Physicochemical, Functional and Nutritional Characteristics of Various Types of Fruit Pomace

Abstract

1. Introduction

2. Materials and Methods

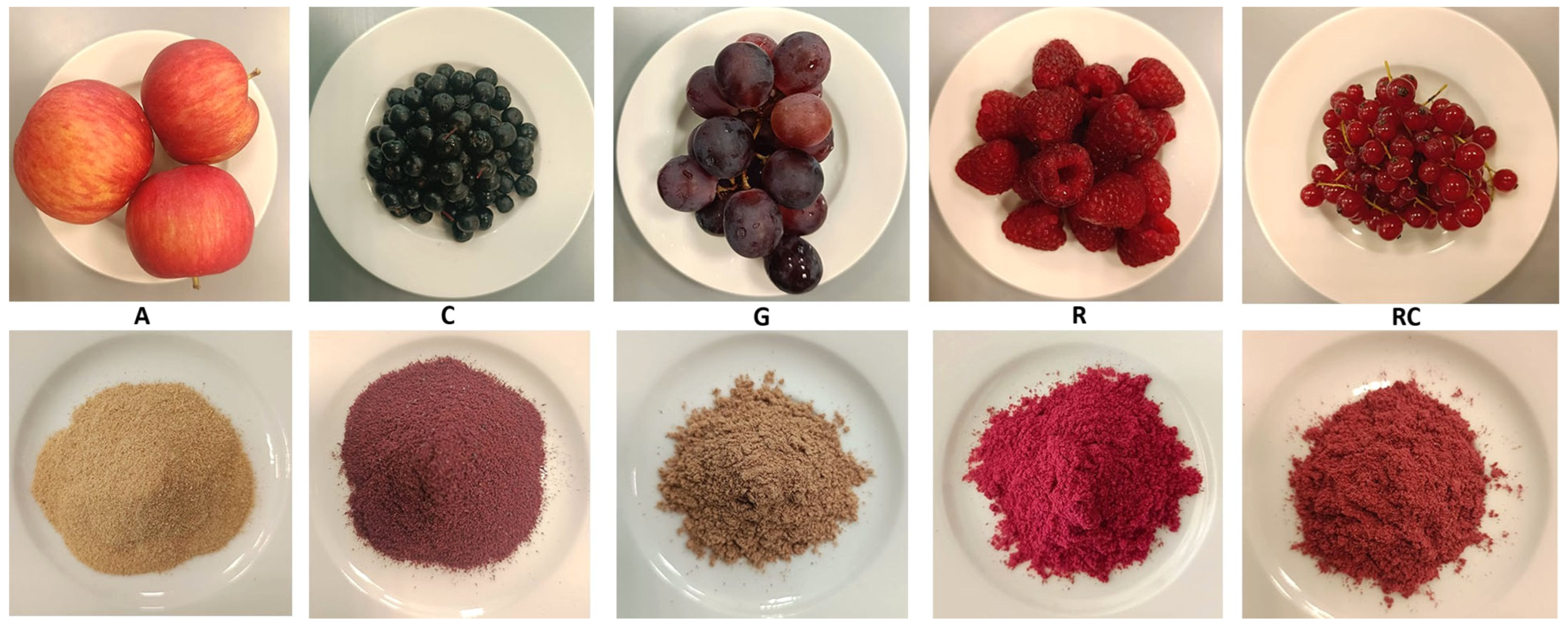

2.1. Research Material

2.2. Reagents

2.3. Determination of Physicochemical and Functional Properties

2.4. Measurement of Colour Parameters

2.5. Determination of the Chemical Composition

2.6. Determination of Element Content

2.7. Statistical Analysis

3. Results and Discussion

3.1. Physicochemical Properties of Fruit Pomace

3.2. Functional Properties of Fruit Pomace

Colour of the Fruit Pomace

3.3. Nutritional Properties of the Fruit Pomace

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| TTA | Total Titratable Acidity |

| TSS | Total Soluble Solid |

| WHC | Water Holding Capacity |

| SC | Swelling Capacity |

| OHC | Oil Holding Capacity |

| L* | Lightness |

| a* | Changes in the colour from green to red |

| b* | Changes in the colour from blue to yellow |

| C* | Chroma |

| A | Apple Pomace |

| C | Chokeberry Pomace |

| G | Grape Pomace |

| R | Raspberry Pomace |

| RC | Red Currant Pomace |

| SDF | Soluble Dietary Fibre |

| IDF | Insoluble Dietary Fibre |

| TDF | Total Dietary Fibre |

| d.w. | Dry weight |

References

- Ciccoritti, R.; Ciorba, R.; Ceccarelli, D.; Amoriello, M.; Amoriello, T. Phytochemical and Functional Properties of Fruit and Vegetable Processing By-Products. Appl. Sci. 2024, 14, 9172. [Google Scholar] [CrossRef]

- Bekavac, N.; Krog, K.; Stanić, A.; Šamec, D.; Šalić, A.; Benković, M.; Jurina, T.; Gajdoš Kljusurić, J.; Valinger, D.; Jurinjak Tušek, A. Valorization of Food Waste: Extracting Bioactive Compounds for Sustainable Health and Environmental Solutions. Antioxidants 2025, 14, 714. [Google Scholar] [CrossRef]

- Amicarelli, V.; Bux, C. Food waste measurement toward a fair, healthy and environmental-friendly food system: A critical review. Br. Food J. 2020, 123, 2907–2935. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations (FAO). The State of Food and Agriculture 2019, Moving forward on Food Loss and Waste Reduction; FAO: Rome, Italy, 2019; Available online: http://www.fao.org/3/ca6030en/ca6030en.pdf (accessed on 15 July 2025).

