Integrating Solar Energy into Fossil Fuel Power Plant with CO2 Capture and Storage: A Bibliographic Survey

Abstract

1. Introduction

- Sequential Combustion in Gas Turbine [16];

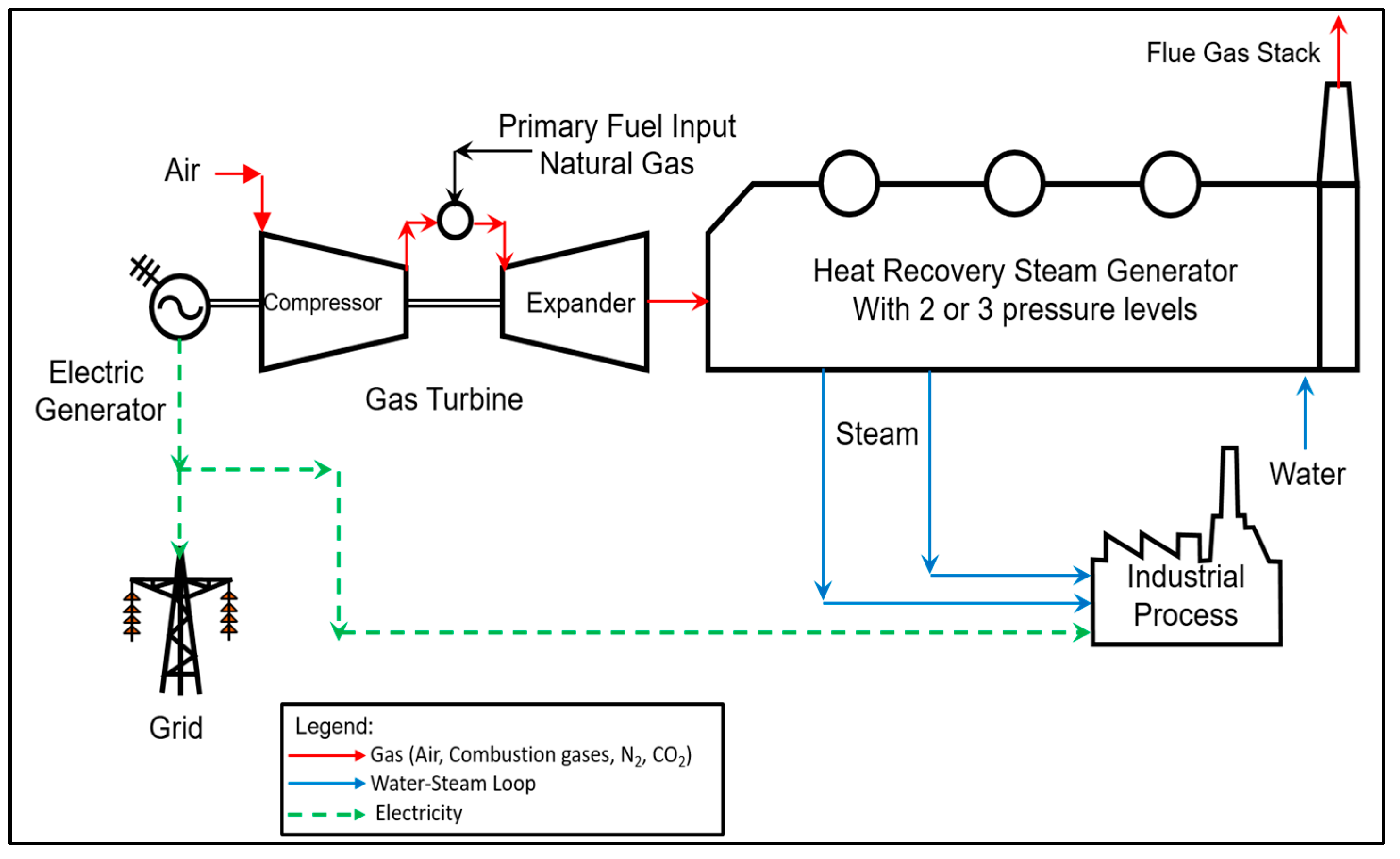

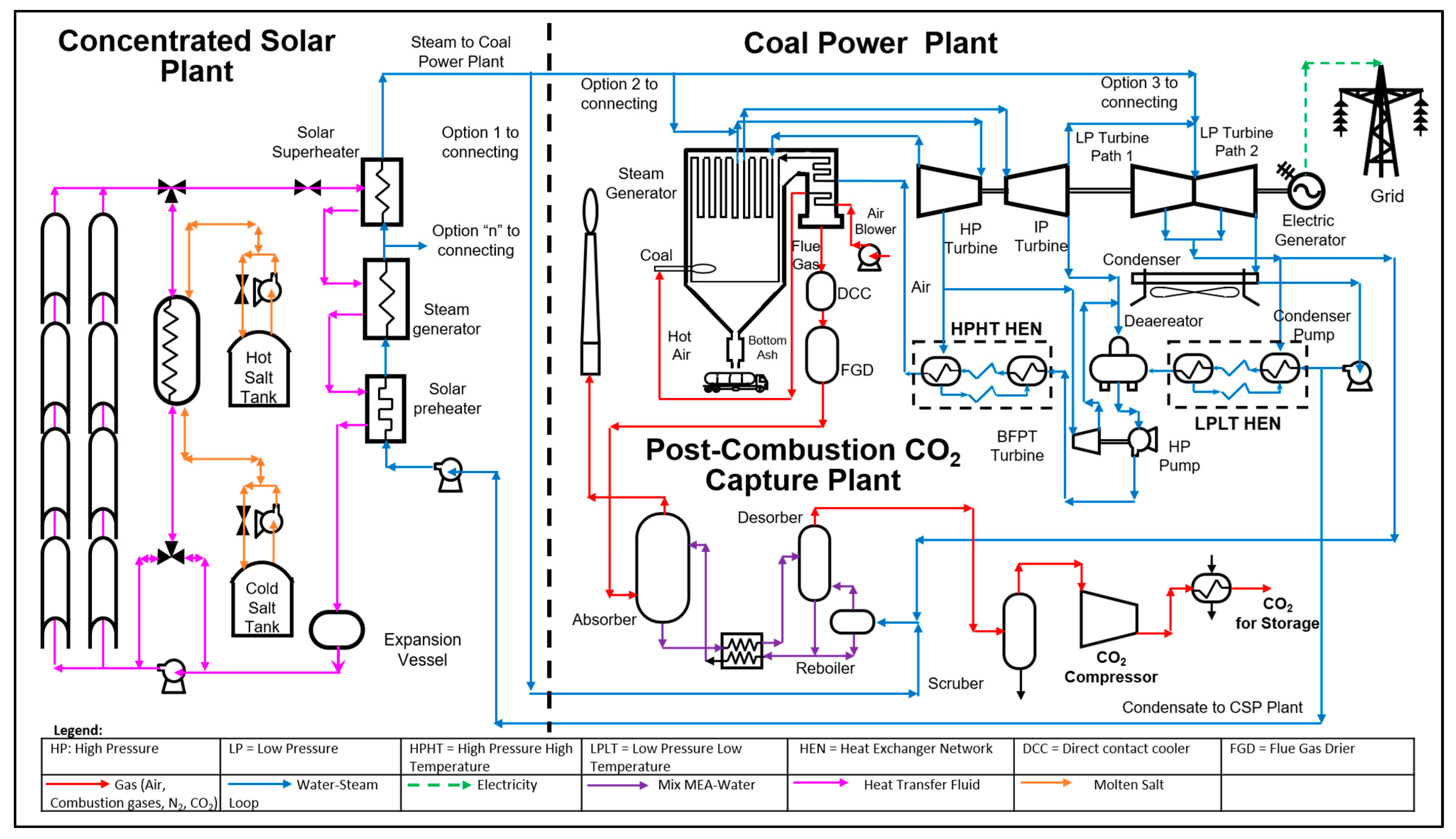

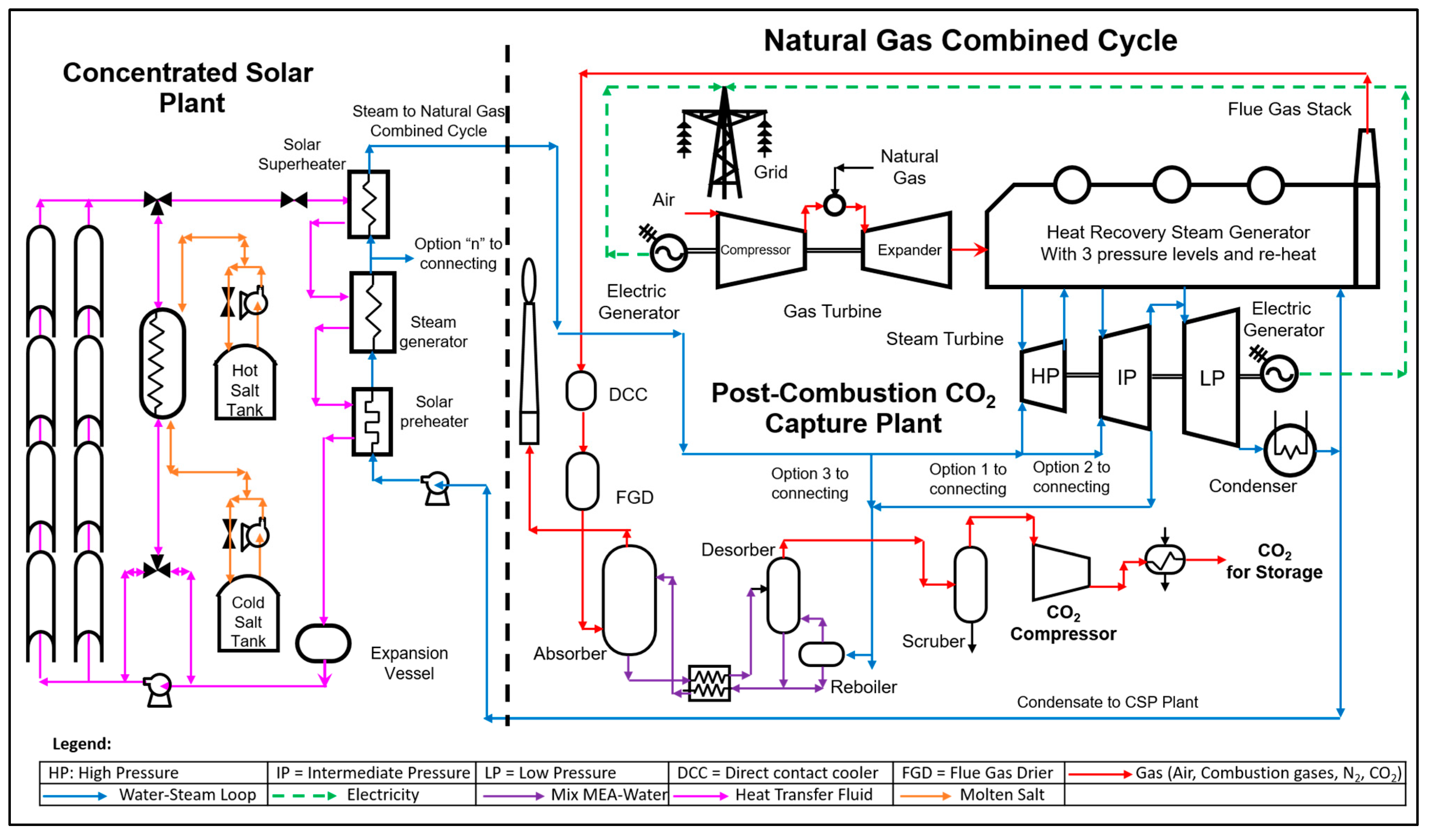

