A Verification Method for a Bay Configuration File of Intelligent Substation Renovation and Expansion in Power Systems

Abstract

1. Introduction

2. Analysis of Configuration Files for Intelligent Substations

3. Configuration File Verification Method Based on CRC Dynamic Verification

3.1. Secondary Circuit CRC Code

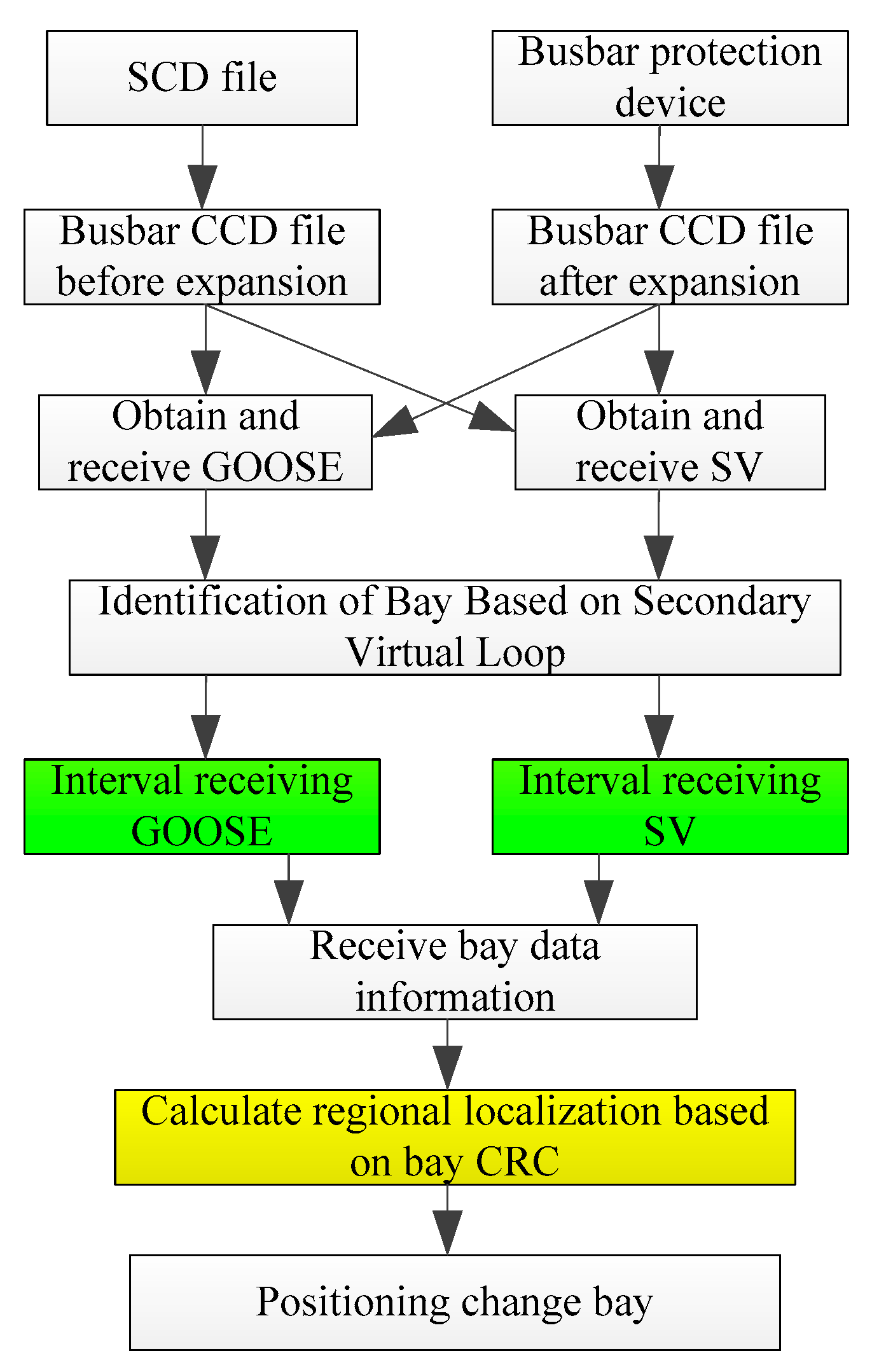