- De Boni, A.; Ottomano Palmisano, G.; De Angelis, M.; Minervini, F. Challenges for a Sustainable Food Supply Chain: A Review on Food Losses and Waste. Sustainability 2022, 14, 16764. [Google Scholar] [CrossRef]

- Ozkan, G.; Günal-Köroğlu, D.; Capanoglu, E. Chapter One—Valorization of fruit and vegetable processing by-products/wastes. In Advances in Food and Nutrition Research; Capanoglu, E., Navarro-Hortal, M.D., Forbes-Hernández, T.Y., Battino, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; Volume 107, pp. 1–39. [Google Scholar] [CrossRef]

- Sagar, N.A.; Pareek, S.; Sharma, S.; Yahia, E.M.; Lobo, M.G. Fruit and Vegetable Waste: Bioactive Compounds, Their Extraction, and Possible Utilization. Compr. Rev. Food Sci. Food Saf. 2018, 17, 512–531. [Google Scholar] [CrossRef]

- Ampese, L.C.; Ziero, H.D.D.; Velásquez, J.; Sganzerla, W.G.; Martins, G.; Forster-Carneiro, T. Apple Pomace Management by Anaerobic Digestion and Composting: A Life Cycle Assessment. Biofuels Bioprod. Biorefining 2023, 17, 29–45. [Google Scholar] [CrossRef]

- Mahato, N.; Sharma, K.; Sinha, M.; Cho, M.H. Citrus Waste-Derived Nutra-/Pharmaceuticals for Health Benefits: Current Trends and Future Perspectives. J. Funct. Foods 2018, 40, 307–316. [Google Scholar] [CrossRef]

- Fraterrigo Garofalo, S.; Demichelis, F.; Peletti, V.; Tommasi, T.; Fino, D. Comparative Study of Polyphenol Extraction Using Physical Techniques and Water as a Solvent: A Sustainable Approach for the Valorization of Apple Pomace. Environ. Sci. Pollut. Res. 2024. [Google Scholar] [CrossRef]

- Mirabella, N.; Castellani, V.; Sala, S. Current Options for the Valorization of Food Manufacturing Waste: A Review. J. Clean. Prod. 2014, 65, 28–41. [Google Scholar] [CrossRef]

- Gołębiewska, E.; Kalinowska, M.; Yildiz, G. Sustainable Use of Apple Pomace (AP) in Different Industrial Sectors. Materials 2022, 15, 1788. [Google Scholar] [CrossRef]

- Galali, Y.; Omar, Z.A.; Sajadi, S.M. Biologically active components in by-products of food processing. Food Sci Nutr. 2020, 8, 3004–3022. [Google Scholar] [CrossRef]

- Lu, K.; Yip, Y.M. Therapeutic Potential of Bioactive Flavonoids from Citrus Fruit Peels toward Obesity and Diabetes Mellitus. Future Pharmacol. 2023, 3, 14–37. [Google Scholar] [CrossRef]

- Rafiq, S.; Kaul, R.; Sofi, S.A.; Bashir, N.; Nazir, F.; Ahmad Nayik, G. Citrus peel as a source of functional ingredient: A review. J. Saudi Soc. Agric. Sci. 2018, 17, 351–358. [Google Scholar] [CrossRef]

- Azman, N.F.I.N.; Azlan, A.; Khoo, H.E.; Razman, M.R. Antioxidant properties of fresh and frozen peels of citrus species. Curr. Res. Nutr. Food Sci. 2019, 7, 331–339. [Google Scholar] [CrossRef]

- Tufail, T.; Bader Ul Ain, H.; Noreen, S.; Ikram, A.; Arshad, M.T.; Abdullahi, M.A. Nutritional Benefits of Lycopene and Beta-Carotene: A Comprehensive Overview. Food Sci. Nutr. 2024, 12, 8715–8741. [Google Scholar] [CrossRef]

- Ali, M.M.; Hashim, N.; Abd Aziz, S.; Lasekan, O. Pineapple (Ananas comosus): A comprehensive review of nutritional values, volatile compounds, health benefits, and potential food products. Food Res. Int. 2020, 137, 109675. [Google Scholar] [CrossRef]

- Banerjee, J.; Singh, R.; Vijayaraghavan, R.; MacFarlane, D.; Patti, A.F.; Arora, A. Bioactives from fruit processing wastes: Green approaches to valuable chemicals. Food Chem. 2017, 225, 10–22. [Google Scholar] [CrossRef]

