Simulation of Compaction Process of Tight Sandstone in Xiashihezi Formation, North Ordos Basin: Insights from SEM, EDS and MIP

Abstract

1. Introduction

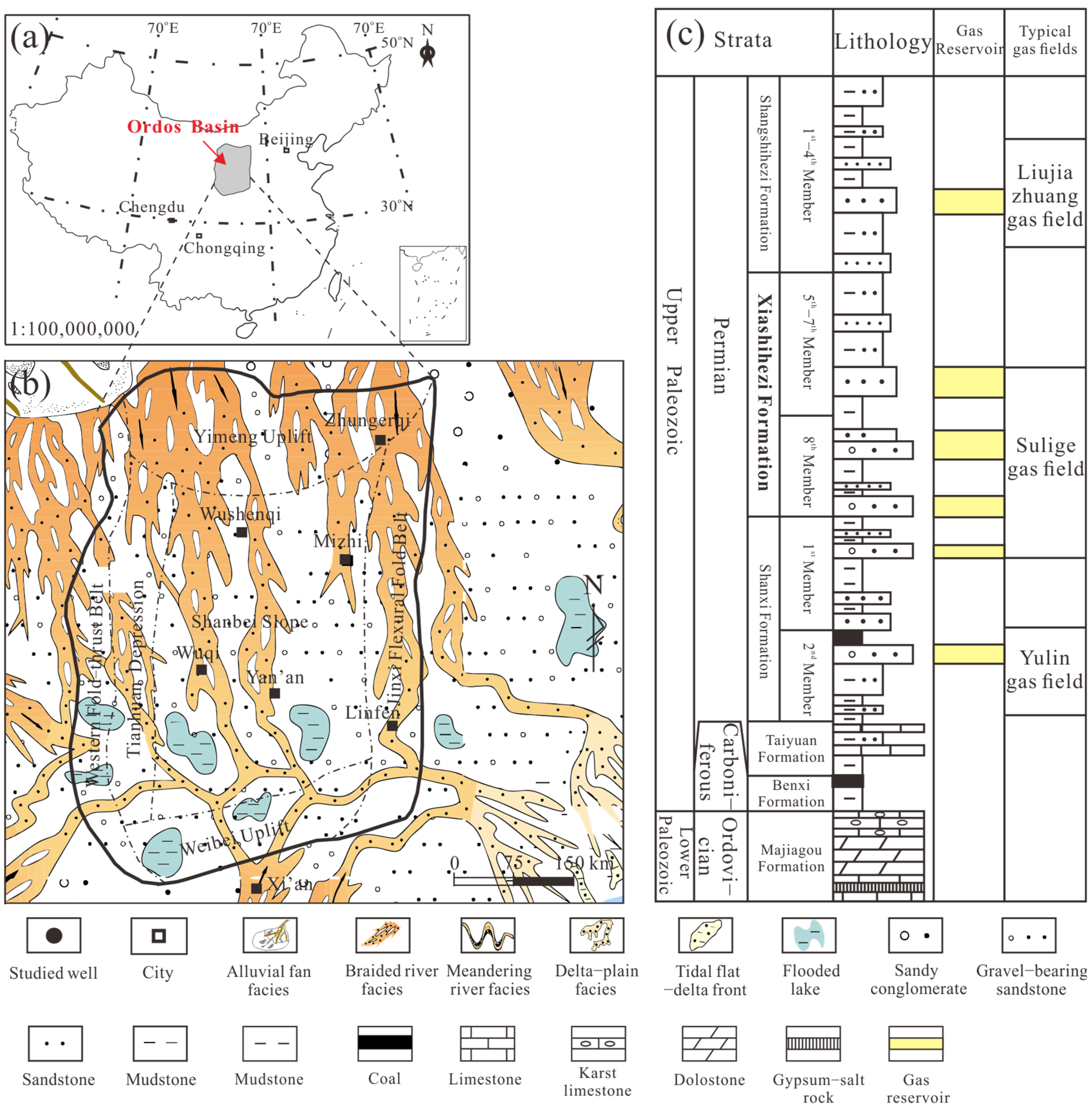

2. Geological Setting

