1. Introduction

An increase in population frequently comes with issues related to resources and the environment. The United Nations forecasts that by 2050, the world’s population will reach 9.7 billion, leading to a steady increase in food requirements. Consequently, the associated agro-industrial waste biomass is projected to escalate, potentially hitting 4 billion tons by 2025 [

1]. Presently, agricultural waste disposal methods focus on incineration and landfills; however, these practices result in significant biomass waste and an increased production of furans and dioxins, which are detrimental to the environment. Concurrently, the value of agricultural waste should not be overlooked, as it can generate energy equivalent to 500 tons of crude oil [

2]. More importantly, during combustion, agricultural waste emits minimal NO

x and SO

x [

3], rendering it more eco-friendly and cleaner than fossil fuels [

4]. Thus, given the non-renewable nature of fossil fuels and the ongoing issue of energy depletion, agricultural waste—a sustainable, renewable, and economical resource—is expected to serve as a clean alternative to fossil fuels.

Wheat is one of the largest grain crops grown globally, and according to the National Bureau of Statistics [

5], China’s wheat production was at 137 million tonnes in 2023. Wheat straw (WS) is a by-product generated after harvesting, and for every ton of wheat harvested, about one ton of WS is left in the field. In China, the primary utilization path of WS as a resource is through fertilizer utilization, meaning WS serves as the primary fertilizer for field return, with fuel utilization constituting a minor fraction. While the natural decomposition of WS is generally considered to be carbon-neutral, its negative effects on the mitigation of other greenhouse gases, e.g., methane and nitrous oxide, have been reported by some studies [

6,

7,

8]. It is worth mentioning that WS, as a renewable resource, has an energy value that deserves significant valorisation. The HHV of WS with a moisture content of 15% is about 13.46 MJ/kg, which is lower than the HHV of lignite (16.76 MJ/kg) [

