Optimization of Production Layer Combinations in Multi-Superposed Coalbed Methane Systems Using Numerical Simulation: A Case Study from Western Guizhou and Eastern Yunnan, China

Abstract

1. Introduction

2. Geological Setting and Production Challenges

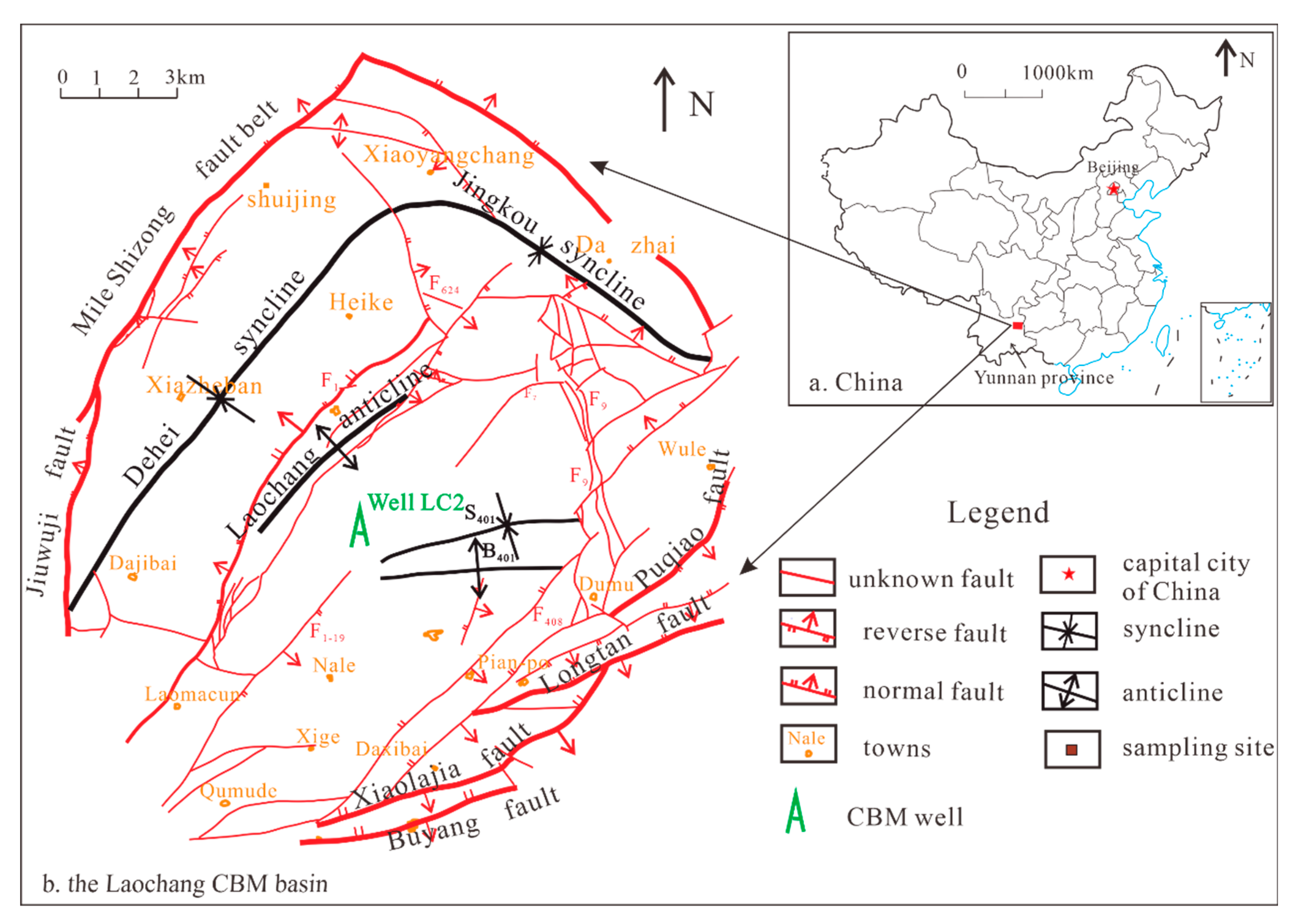

2.1. Geological Setting

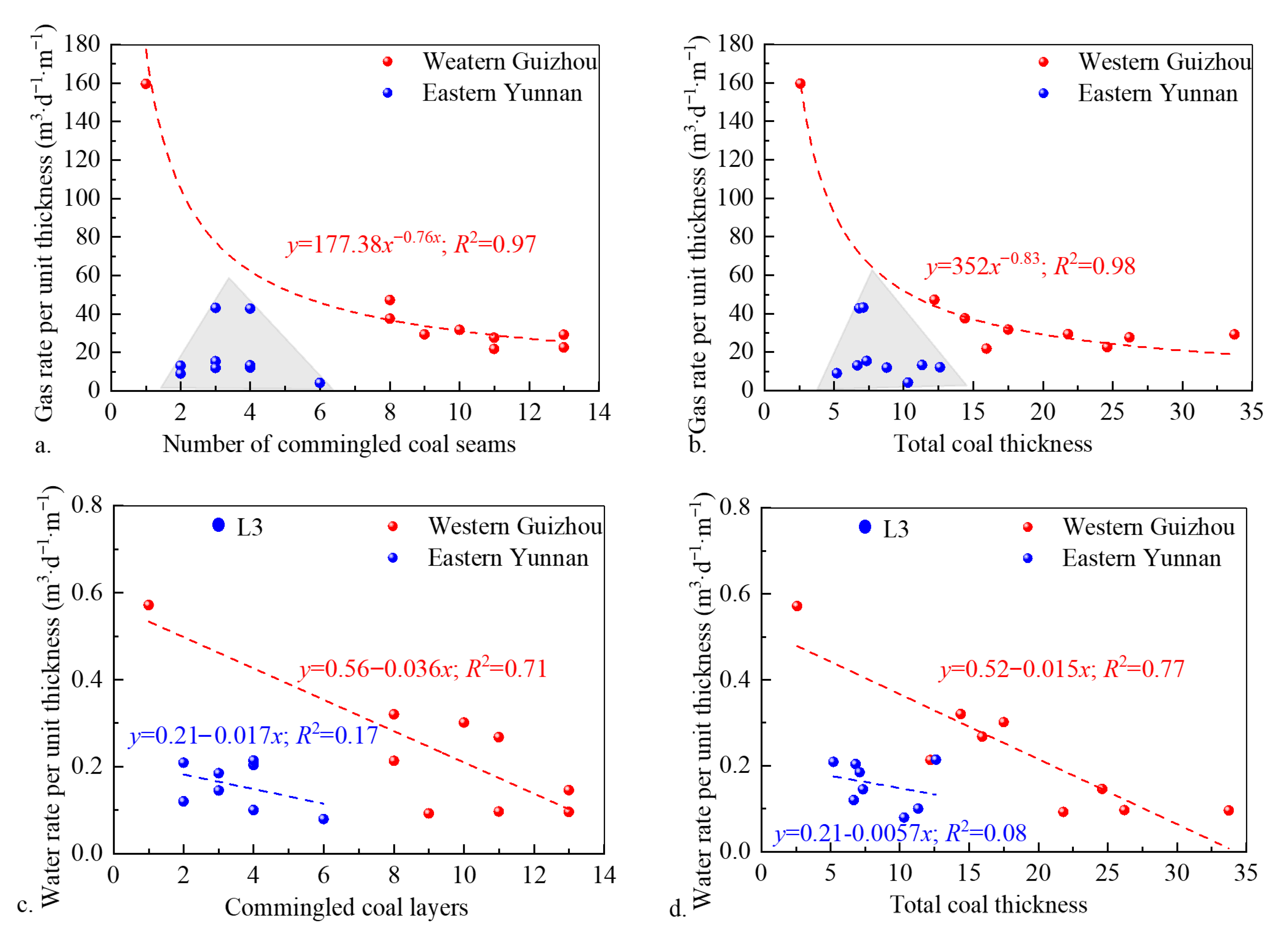

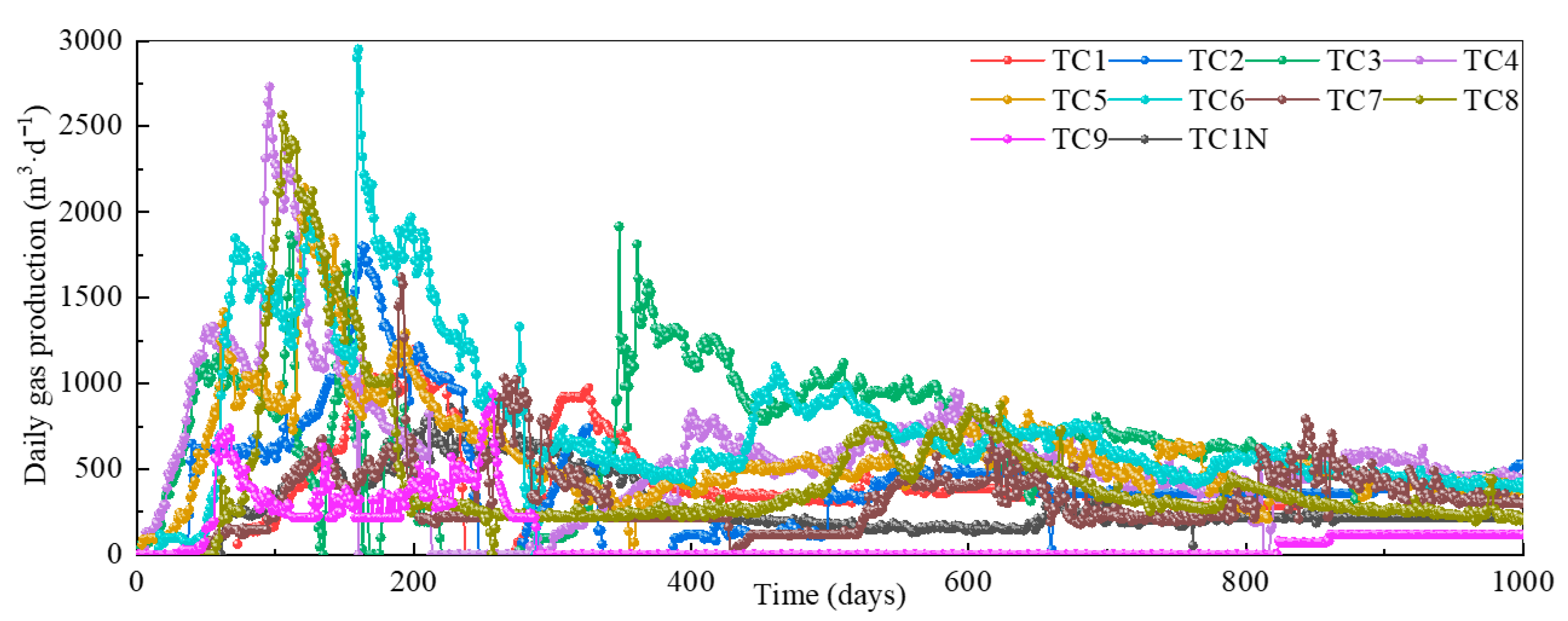

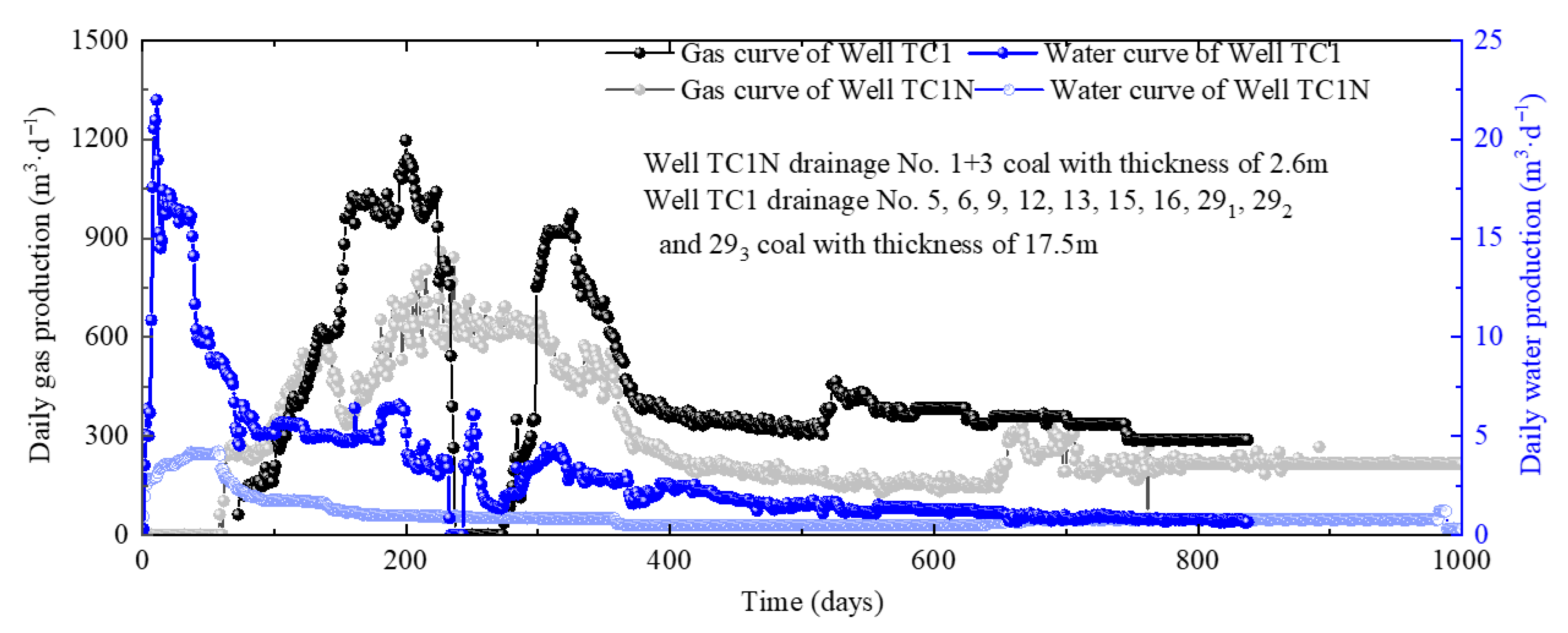

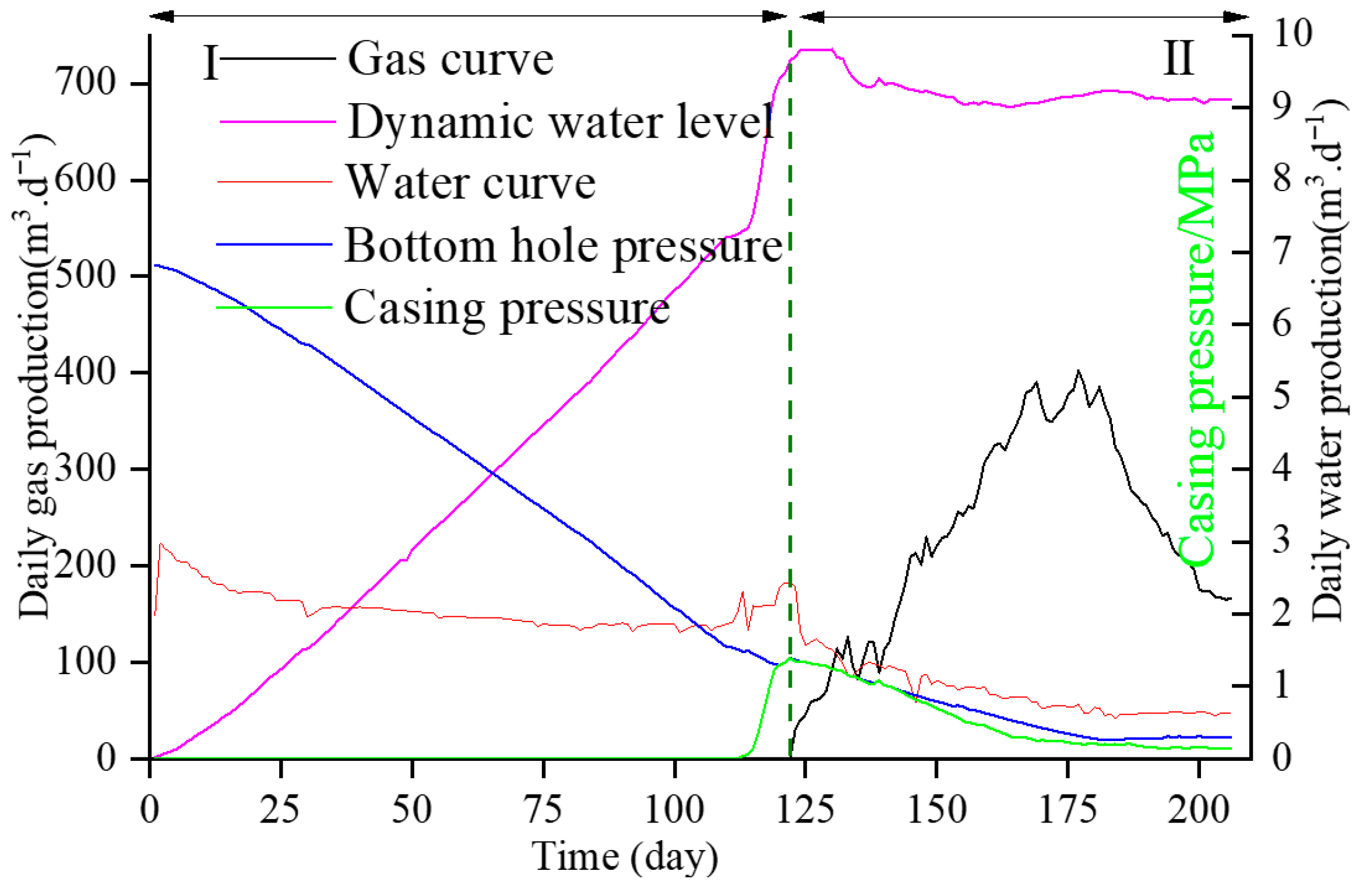

2.2. Production Challenges in Commingled CBM Wells

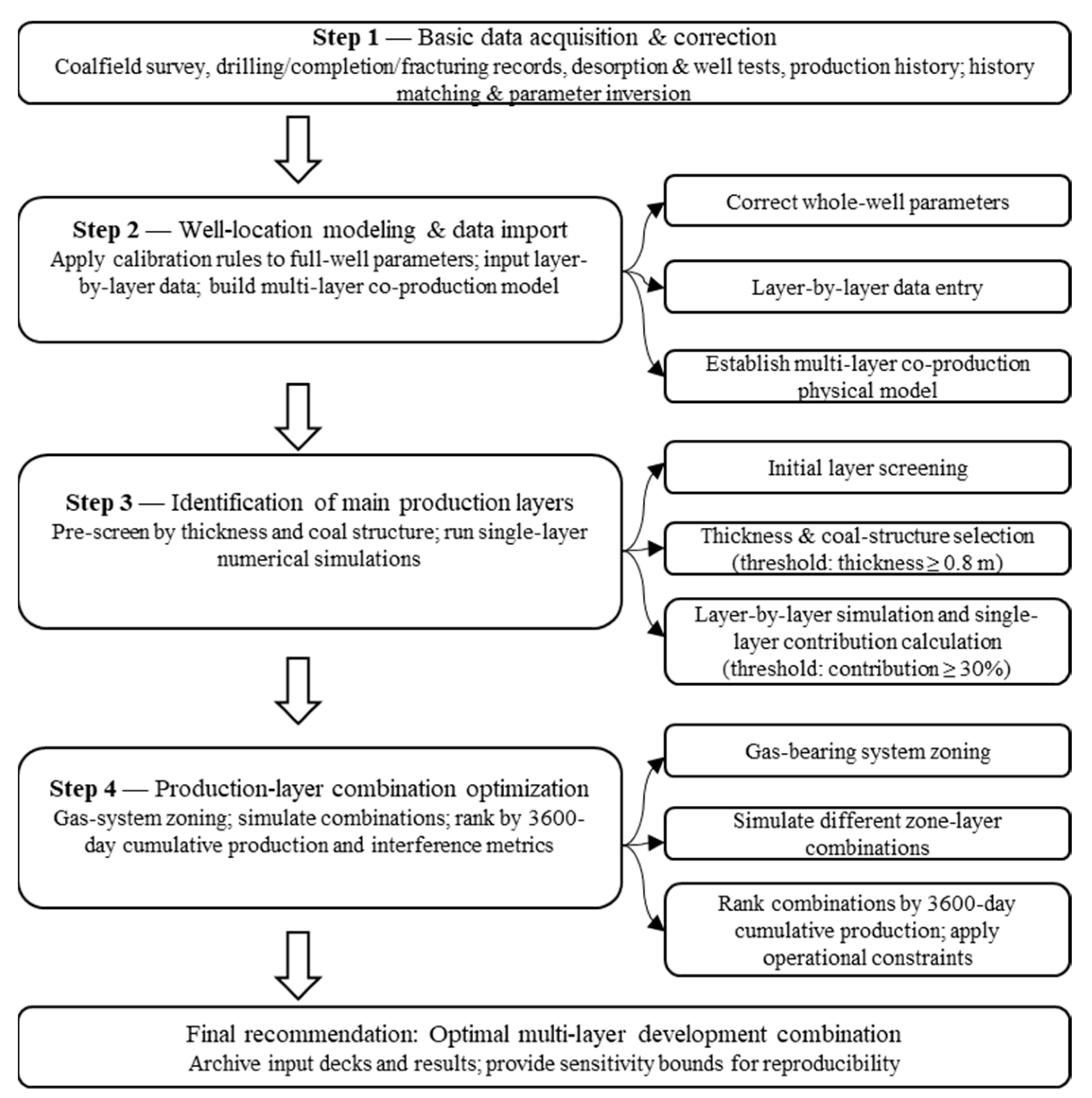

3. Methodology

3.1. Data Collection and Calibration

3.2. Well Model Construction

3.3. Main Production Layer Identification

3.4. Optimization Method for Layer Combinations

4. Case Study: Well LC-C2

4.1. Well Overview and Data Collection

4.2. Building the Full Well Model

5. Results and Discussion

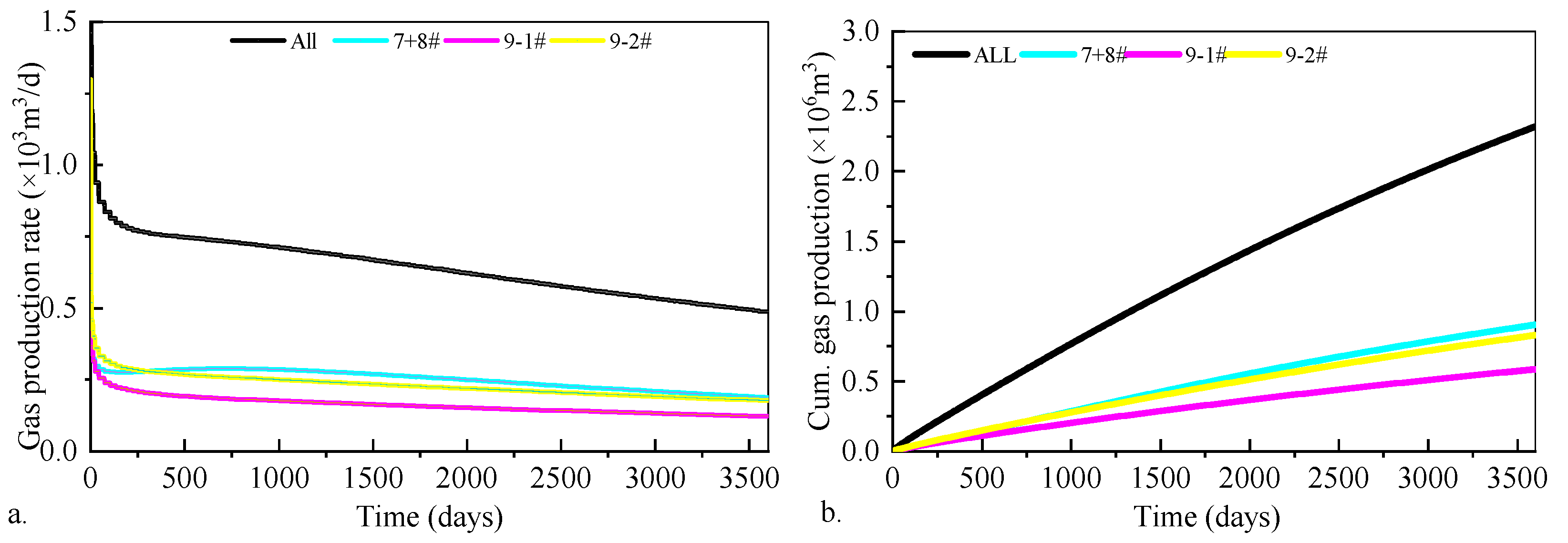

5.1. Main Coal Seam Identification

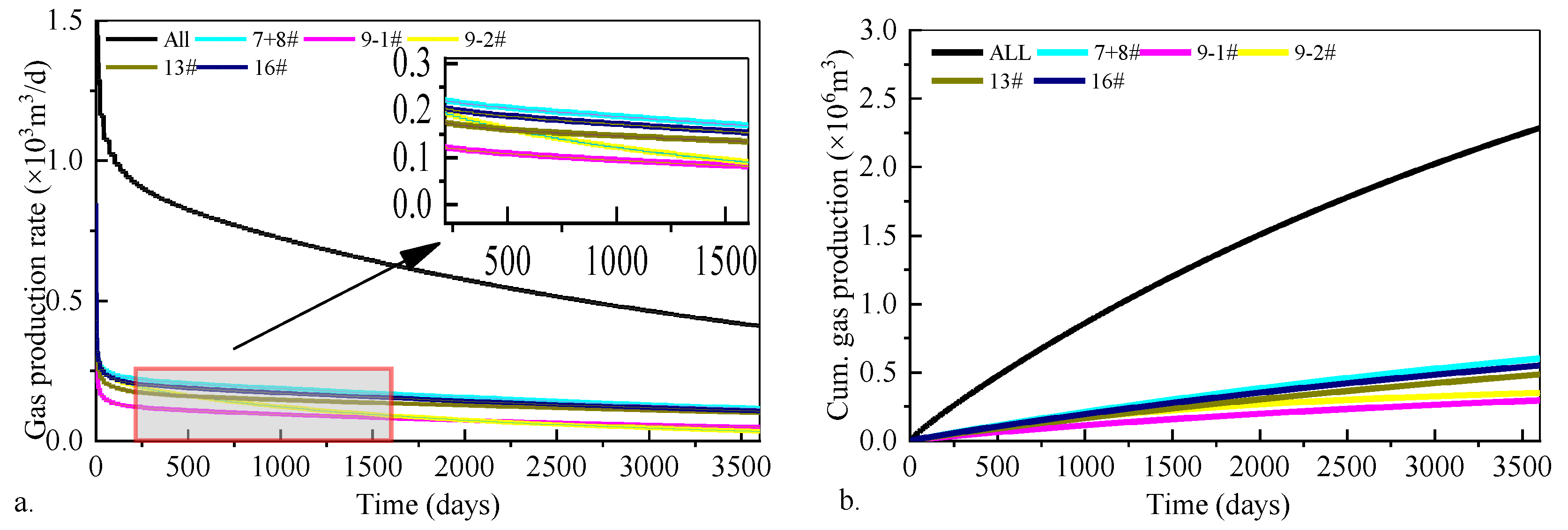

5.2. Optimization of Layer Combinations

6. Conclusions

- (1).