3. Materials and Methods

3.1. Experimental Equipment

3.2. Geological Modeling Process

3.3. Experimental Process

3.4. Supporting Testing Methods

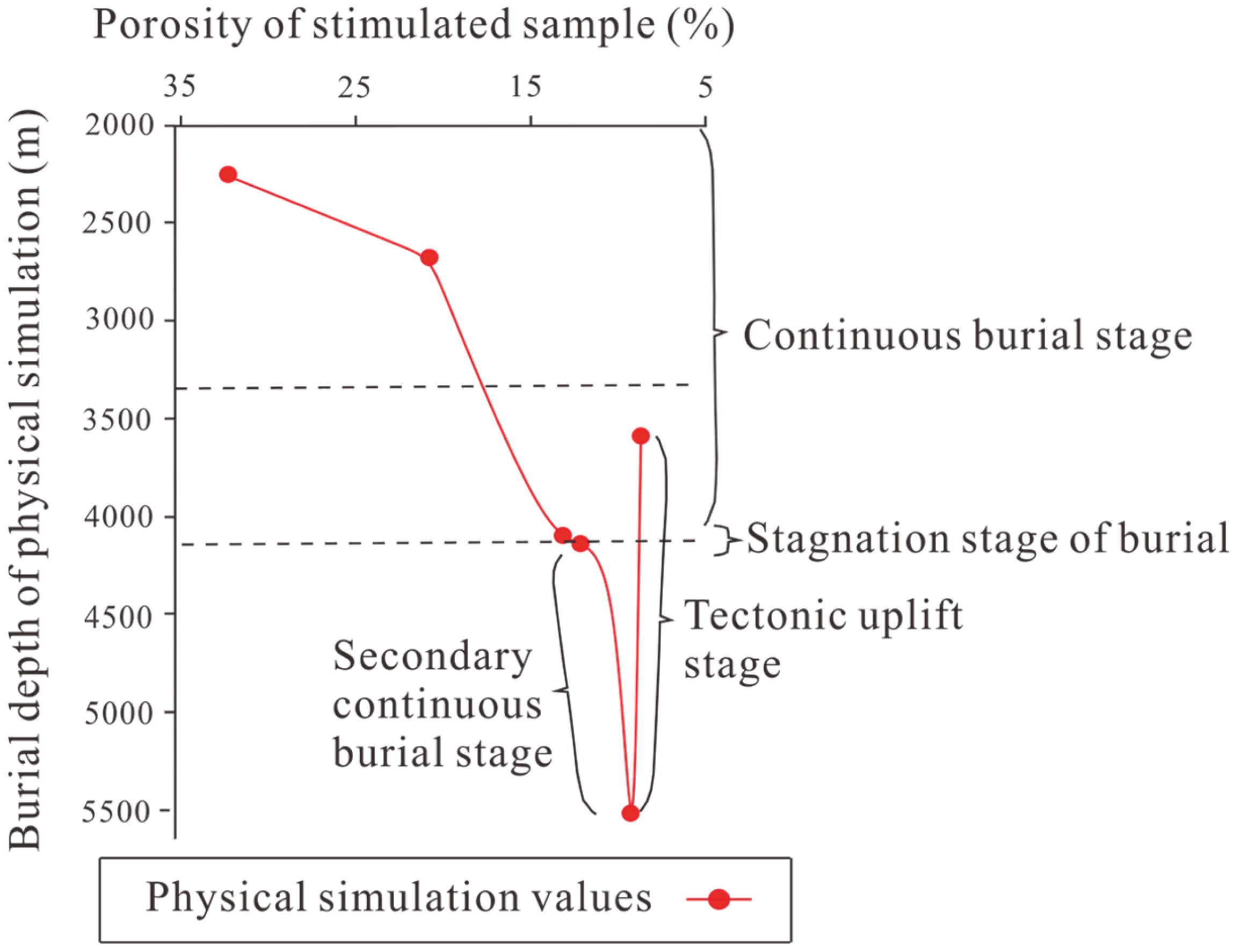

4. Results of Physical Simulation

