Current-Mode Controlled Battery Emulator

Abstract

1. Introduction

- Capability of bidirectional operation, which ensures emulation of both charging and discharging phases;

- Generality in terms of the various battery types and models which can be emulated and implemented;

- Excellent accuracy and dynamical properties, thanks to the application of the I2DCMC;

- Modularity in terms of the emulator’s topology, battery model and control structure;

- Capability of charging/discharging time scaling;

- Possibility of rapid control prototyping with user-friendly interface suitable for researchers and especially students, which also provides its application for educational purposes.

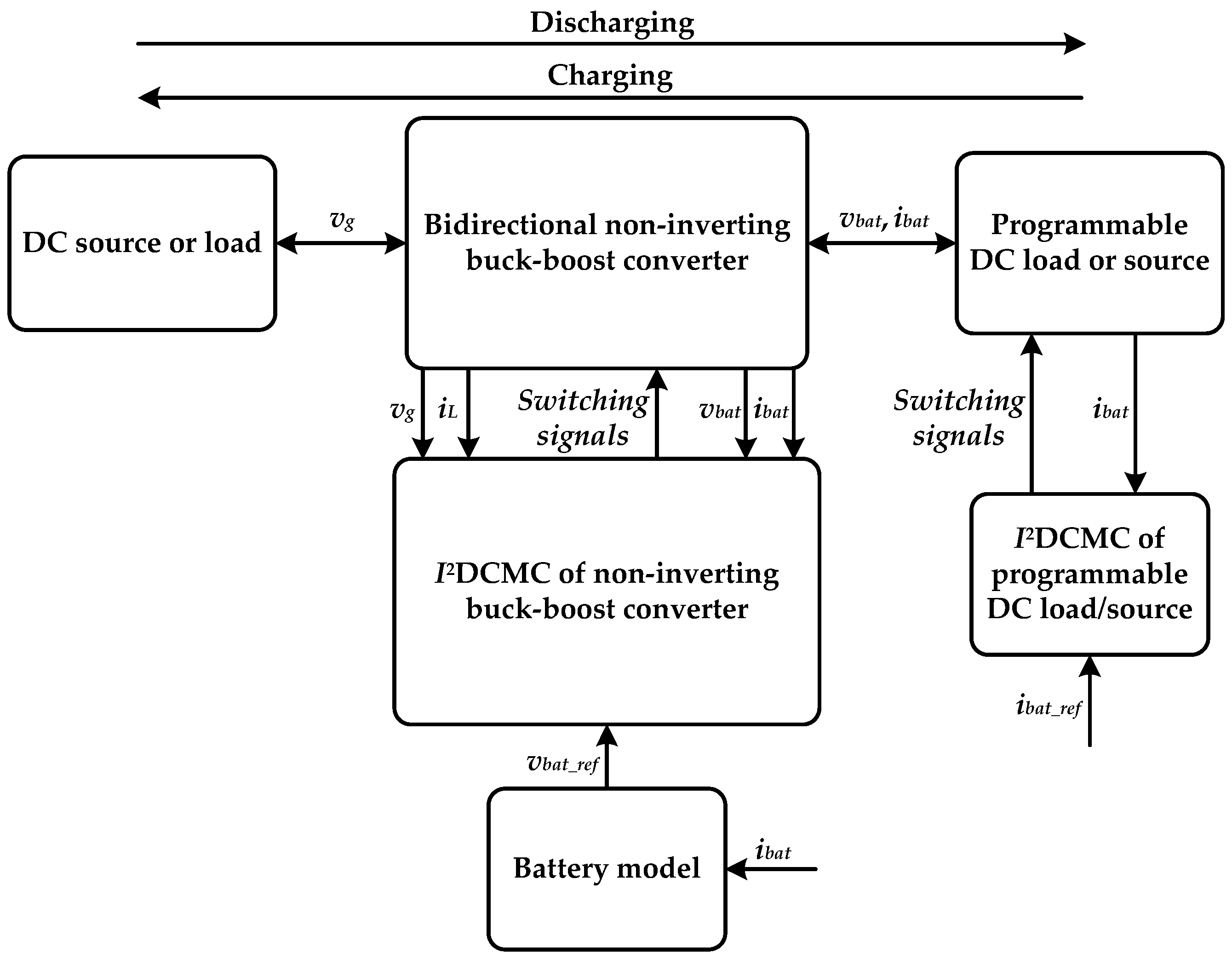

2. Topology of the Proposed Battery Emulator

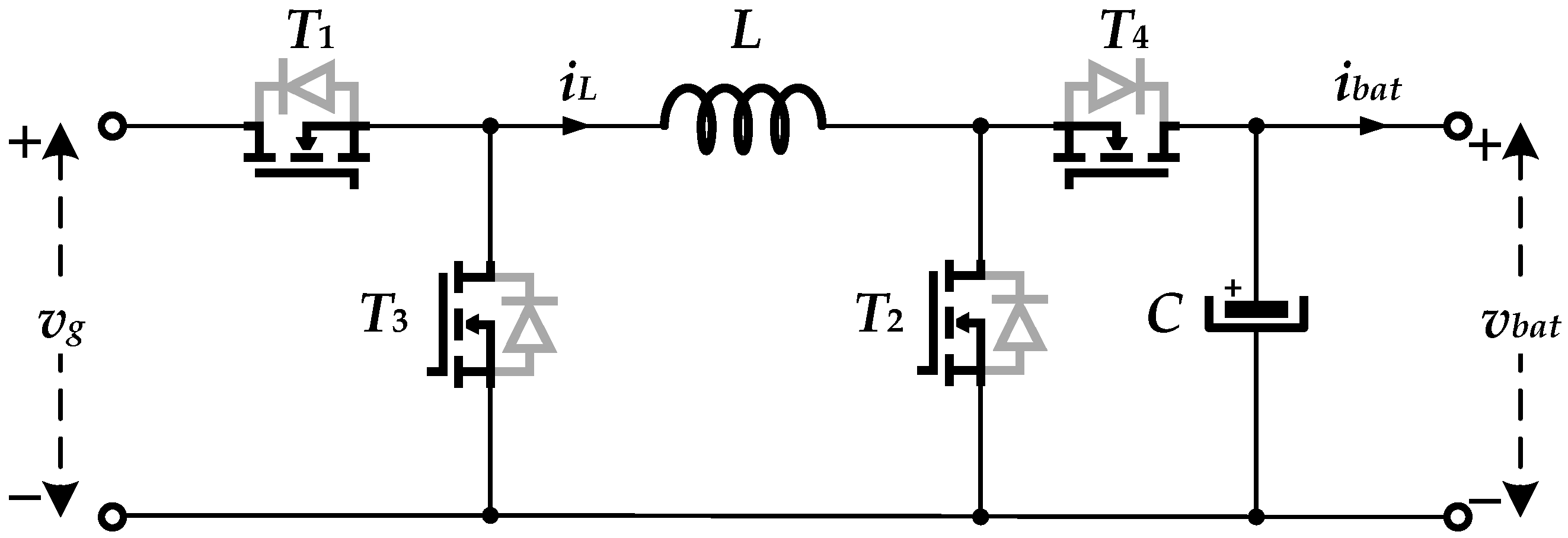

2.1. Bidirectional Non-Inverting Buck-Boost Converter

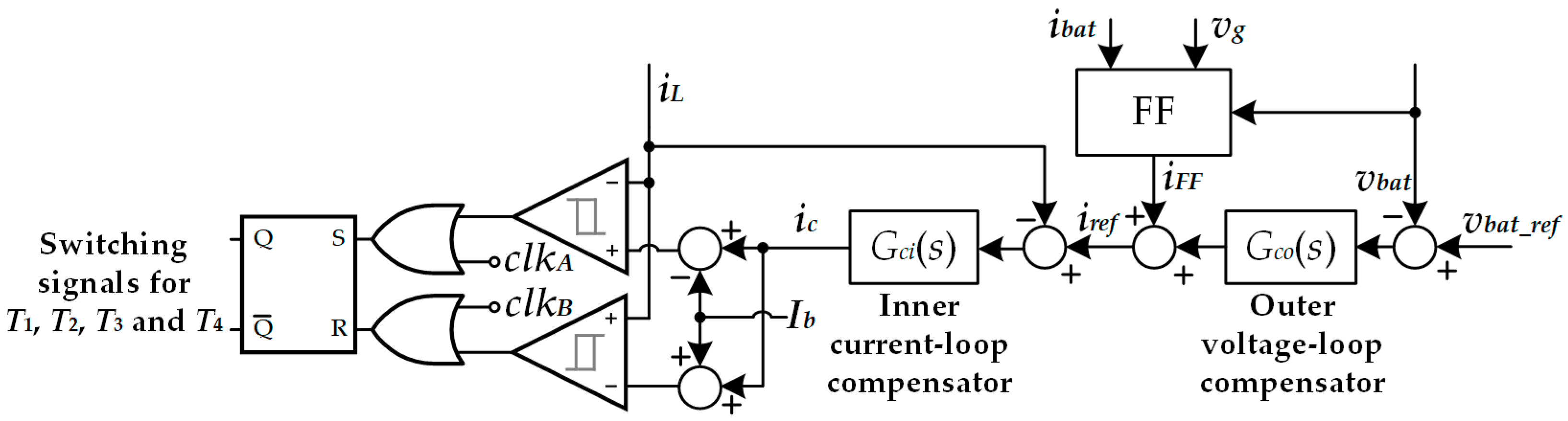

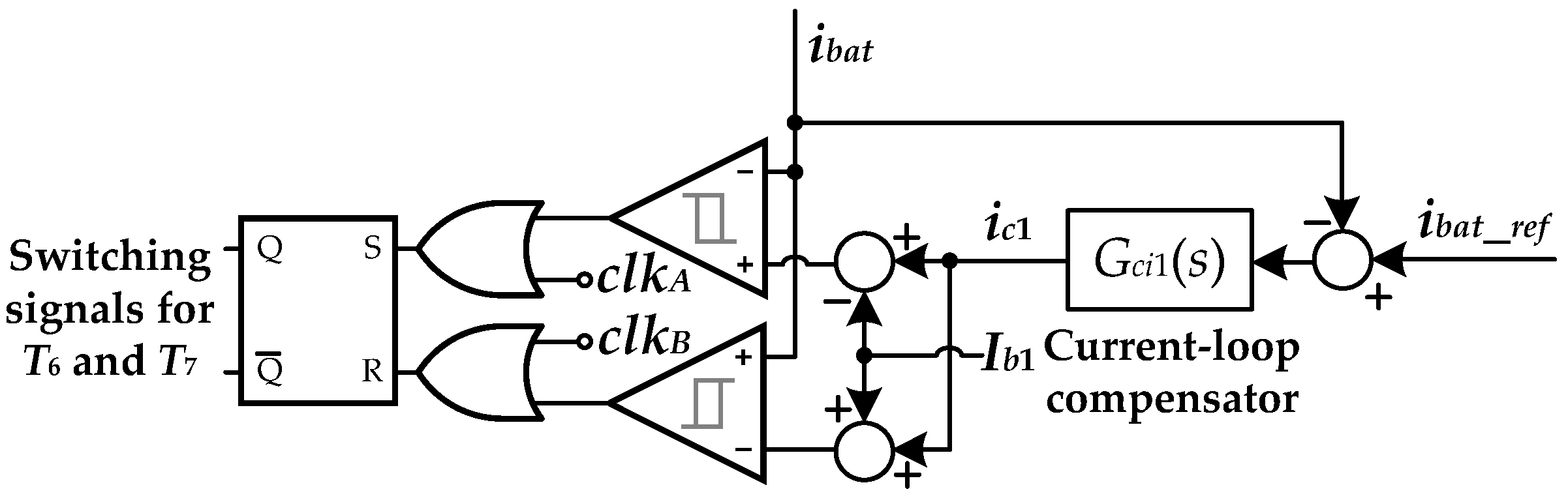

2.2. I2DCMC of Non-Inverting Buck-Boost Converter

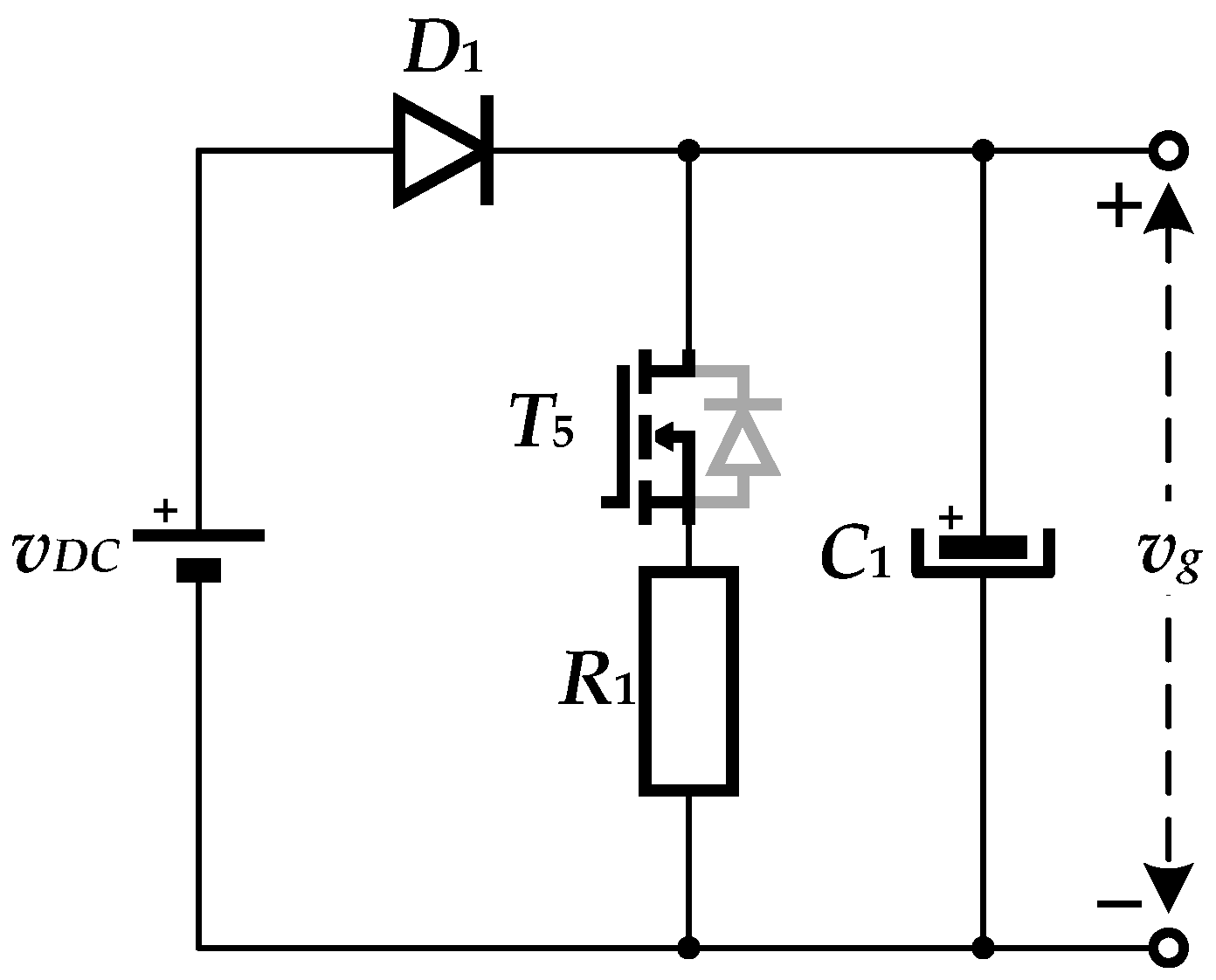

2.3. DC Source or Load

2.4. Programmable DC Load or Source

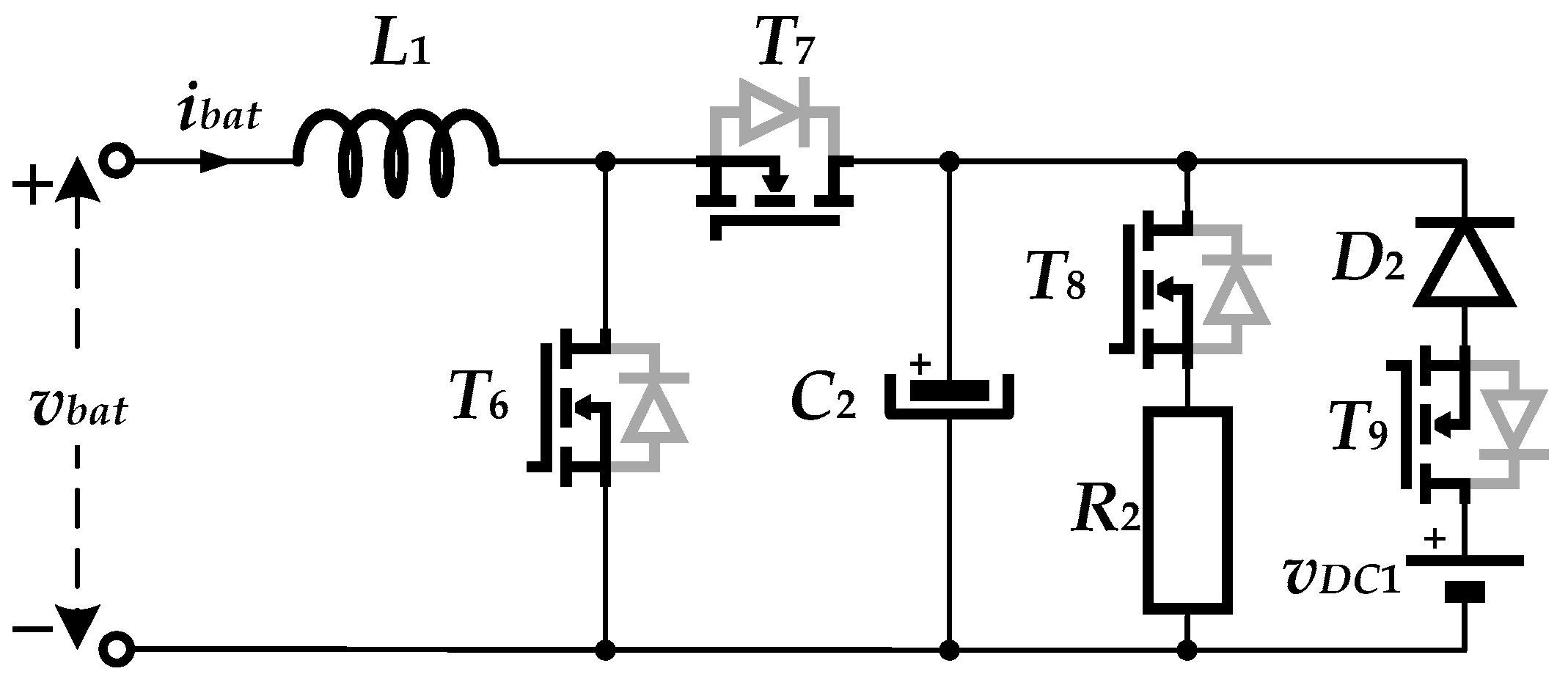

2.5. I2DCMC of Programmable DC Load/Source

2.6. Battery Model

2.6.1. Polymer Li-Ion Battery Model

2.6.2. Conventional Li-Ion Battery Model

