Experimental Study on Stress Sensitivity in Fractured Tight Conglomerate Reservoirs

Abstract

1. Introduction

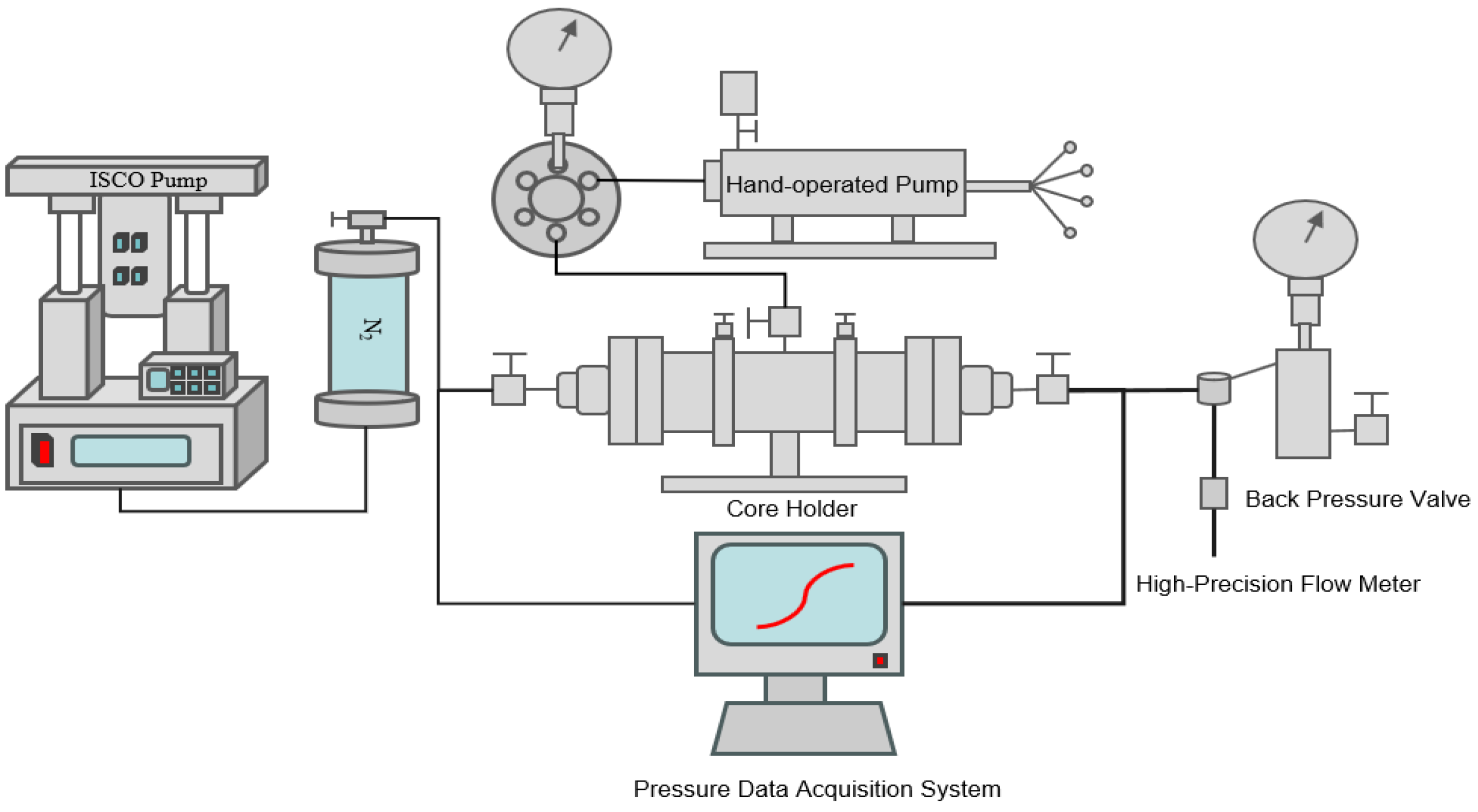