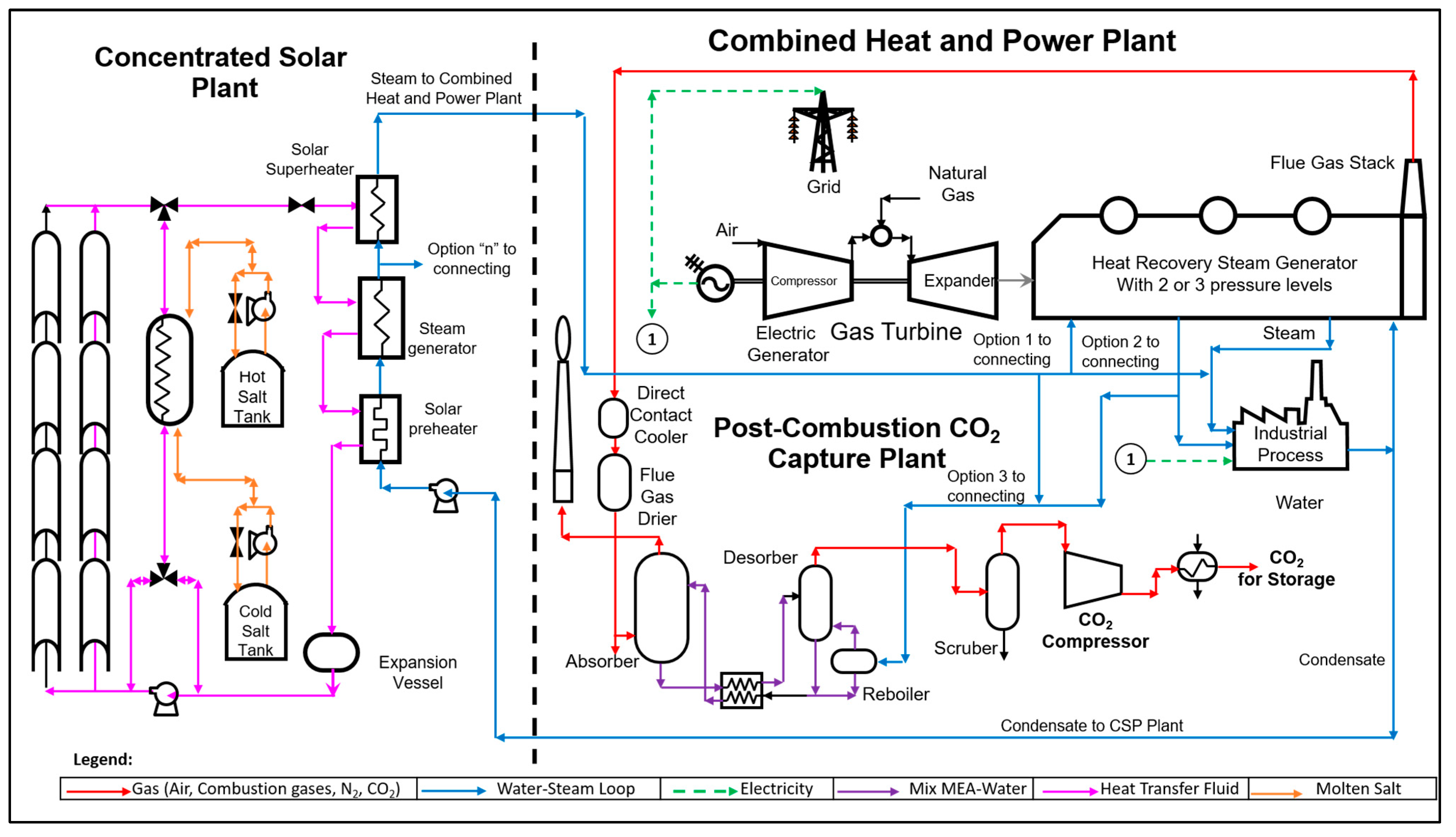

2. Description of Evaluated Power Plant Technologies

2.1. Fossil Fuel Power Plant Technology

2.2. Concentrated Solar Power

2.3. Post-Combustion CO2 Capture Plants

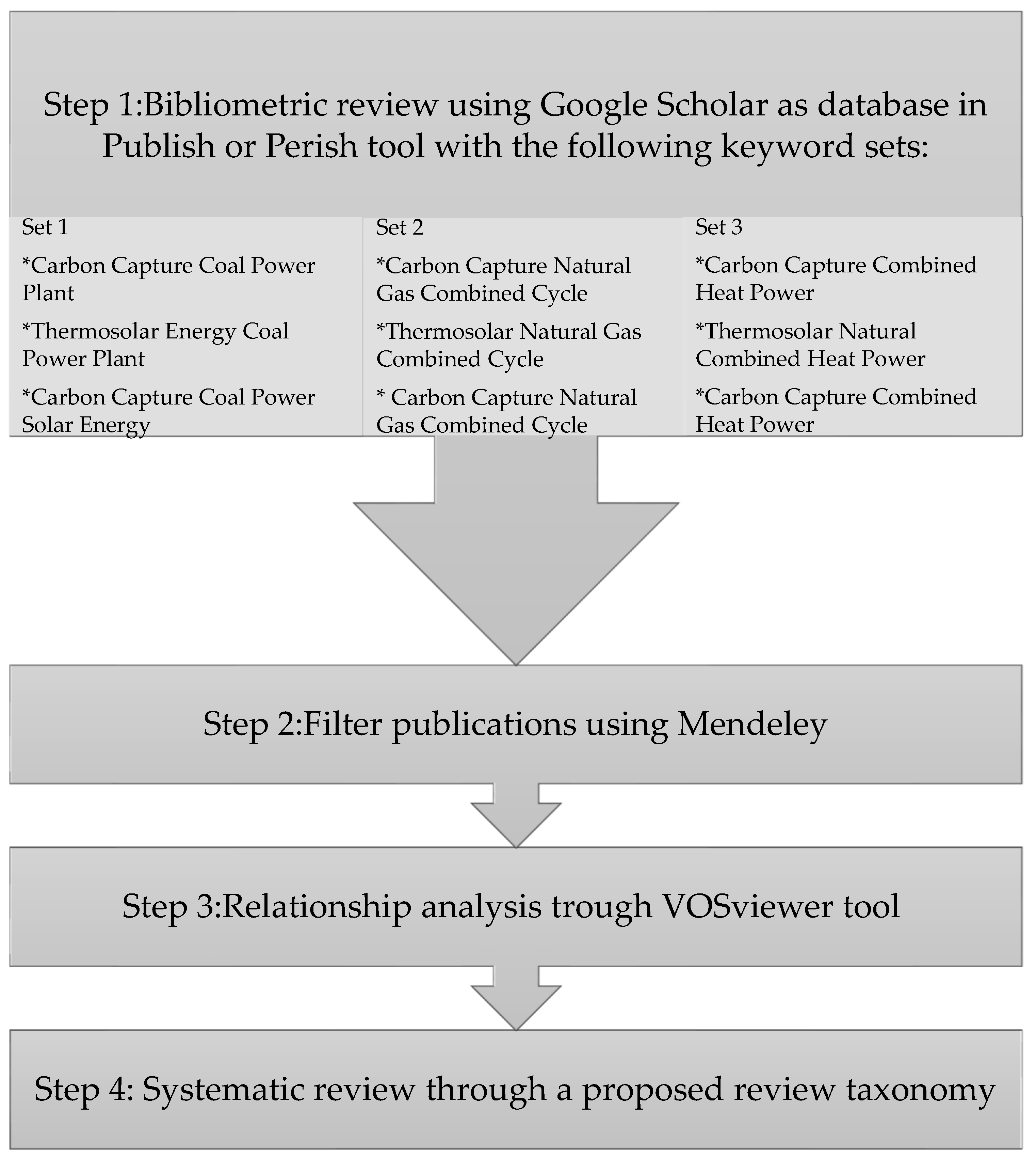

3. Bibliographic Survey Method

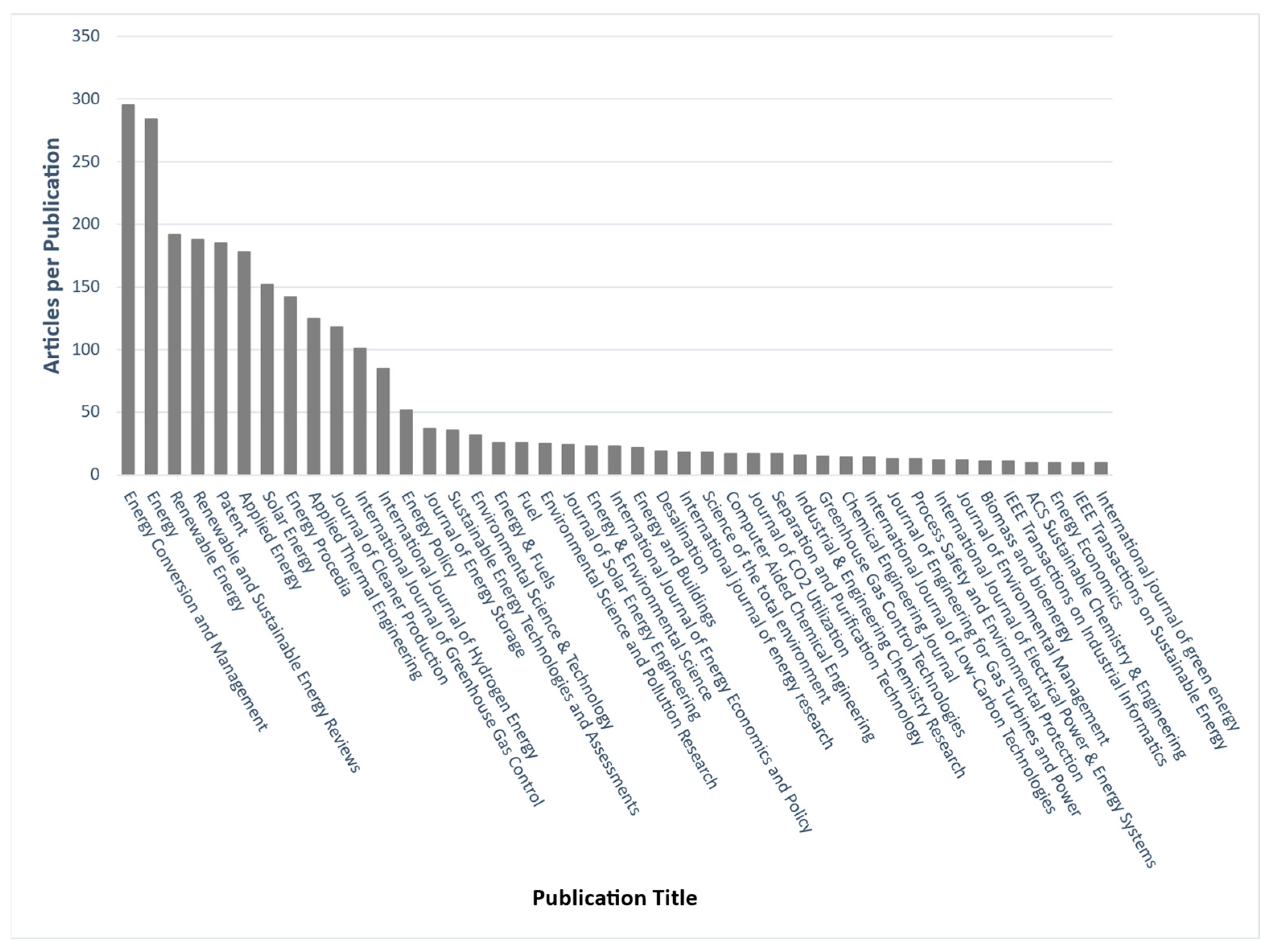