- Commingling too many coal seams across different pressure systems can severely impair CBM well performance. Field trials and simulations confirm that indiscriminate co-production of numerous layers (especially combining high-pressure and low-pressure systems) leads to strong inter-layer interference. In such cases, the higher-pressure seams dominate production while lower-pressure seams contribute little, resulting in total gas output far below the sum of what individual seams could produce (a “1 + 1 < 2” negative synergy effect).

- (2).

- A systematic, simulation-based workflow was developed to optimize multi-seam production design. The proposed four-step method (data gathering and calibration, well modeling, single-seam productivity evaluation, and scenario simulation) provides a quantitative means to identify the most productive coal seams and the optimal combination for co-production. This data-driven approach moves beyond prior qualitative guidelines and trial-and-error field practices, enabling informed decision-making for layer selection in commingled CBM wells.

- (3).

- Application of the method to well LC-C2 demonstrated that an intermediate number of compatible seams yields the best performance. In the case study, only one seam (7 + 8) was identified as a primary “main layer” (>30% of total potential), with a few others as secondary contributors (~10–18% each). The optimal production strategy was to co-produce the six seams from the two higher-pressure systems (Systems I and II), while excluding the shallow low-pressure system (System III). This optimized configuration achieved a 10-year cumulative gas recovery of ~2.53 × 106 m3 (~700 m3/d average), about 75% higher than producing the main seam alone and ~15% higher than commingling all three systems (ten seams).

- (4).

- Selective co-production of seams from similar pressure regimes is recommended for multi-layer CBM reservoirs. By avoiding low-productivity seams that mainly introduce water or siphon pressure drawdown, operators can greatly improve gas recovery and well stability. The findings from LC-C2 indicate that focusing on a moderate number of high-quality seams (in terms of pressure, permeability, and gas content) can maximize gas output, whereas adding marginal seams from other pressure compartments may be counterproductive. This optimized approach to layer selection can be applied to other CBM fields with stacked coal seams, providing valuable guidance to enhance production efficiency in geologically compartmentalized reservoirs.

- (5).