2. Materials and Methods

2.1. Instruments and Materials

2.2. Experimental Methods

3. Results

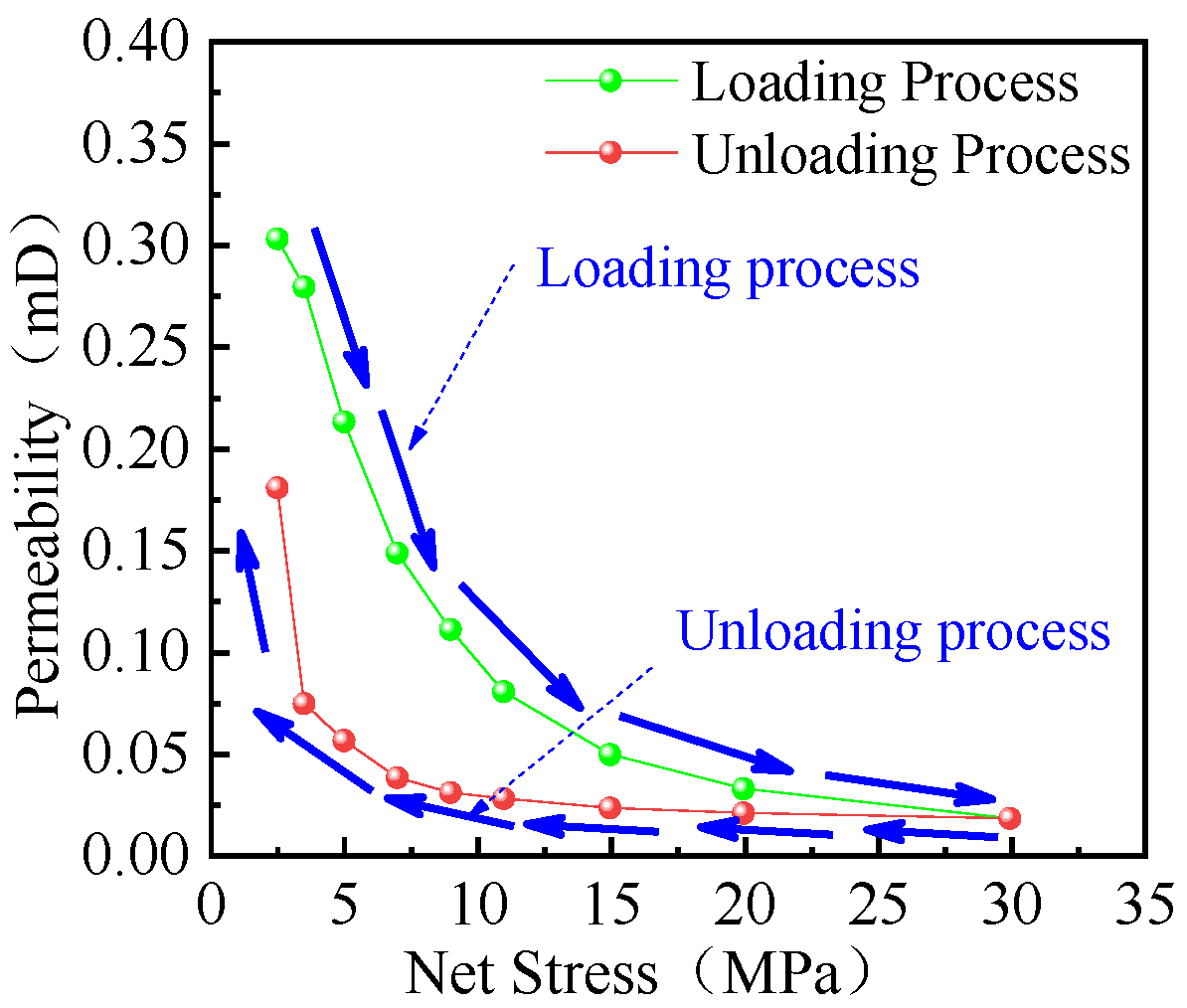