3.2. CRC Dynamic Verification

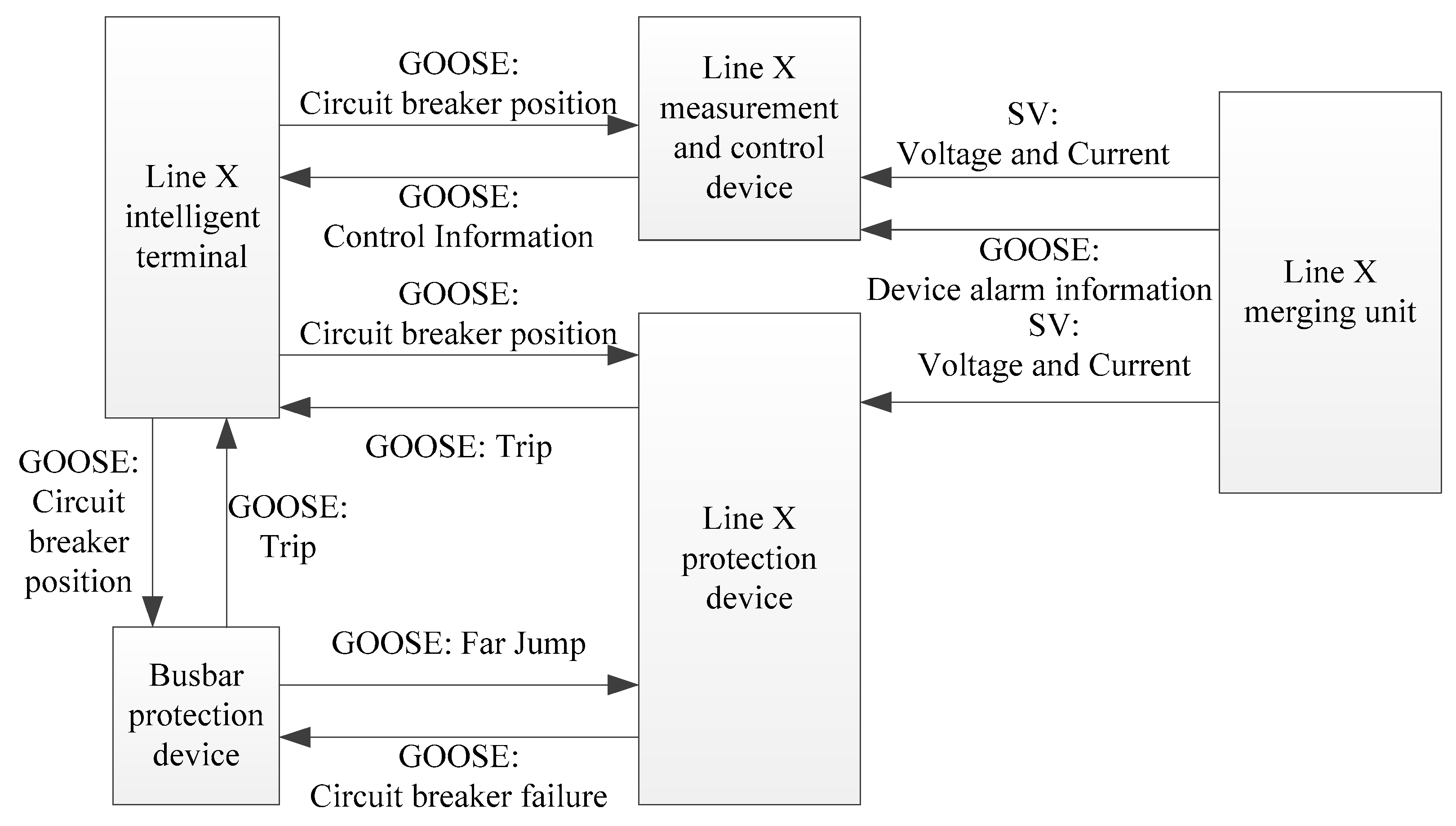

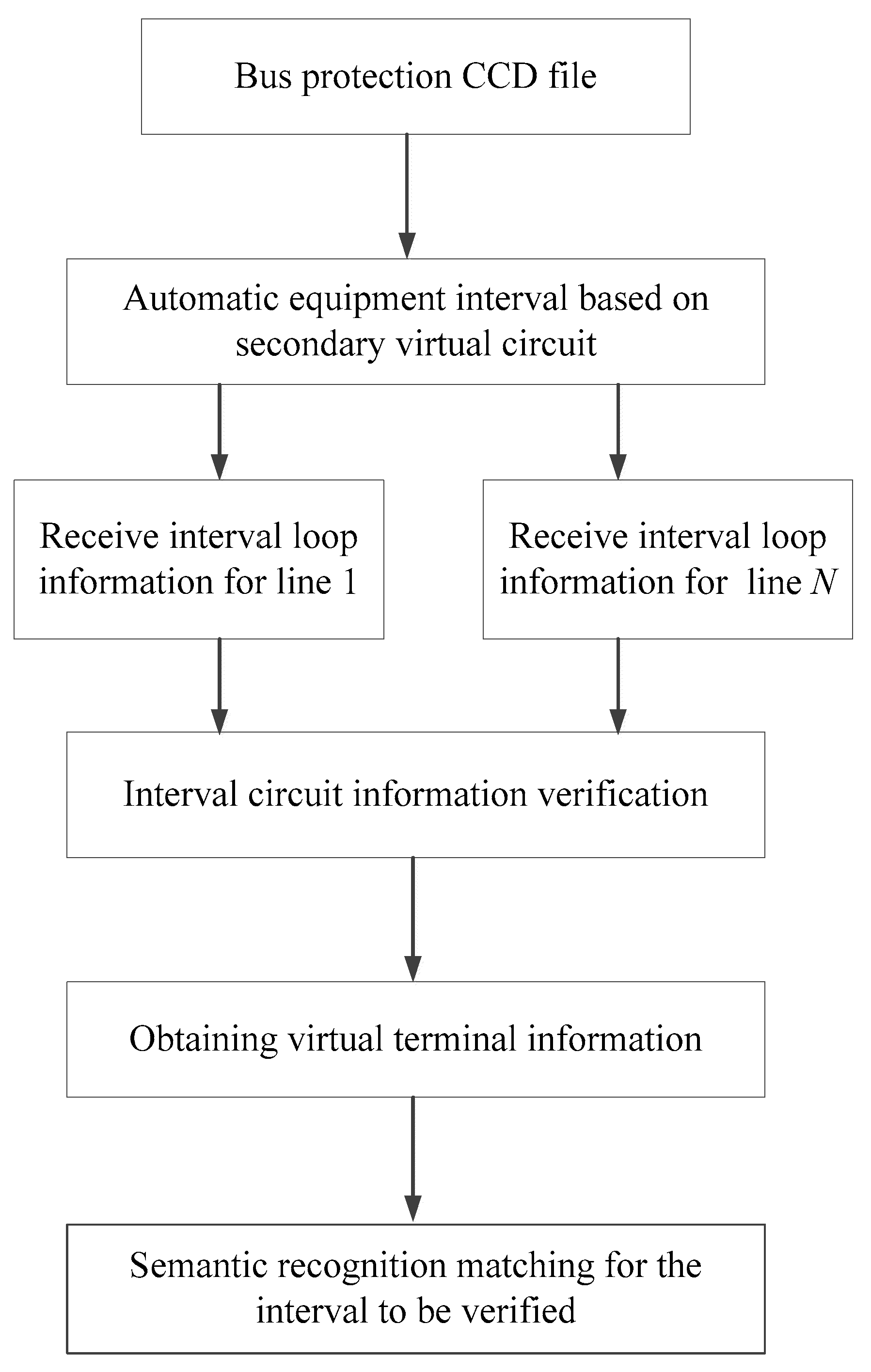

3.3. Verification of Virtual Circuit Configuration Information for Associated Intervals

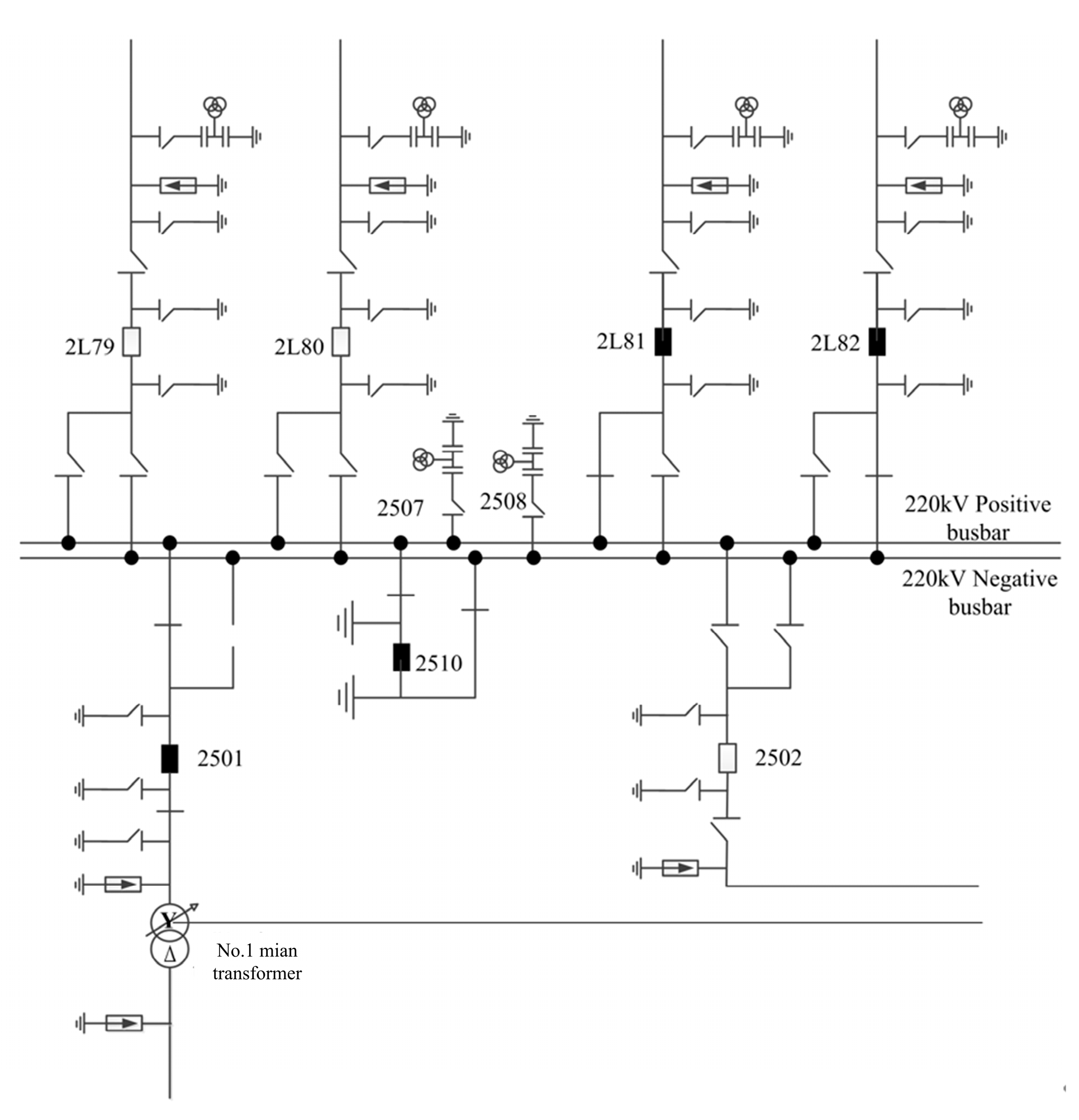

4. Engineering-Application Examples

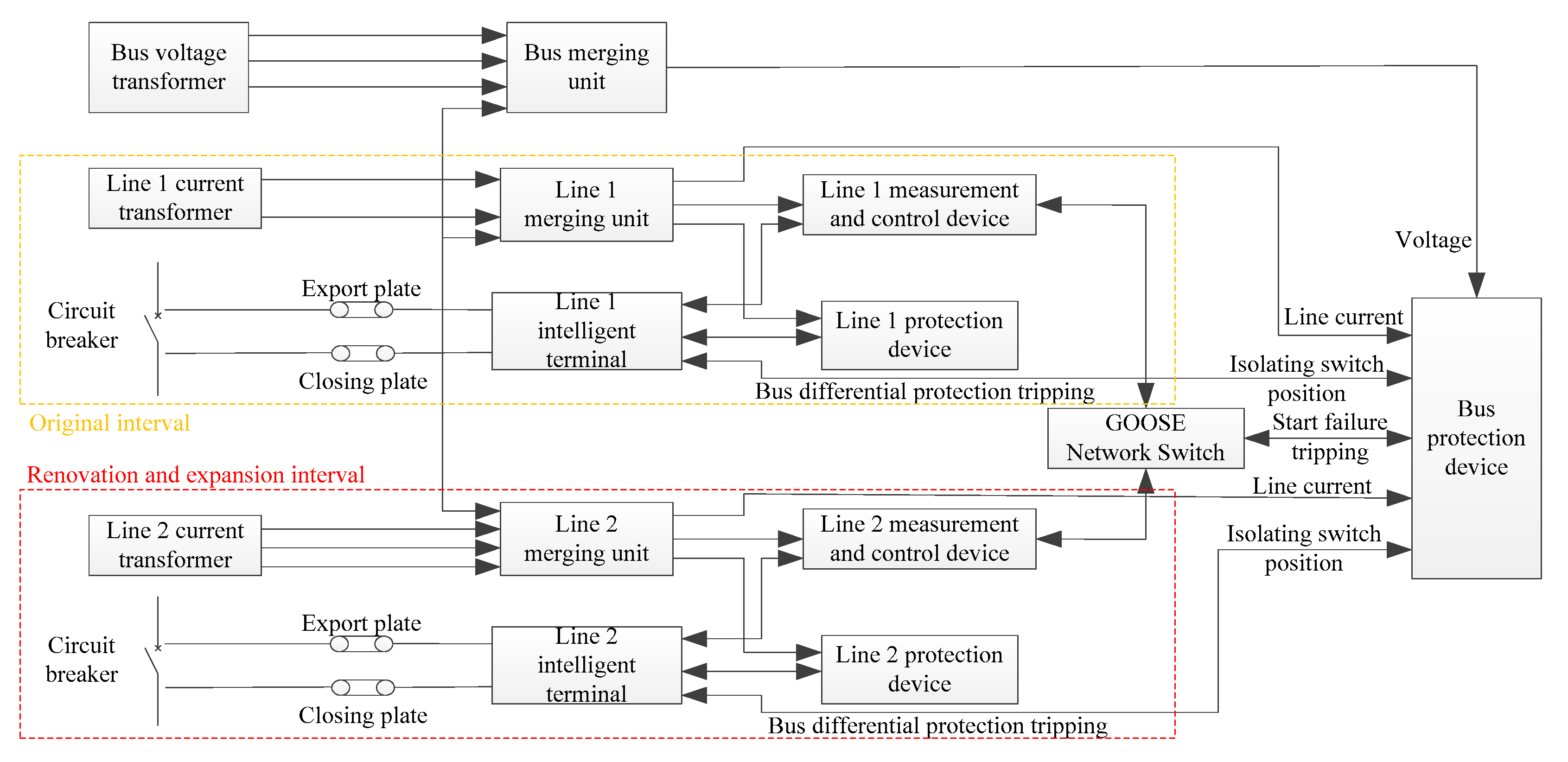

4.1. Project Overview