- Coman, V.; Teleky, B.E.; Mitrea, L.; Martău, G.A.; Szabo, K.; Călinoiu, L.F.; Vodnar, D.C. Bioactive potential of fruit and vegetable wastes. Adv. Food Nutr. Res. 2020, 91, 157–225. [Google Scholar] [CrossRef]

- Maric, M.; Grassino, A.N.; Zhu, Z.; Barba, F.J.; Brncic, M.; Rimac Brncic, S. An overview of the traditional and innovative approaches for pectin extraction from plant food wastes and by-products: Ultrasound-, microwaves-, and enzyme-assisted extraction. Trends Food Sci. Technol. 2018, 76, 28–37. [Google Scholar] [CrossRef]

- Ritika; Rizwana; Shukla, S.; Sondhi, A.; Dutt Tripathi, A.; Lee, J.-K.; Patel, S.K.S.; Agarwal, A. Valorisation of fruit waste for harnessing the bioactive compounds and its therapeutic application. Trends Food Sci. Technol. 2024, 144, 104302. [Google Scholar] [CrossRef]

- Thorsen, M.; Skeaff, S.; Goodman-Smith, F.; Thong, B.; Bremer, P.; Mirosa, M. Upcycled foods: A nudge toward nutrition. Front. Nutr. 2022, 9, 1071829. [Google Scholar] [CrossRef] [PubMed]

- Erinle, T.J.; Adewole, D.I. Fruit pomaces—Their nutrient and bioactive components, effects on growth and health of poultry species, and possible optimization techniques. Anim. Nutr. 2022, 9, 357–377. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Chen, X.; Wang, G.; Xu, L.; Liu, Y.; Yuan, C.; Li, J. The release patterns and potential prebiotic characteristics of soluble and insoluble dietary fiber-bound polyphenols from pinot noir grape pomace in vitro digestion and fermentation. Food Chem. X 2025, 29, 102694. [Google Scholar] [CrossRef] [PubMed]

- Samad, N.; Okonkwo, C.E.; Ayyash, M.; Al-Marzouqi, A.H.; Yuliarti, O.; Kamal-Eldin, A. Valorization of Fruit Pomace by Enzymatic Treatment and Microbial Fermentation. Fermentation 2025, 11, 376. [Google Scholar] [CrossRef]

- Mateos-Aparicio, I.; De la Peña Armada, R.; Pérez-Cózar, M.L.; Rupérez, P.; Redondo-Cuenca, A.; Villanueva-Suárez, M.J. Apple by-product dietary fibre exhibits potential prebiotic and hypolipidemic effects in high-fat fed Wistar rats. Bioact. Carbohydr. Diet Fibre 2020, 23, 100219. [Google Scholar] [CrossRef]

- Gasaly, N.; Hermoso, M.A.; Gotteland, M. Butyrate and the Fine-Tuning of Colonic Homeostasis: Implication for Inflammatory Bowel Diseases. Int. J. Mol. Sci. 2021, 22, 3061. [Google Scholar] [CrossRef]

- Parveen, B.; Rajinikanth, V.; Narayanan, M. Natural plant antioxidants for food preservation and emerging trends in nutraceutical applications. Discov. Appl. Sci. 2025, 7, 845. [Google Scholar] [CrossRef]

- Shahidi, F.; Ambigaipalan, P. Phenolics and Polyphenolics in Foods, Beverages and Spices: Antioxidant Activity and Health Effects—A Review. J. Funct. Foods 2015, 18, 820–897. [Google Scholar] [CrossRef]

- Brewer, M.S. Natural Antioxidants: Sources, Compounds, Mechanisms of Action, and Potential Applications. Compr. Rev. Food Sci. Food Saf. 2011, 10, 221–247. [Google Scholar] [CrossRef]

- Dai, J.; Mumper, R.J. Plant Phenolics: Extraction, Analysis and Their Antioxidant and Anticancer Properties. Molecules 2010, 15, 7313–7352. [Google Scholar] [CrossRef]

- Pisoschi, A.M.; Pop, A. The Role of Antioxidants in the Chemistry of Oxidative Stress: A Review. Eur. J. Med. Chem. 2015, 97, 55–74. [Google Scholar] [CrossRef] [PubMed]

- Lobo, V.; Patil, A.; Phatak, A.; Chandra, N. Free Radicals, Antioxidants and Functional Foods: Impact on Human Health. Pharmacogn. Rev. 2010, 4, 118–126. [Google Scholar] [CrossRef] [PubMed]

- Raczkowska, E.; Serek, P. Health-Promoting Properties and the Use of Fruit Pomace in the Food Industry—A Review. Nutrients 2024, 16, 2757. [Google Scholar] [CrossRef] [PubMed]

- Kumar, H.; Guleria, S.; Kimta, N.; Nepovimova, E.; Dhalaria, R.; Dhanjal, D.S.; Sethi, N.; Alomar, S.Y.; Kuca, K. Selected fruit pomaces: Nutritional profile, health benefits, and applications in functional foods and feeds. Curr. Res. Food Sci. 2024, 9, 100791. [Google Scholar] [CrossRef]

