1. Introduction

In offshore oil and gas development, subsea pipelines are often subjected to harsh deep-sea conditions, such as high pressure, low temperatures, and strong currents. Traditional single-layer steel pipelines have frequently proved inadequate in terms of thermal insulation, corrosion protection, and their ability to withstand external water pressure. These shortcomings are especially pronounced when transporting fluids like high-viscosity crude oil or natural gas condensate. Without effective insulation, these fluids may cool and solidify at low ambient temperatures or form gas hydrates that could block the pipeline [

1,

2].

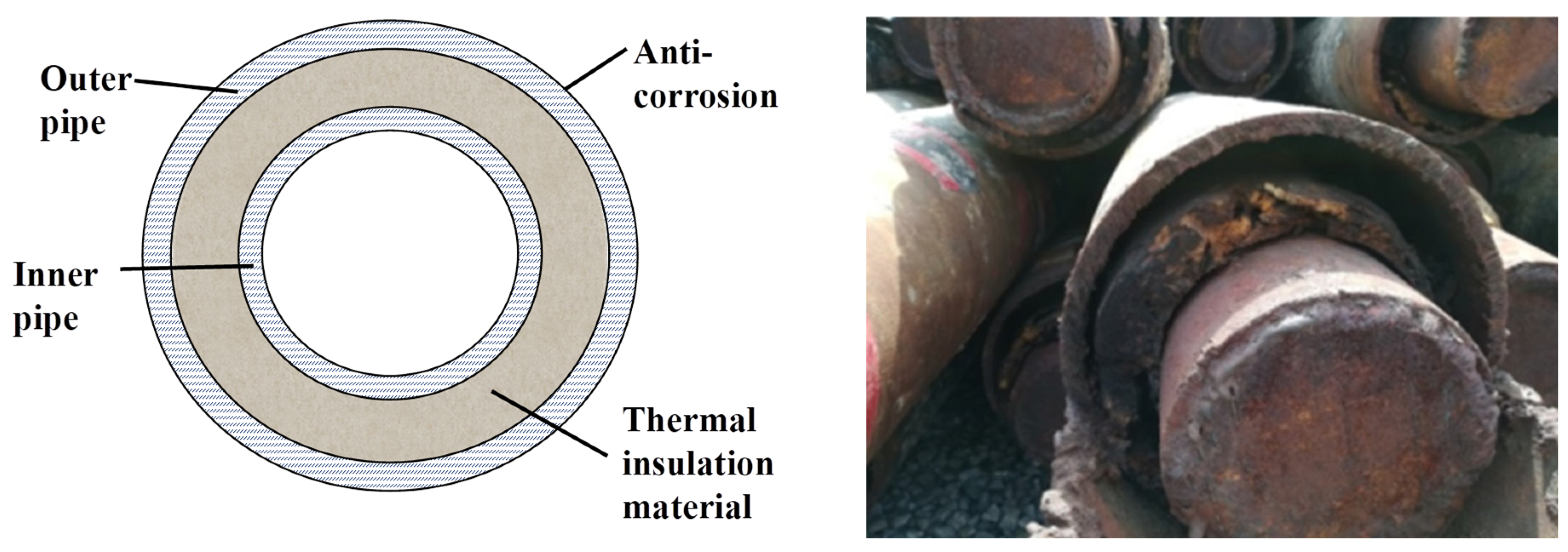

These challenges have spurred the development of marine ‘pipe-in-pipe (PIP)’ systems. A PIP system consists of two concentric steel pipes—an inner flowline housed within an outer carrier pipe—with insulation filling the annular space between them. The outer pipe is typically a high-strength, thick-walled carbon or alloy steel tube, designed to resist external loads such as hydrostatic pressure, seabed soil pressure, and impacts from the marine environment. The inner pipe, by contrast, is usually a smooth, corrosion-resistant steel (or stainless steel) pipeline dedicated to transporting high-temperature, high-pressure fluids (crude oil, natural gas, or multiphase mixtures).

An annular gap between the inner and outer pipes is filled with advanced thermal insulation materials—such as high-performance polyurethane foam, aerogel blankets, or other composite insulating layers—to create an effective thermal barrier. In addition, porous media can be employed as insulating materials due to their favorable thermal characteristics and low weight [

3,

4]. Spacer blocks and centralizers are utilized to maintain concentricity and to isolate the inner and outer pipes. This composite configuration allows the heat of the transported fluid to be efficiently retained during operation (suppressing thermal losses), while the outer pipe’s rigidity and strength protect the system against various external hazards in the subsea environment [

5,

6]. The PIP configuration thus offers two primary advantages.

First, PIP systems greatly enhance insulation and thermal management. Subsea pipelines often carry oil and gas at elevated temperatures. If the flow is rapidly cooled by the surrounding seawater, its viscosity increases, and flow can be hindered; more critically, condensates, gas hydrates, or wax can precipitate on the pipe wall, eventually causing blockages. By incorporating closed-cell polymer foam (e.g., rigid polyurethane) or aerogel insulation into the annulus between the pipes, PIP systems significantly reduce heat loss to the environment. Some PIP designs further improve thermal performance by introducing vacuum-insulated sections in the annulus, thereby minimizing heat transfer. As a result, the fluid inside the inner pipe remains at a sufficiently high temperature—and thus stays free-flowing—significantly lowering the risk of wax or hydrate formation and reducing the maintenance costs associated with flow stability and performance.

Second, the double-layer PIP structure provides significant load-bearing and protective advantages. As the outer pipe carries the vast majority of external loads (such as high hydrostatic pressure, pore-water pressure in the seabed, and impacts from shifting seabed sands), the inner pipe can focus on withstanding internal pressure and thermal stresses. This separation of roles results in a lower probability of structural failure compared to a traditional single-pipe system. Even if the outer pipe suffers from local deformation or corrosion, it is unlikely to directly compromise the inner pipe; as long as the inner pipe remains intact and the insulation layer is not severely degraded, safe fluid transport can continue. Moreover, for long-distance pipelines deployed in deepwater, the combined stiffness and stability of the double-pipe structure help it accommodate local seabed movements and free spans, thereby preventing the occurrence of pipe-wall cracking or fatigue failure due to bending stress concentrations.

In contemporary offshore oil and gas field development, PIP systems have emerged as one of the mainstream technologies for deepwater production and transportation. They have been successfully deployed in several deepwater regions, including the North Sea, the Gulf of Mexico, offshore Brazil, and West Africa. Owing to their superior capabilities in thermal insulation, flow assurance, and resistance to external loads, PIP systems significantly extend the service life of subsea pipelines and reduce the frequency of subsea interventions and maintenance operations. Looking ahead, as offshore exploration advances toward ultra-deepwater and extremely cold environments, future PIP systems are expected to incorporate next-generation insulation materials of lower thermal conductivity, along with vacuum-based technologies and intelligent sensors. These innovations will enable real-time monitoring of temperature, stress, and corrosion within and outside the pipeline, thereby enhancing overall system safety and performance. Accordingly, marine PIP systems will continue to demonstrate their unique advantages in deep-sea oil and gas transportation, flow assurance, and integrated safety protection, offering reliable engineering solutions for global offshore energy development.

In terms of impact resistance, Qu, H. et al. [

7] investigated the impact behavior of circular steel pipes and proposed a damage evaluation method suitable for steel pipe components with impact loads. Jones et al. [

8] introduced a method for idealizing deformed pipe cross-sections and conducted a comprehensive analysis of their impact resistance. Zeinoddini et al. [

9,

10] performed extensive experimental studies on the lateral impact performance of steel pipes. In recent years, many researchers worldwide have adopted numerical simulation techniques to analyze local deformations in pipelines under transverse impact.

Regarding the buckling mechanisms and control measures of PIP systems, Karampour, H. et al. [

11] investigated propagation buckling of subsea single pipes and PIP systems. Bruton et al. [

12] utilized numerical simulations to show that effective axial force, initial geometric imperfections, and soil resistance are critical factors influencing lateral buckling. Goplen et al. [

13] provided structural response analyses and proposed several criteria for global buckling in PIP systems. Kristoffersen et al. [

14] applied finite element analysis to study the global buckling of a PIP system on an uneven seabed and presented a corresponding methodology along with the analysis results.

In the area of dynamic response, Nikoo et al. [

15] simplified the inner and outer pipes of a PIP system as lumped masses and modeled the structure as a non-conventional tuned mass damper (TMD) system for dynamic analysis. Their studies incorporated MATLAB R2017a-based numerical solutions and simulations using ANSYS 17.0 and ABAQUS 2017 to investigate vortex-induced vibrations (VIVs) and their suppression. They further identified the effects of key structural and environmental parameters on pipeline vibration and proposed corresponding mitigation measures [

16]. Bi et al. [

17] developed a vibration control equation by introducing springs and dampers in the annular space between the inner and outer pipes. Fyrileiv et al. [

18] pointed out that the natural frequency of free-spanning subsea pipelines is influenced by the effective axial force rather than the actual axial force. Liu et al. [

19] established three-dimensional dynamic control equations for PIP systems and proposed a VIV suppression method.

Extensive research has been conducted on the thermal effects of deepwater PIP systems using analytical methods. Bokaian [

20] derived a computational model for thermal stress at pipe ends under various loading conditions based on linear superposition, assuming simplified pipeline connections. Guo et al. [

21] found that when thermal effects are considered, the stability of PIP systems is superior to that of single-wall pipelines. Paul et al. [

22] proposed an optimized thermal design method for PIP systems based on heat conduction theory. Kim et al. [

23] developed a leakage detection method based on a threshold value of temperature difference. Moawed et al. [

24] presented an analysis of the heat transfer mechanism for fluid flow inside the inner pipe. Jian Su [

25,

26,

27] analyzed transient thermal conduction during flow initiation and shutdown in multi-layer pipelines and provided the fluid temperature profiles along the pipeline for these processes.