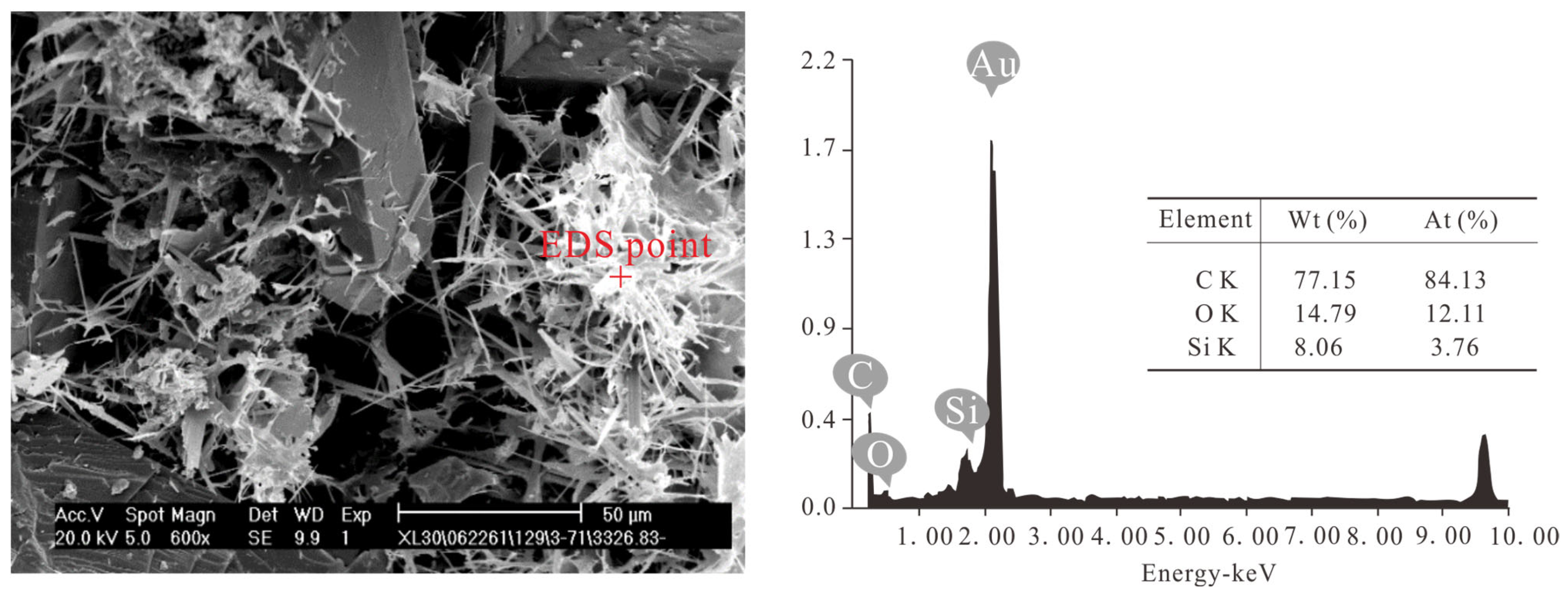

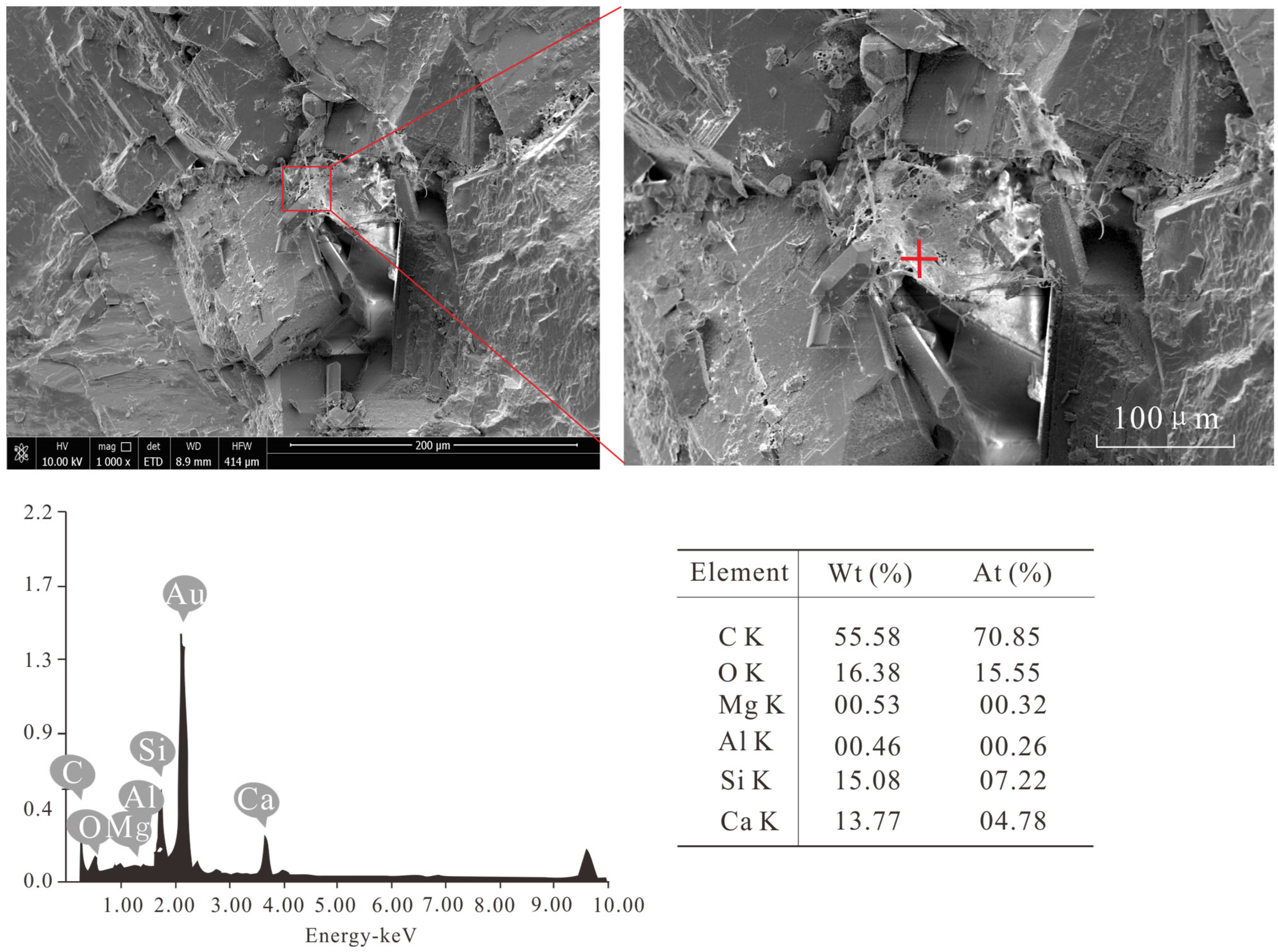

4.1. Diagenesis Type

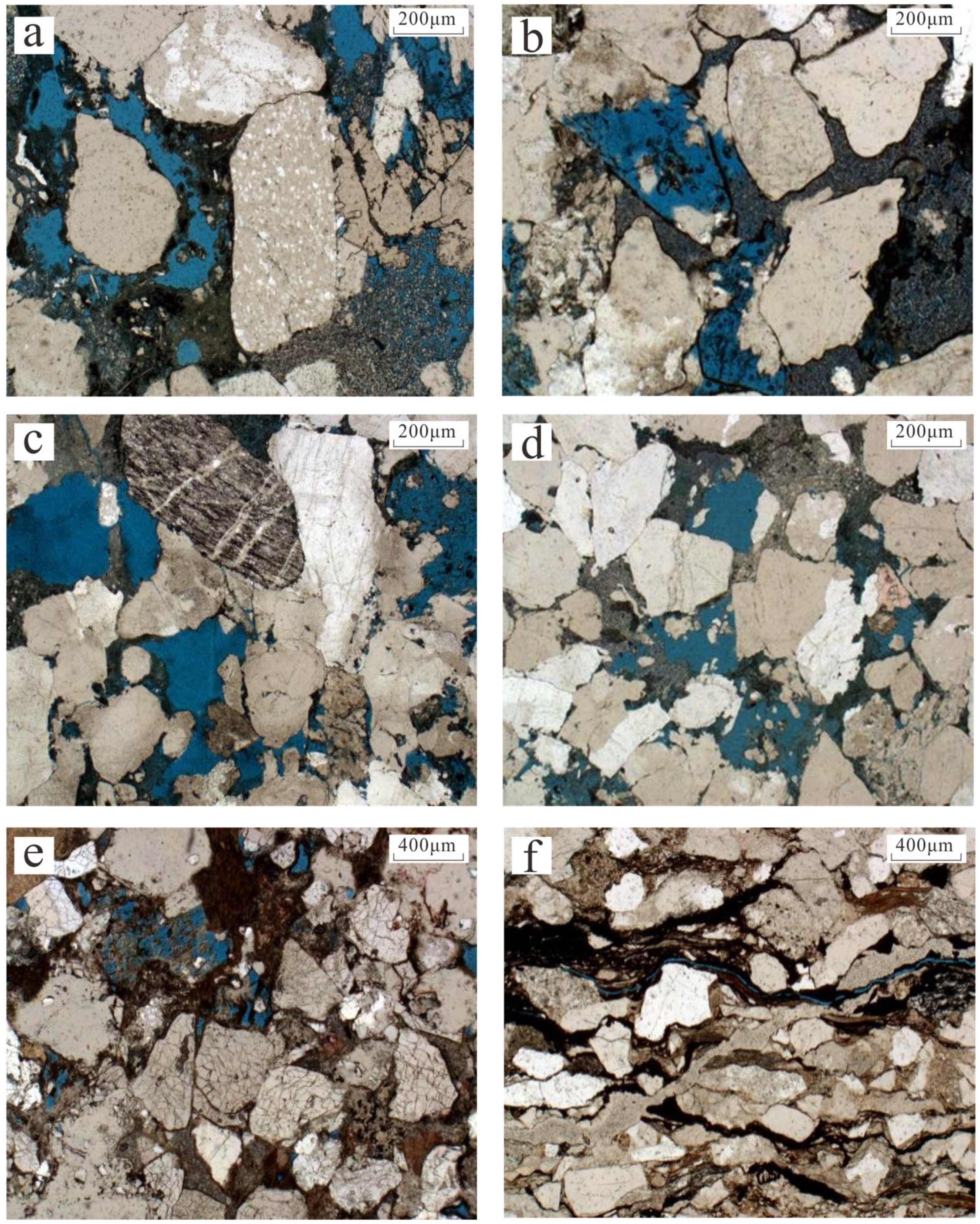

4.1.1. Compaction Effect

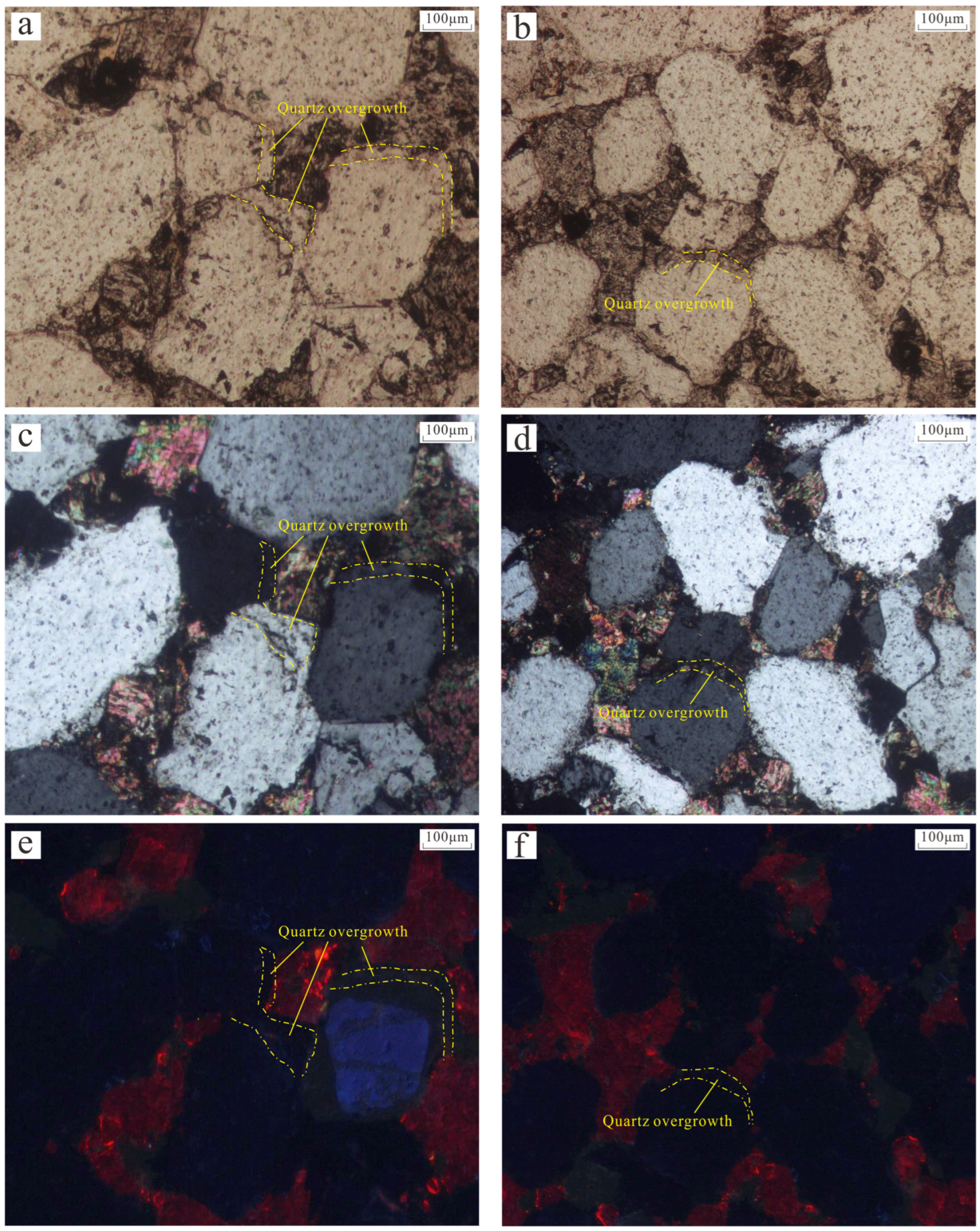

