1. State of the Art

The escalating market requirements for high-quality customized products drive manufacturers to enhance their production optimization methods. Various production optimization domains include human–machine collaboration, layout optimization and simulation, adaptability, environmental sustainability, and artificial intelligence. This chapter organizes recent findings by type and spots necessary research areas.

1.1. Human–Machine Scheduling Optimization

The method presented by Lei et al. [

1] joins worker fatigue assessment with machine operational analysis to create scheduling plans that establish equal periods of rest and work for maintaining sustainable manufacturing output.

Kochańska J. [

2] created a combined management system that boosts operator efficiency through the combination of multiple performance-tracking and management techniques to maximize resource effectiveness.

These research studies embed human elements into production schedules, yet they do not include real-time data processing or adaptive scheduling systems which respond to changing conditions and unanticipated disturbances. Future research needs to develop real-time AI systems which coordinate human and machine operations.

1.2. Layout and Task Assignment Optimization

Zhang Y. [

3] employed genetic algorithms to optimize robotic cell layouts and assign tasks to robots, which resulted in reduced material-handling distances and higher productivity.

Choi H. et al. [

4] designed a comprehensive solution which united layout optimization techniques with production workflow development to achieve coordinated material transportation during production times for enhanced system harmony.

The optimization methods for layout and task distribution operate best in static systems, yet they struggle to handle dynamic production requirements and unexpected interruptions. Research needs to focus on intelligent systems for flexible real-time layout reconfiguration.

1.3. Simulation-Based Performance Enhancement

Poloczek R. and Oleksiak B. [

5] employed simulation tools to evaluate various production line expansion methods, which provided data for making informed planning choices.

Trebuňa P. et al. [

6] used simulation software to discover and solve bottlenecks in stator EM lines, which led to increased production rates and reduced operational expenses through virtual testing.

Santos A.A. et al. [

7] utilized simulation software to evaluate operations in a tyre painting cell, which led to better fluid application and robotic handling efficiency that resulted in better quality alongside faster production rates.

These simulation-based studies deliver valuable performance data, yet they fail to examine how systems behave in the long run with fluctuating production levels or multiple performance trade-offs between cost effectiveness and flexibility. Future work needs to develop adaptive simulation systems that perform multi-scenario analysis and optimization under uncertain conditions.

1.4. Adaptive and Reconfigurable Manufacturing Systems

Barrera-Diaz C.A. et al. [

8] used simulation-based multi-objective optimization to solve manufacturing reconfiguration by balancing throughput with buffer capacity when production demands fluctuate.

Zhou B. [

9] developed a hybrid optimization solution to enhance profitability by integrating preventive maintenance with rework operations within closed-loop production systems.

The research supports flexible production systems, yet they need better real-time capabilities and larger system scalability. The integration of IoT and real-time data analytics into reconfigurable production environments demands further research to enhance responsiveness.

1.5. Equipment and Environmental Optimization

The implementation of Lin T. et al.’s [

10] research transformed industrial equipment to decrease NOx emissions and natural gas consumption, thus demonstrating how environmental enhancement aligns with energy efficiency goals.

Chen M. et al. [

11] built a sustainable manufacturing system for automobile wheel hubs by implementing minimum quantity lubrication and advanced machining, which decreased waste production and improved precision.

Ruzarovsky R. [

12] created robotic manufacturing cells that use optimized energy consumption and production time to show the significance of robot positioning in achieving energy savings.

These contributions advance sustainability and efficiency, but they often do not include lifecycle assessments or broader environmental metrics (e.g., carbon footprint, water usage). Environmental impact modelling research needs to integrate circular economy principles within production system design.

1.6. Artificial Intelligence for System-Wide Optimization

Cavalcanti J.H. et al. [

13] developed an AI (Artificial Intelligence)-based framework which improved system efficiency by implementing various AI algorithms for real-time performance optimization through decision-making enhancement.

AI-based systems have shown promise, yet their opaque operations make it hard to implement them in regulated or safety-sensitive fields. The development of explainable AI models and trustworthy ethical manufacturing integration requires further research efforts.

