1. Introduction

With the continuous increase in the operating speeds of urban rail trains in China, incidents of pantograph–catenary contact loss have correspondingly risen. This loss of contact often results in electric arcs, leading to accelerated wear and deterioration of the pantograph–catenary interfaces and a decline in current collection quality [

1]. In severe cases, such arcs may even cause the contact wire to break. According to statistics, arc-induced faults in pantograph–catenary systems have become the primary factor affecting the reliability of train power supply, posing a significant obstacle to railway development.

Given China’s vast territory and the significant climatic differences between its northern and southern regions, the environment in the southern areas is generally more humid. As a result, the arc initiation threshold and arc intensity in pantograph–catenary systems vary considerably, which can seriously impact the safety and stability of train operations. Therefore, research on the dynamic characteristics of pantograph–catenary arcs under different operational conditions, particularly in northern and southern urban rail transit, is essential.

In recent years, scholars from both domestic and international research communities have conducted extensive investigations into arc characteristics and their influencing environmental factors. The resultant achievements have not only established a crucial foundation for deepening the understanding of pantograph–catenary arcs but also provided substantial theoretical support for the present work. These research efforts can be systematically categorized into four primary directions:

Firstly, in the study of atmospheric pressure effects on electric arcs, Wu et al. developed a finite element model of pantograph–catenary arcs applicable to high-altitude environments based on magnetohydrodynamic (MHD) theory. They analyzed the variation patterns of arc temperature and voltage under low-pressure conditions and revealed the physical mechanism behind arc temperature oscillations [

2]. Meanwhile, they established a multi-field-coupled stress model to investigate the arc drift characteristics under the combined influence of atmospheric pressure and airflow, elucidating the intrinsic driving forces of arc drift in low-pressure environments [

3]. Similarly, Yu constructed a simulation model of pantograph–catenary arcs using MHD theory and quantitatively analyzed the effects of different atmospheric pressures on arc voltage, temperature, and current density [

4]. Additionally, the team developed a two-dimensional pantograph–catenary arc model using COMSOL software to study the influence of atmospheric pressure variations on arc morphology, temperature distribution, voltage fluctuation frequency, and arc root motion characteristics [

5]. Moreover, Kamenetskikh employed the catalytic probe method to investigate changes in the composition of arc plasma under low-pressure conditions [

6], providing experimental evidence for understanding the relationship between atmospheric pressure and arc plasma properties.

Secondly, in the field of research on the influence of airflow on electric arcs, Xu systematically investigated the stability variations in pantograph–catenary arcs under strong airflow disturbances using comparative analysis methods [

7]. Sun incorporated a fluid viscous dissipation term into the model and developed a two-dimensional MHD simulation model of pantograph–catenary arcs in crosswind environments using COMSOL software, providing an in-depth analysis of the evolution patterns and physical mechanisms of arc characteristics under crosswind effects [

8]. Yang established an MHD model of pantograph–catenary arcs, focusing on the temporal evolution characteristics of arc temperature, voltage, and arc root velocity under varying crosswind conditions and input currents. Through multiple linear regression analysis, the sensitivity of pantograph–catenary arcs to factors such as airflow, atmospheric pressure, and current was quantified [

9], offering a reference for quantitative research on the influence of airflow on pantograph–catenary arcs.

Meanwhile, the influence of humidity on other arc-related fields has also garnered significant attention. In the field of welding arcs, Gou et al. found that humidity significantly affects the porosity, microstructure, and fatigue strength of A7N01S-T5 aluminum alloy welded joints used in high-speed trains [

10]. Ardika et al. investigated the impact of atmospheric humidity on pore defects in the arc welding zone of aluminum metal [

11]. In the domain of DC series arcs, Seeley et al. analyzed the influence of relative humidity on the generation and detection of DC series arcs [

12], while Liu et al. studied the discharge characteristics of series fault arcs under environmental humidity [

13]. In the field of transmission line discharge, Fouad et al., Aissou et al., and Chen et al., respectively, explored the effects of humidity on the current–voltage characteristics and discharge mode transitions on different DC corona discharge systems [

14,

15,

16]. These studies demonstrate that humidity, through mechanisms such as electron attachment and enhanced heat dissipation, alters arc behavior and is a pivotal environmental factor influencing arc characteristics.

Finally, in the optimization of multi-physical field coupling models for pantograph–catenary arcs and parameter validation, researchers have conducted a series of explorations focused on improving model accuracy and analyzing key parameters. Regarding model construction, addressing the inadequacy of traditional MHD models in accounting for practical environmental factors, Kai et al. proposed a pantograph–catenary arc model that considered convective heat transfer in air. By incorporating a convective heat transfer term into the thermal balance equation, the deviation between simulated values of the arc core temperature and measurements obtained using a spectrometer was significantly reduced [

17]. Hao et al., based on the flow characteristics of arc plasma, improved the force calculation and energy dissipation terms in the MHD model, markedly enhancing the accuracy of arc morphology evolution simulations [

18]. In parameter influence studies, Zhu et al., through COMSOL simulations, found that as the pantograph–catenary gap continuously decreases, the arc column radius increases. The maximum temperature on the contact wire surface decreased from 1872 K to 956 K, while the maximum temperature on the pantograph strip surface dropped from 5400 K to 3590 K. Furthermore, the temperature gradient significantly flattened as the gap increased [

19]. Cong et al. enhanced the original multi-physical field coupling model by incorporating elements such as electromagnetic force, thermal buoyancy, wind load force, and air drag force, developing an arc chain model based on multi-field coupled dynamics. The results demonstrated that the proposed arc model can effectively account for the influence of wind [

20].

However, existing research still exhibits significant limitations and gaps, which hinder their ability to meet the practical demands of pantograph–catenary systems for arc characteristic studies. Firstly, there is insufficient research on the coupling of multiple environmental factors. Current studies predominantly focus on the individual effects of single environmental factors, such as low pressure [

2,

3,

4,

5] or crosswind [

8,

9], without considering the coupled scenarios where “humidity + airflow” coexist simultaneously during actual train operation. For instance, Yang [

9] only analyzed the impact of crosswind on arc dynamics without introducing humidity variables, thus failing to explain the pantograph–catenary arc characteristics in humid and windy regions such as Southern China. Secondly, a notable research gap exists regarding the influence of humidity on pantograph–catenary arcs. Although humidity has been proven to play a significant role in arc research in fields such as welding and transmission lines [

10,

11,

12,

13,

14,

15,

16], and multi-physical field models can already accurately capture the effects of factors like convection [

17,

18], no existing literature specifically addresses the impact of humidity on pantograph–catenary arcs. This gap prevents a clear understanding of how humidity alters the discharge characteristics and dynamic behavior of pantograph–catenary arcs.