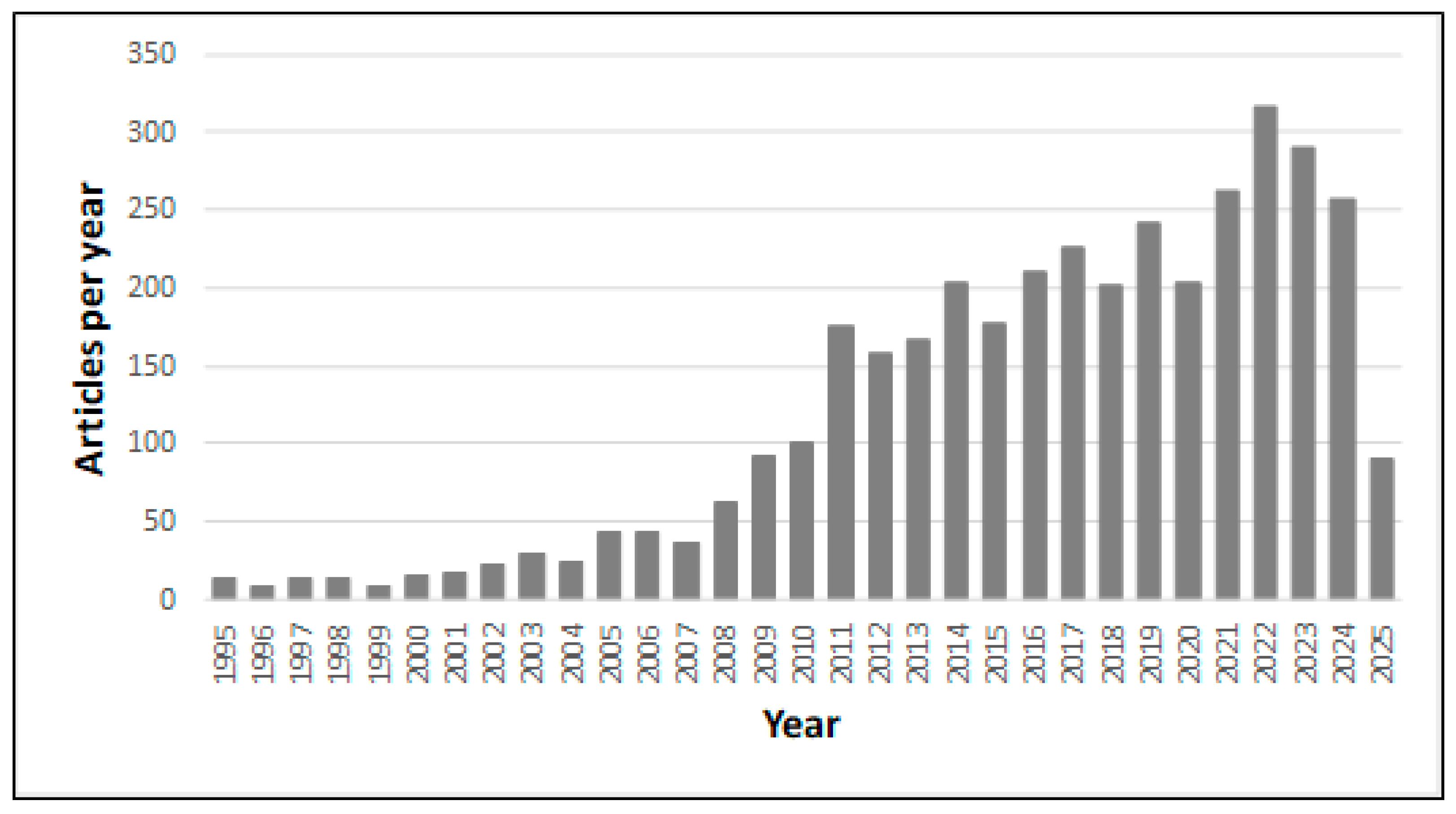

3.1. Bibliometric Review (Step 1)

3.2. Filter Publications (Step 2)

3.3. Bibliometric Analysis (Step 3)

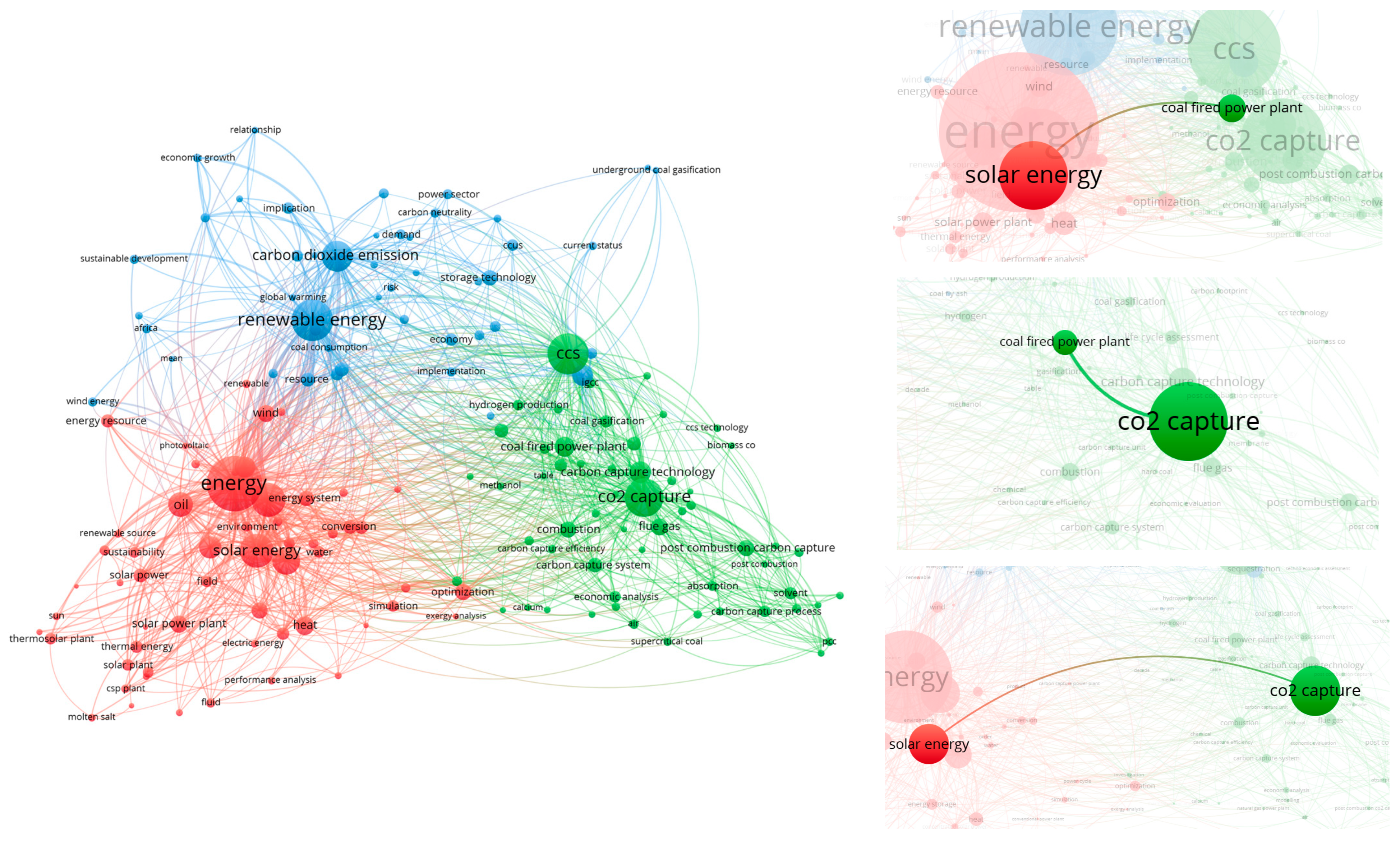

- Set 1: Analysis of the topic “Carbon Capture in Coal Power Plants Utilizing Thermosolar Energy”