The literature review presents an extensive range of production optimization innovations which span from human–machine teaming to AI-powered decision systems. Yet, critical gaps persist. Current research primarily fails to incorporate real-time adaptability alongside handling multiple objectives, sustainable environmental integration, and model interpretability. The existing gaps require the development of intelligent adaptive production systems which should operate efficiently within complex manufacturing environments with rapid changes.

1.7. Research Gap

Assembly-line optimization methods currently depend on static models which do not adjust to changing workloads, resource availability, and machine performance in real time. Most research focuses on maximizing output but ignores essential elements which include resource usage, energy efficiency, and maintenance integration. The limited focus of current methods produces unbalanced systems that result in higher downtime and operational expenses.

This research develops a flexible station-level optimization framework which unites virtual simulation with real-time monitoring and quality management tools (Fishbone, 5S). The proposed method uses data-driven adaptive methods to achieve efficiency, sustainability, and cost effectiveness, which address the current literature gap.

2. Introduction

The target for this research is based on optimizing a specific station from the assembly line, addressing inefficiencies and identifying opportunities for improvement. To visualize clearly the entire line of production, specialized tools will be used to generate virtual representations of the assembly line, enabling a company to assess and confirm decisions in a risk-free setting without wasting time, money, or personnel.

Initially, throughout the production process, the assembly line may experience numerous alterations due to inconsistencies in logistics, processes, or customer-related problems. To assess these matters effectively, it is essential to have implemented clear quality management tools to prevent disruptions in the process. Two examples of these tools are the fishbone diagram (Ishikawa) and the 5S methodology, which can enhance work efficiency and improve process safety.

The fishbone diagram is a tool that allows analyzing an issue during assembly, providing a clear perspective on the factors that contributed to it. It is used when a complex issue that needs detailed analysis appears to easily and efficiently identify the cause. A few instances represented in a fishbone diagram include processes, surroundings, resources, instruments, workload, and metrics [

14].

The second essential quality management tool is the Japanese methodology 5S, which is necessary in a manufacturing company to enhance employees’ safety and minimize downtime in processes [

15]. The purpose of this tool is to establish a neat, organized, and efficient workspace to positively influence production performance and safety. It is based on five clear steps that you need to follow:

Seiri (Sort)—Eliminating unnecessary items from the workplace;

Seiton (Set in order)—Organizing storage areas efficiently to facilitate easy access;

Seiso (Shine)—Keeping the workplace clean and tidy;

Seiketsu (Standardize)—Creating standards to maintain order and cleanliness;

Shitsuke (Sustain)—Maintaining discipline and implementing rules for the long term.

Using the tools discussed earlier does not ensure optimal efficiency in improving production lines. A major concern is the absence of an all-encompassing framework for monitoring performance in real-time and making adaptive changes at each station. Existing approaches frequently depend on fixed models, which do not accommodate the variable changes in workload, resource availability, and machine efficiency.

Furthermore, numerous optimization approaches concentrate mainly on enhancing output, often neglecting the effects on resource use, energy consumption, and maintenance plans. This oversight can lead to less effective performance, greater downtime, and elevated operational expenses. This research aims to address these gaps by developing a more flexible, data-driven approach to optimizing production line stations, with a focus on balancing efficiency, cost, and sustainability.

Contributions:

Create an optimization model for a particular station on the assembly line to solve production problems and optimize performance.

Specialized simulation tools enable the creation of virtual production line models which allow risk-free optimization strategy testing before actual implementation.

The Ishikawa (fishbone diagram) and 5S methodology enable systematic root-cause identification of inefficiencies and workplace organization standardization to enhance safety, quality, and process consistency.

The assembly process becomes more resilient to logistical inconsistencies, process deviations, and customer-related changes through proactive analysis and structured quality management.

The approach will optimize efficiency while minimizing energy/resource usage and maintenance requirements to create a sustainable production model that reduces costs.