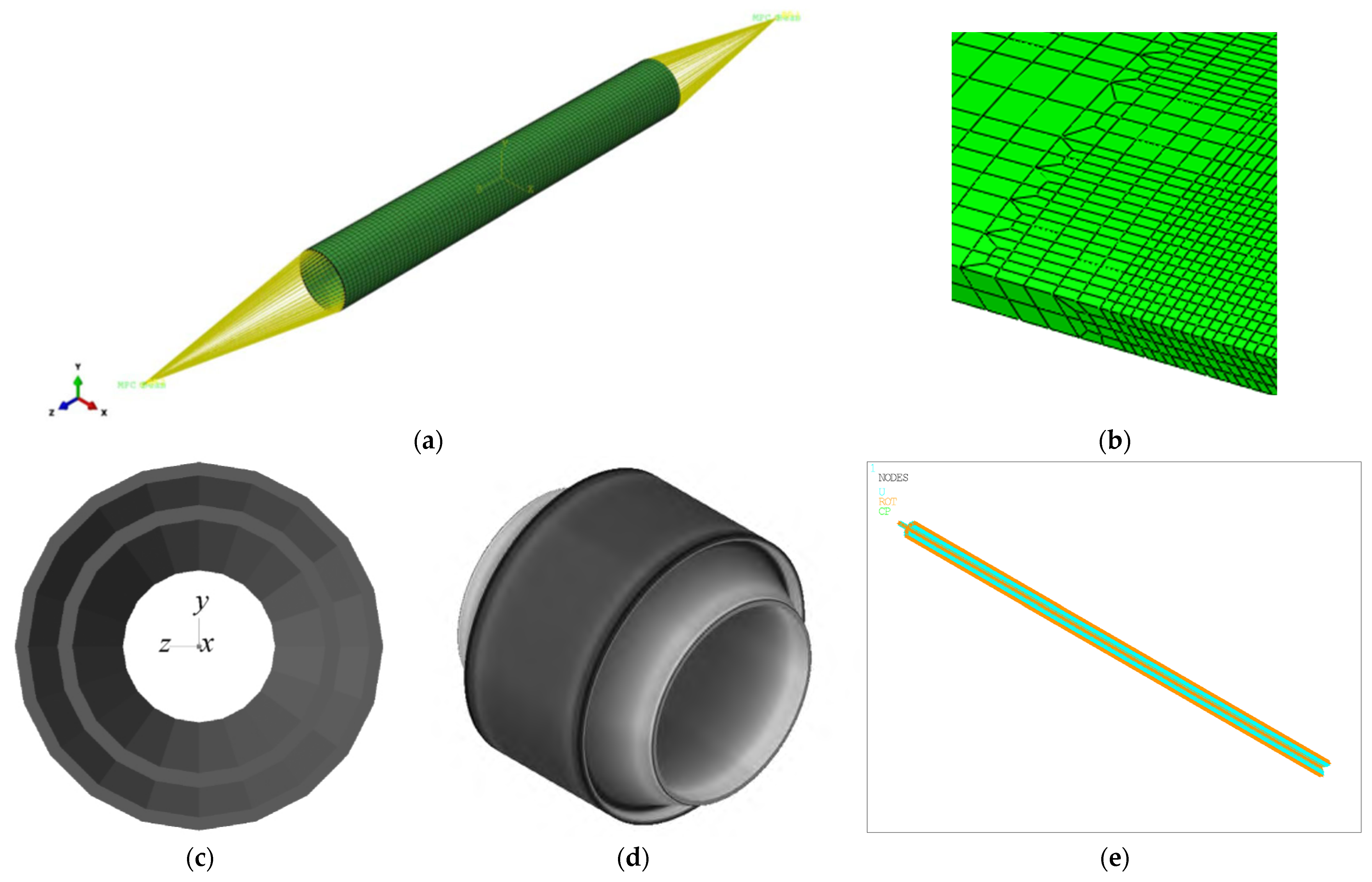

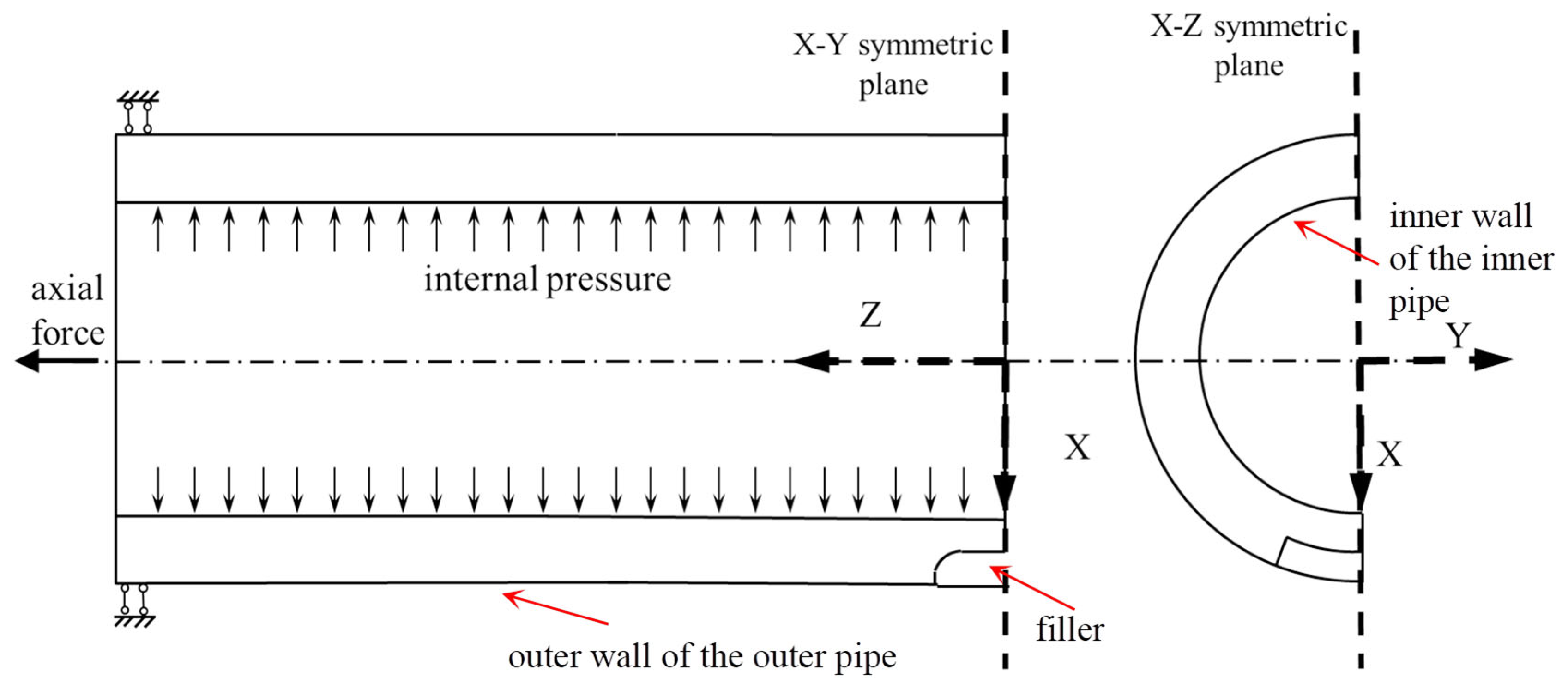

However, finite element simulations that accurately reflect real-world deep-sea conditions—particularly the thermal effects on PIP systems under non-uniform temperature fields—are still lacking; thus, further investigation is warranted. An improved deepwater PIP model is developed by introducing ITT (Interface Thermal Transfer) elements and nonlinear spring elements in the paper. The temperature-induced effects under non-uniform thermal fields are comprehensively simulated, and the resulting stress distribution characteristics under combined internal pressure and thermal loading are clarified. Unlike previous analytical and numerical studies on PIP systems, which typically analyze thermal and pressure effects in isolation, a mechanical response model capturing the differential deformation behavior between the inner and outer pipes is established. The unified mechanical model fully couples temperature-induced stresses and internal pressure loads in double-layer subsea pipelines. The formulation captures the mutual axial stress interaction between inner and outer pipes under extreme thermal expansion and contraction, enabling more realistic stress predictions for high-temperature, high-pressure operating conditions. Furthermore, the model achieves prediction errors within approximately 5% compared with high-fidelity finite element simulations, ensuring both computational efficiency and engineering accuracy. These advancements make the proposed approach a significant improvement over existing models, offering new insights into safe and cost-effective PIP design.

5. Stress Modeling of Pipe-in-Pipe Systems

Considering the mechanical coupling between the inner and outer pipes, the mechanical behavior of the PIP system can be broadly categorized into two types based on the initial deformation stage:

Type I: The inner pipe elongates relative to the outer pipe (e.g., expansion with Extreme Condition I). Type II: The outer pipe elongates relative to the inner pipe (e.g., contraction of the inner pipe with Extreme Condition II).

Table 7 summarizes the stress types in both pipes for these two categories. As shown, in Type I loading scenarios, the inner pipe is predominantly subjected to compressive stress, while the outer pipe experiences tensile stress. This is due to the inner pipe’s thermally induced expansion being constrained by the outer pipe, resulting in internal compressive stress, whereas the outer pipe develops axial tensile stress in response to the inner pipe’s expansion.

In contrast, under Type II loading, the inner pipe experiences tensile stress, while the outer pipe is subjected to compressive stress. This arises because the outer pipe elongates relative to the inner pipe and is constrained at the ends by the inner pipe, which in turn induces compressive stress in the outer pipe and tensile stress in the inner pipe.

