1. Introduction

As a part of the commodity itself, the packaging bag can not only avoid the damage of the commodity in the transportation process, but also directly affect the purchase behavior of consumers. It is a necessary condition for the commodity to enter the circulation field, and the packaging equipment is the main means to realize the commodity packaging [

1]. Although the automatic packaging machine for prefabricated bags has made great progress, there are still some problems, such as low packaging accuracy, low packaging speed, and unstable heat-sealing quality [

2,

3]. As the most critical link in the packaging process, the heat-sealing process plays a decisive role in the packaging production. In the actual production and commodity transportation process, the damage of packaging bags also mostly occurs in the heat-sealing part [

4,

5]. Therefore, it is of great significance to study the heat-sealing device and heat-sealing process parameters for improving the overall quality of packaging products.

The heat-sealing quality of packaging bags mainly depends on the heat-sealing pressure, temperature, and time. When the heat-sealing time is fixed, the higher the frequency of sealing opening and closing, the higher the working efficiency, but the impact on the heat-sealing mechanism is increased, and the working life is reduced, which is the main reason restricting the improvement of the production efficiency of the packaging machine [

6]. At the same time, due to the increase in the speed of the packaging machine, the heat-sealing residence time is shortened in the packaging process. In engineering practice, the shortage of heat-sealing residence time is often offset by increasing the heat-sealing temperature and pressure. However, too high heat-sealing temperature and pressure will scald the surface of the packaging bag material, and the heat-sealing quality of the packaging bag is extremely unstable at high speed [

7]. The academic community generally believes that the heat-sealing between films is the diffusion of molecules in the molten film under the action of external pressure and temperature. After a certain time, the two heat-sealing surfaces are combined and cooled sufficiently to form a bond. The main factors affecting the heat-sealing performance of films are heat-sealing pressure, heat-sealing temperature, and heat-sealing time [

8].

In the production process of the pillow packaging machine, there is a large waste of manpower in the longitudinal sealing and heat-sealing process. The main reason is the difficulty in selecting heat-sealing parameters. Mihindukulasuriya et al. [

9] established a heat transfer model to elucidate the heat transfer of two-layer linear low-density polyethylene (LLDPE) film during the heat-sealing process, and validated the heat transfer model with experimental data on the membrane–membrane interface temperature, which can effectively predict the membrane–membrane interface temperature. Junior et al. [

10] studied the effects of high-pressure treatment on the morphology, thermal properties, and mechanical properties of flexible packaging materials from a thermodynamic perspective under different process conditions. Aiyengar et al. [

11] obtained a second-order model of heat-sealing strength using response surface methodology and replicated center composite statistical experiments by optimizing the heat-sealing strength of 18 µM thick, untreated, double-sided sealable biaxially oriented polypropylene film. Experiments have shown that residence time, temperature, and their interactions have significant effects. Yuan et al. [

12] studied the effect of bar sealing parameters on the heat-sealing strength of oriented polypropylene (OPP)/metal cast polypropylene (MCPP) laminated films. Based on the results of parametric research, a window for the rod sealing process has been established. All drop points within the process window are a combination of pressure plate temperature and dwell time, resulting in an acceptable heat-seal. The above scholars have studied the factors affecting the heat-sealing strength of thin films from different perspectives, but have not simultaneously selected multiple key parameters that affect the heat-sealing strength of thin films.

With the development of finite element simulation technology, scholars use the simulation method to establish the heat-sealing parameters of packaging film. Jang [

13] et al. studied the temperature distribution of the inner layer of the pet/al/cpp composite film by establishing the heat transfer model of the pet/al/cpp composite film and taking the heat-sealing time and the heat-sealing head width as variables, and finally determined that the heat-sealing quality of the composite film was the best when the heat-sealing time was 3S and the heat-sealing head width was 15 mm. Aghkand et al. [

14] used COMSOL (5.6) software to analyze the heat transfer behavior of each layer of pa/pe (polyamide/polyethylene) composite film during the heat-sealing process, and measured the temperature distribution at the junction of the film interface by adding thermocouples at the contact interface of the two layers of composite film, and finally determined the heat-sealing temperature range of pa/pe composite film based on the finite element analysis results. Aghkand et al. [

15] established the rheological model of pa/pe composite film in the heat-sealing process and studied the effects of heat-sealing temperature, heat-sealing time, heat-sealing pressure, and heat-sealing layer material thickness on the heat-sealing performance of multilayer polymer film by using the method of combining theory with experiment, and then optimized the heat-sealing parameters. Ilhan et al. [

16] estimated that the minimum heat-sealing time required for the heat-sealing of bopp/ldpe composite film was 0.5 s by analyzing the heat transfer behavior of bopp/ldpe composite film with different thicknesses under different heat-sealing temperatures and pressures, and verified the correctness of the estimated heat-sealing time through a heat-sealing strength test. Ponnambalam et al. [

17] studied the effects of heat-sealing residence time, heat-sealing temperature, heat-sealing pressure and the presence of pollutants on the heat-sealing performance of pet/al/pe (polyethylene terephthalate/aluminum/polyethylene) composite film, and concluded that when the heat-sealing temperature was greater than 240 °C and the heat-sealing residence time was greater than 1 s, the heat-sealing strength of the composite film would decrease. To sum up, the above research is only to optimize the heat-sealing parameters of composite film from the theoretical aspect, but there is no in-depth study on how to establish the optimal heat-sealing parameters under the given packaging speed in actual production. In this paper, combined with the heat-sealing device and process studied, under the condition that the heat-sealing time is known, the influence of different heat-sealing parameters on the heat-sealing quality of packaging film is further analyzed, and then the heat-sealing parameters in the actual production are determined.