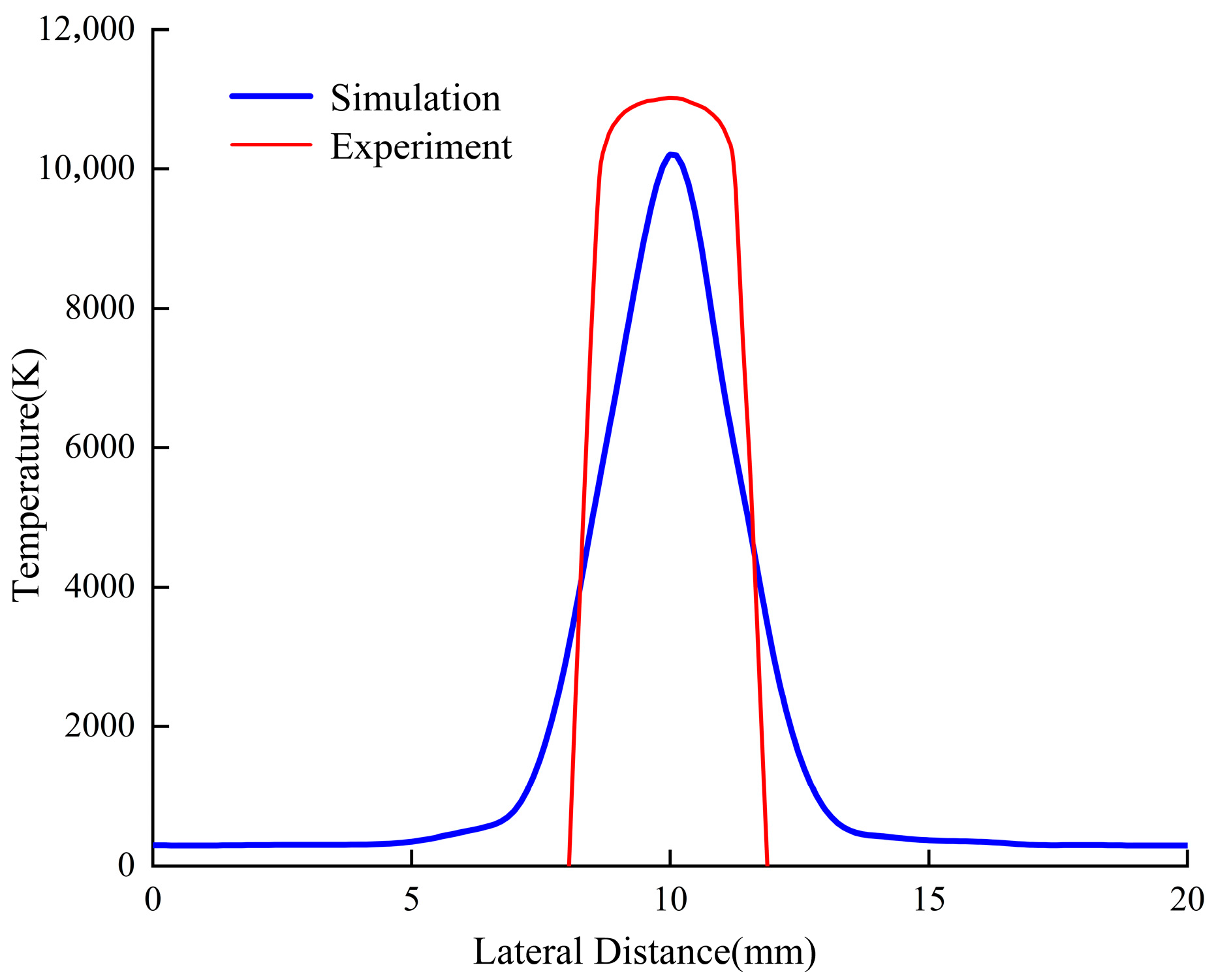

Addressing these aforementioned limitations and research gaps, this paper develops a two-dimensional humidity-dependent finite element model based on magnetohydrodynamics (MHD) theory. The model couples electromagnetic, thermal, and fluid flow fields to elucidate how humidity influences arc discharge characteristics, including temperature, voltage, energy, and pressure. Furthermore, by incorporating airflow as an additional variable, this study analyzes the motion patterns and stability evolution of the arc under coupled humidity–airflow effects. Validation of temperature, voltage, and arc morphology was performed using a self-developed humidity-controlled arc experimental platform across a relative humidity gradient ranging from 25% to 100%. This research aims to provide theoretical and experimental support for developing arc suppression strategies and optimizing pantograph–catenary system design in diverse climatic regions.

2. Research Methodology and MHD Simulation Framework

2.1. Parameter Configuration and Research Framework

The magnetohydrodynamic coupling model in this study was solved using the commercial finite element software COMSOL (Version 6.1, software published in Sweden.)Multiphysics. Computations were performed with a transient solver based on fully coupled multiphysics, utilizing the MUMPS direct solver to enhance computational efficiency. Key numerical configurations were specified as follows: temporal discretization employed the second-order backward difference formula (BDF2); convergence criteria included a relative residual threshold of 1 × 10−6 and an absolute residual limit below 1 × 10−8 for all physical field equations, with a relative tolerance of 0.01. For solver configuration, the memory allocation for MUMPS was set to 64 GB, and an 8-core multithreaded parallel computing approach was implemented to accelerate matrix factorization, thereby reducing solution time for large-scale coupled equations.