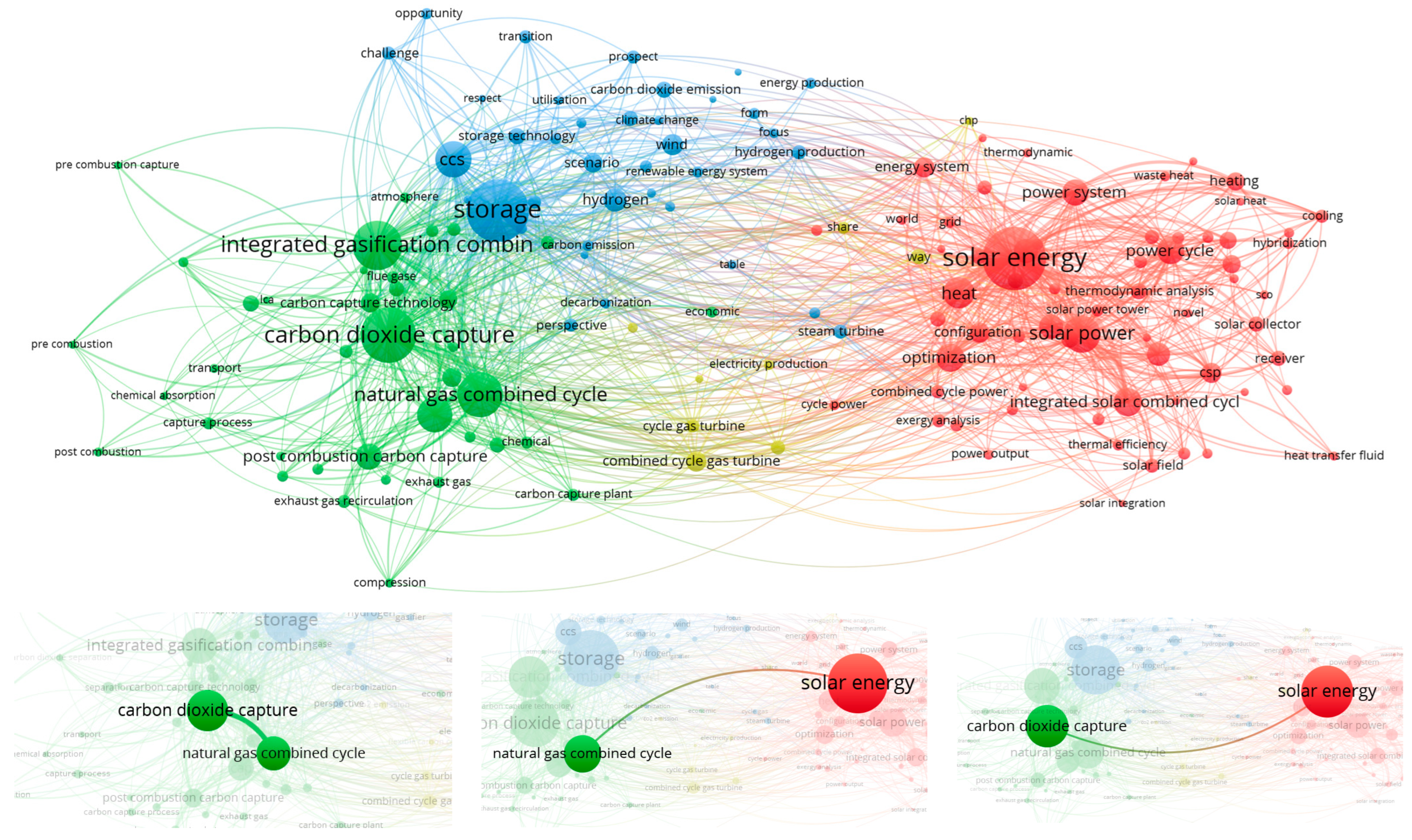

- Set 2: Analysis of the topic Carbon Capture in Natural Gas Combined Cycle using thermosolar energy

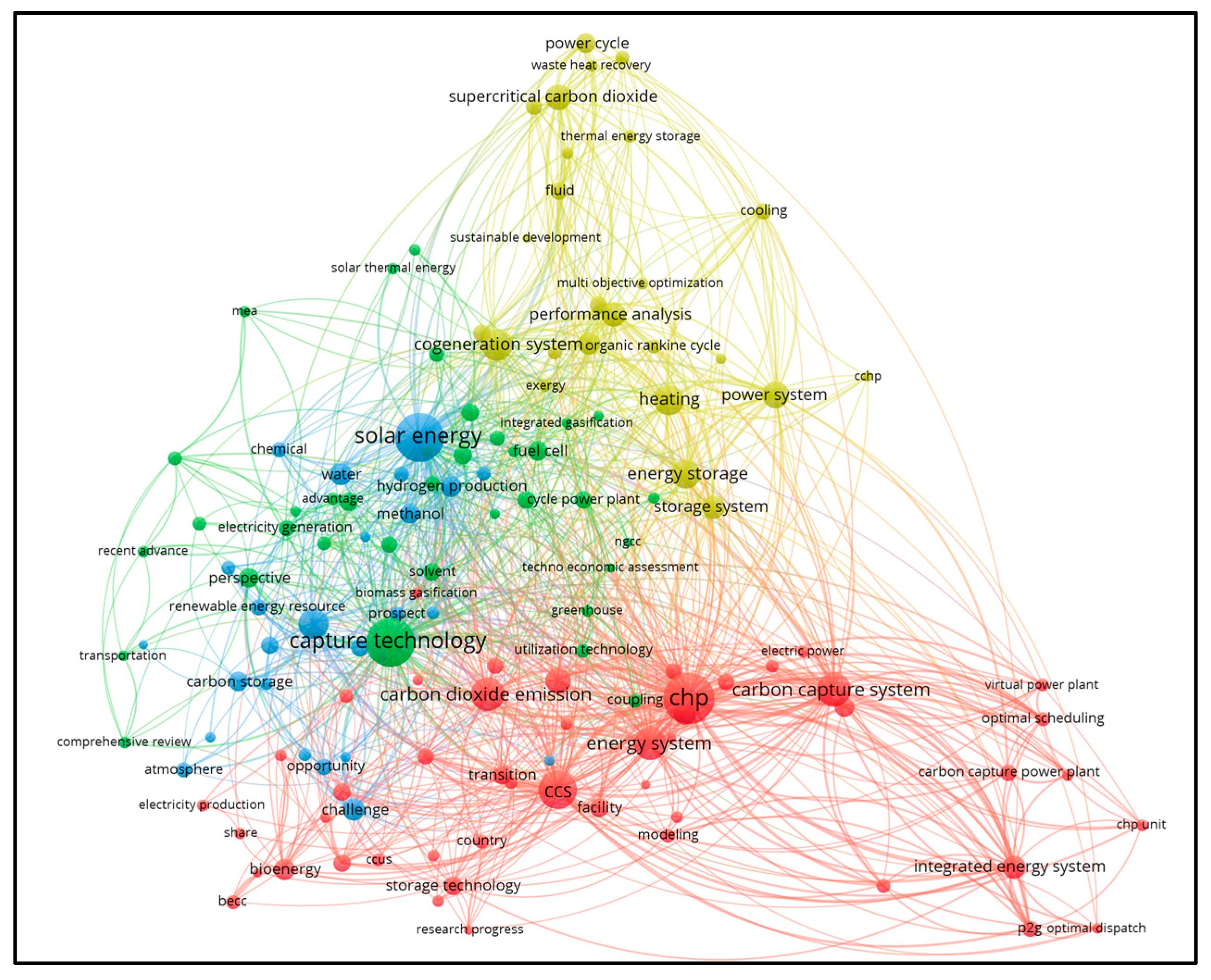

- Set 3: Analysis of the topic “Carbon Capture in Combined Heat and Power utilizing thermosolar energy”