4.2. Analysis of Configuration File Verification Based on CRC Dynamic Check

4.3. Method Comparison

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, L.; Liu, C.M.; Gao, Q.H.; Li, J.H.; Liu, R.; Wang, T. A Method for Improving Voltage Quality and Reducing Substation Construction Costs in Transmission Networks Through Transmission Line Renovation. In Proceedings of the 2023 2nd Asia Power and Electrical Technology Conference (APET), Shanghai, China, 28–30 December 2023. [Google Scholar]

- Jin, C.H.; Deng, C.; Zhong, H. Analysis of Differences and Similarities in the Secondary Coordination of Interval Expansion (Renovation) between 500kV Intelligent Substation and Conventional Station. Electr. Age 2023, 50–52. Available online: https://kns.cnki.net/kcms2/article/abstract?v=dTSX2bdXfeAVrEGo8V2liUB2O0VItWJvxkLQp4wKiXzwyfIokf2UtVai6IfOyHYixymcjxpFDxs8aQQyBrtShnx8ZpmZDnEPG3tJTwk-hQIapgz8pl_JuytpYA2xxyGUQVl5reQR5Jn2PqxMMljcZ91KRW4q_ODECOtCUk81yGNvGRSY_WQ3Zw==&uniplatform=NZKPT&language=CHS (accessed on 1 September 2025).