- Piasecka, I.; Gorska, A. Possible uses of fruit pomaces in food technology as a fortifying additive—A review. Zesz. Probl. Postęp. Nauk Rol. 2020, 600, 43–54. [Google Scholar] [CrossRef]

- Pecyna, A.; Krzywicka, M.; Buczaj, A.; Blicharz-Kania, A.; Kobus, Z. The effect of fruit pomace addition on the color, texture and sensory properties of gluten-free bread. Sci. Rep. 2025, 15, 24510. [Google Scholar] [CrossRef]

- Gómez, M.; Martinez, M.M. Fruit and vegetable by-products as novel ingredients to improve the nutritional quality of baked goods. Crit. Rev. Food Sci. Nutr. 2018, 58, 2119–2135. [Google Scholar] [CrossRef]

- Quiles, A.; Campbell, G.M.; Struck, S.; Rohm, H.; Hernando, I. Fiber from fruit pomace: A review of applications in cereal-based products. Food Rev. Int. 2016, 34, 162–181. [Google Scholar] [CrossRef]

- Kapoor, A.; Kapoor, S.; Aggarwal, P. Rheological, Microstructural and Biochemical Characterisation of Fruit Pomace Jams. J. Food Meas. Charact. 2023, 17, 4267–4279. [Google Scholar] [CrossRef]

- Tama, A.; Karaś, M. The Health-Promoting Potential of Fruit Pomace and Its Application in the Confectionery Industry. Appl. Sci. 2025, 15, 5790. [Google Scholar] [CrossRef]

- Stamenković Stojanović, S.; Živković, L.; Stanojević, J.; Danilović, B.; Mančić, S.; Karabegović, I. Enhancing Kefir with Raspberry Pomace: Storage-Dependent Changes in Quality and Stability. Fermentation 2025, 11, 265. [Google Scholar] [CrossRef]

- Jurevičiūtė, I.; Keršienė, M.; Bašinskienė, L.; Leskauskaitė, D.; Jasutienė, I. Characterization of Berry Pomace Powders as Dietary Fiber-Rich Food Ingredients with Functional Properties. Foods 2022, 11, 716. [Google Scholar] [CrossRef] [PubMed]

- American Association of Cereal Chemistry. American Association of Cereal Chemistry Approved Methods, 10th ed.; American Association of Cereal Chemistry: Saint Paul, MN, USA, 2021; Available online: http://methods.aaccnet.org/toc.aspx (accessed on 2 July 2025).

- AOAC. Method 942.15: Acidity (titratable) of fruit products. In Official Method of Analysis, 16th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 1995. [Google Scholar]

- Gouw, V.P.; Jung, J.; Zhao, Y. Functional properties, bioactive compounds, and in vitro gastrointestinal digestion study of dried fruit pomace powders as functional food ingredients. LWT 2017, 80, 136–144. [Google Scholar] [CrossRef]

- Čechovičienė, I.; Šlepetienė, A.; Gumbytė, M.; Paulauskienė, A.; Tarasevičienė, Ž. Composition and Physicochemical Properties of Pomace of Various Cultivars of Blackberry (Rubus fruticosus L.). Horticulturae 2024, 10, 38. [Google Scholar] [CrossRef]

- PN-A-79011–15:1998; Polish Standard Dry Ford Mixes. Test Methods. Determination of Dietary Fiber Contents. Polish Committee for Standardization: Warsaw, Poland, 1998. (In Polish)

- Ibrahim, M.; Akhtar, N.; Khan, A.; Sara; Anwar, Y.; Wong, L.S.; Subramaniyan, V.; Kumarasamy, V.; Rauf, A.; Ahlawat, Y.K.; et al. Nutritional Profiling of Wild Edible Plants: Quantification of Macronutrients and Minerals via Energy Dispersive X-ray (EDX) Fluorescence Spectroscopy. Braz. J. Biol. 2024, 84, e287349. [Google Scholar] [CrossRef]

- Kaloudi, T.; Tsimogiannis, D.; Oreopoulou, V. Aronia Melanocarpa: Identification and Exploitation of Its Phenolic Components. Molecules 2022, 27, 4375. [Google Scholar] [CrossRef]

- Spinei, M.; Oroian, M. The Potential of Grape Pomace Varieties as a Dietary Source of Pectic Substances. Foods 2021, 10, 867. [Google Scholar] [CrossRef]

- Jung, J.; Cavender, G.; Zhao, Y. Impingement drying for preparing dried apple pomace flour and its fortification in bakery and meat products. J. Food Sci. Technol. 2015, 52, 5568–5578. [Google Scholar] [CrossRef]

- Drosou, C.; Kyriakopoulou, K.; Bimpilas, A.; Tsimogiannis, D.; Krokida, M. A comparative study on different extraction techniques to recover red grape pomace polyphenols from vinification byproducts. Ind. Crops Prod. 2015, 75, 141–149. [Google Scholar] [CrossRef]

