An Energy Storage Unit Design for a Piezoelectric Wind Energy Harvester with a High Total Harmonic Distortion

Abstract

1. Introduction

2. Materials and Methods

2.1. Modeling of Harvester Design

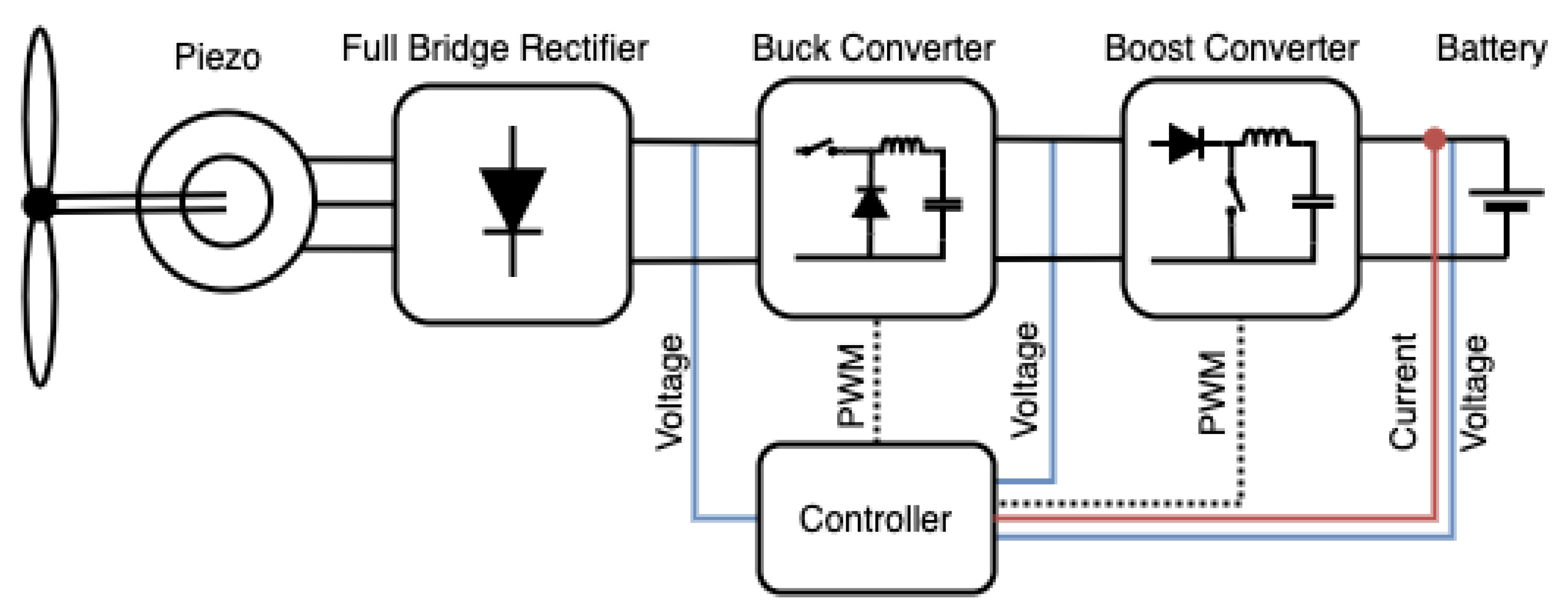

2.2. Topology of the Circuit

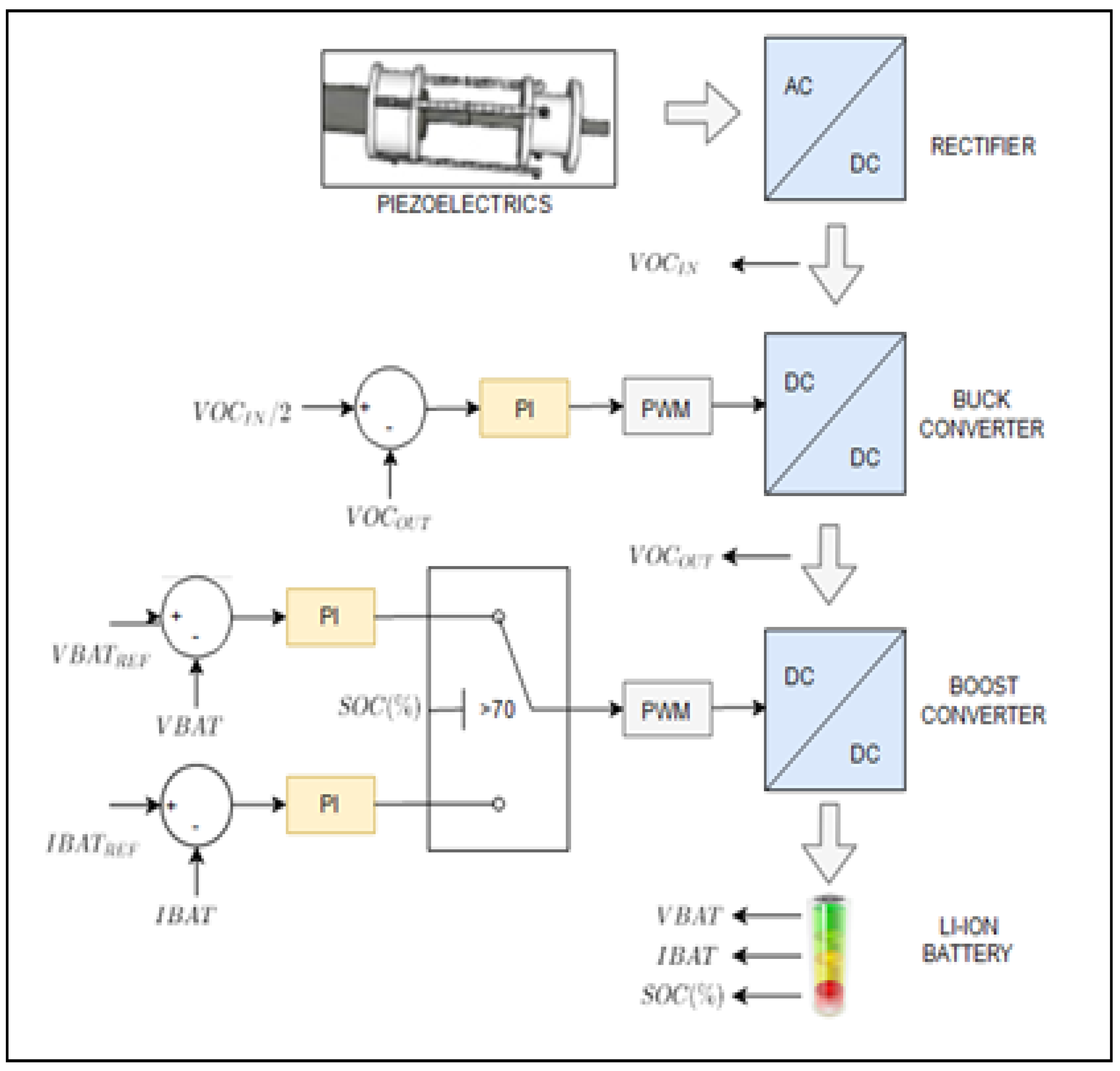

2.3. Controller

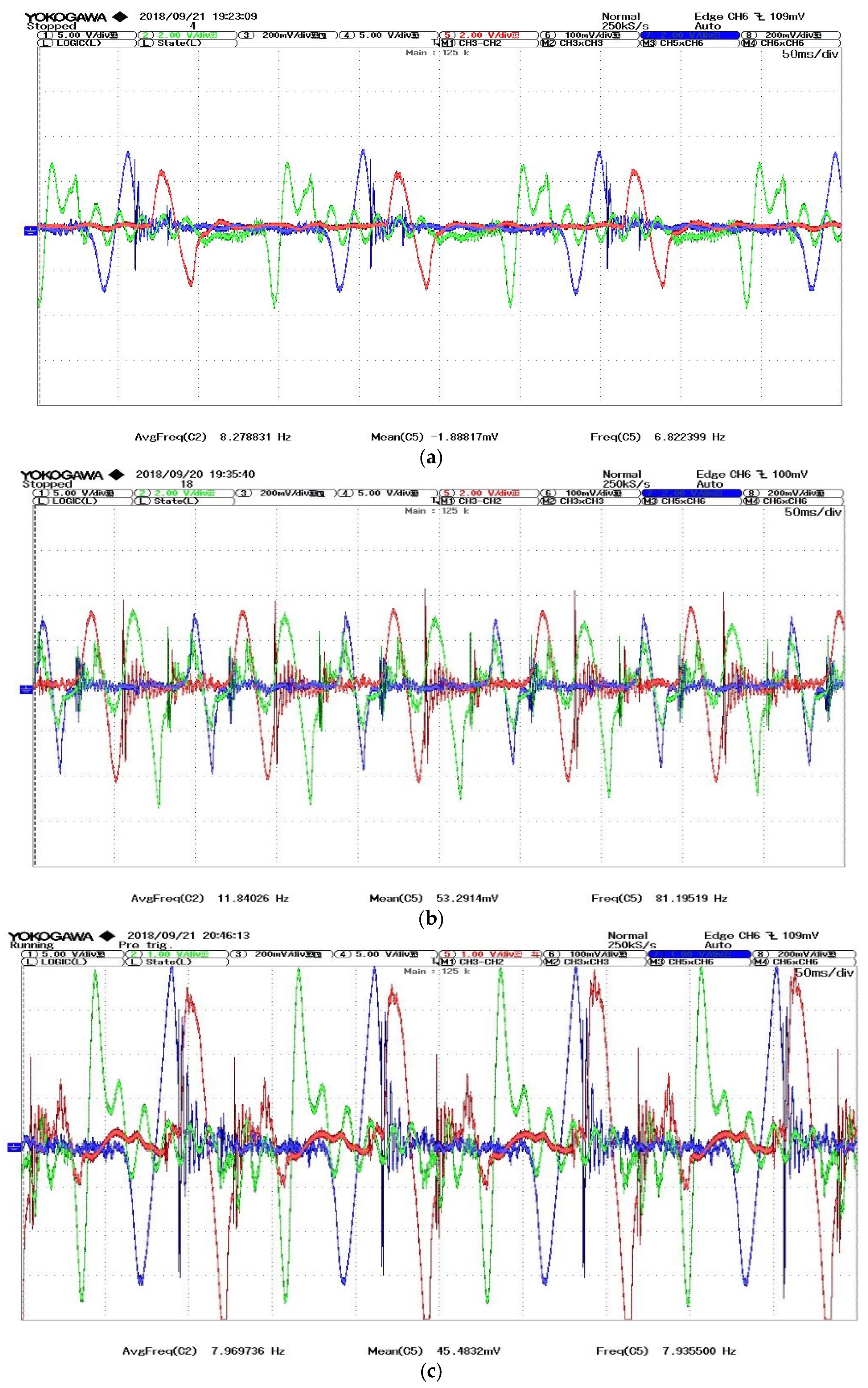

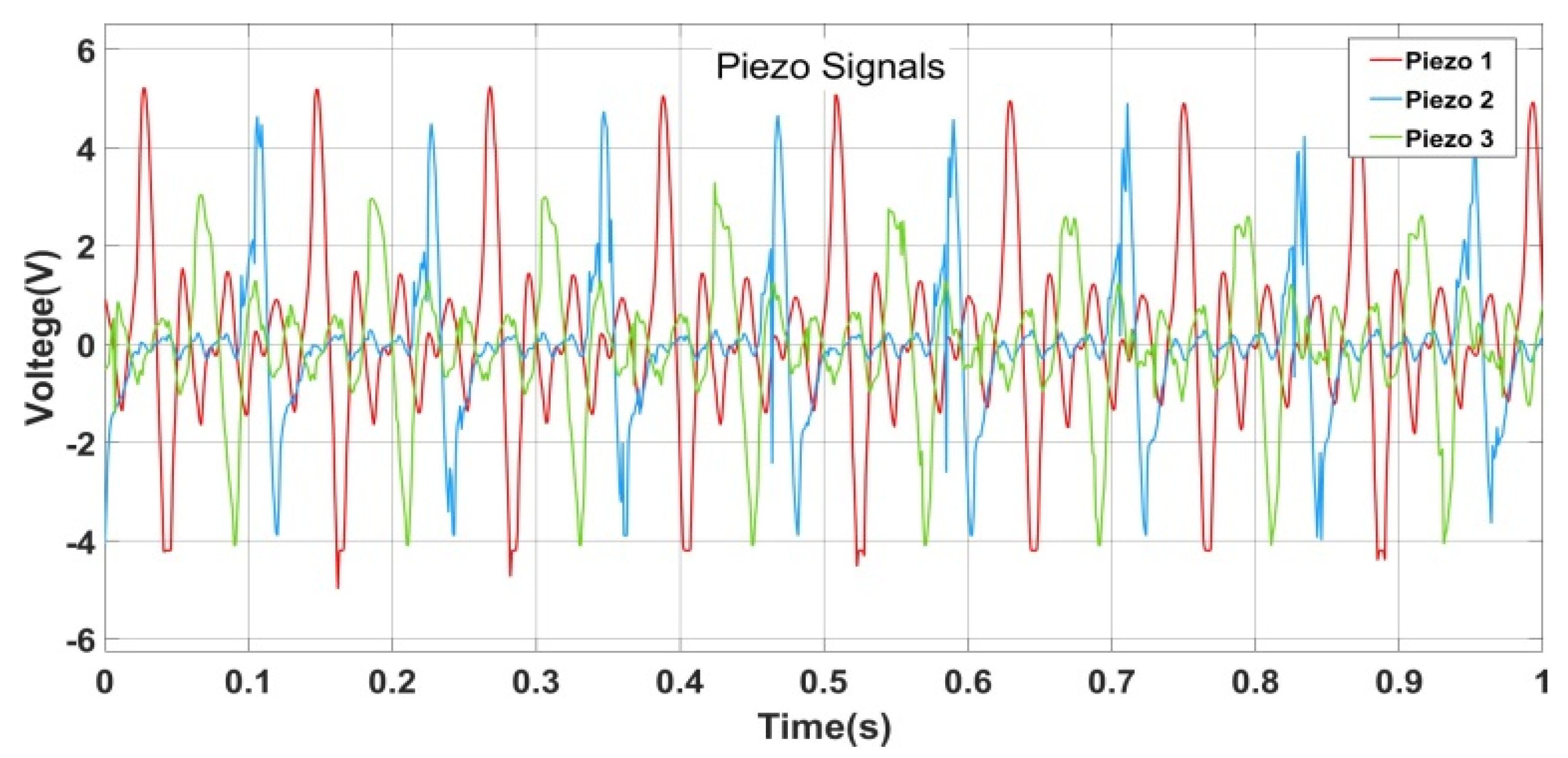