2.6.3. Lead–Acid Battery Model

3. Simulation Results and Discussion

3.1. Simulation Results for the Polymer Li-Ion Battery Model

3.2. Simulation Results for the Conventional Li-Ion Battery Model

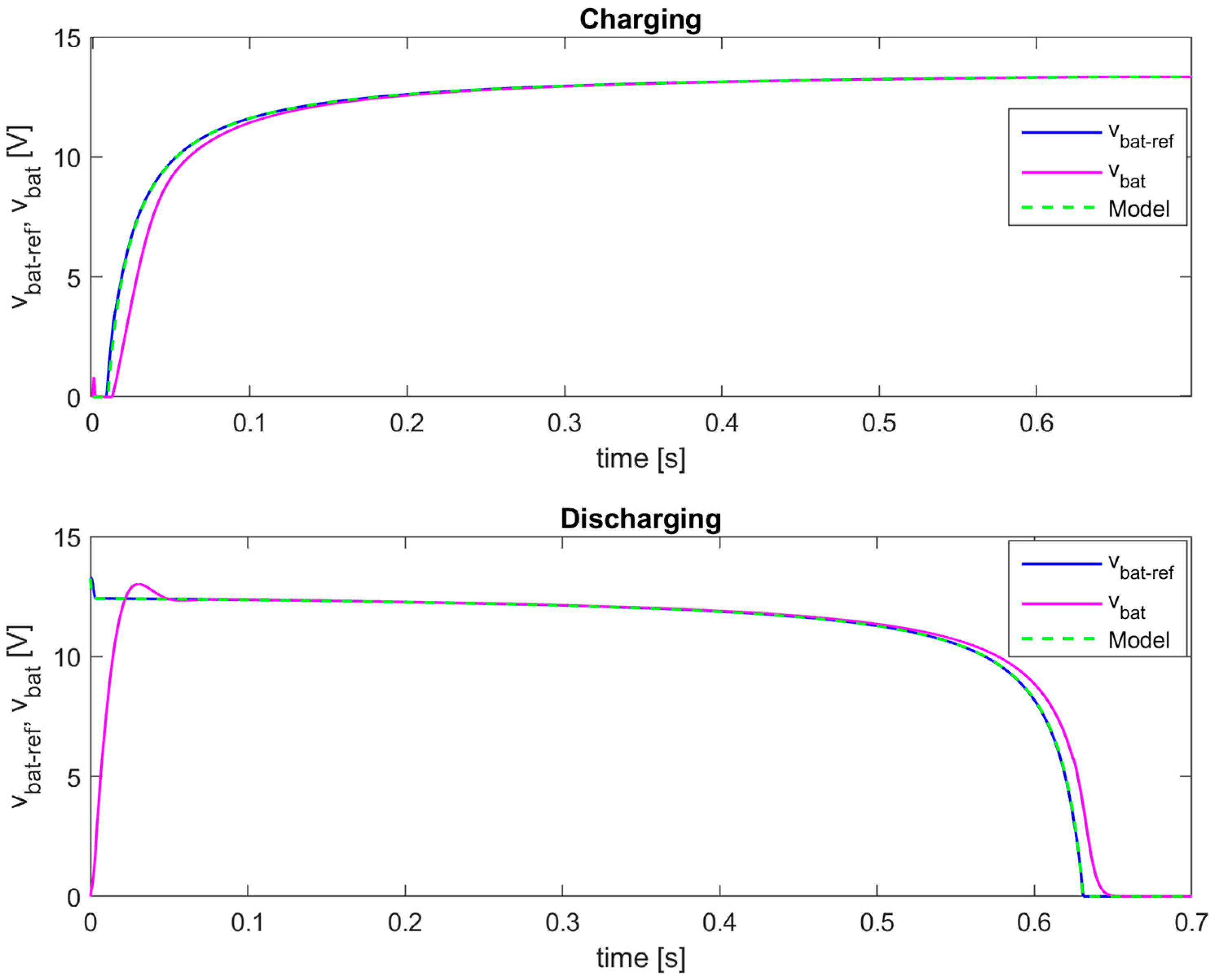

3.3. Simulation Results for the Lead–Acid Battery Model

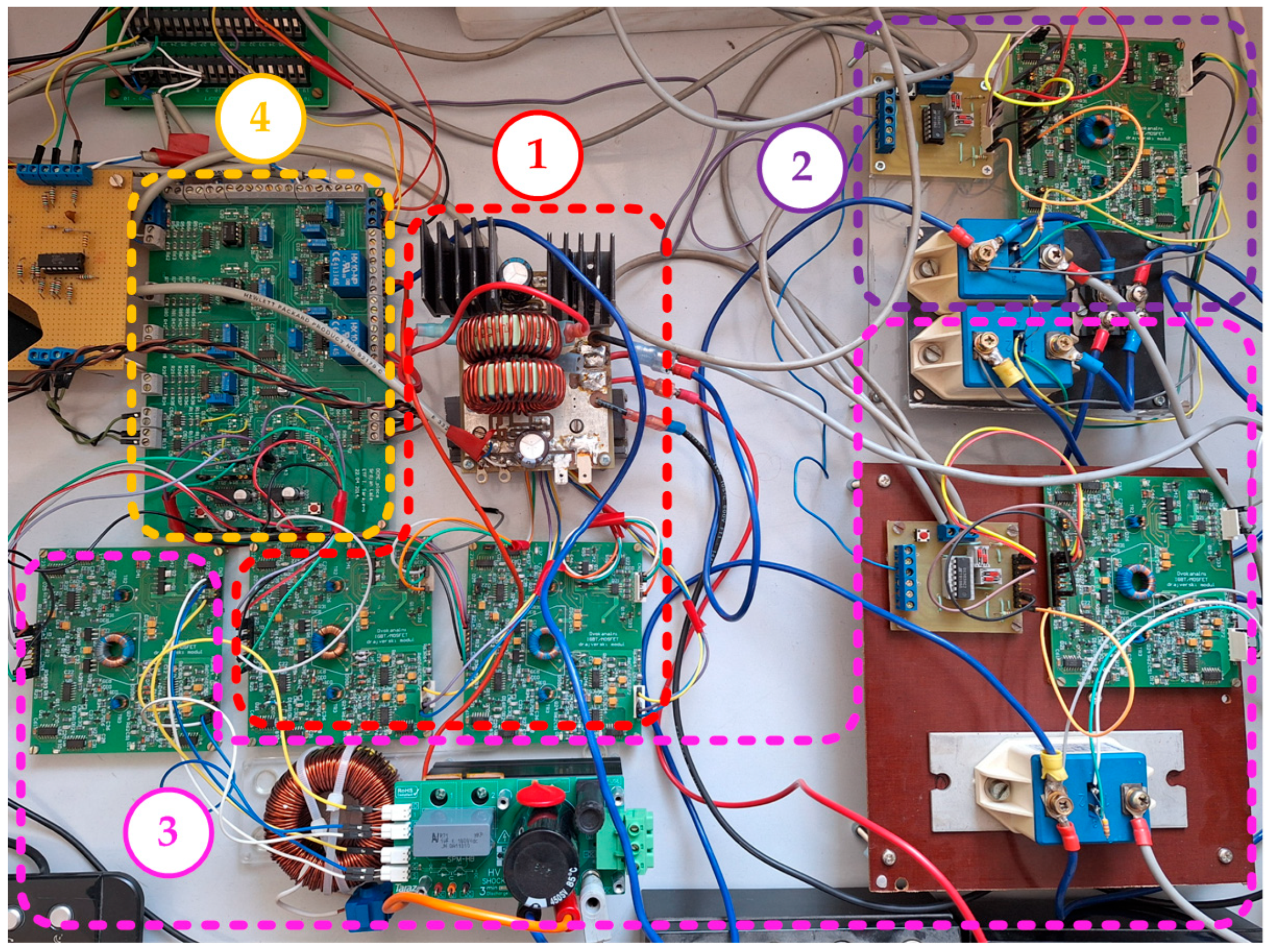

4. Experimental Results and Discussion

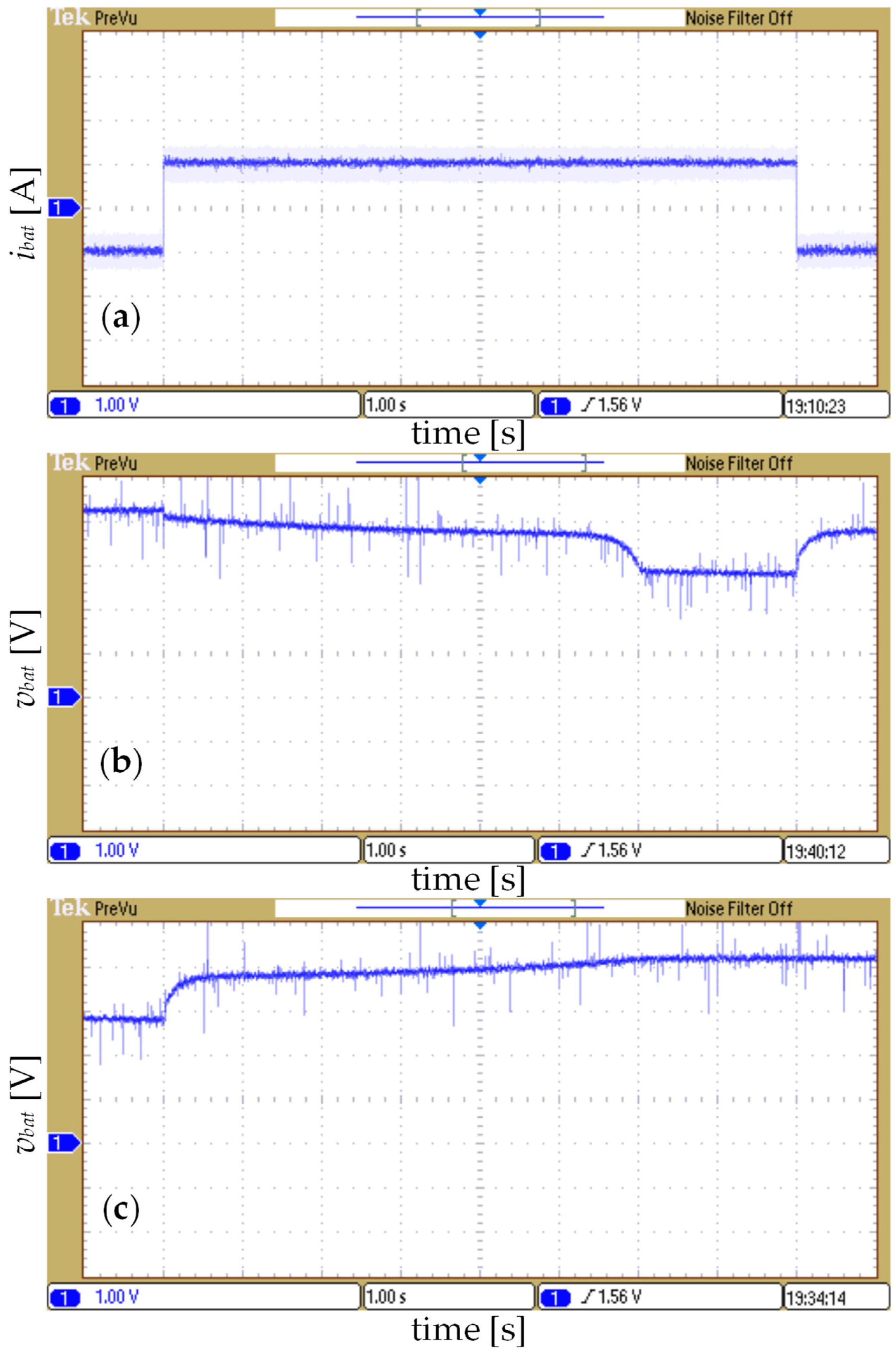

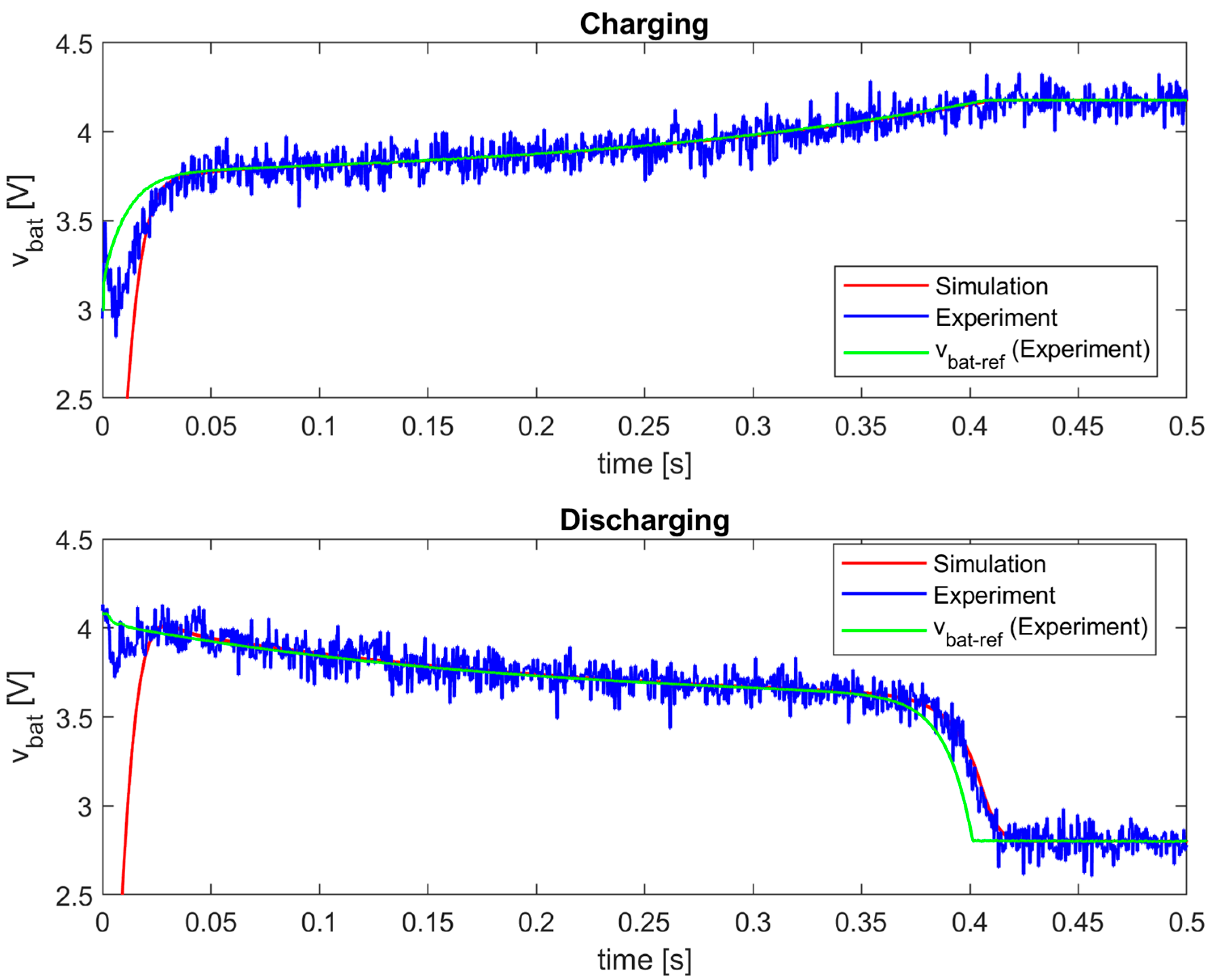

4.1. Experimental Results for the Polymer Li-Ion Battery Model

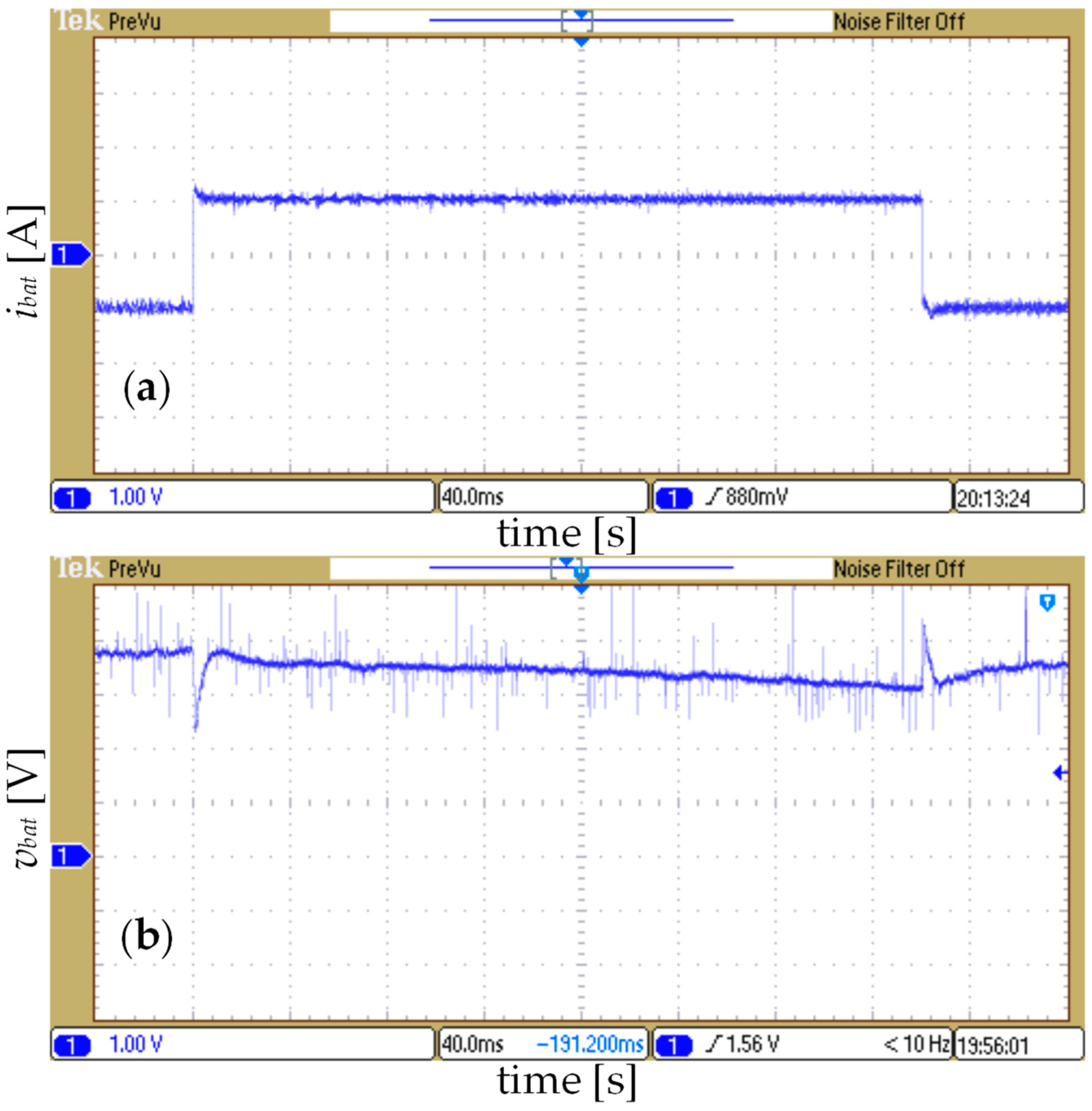

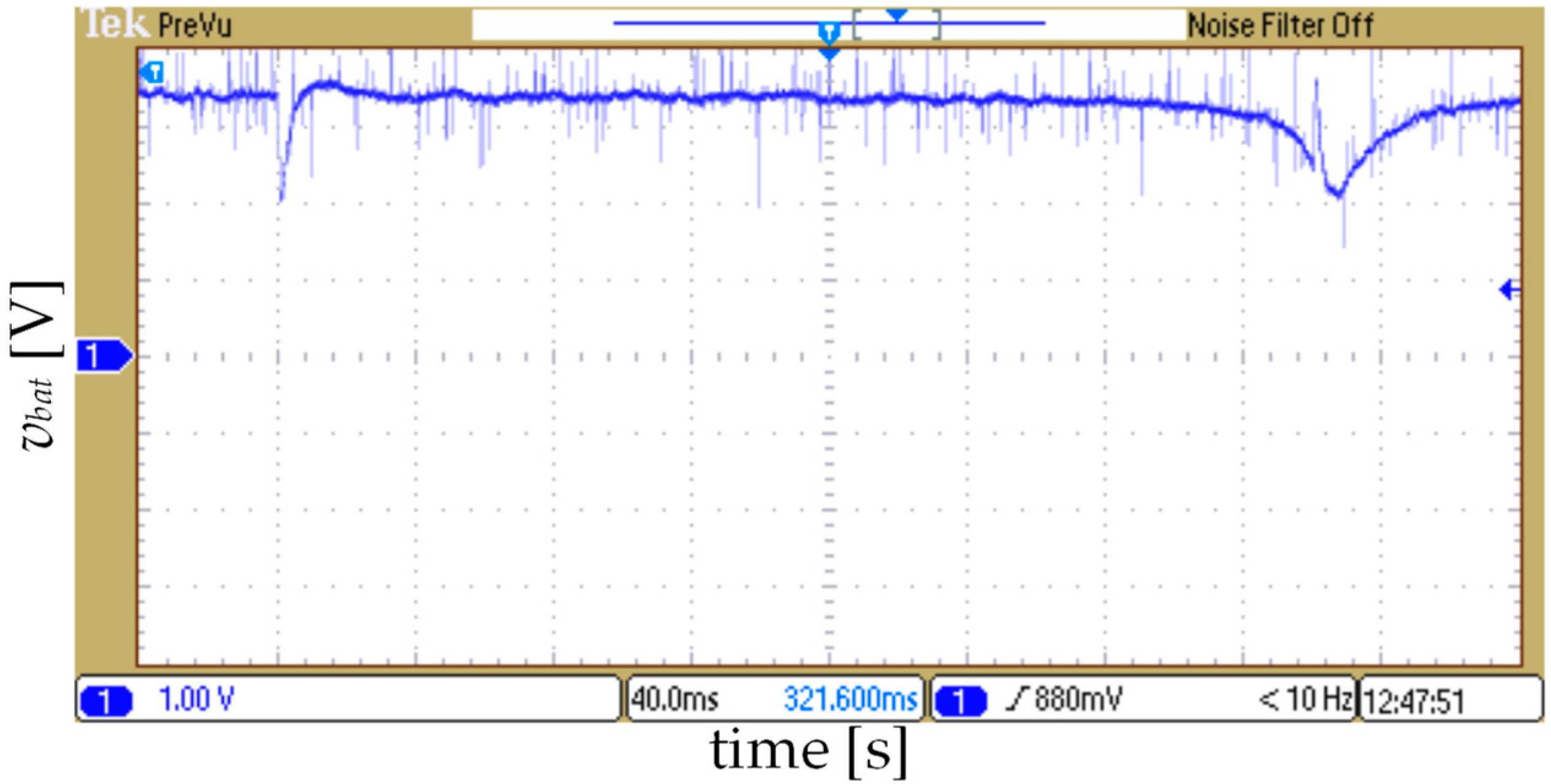

4.2. Experimental Results for the Conventional Li-Ion Battery Model