The existing research work lacks the analysis of the actual production process, especially for the longitudinal sealing and heat-sealing process of the pillow packaging machine. Compared with the laboratory conditions, it is more difficult to apply the heat-sealing process to actual production, so many scholars have not carried out in-depth research on it. After using neural network genetic algorithm to optimize the parameters with reference to the directions of various disciplines [

18,

19], this topic proposes a parameter optimization strategy of RBF neural network (radial basis function neural network)—genetic algorithm for the automatic parameter optimization of longitudinal heat-sealing of pillow packaging machine, so as to realize the automatic optimization of longitudinal heat-sealing process parameters [

20].

In this paper, the PET/Al/PE composite film was used as the object, and the longitudinal heat-sealing processing and heat-sealing strength of the composite film were measured through different process parameters. The relationship between process parameters and heat-sealing strength was established based on a radial basis function (RBF) neural network. After comprehensively considering the fitting accuracy and the amount of calculation, minimum orthogonal multiplication (OLS) is used to realize the iterative calculation of the RBF neural network. The optimization of longitudinal seal and heat-seal process parameters is realized by a genetic algorithm. Because the data types of heat-sealing distance, heat-sealing temperature, and heat-sealing speed are different, different methods are adopted to realize the coding of process parameters. The constraint conditions and target heat-sealing strength are established according to the actual working conditions and the characteristics of the composite membrane. The selection operator, crossover operator, and mutation operator are determined according to the coding method. The objective function of the genetic algorithm is established based on the RBF neural network, and the optimal process parameters are obtained through iterative optimization.