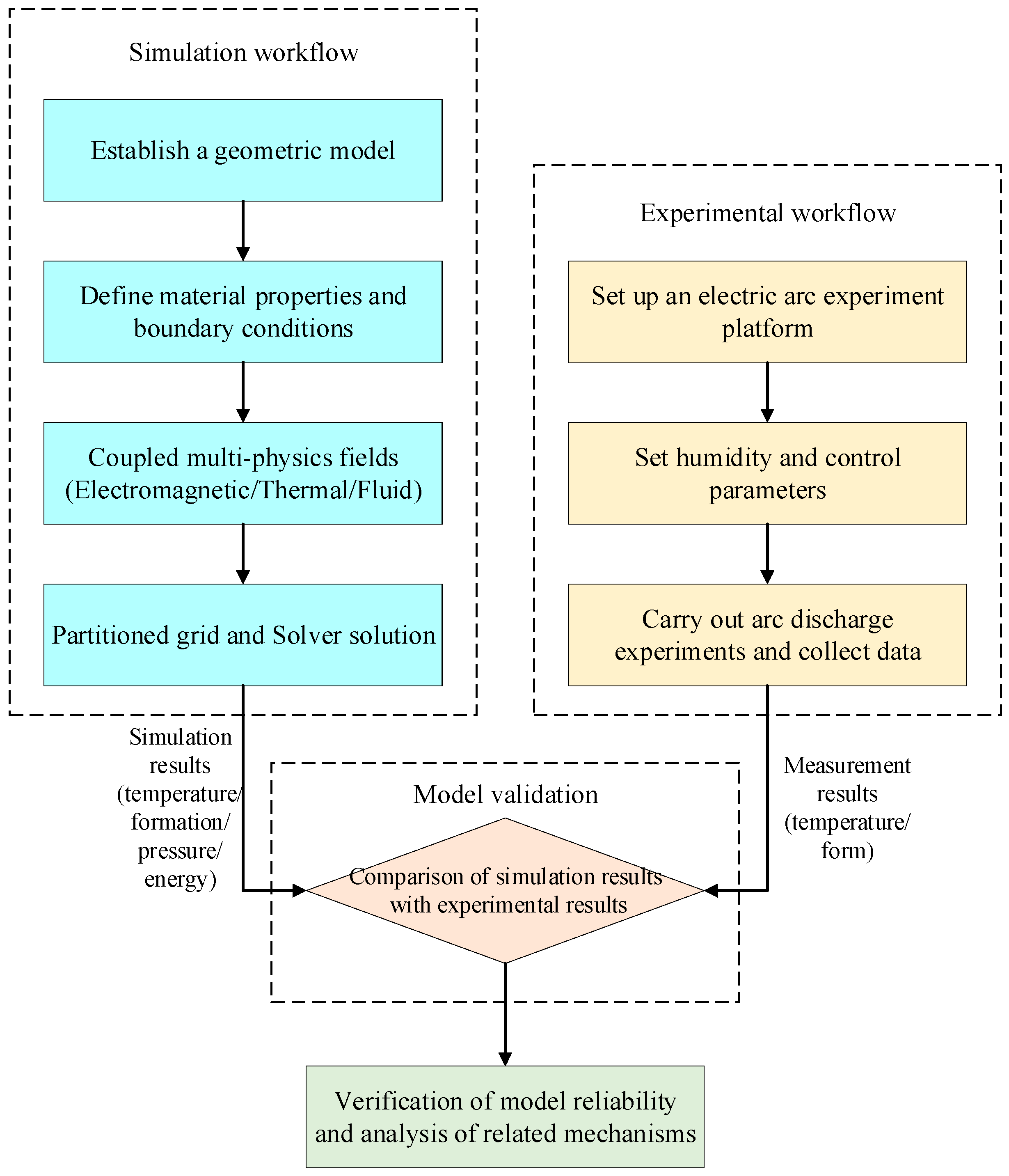

Meanwhile, to provide a transparent and systematic overview of the research process undertaken in this study, this section delineates the integrated methodology employed, which synergistically combines numerical simulation and experimental validation. The overarching research framework is visually summarized in

Figure 1, which outlines the primary workflows and their interconnections.

2.2. Establishment of a Two-Dimensional Arc Simulation Model and Material Parameters

The pantograph–catenary offline arc model was established based on magnetohydrodynamics (MHD) theory using COMSOL Multiphysics, involving four coupled physical fields: electric field, magnetic field, heat transfer in fluids, and laminar flow. The geometric structure of the model is illustrated in

Figure 2. The overall dimensions of the two-dimensional model framework are 80 mm × 25 mm, with the pantograph collector strip measuring 80 mm × 5 mm. The pantograph collector strip was modeled using copper-impregnated carbon material, while the contact wire was modeled using pure copper with a diameter of 13 mm. Given the lateral airflow acting on the train during operation, boundary AF was defined as the air inlet, while boundaries AB and BC were designated as open boundaries.

Relevant physical properties of electrode materials, including electrical conductivity, specific heat capacity, and density, are presented in

Table 1. The parameters in the table are all derived from authoritative reference studies and material databases that have been published and can represent the actual components of the pantograph–rail system [

21,

22]. In addition, the relative humidity of the air domain is configured in the “Moist Air” node under the “Heat Transfer in Fluids” physics interface; for the parameters of relative permittivity and relative permeability in the air, both are set to 1 in this paper.

2.3. Preliminary Assumptions for Arc Simulation

Due to the inherently nonlinear and transient nature of the arc plasma discharge process—which involves strong coupling among electromagnetic, thermal, and fluid fields—it is challenging to analytically resolve the complete physical mechanisms and dynamic behavior of the arc. Therefore, in order to ensure the feasibility of numerical simulation while maintaining the credibility of the model, several reasonable assumptions have been introduced. The specific assumptions are as follows:

- (1)

At the initial stage of the simulation, it is assumed that a self-sustained, steady-state arc discharge channel has already been established within the air domain between the pantograph contact strip and the contact wire;

- (2)

In the simulation, the arc is assumed to satisfy the condition of local thermodynamic equilibrium (LTE);

- (3)

In the pantograph–catenary system, the flow behavior of the arc plasma is assumed to be laminar;

- (4)

Under the current and geometric scales of this model, the reaction of the arc’s self-induced magnetic field on the global current distribution is neglected, i.e., the global coupling of the magnetic field is not considered; however, the local Lorentz force generated thereby is fully retained in the momentum conservation equation to characterize the electromagnetic pinch effect;

- (5)

The phase transition of the contact line and the pantograph slide plate and its production are not considered. Raw copper vapor, carbon vapor and other components.

2.4. Mathematical Model of the Arc

This model is based on the theoretical framework of magnetohydrodynamics (MHD) and establishes a complete set of governing equations by coupling the Navier–Stokes equations (which describe the transport of mass, momentum, and energy) with Maxwell’s equations (which characterize the behavior of electromagnetic fields). Within this framework, the self-induced magnetic field is calculated via Ampère’s law and utilized to solve the Lorentz force term; however, according to the aforementioned Assumption 4, the complete two-way global coupling between the magnetic field and the flow field is not considered in the model.