4.1.2. Mineral Cementation

4.1.3. Dissolution Effect

4.2. Variations in Ion Concentration of Diagenetic Fluids

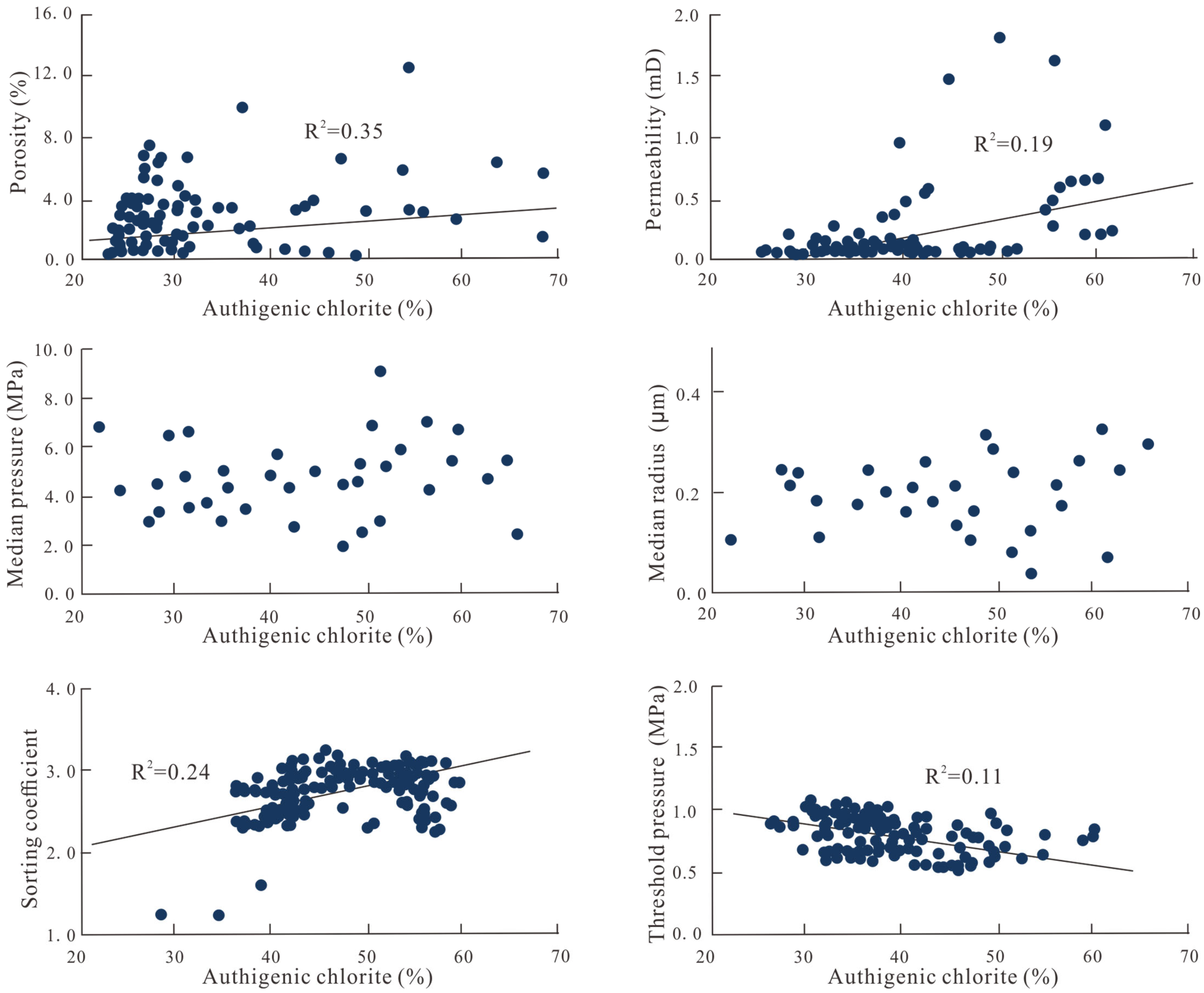

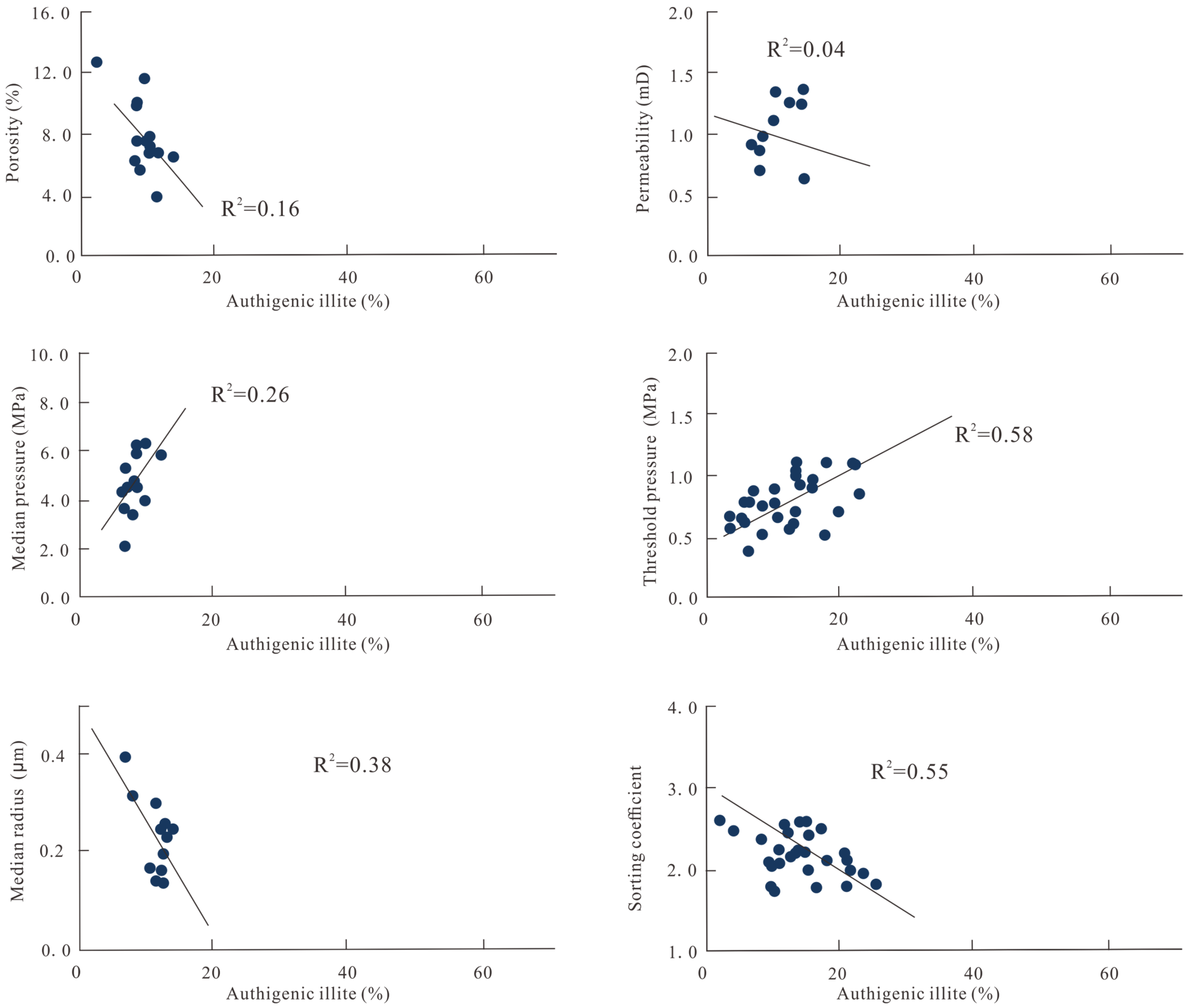

5. Discussions