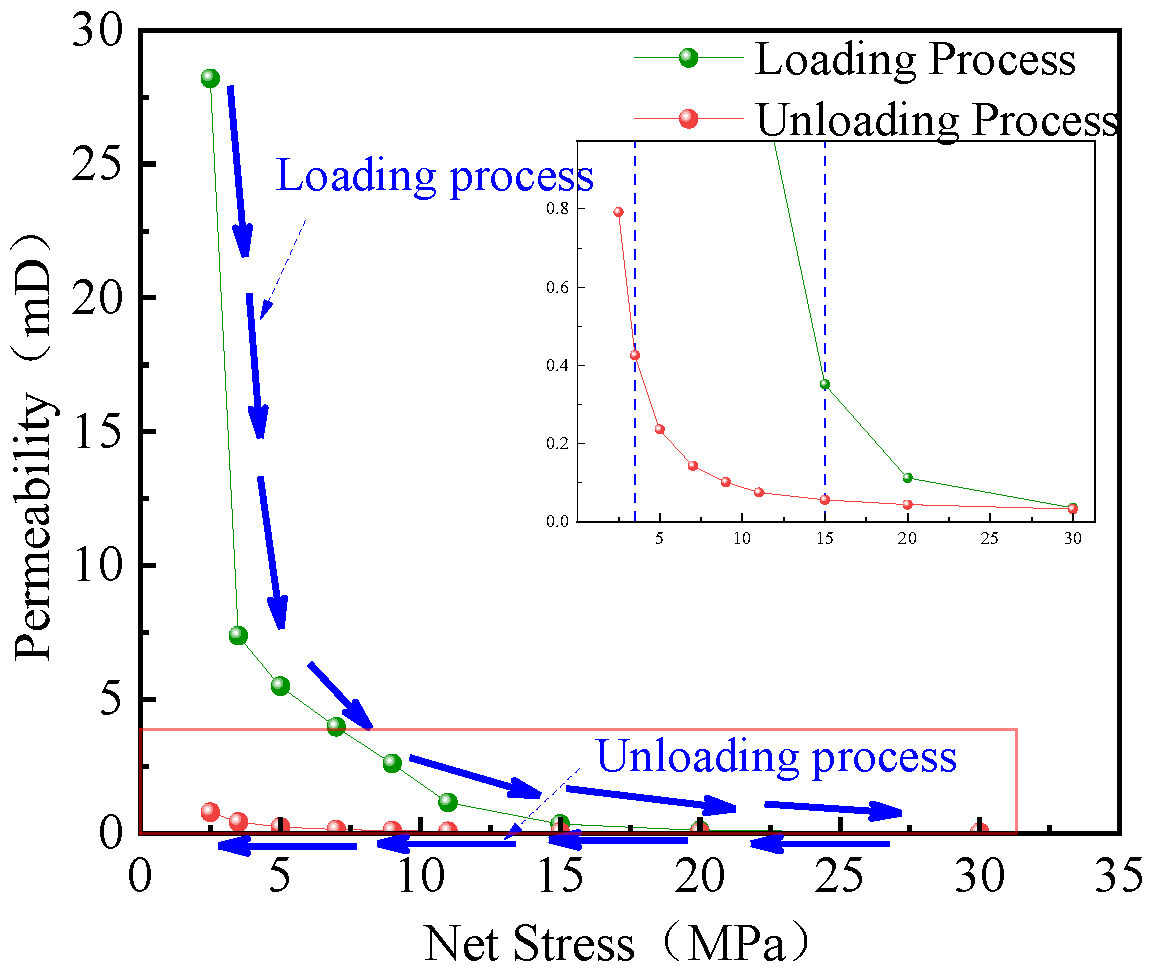

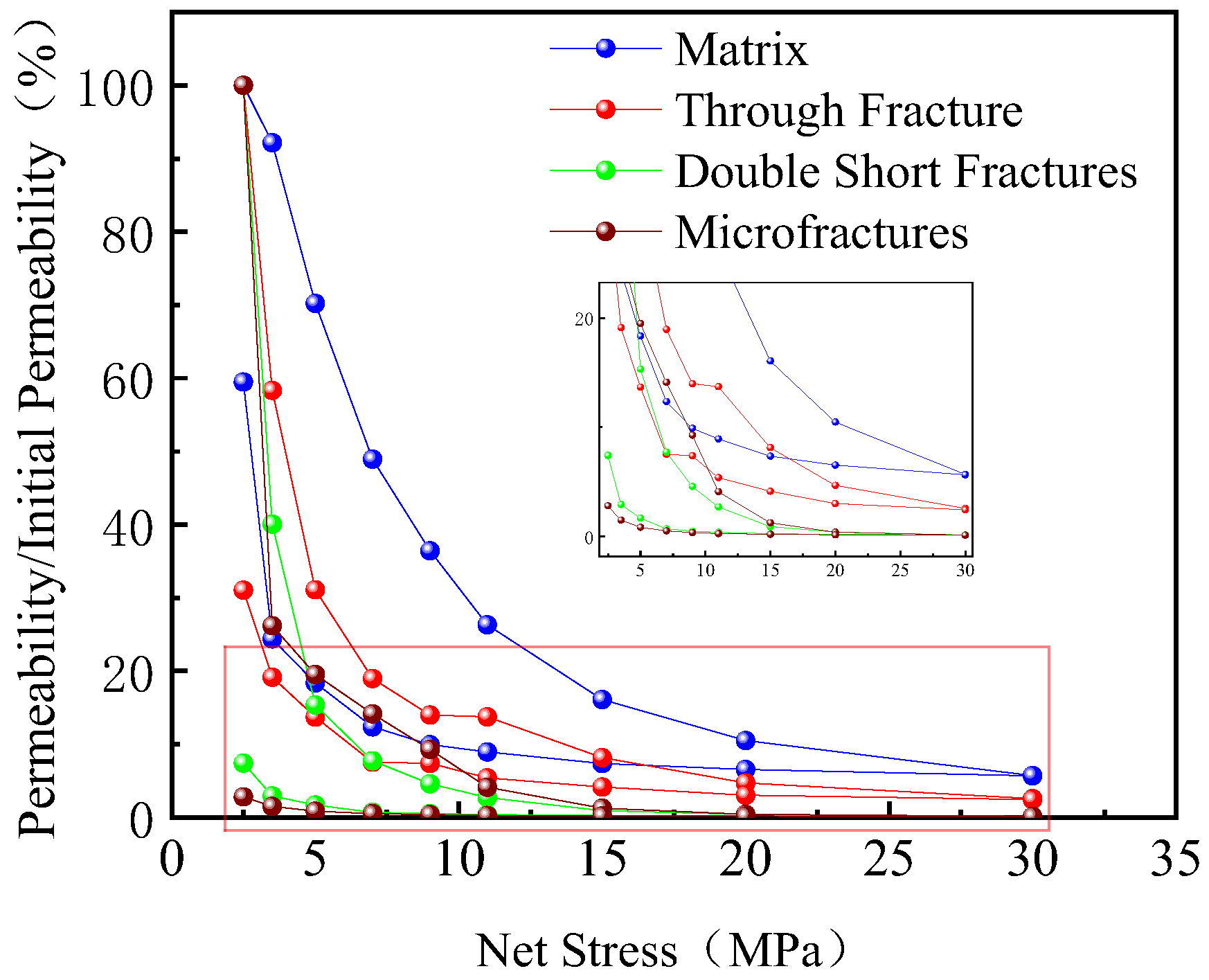

3.1. Stress Sensitivity of Cores