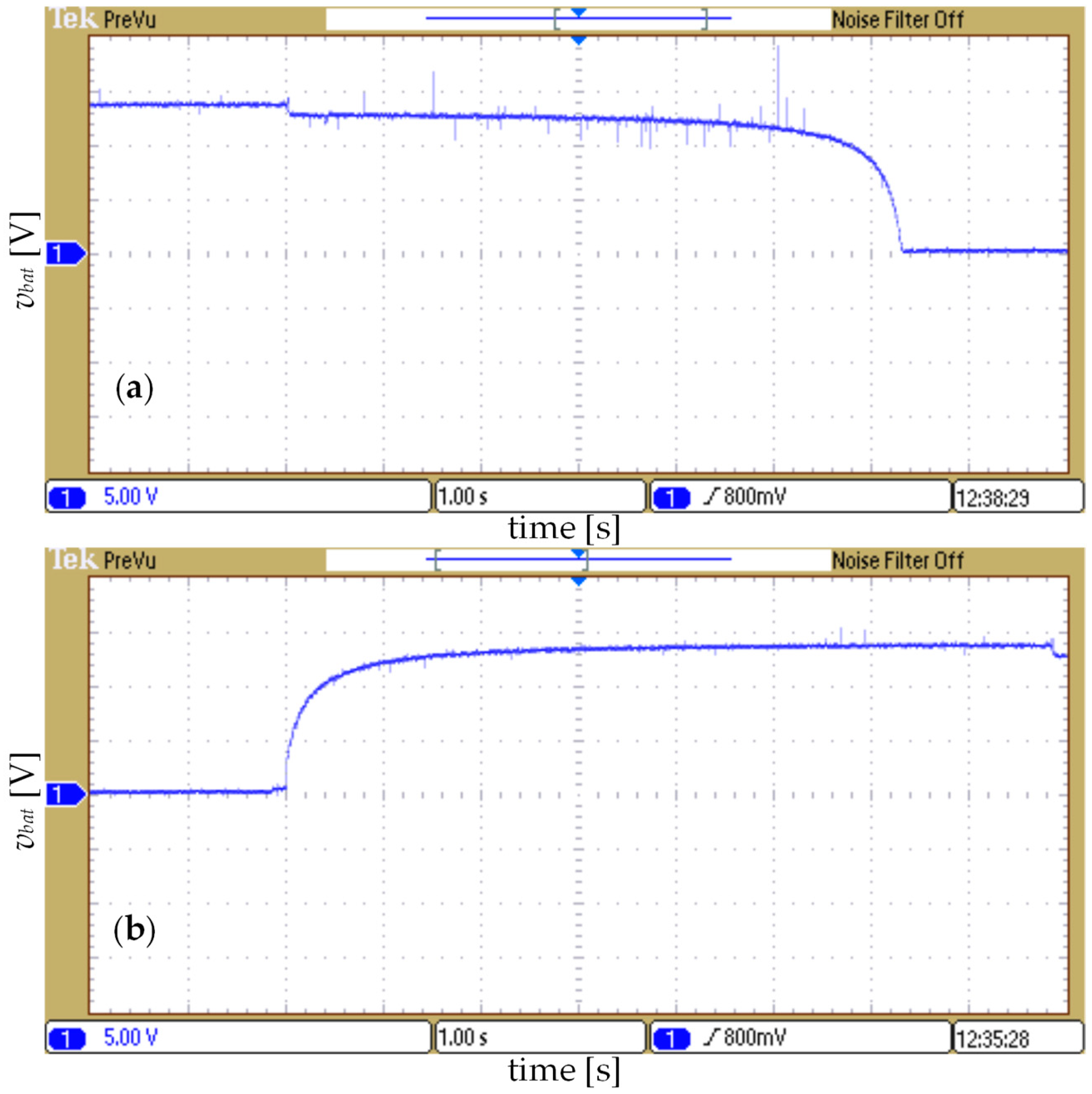

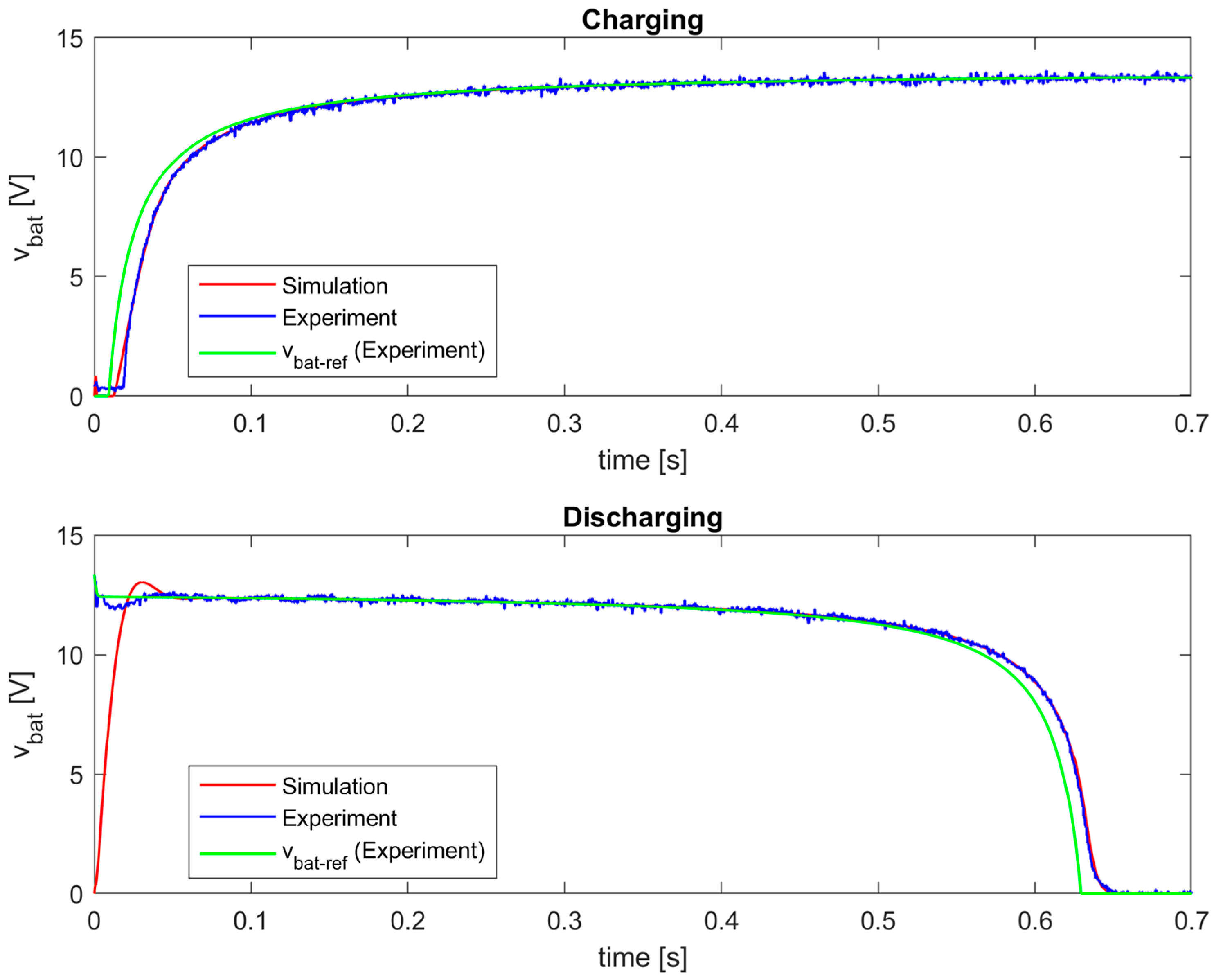

4.3. Experimental Results for the Lead–Acid Battery Model

4.4. Comparison Between Experimental and Simulation Results

5. Conclusions

- Excellent tracking accuracy and dynamics—the implemented I2DCMC ensures precise and fast tracking of the referent battery voltage and current;

- Possibility of charging/discharging time scaling—using simple scaling factor k that speeds up the change in SOC, and thus increasing the charging/discharging velocity, which enables much easier and faster laboratory tests of the battery-based systems;

- Modularity in terms of the implemented real-time battery model—various mathematical models of the batteries can be easily configured and applied in real time, in a user-friendly Matlab/Simulink environment;

- Modularity in terms of the implemented battery types—in this paper, the polymer Li-ion, conventional Li-ion, and lead–acid batteries are considered as examples, although other types of batteries with different voltage and current levels can be implemented, thanks to the applied non-inverting buck-boost converter, which can work with wide range of input/output voltages and currents;

- Modularity in terms of the hardware topology—all hardware parts of the emulator can be easily configured and modified, including the controller, i.e., instead of a used MF624 control board, other control platforms can be implemented.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tie, S.F.; Tan, C.W. A review of energy sources and energy management system in electric vehicles. Renew. Sustain. Energy Rev. 2013, 20, 82–102. [Google Scholar] [CrossRef]

- Luna, M.; Di Piazza, M.C.; La Tona, G.; Accetta, A.; Pucci, M. Exploiting dynamic modeling, parameter identification, and power electronics to implement a non-dissipative Li-ion battery hardware emulator. Math. Comput. Simul. 2021, 183, 48–65. [Google Scholar]