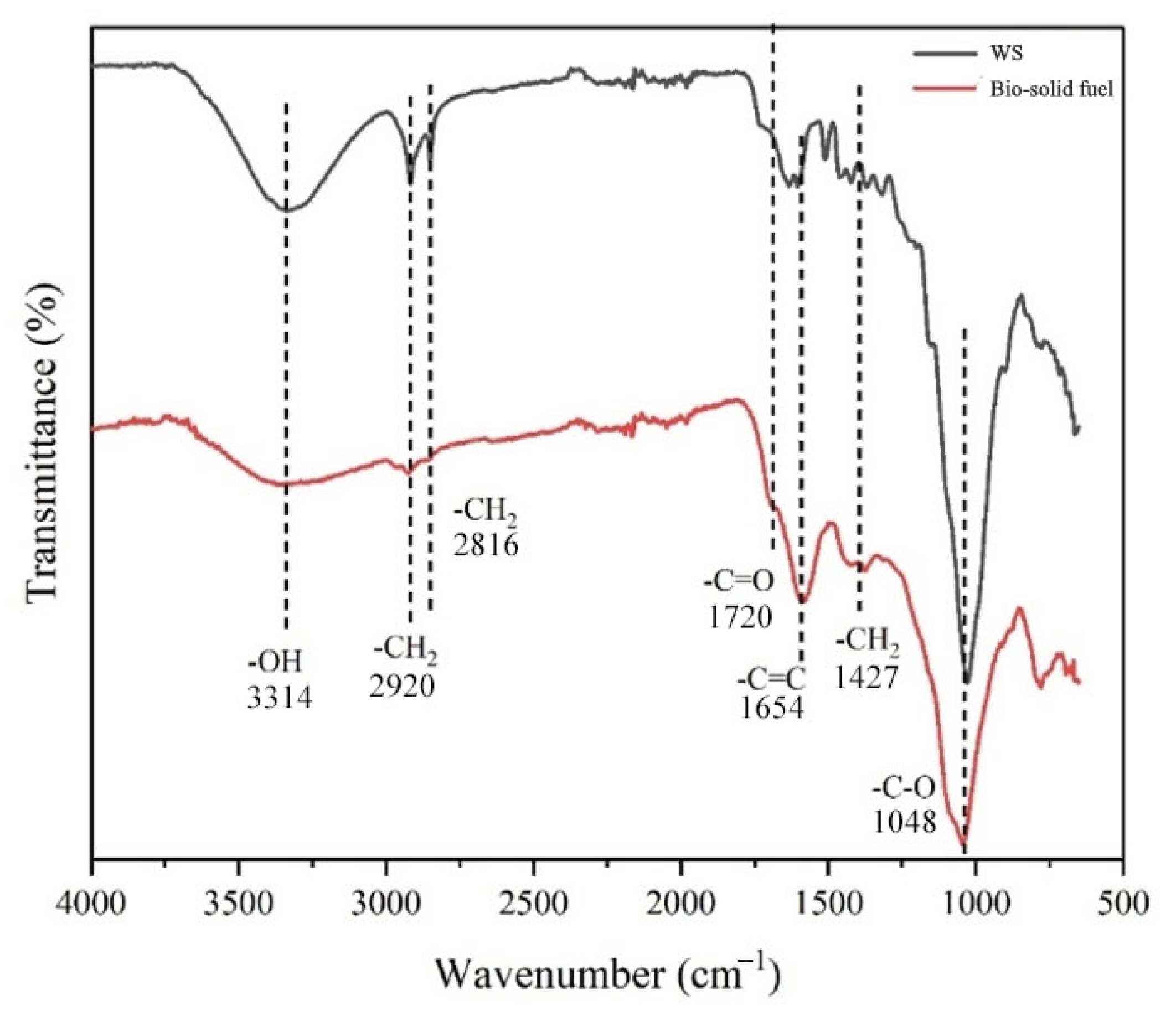

9]. Meanwhile, WS, distinguished by its minimal sulphur, ash, and volatile matter, stands out as a prime source of clean energy, and its conversion into a substitute for coal could be a key path in future energy advancements [

10].

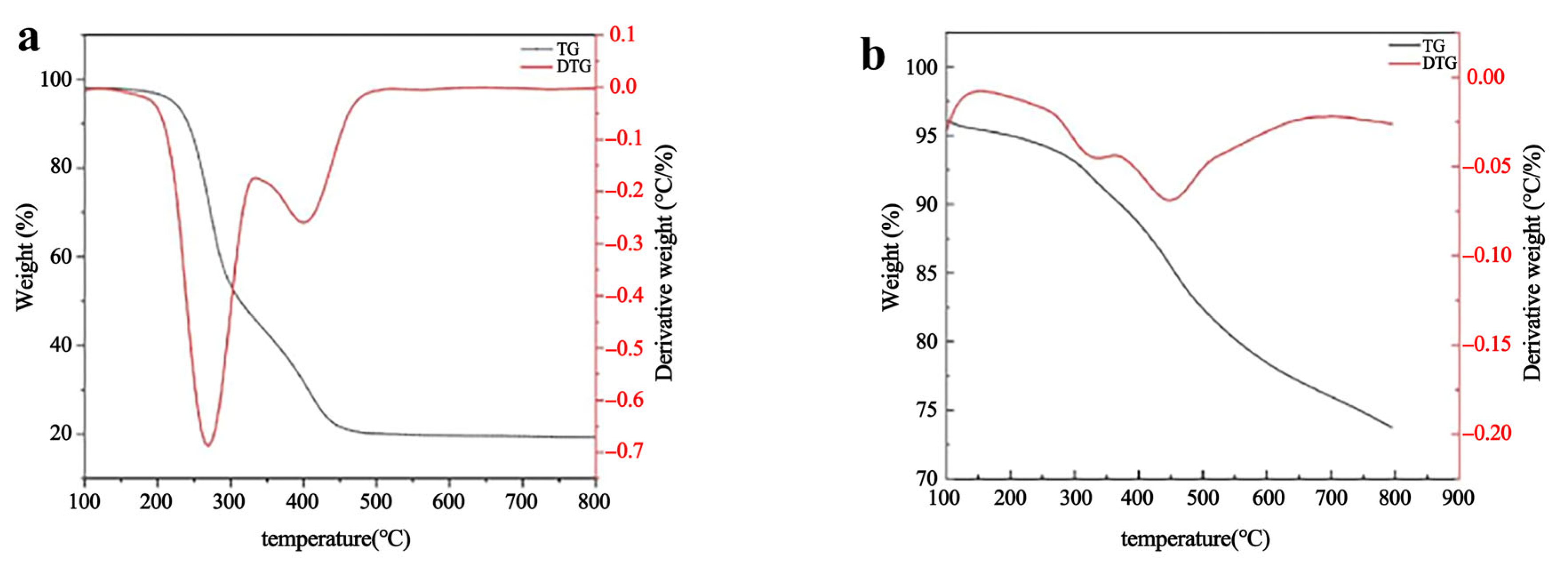

Biomass can be transformed into energy through two primary approaches: thermochemical and biochemical processes. Thermochemical conversion approaches encompass combustion, hydrothermal liquefaction, torrefaction, and gasification, while biochemical conversion processes include anaerobic digestion and microbial fermentation. Biomass properties play a key role in determining the suitable conversion pathway; for instance, lignocellulosic biomass like WS exhibits high thermal efficiency, rendering thermochemical methods more time-efficient compared to biochemical conversion [