Under Various Fracture Morphologies

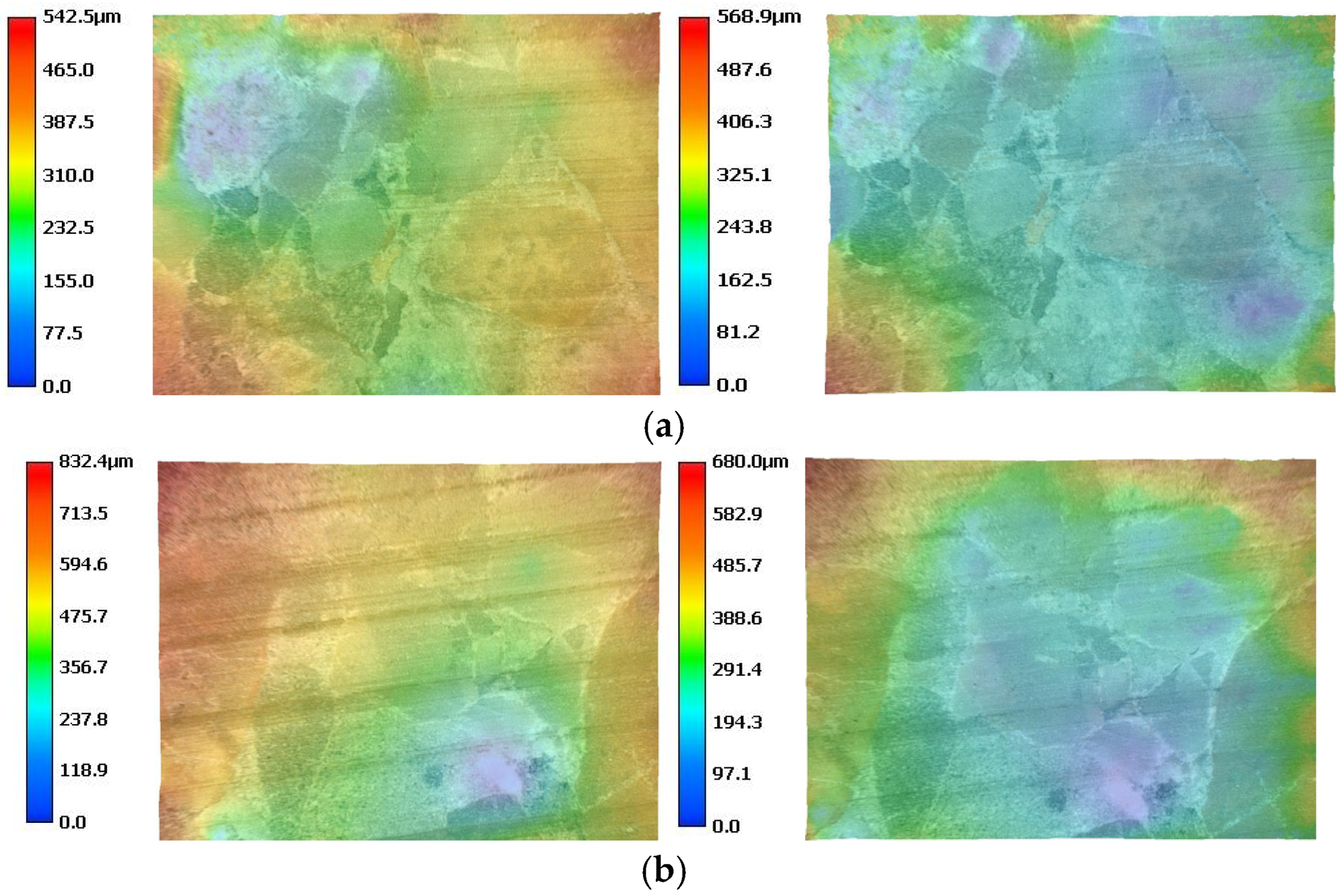

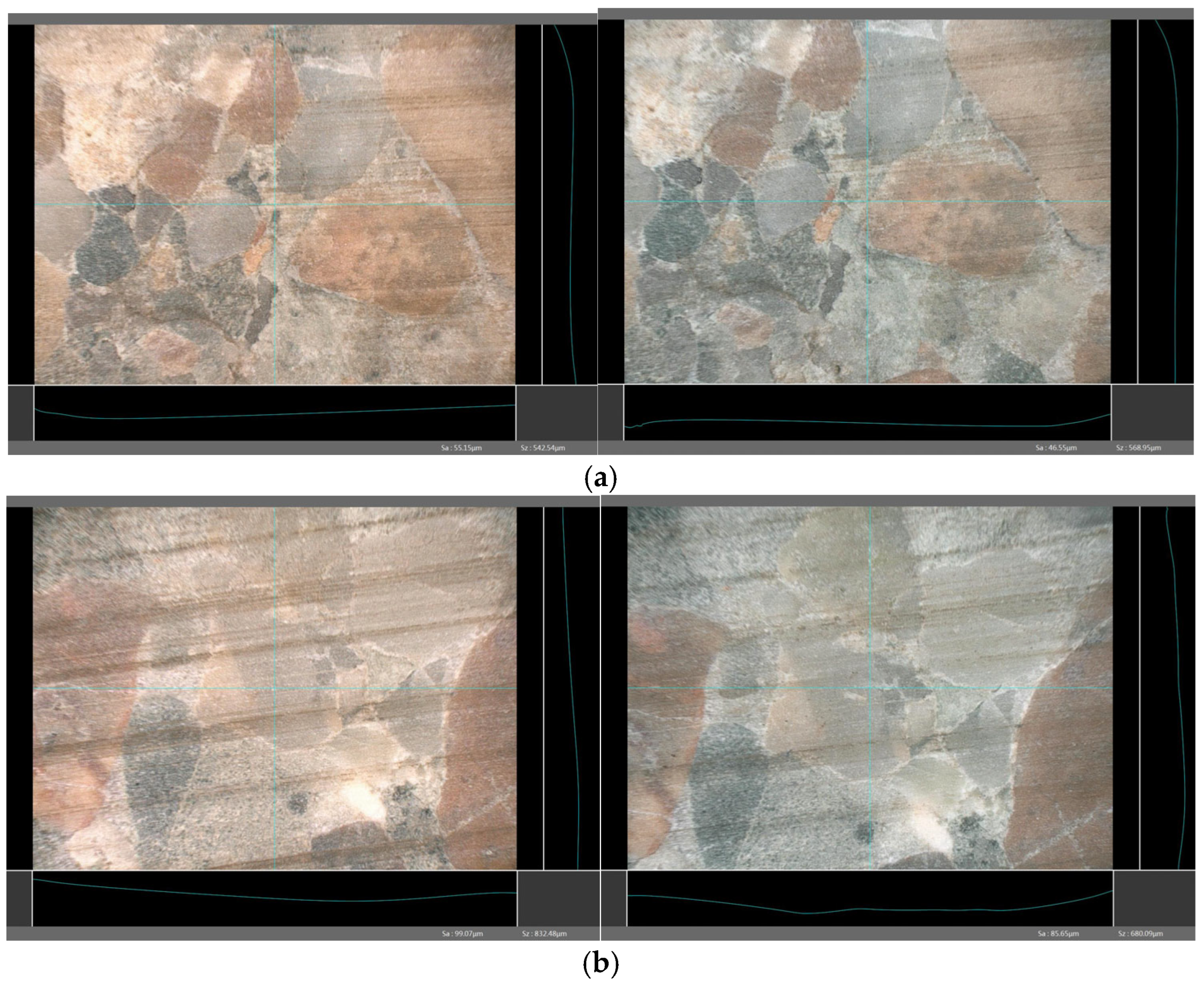