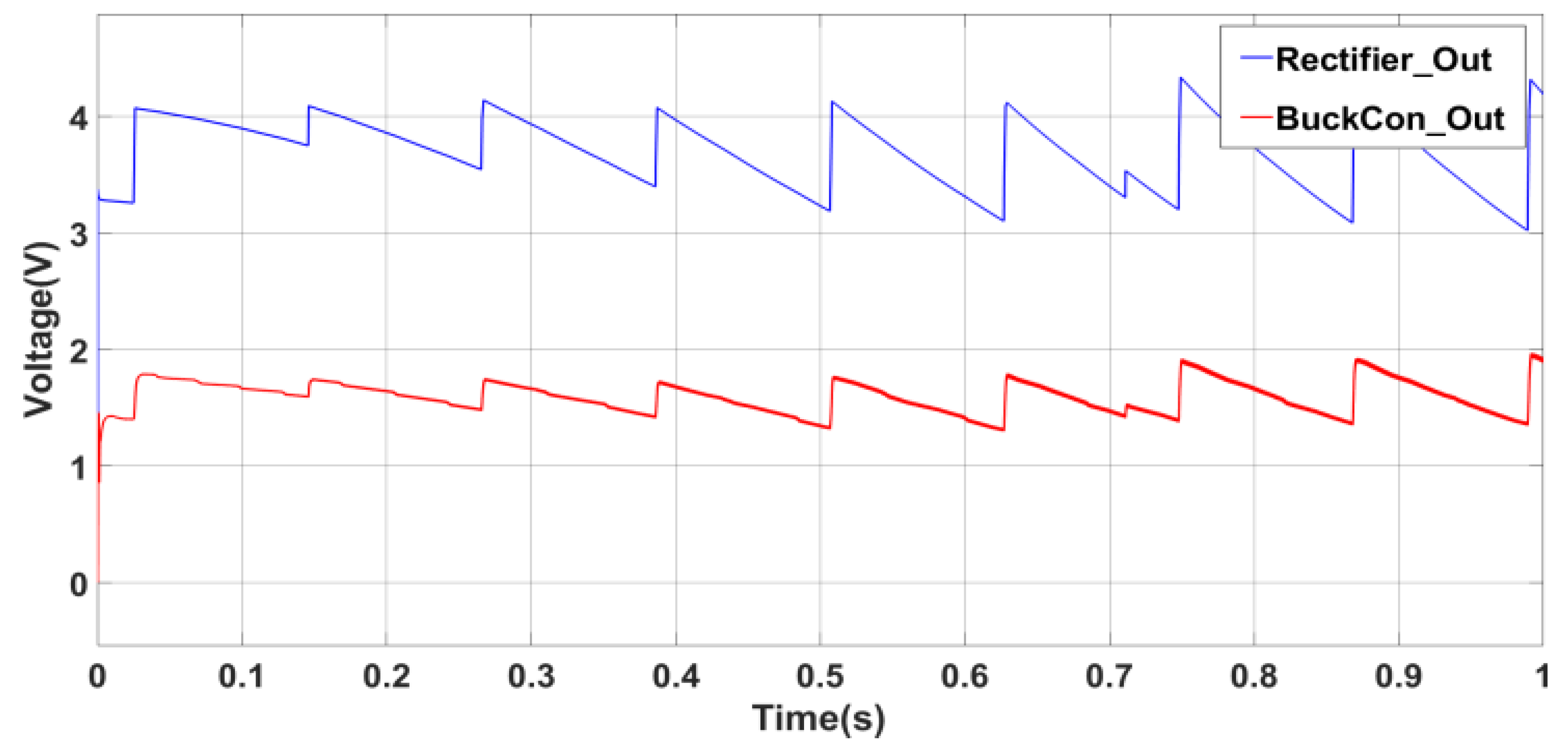

3. Results

4. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bizon, N.; Tabatabaei, N.M.; Blaabjerg, F.; Kurt, E. (Eds.) Energy Harvesting and Energy Efficiency: Technology, Methods, and Applications; Springer International Publishing: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Harne, R.L.; Wang, K. A review of the recent research on vibration energy harvesting via bistable systems. Smart Mater. Struct. 