- This study is limited to a single well in one geological setting, and uncertainties remain in assumed fracture parameters and permeability calibration. Future work will focus on applying the four-step workflow to multi-well pilot tests in different geological blocks, incorporating uncertainty quantification of fracture parameters, and assessing the applicability of the method in other CBM basins worldwide.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ren, J.; Li, Q.; Zhang, M.; Xu, J.; Li, Y.; Yang, P. On the Fluid Behavior Response Characteristics During Early Stage of CBM Co-Production in Superimposed Pressure Systems: Insights from Experimental Analysis. Processes 2025, 13, 1095. [Google Scholar] [CrossRef]

- Qin, Y.; Xiong, M.H.; Yi, T.S.; Yang, Z.B.; Wu, C.F. On unattached multiple superposed coalbed-methane system: In a case of the Shuigonghe Syncline, Zhijin-Nayong Coalfield, Guizhou. Geol. Rev. 2008, 54, 65–70. [Google Scholar]

- Quan, F.; Wei, C.; Ma, J.; Hao, S.; Song, Y. Modeling analysis of coalbed methane co-production interference: A case study in Eastern Yunnan Basin, China. J. Nat. Gas. Sci. Eng. 2022, 103, 104631. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, Z.; Wang, Q.; Shen, J.; Glover, P.W.; Lorinczi, P.; Zhang, J.; Zheng, S. Influence of Coal Stress Sensitivity on the Desorption Production Characteristics and Residual CH4 Distribution of Thin Multilayered Coal Seams. Energ. Fuel 2024, 38, 22820–22832. [Google Scholar] [CrossRef]

- Li, Q.; Xu, J.; Shu, L.; Yan, F.; Pang, B.; Peng, S. Exploration of the induced fluid-disturbance effect in CBM co-production in a superimposed pressure system. Energy 2023, 265, 126347. [Google Scholar] [CrossRef]

- Zhang, Z.; Qin, Y.; You, Z.; Yang, Z. Distribution Characteristics of In Situ Stress Field and Vertical Development Unit Division of CBM in Western Guizhou, China. Nat. Resour. Res. 2021, 30, 3659–3671. [Google Scholar] [CrossRef]

- Zhang, Z.; Qin, Y.; Yang, Z.; Jin, J.; Wu, C. Fluid energy characteristics and development potential of coalbed methane reservoirs with different synclines in Guizhou, China. J. Nat. Gas. Sci. Eng. 2019, 71, 102981. [Google Scholar] [CrossRef]

- Jin, J.; Yang, Z.; Qin, Y.; Cui, Y.; Wang, G.; Yi, T.; Wu, C.; Gao, W.; Chen, J.; Li, G.; et al. Progress, potential and prospects of CBM development in Guizhou Province. J. China Coal Soc. 2022, 47, 4115–4128. [Google Scholar]