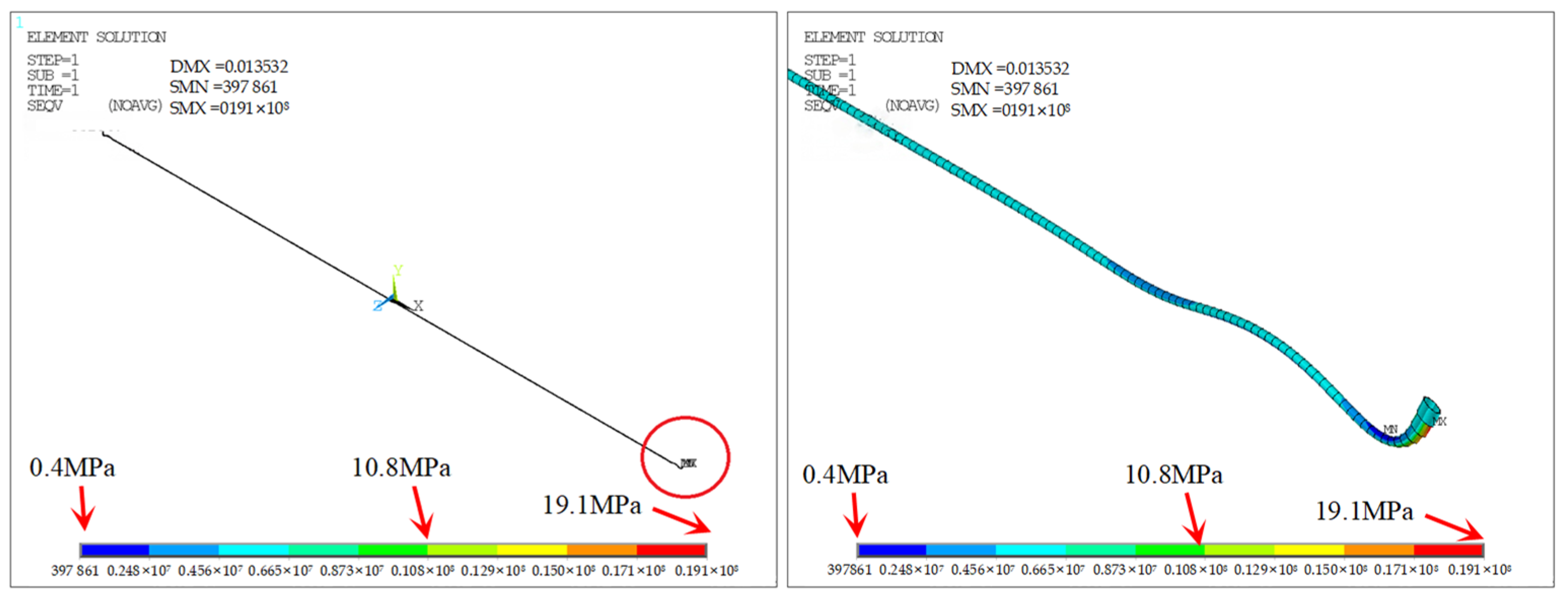

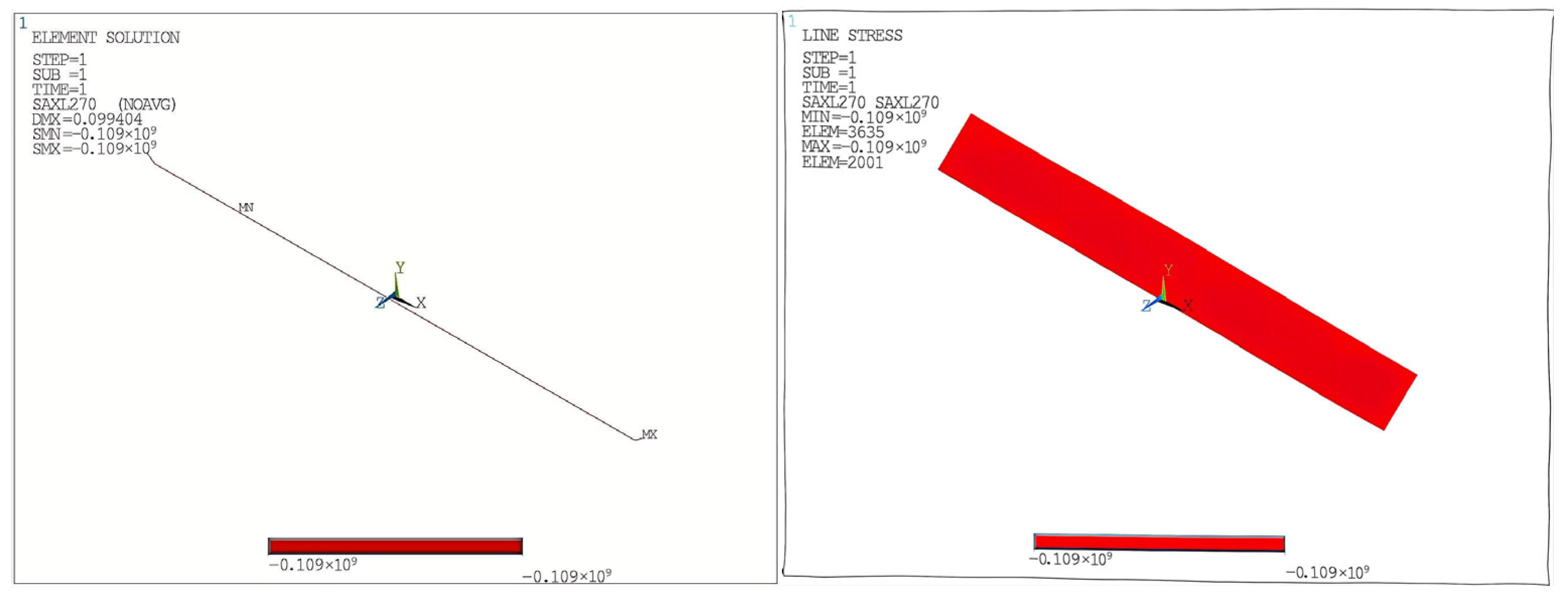

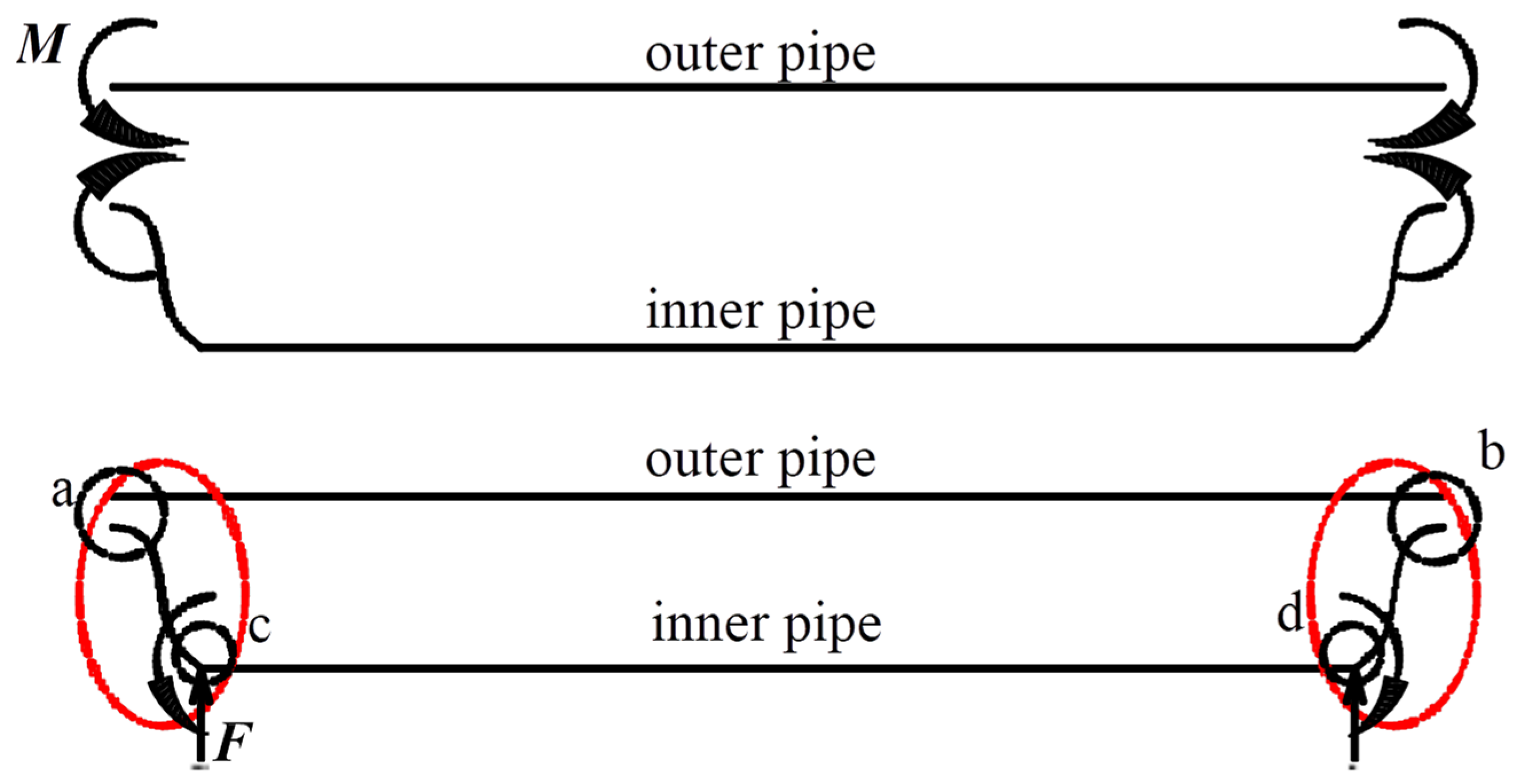

Figure 21 illustrates the end-region stress model of a pipe-in-pipe system under differential deformation conditions. At the ends of the system, both the inner and outer pipes develop bending moments in the Z-direction [

6]. The bending moment direction is consistent: the outer pipe end experiences a negative moment (−

Mz), and the inner pipe end is subjected to a positive moment (+

Mz). At the inflection point of the inner pipe, another negative bending moment (−

Mz) occurs. The bending moment is caused by the differential deformation of the inner and outer pipes and the internal pressure.

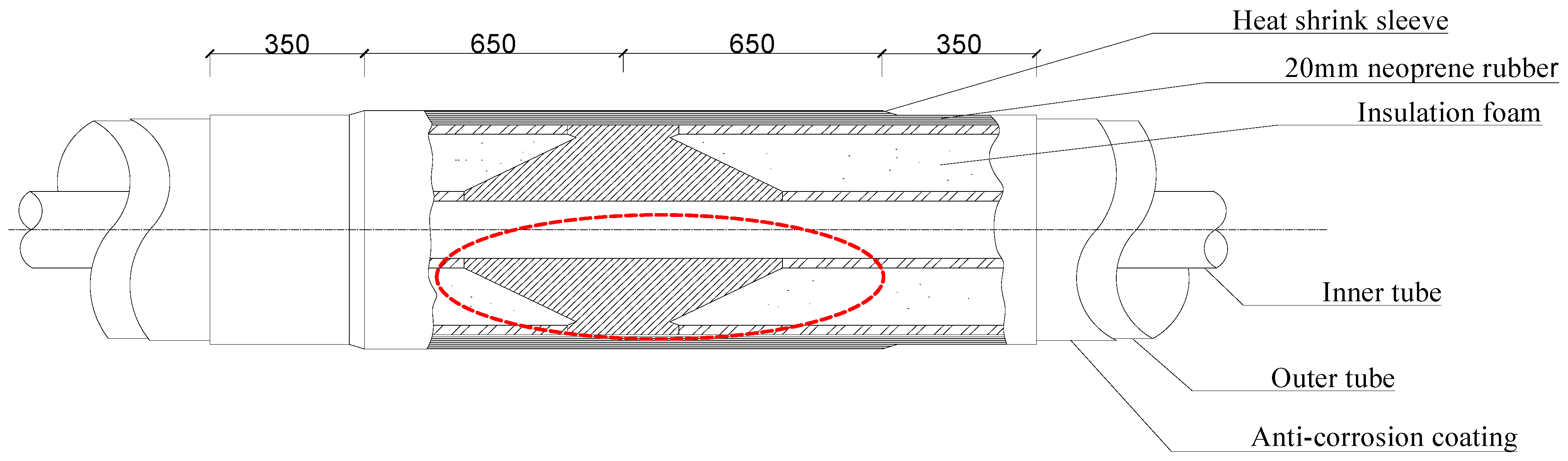

5.1. Stress Model for Inner Pipe Expansion Due to Preheating

For Extreme Condition I, the primary external loads are the thermal stress and internal pressure acting on the inner pipe. Internal pressure mainly contributes to hoop stress in the inner pipe, while its influence on axial stress is relatively small due to its limited magnitude. The principal factor governing the mechanical behavior of the coupled system is thus the thermal expansion of the inner pipe.