The term “station-level optimization” model in this work refers to a simulation-based and lean-enhanced optimization framework, where discrete-event simulation, root-cause analysis (Ishikawa), and 5S methodology are integrated to identify inefficiencies, test improvements (e.g., forklift utilization), and validate their impact on station performance.

3. Case Study

An assembly station is an essential phase in the contemporary manufacturing process, enabling the organized merging of separate components to produce a finished product. These stations can range from fully manual configurations to completely automated systems that incorporate robotics, artificial intelligence, and real-time monitoring capabilities. Their main purposes are to improve operational efficiency, ensure quality, and streamline production flow to satisfy industrial requirements.

The company studied operates a facility dedicated to the manufacturing of military vehicles, focusing primarily on assembling various components to produce fully functional units. This study aims to provide a comprehensive examination of a specific fully manual assembly station responsible for integrating all external parts and accessories of the vehicles. This manual assembly process relies entirely on human labour, making it essential to create an ergonomic and efficient workspace.

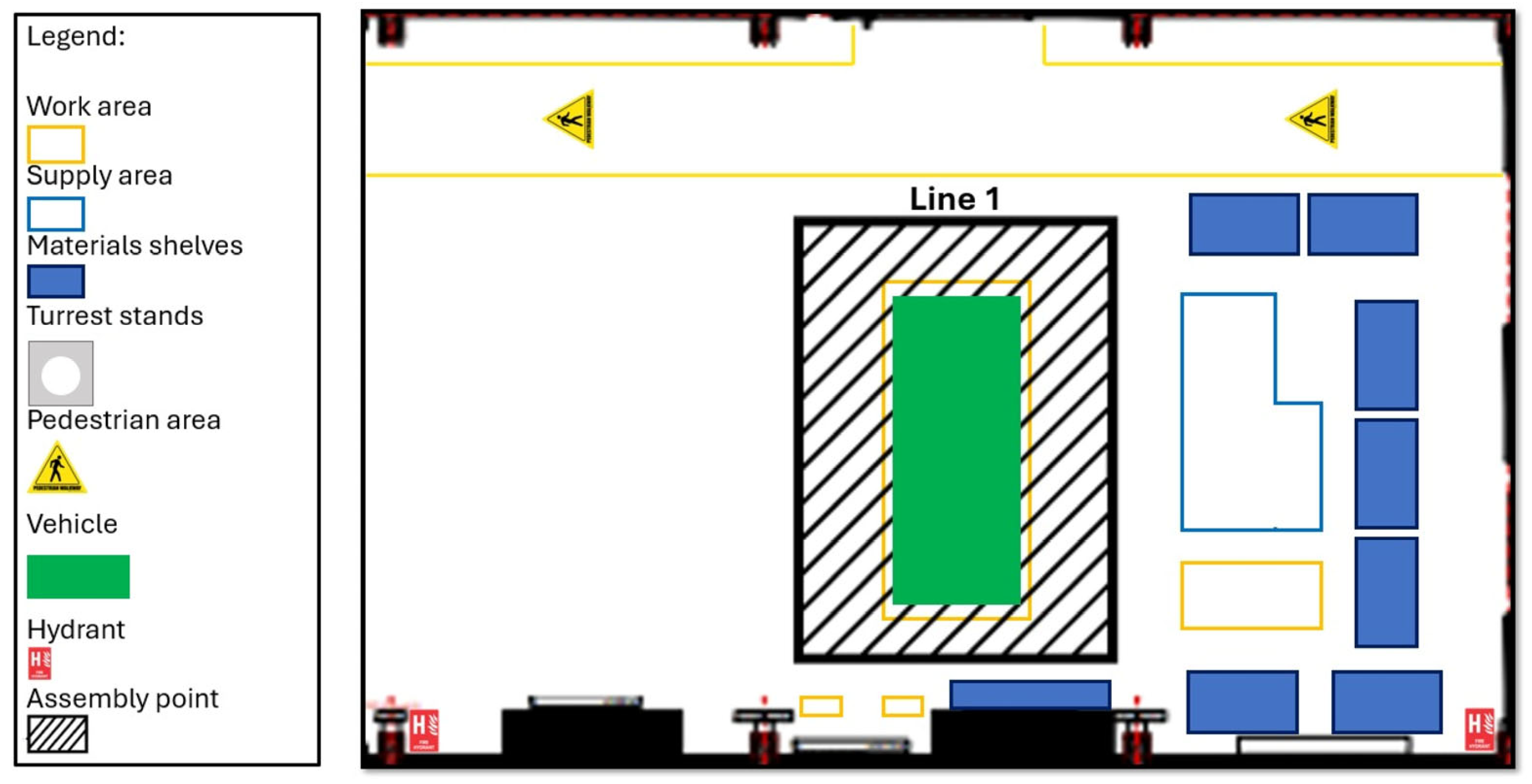

As presented in

Figure 1, the workstation is equipped with a single assembly line (that is black hatching in

Figure 1), each staffed by five workers, along with a team leader who oversees the ongoing tasks and activities. The physical structure of the assembly station features workbenches, adjustable seating, and dedicated storage units for easy access to tools and components. The tools and equipment include a variety of hand tools such as precision screwdrivers, torque wrenches, assembly jigs, and fixtures that help maintain the alignment and positioning of components.

