Zhang, S.; Zhang, R.; Zang, Y. Experimental Study on the Influence of Wind Speed on the Start-Up Characteristics and Thermoelectric Generation Characteristics of Gravity Heat Pipe in Gangue Dump. Processes 2023, 11, 2429. [Google Scholar] [CrossRef]

- Blet, N.; Lips, S.; Sartre, V. Heats pipes for temperature homogenization: A literature review. Appl. Therm. Eng. 2017, 118, 490–509. [Google Scholar] [CrossRef]

- Ling, L.; Xia, Y.; Zhao, L.; Hu, Q.; Zhang, Z.; Xiang, Z.; Song, D. Experimental investigation on the thermal performance of a novel loop heat pipe (LHP) with micro-channel structure. Appl. Therm. Eng. 2024, 238, 122046. [Google Scholar] [CrossRef]

- Liu, S.; Ma, G.; Li, X.; Xu, S. Experimental investigation and application potential analysis of vapor compression refrigeration integrated mechanically-driven loop heat pipe for data centers cooling. Appl. Therm. Eng. 2025, 259, 124958. [Google Scholar] [CrossRef]

- Ding, T.; He, Z.G.; Hao, T.; Li, Z. Application of separated heat pipe system in data center cooling. Appl. Therm. Eng. 2016, 109, 207–216. [Google Scholar] [CrossRef]

- Kuang, Y.; Wang, W. Modeling and numerical investigation on the effects of filling ratio in a large separate heat pipe loop. Int. J. Energy Res. 2021, 46, 415–432. [Google Scholar] [CrossRef]

- Xia, G.; Zhuang, D.; Ding, G.; Lu, J. A quasi-three-dimensional distributed parameter model of micro-channel separated heat pipe applied for cooling telecommunication cabinets. Appl. Energy 2020, 276, 115544. [Google Scholar] [CrossRef]

- Wu, Y.; Cheng, J.; Zhu, H.; Xue, H.; Lu, Q.; Li, Y.; Li, W.; Tao, H. Experimental study on heat transfer characteristics of separated heat pipe with compact structure for spent fuel pool. Ann. Nucl. Energy 2023, 181, 109580. [Google Scholar] [CrossRef]

- Kang, Z.; Shou, D.; Fan, J. Numerical study of a novel Single-loop pulsating heat pipe with separating walls within the flow channel. Appl. Therm. Eng. 2021, 196, 117246. [Google Scholar] [CrossRef]

- Xiong, K.; Huang, Y.; Wang, S. Experimental research on the thermal performance of a flat evaporator loop heat pipe with a new composite wick. Appl. Therm. Eng. 2024, 246, 122927. [Google Scholar] [CrossRef]

- Yue, C.; Zhang, Q.; Zhai, Z.; Ling, L. CFD simulation on the heat transfer and flow characteristics of a microchannel separate heat pipe under different filling ratios. Appl. Therm. Eng. 2018, 139, 25–34. [Google Scholar] [CrossRef]

- Yue, C.; Zhang, Q.; Zhai, Z.; Ling, L. Numerical investigation on thermal characteristics and flow distribution of a parallel micro-channel separate heat pipe in data center. Int. J. Refrig. 2019, 98, 150–160. [Google Scholar] [CrossRef]

- Zhang, H.; Shi, Z.; Liu, K.; Shao, S.; Jin, T.; Tian, C. Experimental and numerical investigation on a CO2 loop thermosyphon for free cooling of data centers. Appl. Therm. Eng. 2017, 111, 1083–1090. [Google Scholar] [CrossRef]

- Tong, Z.; Liu, X.-H.; Jiang, Y. Experimental study of the self-regulating performance of an R744 two-phase thermosyphon loop. Appl. Energy 2017, 186, 1–12. [Google Scholar] [CrossRef]

- Xia, G.; Zhuang, D.; Ding, G.; Lu, J.; Han, W.; Qi, H. A distributed parameter model for multi-row separated heat pipe with micro-channel heat exchangers. Appl. Therm. Eng. 2021, 182, 116113. [Google Scholar] [CrossRef]

- Wu, T.; Wang, T.; Ma, Z.; Zhang, Z.; Liu, W.; Liu, Z. Experimental investigation on the start-up performance of a loop heat pipe with three flat disk evaporators combined. Appl. Therm. Eng. 2022, 216, 119128. [Google Scholar] [CrossRef]

- Wang, L.; Quan, Z.; Zhao, Y.; Yang, M.; Jing, H. Heat transfer process analysis and performance research of micro heat pipe array applied for the thermal management of proton exchange membrane fuel cells. Appl. Therm. Eng. 2023, 219, 119531. [Google Scholar] [CrossRef]

- Ding, T.; Cao, H.; He, Z.; Li, Z. Experiment research on influence factors of the separated heat pipe system, especially the filling ratio and Freon types. Appl. Therm. Eng. 2017, 118, 357–364. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).