3.4. Systematic Review (Step 4)

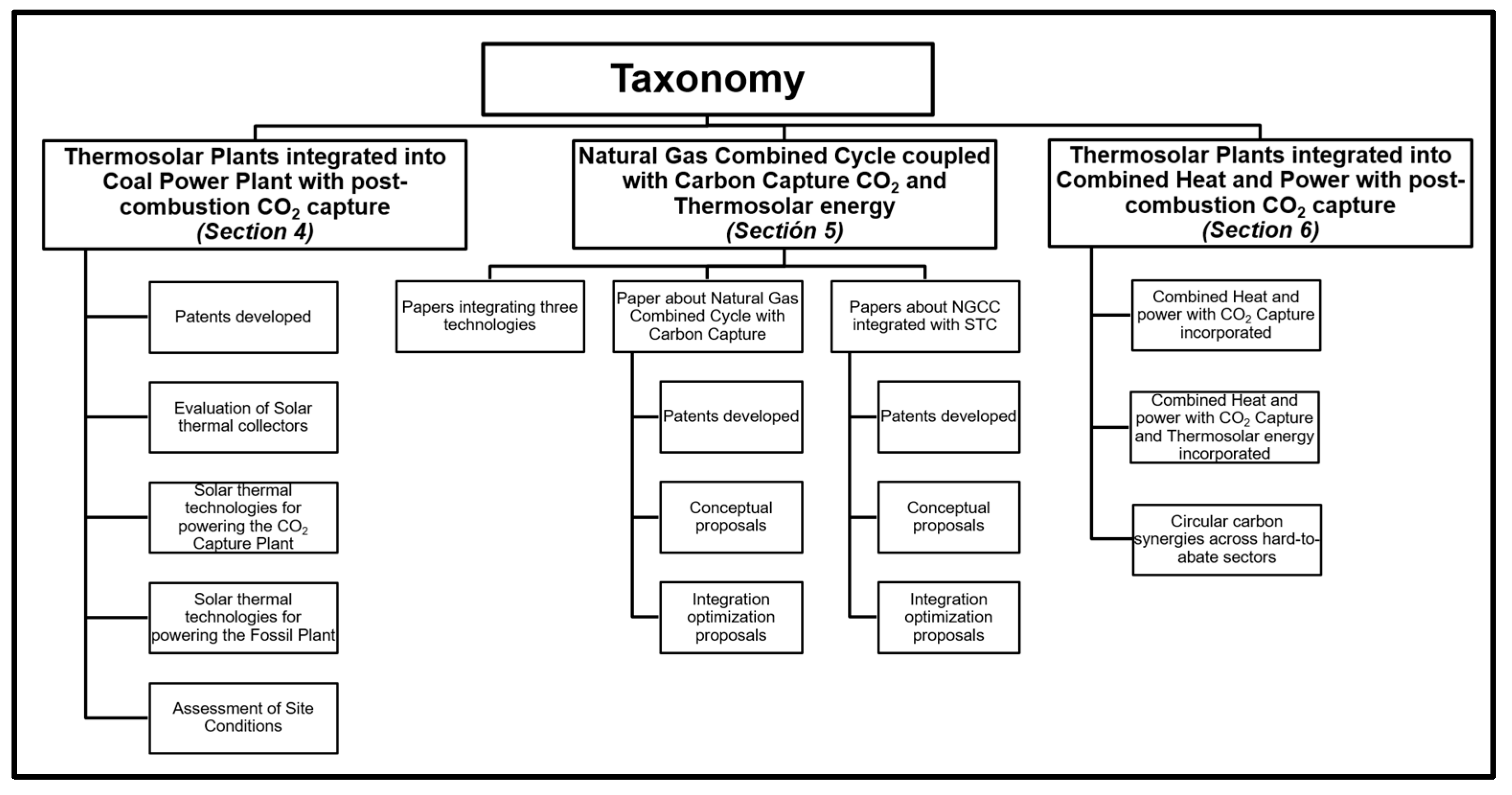

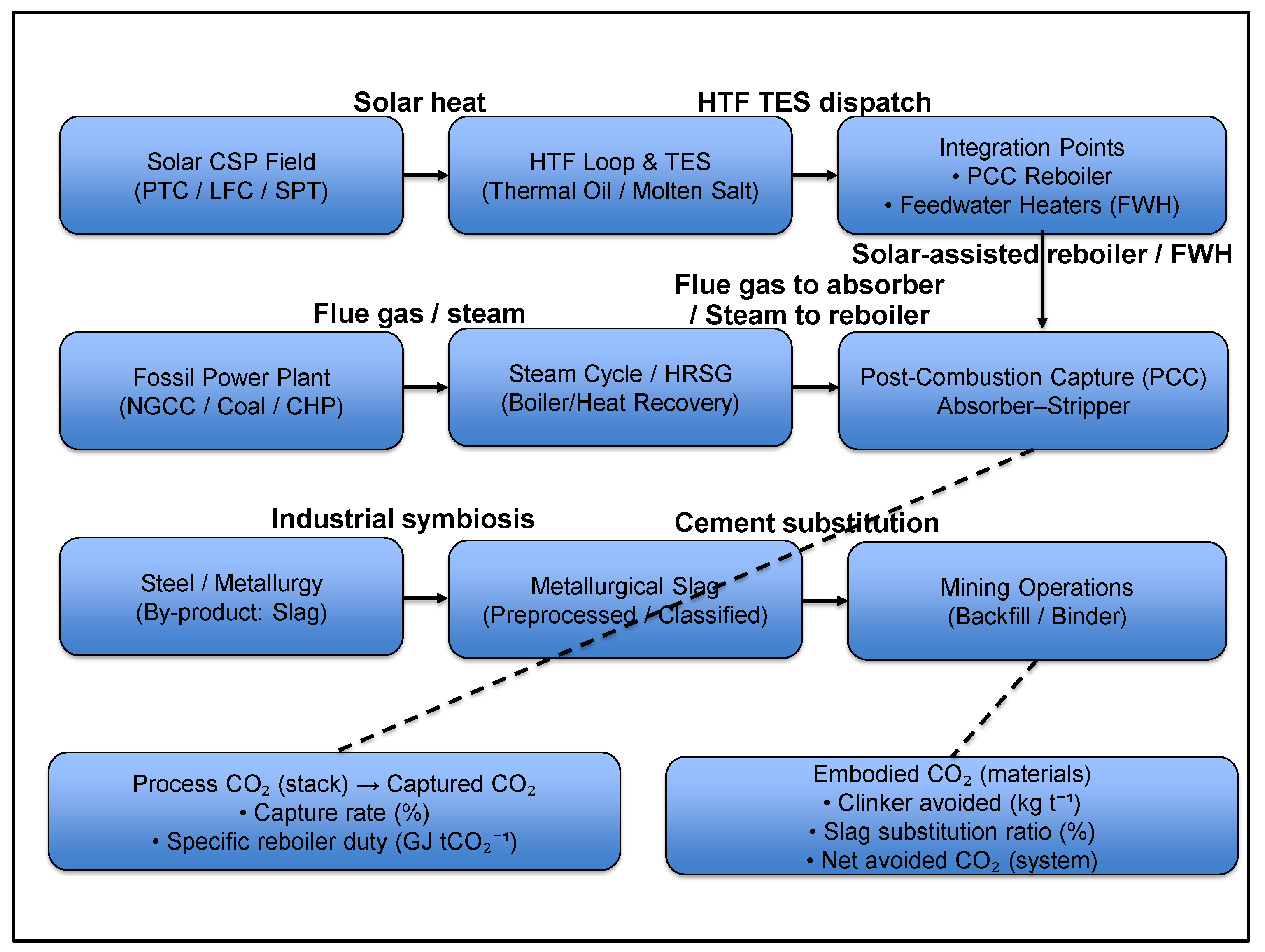

- After conducting the bibliometric analysis in Step 3, it was determined that the research topics addressed in this study were emerging but presented significant opportunities. A more targeted analysis is recommended to achieve a comprehensive review of research papers and patents. This review was carried out using the taxonomy shown in Figure 14.

4. Thermosolar Plants Integrated into a Coal Power Plant with Post-Combustion CO2 Capture

4.1. Patents

4.2. Evaluation of Solar Thermal Collectors

4.3. Solar Thermal Technologies for Powering the CO2 Capture Plant (CCP)

4.4. Solar Thermal Technologies for Powering the Fossil Plant

4.5. Assessment of Site Conditions

4.6. Quantitative Comparison

4.7. Conclusions of the Section

5. NGCC Coupled with Carbon Capture CO2 and Thermosolar Energy

5.1. Papers Integrating Three Technologies

5.2. Publications About NGCC with Carbon Capture

5.2.1. Patents

5.2.2. Conceptual Proposals

5.2.3. Integration Optimization Proposals

5.3. Publications About NGCC Integrated with STC

5.3.1. Patents

5.3.2. Conceptual Proposals

5.3.3. Assessment of Different Types of Thermosolar Collector and Integration Optimization Proposals

5.4. Quantitative Comparison

5.5. Conclusions of the Section

6. Thermosolar Plants Integrated into Combined Heat and Power with Postcombustion CO2 Capture

6.1. Combined Heat and Power with CO2 Capture Incorporated

6.2. Combined Heat and Power with CO2 Capture and Thermosolar Energy Incorporated

6.3. Circular Carbon Synergies Across Hard-to-Abate Sectors

6.4. Quantitative Comparison

6.5. Conclusions of the Section

7. Conclusions

7.1. Technical Viability

7.2. Economic and Operational Challenges

7.3. Integration Complexity

- Cost and performance optimization:

- Reduce capital expenditures through advancements in solar collector materials (e.g., high-reflectivity coatings, modular designs) and thermal storage systems.

- Refine hybrid configurations using multi-objective optimization models to balance LCOE, efficiency, and scalability.

- Policy and market incentives:

- Implement carbon pricing mechanisms, tax credits, and subsidies to offset upfront costs and incentivize private-sector adoption.

- Foster public–private partnerships to pilot large-scale deployments, particularly in regions with high solar potential and fossil-dependent grids.

- Technological synergies:

- Explore circular carbon economies by integrating solar-CCS systems with biomass co-firing, hydrogen production, and enhanced oil recovery (EOR). There is strong evidence that the circular economy contributes to reducing the extraction of primary resources [85]. Incorporating CO2 capture in a circular economy frame would allow the capture of CO2 to be converted into synthetic fuels (Methanol, Methane, or Syngas) or chemical products (carbonates, urea, ethylene, propylene, etc.) instead of being released into the atmosphere. The integration of solar energy could be incorporated, contributing to the required energy to capture CO2 and providing energy to store and convert the CO2 into new products.

- Invest in digital twin technologies and AI-driven predictive maintenance to enhance hybrid plant adaptability to intermittent solar input.

- Research Priorities:

- Address scalability gaps in pilot studies, particularly for NGCC and CHP systems, which face challenges due to low flue gas CO2 concentrations (3–5%).

- Validate long-term performance of solar-thermal storage hybrids under real-world operating conditions, including partial-load and transient scenarios.

- Investigate issues of corrosion and material degradation because of solvents in the CO2 capture plant. Also, operational flexibility due to the unpredictability of solar thermal energy requires further research.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bilgili, M.; Tumse, S.; Nar, S. Comprehensive Overview on the Present State and Evolution of Global Warming, Climate Change, Greenhouse Gasses and Renewable Energy. Arab. J. Sci. Eng. 2024, 49, 14503–14531. [Google Scholar] [CrossRef]

- Aidam, K. COP28 and the global stocktake: A weak attempt to address climate change. Front. Sustain. 2024, 5, 1388266. [Google Scholar] [CrossRef]

- Ma, J.; Li, L.; Wang, H.; Du, Y.; Ma, J.; Zhang, X.; Wang, Z. Carbon Capture and Storage: History and the Road Ahead. Engineering 2022, 14, 33–43. [Google Scholar] [CrossRef]

- Zhang, G.; Liu, J.; Qian, J.; Zhang, X.; Liu, Z. Review of research progress and stability studies of amine-based biphasic absorbents for CO2 capture. J. Ind. Eng. Chem. 2024, 134, 28–50. [Google Scholar] [CrossRef]

- Chao, C.; Deng, Y.; Dewil, R.; Baeyens, J.; Fan, X. Post-combustion carbon capture. Renew. Sustain. Energy Rev. 2021, 138, 110490. [Google Scholar] [CrossRef]

- Vega, F.; Cano, M.; Camino, S.; Fernández, L.M.G.; Portillo, E.; Navarrete, B. Solvents for Carbon Dioxide Capture. In Carbon Dioxide Chemistry, Capture and Oil Recovery; InTech: London, UK, 2018. [Google Scholar] [CrossRef]

- Sultan, H.; Muhammad, H.A.; Bhatti, U.H.; Min, G.H.; Baek, I.H.; Baik, Y.-J.; Nam, S.C. Reducing the efficiency penalty of carbon dioxide capture and compression process in a natural gas combined cycle power plant by process modification and liquefied natural gas cold energy integration. Energy Convers. Manag. 2021, 244, 114495. [Google Scholar] [CrossRef]

- Cohen, S.M.; Webber, M.E.; Rochelle, G.T. Utilizing Solar Thermal Energy for Post-Combustion CO2 Capture. In Proceedings of the ASME 2010 4th International Conference on Energy Sustainability, Phoenix, AZ, USA, 17–22 May 2010; ASME: Phoenix, AZ, USA, 2010; pp. 663–672. [Google Scholar] [CrossRef]

- Lambert, T.; Hoadley, A.; Hooper, B. Process integration of solar thermal energy with natural gas combined cycle carbon capture. Energy 2014, 74, 248–253. [Google Scholar] [CrossRef]

- Bravo, J.; Charles, J.; Neti, S.; Caram, H.; Oztekin, A.; Romero, C. Integration of solar thermal energy to improve NGCC with CO2 capture plant performance. Int. J. Greenh. Gas. Control 2020, 100, 103111. [Google Scholar] [CrossRef]