Control systems employ meticulously structured visual inspection methods, comprehensive process checklists, and unwavering adherence to standard operating procedures. This rigorous approach ensures unparalleled consistency and significantly minimizes errors, ultimately driving excellence and reliability in our processes. To maintain quality throughout the process, it is essential to have skilled operators responsible for each stage of the production process. These operators must possess a high level of dexterity, hand–eye coordination, and adherence to strict quality standards. To ensure they remain in top form, they participate in regular training sessions and certification programmes on a monthly basis.

A structured manual workflow is essential to optimize efficiency and maintain consistency in product assembly. To complete each assembly step, they follow detailed work instructions to retrieve, sort, and align required components on designated trays or work surfaces before beginning the assembly process. The system includes various standard mechanical components designed for enhanced performance and protection. These components consist of an armoured cover for increased durability, advanced optical equipment for precise targeting and monitoring, and an integrated turret system for improved maneuverability. Additionally, the system features marker lights for better visibility and signalling, mirrors to enhance situational awareness, and smoke grenade launchers for tactical deployment.

Fastening methods involve manually tightening bolts and screws to specific torque values, ensuring structural integrity and durability under operational conditions. Collectively, these components contribute to the system’s reliability, functionality, and overall operational effectiveness.

To clarify the study scope,

Figure 1 provides an expanded view of the workstation area. The analysis in this paper focuses on a single line—the manual assembly line diagonally hatched “Line 1” in

Figure 1. The remaining lines and resources are shown only to provide layout and logistics context (e.g., neighbouring flows, forklift routes, and shared buffers); no performance metrics are computed or reported for those lines. Throughout the paper, any mention of “the line” or “the station” refers exclusively to this highlighted line.