11]. In addition, thermochemical technology is the way to achieve a high energy conversion rate of up to 95.5 percent [

12]. Among thermochemical methods, torrefaction of biomass to bio-solid fuel is a practical and promising process. Torrefaction, a mild heat treatment process, aims to alter the physicochemical properties of biomass at specific temperatures and times to maximize its quality and energy yield, while simultaneously minimizing elemental ratios (especially O/C and H/C) [

13]. Torrefaction enhances the energy density of biomass, removes moisture and low molecular weight organic volatiles, and produces hydrophobic bio-solid fuel with high energy density and grindability. These changes thus make bio-solid fuel convenient for storage and transport, along with combustion in power plants, boilers, and other combustion systems. In recent years, different authors have studied the effects of various operating parameters on the quality of torrefied biomass. For example, studies have been conducted on jute sticks [

14], coconut shell [

15], sugarcane bagasse [

16], WS [

17], etc. They observed that high-grade bio-solid fuel can be generated under optimum operational conditions, with its quality matching that of bituminous and anthracite coal [

14].

Conventional heating and microwave heating are two common heating technologies employed in thermochemical conversion processes. Traditional heating transfers energy from external sources to the core of the sample through radiation, convection, and conduction, while microwave heating converts electromagnetic energy to heat inside the sample [

18]. The merits of microwave heating comprise lower energy usage, high thermal efficiency, easy control, and selective heating. Microwave heating has been emerging as a novel integrated technology in biomass conversion recently. It has been shown that through microwave heating, various biomass feedstocks can be converted into products such as bio-oil, biochar, syngas, and hydrogen, depending on operating parameters, biomass characteristics, etc. [

19,

20,

21,

22,

23,

24]. Microwave heats biomass via dielectric heating, which principally depends on the internal electric field intensity and dielectric properties of materials. Biomass has low susceptibility to microwave irradiation and poor dielectric properties, meaning a higher dose of microwave absorber is required to heat biomass samples via electromagnetic heating [

24,

25]. The tangent loss angle of WS under the conditions of this study was 0.147, while only materials with a tangent loss angle greater than 0.2 are considered to have excellent microwave absorption capacity [

21]. Microwave absorbers encompass silicon carbide (SiC), ferrites, and carbon-based materials, among others. Silicon carbide exhibits restricted microwave absorption capability, though its stability is maintained at elevated temperatures [

26]. Meanwhile, traditional magnetic loss materials—including ferrites and other iron-based compounds—demonstrate robust microwave absorption due to their distinct magnetic properties. However, ferric oxide powder is challenging to recycle during microwave torrefaction and can be costly. Carbonaceous materials, such as activated carbon and graphite, exhibit a superior capacity to absorb microwave energy and convert it into thermal energy owing to their higher loss factors [

27]. Thereby, incorporating activated carbon as a microwave absorber into dry biomass can enhance heating efficiency.

While a number of reports on biomass torrefaction have used microwave heating [

24,

28,

29], the optimization of this method remains underexplored, especially when considering an advanced torrefaction performance index such as the Energy-Mass Co-efficiency Index (EMCI). Furthermore, research on the optimization of microwave torrefaction is relatively limited, with inadequate exploration of torrefaction process parameters (e.g., torrefaction temperature, irradiation time, and various biomass types). To the best of our knowledge, no study has focused on the effect of different microwave absorber doses on the three torrefaction indices (mass yield, HHV, and EMCI) of WS. To advance this research, this study not only systematically investigates the impact of microwave absorber dose on three core torrefaction indicators: mass yield, HHV, and EMCI, but also elaborates on the characteristics of EMCI for evaluating the storage and transportation of bio-solid fuel, and conducts an in-depth analysis of the response characteristics of these indicators to microwave power, irradiation time, and microwave absorber dose, including the impact of synergistic effects between variables on such characteristics. The in-depth exploration of EMCI and microwave absorber dose distinguishes this study from existing optimization studies, thus complementing research on understanding microwave-specific process-efficiency relationships during WS torrefaction. Over the past several decades, Response Surface Methodology (RSM) has been frequently utilized in optimization studies as an integrative approach combining experimental design, mathematical statistics, and optimization techniques [