- Calderón, A.M.A.; Salgado, O.A.J.; Limón, N.V.; Perez, M.R.; Aguilar, J.O.A.; Díaz, M.O.G.; Díaz, A.G. Optimisation of an Integrated System: Combined Heat and Power Plant with CO2 Capture and Solar Thermal Energy. Processes 2023, 11, 155. [Google Scholar] [CrossRef]

- Hellat, J.; Hoffmann, J. Combined Cycle Power Plant with Flue Gas Recirculation. U.S. Patent 9249689B2, 2 February 2016. [Google Scholar]

- Alcaráz-Calderon, A.M.; González-Díaz, M.O.; Mendez, Á.; González-Santaló, J.M.; González-Díaz, A. Natural gas combined cycle with exhaust gas recirculation and CO2 capture at part-load operation. J. Energy Inst. 2019, 92, 370–381. [Google Scholar] [CrossRef]

- Voleno, A.; Romano, M.C.; Turi, D.M.; Chiesa, P.; Ho, M.T.; Wiley, D.E. Post-combustion CO2 capture from natural gas combined cycles by solvent supported membranes. In Energy Procedia; Elsevier Ltd.: Amsterdam, The Netherlands, 2014; pp. 7389–7397. [Google Scholar] [CrossRef]

- Diego, M.E.; Bellas, J.M.; Pourkashanian, M. Techno-economic analysis of a hybrid CO2 capture system for natural gas combined cycles with selective exhaust gas recirculation. Appl. Energy 2018, 215, 778–791. [Google Scholar] [CrossRef]

- Ásen, K.I.; Eimer, D.A. Method for Removing and Recovering CO2 from Exhaust Gas. U.S. Patent 6,655,150 B1, 2 December 2003. [Google Scholar]

- Díaz, A.G.; Fernández, E.S.; Gibbins, J.; Lucquiaud, M. Sequential supplementary firing in natural gas combined cycle with carbon capture: A technology option for Mexico for low-carbon electricity generation and CO2 enhanced oil recovery. Int. J. Greenh. Gas. Control 2016, 51, 330–345. [Google Scholar] [CrossRef]

- Díaz, A.G. Sequential Supplementary Firing in Natural Gas Combined Cycle Plants with Carbon Capture for Enhanced Oil Recovery. Master’s Thesis, The University of Edinburgh, Edinburgh, UK, 2016. Available online: https://era.ed.ac.uk/bitstream/handle/1842/22935/Gonz%c3%a1lez%20D%c3%adaz2016.pdf?sequence=1&isAllowed=y (accessed on 23 April 2025).

- Dion, L.M.; Lefsrud, M.; Orsat, V. Review of CO2 recovery methods from the exhaust gas of biomass heating systems for safe enrichment in greenhouses. Biomass Bioenergy 2011, 35, 3422–3432. [Google Scholar] [CrossRef]

- Parvareh, F.; Sharma, M.; Abbas, A. Renewable energy integration in liquid absorbent-based post-combustion CO2 capture plants. In Absorption-Based Post-Combustion Capture of Carbon Dioxide; Elsevier Inc.: Amsterdam, The Netherlands, 2016; pp. 623–648. [Google Scholar] [CrossRef]

- Halkos, G.E.; Gkampoura, E.C. Reviewing usage, potentials, and limitations of renewable energy sources. Energies 2020, 13, 2906. [Google Scholar] [CrossRef]

- Tahir, M.F.; Haoyong, C.; Guangze, H. A comprehensive review of 4E analysis of thermal power plants, intermittent renewable energy and integrated energy systems. Energy Rep. 2021, 7, 3517–3534. [Google Scholar] [CrossRef]

- Di Gianfrancesco, A. The fossil fuel power plants technology. In Materials for Ultra-Supercritical and Advanced Ultra-Supercritical Power Plants; Elsevier Inc.: Amsterdam, The Netherlands, 2017; pp. 1–49. [Google Scholar] [CrossRef]

- Porto-Hernandez, L.; Vargas, J.; Munoz, M.; Galeano-Cabral, J.; Ordonez, J.; Balmant, W.; Mariano, A. Fundamental optimization of steam Rankine cycle power plants. Energy Convers. Manag. 2023, 289, 117148. [Google Scholar] [CrossRef]

- Khalilpour, R.; Milani, D.; Qadir, A.; Chiesa, M.; Abbas, A. A novel process for direct solvent regeneration via solar thermal energy for carbon capture. Renew. Energy 2017, 104, 60–75. [Google Scholar] [CrossRef]

- Jarre, M.; Noussan, M.; Poggio, A. Operational analysis of natural gas combined cycle CHP plants: Energy performance and pollutant emissions. Appl. Therm. Eng. 2016, 100, 304–314. [Google Scholar] [CrossRef]

- Gülen, S.C. Gas Turbine Combined Cycle Power Plants, 1st ed.; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar] [CrossRef]

- Struchtrup, H. Thermodynamics and Energy Conversion, 1st ed.; Springer: London, UK, 2014; Volume 8. [Google Scholar] [CrossRef]

- Kerr, T. Combined Heat and Power: Evaluating the Benefits of Greater Global Investment in Combined Heat and Power. Paris. February 2008. Available online: https://iea.blob.core.windows.net/assets/d459f7d5-1ba7-49d9-ad56-915fba22f267/chp_report.pdf (accessed on 23 April 2025).

- Thorin, E.; Sandberg, J.; Yan, J. Combined Heat and Power. In Handbook of Clean Energy Systems; Wiley: Hoboken, NJ, USA, 2015; pp. 1–11. [Google Scholar] [CrossRef]

- Okoroigwe, E.; Madhlopa, A. An integrated combined cycle system driven by a solar tower: A review. Renew. Sustain. Energy Rev. 2016, 57, 337–350. [Google Scholar] [CrossRef]

- Baharoon, D.A.; Rahman, H.A.; Omar, W.Z.W.; Fadhl, S.O. Historical development of concentrating solar power technologies to generate clean electricity efficiently—A review. Renew. Sustain. Energy Rev. 2015, 41, 996–1027. [Google Scholar] [CrossRef]

- Ahmadi, M.H.; Ghazvini, M.; Sadeghzadeh, M.; Alhuyi Nazari, M.; Kumar, R.; Naeimi, A.; Ming, T. Solar power technology for electricity generation: A critical review. Energy Sci. Eng. 2018, 6, 340–361. [Google Scholar] [CrossRef]

- Pramanik, S.; Ravikrishna, R.V. A review of concentrated solar power hybrid technologies. Appl. Therm. Eng. 2017, 127, 602–637. [Google Scholar] [CrossRef]

- Rovira, A.; Sánchez, C.; Valdés, M.; Abbas, R.; Barbero, R.; Montes, M.J.; Muñoz, M.; Muñoz-Antón, J.; Ortega, G.; Varela, F. Comparison of different technologies for integrated solar combined cycles: Analysis of concentrating technology and solar integration. Energies 2018, 11, 1064. [Google Scholar] [CrossRef]

- Hou, F.; Guo, Y.; Wu, W.; Yan, Z.; Wang, J. Thermodynamic Analysis and Optimization of a Solar-Powered Organic Rankine Cycle with Compound Parabolic Collectors. J. Energy Eng. 2020, 146, 04020067. [Google Scholar] [CrossRef]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to conduct a bibliometric analysis: An overview and guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Harzing, A.W. The Publish or Perish Book, 1st ed.; Tarma Software Research Pty Ltd.: Melbourn, Australia, 2010; ISBN 9780980848502. [Google Scholar]

- MacMillan, D. Mendeley: Teaching Scholarly Communication and Collaboration through Social Networking. In Proceedings of the IATUL Conferences, Singapore, 4–7 June 2012; Available online: https://docs.lib.purdue.edu/iatul/2012/papers/37 (accessed on 12 May 2025).

- van Eck, N.J.; Waltman, L. VOSviewer Manual. Univeristeit Leiden. 2023. Available online: http://www.vosviewer.com/documentation/Manual_VOSviewer_1.6.1.pdf (accessed on 12 May 2025).

- Liao, H.; Tang, M.; Luo, L.; Li, C.; Chiclana, F.; Zeng, X.-J. A Bibliometric Analysis and Visualization of Medical Big Data Research. Sustainability 2018, 10, 166. [Google Scholar] [CrossRef]

- Islam, M.T.; Huda, N.; Abdullah, A.B.; Saidur, R. A comprehensive review of state-of-the-art concentrating solar power (CSP) technologies: Current status and research trends. Renew. Sustain. Energy Rev. 2018, 91, 987–1018. [Google Scholar] [CrossRef]

- Alie, C.; Backham, L.; Croiset, E.; Douglas, P.L. Simulation of CO2 capture using MEA scrubbing: A flowsheet decomposition method. Energy Convers. Manag. 2005, 46, 475–487. [Google Scholar] [CrossRef]

- Kribus, A.; Zaibel, R.; Carey, D.; Segal, A.; Karni, J. A solar-driven combined cycle power plant. Solar Energy 1998, 62, 121–129. [Google Scholar] [CrossRef]

- Bolland, O.; Mathieu, P. Comparison of two CO2 removal options in combined cycle power plants. Energy Convers. Manag. 1998, 39, 1653–1663. [Google Scholar] [CrossRef]

- Bolland, O.; Undrum, H. A novel methodology for comparing CO2 capture options for natural gas-fired combined cycle plants. Adv. Environ. Res. 2003, 7, 901–911. [Google Scholar] [CrossRef]

- Bianchi, M.; Cordella, M. Does circular economy mitigate the extraction of natural resources. Empirical evidence based on analysis of 28 European economies over the past decade. Ecol. Econ. 2022, 203, 107607. [Google Scholar] [CrossRef]

- Behar, O.; Khellaf, A.; Mohammedi, K.; Ait-Kaci, S. A Review of Integrated Solar Combined Cycle System (ISCCS) with a Parabolic Trough Technology; Elsevier Ltd.: Amsterdam, The Netherlands, 2014. [Google Scholar] [CrossRef]

- Mokhtar, M.; Ali, M.T.; Khalilpour, R.; Abbas, A.; Shah, N.; Al Hajaj, A.; Armstrong, P.; Chiesa, M.; Sgouridis, S. Solar-assisted Post-Combustion Carbon Capture feasibility study. Appl. Energy 2012, 92, 668–676. [Google Scholar] [CrossRef]

- Biliyok, C.; Yeung, H. Evaluation of natural gas combined cycle power plant for post-combustion CO2 capture integration. Int. J. Greenh. Gas. Control 2013, 19, 396–405. [Google Scholar] [CrossRef]

- Sipöcz, N.; Tobiesen, F.A. Natural Gas Combined Cycle Power Plants with CO2 Capture—Opportunities to Reduce Cost; Elsevier Ltd.: Amsterdam, The Netherlands, 2012. [Google Scholar] [CrossRef]