- Boles, J.D.; Ma, Y.; Wang, J.; Osipov, D.; Tolbert, L.M.; Wang, F. Converter-based emulation of battery energy storage systems (BESS) for grid applications. IEEE Trans. Ind. Appl. 2019, 55, 4020–4032. [Google Scholar] [CrossRef]

- Mesbahi, T.; Rizoug, N.; Bartholomeus, P.; Le Moigne, P. Li-Ion battery emulator for electric vehicle applications. In Proceedings of the IEEE Vehicle Power and Propulsion Conference (VPPC), Beijing, China, 15–18 October 2013. [Google Scholar]

- Dai, H.; Zhang, X.; Wei, X.; Sun, Z.; Wang, J.; Hu, F. Cell-BMS validation with a hardware-in-the-loop simulation of lithium-ion battery cells for electric vehicles. Int. J. Electr. Power Energy Syst. 2013, 52, 174–184. [Google Scholar]

- Buccolini, L.; Orcioni, S.; Longhi, S.; Conti, M. Cell battery emulator for hardware-in-the-loop BMS test. In Proceedings of the IEEE International Conference on Environment and Electrical Engineering and IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Palermo, Italy, 12–15 June 2018. [Google Scholar]

- Messier, P.; LeBel, F.; Rouleau, J.; Trovao, J.P.F. Multi-cell emulation for battery management system validation. In Proceedings of the IEEE Vehicle Power and Propulsion Conference (VPPC), Chicago, IL, USA, 27–30 August 2018. [Google Scholar]

- Dai, H.; Wei, X.; Sun, Z.; Wang, J. A hardware-in-the-loop system for development of automotive battery management system. In Measuring Technology and Mechatronics Automation in Electrical Engineering, Lecture Notes in Electrical Engineering; Hou, Z., Ed.; Springer: New York, NY, USA, 2012; Volume 135, pp. 27–36. [Google Scholar]

- Wu, S.; Zou, Y.; Peng, X.; Li, H. Hardware-in-loop verification of battery management system with RT-LAB. In Proceedings of the IEEE Conference and Expo Transportation Electrification Asia-Pacific (ITEC Asia-Pacific), Beijing, China, 31 August–3 September 2014. [Google Scholar]

- Thanheiser, A.; Kohler, T.P.; Bertram, C.; Herzog, H.-G. Battery emulation considering thermal behavior. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 6–9 September 2011. [Google Scholar]

- Seitl, C. Development and Implementation of a Battery Emulator for Power Hardware-In-The-Loop Simulations. Master’s Thesis, Vienna University of Technology, Vienna, Austria, 2014. [Google Scholar]

- Shekoofa, O.; Pouryaie, N.; Sohrabzadeh, K.; Rezvani, M. Improving the EGSE of power subsystem by design and development of a battery emulator for space applications. In Proceedings of the 4th International Conference on Recent Advances in Space Technologies, Istanbul, Turkey, 11–13 June 2009. [Google Scholar]

- Daniil, N.; Drury, D. Improving the stability of the battery emulator—Pulsed current load interface in a Power Hardware-in-the-Loop Simulation. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016. [Google Scholar]

- Daniil, N.; Drury, D. Investigation and validation of methods to implement a two-quadrant battery emulator for power Hardware-in-the-Loop Simulation. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016. [Google Scholar]

- Varais, A.; Roboam, X.; Lacressonnière, F.; Bru, E.; Roux, N. Reduced Scale PHIL Emulation Concepts Applied to Power Conversion Systems With Battery Storage. IEEE Trans. Ind. Electron. 2021, 68, 3973–3981. [Google Scholar]

- Cabello, J.M.; Roboam, X.; Junco, S.; Bru, E.; Lacressonniere, F. Scaling Electrochemical Battery Models for Time-Accelerated and Size-Scaled Experiments on Test-Benches. IEEE Trans. Power Syst. 2017, 32, 4233–4240. [Google Scholar]

- Fan, B.; Zhang, B.; Shi, Y.; Chang, Y. A high-fidelity lithium-ion battery emulator for electric vehicle application. Sci. Rep. 2024, 14, 19742. [Google Scholar] [CrossRef] [PubMed]

- Peskar, J.; Downey, A.R.J.; Khan, J.; Booth, K. Progress Towards a Coupled Electro-thermo Battery Emulator. In Proceedings of the IEEE Electric Ship Technologies Symposium (ESTS), Alexandria, VA, USA, 1–4 August 2023. [Google Scholar]

- Halivni, B.; Beniaminson, D.; Maman, L.; Yankovich, A.; Evzelman, M.; Peretz, M. Scalable High-Power Battery Emulator for Power Hardware-in-the-Loop Applications. In Proceedings of the IEEE 24th Workshop on Control and Modeling for Power Electronics (COMPEL), 25–28 June 2023. [Google Scholar]

- Madden, C.; Peskar, J.; Sado, K.; Downey, A.; Khan, J. Electro-Thermal Hardware-in-the-Loop Battery Emulator for Shipboard Systems Testing. In Proceedings of the IEEE Electric Ship Technologies Symposium (ESTS), Alexandria, VA, USA, 5–8 August 2025. [Google Scholar]

- Lacressonnière, F.; Varais, A.; Roboam, X.; Bru, E.; Mullins, T. Scale electro-thermal model of a lithium-ion battery for time-accelerated experiments in a hardware in the loop process. J. Energy Storage 2021, 39, 102576. [Google Scholar] [CrossRef]

- Chou, P.H.; Park, C.; Park, J.; Pham, K.; Liu, J. B#: A battery emulator and power profiling instrument. In Proceedings of the International Symposium on Low Power Electronics and Design, Seoul, Republic of Korea, 25–27 August 2003. [Google Scholar]

- Vicidomini, G.; Petrone, G.; Monmasson, E.; Spagnuolo, G. FPGA based implementation of a sliding-mode observer for battery state of charge estimation. In Proceedings of the IEEE 26th International Symposium on Industrial Electronics (ISIE), Edinburgh, UK, 19–21 June 2017. [Google Scholar]

- Rienzo, R.D.; Roncella, R.; Morello, R.; Baronti, F.; Saletti, R. Low-cost modular battery emulator for battery management system testing. In Proceedings of the IEEE International Conference on Industrial Electronics for Sustainable Energy Systems (IESES), Hamilton, New Zealand, 31 January–2 February 2018. [Google Scholar]

- Verani, A.; Di Rienzo, R.; Nicodemo, N.; Baronti, F.; Roncella, R.; Saletti, R. Modular Battery Emulator for Development and Functional Testing of Battery Management Systems: Hardware Design and Characterization. Electronics 2023, 12, 1232. [Google Scholar] [CrossRef]

- Verani, A.; Rienzo, R.D.; Nicodemo, N.; Baronti, F.; Roncella, R.; Saletti, R. Open Hardware/Software Modular Battery Emulator for Battery Management Systems Development and Functional Testing. IEEE Access 2024, 12, 84488–84497. [Google Scholar] [CrossRef]

- Santoni, F.; De Angelis, A.; Moschitta, A.; Carbone, P. Digital Impedance Emulator for Battery Measurement System Calibration. Sensors 2021, 21, 7377. [Google Scholar] [CrossRef]

- Högerl, T.; Buberger, J.; Schwitzgebel, F.; Obkricher, L.; Estaller, J.; Hohenegger, M.; Kersten, A.; Kuder, M.; Eckerle, R.; Weyh, T. Battery Emulation for Battery Modular Multilevel Management (BM3) Converters and Reconfigurable Batteries with Series, Parallel and Bypass Function. In Proceedings of the IEEE International Conference on Environment and Electrical Engineering and IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Bari, Italy, 7–10 September 2021. [Google Scholar]

- Jassim, H.M.; Ziuzev, A.M.; Mudrov, M.V. Power hardware-in-loop emulation of a battery for charging systems and grid applications. Bull. Tomsk. Polytech. Univ. Geo Assets Eng. 2024, 335, 200–211. [Google Scholar] [CrossRef]

- Michalczuk, M.; Ufnalski, B.; Grzesiak, L.M.; Rumniak, P. Power converter-based electrochemical battery emulator. Prz. Elektrotechniczny 2014, 90, 18–22. [Google Scholar]

- König, O.; Hametner, C.; Prochart, G.; Jakubek, S. Battery Emulation for Power-HIL Using Local Model Networks and Robust Impedance Control. IEEE Trans. Ind. Electron. 2014, 61, 943–955. [Google Scholar]

- König, O.; Jakubek, S.; Prochart, G. Battery impedance emulation for hybrid and electric powertrain testing. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, Seoul, Republic of Korea, 9–12 October 2012. [Google Scholar]