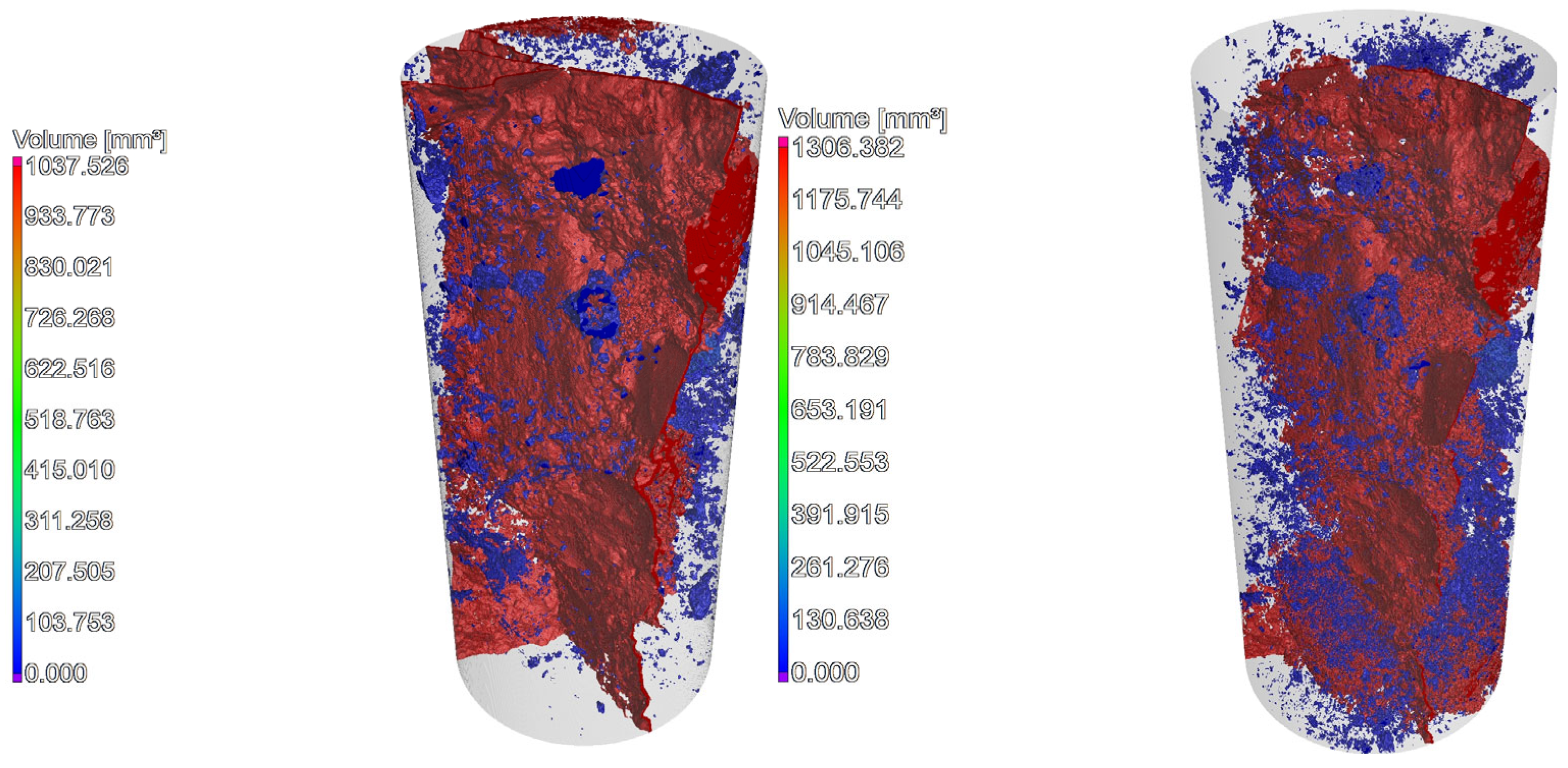

3.2. Measurement of Fracture Surface Damage in Cores Under Different Fracture Types

4. Conclusions

- (1)