- Li, H.; Yan, J.; Campana, P.E. Feasibility of integrating solar energy into a power plant with amine-based chemical absorption for CO2 capture. Int. J. Greenh. Gas. Control 2012, 9, 272–280. [Google Scholar] [CrossRef]

- Mokheimer, E.M.A.; Dabwan, Y.N.; Habib, M.A. Optimal integration of solar energy with fossil fuel gas turbine cogeneration plants using three different CSP technologies in Saudi Arabia. Appl. Energy 2017, 185, 1268–1280. [Google Scholar] [CrossRef]

- Zhao, Y.; Hong, H.; Zhang, X.; Jin, H. Integrating mid-temperature solar heat and post-combustion CO 2-capture in a coal-fired power plant. Sol. Energy 2012, 86, 3196–3204. [Google Scholar] [CrossRef]

- Akram, M.; Ali, U.; Best, T.; Blakey, S.; Finney, K.N.; Pourkashanian, M. Performance evaluation of PACT Pilot-plant for CO2 capture from gas turbines with Exhaust Gas Recycle. Int. J. Greenh. Gas. Control 2016, 47, 137–150. [Google Scholar] [CrossRef]

- Botero, C.; Finkenrath, M.; Bartlett, M.; Chu, R.; Choi, G.; Chinn, D. Redesign, Optimization, and Economic Evaluation of a Natural Gas Combined Cycle with the Best Integrated Technology CO2 Capture. Energy Procedia 2009, 1, 3835–3842. [Google Scholar] [CrossRef]

- Wang, F.; Li, H.; Zhao, J.; Deng, S.; Yan, J. Technical and economic analysis of integrating low-medium temperature solar energy into power plant. Energy Convers. Manag. 2016, 112, 459–469. [Google Scholar] [CrossRef]

- Qadir, A.; Mokhtar, M.; Khalilpour, R.; Milani, D.; Vassallo, A.; Chiesa, M.; Abbas, A. Potential for solar-assisted post-combustion carbon capture in Australia. Appl. Energy 2013, 111, 175–185. [Google Scholar] [CrossRef]

- Wibberley, L. CO2 Capture Using Solar Thermal Energy. U.S. Patent 20100005966A1, 14 January 2010. [Google Scholar]

- Parvareh, F.; Sharma, M.; Qadir, A.; Milani, D.; Khalilpour, R.; Chiesa, M.; Abbas, A. Integration of solar energy in coal-fired power plants retrofitted with carbon capture: A review. Renew. Sustain. Energy Rev. 2014, 38, 1029–1044. [Google Scholar] [CrossRef]

- Wang, F.; Zhao, J.; Li, H.; Deng, S.; Yan, J. Preliminary experimental study of post-combustion carbon capture integrated with solar thermal collectors. Appl. Energy 2017, 185, 1471–1480. [Google Scholar] [CrossRef]

- Carapellucci, R.; Giordano, L.; Vaccarelli, M. Analysis of CO2 post-combustion capture in coal-fired power plants integrated with renewable energies. Energy Procedia 2015, 82, 350–357. [Google Scholar] [CrossRef]

- Zhai, R.; Qi, J.; Zhu, Y.; Zhao, M.; Yang, Y. Novel system integrations of 1000 MW coal-fired power plant retrofitted with solar energy and CO2 capture system. Appl. Therm. Eng. 2017, 125, 1133–1145. [Google Scholar] [CrossRef]

- Alzhrani, A.; Romero, C.E.; Baltrusaitis, J. Sustainability assessment of a solar energy-assisted flue gas amine-based CO2 capture process using fully dynamic process models. ACS Sustain. Chem. Eng. 2023, 11, 11385–11398. [Google Scholar] [CrossRef]

- Ordorica-Garcia, G.; Delgado, A.V.; Garcia, A.F. Novel integration options of concentrating solar thermal technology with fossil-fuelled and CO2 capture processes. Energy Procedia 2011, 4, 809–816. [Google Scholar] [CrossRef]

- Al-Elanjawy, Y.A.H.; Yilmaz, M. Solar-assisted carbon capture process integrated with a natural gas combined cycle (NGCC) power plant—A simulation-based study. Processes 2024, 12, 613. [Google Scholar] [CrossRef]

- Li, H.; Holger, N.; Nugroho, T.; Mahieux, C. Power Plant with CO.SUB.2 Capture. U.S. Patent 8365537-B2, 5 February 2013. [Google Scholar]

- Gulen, S.C. Gas Turbine Combined Cycle Optimized for Post-Combustion CO2 Capture. U.S. Patent 10,641,173 B2, 5 May 2020. Available online: https://patentcenter.uspto.gov/applications/15142783 (accessed on 25 April 2025).

- Undrum, H.; Bolland, O.; Aarebrot, E. Economical assessment of natural gas fired combined cycle power plant with CO2 capture and sequestration. In Proceedings of the Fifth Greenhouse Gas Technologies Conference, Cairns, Australia, 13–16 August 2000; Durie, R.A., McMullan, P., Smith, A.Y., Williams, D.J., Eds.; CSIRO: Cairns, Australia, 2000; pp. 132–137. [Google Scholar] [CrossRef]

- Sander, F.; Carroni, R.; Rofka, S.; Benz, E. Flue Gas Recirculation in A Gas Turbine: Impact on Performance and Operational Behavior. In Proceedings of the ASME 2011 Turbo Expo: Turbine Technical Conference and Exposition, Vancouver, BC, Canada, 6–10 June 2011; ASME: New York, NY, USA, 2011; pp. 123–132. [Google Scholar] [CrossRef]

- Canepa, R.; Wang, M.; Biliyok, C.; Satta, A. Thermodynamic analysis of combined cycle gas turbine power plant with postcombustion CO2 capture and exhaust gas recirculation. Proc. Inst. Mech. Eng. Part. E J. Process Mech. Eng. 2013, 227, 89–105. [Google Scholar] [CrossRef]

- Moore, R.M. Solar-Gas Combined Cycle Electrical Generating System. U.S. Patent 5,444,972, 29 August 1995. [Google Scholar]

- NREL. Concentrating Solar Power Projects. ISCC Ain Beni Mathar CSP Project; 2011. Available online: https://solarpaces.nrel.gov/project/iscc-ain-beni-mathar (accessed on 18 October 2025).

- NREL. Concentrating Solar Power Projects ISCC Kuraymat CSP Project. 2014. Available online: https://solarpaces.nrel.gov/project/iscc-kuraymat (accessed on 18 October 2025).

- Pak, P.S.; Hatikawa, T.; Suzuki, Y. A hybrid power generation system utilizing solar thermal energy with CO2 recovery based on oxygen combustion method. Energy Convers. Manag. 1995, 36, 823–826. [Google Scholar] [CrossRef]

- Williams, T.A.; Mark, S.B.; Henry, W.P. Solar Thermal Electric Hybridization Issues. Maui; March 1995. Available online: https://www.nrel.gov/docs/legosti/old/7019.pdf (accessed on 23 April 2025).

- Bohn, M.; Williams, T.A.; Price, H.W. Combined-Cycle Power Tower. In Proceedings of the ASME/JSME International Solar Energy Conference, San Francisco, CA, USA, 27–30 March 1994; ASME: New York, NY, USA, 1994; pp. 597–606. [Google Scholar]

- Pak, P.S.; Suzuki, Y.; Kosugi, T. A CO2-capturing hybrid power-generation system with highly efficient use of solar thermal energy. Energy 1997, 22, 295–299. [Google Scholar] [CrossRef]

- Kelly, B.; Herrmann, U.; Hale, M.J. Optimization Studies for Integrated Solar Combined Cycle Systems. In Proceedings of the ASME 2001 Solar Engineering: International Solar Energy Conference (FORUM 2001: Solar Energy—The Power to Choose), Washington, DC, USA, 21–25 April 2001; pp. 393–398. [Google Scholar] [CrossRef]

- Gunasekaran, S.; Mancini, N.D.; El-Khaja, R.; Sheu, E.J.; Mitsos, A. Solar–thermal hybridization of advanced zero emissions power cycle. Energy 2014, 65, 152–165. [Google Scholar] [CrossRef]

- Gelowitz, D.; Kritpiphat, W.; Tontiwachwuthikul, P. Cogeneration concepts for CO2 separation from power plants for enhanced oil recovery applications. Energy Convers. Manag. 1995, 36, 563–566. [Google Scholar] [CrossRef]

- EIA Greenhouse Gas R&D Programme (IEA GHG) “CO2 Capture ready plants” 2007/4. May 2007. Available online: https://publications.ieaghg.org/technicalreports/2007-04%20CO2%20Capture%20Ready%20Power%20Plants.pdf (accessed on 12 April 2025).

- Leduc, J.; Mottaghi, M.; Moran-Gonzalez, D.; Sigler, E.; Mahé, H.; Castel, J. Integration of a carbon capture-ready cogeneration plant: From requirements to design, facilities optimization and energy efficiency opportunities. Energy Procedia 2011, 4, 2432–2439. [Google Scholar] [CrossRef]

- Jordán, P.S.; Eduardo, A.M.J.; Zdzislaw, M.C.; Martín, Z.G.A.; Liborio, H.P.; Antonio, F.Z.J.; Román, D.G.M. Techno-economic analysis of solar-assisted post-combustion carbon capture to a pilot cogeneration system in Mexico. Energy 2019, 167, 1107–1119. [Google Scholar] [CrossRef]

- Born, K. Exploring the spatial dynamics of circular economy transitions: Insights and lessons from Chile’s mining territories. Prog. Econ. Geogr. 2025, 3, 100041. [Google Scholar] [CrossRef]