- Wang, M.H. Research and Application on the Reconstruction Plans of the Smart Substation Based IEC61850; North China Electric Power University: Beijing, China, 2016. [Google Scholar]

- Li, B.; Ding, L.R.; Song, Y.; Chu, H.Y. Research on Verification Scheme for Secondary Circuit of 500kV Intelligent Substation Reconstruction and Expansion. Electrotech. Electr. 2023, 70–71. Available online: https://kns.cnki.net/kcms2/article/abstract?v=dTSX2bdXfeBKmU2TabVXyIpA4YA9lHEzSDFd46RLnxmpw8-qJs7wUobKNAPZe5UCrTxXjdoz3_zMu5-rH6ho8DjID-ftVjWShiTyr_PnUTpocy1f8j_QWwxClRvvQ_AggYxDl3_XhnA1OvmTv46P5-frpx6coc_WqPPrsMMhw7aBGGAaG8uUqA==&uniplatform=NZKPT&language=CHS (accessed on 1 September 2025).

- Xiong, W.B.; Yu, X.; Li, Y.H.; Liu, J.; Chen, J.; Chen, P. Research on Automatic Configuration Technology of Secondary Equipment File in Smart Substation. In Proceedings of the 2024 IEEE 6th Advanced Information Management, Communicates, Electronic and Automation Control Conference (IMCEC), Chongqing, China, 24–26 May 2024. [Google Scholar]

- Wang, F.; Li, Y.Q.; Tan, Q.; Wu, Z.; Suo, J.; Gu, Q. Multi-dimensional Visualization Method of SCD File Information of Intelligent Substation Based on Knowledge Graph. In Proceedings of the 2023 6th International Conference on Energy, Electrical and Power Engineering (CEEPE), Guangzhou, China, 12–14 May 2023. [Google Scholar]

- Peng, Z.Q.; Liu, Y.; Luo, J.; Xiong, H.; Fan, Q. Architecture and Key Technologies of Smart Substation’s Monitoring and Control Information Automatic Acceptance System. Power Syst. Prot. Control 2020, 48, 174–181. [Google Scholar]

- Tao, Y. Configuration Change Positioning and Verification Technology for Intelligent Substation Reconstruction and Expansion. Autom. Appl. 2024, 65, 115–117. [Google Scholar]

- Li, T.C.; Ren, J.B.; Liu, Q.Q.; Geng, S.; He, Y.; Zhang, B. Research on Substation Intelligent Diagnosis Technology Based on Secondary Cable Circuit Modeling. In Proceedings of the 2019 IEEE 3rd Conference on Energy Internet and Energy System Integration (EI2), Changsha, China, 8–10 November 2019. [Google Scholar]

- Gao, L.; Liu, P.; Cui, Y.; Bu, Q.S.; Zhang, Z.; Gu, J.J.; Zhang, G.H. Study on automatic reconfiguration technology of secondary system configuration file based on SED file for smart substation reconstruction and expansion. Power Syst. Prot. Control 2019, 47, 153–158. [Google Scholar]

- Li, H.; Pan, H.; Yan, Y.B.; Mao, W.; Li, G. Analysis on New Techniques of Secondary and Auxiliary Control System in Intelligent Substation. In Proceedings of the 2020 IEEE 4th Conference on Energy Internet and Energy System Integration (EI2), Wuhan, China, 30 October–1 November 2020. [Google Scholar]

- Yang, Y.; Song, L.L.; Cao, H.O.; Guan, Y.B.; Gao, Y.W.X.; Gao, L.; Yuan, Y.B. Smart Substation Secondary System Visualization and Intelligent Diagnosis Based on Improved SCD Model. In Proceedings of the International Conference on Renewable Power Generation (RPG 2015), Beijing, China, 17–18 October 2015. [Google Scholar]

- Chen, L.; Chen, Q.L.; Huang, Y.X.; Xia, R.; Qian, B.; Dai, Q. Automatic Generation Technology of Secondary System Configuration in Substations. In Proceedings of the 2023 IEEE 7th Conference on Energy Internet and Energy System Integration (EI2), Hangzhou, China, 15–18 December 2023. [Google Scholar]

- Cao, H.O.; Cui, Y.; Song, L.L.; Ye, W.; Xu, R.; Wei, X. Visual Calibrator for Configuration File of Intelligent Substation Reconstruction and Expansion. In Proceedings of the 2022 IEEE/IAS Industrial and Commercial Power System Asia (I&CPS Asia), Shanghai, China, 8–11 July 2022. [Google Scholar]

- Li, X.B.; Xi, W.; Zhou, K. Research on Mirror Image Control Technology of Project Configuration in the Intelligent Substation. J. Electr. Power Sci. Technol. 2022, 37, 209–216. [Google Scholar]