30]. The advantage of RSM is that it takes into account both the interactions between influencing variables and the effect of combined variables on the response. The use of RSM enables the construction of a continuous variable surface model that assesses process-influencing factors and their interactions, thereby determining the optimal experimental level range and saving human and material resources [

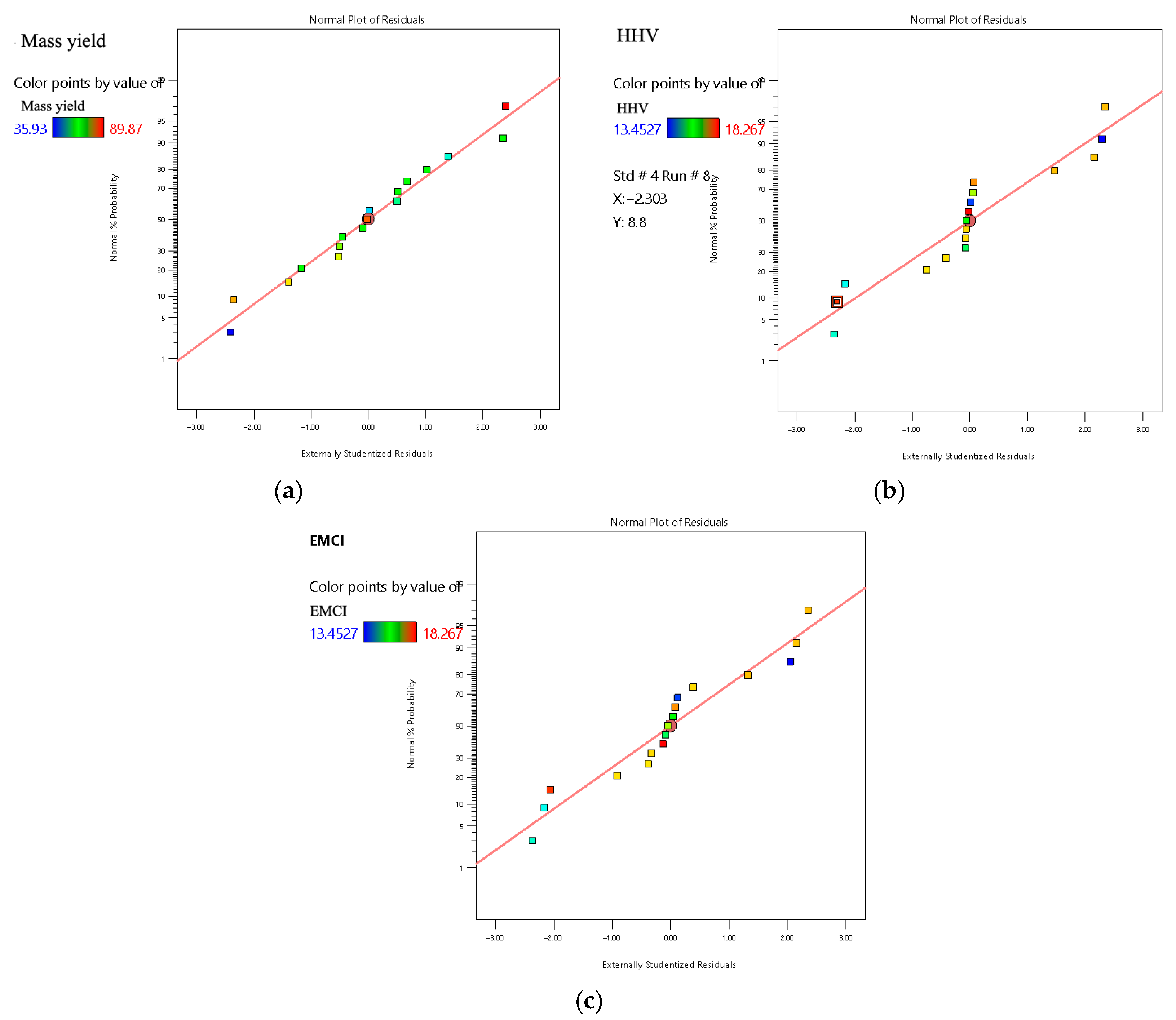

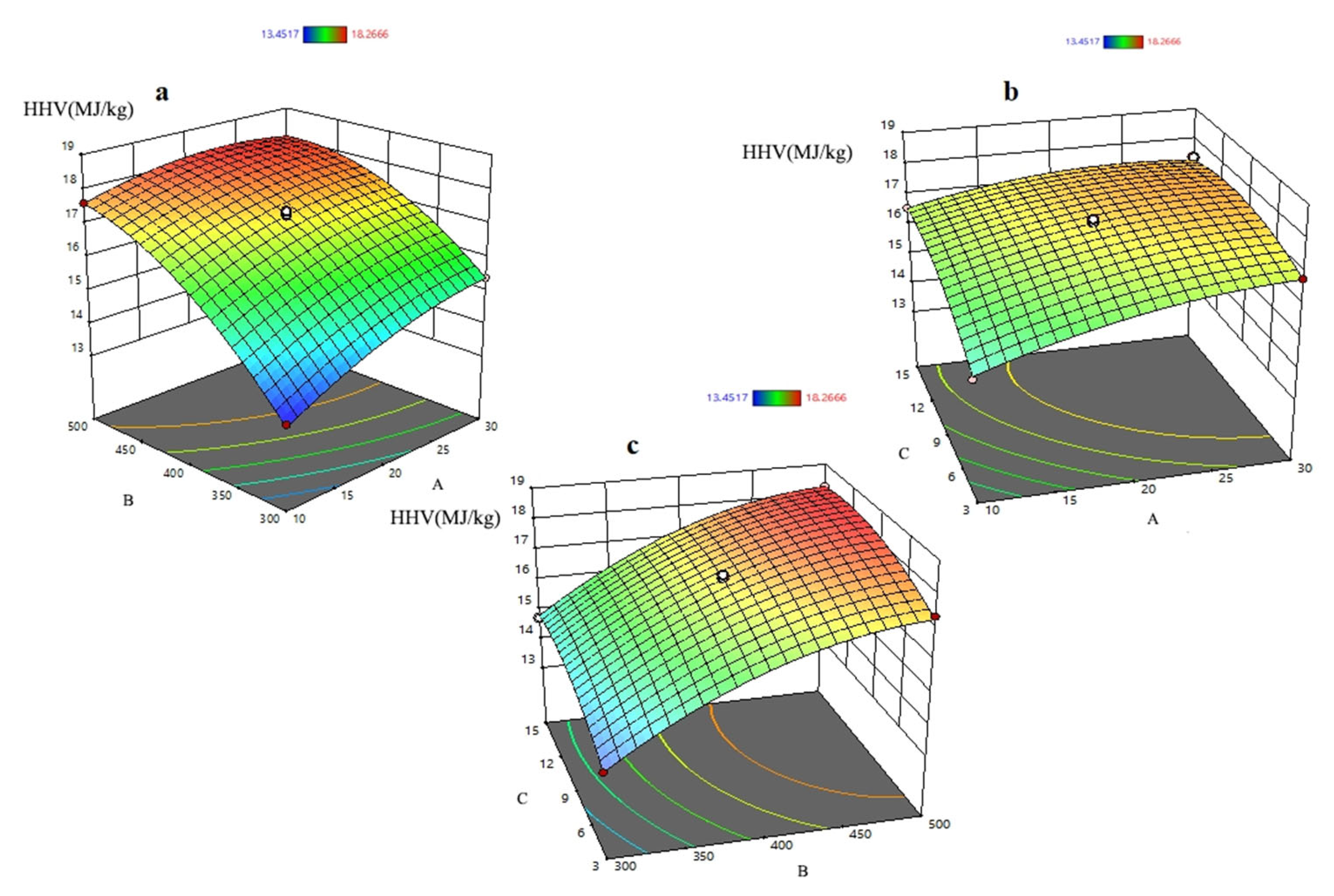

31]. In this study, the optimization process was designed and conducted using the Box–Behnken design (BBD) within RSM.