5.1. Experimental Verification of Sandstone Compaction Mechanism

5.2. Formation Mechanism of Key Diagenetic Minerals

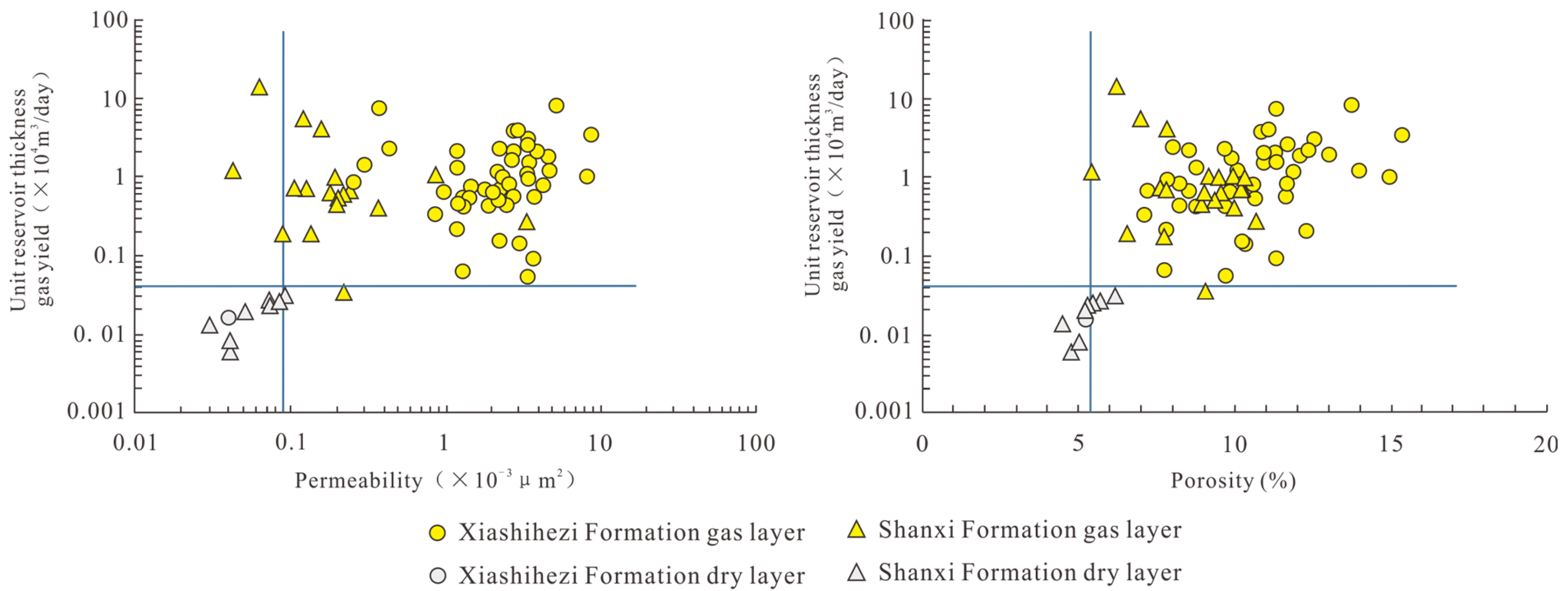

5.3. Implication for Sweet-Spot Prediction

6. Conclusions

- (1)