In the first loading stage, thermal expansion of the inner pipe induces axial displacements at the connection points a and b, directed toward the midsection of the pipe. However, these displacements are constrained by external soil resistance. Furthermore, since the top elevation of the outer pipe is higher than that of the inner pipe, expansion of the inner pipe produces a negative bending moment (−Mz) at the outer pipe ends. The inner pipe, in response to the outer pipe’s constraint, develops a positive moment (+Mz) at its ends. This results in an increase in tensile stress at the 0° position of the outer pipe and a decrease at the 180° position. The inner pipe, conversely, experiences increased compressive stress at the 0° direction and reduced stress at 180°.

As both ends of the inner pipe are constrained, it bends under thermal expansion. However, as it is embedded inside the outer pipe, the deformation is confined, and the midsection remains restricted. The ends of the inner pipe consequently develop symmetrical L-shaped deformations. The outer pipe, being in tension, develops tensile stress, while the constrained ends a and b exert compressive forces on the inner pipe.

In the second loading stage, the continued constraint of the expanding inner pipe by the outer pipe leads to vertical displacement. Without outer pipe confinement, the inner pipe would deform into an arch shape. Considering the influence of the outer wall, the deformation instead results in an L-shaped profile as shown in

Figure 21. The corners of this L-shape (points

c and

d) act as pivot points for bending deformation, where the outer pipe wall imposes reactive forces

F onto the inner pipe.

Given that points

a and

b are constrained by soil, points

c and

d experience negative bending moments (−

Mz) under the action of

F. This induces decreased compressive stress at 0° and increased compressive stress at 180° in those regions. The red regions in

Figure 21 represent the stress-affected zones arising from the mechanical interaction between inner and outer pipes. Beyond these areas, the remaining pipe segments are largely unaffected by the end bending moments, and the stress fields remain stable.

Table 8 presents the axial stress influence zones of the connecting forgings at ends

a and

b. The influence zones differ between inner and outer pipes. For example, in Extreme Condition I, the outer pipe acts as the passive load bearer and has more rigid boundary constraints, making it less deformable. As a result, the outer pipe has a reduced capacity for internal stress redistribution, and its stress-affected region is broader, with an average length of 16.5 m, compared to 10.2 m for the inner pipe.

The middle sections of the outer pipe are not affected by external loads at the ends because these forces are absorbed by the end constraints. Similarly, the middle section of the inner pipe remains unaffected due to the L-shaped deformation at both ends, where points c and d act as pivot supports that neutralize external loads through reaction forces.

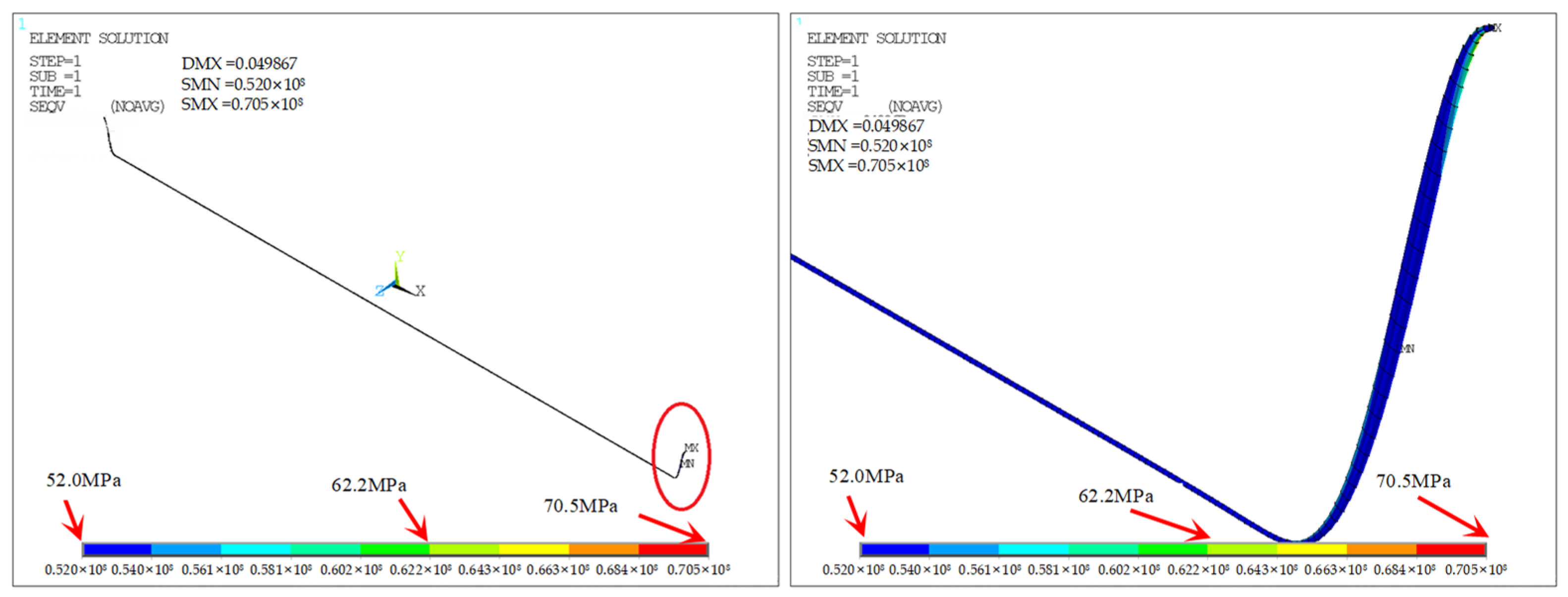

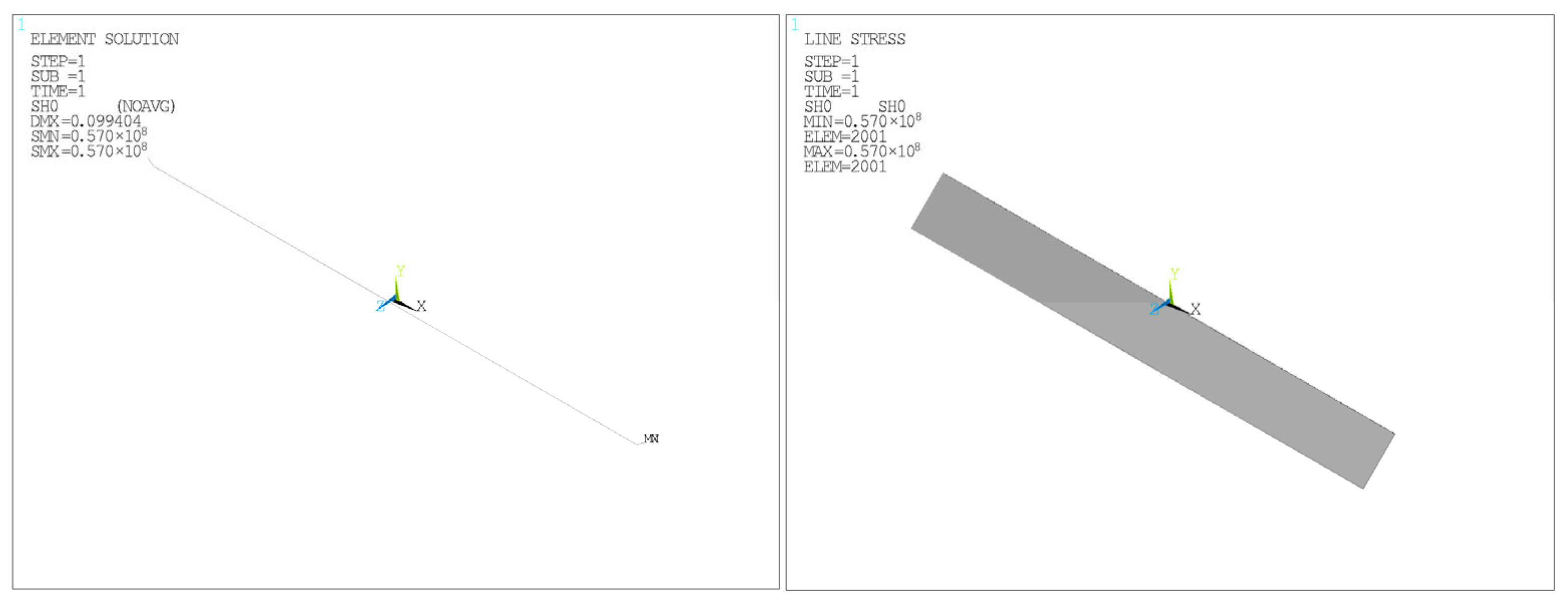

5.2. Mechanical Interaction Model of Pipe-in-Pipe System with Inner Pipe Pre-Cooling Contraction

In Extreme Condition II, the dominant external loads acting on the system include thermal contraction stress and internal pressure within the inner pipe. The principal factor altering the mechanical interaction model between the inner and outer pipes is the shrinkage deformation of the inner pipe under pre-cooling conditions.

Figure 21 illustrates the mechanical response model of the PIP system during inner pipe contraction.