- Wasserburger, A.; König, O.; Jakubek, S. Estimation and compensation of DC-Link voltage disturbances in a DC–DC converter for battery emulation. Int. J. Control. 2020, 93, 922–933. [Google Scholar]

- König, O.; Gregorčič, G.; Jakubek, S. Model predictive control of a DC–DC converter for battery emulation. Control. Eng. Pract. 2013, 21, 428–440. [Google Scholar]

- Thanheiser, A.; Meyer, W.; Buecherl, D.; Herzog, H.-G. Design and investigation of a modular battery simulator system. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, Dearborn, MI, USA, 7–11 September 2009. [Google Scholar]

- Zauner, M.; Mandl, P.; Hametner, C.; König, O.; Jakubek, S. Flatness-Based Discrete-Time Control of a Battery Emulator Driving a Constant Power Load. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 9, 6864–6874. [Google Scholar]

- Kleutgens, P.H.J.; Hagemann, L.; Meißen, A.; Mortimer, B.J.; De Doncker, R.W. A power hardware-in-the-loop test bench for emulation of test scenarios and mission profiles for high-power DC charging stations. Elektrotech. Inftech. 2025, 142, 30–41. [Google Scholar] [CrossRef]

- Kulsangcharoen, P.; Rashed, M.; Klumpner, C.; De, D.; Patel, C.; Asher, G.; Chen, G.Z. Evaluation of a digitally controlled power electronic emulator for supercapattery. In Proceedings of the 6th IET International Conference on Power Electronics, Machines and Drives (PEMD 2012), Bristol, UK, 27–29 March 2012. [Google Scholar]

- Baumhöfer, T.; Waag, W.; Sauer, D.U. Specialized battery emulator for automotive electrical systems. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, Lille, France, 1–3 September 2010. [Google Scholar]

- Farag, S.; Lerman, C.; Lineykin, S.; Kuperman, A. Off-the-Shelf Power Supply-Based Battery/Supercapacitor Emulator for Charger Functionality Testing. IEEE Trans. Transp. Electrif. 2016, 2, 129–139. [Google Scholar]

- Hidalgo-León, R.; Jácome-Ruiz, P.; Almeida-Pazmiño, G.; Urquizo-Guevara, J.; Soriano-Idrovo, G. A Survey on Technologies to Implement Battery Emulators Based on DC/DC Power Converters. In Proceedings of the 14th LACCEI International Multi-Conference for Engineering, Education, and Technology: “Engineering Innovations for Global Sustainability”, San José, Costa Rica, 20–22 July 2016. [Google Scholar]

- Mesbahi, T.; Rizoug, N.; Khenfri, F.; Bartholomeüs, P.; Le Moigne, P. Dynamical modelling and emulation of Li-ion batteries–supercapacitors hybrid power supply for electric vehicle applications. IET Electr. Syst. Transp. 2017, 7, 161–169. [Google Scholar] [CrossRef]

- Hidalgo-León, R.; Urquizo, J.; Litardo, J.; Muñoz-Jadán, Y.; Singh, P.; Wu, J. Simulation of battery discharge emulator using power electronics device with cascaded P-I control. In Proceedings of the IEEE International Conference on Industrial Technology (ICIT), Buenos Aires, Argentina, 26–28 February 2020. [Google Scholar]

- Thale, S.; Wandhare, R.; Agarwal, V. A novel low cost portable integrated solar PV, fuel cell and battery emulator with fast tracking algorithm. In Proceedings of the IEEE 40th Photovoltaic Specialist Conference (PVSC), Denver, CO, USA, 8–13 June 2014. [Google Scholar]

- Santos León, A.I.; Peña Acosta, Á.A.; Trujillo Rodríguez, C.L.; Santamaría Piedrahita, F. Design and Implementation of a Lead-Acid Battery Emulator. J. Eng. Sci. Technol. Rev. 2020, 13, 172–180. [Google Scholar] [CrossRef]

- Mishra, S.; Tamballa, S.; Pallantala, M.; Raju, S.; Mohan, N. Cascaded Dual-Active Bridge Cell Based Partial Power Converter for Battery Emulation. In Proceedings of the 20th Workshop on Control and Modeling for Power Electronics (COMPEL), Toronto, ON, Canada, 17–20 June 2019. [Google Scholar]

- Dingrui, L. Development of a Converter-Based Testing Platform and Battery Energy Storage System (BESS) Emulator for Microgrid Controller Function Evaluation. Master’s Thesis, University of Tennessee, Knoxville, TN, USA, 2021. [Google Scholar]

- Wang, Q.; Wei, X.Z.; Dai, H.F. Hardware-in-Loop Test Platform for Electric Vehicle Cell Battery Management System. Appl. Mech. Mater. 2010, 29–32, 2398–2403. [Google Scholar] [CrossRef]

- Spataru, S.; Martins, J.; Stroe, D.-I.; Sera, D. Test Platform for Photovoltaic Systems with Integrated Battery Energy Storage Applications. In Proceedings of the IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC) (A Joint Conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC), Waikoloa, HI, USA, 10–15 June 2018. [Google Scholar]

- Filho, P.S.N.; Silveira, J.P.C.; Neto, P.J.d.S.; de Paula, M.V.; Barros, T.A.d.S.; Filho, E.R. Modeling and Experimental Evaluation of Energy Storage Emulator for Microgrids Application. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 9, 6662–6670. [Google Scholar] [CrossRef]

- Li, R.; Ji, Y.; Fu, Y.; Hu, B.; Hu, H. Design and implementation of a parametric battery emulator based on a power converter. IET Electr. Power Appl. 2022, 16, 1300–1316. [Google Scholar] [CrossRef]

- Lale, S.; Šoja, M.; Lubura, S.; Mančić, D. Application of I2 technique on dual current mode control of power electronics converters. Electr. Eng. 2018, 100, 1761–1772. [Google Scholar] [CrossRef]

- Redl, R.; Sokal, N.O. Near-optimum dynamic regulation of DC-DC converters using feed-forward of output current and input voltage with current-mode control. IEEE Trans. Power Electron. 1986, PE-1, 181–192. [Google Scholar] [CrossRef]

- Chen, M.; Rincon-Mora, G.A. Accurate electrical battery model capable of predicting runtime and I-V performance. IEEE Trans. Energy Convers. 2006, 21, 504–511. [Google Scholar] [CrossRef]

- Tremblay, O.; Dessaint, L.A. Experimental validation of a battery dynamic model for ev applications. World Electr. Veh. J. 2009, 3, 289–298. [Google Scholar] [CrossRef]

| Name | Value | |

|---|---|---|

| DC source/load | vDC | 6 V |

| R1 | 20 Ω | |

| C1 | 1000 µF | |

| Non-inverting buck-boost converter | L | 220 µH |

| C | 1000 µF | |

| Programmable DC load/source | L1 | 1 mH |

| C2 | 470 µF | |

| R2 | 20 Ω | |

| vDC1 | 10 V | |

| Polymer Li-ion battery model | Rself-discharge | +∞ (open circuit) |

| Ccapacity | 3060 F | |

| Conventional Li-ion battery model | E0 | 3.366 V |

| R | 0.01 Ω | |

| K | 0.0076 Ω or V/(Ah) | |

| Q | 2.3 Ah | |

| A | 0.26422 V | |

| B | 26.5487 1/(Ah) | |

| Lead–acid battery model | E0 | 12.4659 V |

| R | 0.04 Ω | |

| K | 0.047 Ω or V/(Ah) | |

| Q | 7.2 Ah | |

| A | 0.83 V | |

| B | 125 1/(Ah) | |

| I2DCMC | fs | 25 kHz |

| Ib | 0.4 A | |

| Ib1 | 0.1 A | |

| kp | 0.499 | |

| ki | 59.835 | |

| Ki | 5000 | |

| Ki1 | 500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lale, S.; Bašić, M.; Lubura, S.; Popović, B.; Ikić, M. Current-Mode Controlled Battery Emulator. Processes 2025, 13, 3281. https://doi.org/10.3390/pr13103281

Lale S, Bašić M, Lubura S, Popović B, Ikić M. Current-Mode Controlled Battery Emulator. Processes. 2025; 13(10):3281. https://doi.org/10.3390/pr13103281

Chicago/Turabian StyleLale, Srđan, Mateo Bašić, Slobodan Lubura, Božidar Popović, and Marko Ikić. 2025. "Current-Mode Controlled Battery Emulator" Processes 13, no. 10: 3281. https://doi.org/10.3390/pr13103281

APA StyleLale, S., Bašić, M., Lubura, S., Popović, B., & Ikić, M. (2025). Current-Mode Controlled Battery Emulator. Processes, 13(10), 3281. https://doi.org/10.3390/pr13103281