- Lyu, F.; Luiz, S.F.; Azeredo, D.R.P.; Cruz, A.G.; Ajlouni, S.; Ranadheera, C.S. Apple Pomace as a Functional and Healthy Ingredient in Food Products: A Review. Processes 2020, 8, 319. [Google Scholar] [CrossRef]

- Sharma, P.; Gupta, A.; Issar, K. Effect of Packaging and Storage on Dried Apple Pomace and Fiber Extracted from Pomace. J Food Process Preserv. 2017, 41, e12913. [Google Scholar] [CrossRef]

- Sant’Anna, V.; Englert, A.H.; Corrêa, A.P.F.; Brandelli, A.; Ferreira Marczak, L.D.; Tessaro, I.C. Grape Marc Powder: Physicochemical and Microbiological Stability During Storage and Moisture Sorption Isotherm. Food Bioprocess. Technol. 2014, 7, 2500–2506. [Google Scholar] [CrossRef]

- Jin, Q.; O’Hair, J.; Stewart, A.C.; O’Keefe, S.F.; Neilson, A.P.; Kim, Y.-T.; McGuire, M.; Lee, A.; Wilder, G.; Huang, H. Compositional Characterization of Different Industrial White and Red Grape Pomaces in Virginia and the Potential Valorization of the Major Components. Foods 2019, 8, 667. [Google Scholar] [CrossRef]

- Pecyna, A.; Krzywicka, M.; Blicharz-Kania, A.; Buczaj, A.; Kobus, Z.; Zdybel, B.; Domin, M.; Siłuch, D. Impact of Incorporating Two Types of Dried Raspberry Pomace into Gluten-Free Bread on Its Nutritional and Antioxidant Characteristics. Appl. Sci. 2024, 14, 1561. [Google Scholar] [CrossRef]

- Li, M.; Liu, Y.; Yang, G.; Sun, L.; Song, X.; Chen, Q.; Bao, Y.; Luo, T.; Wang, J. Microstructure, physicochemical properties, and adsorption capacity of deoiled red raspberry pomace and its total dietary fiber. LWT 2022, 153, 112478. [Google Scholar] [CrossRef]

- Nemetz, N.J.; Schieber, A.; Weber, F. Application of Crude Pomace Powder of Chokeberry, Bilberry, and Elderberry as a Coloring Foodstuff. Molecules 2021, 26, 2689. [Google Scholar] [CrossRef] [PubMed]

- Reißner, A.-M.; Al-Hamimi, S.; Quiles, A.; Schmidt, C.; Struck, S.; Hernando, I.; Turner, C.; Rohm, H. Composition and physicochemical properties of dried berry pomace. J. Sci. Food Agric. 2019, 99, 1284–1293. [Google Scholar] [CrossRef]

- Chu, J.; Zhao, H.; Lu, Z.; Lu, F.; Bie, X.; Zhang, C. Improved physicochemical and functional properties of dietary fiber from millet bran fermented by Bacillus natto. Food Chem. 2019, 294, 79–86. [Google Scholar] [CrossRef]

- Richards, J.; Lammert, A.; Madden, J.; Kang, I.; Amin, S. Physical Treatments Modified the Functionality of Carrot Pomace. Foods 2024, 13, 2084. [Google Scholar] [CrossRef]

- Fidriyanto, R.; Singh, B.P.; Manju, K.M.; Singh, R.R.B.; Riar, C.S. Multivariate Analysis of Structural and Functional Properties of Fibres from Apple Pomace Using Different Extraction Methods. Food Prod. Process. Nutr. 2023, 5, 6. [Google Scholar] [CrossRef]

- Fernández-Ginés, J.M.; Fernández-López, J.; Sayas-Barberá, E.; Sendra, E.; Pérez-Alvarez, J.A. Effect of storage conditions on quality characteristics of bologna sausages made with citrus fiber. J. Food Sci. 2003, 68, 710–714. [Google Scholar] [CrossRef]

- Huang, L.; Liu, J.; Addy, M.; Ding, B.; Cheng, Y.; Peng, P.; Wang, Y.; Liu, Y.; Chen, P.; Ruan, R. Physicochemical and Emulsifying Properties of Orange Fibers Stabilized Oil-in-Water Emulsions. LWT 2020, 133, 110054. [Google Scholar] [CrossRef]

- Kieserling, K.; Vu, T.M.; Drusch, S.; Schalow, S. Impact of pectin-rich orange fibre on gel characteristics and sensory properties in lactic acid fermented yoghurt. Food Hydrocoll. 2019, 94, 152–163. [Google Scholar] [CrossRef]

- Pakulska, A.; Kawecka, L.; Galus, S. Physical Properties of Selected Fruit Fibre and Pomace in the Context of Their Sustainable Use for Food Applications. Appl. Sci. 2024, 14, 9051. [Google Scholar] [CrossRef]

- Petković, M.; Filipović, V.; Filipović, J.; Ðurović, I.; Miletić, N.; Radovanović, J. Chemical, antioxidative, and sensory characteristics of wheat bread partially substituted with black chokeberry (Aronia melanocarpa L.) powder. J. Food Process. Preserv. 2021, 45, e15027. [Google Scholar] [CrossRef]