In the first loading stage, the inner pipe undergoes thermal expansion, causing the interface locations—denoted as ends a and b—to displace toward the center of the pipeline segment. However, because the ends a and b are constrained by the surrounding soil, and due to the fact that the outer pipe is located at a higher elevation than the inner pipe, the inner pipe undergoes thermal contraction. This results in the generation of a negative bending moment (−Mz) at the outer pipe ends, while a positive bending moment (+Mz) is produced at the inner pipe ends due to the reaction force from the outer pipe.

The asymmetric loading leads to a decrease in compressive stress at the 0° circumferential direction of the outer pipe and an increase at 180°. Correspondingly, tensile stress in the inner pipe decreases at 0° and increases at 180°. Due to gravitational effects, the inner pipe exhibits symmetric “L”-shaped deformations at both ends. While the outer pipe experiences compressive stress, the inner pipe is predominantly subjected to tensile stress.

In the second loading stage, as the inner pipe attempts to expand, it is constrained by the outer pipe. Without this confinement, the inner pipe would deform into a bow-shaped profile. However, accounting for the stiffness of the outer pipe wall, the inner pipe instead assumes an “L”-shaped deformation along its segment, as shown in

Figure 21. At locations

c and

d—the corners of the “L” shape—the pipe wall of the outer pipe exerts a reaction force

F on the inner pipe. These points function as structural supports for the “L”-shaped riser section of the inner pipe. Given that ends

a and

b are constrained by external soil, the reaction forces

F at

c and

d produce negative bending moments (−

Mz), leading to a reduction in compressive stress at the 0° direction and an increase at 180° in those regions.

In

Figure 21, the red-highlighted zones represent the influence regions where mechanical interaction between the inner and outer pipes occurs due to end connectivity. The remaining pipe segments remain largely unaffected by end-induced bending moments, showing little to no change in equivalent stress values.

Table 9 presents the axial stress influence ranges of the forged joints at ends

a and

b for both pipes. Compared to Extreme Condition II, the influence range in this case is significantly larger. This difference is attributed to the tensile forces acting on the inner pipe in Extreme Condition II, where the vertical component of the tensile force partially counteracts the weight of the bent segments. As a result, the reaction force

F at the bends is smaller in Extreme Condition II, yielding a narrower influence region for the generated bending moments.

In this scenario, the outer pipe—which passively bears the loads—has a stricter confinement condition and higher structural stiffness than the inner pipe, making it less susceptible to deformation. Consequently, the outer pipe does not follow the same stress evolution pattern as the inner pipe. The outer pipe also demonstrates poorer self-regulation of its stress field, resulting in a broader influence zone at the pipe ends, with an average range of 16.875 m—larger than the inner pipe’s influence range of 13.375 m. The midsection of the outer pipe remains unaffected by external loads from the pipe ends due to boundary constraint dissipation. Similarly, the midsection of the inner pipe is also unaffected, as the “L”-shaped deformation at the ends and the reaction force at points c and d effectively cancel out the axial transmission of end loads along the pipe axis.

5.3. Calculation Method of Dual-Layer Pipe

5.3.1. Principal Stresses

For pipelines subjected to both internal pressure and thermal gradients, the radial stress is typically negligible. The dominant stress components are the axial stress and the hoop stress:

Axial stress in buried pipelines arises from thermal expansion or contraction and from Poisson’s effect due to hoop stress. It is calculated with Equation (2).

where

σz is the axial stress;

σt is the thermal stress caused by temperature difference;

σa is the axial stress due to internal pressure (Poisson effect);

E is the Young’s modulus of the pipe material; Δ

T is the temperature variation;

p is the internal pressure;

α is the coefficient of linear thermal expansion;

μ is the Poisson’s ratio;

t is the wall thickness of the pipe.

Hoop stress is directly induced by internal pressure and is one of the principal stresses determining the pipe’s stress state. It is given by Equation (3):