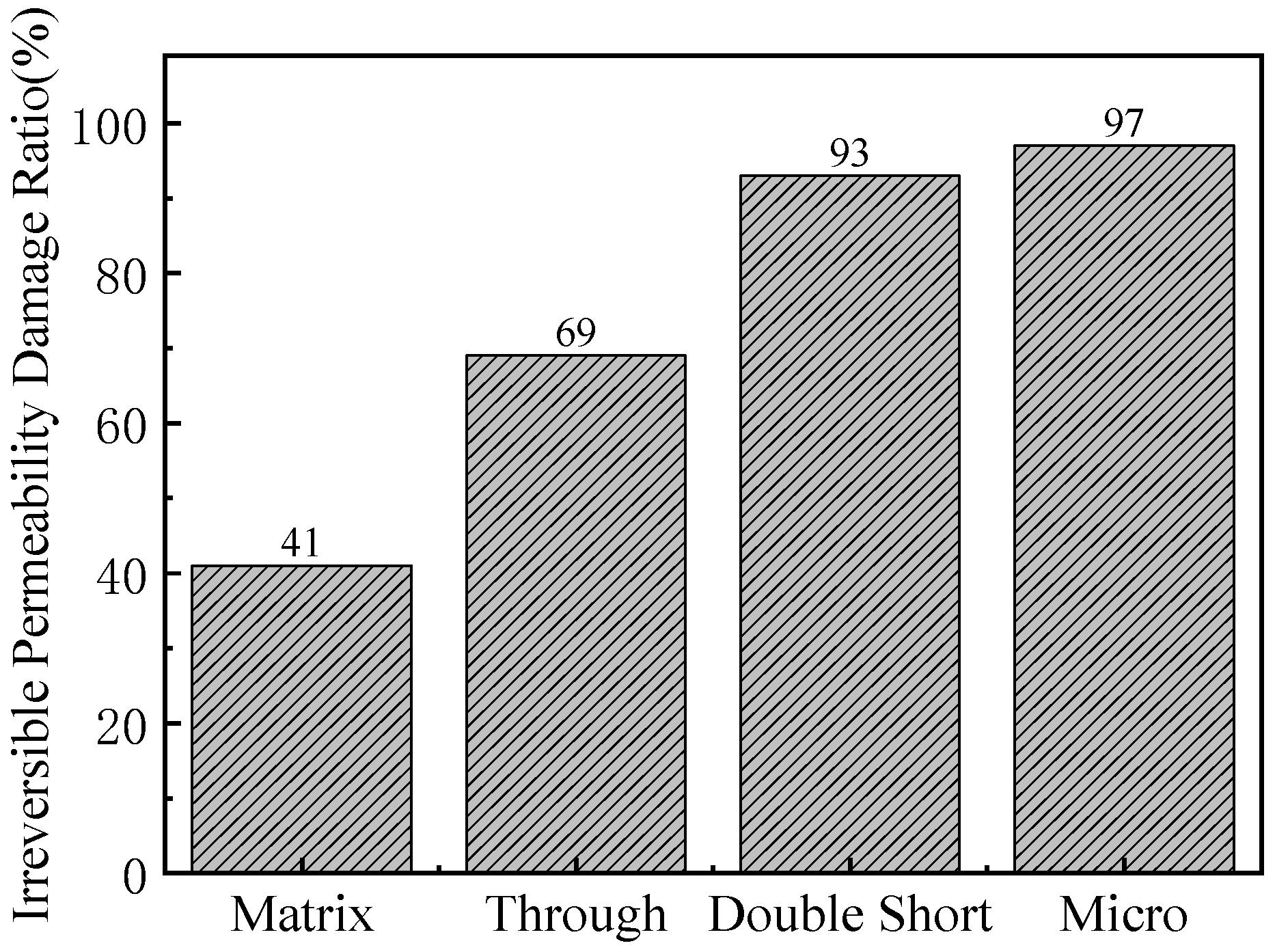

- The irrecoverable permeability damage of matrix cores from the Mahu tight conglomerate reservoir reaches 41%, while that of tight sandstone matrix cores from the Ordos Basin is 46.4%, indicating comparable stress sensitivity between the two lithologies. In the presence of fractures, the irrecoverable permeability damage of through-fracture, double-short-fracture, and micro-fracture cores increases to 69%, 93%, and 97%, respectively—representing 28–56% higher damage than that of matrix cores. These results indicate that fractures significantly amplify the stress sensitivity of tight reservoirs, and the degree of sensitivity increases with fracture complexity.

- (2)

- During the loading stage, permeability reduction mainly results from fracture closure and matrix compaction. In the early stage of unloading, fractures cannot reopen immediately with decreasing net stress, and the recovery of matrix pore structure remains limited, leading to a slow permeability recovery rate. As fractures gradually reopen and the matrix pores partially recover, permeability recovery accelerates. Despite high permeability loss, the final permeability of through-fracture, double-short-fracture, and micro-fracture cores—20.05 mD, 2.02 mD, and 0.79 mD, respectively—remains higher than the initial matrix permeability of 0.31 mD, confirming that fractures substantially enhance flow capacity even after stress-induced damage.

- (3)

- With increasing fracture development, the superimposed closure of multiple fractures, combined with pore collapse and clay mineral migration, causes severe structural degradation and increased permeability damage. For micro-fractured cores, porosity decreases from 6.48% to 5.93% after loading, suggesting that although secondary fractures are generated, reduced fracture connectivity is the dominant factor controlling flow capacity loss.