2. Processing Technology and Algorithm Applicability Analysis

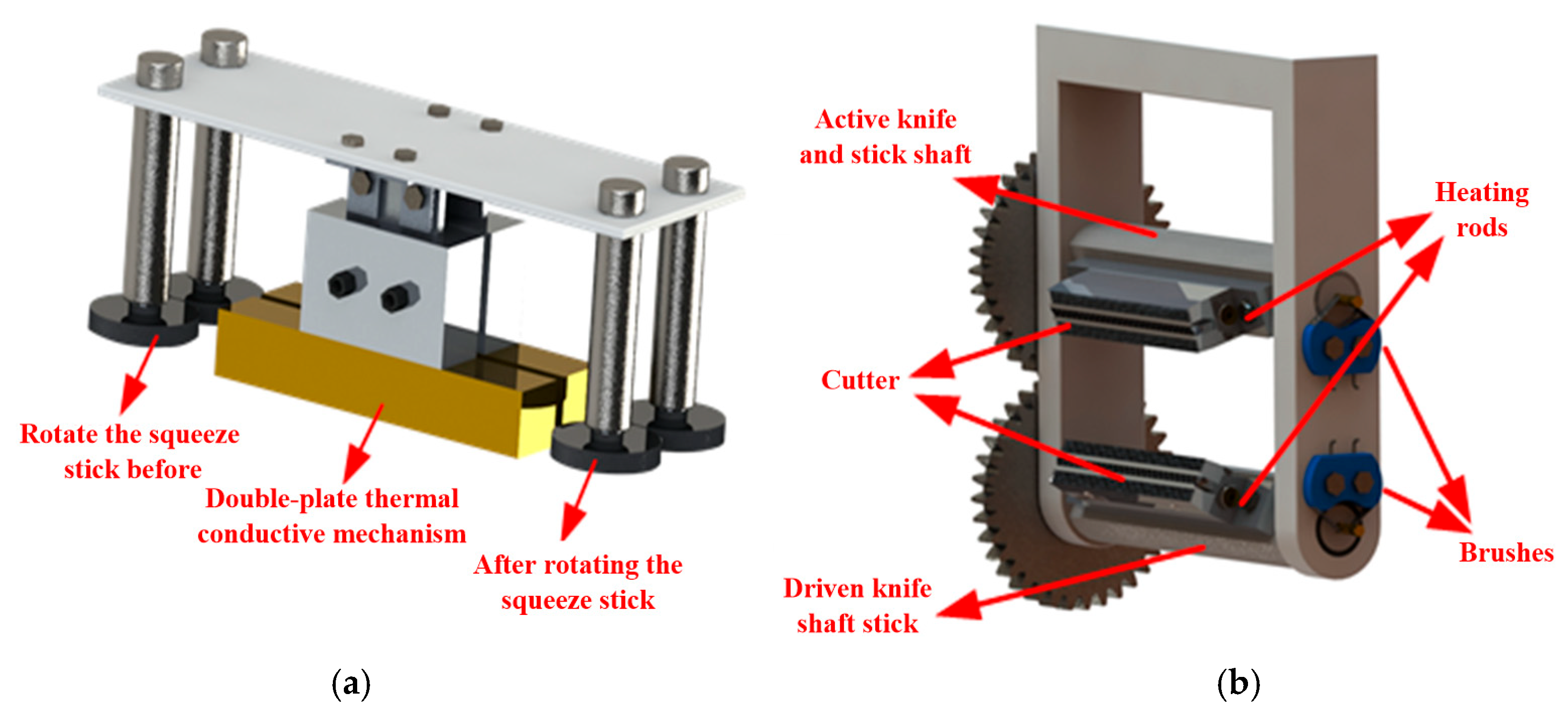

The two most important mechanisms of the pillow packaging machine are the longitudinal sealing mechanism and the transverse sealing mechanism, and both include the heat-sealing process. The longitudinal sealing mechanism adopts a double plate structure, as shown in

Figure 1a. The front rotary extrusion roll rotates to drive the composite film forward, while ensuring that the composite film is in a tensioned state. The double plate mechanism controls the temperature between the two plates by means of electric heat generation to reach the heat-sealing temperature. Driven by the front extrusion roll, the composite membrane moves forward to make the inner membrane close. At the same time, when the composite film passes through the gap between the two plates, the high temperature between the two plates makes the composite film preheat and melt. The rear rotary extrusion roller compresses and fits the preheated composite film to further achieve the heat-sealing effect. As shown in

Figure 1b, there are two cutter roller shafts in the transverse seal heat-seal wheel cutting mechanism, one of which is the driving shaft and the other is the driven shaft. The two shafts rotate synchronously. A heating rod is embedded in the cutter head, which is electrically heated by rotating the brush during rotation. When the composite film is sent into the mechanism, the high-temperature cutter head will conduct transverse heat-sealing on the composite film and cut the composite film at the same time. In the cutting process, the cutter has a forward traction force on the composite film, which helps the composite film move forward smoothly.

2.1. Process Parameter Analysis

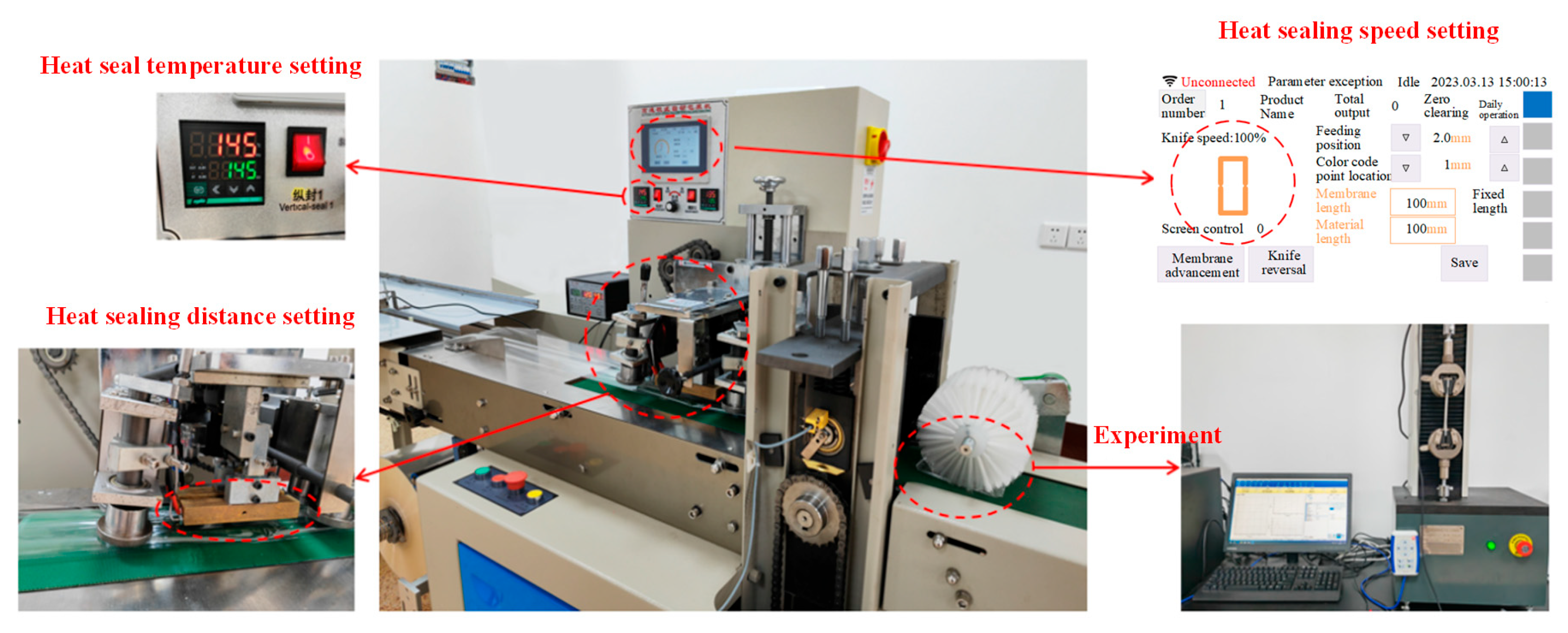

The pillow packing machine adopts double plate heat-sealing, as shown in

Figure 2. In

Figure 2, 1 shows the heating plate heated by heat-seal; 2 is the heating wire, which controls the temperature of the heat-sealing plate according to the temperature controller to reach the heat-sealing temperature

; 3 is the heat-sealing distance

control knob, which can adjust the distance according to the mechanical structure design, and the common parameters are 5 mm, 6 mm and 7 mm; 4 is the heat-sealing distance. During the processing, the composite film is heated by heating the double plate gap, and the heat-sealing distance

will have an important impact on the heat transfer effect, which then affects the heat-sealing strength.