(1) According to Maxwell’s equations, the governing equation for the electric potential is given by

(2) The governing equation for the arc current density is given by

(3) The governing equation for the self-induced magnetic field generated by the arc current is given by

where

denotes the electric potential;

represents the current density vector;

is the vector operator (

and

denote the curl and divergence operators, respectively);

is the electrical conductivity;

refers to the electromagnetic vector potential;

is the component of the electromagnetic vector potential perpendicular to the electric field lines;

is the component of the electromagnetic vector potential parallel to the electric field lines; and

denotes the relative permeability.

- 2.

Governing equations of fluid dynamics:

The fluid dynamics equations consist of three components: the continuity equation (mass conservation), the energy conservation equation, and the momentum conservation equation. The governing equations are given as follows:

(1) Continuity equation:

where

denotes the density of the arc plasma,

corresponds to time, and

represents the velocity vector of the arc-induced flow field.

(2) Energy conservation equation:

where

denotes the enthalpy;

is the thermal conductivity;

represents the specific heat capacity at constant pressure;

denotes the viscous dissipation term of the fluid;

is the Joule heating generated by the current passing through the arc plasma, which is the primary cause of the temperature rise in the arc column [

23]; and

represents the radiative energy loss from the arc plasma to the surroundings.

(3) In the momentum conservation equation, the velocity field of the arc plasma is solved using the Navier–Stokes governing equations (Equation (7)).

where

denotes the velocity component in the

direction;

is the dynamic viscosity of air;

represents the pressure;

is the current density; and

denotes the magnetic flux density.

2.5. Boundary Condition Settings for Arc Simulation

1. In the multiphysics-coupled arc plasma model, the global thermodynamic boundary conditions for the temperature field are defined as follows:

(1) Temperature settings for the air domain and the AB, BC, and AF boundaries:

where

298.15 K.

(2) Temperature boundary settings for the catenary wire segment GH and the pantograph contact strip edge ED in the catenary–pantograph system:

Due to the extremely high temperature of the arc, natural convective heat transfer is applied to the remaining boundaries as the thermal boundary condition, which satisfies the temperature boundary constraint equation:

where

is the convective heat transfer coefficient;

T is the temperature of the air domain; and

is the normal vector to the surface of the contact strip.

2. In the magnetohydrodynamic (MHD) model of the arc plasma, the open-domain flow boundaries AB, BC, and AF are defined according to the following parameters:

where

= 101.325 kPa (one standard atmosphere).

3. In the multiphysics-coupled numerical model of arc discharge, the catenary wire is defined as the current inlet, and thus the current source is applied at boundary GH. The pantograph contact strip serves as the current outlet, and accordingly, boundary DE is set as the grounding condition. The specific parameters are listed in

Table 2.

2.6. Grid Parameter Configuration and Analysis of the Independence of Grids and Time Steps

To ensure the simulation model in this paper meets well-posed conditions, two core factors—solution accuracy and computational efficiency—must be considered simultaneously. For the geometric structure of the pantograph–catenary arc, an optimized meshing strategy was designed and applied: the computational domain uses unstructured triangular meshes, while the arc region and the area near the electrodes undergo intensive local refinement. As shown in

Figure 3, this meticulously designed mesh layout effectively improves the accuracy of numerical calculations while keeping the computational time within a reasonable range.

To evaluate the influence of mesh density on the solution, three meshes with systematic variations were constructed in this study: a coarse mesh (13,173 elements), an optimized mesh (33,295 elements), and a fine mesh (78,647 elements). The optimized mesh was extremely refined in the arc core region and near the electrode edges to resolve the extremely steep physical gradients in these areas. Simulations were conducted on these three meshes under the baseline operating conditions (25% relative humidity, no crosswind), and key physical quantities at the steady-state moment (t = 2 ms) were extracted for comparison, with the results presented in

Table 3.

It can be concluded from the results that the variations in key parameters of the optimized mesh are all less than 0.5%. This indicates that the solution of the medium mesh has entered the asymptotic convergence range and has basically achieved mesh independence. Given that the optimized mesh achieves the optimal balance between computational accuracy and resource consumption, it is ultimately adopted in this study for all parametric investigations.

Meanwhile, to evaluate the temporal discretization error, this study compared the transient simulation results under three different time steps (0.5 ms, 0.1 ms, 0.05 ms) using the optimized mesh. Monitoring the transient evolution of the arc peak temperature shows that the difference between the results obtained with the 0.1 ms and 0.05 ms time steps is negligible (time-averaged error < 0.5%). Therefore, a time step of 0.1 ms was selected in this study for all transient calculations.