- (4)

- From an engineering perspective, maintaining an appropriate production pressure differential is critical for tight conglomerate reservoir development. Excessively low pressure differentials limit elastic energy release, while overly high differentials exacerbate permeability damage and hinder subsequent stimulation. During hydraulic fracturing, uniform proppant placement is essential to prevent premature fracture closure and mitigate permeability loss associated with high fracture stress sensitivity.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Qin, D.; Jiang, S. Adsorption behavior of different components of a polymer/surfactant composite control system along an injection-production channel in sand conglomerate reservoirs. ACS Omega 2024, 9, 40665–40675. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Xu, J.; Zhang, X.; Wang, R.; Zhang, L.; Li, H. Xinjiang Oilfield strong water-sensitive conglomerate reservoir CO2 flooding connectivity characteristics. Xinjiang Pet. Nat. Gas 2024, 20, 44–51. [Google Scholar] [CrossRef]

- Akram, M.S.; Sharrock, G.B.; Mitra, R. Investigating mechanics of conglomeratic rocks: Influence of clast size distribution, scale and properties of clast and interparticle cement. Bull. Eng. Geol. Environ. 2019, 78, 2769–2788. [Google Scholar] [CrossRef]

- Zhu, Y.; Deng, Y.; Qin, J.; Zhang, J.; Zou, Y.; Zhang, S.; Liu, S. Fracture propagation mechanism of tight conglomerate reservoirs in Mahu Sag. Processes 2023, 11, 1958. [Google Scholar] [CrossRef]

- Wang, S.; Zhong, W.; Chen, J.; Liu, H.; Wang, R.; Liu, J. Study of the effect of mineral components on the permeability impairment rate and stress sensitivity factor of shale. Geofluids 2022, 2022, 4407252. [Google Scholar] [CrossRef]

- Kuang, H.; Liu, H.; Tan, X.; Yu, J.; Song, H.; Zhou, R.; Liu, F. Study on factors affecting the petrophysical properties of sandstone and conglomerate reservoirs of Baikouquan. Formation, Junggar Basin. Front. Earth Sci. 2023, 10, 1033344. [Google Scholar] [CrossRef]

- Tian, Y. Experimental study on stress sensitivity of naturally fractured reservoirs. In Proceedings of the SPE Annual Technical Conference and Exhibition, Amsterdam, The Netherlands, 27–29 October 2014; SPE: Richardson, TX, USA, 2014; p. SPE-173463-STU. [Google Scholar]

- Liu, Y.; Yu, P.; Ding, Z. Research on stress-sensitivity of fractured porous media. J. Pet. Sci. Eng. 2018, 171, 879–889. [Google Scholar] [CrossRef]

- Xiao, Y.; Liu, Y.; He, Y.; Wang, L.; Guo, B.; Li, G.; Du, Z. Impacts of mineralogy and pore structure on spontaneous imbibition in tight glutenite reservoirs. Geoenergy Sci. Eng. 2023, 227, 211943. [Google Scholar] [CrossRef]

- Wang, T.; Cheng, L.; Xiang, Y.; Cheng, N.; Wang, B.; Zhou, H. Numerical simulation of fracture propagation laws under the influence of gravel. Xinjiang Pet. Nat. Gas 2023, 19, 42–48. [Google Scholar] [CrossRef]

- Yan, J.; Fan, J.; Wang, M.; Li, Z.; Hu, Q.; Chao, J. Rock fabric and pore structure of the Shahejie sandy conglomerates from the Dongying depression in the Bohai Bay Basin, East China. Mar. Pet. Geol. 2018, 97, 624–638. [Google Scholar] [CrossRef]

- Smart, B.G.D.; Somerville, J.M.; Edlman, K.; Jones, C. Stress sensitivity of fractured reservoirs. J. Pet. Sci. Eng. 2001, 29, 29–37. [Google Scholar] [CrossRef]

- Sheng, M.; Jiang, F.; Hu, S.; Lü, Z.; Kong, M.; Si, L. Interpretation of in-situ stress and optimization of fracturing design in heterogeneous glutenite reservoirs. Xinjiang Pet. Nat. Gas 2024, 20, 1–10. [Google Scholar] [CrossRef]

- Liu, J.; Xian, B.; Wang, J.; Ji, Y.; Lu, Z.; Liu, S. Sedimentary architecture of a sub-lacustrine debris fan: Eocene Dongying Depression, Bohai Bay Basin, East China. Sediment. Geol. 2017, 362, 66–82. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, Q.; Ning, Z.; Zhang, R.; Huang, L.; Cheng, Z. Relationship between the stress sensitivity and pore structure of shale. J. Nat. Gas Sci. Eng. 2018, 59, 440–451. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Fan, X.; Hu, H.; Yang, X.; Li, M. Evaluation of stress sensitivity in tight sandstone–conglomerate reservoirs. China Offshore Oil Gas 2020, 32, 105–110. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, J.; Li, X.; Xiao, H.; Liu, X.; Rao, Y.; Ma, L. Influence of microcracks on stress sensitivity in tight sandstone. Lithosphere 2021, 2021, 7073494. [Google Scholar] [CrossRef]

- Cao, N.; Lei, G.; Dong, P.; Li, H.; Wu, Z.; Li, Y. Stress-dependent permeability of fractures in tight reservoirs. Energies 2018, 12, 117. [Google Scholar] [CrossRef]

- Moradi, M.; Shamloo, A.; Asadbegi, M.; Dezfuli, A.D. Three dimensional pressure transient behavior study in stress sensitive reservoirs. J. Pet. Sci. Eng. 2017, 152, 204–211. [Google Scholar] [CrossRef]