The main influencing factors of the composite film’s heat-sealing effect include heat-sealing time

and heat-sealing temperature

, and the heat-sealing effect is evaluated by the heat-sealing strength

. In the longitudinal heat-sealing process of a pillow-type packaging machine, the heat-sealing time

is also an important factor affecting the heat-sealing strength

, but the processing process of the pillow-type packaging machine adopts speed control, so the heat-sealing speed

(packets/min) is used to replace the heat-sealing time

, and the relationship between the two is as follows:

where

is the length of the heating plate, mm;

is the standard film length of the prediction model, mm.

According to the formula, there is a certain relationship between the heat-sealing speed

and the heat-sealing time

. The faster the heat-sealing speed, the shorter the heat-sealing time, and the corresponding heat-sealing strength will decrease. For other inputs with different film lengths, it is necessary to convert the heat-sealing speed according to the standard film length

of the prediction model. The conversion process is as follows:

where

represents the set speed under the film length

.

2.2. Heat-Seal Strength Analysis

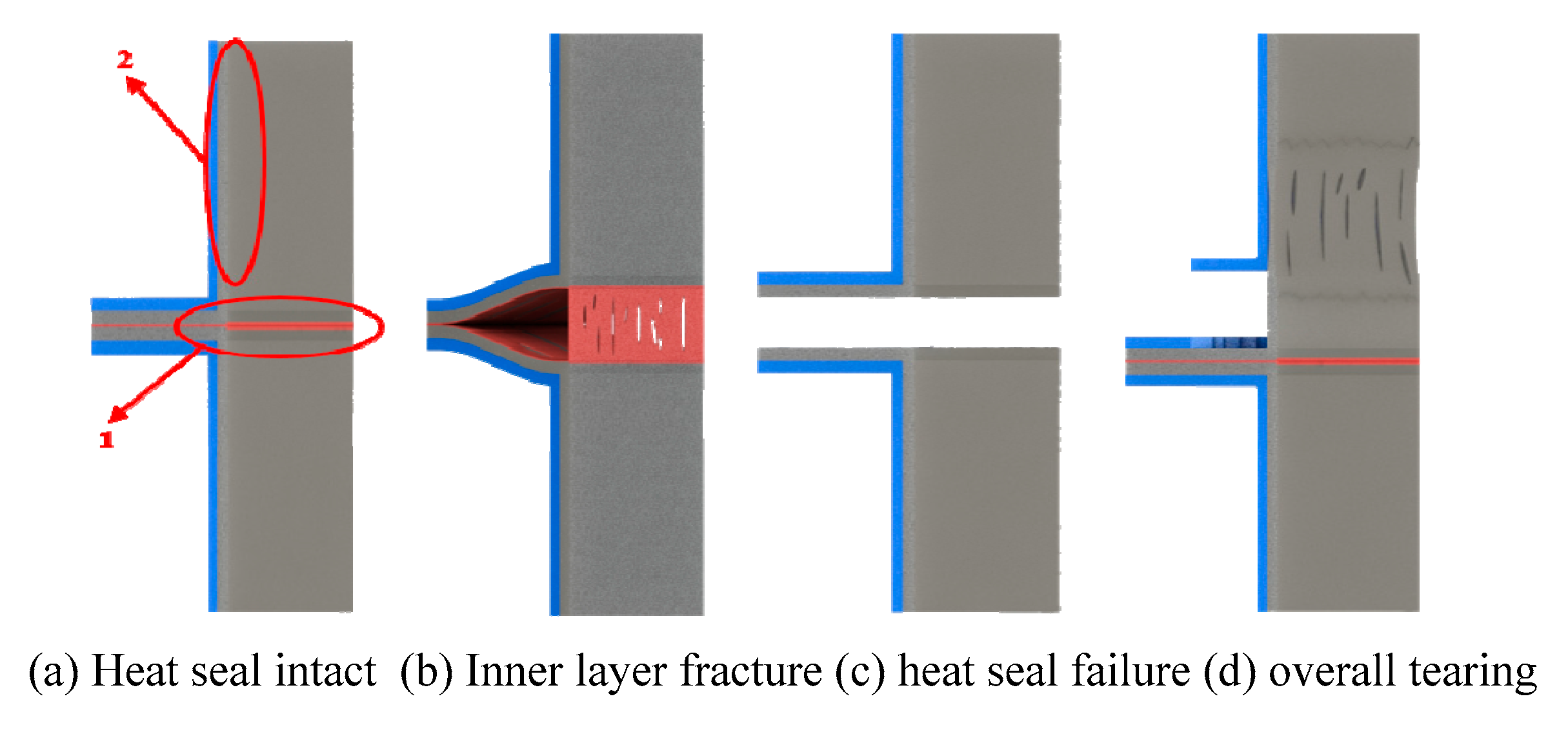

The heat-sealing strength is an important factor in determining the heat-sealing effect of composite film. It is usually obtained by measuring the yield stress of the composite film material at the time of sending fracture at the heat-seal using a tensile machine. After heat-sealing treatment of bopp/cpp composite membrane material, longitudinal tension will produce three different situations, as shown in

Figure 3.