2013, 22, 023001. [Google Scholar] [CrossRef]

- Toprak, A.; Tigli, O. Piezoelectric energy harvesting: State-of-the-art and challenges. Appl. Phys. Rev. 2014, 1, 031104. [Google Scholar] [CrossRef]

- Siddique, A.R.M.; Mahmud, S.; Van Heyst, B. A comprehensive review on vibration based micro power generators using electromagnetic and piezoelectric transducer mechanisms. Energy Convers. Manag. 2015, 106, 728–747. [Google Scholar] [CrossRef]

- Xie, Z.; Kwuimy, C.A.K.; Wang, Z.; Huang, W. A piezoelectric energy harvester for broadband rotational excitation using buckled beam. AIP Adv. 2018, 8, 015125. [Google Scholar] [CrossRef]

- Singla, P.; Sarangi, S.R. A survey and experimental analysis of checkpointing techniques for energy harvesting devices. J. Syst. Archit. 2022, 126, 102464. [Google Scholar] [CrossRef]

- Lin, W.; Wei, Y.; Wang, X.; Zhai, K.; Ji, X. Study on human motion energy harvesting devices: A review. Machines 2023, 11, 977. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, Z.; Jiang, X.; Zhao, Y.; Luo, Y.; Wang, Y.; Wang, Z.; Zhang, Y.; Liu, X.; Fang, B. A Comprehensive Review on Iron-Based Sulfate Cathodes for Sodium-Ion Batteries. Nanomaterials 2024, 14, 1915. [Google Scholar] [CrossRef]