- Qin, Y.; Wu, J.; Zhang, Z.; Yi, T.; Yang, Z.; Jin, J.; Zhang, B. Analysis of geological conditions for coalbed methane co-production based on production characteristics in early stage of drainage. J. China Coal Soc. 2020, 45, 241–257. [Google Scholar]

- Guo, C.; Qin, Y.; Ma, D.; Lu, L. Pore structure response of sedimentary cycle in coal-bearing strata and implications for independent superposed coalbed methane systems. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 47, 1014–1033. [Google Scholar] [CrossRef]

- Yang, Z.; Qin, Y.; Qin, Z.; Yi, T.; Li, C.; Zhang, Z. Characteristics of dissolved inorganic carbon in produced water from coalbed methane wells and its geological significance. Pet. Explor. Dev. 2020, 47, 1074–1083. [Google Scholar] [CrossRef]

- Cheng, G.; Jiang, B.; Li, M.; Liu, J.; Li, F. Effects of pore structure on methane adsorption behavior of ductile tectonically deformed coals: An inspiration to coalbed methane exploitation in structurally complex area. J. Nat. Gas. Sci. Eng. 2020, 74, 103083. [Google Scholar] [CrossRef]

- Quan, F.; Lu, W.; Song, Y.; Wei, C.; Ma, J. Direct Quantification of Coal Pore Dynamics During Methane Depletion Via Low-Field Nuclear Magnetic Resonance. Energ. Fuel. 2025, 39, 12538–12550. [Google Scholar] [CrossRef]

- Li, Q.; Xu, J.; Peng, S.; Yan, F.; Zhou, B.; Han, E.; Jiang, C. Physical Simulations of Gas Production Mechanism in Constant-Rate Co-production from Multiple Coal Reservoirs. Nat. Resour. Res. 2021, 30, 1427–1443. [Google Scholar] [CrossRef]

- Wang, Z.; Qin, Y.; Li, T.; Zhang, X. A numerical investigation of gas flow behavior in two-layered coal seams considering interlayer interference and heterogeneity. Int. J. Min. Sci. Technol. 2021, 31, 699–716. [Google Scholar] [CrossRef]

- Guo, C.; Qin, Y.; Sun, X.; Wang, S.; Xia, Y.; Ma, D.; Bian, H.; Shi, Q.; Chen, Y.; Bao, Y.; et al. Physical simulation and compatibility evaluation of multi-seam CBM co-production: Implications for the development of stacked CBM systems. J. Pet. Sci. Eng. 2021, 204, 108702. [Google Scholar] [CrossRef]

- Peng, S.; Jia, L.; Xu, J.; Zhang, C.; Li, Q.; Han, E. The production schedule optimization of a multilayer superposed CBM system: An experimental study. Powder Technol. 2020, 373, 99–108. [Google Scholar] [CrossRef]

- Li, Q.; Xu, J.; Peng, S.; Yan, F.; Zhou, B.; Han, E.; Jiang, C. Dynamic Evolution of the Fluid Effect of Multiple Reservoirs Due to CBM Coproduction: An Experimental Investigation. Energ. Fuel 2020, 34, 10947–10957. [Google Scholar] [CrossRef]

- Wang, Z.; Qin, Y. Physical experiments of CBM coproduction: A case study in Laochang district, Yunnan province, China. Fuel 2019, 239, 964–981. [Google Scholar] [CrossRef]

- Zhang, Z.; Qin, Y.; Yang, Z.; Li, G.; You, Z. Primary controlling factors of coalbed methane well productivity and high productive well patterns in eastern Yunnan and western Guizhou, China. Nat. Resour. Res. 2023, 32, 2711–2726. [Google Scholar] [CrossRef]

- Chen, S.; Tang, D.; Tao, S.; Chen, Z.; Xu, H.; Li, S. Coal Reservoir Heterogeneity in Multicoal Seams of the Panguan Syncline, Western Guizhou, China: Implication for the Development of Superposed CBM-Bearing Systems. Energ. Fuel 2018, 32, 8241–8253. [Google Scholar] [CrossRef]

- Miao, H.Y.; Veerle, V.; Zhang, J.J.; Chen, S.B.; Chang, X.C.; Du, Y.; Wang, Y.; Wei, C.T.; Luo, J.H.; Quan, F.K.; et al. Control mechanism of pressure drop rate on coalbed methane productivity by using production data and physical simulation technology. Fuel 2026, 406, 137060. [Google Scholar] [CrossRef]

- Shen, Y.; Qin, Y.; Guo, Y.; Yi, T.; Yuan, X.; Shao, Y. Characteristics and sedimentary control of a coalbed methane-bearing system in lopingian (late permian) coal-bearing strata of western Guizhou Province. J. Nat. Gas. Sci. Eng. 2016, 33, 8–17. [Google Scholar] [CrossRef]

- Li, C.; Yang, Z.; Huang, D.; Li, H.; Wang, G.; Lu, B.; Wang, J.; Liu, C. Occurrence and transformation mechanism of deep coalbed methane in medium and high rank coal under temperature and pressure coupling control. Fuel 2026, 404, 136188. [Google Scholar] [CrossRef]

- Shen, Y.; Qin, Y.; Wang, G.G.; Guo, Y.; Shen, J.; Gu, J.; Xiao, Q.; Zhang, T.; Zhang, C.; Tong, G. Sedimentary control on the formation of a multi-superimposed gas system in the development of key layers in the sequence framework. Mar. Pet. Geol. 2017, 88, 268–281. [Google Scholar] [CrossRef]

- Quan, F.; Wei, C.; Li, R.; Hao, S.; Zhang, J.; Song, Y.; Yan, G. Reservoir Damage in Coalbed Methane Commingled Drainage Wells and Its Fatal Impact on Well Recovery. Nat. Resour. Res. 2023, 32, 295–319. [Google Scholar] [CrossRef]

- Zhang, J.; Wei, C.; Yan, G.; Lu, G. Structural and fractal characterization of adsorption pores of middle–high rank coal reservoirs in western Yunnan and eastern Guizhou: An experimental study of coals from the Panguan syncline and Laochang anticline. Energ. Explor. Exploit. 2019, 37, 251–272. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, S.; Qiao, Y.; Xie, D.; Chang, L. Multifractal Characterization of Pore Heterogeneity and Water Distribution in Medium-and High-Rank Coals via Nuclear Magnetic Resonance. Fractal Fract. 2025, 9, 290. [Google Scholar] [CrossRef]