- Rocha-Parra, A.F.; Belorio, M.; Ribotta, P.D.; Ferrero, C.; Gómez, M. Effect of the particle size of pear pomace on the quality of enriched layer and sponge cakes. Int. J. Food Sci. Technol. 2018, 54, 1265–1275. [Google Scholar] [CrossRef]

- Kruczek, M.; Gumul, D.; Korus, A.; Buksa, K.; Ziobro, R. Phenolic Compounds and Antioxidant Status of Cookies Supplemented with Apple Pomace. Antioxidants 2023, 12, 324. [Google Scholar] [CrossRef] [PubMed]

- Matsumoto, M.; Hara, H.; Chiji, H.; Kasai, T. Gastroprotective effect of red pigments in black chokeberry fruit (Aronia melanocarpa Elliot) on acute gastric hemorrhagic lesions in rats. J. Agric. Food Chem. 2004, 52, 2226–2229. [Google Scholar] [CrossRef]

- Zbikowska, A.; Lukasiak, P.; Kowalska, M.; Lukasiak, A.; Kozłowska, M.; Marciniak-Lukasiak, K. Incorporation of Chokeberry Pomace into Baked Products: Influence on the Quality of the Dough and the Muffins. Appl. Sci. 2024, 14, 9675. [Google Scholar] [CrossRef]

- Mandache, M.B.; Vijan, L.E.; Cosmulescu, S. Insight into Bioactive Compounds and Antioxidant Activity of Bakery Products Fortified with Fruit Pomace. Foods 2025, 14, 806. [Google Scholar] [CrossRef]

- Chikpah, S.K.; Korese, J.K.; Osman, S. Characterization of physicochemical, antioxidants and sensory properties of cookies enriched with shea (Vitellaria paradoxa) fruit pulp as a functional ingredient. Food Prod. Process. Nutr. 2023, 5, 44. [Google Scholar] [CrossRef]

- Szymanowska, U.; Karaś, M.; Bochnak-Niedźwiecka, J. Antioxidant and Anti-Inflammatory Potential and Consumer Acceptance of Wafers Enriched with Freeze-Dried Raspberry Pomace. Appl. Sci. 2021, 11, 6807. [Google Scholar] [CrossRef]

- Gordillo, B.; Cejudo-Bastante, M.J.; Rodríguez-Pulido, F.J.; Jara-Palacios, M.J.; Ramirez-Perez, P.; González-Miret, M.L.; Heredia, F.J. Impact of adding white pomace to red grapes on the phenolic composition and color stability of Syrah wines from a warm climate. J. Agric. Food Chem. 2014, 62, 2663–2671. [Google Scholar] [CrossRef] [PubMed]

- Eksi Karaagac, H.; Cavus, F.; Kadioglu, B.; Ugur, N.; Tokat, E.; Sahan, Y. Evaluation of nutritional, color and volatiles properties of currant (Ribes spp.) cultivars in Turkey. Food Sci. Technol. 2021, 41, 304–313. [Google Scholar] [CrossRef]

- Tejeda-Miramontes, J.P.; Espinoza-Paredes, B.C.; Zatarain-Palffy, A.; García-Cayuela, T.; Tejada-Ortigoza, V.; Garcia-Amezquita, L.E. Process modeling and convective drying optimization of raspberry pomace as a fiber-rich functional ingredient: Effect on techno-functional and bioactive properties. Foods 2024, 13, 3597. [Google Scholar] [CrossRef]

- Slavin, J. Fiber and Prebiotics: Mechanisms and Health Benefits. Nutrients 2013, 5, 1417–1435. [Google Scholar] [CrossRef]

- Czachajda, M.; Góral, A.; Duszyńska, K.; Dolepski, K.; Żuk, K.; Firlej, E. Short chain fatty acids and their impact on human health—A review. Med. Og. Nauk. Zdr. 2024, 30, 181–185. [Google Scholar] [CrossRef]

- Facchin, S.; Bertin, L.; Bonazzi, E.; Lorenzon, G.; De Barba, C.; Barberio, B.; Zingone, F.; Maniero, D.; Scarpa, M.; Ruffolo, C.; et al. Short chain fatty acids and human health: From metabolic pathways to current therapeutic implications. Life 2024, 14, 559. [Google Scholar] [CrossRef]

- Bader Ul Ain, H.; Saeed, F.; Ahmed, A.; Asif Khan, M.; Niaz, B.; Tufail, T. Improving the physicochemical properties of partially enhanced soluble dietary fiber through innovative techniques: A coherent review. J. Food Process. Preserv. 2019, 43, e13917. [Google Scholar] [CrossRef]

- Garrido, M.D.; Auqui, M.; Martí, N.; Linares, M.B. Effect of two different red grape pomace extracts obtained under different extraction systems on meat quality of pork burgers. LWT-Food Sci. Technol. 2011, 44, 2238–2243. [Google Scholar] [CrossRef]

- Antonić, B.; Jančíková, S.; Dordević, D.; Tremlová, B. Grape Pomace Valorization: A Systematic Review and Meta-Analysis. Foods 2020, 9, 1627. [Google Scholar] [CrossRef] [PubMed]