- Uchino, K. Piezoelectric energy harvesting systems—Essentials to successful developments. Energy Technol. 2018, 6, 829–848. [Google Scholar] [CrossRef]

- Paul, T.; Maiti, S.; Mukherjee, U.; Mondal, S.; Sahoo, A.; Chattopadhyay, K.K. Cube shaped FAPbBr3 for piezoelectric energy harvesting devices. Mater. Lett. 2021, 301, 130264. [Google Scholar] [CrossRef]

- Khasawneh, M.A. Energy harvesting devices in pavement structures. Innov. Infrastruct. Solut. 2025, 10, 183. [Google Scholar] [CrossRef]

- Friswell, M.I.; Adhikari, S. Sensor shape design for piezoelectric cantilever beams to harvest vibration energy. J. Appl. Phys. 2010, 108, 014901. [Google Scholar] [CrossRef]

- Luo, S.-H.; Wang, Y.; Liu, Q.; Li, P.; Wang, Z.; Yan, S.; Teng, F. Recent progress and perspective of cathode recycling technology for spent LiFePO4 batteries. J. Ind. Eng. Chem. 2024, 133, 65–73. [Google Scholar] [CrossRef]

- Adhikari, S.; Friswell, M.A.; Inman, D. Piezoelectric energy harvesting from broadband random vibrations. Smart Mater. Struct. 2009, 18, 115005. [Google Scholar] [CrossRef]

- Kim, H.S.; Kim, J.-H.; Kim, J. A review of piezoelectric energy harvesting based on vibration. Int. J. Precis. Eng. Manuf. 2011, 12, 1129–1141. [Google Scholar] [CrossRef]

- Jin, K.; Yan, X.; Li, J.; Zhou, M.; Fu, K.; Wei, X.; Meng, F.; Liu, J. Recent progress in aqueous underwater power batteries. Discov. Appl. Sci. 2024, 6, 441. [Google Scholar] [CrossRef]

- Nechibvute, A.; Chawanda, A.; Luhanga, P. Piezoelectric energy harvesting devices: An alternative energy source for wireless sensors. Smart Mater. Res. 2012, 2012, 853481. [Google Scholar] [CrossRef]

- Glynne-Jones, P.; Tudor, M.; Beeby, S.; White, N. An electromagnetic, vibration-powered generator for intelligent sensor systems. Sens. Actuators A Phys. 2004, 110, 344–349. [Google Scholar] [CrossRef]

- Torah, R.N.; Tudor, M.J.; Patel, K.; Garcia, I.N.; Beeby, S.P. Autonomous low power microsystem powered by vibration energy harvesting. In Proceedings of the SENSORS, 2007 IEEE, Atlanta, GA, USA, 28–31 October 2007. [Google Scholar]

- Ambrożkiewicz, B.; Litak, G.; Wolszczak, P. Modelling of electromagnetic energy harvester with rotational pendulum using mechanical vibrations to scavenge electrical energy. Appl. Sci. 2020, 10, 671. [Google Scholar] [CrossRef]

- Płaczek, M.; Dulat, Ł. Supporting the Design of Systems for Energy Recovery from Mechanical Vibrations Containing MFC Piezoelectric Transducers. Appl. Sci. 2025, 15, 5530. [Google Scholar] [CrossRef]

- von Büren, T.; Tröster, G. Design and optimization of a linear vibration-driven electromagnetic micro-power generator. Sens. Actuators A Phys. 2007, 135, 765–775. [Google Scholar] [CrossRef]

- Mitcheson, P.D.; Miao, P.; Stark, B.; Yeatman, E.; Holmes, A.; Green, T. MEMS electrostatic micropower generator for low frequency operation. Sens. Actuators A Phys. 2004, 115, 523–529. [Google Scholar] [CrossRef]

- Ghashami, G.; Mahnama, M.; Zand, M.M.; Allaei, S.M.V.; López-Suárez, M. Energy harvesting from mechanical vibrations: Self-rectification effect. Phys. Chem. Chem. Phys. 2023, 25, 14400–14405. [Google Scholar] [CrossRef]