- Yang, Z.; Qin, Y.; Zhang, Z.; Sun, H.; Li, Y.; Wu, C. Optimization methods of production layer combination for coalbed methane development in multi-coal seams. Pet. Explor. Dev. Online 2018, 45, 312–320. [Google Scholar] [CrossRef]

| Coal Seam | Depth (m) | Thickness (m) | Pressure (MPa) | Pressure Grad. (MPa/100 m) | Critical Desor. P (MPa) | Permeability (mD) | Coal Structure |

|---|---|---|---|---|---|---|---|

| 16# | 699.2 | 1.40 | 7.73 | 1.11 | 0.79 | 0.0771 | Primary (intact) |

| 18# | 724.8 | 2.90 | 7.47 | 1.03 | 0.59 | 0.1126 | Primary (intact) |

| 19# | 734.7 | 1.80 | 7.62 | 1.04 | 0.80 | 0.0869 | Primary (intact) |

| Parameter | Seam 16 (Initial) | Seam 16 (Matched) | Seam 18 (Initial) | Seam 18 (Matched) | Seam 19 (Initial) | Seam 19 (Matched) |

|---|---|---|---|---|---|---|

| Permeability (mD) | 0.270 | 0.077 | 0.394 | 0.113 | 0.304 | 0.087 |

| Fracture half-length (m) | / | 80 | / | 80 | / | 80 |

| Fracture permeability (mD) | / | 0.50 | / | 0.50 | / | 0.50 |

| Critical desorption P (MPa) | 0.79 | 0.75 | 0.59 | 0.54 | 0.80 | 0.75 |

| Seam No. | 10-Year Cumulative Gas (m3) | Average Daily Gas (m3/d) | Percentage of Total (%) |