- Pieszka, M.; Gogol, P.; Pietras, M.; Pieszka, M. Valuable Components of Dried Pomaces of Chokeberry, Black Currant, Strawberry, Apple and Carrot as a Source of Natural Antioxidants and Nutraceuticals in the Animal Diet. Ann. Anim. Sci. 2015, 15, 475–491. [Google Scholar] [CrossRef]

- Schieber, A. Side Streams of Plant Food Processing as a Source of Valuable Compounds: Selected Examples. Annu. Rev. Food Sci. Technol. 2017, 8, 97–112. [Google Scholar] [CrossRef] [PubMed]

- Raczkowska, E.; Nowicka, P.; Wojdyło, A.; Styczyńska, M.; Lazar, Z. Chokeberry Pomace as a Component Shaping the Content of Bioactive Compounds and Nutritional, Health-Promoting (Anti-Diabetic and Antioxidant) and Sensory Properties of Shortcrust Pastries Sweetened with Sucrose and Erythritol. Antioxidants 2022, 11, 190. [Google Scholar] [CrossRef]

- Kettritz, R.; Loffing, J. Potassium homeostasis—Physiology and pharmacology in a clinical context. Pharmacol. Ther. 2023, 249, 108489. [Google Scholar] [CrossRef]

- Bird, R.P.; Eskin, N.A.M. The emerging role of phosphorus in human health. Adv. Food Nutr. Res. 2021, 96, 27–88. [Google Scholar] [CrossRef]

- Peacock, M. Calcium Metabolism in Health and Disease. Clin. J. Am. Soc. Nephrol. 2010, 5, S23–S30. [Google Scholar] [CrossRef]

- Harris, G.K.; Marshall, M.R. Ash analysis. In Food Analysis; Springer International Publishing: Cham, Switzerland, 2017; pp. 287–297. [Google Scholar]

- Mohamed Ahmed, I.A.; Özcan, M.M.; Al Juhaimi, F.; Babiker, E.F.E.; Ghafoor, K.; Banjanin, T.; Osman, M.A.; Gassem, M.A.; Alqah, H.A.S. Chemical composition, bioactive compounds, mineral contents, and fatty acid composition of pomace powder of different grape varieties. J. Food Process. Preserv. 2020, 44, 14539. [Google Scholar] [CrossRef]

- Ferrer-Gallego, R.; Silva, P. The Wine Industry By-Products: Applications for Food Industry and Health Benefits. Antioxidants 2022, 11, 2025. [Google Scholar] [CrossRef]

- Prata, C.; Zalambani, C.; Rossi, F.; Rossello, S.; Cerchiara, T.; Cappadone, C.; Malucelli, E. Nutrients and Nutraceuticals from Vitis vinifera L. Pomace: Biological Activities, Valorization, and Potential Applications. Nutrients 2025, 17, 583. [Google Scholar] [CrossRef]

- Sousa, E.C.; Uchôa-Thomaz, A.M.A.; Carioca, J.O.B.; de Morais, S.M.; de Lima, A.; Martins, C.G.; Alexandrino, C.D.; Ferreira, P.A.T.; Rodrigues, A.L.M.; Rodrigues, S.P.; et al. Chemical composition and bioactive compounds of grape pomace (Vitis vinifera L.), Benitaka variety, grown in the semiarid region of Northeast Brazil. Food Sci. Technol. 2014, 34, 135–142. [Google Scholar] [CrossRef]

- Machado, A.R.; Voss, G.B.; Machado, M.; Paiva, J.A.; Nunes, J.; Pintado, M. Chemical characterization of the cultivar ‘Vinhão’ (Vitis vinifera L.) grape pomace towards its circular valorisation and its health benefits. Meas. Food 2024, 15, 100175. [Google Scholar] [CrossRef]

- Cvetković, M.; Ilić, D.; Petrović, S.; Miladinović, B. Mineral composition of the red currant (Ribes rubrum L.) variety Redpoll lyophilized waste extract. Arch. Pharm. 2022, 72 Suppl. S4, S501–S502. [Google Scholar]

| Sample | Moisture After Pressing [%] | Moisture After Drying [%] | TTA [g·100 g−1d.w.] | TSS [°Brix] |