As shown in

Figure 3a, the connection state of the composite film after heat-sealing is shown. One is the interlayer joint of the heat-sealing layer, and the other is the interlayer joint of the composite film; It is the fracture state of the inner layer of the composite film. When the heat-sealing strength is close to the bonding strength between the layers of the composite film, the interlayer fracture separation phenomenon occurs at the heat-sealing position of the composite film. At this time, the heat-sealing effect of the composite film is the best, as shown in

Figure 3b; The state in

Figure 3c is the heat-seal failure state. The heat-seal strength at the heat-seal of the composite film is low, and the bonding strength between the layers of the composite film is far greater than the heat-seal strength. Under this state, the heat-seal requirement cannot be met; When the heat-seal strength is greater than the fracture yield strength of the composite film, the overall tearing state occurs. At this time, the heat-seal strength at the heat-seal of the composite film is too large, and the heat-seal surface is distorted, and its toughness and appearance surface cannot meet the heat-seal requirements, as shown in

Figure 3d. To sum up, the heat-sealing strength can greatly reflect the heat-sealing effect of composite membrane materials, and the target heat-sealing strength

of bopp/cpp composite membrane is 27.67 N per 15 mm.

In this paper, the bopp/cpp composite film is longitudinally sealed and heat-sealed. Based on the standard qb/t 2358-1998, the cutting length is set to 15 mm. The tensile test is carried out on the products processed with the same process parameters, and the average value is taken as the heat-sealing strength in a group of 10. The measured results are shown in

Table 1.

According to the test data, there is a nonlinear relationship between the heat-seal distance, heat-seal temperature, heat-seal speed, and heat-seal strength, and there is a complex coupling relationship between the force field and temperature field, so it is difficult to establish a general mathematical model. To solve this problem, this paper uses an RBF neural network training model to replace the mathematical model and optimizes it using the genetic algorithm. The design structure diagram of the decision method model is shown in

Figure 4. Input the material yield strength to calculate the target heat-sealing strength, and set some process parameters as constraints according to the actual processing requirements. The RBF neural network regression model was established, and its accuracy was verified. The iterative population of the genetic algorithm is input into the regression model for fitness calculation. The optimal process parameters of heat-seal strength close to the target heat-seal strength were obtained by the genetic algorithm.