|---|---|---|---|

| 2 | 179,560 | 50 | 3.90% |

| 3 | 99,306 | 28 | 2.16% |

| 4 | 439,189 | 122 | 9.54% |

| 7 + 8 | 1,450,811 | 403 | 31.54% |

| 9-1 | 367,266 | 102 | 7.98% |

| 9-2 | 107,021 | 30 | 2.32% |

| 13 | 444,770 | 124 | 9.67% |

| 16 | 411,368 | 114 | 8.94% |

| 18 | 836,432 | 232 | 18.18% |

| 19 | 264,161 | 73 | 5.74% |

| All coal seams | 4,599,884 | 1278 | 100.00% |

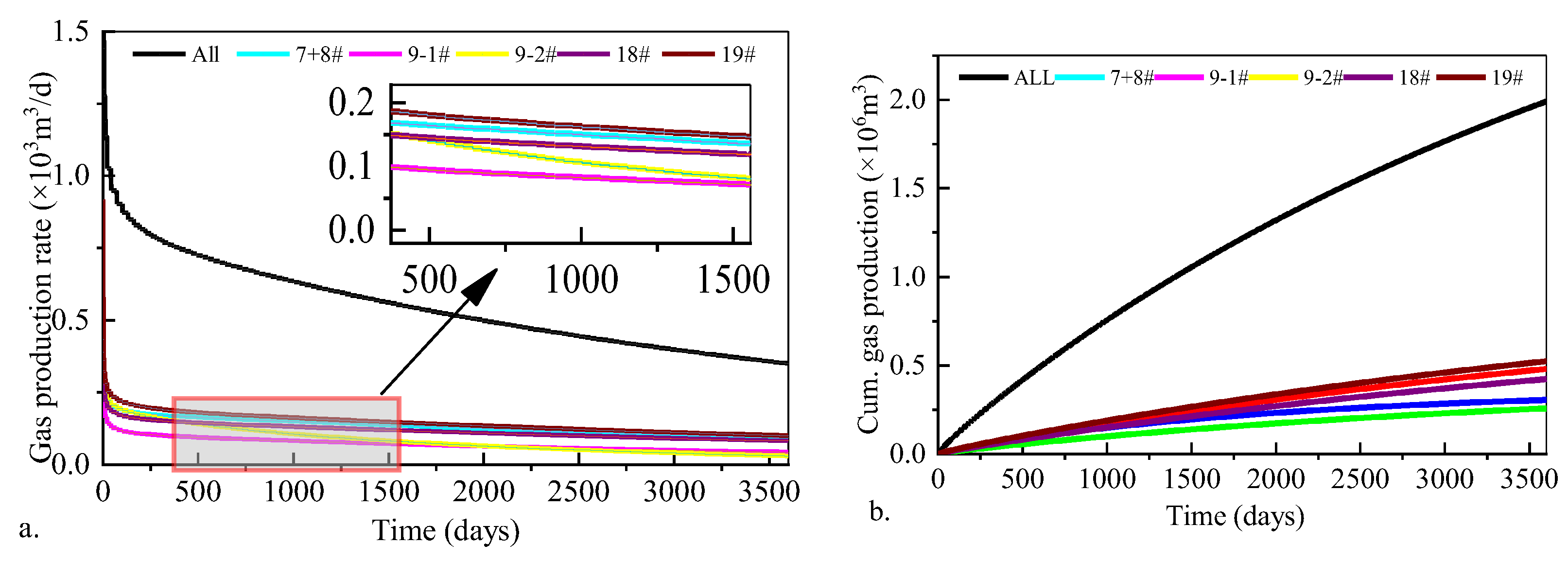

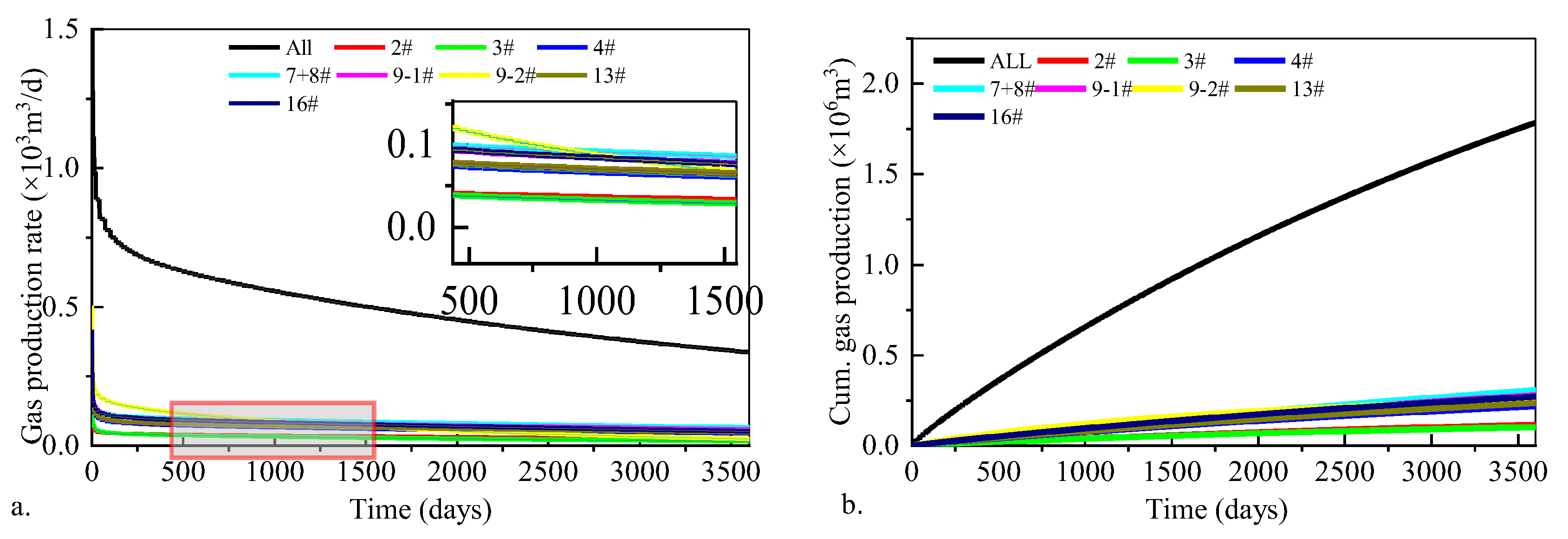

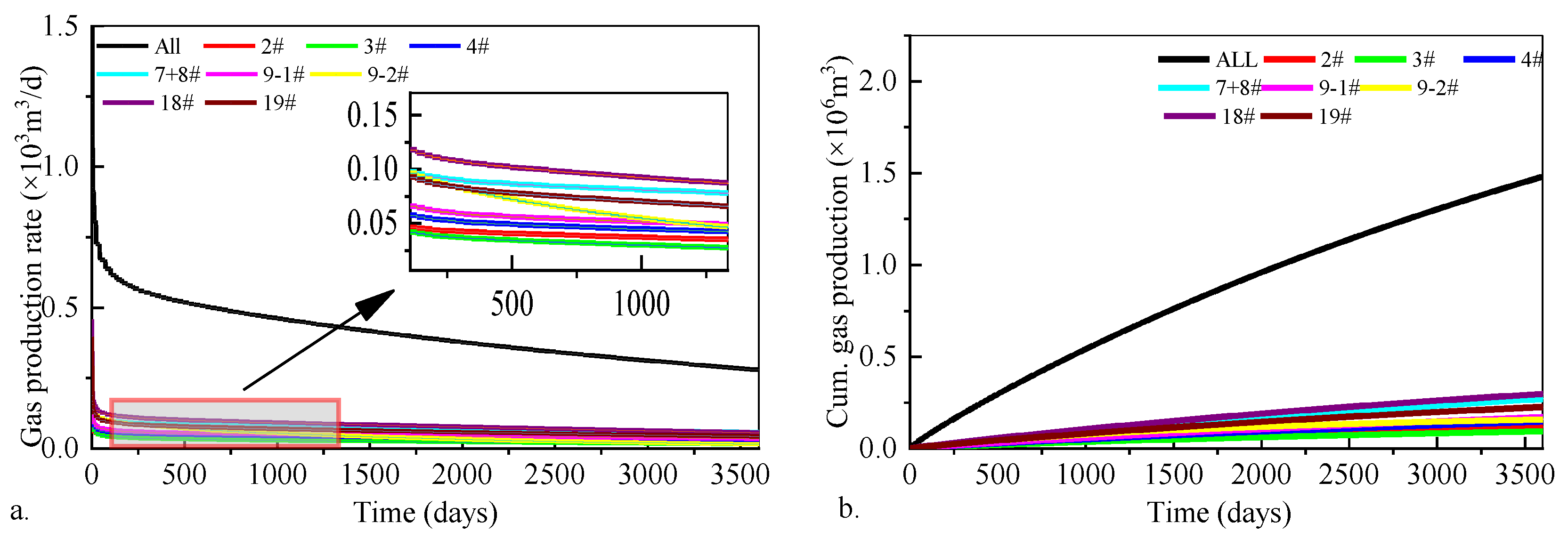

| Scenario | Co-Produced Seams | 10-Year Cumulative Gas (m3) | Average Gas Rate (m3/d) |

|---|---|---|---|

| 1. Main Seam Only | 7 + 8 (System II) | 1,450,811 | 403 |

| 2. All Seams in System II | 7 + 8, 9-1, 9-2 (System II) | 2,437,311 | 677 |

| 3. Systems I + II (Optimal) | 16, 18, 19 + 7 + 8, 9-1, 9-2 | 2,525,074 | 701 |

| 4. Systems II + III | 7 + 8, 9-1, 9-2 + 2, 3, 4, 13 | 2,286,024 | 635 |

| 5. All Systems (I + II + III) | 16, 18, 19 + 7 + 8, 9-1, 9-2 + 2, 3, 4, 13 | 2,200,000 | 610 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Quan, F.; Li, H.; Lu, W.; Song, T.; Wang, H.; Qin, Z. Optimization of Production Layer Combinations in Multi-Superposed Coalbed Methane Systems Using Numerical Simulation: A Case Study from Western Guizhou and Eastern Yunnan, China. Processes 2025, 13, 3280. https://doi.org/10.3390/pr13103280

Quan F, Li H, Lu W, Song T, Wang H, Qin Z. Optimization of Production Layer Combinations in Multi-Superposed Coalbed Methane Systems Using Numerical Simulation: A Case Study from Western Guizhou and Eastern Yunnan, China. Processes. 2025; 13(10):3280. https://doi.org/10.3390/pr13103280

Chicago/Turabian StyleQuan, Fangkai, Hongji Li, Wei Lu, Tao Song, Haiying Wang, and Zhengyuan Qin. 2025. "Optimization of Production Layer Combinations in Multi-Superposed Coalbed Methane Systems Using Numerical Simulation: A Case Study from Western Guizhou and Eastern Yunnan, China" Processes 13, no. 10: 3280. https://doi.org/10.3390/pr13103280

APA StyleQuan, F., Li, H., Lu, W., Song, T., Wang, H., & Qin, Z. (2025). Optimization of Production Layer Combinations in Multi-Superposed Coalbed Methane Systems Using Numerical Simulation: A Case Study from Western Guizhou and Eastern Yunnan, China. Processes, 13(10), 3280. https://doi.org/10.3390/pr13103280