5. Motion Characteristics of the Pantograph–Catenary Arc Under the Combined Effects of Humidity and Crosswind

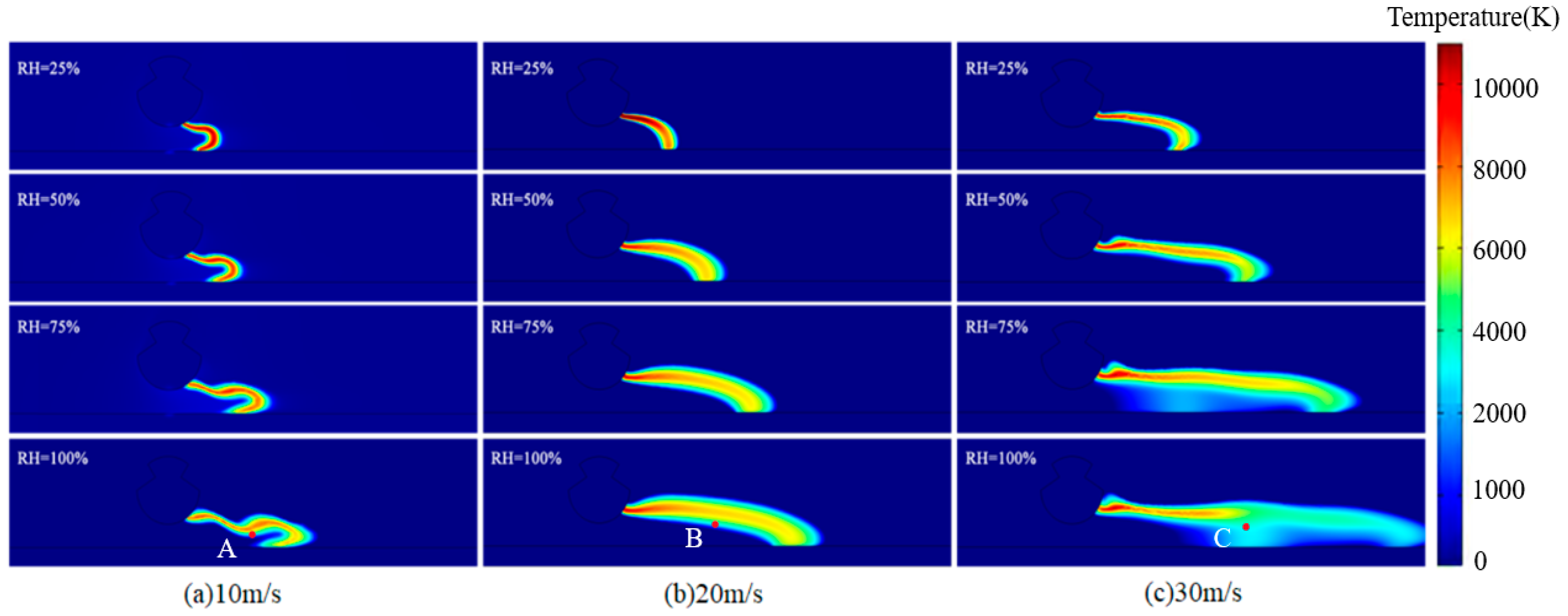

In the study of pantograph–catenary arcs, airflow is one of the key factors influencing the motion characteristics of the arc. The intensity of airflow can have different effects on the arc. During train operation, the train frequently encounters crosswinds, which, as a form of airflow, also have a significant impact on the pantograph–catenary arc. Since the crosswind encountered by the train typically ranges between 10 m/s and 30 m/s, simulations were conducted to analyze the motion characteristics of the pantograph–catenary arc under crosswind levels of 10 m/s, 20 m/s, and 30 m/s, as well as relative humidities of 25%, 50%, 75%, and 100%. The arc burning time was set to 5 ms, and the simulation results are shown in

Figure 14.

As shown in

Figure 14, with decreasing humidity, the arc’s travel distance becomes shorter. This phenomenon occurs because the reduced density of water molecules in the air diminishes the ionization process caused by molecular collisions, thereby weakening the arc’s motion. Therefore, at lower humidity, the arc not only remains stagnant in the pantograph–catenary system for a longer duration but also stretches at a slower rate, resulting in a consistently shorter arc length that is more difficult to extinguish. Consequently, under low-humidity conditions, the pantograph–catenary arc causes more severe erosion to the electrodes in the pantograph–catenary system.

To investigate the effects of humidity and airflow on the pantograph–catenary arc, temperature measurements were taken at three designated points—A, B, and C, as illustrated in

Figure 15. The results demonstrate that with increasing crosswind intensity, the overall arc temperature decreases while oscillations become more pronounced. Under conditions of 100% relative humidity and a crosswind velocity of 30 m/s, the arc exhibits the maximum amplitude of oscillation.

These oscillatory phenomena originate from arc instability induced by intensified crosswinds and the formation of new arc roots. The mechanism involves coupled interference of airflow and humidity with the ionization process: transverse airflow not only reduces arc temperature through convective cooling but, more critically, continuously disperses the ionization core at the arc front, compelling repeated “re-breakdown” of the arc in the airflow downstream. This process is closely related to the effective ionization coefficient of the gas—the breakdown condition is jointly determined by the ionization coefficient (α) and attachment coefficient (η), where in humid environments, water molecules significantly increase η and reduce α through strong attachment effects [

31].

Under the coupled effects of airflow and humidity, the airflow induces frequent breakdowns, while the high-humidity environment requires increased electric field strength for each breakdown. This synergistic effect intensifies both arc root migration and temperature fluctuations. The observed arc instability fundamentally results from the combined action of physical disturbance by airflow and ionization suppression by humidity, thereby leading to progressive deterioration of arc stability and higher extinction probability with increasing flow velocity.