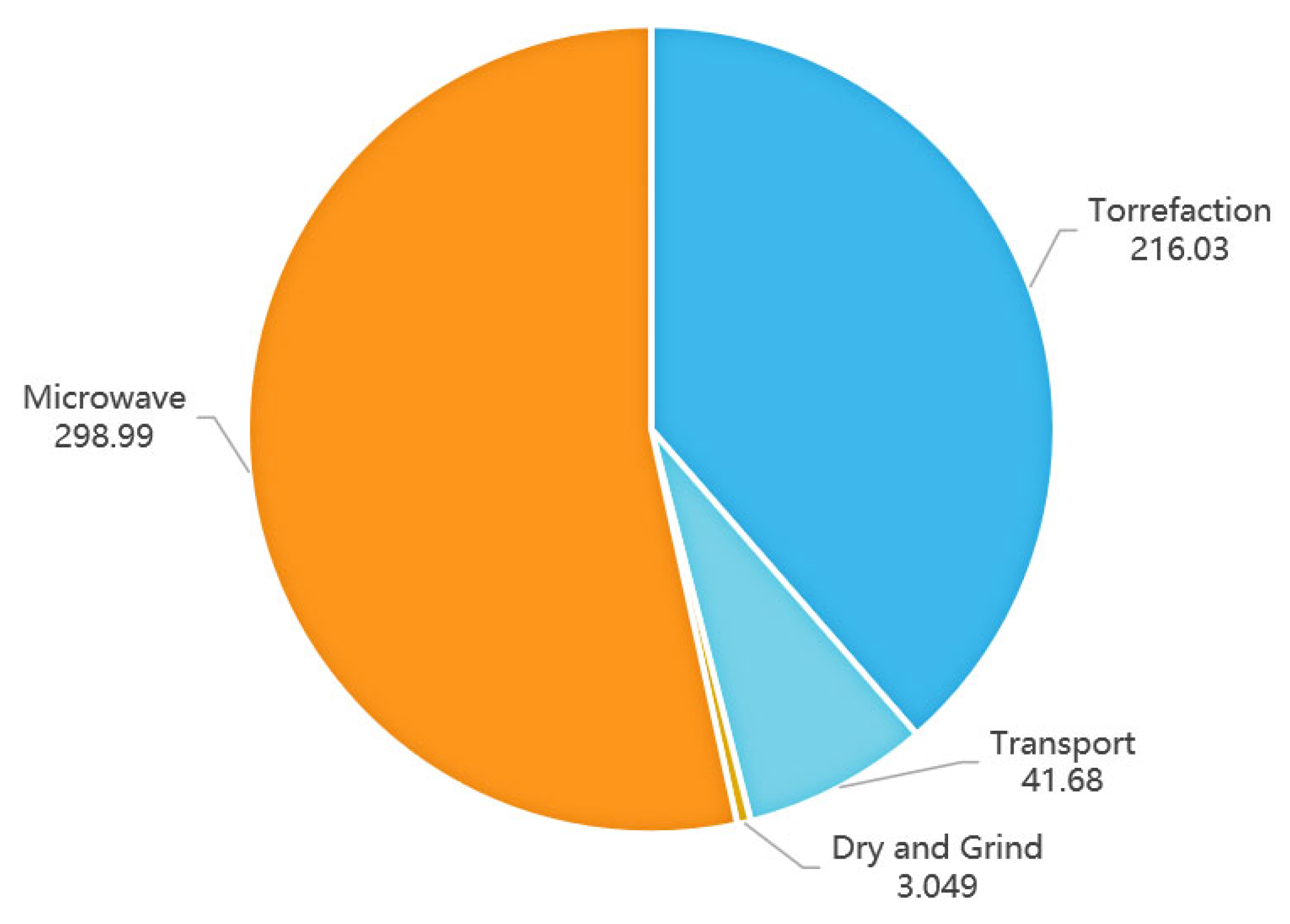

Additionally, to fully understand and assess the potential of WS as a biofuel, the microwave torrefaction process of WS should be evaluated from economic and environmental perspectives. Prior studies lack an integrated perspective combining process optimization with environmental and economic assessments of bio-solid fuel. In this study, a Life Cycle Assessment (LCA) approach was applied to evaluate the environmental sustainability of bio-solid fuel, from its production under optimal conditions to its combustion as a substitute fuel. The main objective of this study was to optimize the torrefaction process parameters for WS using the RSM approach, to enhance its potential as a high-quality fuel, and to analyse its environmental feasibility and economic benefits as an alternative fuel.