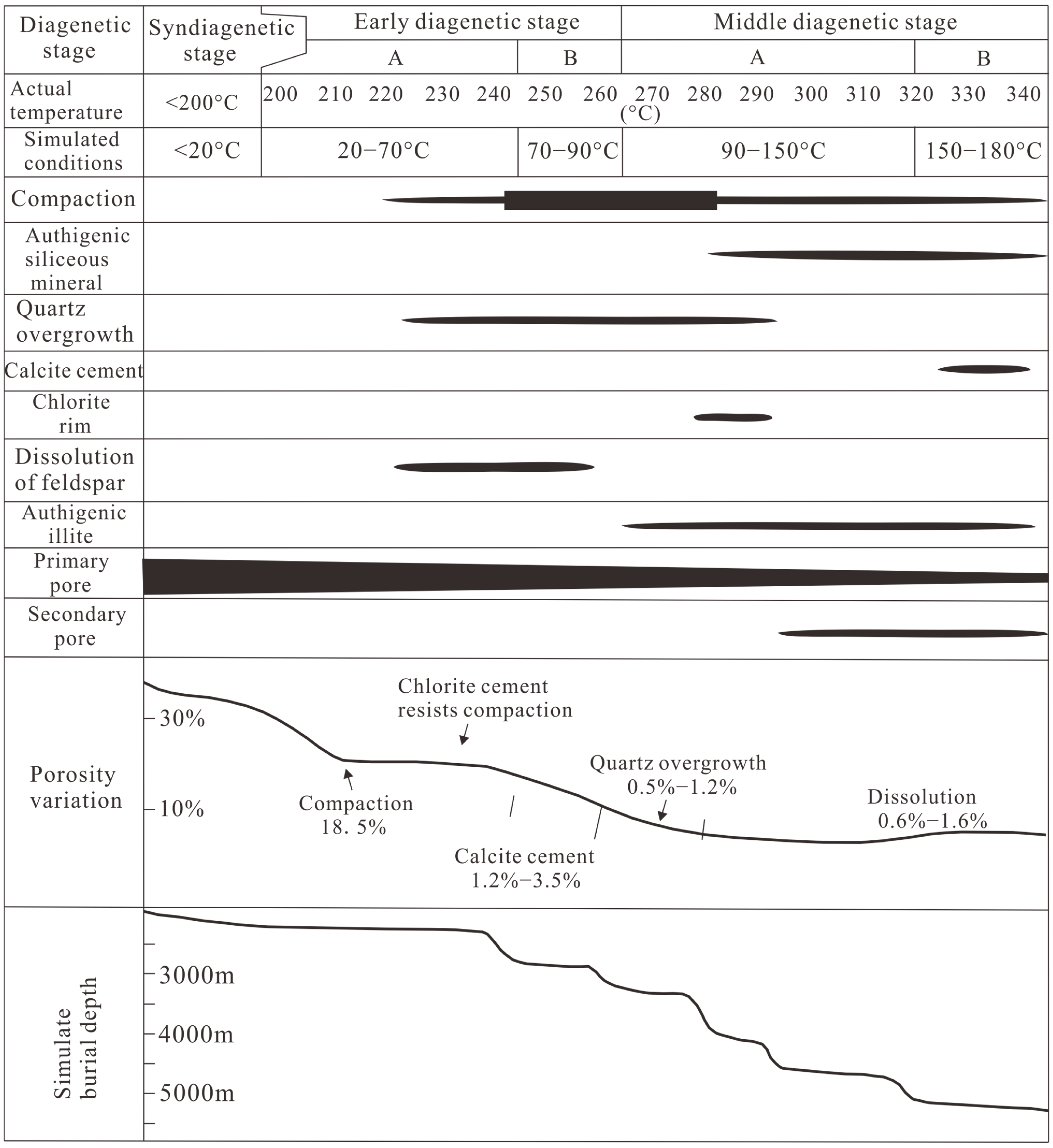

- The physical simulation experiments successfully replicated the complex diagenetic evolution sequence of the Permian Xiashihezi Formation sandstone. This sequence includes mechanical compaction, early calcite and chlorite cementation, feldspar dissolution, quartz overgrowth, and late-stage illite and ferroan calcite cementation. These results validate the diagenetic model established from geological sample analysis.

- (2)

- Mechanical compaction is the primary factor driving reservoir compaction, characterized by a three-stage process: rapid early-stage, stable mid-stage, and slow late-stage porosity reduction. Chemical cementation further densifies the reservoir, with early calcite and late-stage silica and illite cementation having the most detrimental impacts on reservoir quality.

- (3)

- The formation of key diagenetic minerals is governed by specific temperature, pressure, and geochemical conditions. Experiments confirm that underlying magnesium-rich strata can supply diagenetic materials to overlying sandstones through fluid migration, which is crucial for the early development of chlorite rims in the Permian Xiashihezi Formation. Chlorite rims help inhibit quartz overgrowth and preserve primary porosity, while the “bridging” infill of illite contributes to the development of “high-porosity, low-permeability” reservoirs. The burial depth of 3560 m is the most favorable range for maintaining porosity of chlorite.

- (4)

- The effectiveness of dissolution processes depends on the supply and retention of acidic fluids. In a closed experimental system, “acid consumption” reactions limit the impact of acidic fluids. This suggests that, under natural geological conditions, continuous supply of acidic fluids (such as those adjacent to hydrocarbon kitchens and fractures) is a prerequisite for forming large-scale secondary porosity “sweet-spot” reservoirs. The diagenetic evolution model, based on physical simulation, provides a dynamic basis for understanding the mechanisms of differential compaction in tight sandstones from various provenance and structural backgrounds. This study offers significant theoretical guidance for predicting “sweet-spot” reservoirs in the Ordos Basin and similar basins. The porosity of the sweet spot should be greater than 5% in order to acquire natural production.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chi, Y.; Liu, B.; Chen, Y.; Wang, B.; Bai, L.; Wang, L.; Xu, Y. Geochemical characteristics and mechanisms of densification of pre-Jurassic crude oil in the Tainan Sag, Turpan-Hami Basin, China. Unconv. Resour. 2022, 2, 183–191. [Google Scholar] [CrossRef]

- Ahmadi, S.; Khormali, A.; Kazemzadeh, Y. A critical review of the phenomenon of inhibiting asphaltene precipitation in the petroleum industry. Processes 2025, 13, 212. [Google Scholar] [CrossRef]

- Li, J.; Guo, B.; Zheng, M.; Yang, T. Main types, geological features and re-source potential of tight sandstone gas in China. Nat. Gas Geosci. 2012, 23, 607–615. [Google Scholar]

- Zhou, H.; Li, D.; Liu, X.; Du, Y.; Gong, W. Sweet spot prediction in tight sandstone reservoir based on well-bore rock physical simulation. Pet. Sci. 2019, 16, 1285–1300. [Google Scholar] [CrossRef]