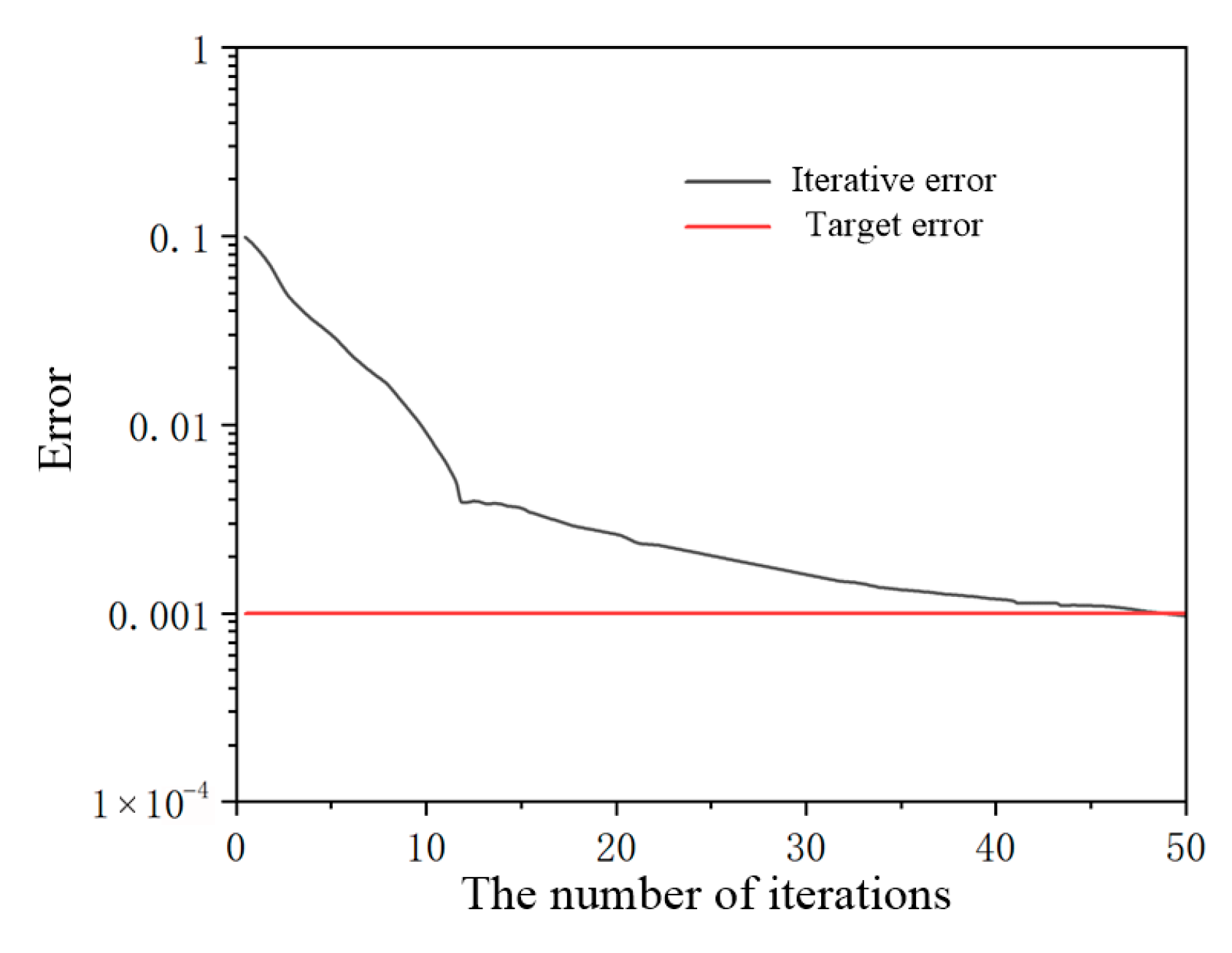

2.3. Implementation of RBF Neural Network Based on OLS

In the iterative calculation of the RBF neural network, the parameters to be confirmed include the expansion coefficient spread, the number of neurons in the hidden layer , and the center vector corresponding to each hidden layer. The width parameter spread is set manually, while the number of neurons and the center vector are solved iteratively by orthogonal least squares (OLS).

It is necessary to input all training sets and calculate the radial basis function value with the center vector composed of all training sets:

where (

Mr)

ij represents the radial basis function value of

Xj when

is the center vector, and

is the column pool to be selected.

The column vectors selected from the column pool to be selected are combined into a matrix

, which is called the selected column pool, and the corresponding output vector is

. If

is a unit orthogonal matrix, the theoretical error calculated by the least square method is:

At this time, if the

k-th column vector

is selected from the column pool to be selected

and added to the selected column pool

, the error reduction is calculated as follows:

Column vector must be the one with the largest error reduction among all column vectors . At this time, add in the corresponding training set as the center vector. For most cases, and are not unit orthogonal matrices, but because the space represented by the two matrices after standard orthogonalization is the same, the corresponding error reduction is the same. and are obtained by standard orthogonalization of and . At this time, the column with the largest error reduction in can be added to , and the corresponding column in can be added to . Through the above method, the center vector is continuously selected to add, and finally, the error meets the target requirements.