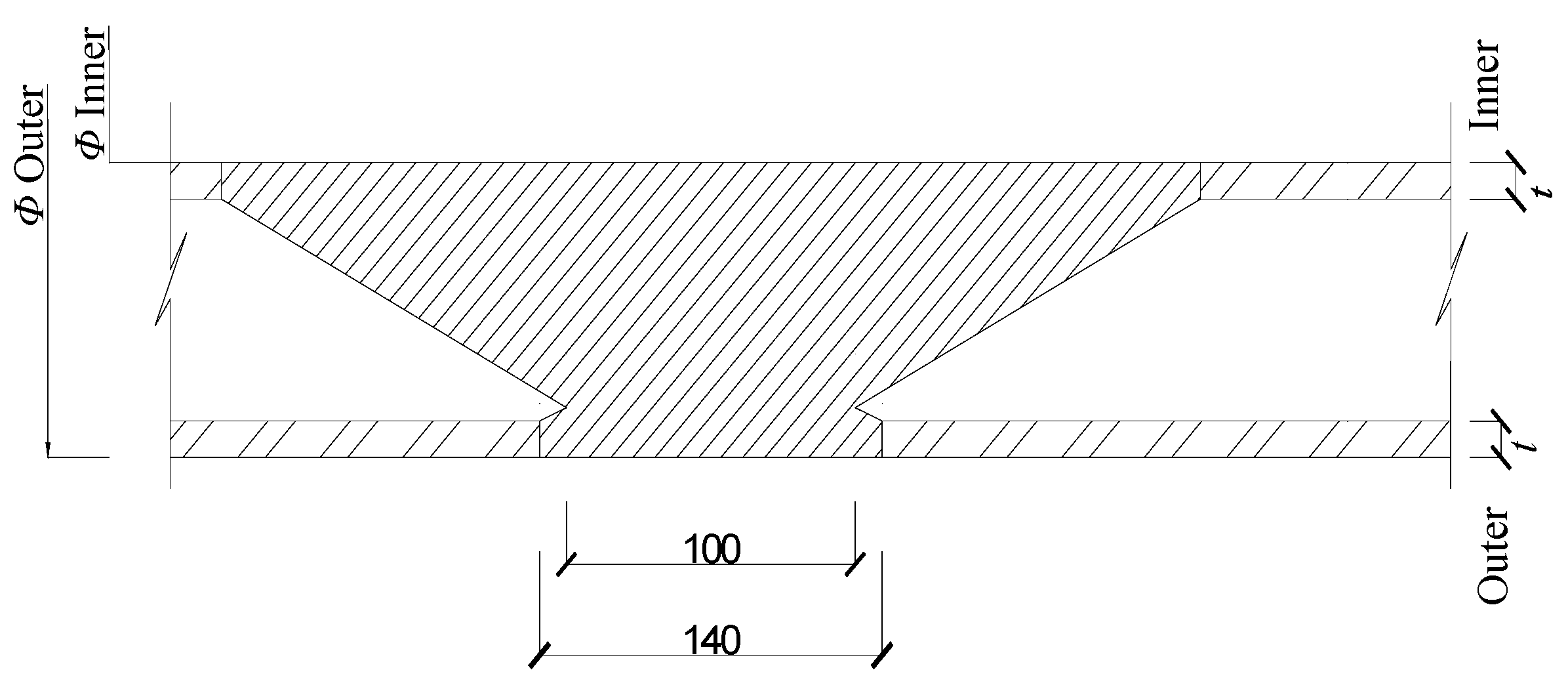

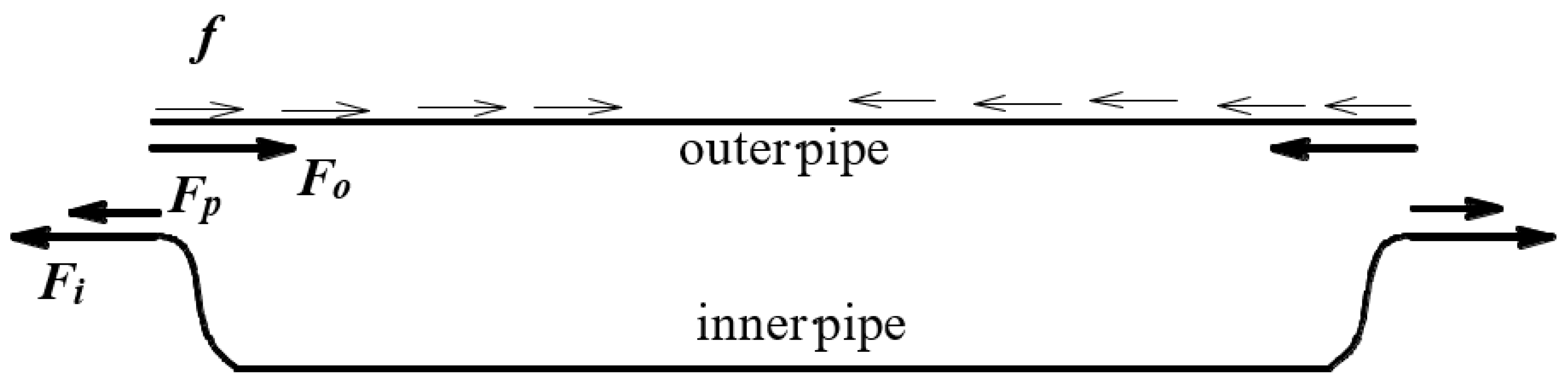

5.3.2. Computation Model of Pipe-in-Pipe System

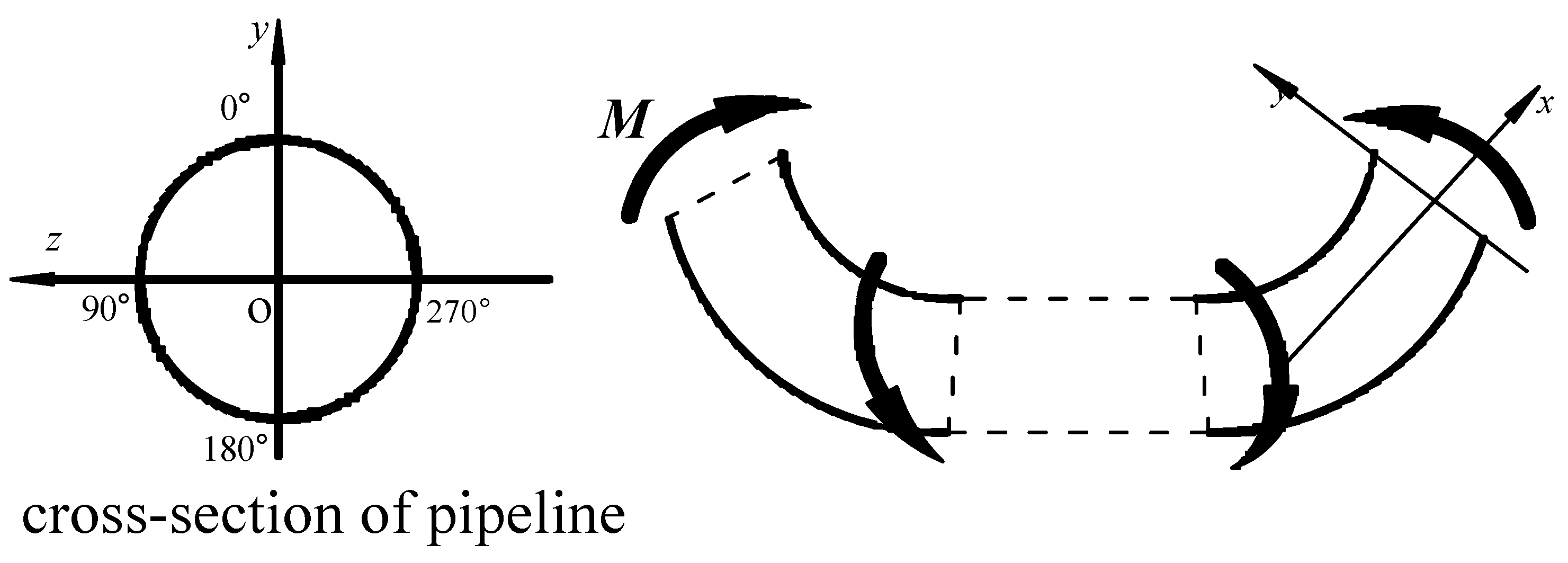

As the inner pipe undergoes temperature-induced expansion or contraction, thermal stress is generated due to the restraint imposed by the outer pipe. This constraint also results in secondary stress in the outer pipe. As illustrated in

Figure 22, where

f denotes the frictional force between the outer pipe and the surrounding soil, the inner pipe’s thermal deformation is transferred through mechanical coupling to the outer pipe, which is assumed to be fixed at both ends [

6]. The system achieves force equilibrium according to Equations (4)–(7):

where

Fi is the axial force in the inner pipe;

Fo is the axial force in the outer pipe;

Ft is the axial force caused by thermal expansion of the inner pipe;

Fp is the axial force due to Poisson’s effect of internal pressure;

σo and

σi are the axial stresses in the outer and inner pipe, respectively;

Ao and

Ai are the cross-sectional areas of the outer and inner pipe, respectively.