- Wang, E.; Liu, G.; Pang, X.; Wu, Z.; Li, C.; Bai, H.; Zhang, Z. Sedimentology, diagenetic evolution, and sweet spot prediction of tight sandstone reservoirs: A case study of the third member of the Upper Paleogene Shahejie Formation, Nanpu Sag, Bohai Bay Basin, China. J. Pet. Sci. Eng. 2020, 186, 106718. [Google Scholar] [CrossRef]

- Wu, W.; Zhao, J.; Wei, X.; Wang, Y.; Zhang, J.; Wu, H.; Li, J. Evaluation of gas-rich “sweet-spot” and controlling factors of gas-water distribution in tight sandstone gas provinces: An example from the Permian He8 Member in Sulige Gas Province, central Ordos Basin, Northern China. J. Asian Earth Sci. 2022, 227, 105098. [Google Scholar] [CrossRef]

- Wang, W.; Lin, C.; Zhang, X.; Dong, C.; Ren, L.; Lin, J. Diagenesis, diagenetic facies and their relationship with reservoir sweet spot in low-permeability and tight sandstone: Jiaxing Area of the Xihu Sag, East China Sea Basin. Minerals 2023, 13, 404. [Google Scholar] [CrossRef]

- Wang, W.; Lin, C.; Zhang, X. Fractal Characteristics of Pore Throat and Throat of Tight Sandstone Sweet Spot: A Case Study in the East China Sea Basin. Fractal Fract. 2024, 8, 684. [Google Scholar] [CrossRef]

- Ma, C.; Song, H.; Wu, Y.; Cao, X.; Liu, H.; Zhang, H.; Fu, Y.; Wang, W.; Huang, C.; Fang, X. Differential diagenetic controls on petrophysical heterogeneity of lacustrine beach-bar tight sandstones: Insights from the Boxing Sag, eastern China. Mar. Pet. Geol. 2025, 181, 107537. [Google Scholar] [CrossRef]

- Tang, Y.; Jiang, W.; Tan, X.; Luo, L.; Garzanti, E.; Gluyas, J.; Yan, X.; Liu, J.; Lei, T.; Qu, X.; et al. Diagenetic processes controlled by volcanic detritus of the lower-middle permian shanxi and shihezi sandstone formations, north ordos basin, China. Depos. Rec. 2025, 1–24. [Google Scholar] [CrossRef]

- Cao, T.; Tan, X.; Luo, L.; Tian, J.; Tan, D.; Zhou, H.; Zha, X.; Wang, J.; Gao, X.; Zhu, C.; et al. Evolution mechanism of differential diagenesis combination and its effect on the reservoir quality in the tights and stone: A case from the Lower Shihezi Formation in the Hangjinqi area of Ordos Basin, China. Lithosphere 2021, 2021, 6832767. [Google Scholar] [CrossRef]

- Xiao, H.; Liu, R.; Zhang, F.; Lin, C.; Zhang, M. Sedimentary model reconstruction and exploration significance of Permian He 8 Member in Ordos Basin, NW China. Pet. Explor. Dev. 2019, 46, 268–280. [Google Scholar] [CrossRef]

- Jiang, Y.; Tao, Y.; Shen, Y.; Jiang, C.; Wang, Z.; Zhang, B.; Li, S.; Zhang, G. A new understanding of sedimentary facies of sandstones in the 2nd, 4th, and 6th members of the Upper Triassic Xu-jiahe Formation in the Large-Scale Middle Sichuan Basin. Nat. Gas Ind. 2011, 31, 39–50. [Google Scholar]

- Jiang, Y.; Zhang, C.; Zhang, B.; Xu, C.; Wang, M.; Fang, L.; Hu, C. Characteristics and identification of lithofacies in complex siliceous clastic reservoirs: A case study from Northwestern Sichuan Basin. Nat. Gas Ind. 2013, 33, 31–36. [Google Scholar]

- Jiang, Y.; Zhang, C.; Deng, H.; Wang, M.; Luo, M. Influences of clay minerals on physical properties of low permeability and tight sandstones. J. Southwest Pet. Univ. Sci. Technol. Ed. 2013, 35, 39–47. [Google Scholar]

- Cheng, B.; Liao, Z.; Lü, Z.; Xie, C.; Cai, Y.; Liu, S.; Li, F.; Zhang, S. Pore evolution characteristics and “sweet spot” reservoir development model in deep ultra-tight sandstones: A case study of the second member of Xujiahe Formation in eastern slope of western Sichuan Depression. Pet. Reserv. Eval. Dev. 2025, 15, 394–405. [Google Scholar]

- Meng, D.; Jia, A.; Ji, G.; He, D. Water and gas distribution and its controlling factors of large scale tight sand gas: A case study of western Sulige gas field, Ordos Basin, NW China. Pet. Explor. Dev. 2016, 43, 607–614. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, C.; Jiang, Y.; Bai, G. Overpressure and gas charging in tight sandstone: Permian Xujiahe Formation, northeastern Sichuan Basin. Pet. Sci. 2022, 19, 2583–2600. [Google Scholar] [CrossRef]

- Xia, L.; Liu, Z.; Li, W.; Lu, C.; Yang, X.; Liu, M. Ternary analytic porosity-reduction model of sandstone compaction trend and its significance in petroleum geology: A case study of tight sandstones in Permian Lower Shihezi Formation of Shilijiahan area, Ordos Basin, China. Pet. Explor. Dev. 2018, 45, 275–286. [Google Scholar] [CrossRef]

- Zheng, J.; Lin, L.; Yu, Y.; Yuan, Q.; Wen, L.; Deng, X.; Huang, Y.; Qiu, Y.; Wei, J.; Zheng, C.; et al. Chronology and geofluids characteristics of calcite cement in the Upper Triassic Xujiahe Formation tight sandstone reservoir, Western Sichuan Basin, SW China. Mar. Pet. Geol. 2024, 170, 107148. [Google Scholar] [CrossRef]

- Zhao, J.; Yang, Y.; Chen, G.; Zheng, X.; Yin, S.; Tian, L. Controls of Multi-Scale Fractures in Tight Sandstones: A Case Study in the Second Member of Xujiahe Formation in Xinchang Area, Western Sichuan Depression. Lithosphere 2024, 343, 25. [Google Scholar] [CrossRef]

- Cai, W.; Xie, R.; Li, H.; Dou, S.; Li, S.; Deng, S.; Ma, T. Developmental characteristics of fractures in deep tight sandstone reservoirs in the second Member of the Xujiahe Formation of Zhongjiang Gas Field. Unconvention. Resour. 2024, 4, 100073. [Google Scholar] [CrossRef]

- Xia, X.; Han, B.; Xie, B.; Lai, Q.; Wang, Y.; Zhu, S. Estimation of water saturation based on optimized models in tight gas sandstone reservoirs: A case study of Triassic Xujiahe Formation in northwestern Sichuan Basin. Acta Geophys. 2025, 73, 407–419. [Google Scholar] [CrossRef]