5. Conclusions

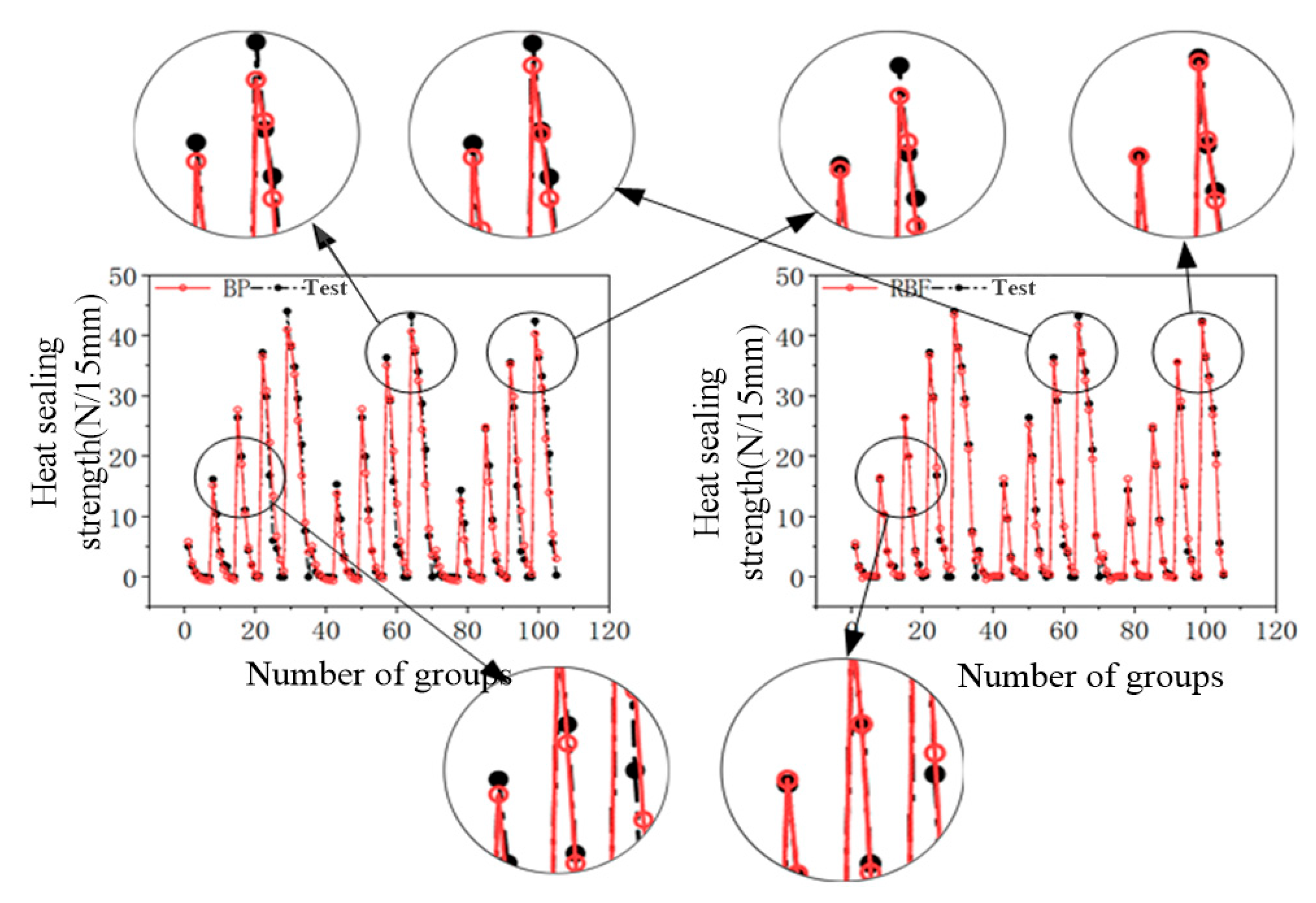

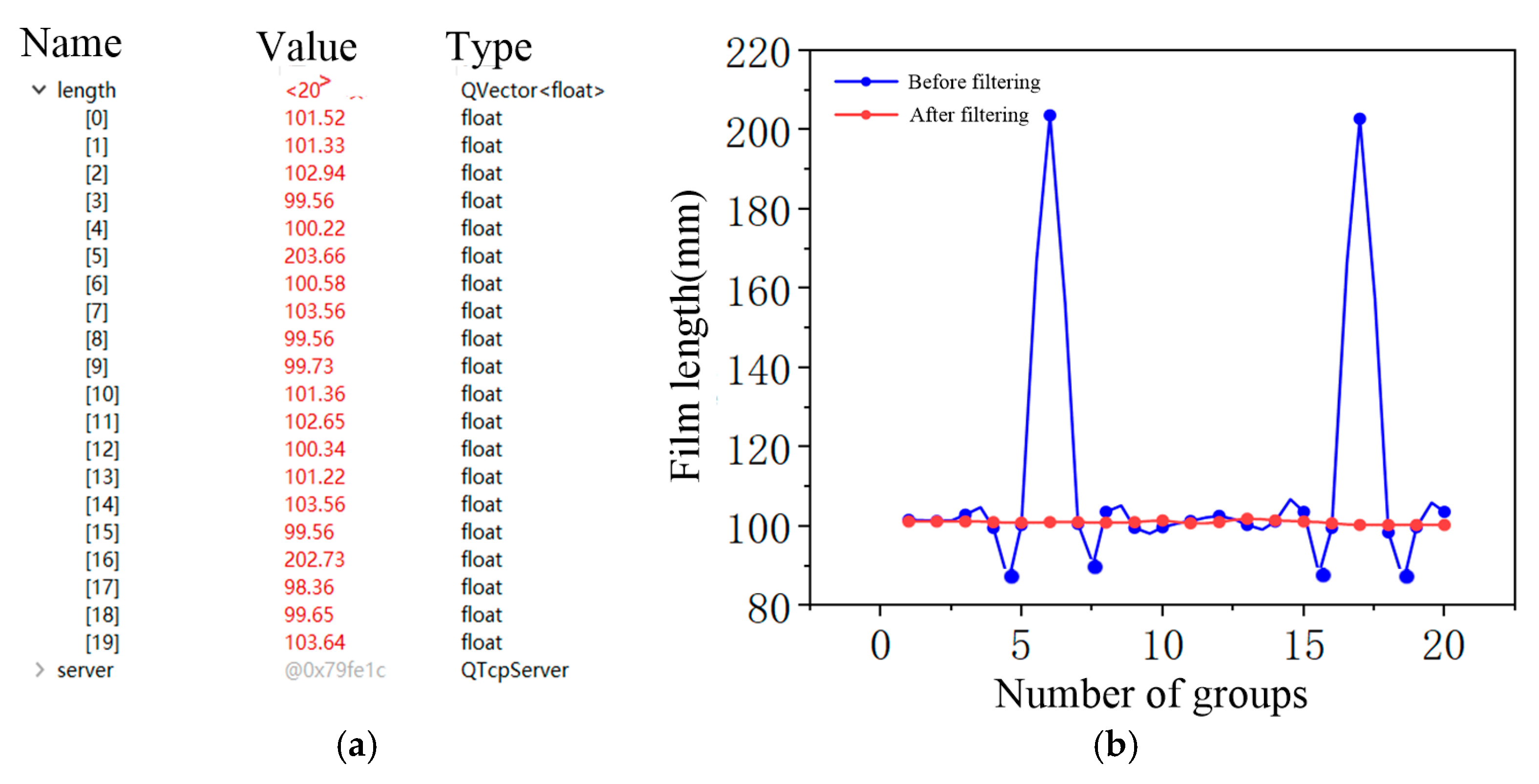

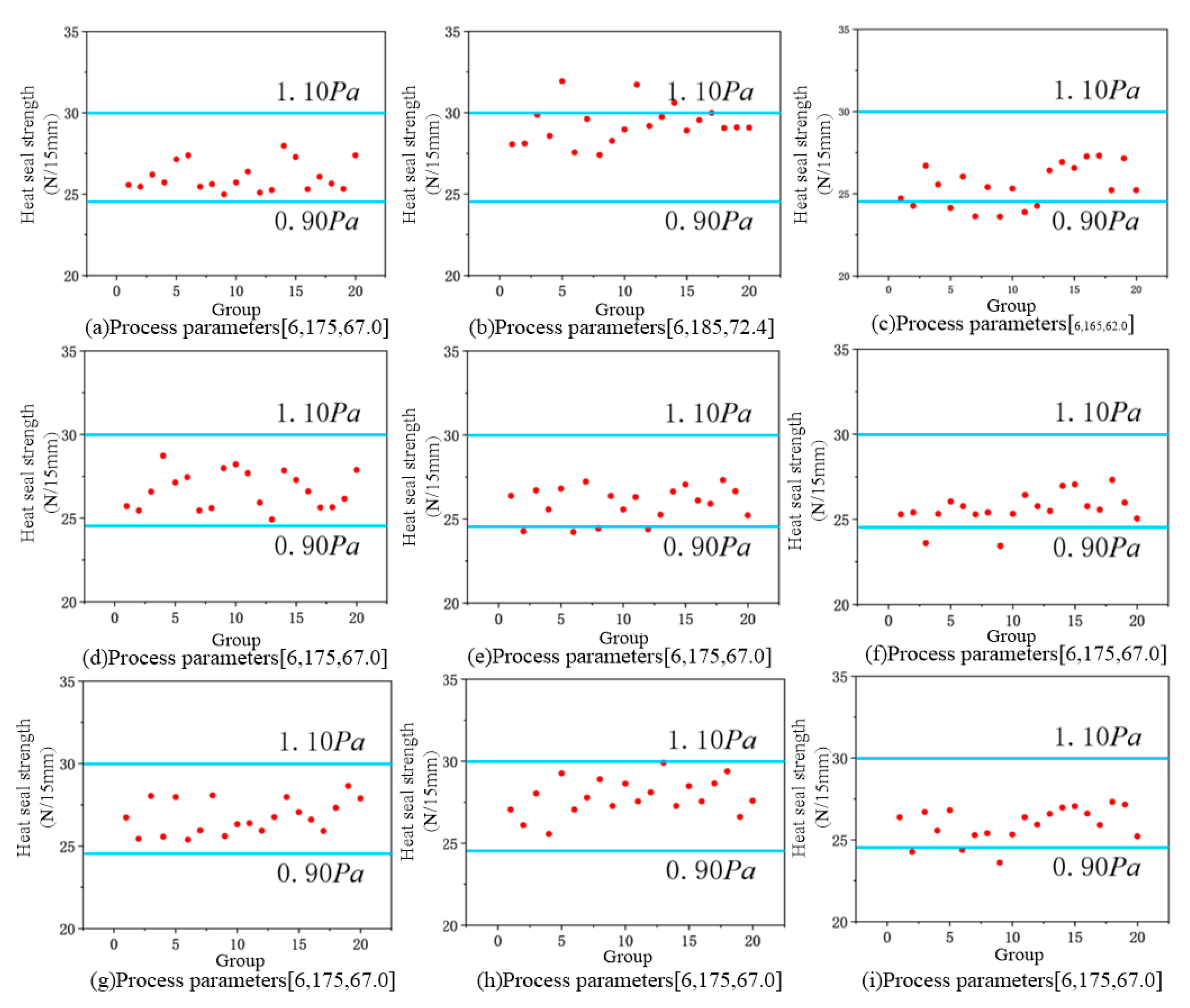

In order to improve the processing efficiency and reduce the labor cost of the pillow-type packaging machine through pre-parameter input, a process parameter decision method based on rbf-ols is constructed in this paper. The nonlinear relationship between different process parameters and heat-sealing strength was obtained from the experimental data, and an RBF network was used to predict the heat-sealing strength. The comparison of data sets shows that the regression model based on the RBF neural network has high accuracy and fast convergence, and the overall error of the effective part of the model is less than 5%, so the model can effectively predict the heat-seal strength. According to different input parameters, the fitness function is designed based on the RBF network, and the optimal process parameters are selected by the genetic algorithm. Finally, the optimal process parameters are obtained. The final results were brought into the actual processing process, and the results were measured. All 20 groups of products were within the processing requirements and met the processing requirements. The decision-making method proposed in this paper replaces the manual parameter selection, which effectively reduces the labor cost and improves the decision-making efficiency.

For different composite membrane materials, it is necessary to relearn the RBF neural network prediction model. In the future, other characteristics, such as composite membrane materials, can be considered to be added to the prediction model of the RBF neural network to increase its universality.