- Chen, D.; Pan, Z.; Ye, Z.; Hou, B.; Wang, D.; Yuan, L. A unified permeability and effective stress relationship for porous and fractured reservoir rocks. J. Nat. Gas Sci. Eng. 2016, 29, 401–412. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, X.; Yang, T.; Zhou, Z.; Luo, X.; Fan, J.; Gao, H. Stress sensitivity mechanism of pores in unconsolidated sandstone reservoir using NMR technology. Geoenergy Sci. Eng. 2024, 240, 212999. [Google Scholar] [CrossRef]

- Tan, Q.; Kang, Y.; You, L.; Xu, C.; Zhang, X.; Xie, Z. Stress-sensitivity mechanisms and its controlling factors of saline-lacustrine fractured tight carbonate reservoir. J. Nat. Gas Sci. Eng. 2021, 88, 103864. [Google Scholar] [CrossRef]

- Zhong, X.; Zhu, Y.; Liu, L.; Yang, H.; Li, Y.; Xie, Y.; Liu, L. The characteristics and influencing factors of permeability stress sensitivity of tight sandstone reservoirs. J. Pet. Sci. Eng. 2020, 191, 107221. [Google Scholar] [CrossRef]

- Yu, M.; Huang, H.; Zhou, D.; Li, H. Determination of stabilization time during stress-sensitivity tests. Geoenergy Sci. Eng. 2024, 235, 212682. [Google Scholar] [CrossRef]

- Cao, N.; Lei, G. Stress sensitivity of tight reservoirs during pressure loading and unloading process. Pet. Explor. Dev. 2019, 46, 138–144. [Google Scholar] [CrossRef]

- Ju, W.; Huang, P.; Zhong, Y.; Hu, H.; Liang, Y.; Liu, B.; Zhang, X. Experimental study of sandstone stress sensitivity under different fluids: Characteristics and mechanisms. Geoenergy Sci. Eng. 2023, 223, 211537. [Google Scholar] [CrossRef]

- Liu, K.; Yin, D.; Sun, Y.; Xia, L. Analytical and experimental study of stress sensitivity effect on matrix/fracture transfer in fractured tight reservoir. J. Pet. Sci. Eng. 2020, 195, 107958. [Google Scholar] [CrossRef]

- Han, D.; Wang, H.; Wang, C.; Yuan, W.; Hu, R. Differential characterization of stress sensitivity and its main control mechanism in deep pore-fracture clastic reservoirs. Sci. Rep. 2021, 11, 7374. [Google Scholar] [CrossRef] [PubMed]

- Chang, Y.; Yang, Z.; Zhang, Y.; Niu, Z.; Chen, X. Permeability characterization and its correlation with pore microstructure of stress-sensitive tight sandstone: Take Chang 6 in Ordos Basin for example. Geofluids 2022, 2022, 3334658. [Google Scholar] [CrossRef]

| Core No. | Diameter/cm | Length/cm | Permeability/mD | Fracture Characteristics |

|---|---|---|---|---|

| 1 | 6.004 | 2.472 | 0.244 | Matrix |

| 2 | 6.018 | 2.460 | 0.258 | Through-going Fracture |

| 3 | 5.990 | 2.462 | 0.213 | Double Short Fractures |

| 4 | 6.014 | 2.454 | 0.065 | Microfractures |

| Permeability Recovery Degree Under Different Net Stresses During Stress Unloading/% | Matrix | Through-Fracture | Double-Short-Fracture | Microfracture Cores |

|---|---|---|---|---|

| 2.5 MPa | 59.49 | 31.01 | 7.42 | 2.81 |

| 3.5 MPa | 24.36 | 19.12 | 2.93 | 1.51 |

| 5 MPa | 18.37 | 13.68 | 1.69 | 0.83 |

| 7 MPa | 12.36 | 7.52 | 0.70 | 0.51 |

| 9 MPa | 9.92 | 7.38 | 0.50 | 0.36 |

| 11 MPa | 8.93 | 5.39 | 0.37 | 0.26 |

| 15 MPa | 7.36 | 4.14 | 0.26 | 0.20 |

| 20 MPa | 6.53 | 3.01 | 0.19 | 0.15 |

| 30 MPa | 5.65 | 2.44 | 0.13 | 0.11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Xing, W.; Meng, X.; Liu, K.; Zheng, W.; Li, B. Experimental Study on Stress Sensitivity in Fractured Tight Conglomerate Reservoirs. Processes 2025, 13, 3441. https://doi.org/10.3390/pr13113441

Wang B, Xing W, Meng X, Liu K, Zheng W, Li B. Experimental Study on Stress Sensitivity in Fractured Tight Conglomerate Reservoirs. Processes. 2025; 13(11):3441. https://doi.org/10.3390/pr13113441

Chicago/Turabian StyleWang, Bin, Wanli Xing, Xue Meng, Kaixin Liu, Weijie Zheng, and Binfei Li. 2025. "Experimental Study on Stress Sensitivity in Fractured Tight Conglomerate Reservoirs" Processes 13, no. 11: 3441. https://doi.org/10.3390/pr13113441

APA StyleWang, B., Xing, W., Meng, X., Liu, K., Zheng, W., & Li, B. (2025). Experimental Study on Stress Sensitivity in Fractured Tight Conglomerate Reservoirs. Processes, 13(11), 3441. https://doi.org/10.3390/pr13113441