- Khbeis, M.; McGee, J.; Ghodssi, R. Development of a simplified hybrid ambient low frequency, low intensity vibration energy scavenger system. In Proceedings of the TRANSDUCERS 2009–2009 International Solid-State Sensors, Actuators and Microsystems Conference, Denver, CO, USA, 21–25 June 2009. [Google Scholar]

- Erturk, A. Electromechanical Modeling of Piezoelectric Energy Harvesters. Ph.D. Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2009. [Google Scholar]

- Choi, W.J.; Jeon, Y.; Jeong, J.-H.; Sood, R.; Kim, S.G. Energy harvesting MEMS device based on thin film piezoelectric cantilevers. J. Electroceram. 2006, 17, 543–548. [Google Scholar] [CrossRef]

- Sodano, H.A.; Inman, D.J.; Park, G. Comparison of piezoelectric energy harvesting devices for recharging batteries. J. Intell. Mater. Syst. Struct. 2005, 16, 799–807. [Google Scholar] [CrossRef]

- Bahrami, A.; Motaei, F. A review of phononic-crystal-based energy harvesters. Prog. Energy 2024, 7, 012002. [Google Scholar] [CrossRef]

- Mastouri, H.; Ennawaoui, A.; Remaidi, M.; Sabani, E.; Derraz, M.; El Hadraoui, H.; Ennawaoui, C. Design, Modeling, and Experimental Validation of a Hybrid Piezoelectric–Magnetoelectric Energy-Harvesting System for Vehicle Suspensions. World Electr. Veh. J. 2025, 16, 237. [Google Scholar] [CrossRef]

- Wang, H.; Huang, X.; Li, Z.; Fang, L. Design of a Portable Integrated Fluid–Structure Interaction-Based Piezoelectric Flag Energy-Harvesting System. Fluids 2025, 10, 121. [Google Scholar] [CrossRef]

- Mitcheson, P.D.; Green, T.C.; Yeatman, E.M. Power processing circuits for electromagnetic, electrostatic and piezoelectric inertial energy scavengers. Microsyst. Technol. 2007, 13, 1629–1635. [Google Scholar] [CrossRef]

- Chopra, I. Review of state of art of smart structures and integrated systems. AIAA J. 2002, 40, 2145–2187. [Google Scholar] [CrossRef]

- Priya, S. Advances in energy harvesting using low profile piezoelectric transducers. J. Electroceram. 2007, 19, 167–184. [Google Scholar] [CrossRef]

- Fu, H.; Yeatman, E.M. A miniaturized piezoelectric turbine with self-regulation for increased air speed range. Appl. Phys. Lett. 2015, 107, 243905. [Google Scholar] [CrossRef]

- Uchino, K.; Ishii, T. Energy flow analysis in piezoelectric energy harvesting systems. Ferroelectrics 2010, 400, 305–320. [Google Scholar] [CrossRef]

- Renaud, M.; Fiorini, P.; van Schaijk, R.; van Hoof, C. Harvesting energy from the motion of human limbs: The design and analysis of animpact-based piezoelectric generator. Smart Mater. Struct. 2009, 18, 035001. [Google Scholar]

- Uzun, Y.; Kurt, E. Performance exploration of an energy harvester near the varying magnetic field of an operating induction motor. Energy Convers. Manag. 2013, 72, 156–162. [Google Scholar] [CrossRef]

- Song, Y.; Yang, C.H.; Hong, S.K.; Hwang, S.J.; Kim, J.H.; Choi, J.Y.; Ryu, S.K.; Sung, T.H. Road energy harvester designed as a macro-power source using the piezoelectric effect. Int. J. Hydrogen Energy 2016, 41, 12563–12568. [Google Scholar] [CrossRef]

- Ranjit, P.; Thakur, A.K. ENERGY HARVESTING & STORAGE. In Energy Harvesting Technologies for Powering WPAN and IoT Devices for Industry 4.0 Up-Gradation; Nova Science Publishers: Hauppauge, NY, USA, 2020. [Google Scholar]

- Uzun, Y.; Demirbas, S.; Kurt, E. Implementation of a new contactless piezoelectric wind energy harvester to a wireless weather station. Elektron. Ir Elektrotechnika 2014, 20, 35–39. [Google Scholar]