- Guan, X.; Xiao, D.; Jin, H.; Cui, J.; Wang, M.; Shao, H.; Zheng, L.; Wang, R. Classification and Controlling Factors of Different Types of Pore Throat in Tight Sandstone Reservoirs Based on Fractal Features—A Case Study of Xujiahe Formation in Western Sichuan Depression. Minerals 2025, 15, 18. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Chen, X.; Li, X.; Wu, J.; Gao, X.; Peng, J.; Wang, B.; Xie, Y.; Wu, H. Classification and origin of pore-throat systems in tight sandstone reservoirs: A case study of the Xujiahe Formation in the Northeastern Sichuan Basin, China. Front. Earth Sci. 2025, 13, 1572136. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, M.; Cao, B.; Huang, P.; Wang, Z. Genesis of differential cementation by authigenic kaolinite in deep-buried tight sandstone reservoirs for the upper Triassic Xujiahe Formation, western Sichuan foreland basin, China. Mar. Pet. Geol. 2025, 181, 107526. [Google Scholar] [CrossRef]

- Gao, J.; Sun, N.; Hao, B.; Zhong, J.; Chen, Z.; Cao, Z. Lithologic characteristics and reservoir evolution of tight sandstones in the upper Triassic Xujiahe formation, northeast Sichuan Basin, China. Unconvention. Resour. 2025, 6, 100162. [Google Scholar] [CrossRef]

- Yang, J.; Jiang, Y.; Tang, B.; Pan, H.; Ye, J.; Zhou, Y.; Wang, J.; Wang, T.; Wang, Z. The classification evaluation of a tight sandstone reservoir and the controlling factors of the desert reservoir in the fourth member of the Xujiahe Formation in the Tianfu area, central Sichuan Basin, China. Interpretation 2025, 13, T277–T289. [Google Scholar] [CrossRef]

- Jiang, L.; Sun, X.; Chen, D.; Lei, W.; Yang, H.; Deng, Y.; Wang, Z.; Li, C.; Liu, T.; Geng, C.; et al. Tight sandstone gas reservoir types and formation mechanisms in the second member of the Xujiahe Formation in the Anyue Area, Sichuan Basin. Energies 2025, 18, 3009. [Google Scholar] [CrossRef]

- Gao, Z.; Feng, J.; Cui, J.; Wang, X.; Zhou, C.; Shi, Y. Physical simulation and quantitative calculation of increased feldspar dissolution pores in deep reservoirs. Pet. Explor. Dev. 2017, 44, 359–369. [Google Scholar] [CrossRef]

- Gao, Z.; Ma, J.; Cui, J.; Feng, J.; Zhou, C.; Wu, H. Deep reservoir pore evolution model of a geological process from burial compaction to lateral extrusion. Acta Sedimentol. Sin. 2018, 36, 176–187. [Google Scholar]

- Cui, H.; Zhu, S.; Tan, M.; Tong, H. Depositional and diagenetic processes in volcanic matrix—Rich sandstones from the shanxi and shihezi formations, ordos basin, china: Implication for volcano—Sedimentary systems. Basin Res. 2022, 34, 1859–1893. [Google Scholar] [CrossRef]

- Gao, J.; Ma, B.; Lu, Y.; Zhang, W.; Cao, Q. Origin of authigenic kaolinite with implications for permian tight gas sandstone reservoirs in the northern ordos basin, central china. J. Nat. Gas Sci. Eng. 2022, 99, 104429. [Google Scholar] [CrossRef]

| Well No. | Depth (m) | Strata | Detrital Type | Composition | Content (%) | Interstitial Material | Composition | Content (%) |

|---|---|---|---|---|---|---|---|---|

| A1 | 3300 | Permian Xiashihezi Formation | Quartz | Quartz | 52 | Matrix | argillaceous | 9 |

| Feldspar | K-feldspar | 12 | Cement | Calcite | 0 | |||

| Plagioclase | 8 | Dolomite | 0 | |||||

| Debris | Biotite | 3 | Chlorite | 2 | ||||

| Volcanic rock | 8 | Quartz overgrowth | 2 | |||||

| Quartzite | 0 | Authigenic siliceous mineral | 0 | |||||

| Schist | 1 | Illite | 1 | |||||

| Siltstone | 1 | |||||||

| Slate | 1 | |||||||

| Total content (%) | 86 | 14 | ||||||

| Water Type | Value Type | Ion Concentration (mg/L) | Total Mineralization Degree (g/L) | PH Value | ||||

|---|---|---|---|---|---|---|---|---|

| K++Na+ | Ca2+ | Mg2+ | Cl− | HCO3− | ||||

| CaCl2 | minimum value | 28,566 | 15,029 | 725 | 58,920 | 88 | 109 | 5 |

| Maximum value | 59,328 | 19,536 | 12,361 | 123,560 | 538 | 255 | 7 | |

| average value | 45,625 | 15,255 | 5869 | 105,690 | 160 | 282 | 6 | |

| Unit | Detrital Composition | Interstitial Material | Total | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Quartz | K-Feldspar | Basalt | Biotite | Schist | Siltstone | Granite | Mudstone | Argillaceous | Siliceous | ||

| % | 55 | 18 | 7 | 4 | 3 | 2 | 3 | 1 | 5 | 2 | 100 |

| g | 70.2 | 23.4 | 9 | 6.6 | 7.8 | 6.6 | 5.4 | 6.6 | 9 | 5.4 | 150 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, H.; Wang, F.; Han, C.; Wang, C.; Wu, Y.; Hu, Y. Simulation of Compaction Process of Tight Sandstone in Xiashihezi Formation, North Ordos Basin: Insights from SEM, EDS and MIP. Processes 2025, 13, 3191. https://doi.org/10.3390/pr13103191

Jin H, Wang F, Han C, Wang C, Wu Y, Hu Y. Simulation of Compaction Process of Tight Sandstone in Xiashihezi Formation, North Ordos Basin: Insights from SEM, EDS and MIP. Processes. 2025; 13(10):3191. https://doi.org/10.3390/pr13103191

Chicago/Turabian StyleJin, Hongxiang, Feiyang Wang, Chong Han, Chunpu Wang, Yi Wu, and Yang Hu. 2025. "Simulation of Compaction Process of Tight Sandstone in Xiashihezi Formation, North Ordos Basin: Insights from SEM, EDS and MIP" Processes 13, no. 10: 3191. https://doi.org/10.3390/pr13103191

APA StyleJin, H., Wang, F., Han, C., Wang, C., Wu, Y., & Hu, Y. (2025). Simulation of Compaction Process of Tight Sandstone in Xiashihezi Formation, North Ordos Basin: Insights from SEM, EDS and MIP. Processes, 13(10), 3191. https://doi.org/10.3390/pr13103191