6. Conclusions and Prospect

6.1. Conclusions

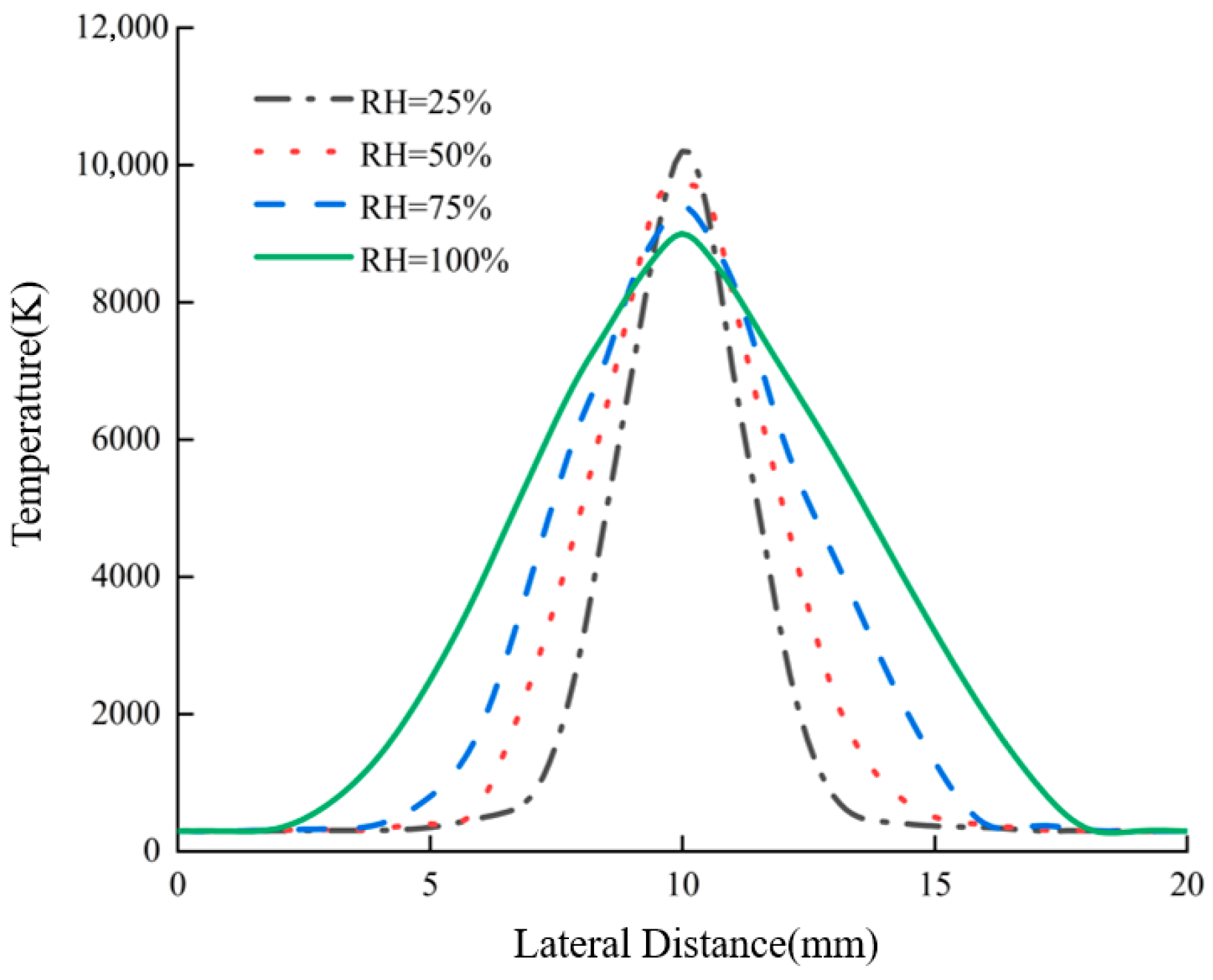

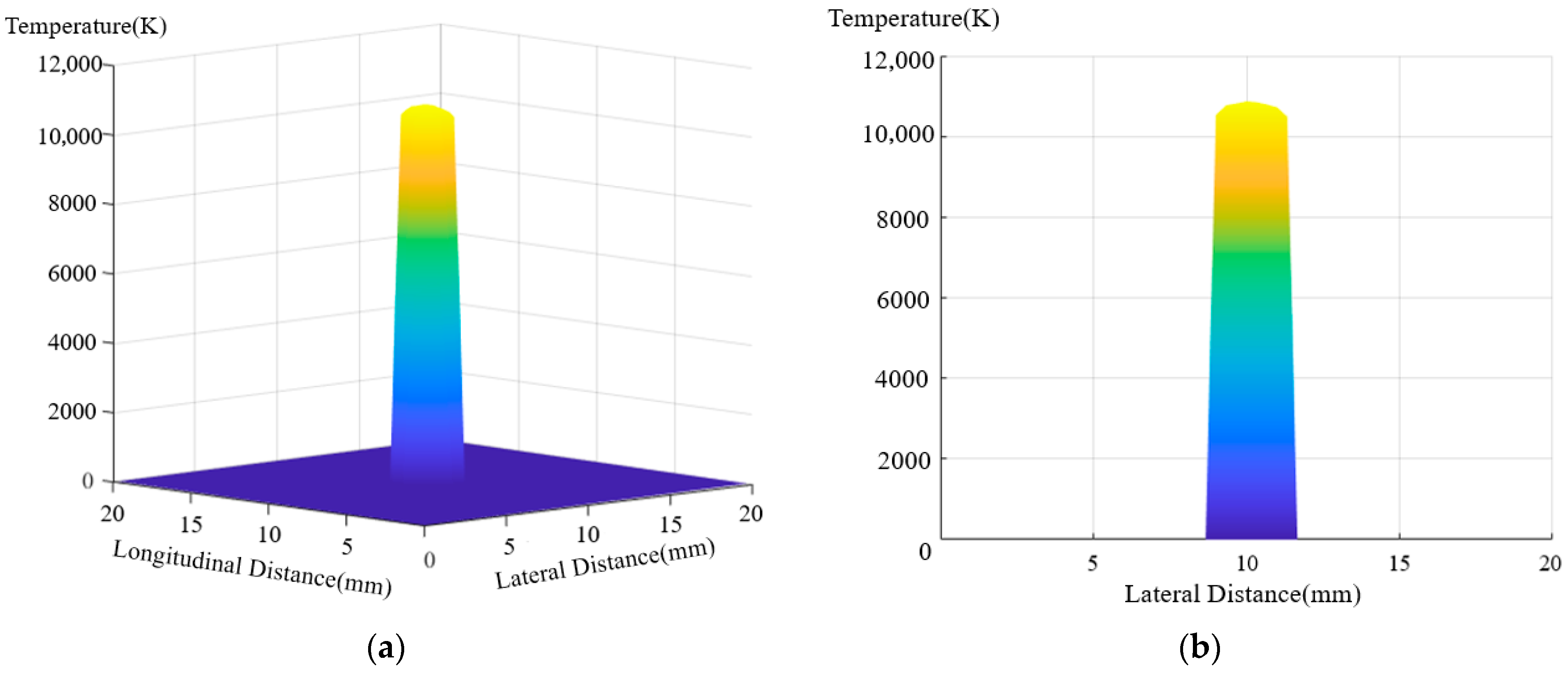

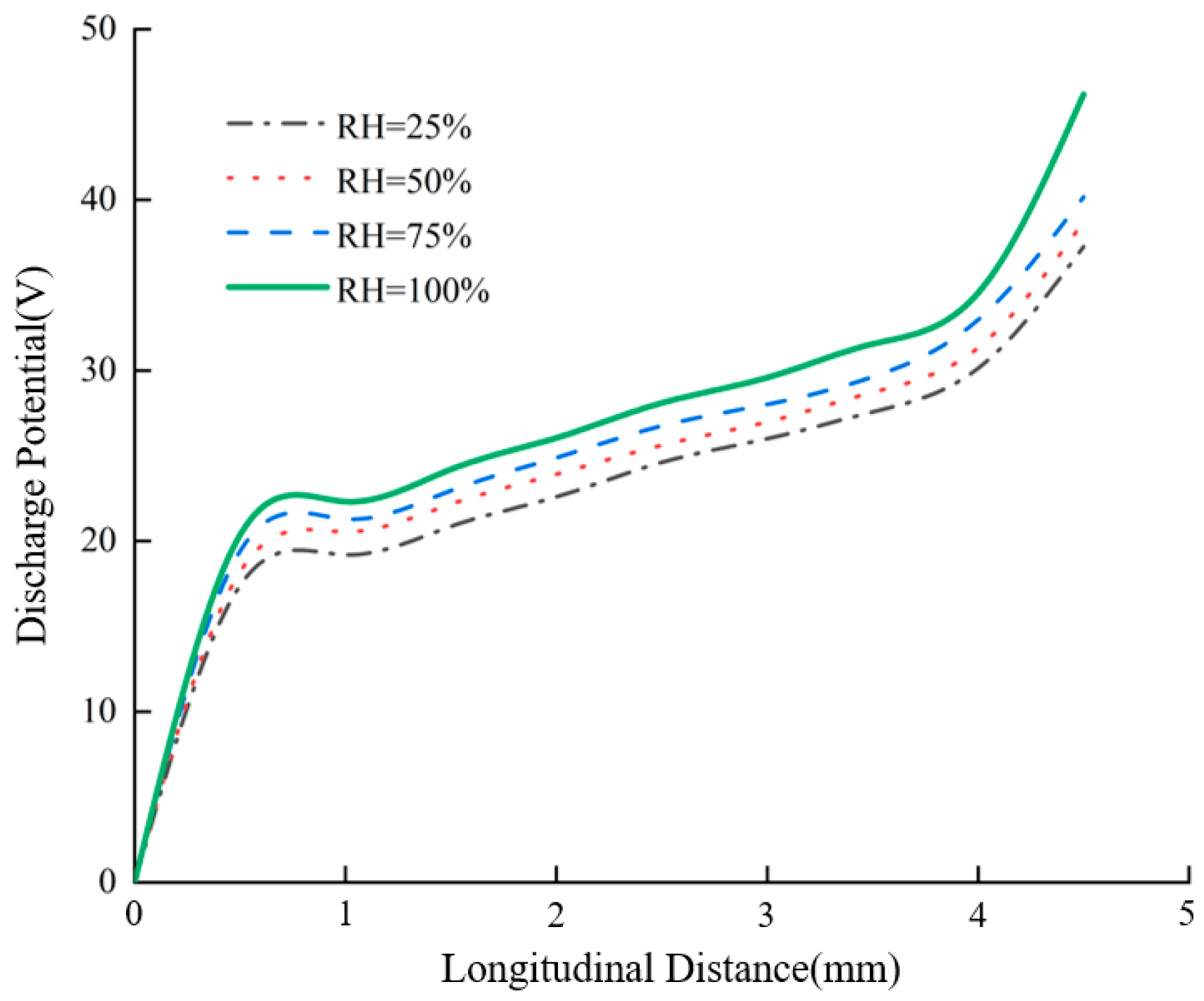

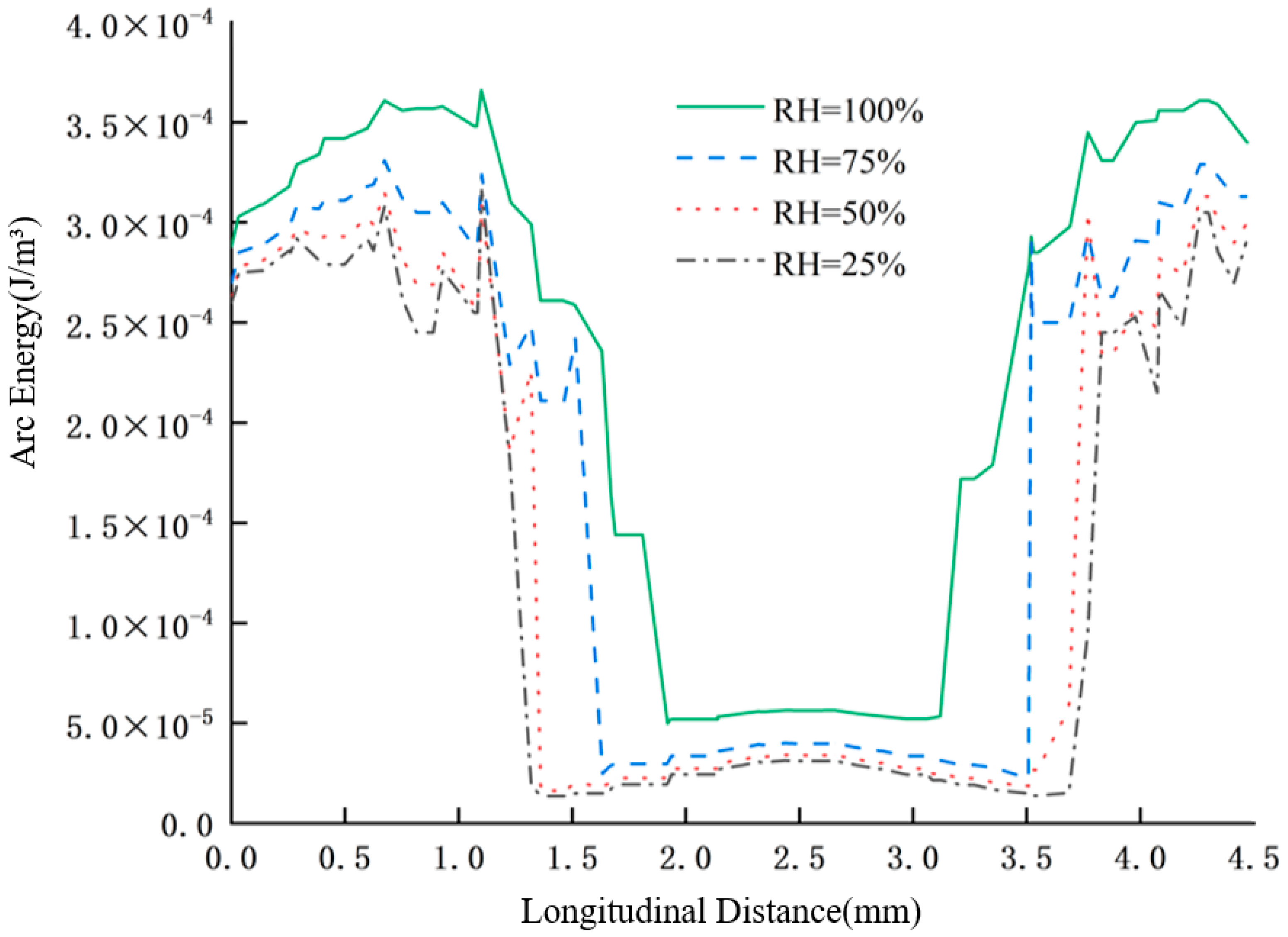

(1) As humidity increases, the peak temperature of the pantograph–catenary arc decreases, while both its volume and diameter expand. Specifically, as the relative humidity rises from 25% to 100%, the maximum temperature drops from 10,500 K to 9000 K, with the temperature in the arc core remaining significantly higher than in other regions. Concurrently, the maximum arc discharge potential increases from 37.25 V to 48.17 V, with the voltage drop per unit distance near the electrodes being notably higher than in the arc column. The arc energy also increases with rising humidity; when the relative humidity increases from 25% to 100%, the maximum arc energy increases from 2.5 × 10−4 J/m3 to 3.5 × 10−4 J/m3, with the energy in the polar regions being much higher than in the arc core. This results in a saddle-shaped energy distribution.