|---|---|---|---|---|

| A | 64.99 ± 0.85 a | 6.73 ± 0.13 d | 1.62 ± 0.05 c | 5.43 ± 0.05 a |

| C | 64.06 ± 0.08 a | 8.13 ± 0.18 b | 3.52 ± 0.01 b | 1.00 ± 0.08 e |

| G | 65.10 ± 1.11 a | 7.26 ± 0.15 cd | 1.41 ± 0.52 c | 4.30 ± 0.00 c |

| R | 63.86 ± 0.58 a | 9.55 ± 0.37 a | 7.96 ± 0.27 a | 4.50 ± 0.00 b |

| RC | 60.73 ± 0.54 b | 7.77 ± 0.07 bc | 4.21 ± 0.08 b | 2.03 ± 0.05 d |

| Sample | WHC [g·g−1] | SC [mL·g−1] | OHC [g·g−1] |

|---|---|---|---|

| A | 4.25 ± 0.08 a | 6.54 ± 0.16 a | 1.89 ± 0.02 c |

| C | 2.36 ± 0.04 e | 1.57 ± 0.01 d | 1.86 ± 0.04 c |

| G | 3.63 ± 0.12 b | 1.79 ± 0.01 c | 2.41 ± 0.01 a |

| R | 2.63 ± 0.01 d | 2.80 ± 0.00 b | 1.91 ± 0.01 c |

| RC | 3.12 ± 0.03 c | 1.58 ± 0.01 d | 2.03 ± 0.02 b |

| Sample | L* | a* | b* | C* |

|---|---|---|---|---|

| A | 66.29 ± 0.85 a | 9.05 ± 0.52 e | 28.54 ± 0.60 a | 29.95 ± 0.60 c |

| C | 18.68 ± 0.79 e | 11.66 ± 0.28 d | 6.78 ± 0.29 e | 13.48 ± 0.36 e |

| G | 48.01 ± 0.91 b | 12.82 ± 0.54 c | 22.84 ± 1.63 b | 26.20 ± 1.43 d |

| R | 42.65 ± 0.85 c | 26.76 ± 0.49 b | 20.40 ± 1.51 c | 33.66 ± 1.07 b |

| RC | 38.66 ± 0.66 d | 32.99 ± 0.64 a | 12.08 ± 0.37 d | 35.13 ± 0.71 a |

| Sample | Protein [%d.w.] | Fat [%d.w.] | Ash [%d.w.] | Carbohydrates [%d.w.] | TDF [%d.w.] |

|---|---|---|---|---|---|

| A | 2.91 ± 0.02 e | 0.92 ± 0.04 e | 2.38 ± 0.04 bc | 56.34 ± 0.18 a | 37.45 ± 0.18 e |

| C | 4.19 ± 0.06 d | 2.07 ± 0.15 d | 2.13 ± 0.05 c | 49.50 ± 0.08 b | 42.10 ± 0.15 d |

| G | 7.45 ± 0.04 c | 4.06 ± 0.14 c | 3.71 ± 0.02 a | 34.08 ± 0.25 d | 50.70 ± 0.15 b |

| R | 8.71 ± 0.05 b | 5.92 ± 0.04 b | 2.70 ± 0.28 b | 35.59 ± 0.13 c | 47.07 ± 0.06 c |

| RC | 13.01 ± 0.05 a | 6.82 ± 0.03 a | 3.39 ± 0.01 a | 9.39 ± 0.56 e | 67.38 ± 0.53 a |

| Sample | Macroelements [g·kg−1d.w.] | Microelements [mg·kg−1d.w.] | ||||

|---|---|---|---|---|---|---|

| K | P | Ca | Fe | Zn | Mn | |

| A | 8.29 ± 0.12 d | 1.00 ± 0.02 e | 0.48 ± 0.02 c | 18.24 ± 0.83 b | 3.05 ± 0.19 c | - |

| C | 8.41 ± 0.02 d | 1.16 ± 0.02 d | 2.11 ± 0.05 b | 5.59 ± 0.66 b | 5.59 ± 0.66 d | 12.29 ± 0.23 b |

| G | 17.46 ± 0.03 a | 1.52 ± 0.02 c | 1.68 ± 0.03 d | 24.53 ± 0.14 b | 6.88 ± 0.42 d | - |

| R | 10.84 ± 0.47 c | 2.72 ± 0.02 a | 1.82 ± 0.03 d | 51.56 ± 7.75 a | 17.48 ± 0.45 a | 67.32 ± 0.91 a |

| RC | 14.56 ± 0.73 b | 2.31 ± 0.10 b | 2.80 ± 0.22 a | 42.91 ± 2.18 a | 13.39 ± 1.26 b | 12.64 ± 0.66 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blicharz-Kania, A.; Pecyna, A.; Zdybel, B.; Andrejko, D. Physicochemical, Functional and Nutritional Characteristics of Various Types of Fruit Pomace. Processes 2025, 13, 3182. https://doi.org/10.3390/pr13103182

Blicharz-Kania A, Pecyna A, Zdybel B, Andrejko D. Physicochemical, Functional and Nutritional Characteristics of Various Types of Fruit Pomace. Processes. 2025; 13(10):3182. https://doi.org/10.3390/pr13103182

Chicago/Turabian StyleBlicharz-Kania, Agata, Anna Pecyna, Beata Zdybel, and Dariusz Andrejko. 2025. "Physicochemical, Functional and Nutritional Characteristics of Various Types of Fruit Pomace" Processes 13, no. 10: 3182. https://doi.org/10.3390/pr13103182

APA StyleBlicharz-Kania, A., Pecyna, A., Zdybel, B., & Andrejko, D. (2025). Physicochemical, Functional and Nutritional Characteristics of Various Types of Fruit Pomace. Processes, 13(10), 3182. https://doi.org/10.3390/pr13103182