- Ma, L.; Ghorbani, Y.; Kongar-Syuryun, C.B.; Khayrutdinov, M.M.; Klyuev, R.V.; Petenko, A.; Brigida, V. Dynamics of backfill compressive strength obtained from enrichment tails for the circular waste management. Resour. Conserv. Recycl. Adv. 2024, 23, 200224. [Google Scholar] [CrossRef]

| # | Article Title | Journal | Accumulated Citations |

|---|---|---|---|

| 1 | A comprehensive review of state-of-the-art concentrating solar power (CSP) technologies: Current status and research trends [42] | Renewable and Sustainable Energy Reviews | 992 |

| 2 | Simulation of CO2 capture using MEA scrubbing: A flowsheet decomposition method [43] | Energy Conversion and Management | 477 |

| 3 | Historical development of concentrating solar power technologies to generate clean electricity efficiently—A review [32] | Renewable and Sustainable Energy Reviews | 459 |

| 4 | A solar-driven combined cycle power plant [44] | Solar energy | 293 |

| 5 | Comparison of two CO2 removal options in combined cycle power plants [45] | Energy Conversion and Management | 273 |

| 6 | A review of concentrated solar power hybrid technologies [34] | Applied Thermal Engineering | 218 |

| 7 | A novel methodology for comparing CO2 capture options for natural gas-fired combined cycle plants [46] | Advances in Environmental Research | 206 |

| 8 | Does circular economy mitigate the extraction of natural resources? Empirical evidence based on analysis of 28 European economies over the past decade [47] | Ecological Economics | 189 |

| 9 | A review of integrated solar combined cycle system (ISCCS) with a parabolic trough technology [48] | Renewable and Sustainable Energy Reviews | 180 |

| 10 | Solar-assisted Post-Combustion Carbon Capture feasibility study [49] | Applied Energy | 160 |

| 11 | Evaluation of natural gas combined cycle power plant for post-combustion CO2 capture integration [50] | International Journal of Greenhouse Gas Control | 134 |

| 12 | An integrated combined cycle system driven by a solar tower: A review [31] | Renewable and Sustainable Energy Reviews | 131 |

| 13 | Natural gas combined cycle power plants with CO2 capture—Opportunities to reduce cost [51] | International Journal of Greenhouse Gas Control | 112 |

| 14 | Feasibility of integrating solar energy into a power plant with amine-based chemical absorption for CO2 capture [52] | International Journal of Greenhouse Gas Control | 111 |

| 15 | Optimal integration of solar energy with fossil fuel gas turbine cogeneration plants using three different CSP technologies in Saudi Arabia [53] | Applied Energy | 104 |

| 16 | Integrating mid-temperature solar heat and post-combustion CO2-capture in a coal-fired power plant [54] | Solar Energy | 98 |

| 17 | Performance evaluation of PACT Pilot-plant for CO2 capture from gas turbines with Exhaust Gas Recycle [55] | International Journal of Greenhouse Gas Control | 92 |

| 18 | Redesign, Optimization, and Economic Evaluation of a Natural Gas Combined Cycle with the Best Integrated Technology CO2 Capture [56] | Energy Procedia | 85 |

| 19 | Technical and economic analysis of integrating low-medium temperature solar energy into power plant [57] | Energy Conversion and Management | 79 |

| 20 | Potential for solar-assisted post-combustion carbon capture in Australia [58] | Applied Energy | 78 |

| Refs. | Technologies | Total Gross Power [kWe] | Efficiency [%] | CO2 Emission [tons/yr] | LCOE USD/MWh | Solvent | Solar Thermal Heat Input | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CPP | PCC | PTC | LFC | SPT | EGR | SSF | TES | |||||||

| [58] Qadir, et al. | X | 660,000 | 30 | 4,430,370 | ||||||||||

| X | X | 621,000 | 24 | 443,037 | MEA | |||||||||

| [57] Wang et al. | X | 299,800 | 37.50 | 2,476,552 | ||||||||||

| X | X | 312,740 | 39.22 | 2,368,151 | LP feedwater preheaters | |||||||||

| X | X | 343,000 | 43.23 | 2,148,330 | HP feedwater preheaters as shown | |||||||||

| X | X | 379,800 | 48.11 | 1,930,557 | To Steam turbine | |||||||||

| X | X | X | 299,760 | 34.15 | 271,935 | MEA | to the striper reboiler | |||||||

| X | X | X | 254,910 | 28.20 | 329,264 | MEA | LP feedwater preheaters | |||||||

| X | X | X | 292,400 | 33.17 | 279,942 | MEA | HP feedwater preheaters | |||||||

| X | X | X | 329,250 | 38.06 | 244,000 | MEA | To Steam turbine | |||||||

| [63] Zhai et al. | X | 1000,000 | 48.95 | 6,689,249 | 34.94 | |||||||||

| X | X | 1057,850 | 51.78 | 6,689,249 | 39.41 | |||||||||

| X | X | 839,500 | 41.10 | 1,337,850 | 66.10 | MEA | ||||||||

| X | X | X | 896,670 | 43.89 | 1,337,850 | 70.94 | MEA | HP feedwater preheaters as | ||||||

| X | X | X | 878,500 | 43.01 | 1,337,850 | 71.49 | MEA | to the striper reboiler | ||||||

| X | X | X | 886,900 | 43.42 | 1,337,850 | 71.23 | MEA | HP feedwater preheaters and striper reboiler | ||||||

| [64] Li et al. | X | 520,000 (Net Power) | 44.5 | 2,769,562 | 42.9 | |||||||||

| X | X | 408,000 | 34.9 | 414,593 | 70.9 | |||||||||

| X | X | X | X | 450,600 | 37.1 | 414,593 | 71.2 | to the striper reboiler | ||||||

| X | X | X | X | 482,000 | 41.5 | 414,593 | 79.8 | to the striper reboiler | ||||||

| X | X | X | X | 482,000 | 44.5 | 414,593 | 87.2 | to the striper reboiler | ||||||

| Refs. | Technologies | Total Gross Power [kWe] | Efficiency [%] | CO2 Emission [tons/yr] * | LCOE USD/MWh | Solvent | HTF | SC | Solar Thermal Heat Input | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NGCC | PCC | PTC | LFC | SPT | EGR | SSFC | TES | |||||||||

| [10] Bravo et al. | X | 547,874 | 49.7 | 1,452,281 | ||||||||||||

| X | X | 485,861 | 41.3 | 145,262 | MEA | |||||||||||

| X | X | X | 547,923 | 46.8 | 145,262 | 45.7 | MEA | Dowtherm Q | PTC, Siemens SunField 6 | to the striper reboiler | ||||||

| [66] Elanjawy and M. Yilmaz | X | 751,340 | 49.8 | 2,119,318 | ||||||||||||

| X | X | X | 751,340 | 48.0 | 18,064 | 18 | MEA | Dowtherm Q | PTC, Siemens SunField 6 | to the striper reboiler | ||||||

| [69] Undrum et al. | X | 400 000 | 58 | 363 g/kWh | ||||||||||||

| X | X | 338 000 | 49 | 60 g/kWh | 90 | MEA | ||||||||||

| [56] Botero et al. | X | 413 000 | 50.71 | 363 g/kWh | ||||||||||||

| X | X | 367 000 | 50 | 60 g/kWh | 80 | MEA | ||||||||||

| [50] Biliyok and Yeung | X | 440,600 | 59.62 | 354.5 (kg CO2/MWh) | ||||||||||||

| X | X | 376,000 | 49.38 | 40.1 (kg CO2/MWh) | MEA | |||||||||||

| [43] Alie et al. | X | X | X | 386,100 | 50.71 | 39.5 (kg CO2/MWh) | MEA | |||||||||

| [13] Alcaraz et al. | X | X | 674,000 | 52.5 | MEA | |||||||||||

| X | X | x | 672,800 | 51 | MEA | |||||||||||

| [17] González et al. | X | 835,000 | 51.3 | |||||||||||||

| X | X | 840,000 | 43.1 | |||||||||||||

| X | X | X supercritical | 884,000 | 45.6 | MEA | |||||||||||

| X | X | X subcritical | 834,000 | 43.1 | MEA | |||||||||||

| CE Lever (Example) | Sector (s) | Mechanism | Primary Metric (s) | Interaction with Solar-Assisted PCC |

|---|---|---|---|---|

| Slag-based cement substitution in mine backfill | Steel → Mining | Avoided clinker production | Substitution ratio (%), kg clinker avoided·t−1, Δembodied CO2 (kgCO2·t−1) | Lowers life-cycle CO2; improves avoided-CO2 cost when credited |

| Reuse of waste heat in pre-processing | Mining | Thermal offset | kWhth·t−1, Δfuel | Reduces auxiliary loads; may downsize solar field |

| Solvent/amine reclaim via circular reagent loops | Power/CCS | Closed-loop chemicals | % solvent recovered, waste reduction | Cuts OPEX; lowers environmental footprint |

| Refs. | Technologies | Total Gross Power [kWe] | Efficiency [%] | CO2 Emission [tons/yr] | Solvent | Solar Thermal Heat Input | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CHP | PCC | PTC | LFC | SPT | EGR | SSFC | TES | ||||||

| [81] Gelowitz et al. | X | X | 5929 | 39.81 | 23,824.28 | MEA | |||||||

| X | X | 12,546 | 40.23 | 49,888.565 | MEA | ||||||||

| X | X | 18,832 | 40.53 | 9016.96 | MEA | ||||||||

| X | X | 28,974 | 43.78 | 105,879.2 | MEA | ||||||||

| X | X | 61,887 | 41.46 | 238,776.43 | MEA | ||||||||

| [83] Leduc et al. | X | X | 150,000 | 55.0 | MEA | ||||||||

| [53] Mokheimer et al. | X | X | 150,000 | 32.7 | 706,300.00 | To process | |||||||

| X | X | 150,000 | 32.7 | 709,900.00 | To process | ||||||||

| X | X | 150,000 | 32.7 | 288,800.00 | To Gas Turbine | ||||||||

| [84] Jordan et al. | X | X | X | 146.3 | 50.7 | 1025.05 | MEA | to the striper reboiler | |||||

| [11] Alcaraz et al. | X | 511,800 | 80.07 | 1,997,254 | MEA | ||||||||

| X | X | 511,800 | 72.86 | 252,743 | MEA | ||||||||

| X | X | X | 511,800 | 80.18 | 229,593 | MEA | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alcaraz Calderón, A.M.; Jaramillo, O.A.; Garcia, J.C.; Navarrete Procopio, M.; González Díaz, A. Integrating Solar Energy into Fossil Fuel Power Plant with CO2 Capture and Storage: A Bibliographic Survey. Processes 2025, 13, 3581. https://doi.org/10.3390/pr13113581

Alcaraz Calderón AM, Jaramillo OA, Garcia JC, Navarrete Procopio M, González Díaz A. Integrating Solar Energy into Fossil Fuel Power Plant with CO2 Capture and Storage: A Bibliographic Survey. Processes. 2025; 13(11):3581. https://doi.org/10.3390/pr13113581

Chicago/Turabian StyleAlcaraz Calderón, Agustín Moisés, O. A. Jaramillo, J. C. Garcia, Miriam Navarrete Procopio, and Abigail González Díaz. 2025. "Integrating Solar Energy into Fossil Fuel Power Plant with CO2 Capture and Storage: A Bibliographic Survey" Processes 13, no. 11: 3581. https://doi.org/10.3390/pr13113581

APA StyleAlcaraz Calderón, A. M., Jaramillo, O. A., Garcia, J. C., Navarrete Procopio, M., & González Díaz, A. (2025). Integrating Solar Energy into Fossil Fuel Power Plant with CO2 Capture and Storage: A Bibliographic Survey. Processes, 13(11), 3581. https://doi.org/10.3390/pr13113581