- Cao, H.O.; Cui, Y.; Song, L.L.; Du, Y.L.; Yi, X.; Huang, X. The Intelligent Verification Technology of Bus Protection SCD File in Intelligent Substation Reconstruction and Expansion Project Based on Convolutional Neural Network. Microcomput. Appl. 2024, 40, 87–91. Available online: https://kns.cnki.net/kcms2/article/abstract?v=dTSX2bdXfeDQ5ViKsybDaqL6iOI2YXSnea70j2ie0kLwg-5rJJEL4me7x5EU4DlzrFU0uFELYnNSgXm2SnuKqbwRTv9LSdxCuy--bKrANnxdUUdHQncNfhS-T-szx7MZ9LJ8TRFdgHcxHKsHuXu54iVoj5GJJOUas06dMjQj8NNaSmf011Jk3A==&uniplatform=NZKPT&language=CHS (accessed on 1 September 2025).

- Cao, H.; Cui, Y.; Song, L.; Du, Y.; Yi, X.; Huang, X. Research on Intelligent Verification Technology of Bus Protection SCD File in Intelligent Substation Reconstruction and Expansion Project Based on Convolutional Neural Network. In Proceedings of the 2022 IEEE/IAS Industrial and Commercial Power System Asia (I&CPS Asia), Shanghai, China, 8–11 July 2022. [Google Scholar]

- Zong, P.; Gao, Z.J.; Yang, T.; Zhou, F.Y. A Method of Fault Diagnosis for Secondary Loop in Intelligent Substation Based on Bayesian Algorithm. In Proceedings of the 2020 IEEE 3rd Student Conference on Electrical Machines and Systems (SCEMS), Jinan, China, 4–6 December 2020. [Google Scholar]

- Zhou, K.; Wang, X.M.; Wu, C.Y. Research and Application of Mirroring Debugging Technology in Reconstruction and Expansion of An Intelligent Substation. Autom. Electr. Power Syst. 2021, 49, 168–176. [Google Scholar]

- Hu, Y.J.; Huang, X.; Gao, J.; Shen, H.; Xiang, W. Research on the Test Boundary Technology of the Reconstruction and Expansion of Intelligent Substation Based on CRC. In Proceedings of the 2023 Panda Forum on Power and Energy (PandaFPE), Chengdu, China, 27–30 April 2023. [Google Scholar]

- Hu, Y.J.; Huang, X.; Gao, J. Research on Test Boundary Technology of Smart Substation Reconstruction and Expansion Based on Sub-CRC. Qinghai Electr. Power 2022, 41 (Suppl. S36), 42–49. [Google Scholar]

- Chen, J.; Wu, Y.G.; Hu, B.Q.; Cheng, T. Improved Mathematical Model of Minimum Energy Consumption for Load Distribution of Cascade Hydropower Plants. Autom. Electr. Power Syst. 2017, 41, 155–160. [Google Scholar]

- Dou, H.G.; Wang, Y.B.; Mao, Y.R.; Wang, Q.; Song, Y. Research on Configuration Change Location and Verification Technology for Reconstruction and Expansion of intelligent Substation. Electrotech. Appl. 2023, 42, 1–6. [Google Scholar]

- Zhai, X.Y.; He, Z.Q.; Zhang, Y.Y. Research on Optical Fiber-based Longitudinal Differential Protection Debugging for Lines of Smart Substations. Electr. Saf. Technol. 2024, 26, 47–50. [Google Scholar]

- IEEE Std 1615-2019 (Revision of IEEE Std 1615-2007); IEEE Recommended Practice for Network Communication in Electric Power Substations. IEEE: New York, NY, USA, 2019. [CrossRef]

- BS 07/30168422 DC, BS EN 61850-8-1; Communication Networks and Systems for Power Utility Automation. Part 8-1. Specific Communication Service Mapping (SCSM). Mappings to MMS (ISO 9506-1 and ISO 9506-2) and to ISO/IEC 8802-3. International Electrotechnical Commission: Geneva, Switzerland, 2011.