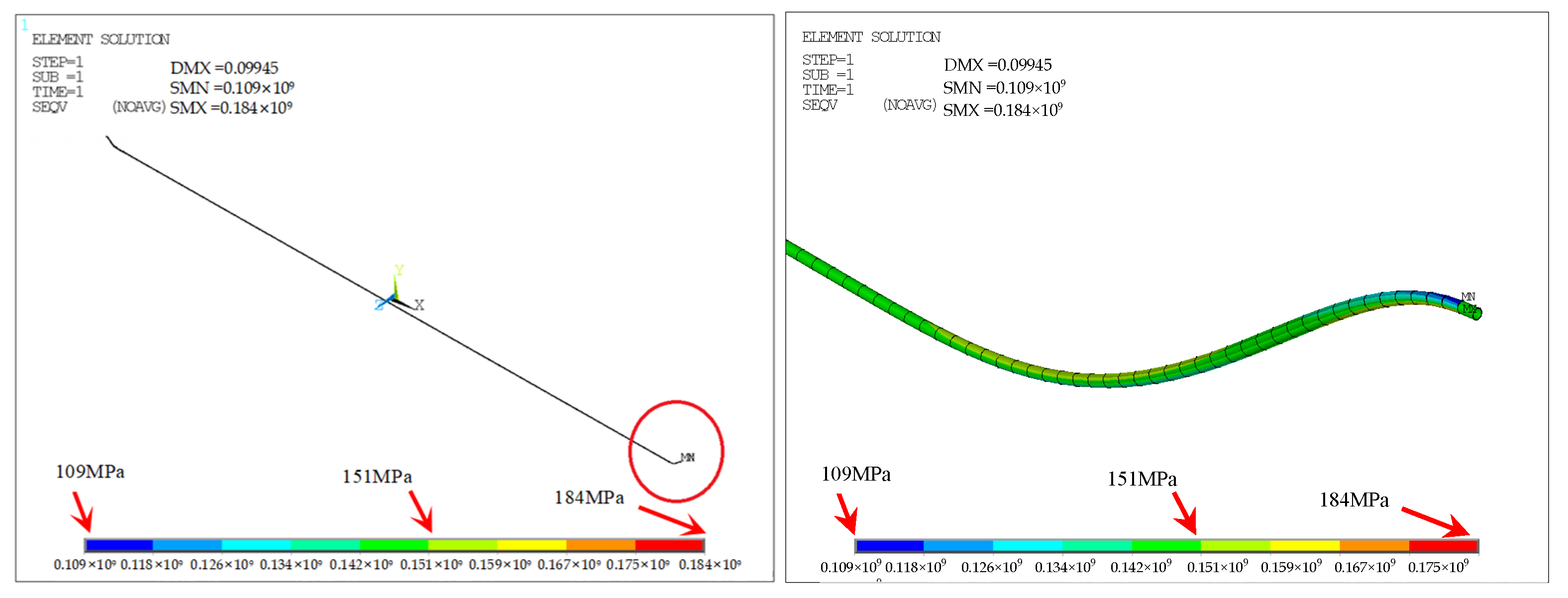

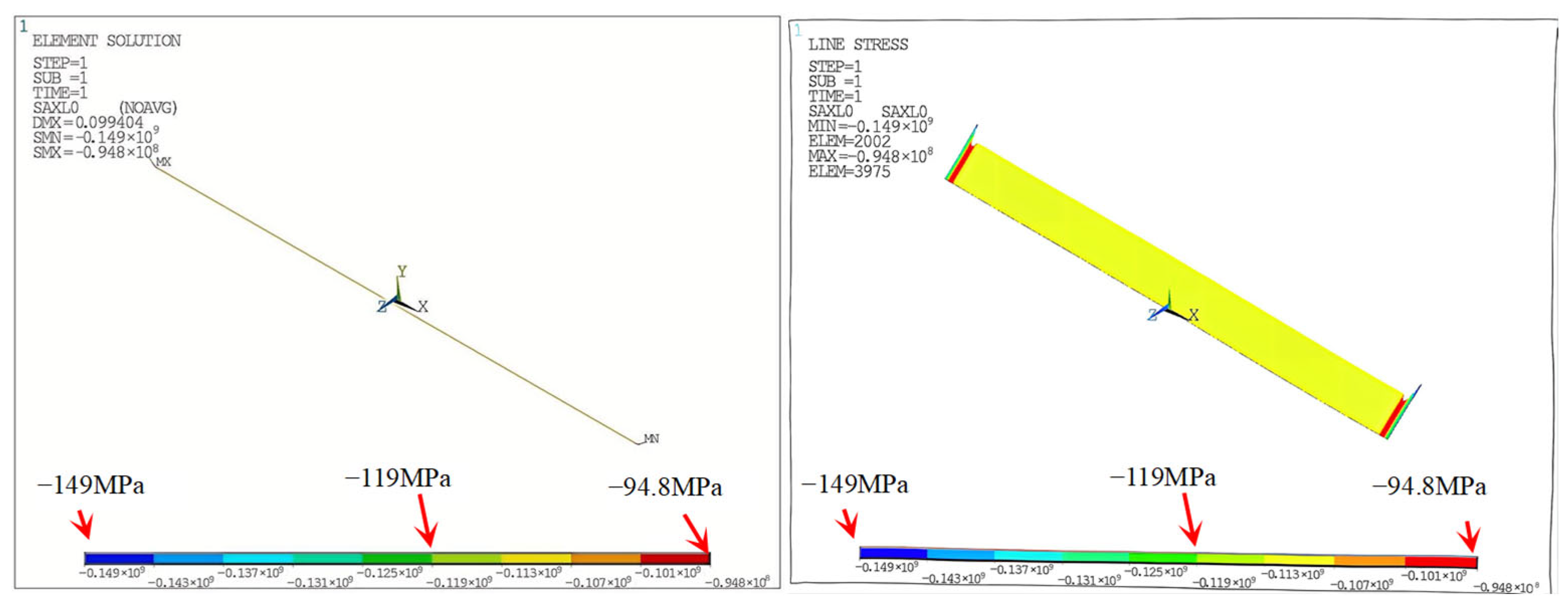

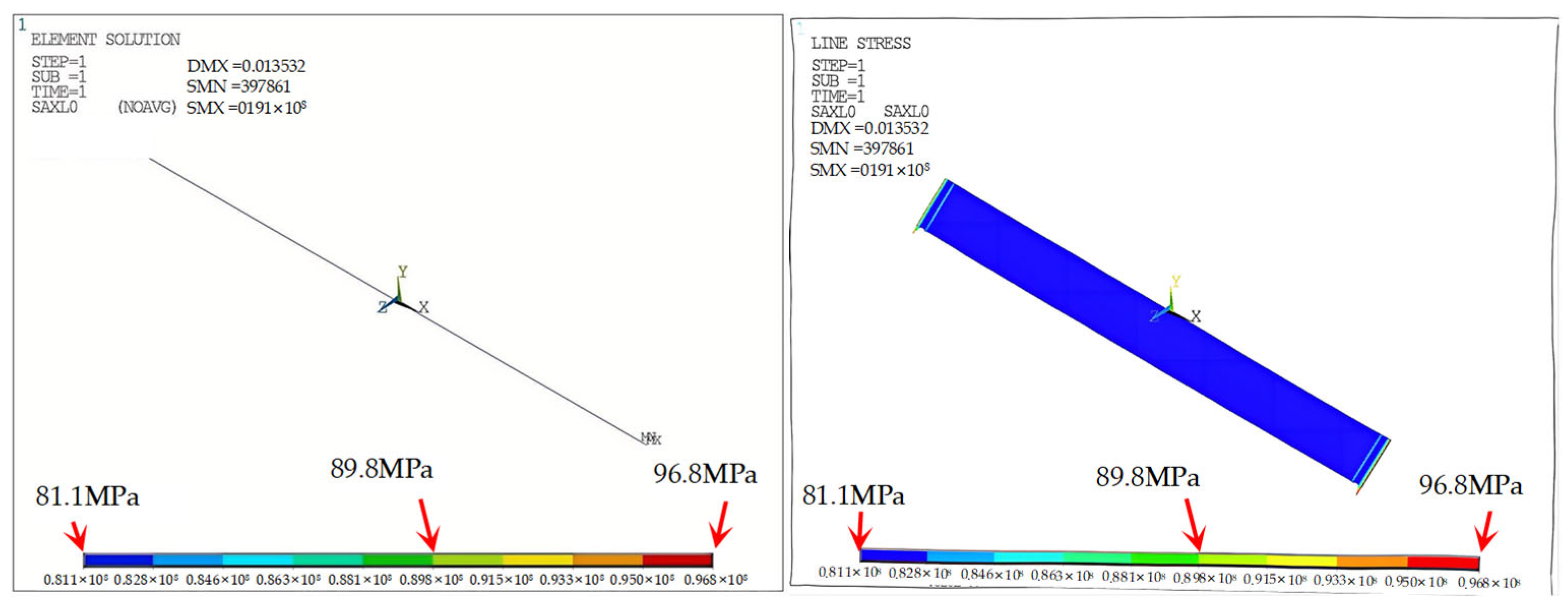

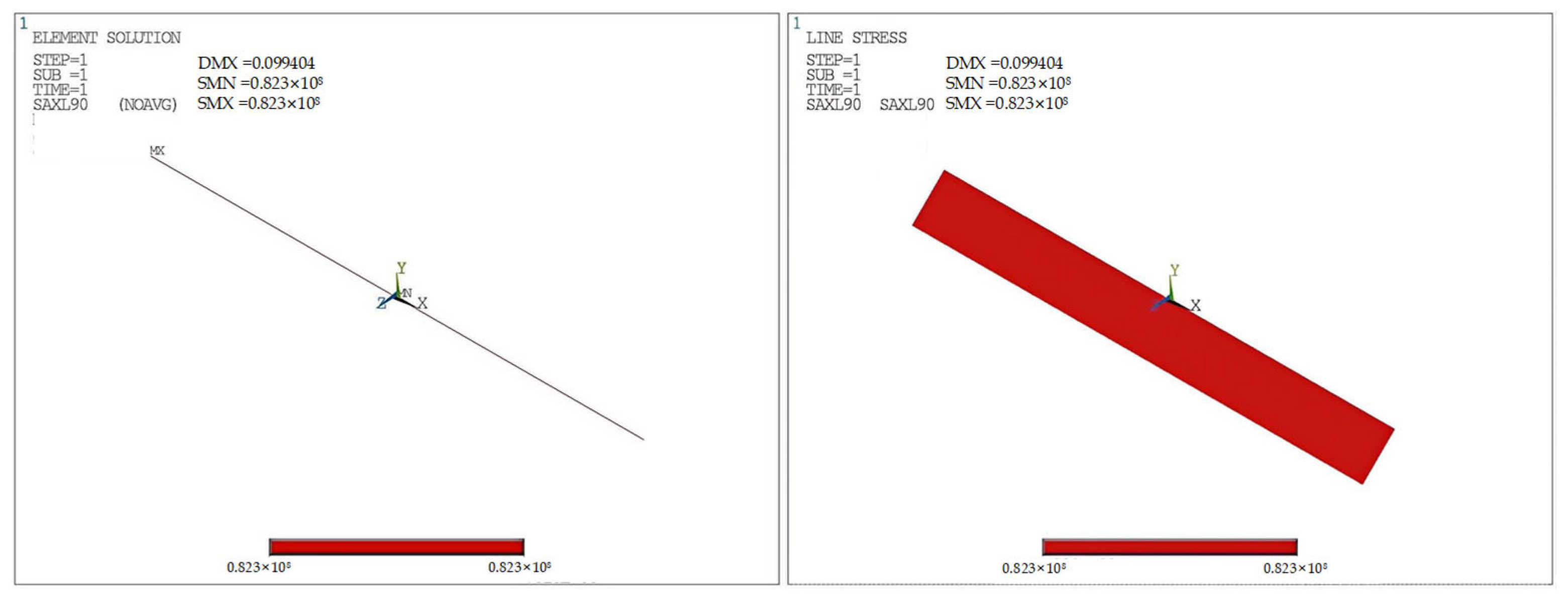

5.3.3. Validation with Extreme Condition I

The analytical and finite element results for Extreme Condition I are summarized in

Table 10 and

Table 11. The theoretical hoop stress in the inner pipe is

σh = 57 MPa =

pD/2

t, consistent with the FEM result.

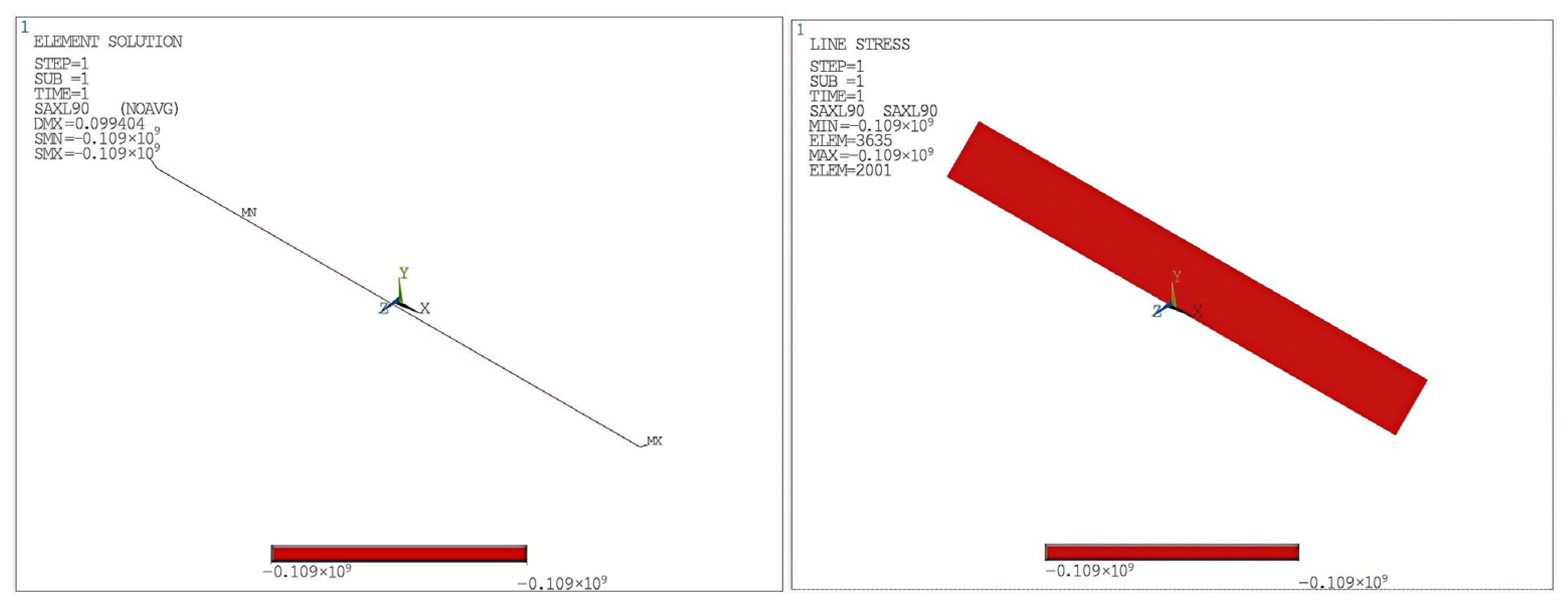

Thermal stress with free expansion is computed as σ’t = αEΔT = 206 MPa, corresponding to a free elongation of Δl = αLΔT =0.498 m. Accounting for constrained displacement of 0.09945 m, the effective thermal stress is: σt = σ’t × (1 − 0.09945/0.498) = 124 MPa. Given a measured Poisson’s ratio of 0.26, the axial stress due to Poisson’s effect is σa = μσh = 14.82 MPa. Since Poisson and thermal stresses act in opposite directions, the net axial stress is: σi =σt − σa = 109.18 MPa according to Equation (2). This matches the FEM result with only 0.06% error, confirming the validity of Equation (4).

The axial force in the inner pipe is calculated as:

Fi =

σiAi = 438.79 kN. Based on the soil parameters listed in

Table 12, the soil friction force is computed with Equation (8).

where

μs is the friction coefficient,

γ is the effective weight,

h is the burial depth of the pipeline,

Lf is the length of the single-sided friction zone (taken as the average influence range of the outer pipe deformation of 16.5 m), and

f = 107.46 kN.

For Extreme Condition I, the inner pipe is relatively free to expand, whereas the outer pipe is heavily constrained by soil friction and end anchoring. Therefore, the load path of the thermal force is: Inner pipe → Support → Outer pipe → Soil. The thermal deformation is mainly absorbed by the inner pipe, while the thermal load is mainly resisted by the outer pipe. Hence, the axial force in the outer pipe is: Fo = f + Fi = 546.25 kN≈547.91 kN with error of 0.3%. Equation (5) is validated.