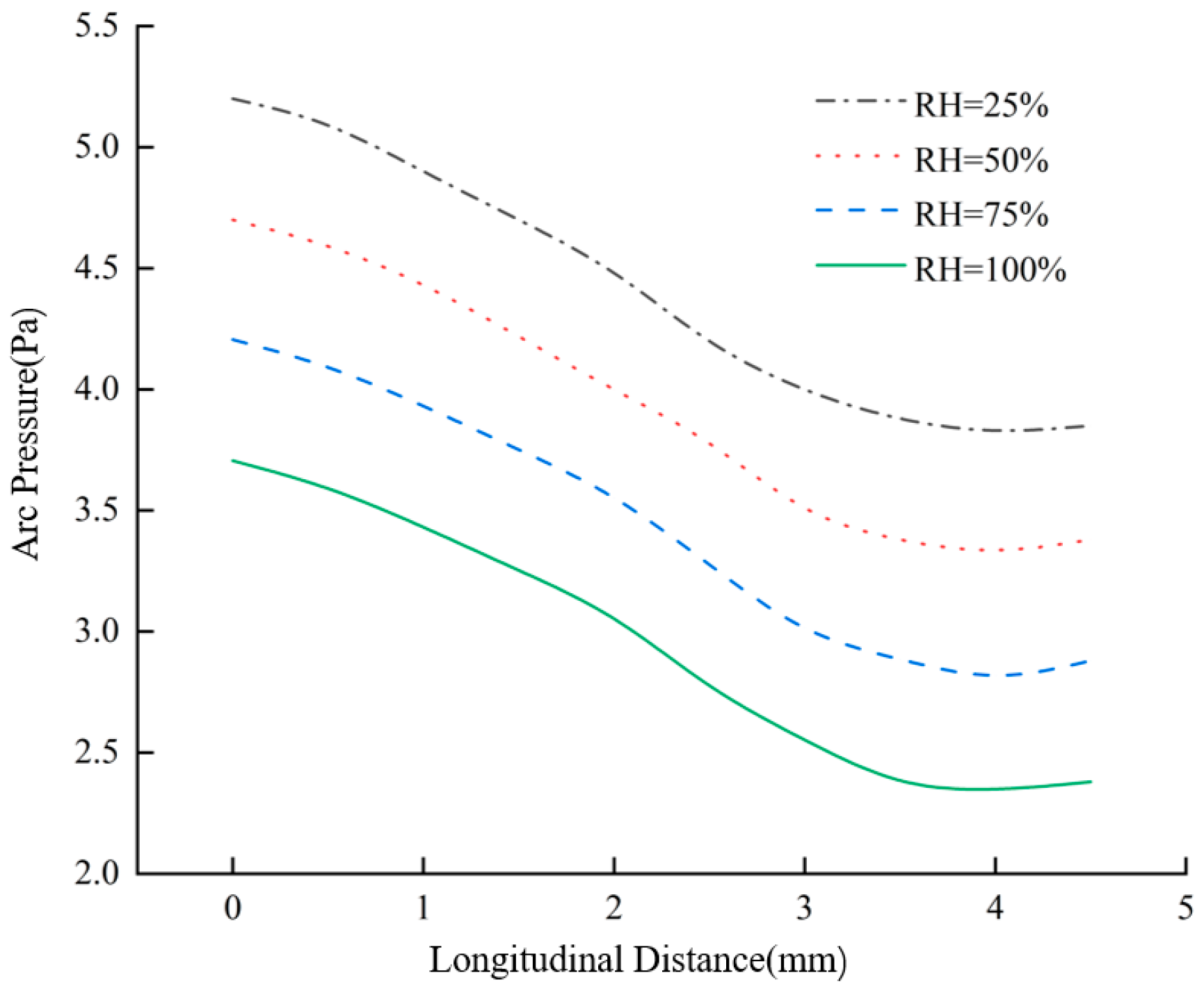

(2) As the relative humidity increases, the pantograph–catenary arc pressure decreases. Notably, the pressure experienced by the cathode is significantly higher than that experienced by the anode, leading to more severe damage to the cathode.

(3) Crosswind has a considerable impact on arc stability. When crosswind intensity is high, the overall temperature of the arc decreases, and the alternation between new and old arc roots becomes more frequent. This disruption results in a significant reduction in arc stability, weakening the arc’s self-sustaining ability and making it more prone to extinction.

6.2. Research Limitations and Future Prospects

The simulation model for pantograph–catenary arc discharge under humidity and airflow conditions established in this study is a preliminary exploration, which has not yet incorporated key factors such as electrode material ablation and deposition, the luminous characteristics of arc discharge paths, dynamic fluctuations in ambient temperature and humidity, and the lack of camera calibration. These limitations may compromise the accurate prediction of long-term electrode wear and the evolutionary process of arc plasma composition, as well as the stable measurement of arc temperature. To enhance the accuracy and applicability of the model, subsequent research will be conducted along the following avenues:

- (1)

Develop a more comprehensive arc model that integrates metal erosion mechanisms, diverse aerodynamic patterns, and complete chemical kinetics;

- (2)

Employ spectroscopic diagnostic techniques to investigate the effects of environmental factors on arc radiative characteristics and plasma microscale processes, and clarify the intrinsic correlation between arc morphological instability and radiative behavior;

- (3)

Perform camera calibration and accurate plasma emissivity modeling to reduce systematic errors in experimental measurements.

It is important to emphasize that despite the aforementioned limitations, the model proposed in this paper introduces a novel methodology for elucidating the fundamental mechanisms by which humidity and airflow influence pantograph–catenary arc behavior, thereby laying down a crucial foundation for the development of more sophisticated models in subsequent research.

All fundamental data employed in the simulation model of this study have been procured from traceable, authoritative sources, including internationally recognized databases such as LXCat, rigorously peer-reviewed classical literature, and standard reference texts within the plasma physics community, thereby ensuring the reliability and scientific validity of the model’s input parameters.