- Pu, Z.Z.; Luo, N.N. Construction of automatic language verification model based on long and short term memory and cyclic neural network. Autom. Instrum. 2023, 23–27. [Google Scholar] [CrossRef]

- Wei, J.; Ma, J.; Hu, J.; Zhu, F. Uncertainty-aware voltage control for distribution substations based on bayesian deep learning and probabilistic graph self-encoder fusion. In Proceedings of the 2024 4th International Conference on Intelligent Power and Systems (ICIPS), Yichang, China, 6–8 December 2024; pp. 189–196. [Google Scholar] [CrossRef]

- Feng, X.Z.; Liao, X.J. Diagnostic method of virtual circuit faults in intelligent substation based on decision tree algorithm. Rural. Electrif. 2019, 43–45. [Google Scholar] [CrossRef]

| Before Expansion | After Expansion | CRC Value Before Expansion | CRC Value After Expansion | Consistency |

|---|---|---|---|---|

| Send the CRC | Send the CRC | 2FFFCA7B | 2FFFCA7B | Yes |

| / | ML2209AMUSV01 4045: no. 2 main transformer high voltage side 2502 cell A merger | / | 6487E627 | No |

| / | PT2202APIGO 1150.2 main transformer in the first set of protection | / | 16E9687E | No |

| / | IE2209ARPIT_ 155.2 main transformer high voltage side 2502 intelligent terminal A | / | 8DC52EB6 | No |

| 1056.220kV 2510 bus coupler IE2201ARPIT intelligent terminal A | 1056.220 kV 2510 bus coupler IE2201ARPIT intelligent terminal A | DECD3946 | DECD3946 | Yes |

| IL2202ARPIT_101B: 2 days crossing the line 2L79 intelligent terminal A | IL2202ARPIT_101B: 2 days crossing the line 2L79 intelligent terminal A | 7E87E5C2 | 7E87E5C2 | Yes |

| IL2204ARPIT_1043: professional 2L81 line intelligent terminal 2 A day | IL2204ARPIT_1043: professional 2L81 line intelligent terminal 2 A day | 1D634657 | 1D634657 | Yes |

| ML2201AMUSV01:4001 days crossing the line 2L80 cell A merger | ML2201AMUSV01:4001 days crossing the line 2L80 cell A merger | 1768B05F | 1768B05F | Yes |

| ML2203AMUSV01_4009:2 days professional 2L82 line cell A merger | ML2203AMUSV01_4009:2 days professional 2L82 line cell A merger | 3A63EF8B | 3A63EF8B | Yes |

| MM2205AMUSV 4015:220 kV bus bar cell A merger | MM2205AMUSV 4015:220 kV bus bar cell A merger | 6E634739 | 6E634739 | Yes |

| PE2201APIGO_1054:220 kV bus coupler 2510 first set of protection | PE2201APIGO_1054:220 kV bus coupler 2510 first set of protection | 4A804526 | 4A804526 | Yes |

| 1005: days PL2201APIGO 2L80 line crossing the first set of protection | 1005: days PL2201APIGO 2L80 line crossing the first set of protection | 88A8C3A1 | 88A8C3A1 | Yes |

| Method | Time/min | Accuracy/% | Change Positioning | Training Data |

|---|---|---|---|---|

| Bayesian network | 72.9 | 92.54 | Medium | Medium |

| Sub-CRC | 78.6 | 98.96 | Poor | None |

| Decision tree algorithm | / | / | Medium | Huge quantity |

| Convolutional neural network | 56.5 | 96.09 | medium | Medium |

| CRC dynamic verification | 42.6 | 98.46 | strong | none |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, D.; Ru, S.; Yu, P.; Hu, M.; Yang, W.; Wang, H.; Zou, H. A Verification Method for a Bay Configuration File of Intelligent Substation Renovation and Expansion in Power Systems. Processes 2025, 13, 3273. https://doi.org/10.3390/pr13103273

Lu D, Ru S, Yu P, Hu M, Yang W, Wang H, Zou H. A Verification Method for a Bay Configuration File of Intelligent Substation Renovation and Expansion in Power Systems. Processes. 2025; 13(10):3273. https://doi.org/10.3390/pr13103273

Chicago/Turabian StyleLu, Di, Shi Ru, Peiyong Yu, Minhao Hu, Wei Yang, Hao Wang, and Hongbo Zou. 2025. "A Verification Method for a Bay Configuration File of Intelligent Substation Renovation and Expansion in Power Systems" Processes 13, no. 10: 3273. https://doi.org/10.3390/pr13103273

APA StyleLu, D., Ru, S., Yu, P., Hu, M., Yang, W., Wang, H., & Zou, H. (2025). A Verification Method for a Bay Configuration File of Intelligent Substation Renovation and Expansion in Power Systems. Processes, 13(10), 3273. https://doi.org/10.3390/pr13103273