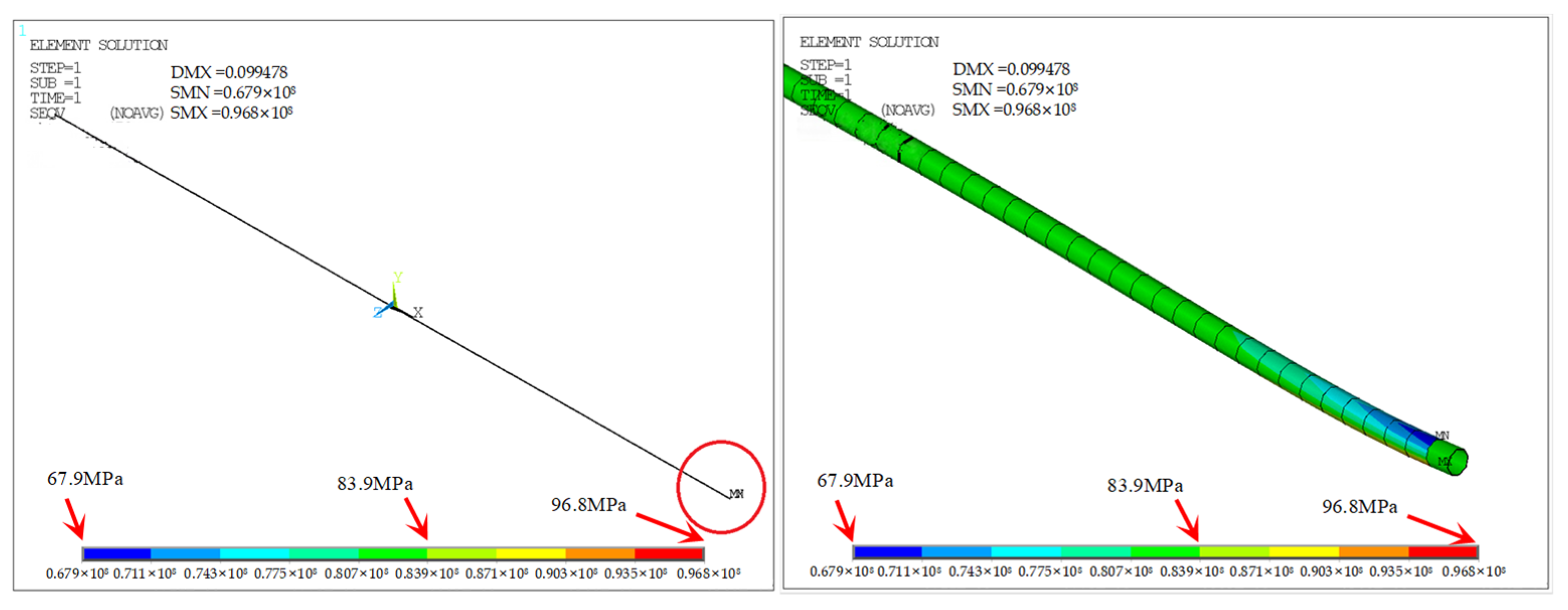

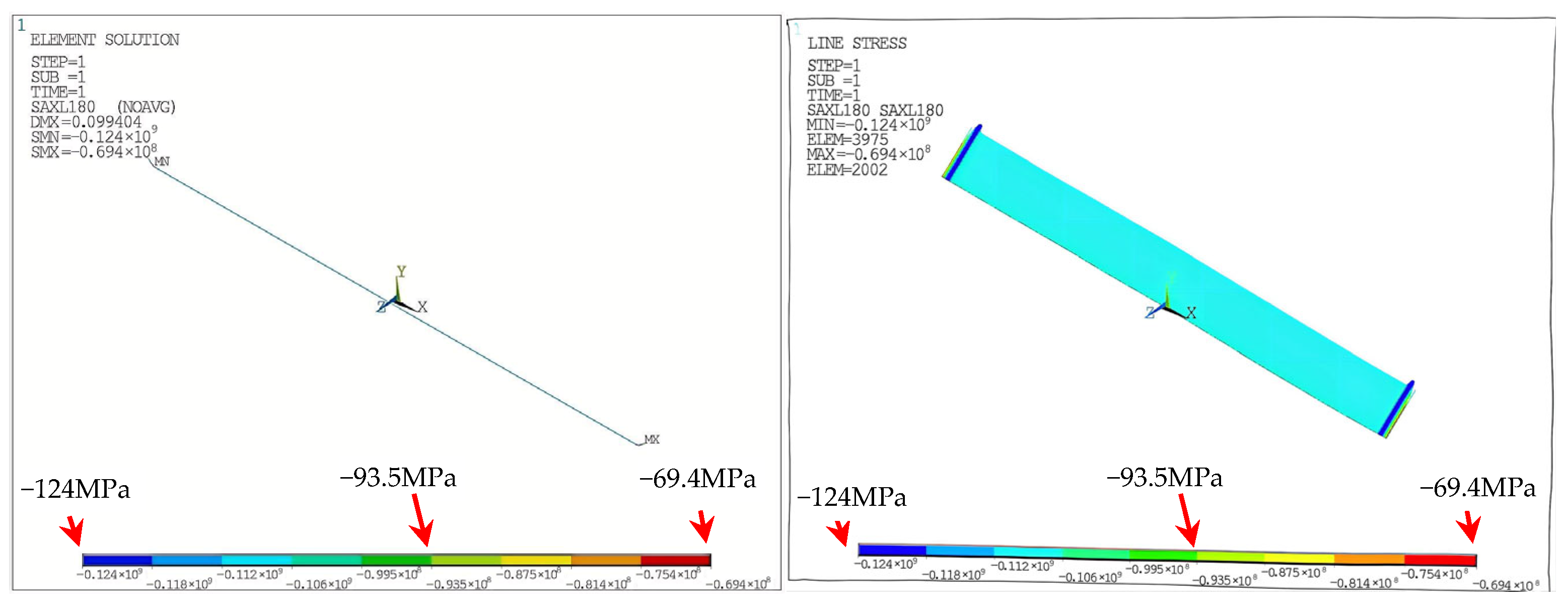

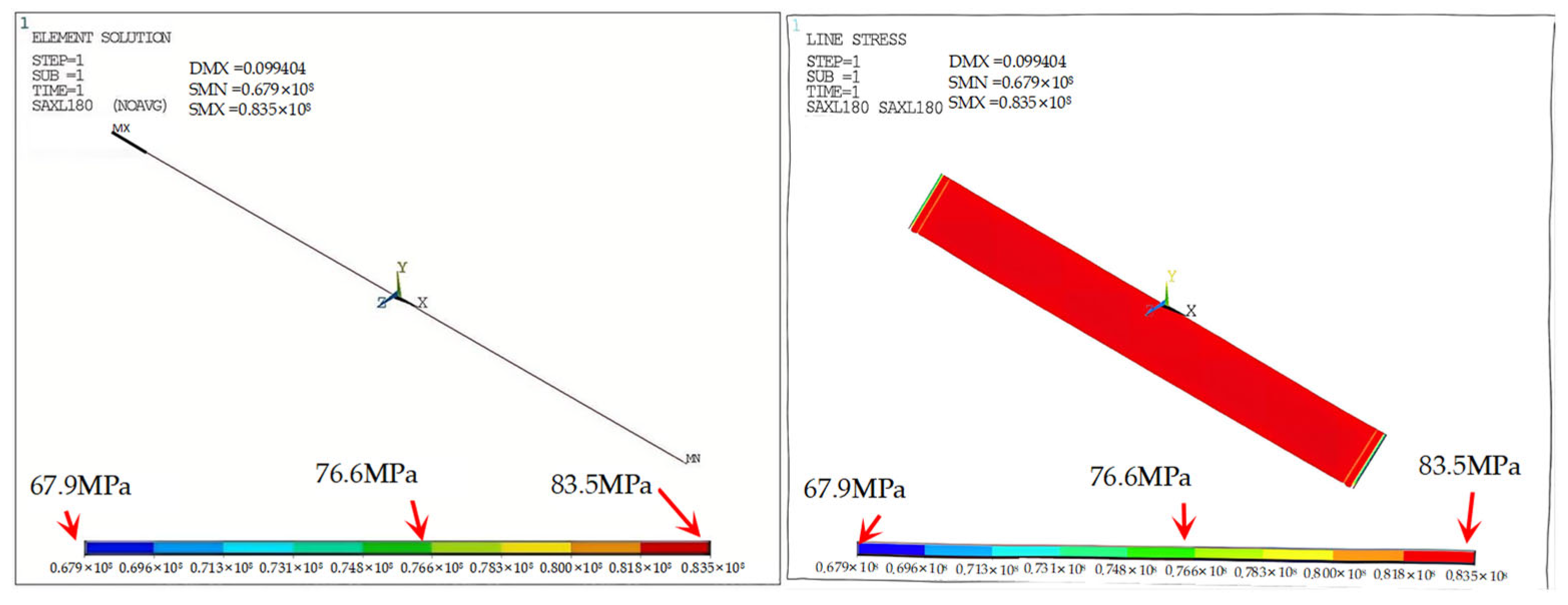

5.3.4. Validation with Extreme Condition II

The parameters and FEM results for Extreme Condition II are listed in

Table 13. Theoretical hoop stress is

σh = 47.5 MPa =

pD/2

t, consistent with the FEM result. Unrestrained thermal stress:

σ’t =

αEΔ

T = 58.6 MPa. Free expansion is Δ

l =

αLΔ

T = 0.142 m. Measured displacement is 0.049867 m; thus effective thermal stress is

σt =

σ’t × (1 − 0.049867/0.142) = 38 MPa. The axial force generated by the Poisson effect is

σa = μσh = 12.35 MPa.

Since Poisson and thermal stresses act in the same direction, σi = σt + σa = 50.35 MPa. This result differs from the FEM value by 2.25 MPa (error = 4.27%), which is within acceptable range and confirms Equation (4). Axial force of inner pipe is Fi = σiAi = 211.4 kN. Assuming outer pipe deformation influences an average length of 15.625 m, soil friction is calculated as f = 101.75 kN.

In this case, the inner pipe contracts due to a temperature decrease, while the outer pipe remains relatively unaffected due to external constraints. The inner pipe’s contraction is hindered by internal constraints or end fixities, resulting in significant axial tensile stress within the pipe. Meanwhile, the outer pipe bears minimal reaction force. Thus the axial force in the outer pipe is Fo = Fi − f = 109.64 kN≈111.83 kN. This confirms the accuracy of Equation (5) with an error of 1.96%.

5.4. Applicability in Normal and Slightly Acidic Water

While the proposed mechanical model has been validated for marine conditions with high salinity, its applicability extends to other aqueous environments. In normal freshwater (pH ≈ 7.0), the absence of significant salinity ensures that the thermal–mechanical coupling mechanisms remain unchanged, as the governing equations are independent of dissolved salt content. For slightly acidic water (pH 5.5–6.5), which may occur in certain industrial or inland river systems, the primary consideration is the potential for accelerated corrosion of metallic pipeline components.

It should be emphasized that the present study focuses on intact PIP systems without corrosion defects. This intact-condition analysis provides a necessary baseline for understanding the fundamental thermomechanical responses of the system, which can then be extended to cases involving material degradation. In the context of corrosion, the model can incorporate defect effects by introducing a time-dependent wall-thickness reduction based on corrosion rate data, accompanied by the corresponding reduction in Young’s modulus and yield strength. Such modifications allow simulation of different corrosion severities (e.g., uniform corrosion and localized pitting) by locally altering the finite element mesh and material property assignments. Comparative simulations between intact and corroded conditions can then quantify the increase in stress concentration, radial deformation mismatch, and potential fatigue life reduction caused by corrosion. This approach ensures that the proposed model remains applicable not only to pristine PIP systems but also as a foundation for life-extension assessment and integrity management in corrosive environments.