- Kim, H.; Priya, S.; Stephanou, H.; Uchino, K. Consideration of impedance matching techniques for efficient piezoelectric energy harvesting. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2007, 54, 1851–1859. [Google Scholar] [CrossRef]

- Kurt, E.; Özhan, D.; Bizon, N.; Lopez-Guede, J.M. Design and implementation of a maximum power point tracking system for a piezoelectric wind energy harvester generating high harmonicity. Sustainability 2021, 13, 7709. [Google Scholar] [CrossRef]

- Touairi, S.; Ghalim, N.; Ouaomar, H.; Kouider, N. Optimization strategies for cost-effectiveness in piezoelectric energy harvesting systems. Int. J. Dyn. Control 2025, 13, 156. [Google Scholar] [CrossRef]

- Du, S.; Jia, Y.; Arroyo, E.; Seshia, A.A. Rectified Output Power Analysis of Piezoelectric Energy Harvester Arrays under Noisy Excitation. In Proceedings of the 17th International Conference on Micro and Nanotechnology for Power Generation and Energy Conversion Applications (PowerMEMS 2017), Kanazawa, Japan, 14–17 November 2017. [Google Scholar]

- Kurt, E.; Cottone, F.; Uzun, Y.; Orfei, F.; Mattarelli, M.; Özhan, D. Design and implementation of a new contactless triple piezoelectrics wind energy harvester. Int. J. Hydrogen Energy 2017, 42, 17813–17822. [Google Scholar] [CrossRef]

- Kong, N.; Ha, D.S. Low-power design of a self-powered piezoelectric energy harvesting system with maximum power point tracking. IEEE Trans. Power Electron. 2012, 27, 2298–2308. [Google Scholar] [CrossRef]

- Chowdary, G.; Singh, A.; Chatterjee, S. An 18 nA, 87% efficient solar, vibration and RF energy-harvesting power management system with a single shared inductor. IEEE J. Solid-State Circuits 2016, 51, 2501–2513. [Google Scholar] [CrossRef]

- Chew, Z.J.; Zhu, M. Adaptive maximum power point finding using direct V OC/2 tracking method with microwatt power consumption for energy harvesting. IEEE Trans. Power Electron. 2017, 33, 8164–8173. [Google Scholar] [CrossRef]

- Sinkaram, C.; Asirvadam, V.S.; Nor, N.B.M. Capacity study of lithium ion battery for hybrid electrical vehicle (HEV) a simulation approach. In Proceedings of the 2013 IEEE International Conference on Signal and Image Processing Applications, Melaka, Malaysia, 8–10 October 2013. [Google Scholar]

| Title 1 | Buck Converter | Boost Converter |

|---|---|---|

| Inductance (L)entry 1 | 1 mH data | 1 mH data |

| Capacitance (C)entry 2 | 1 mF data | 1 mF data 1 |

| Switching Frequency (f) | 10 kHz | 10 kHz |

| PI Control (P-I) | 200–300 | 200–300 |

| Sample Time (Tss) | 1 × 10−6 s | 1 × 10−6 s |

| Battery | Li-ion, 0.1 Ah, 3.6 V | Li-ion, 0.1 Ah, 3.6 V |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Özhan, D.; Kurt, E. An Energy Storage Unit Design for a Piezoelectric Wind Energy Harvester with a High Total Harmonic Distortion. Processes 2025, 13, 3217. https://doi.org/10.3390/pr13103217

Özhan D, Kurt E. An Energy Storage Unit Design for a Piezoelectric Wind Energy Harvester with a High Total Harmonic Distortion. Processes. 2025; 13(10):3217. https://doi.org/10.3390/pr13103217

Chicago/Turabian StyleÖzhan, Davut, and Erol Kurt. 2025. "An Energy Storage Unit Design for a Piezoelectric Wind Energy Harvester with a High Total Harmonic Distortion" Processes 13, no. 10: 3217. https://doi.org/10.3390/pr13103217

APA StyleÖzhan, D., & Kurt, E. (2025). An Energy Storage Unit Design for a Piezoelectric Wind Energy Harvester with a High Total Harmonic Distortion. Processes, 13(10), 3217. https://doi.org/10.3390/pr13103217