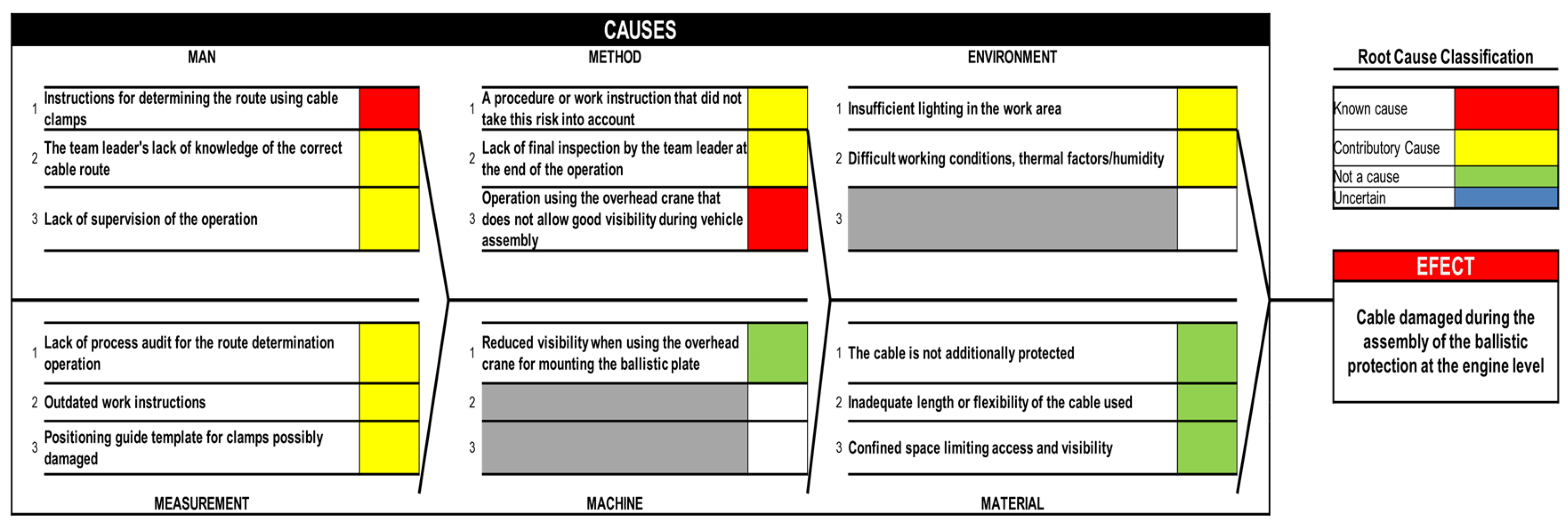

Based on repeated issues observed at the assembly station, such as cable damage during protection plate installation, the team applied the Ishikawa diagram to conduct a structured root-cause analysis. Following this, a 5S implementation plan was developed to reorganize the workstation and eliminate the identified contributing factors. The simulations confirm cycle time and workflow continuity.

The following section details the practical case study conducted on the manual assembly station of military vehicles. This study forms the basis for the application of lean tools (Ishikawa diagram and 5S methodology), validated through simulation. The full methodology and results are expanded in

Section 7 and

Section 8.

4. Analytical Characterization of the Assembly Flow Process

The assembly process operates on a structured five-day work schedule, where each day’s workload is precisely planned and allocated to ensure an efficient and balanced production flow. Each stage of the process is systematically distributed across the five days, optimizing resource utilization and maintaining a consistent workflow. The plan was fully defined following a structured ramp-up period, during which all assembly and pre-assembly times were carefully analyzed, refined, and optimized. This phase involved continuous monitoring, adjustments, and improvements to streamline the workflow, enhance efficiency, and ensure a balanced distribution of tasks throughout the production process. The process is further explained below according to the data given in

Table 1.

To operationalize the five-day observation campaign, data from days one and two (time-and-motion logs) were fitted to parametric or empirical distributions and assigned to the corresponding process blocks as activity durations. Measurements from day three (forklift travel, waiting and blocking) were used to define the route network in WITNESS Horizon Version Release 23.0c (Build 3562) to consider paths with aisle constraints, buffer capacities and priority rules. Meanwhile, day four (tool changes and changeovers) populated the setup matrix with sequence-dependent setup times. Finally, day five was used for baseline calibration and validation (shift calendars, arrivals, and batch sizes) so that the one-week simulated output matched the observed throughput before running the six-week experiments.

4.1. Disassembly of Exterior Components/Installation of Vehicle Roof Components

On the first day (

Table 1, day 1) at the specific station, the vehicle is carefully transported from the previous station to prevent any damage during the move. Once it is in place, the process of disassembling the exterior components begins. This involves removing parts such as the side mirrors, hatch locking mechanisms, side lights, and headlights. Careful attention is given to detach each component without damaging the surrounding structures of the vehicle.

After disassembling all the exterior components, the operators refer to the technical assembly drawings to ensure precision and compliance with the vehicle’s specifications. They carefully examine these drawings to identify every component necessary for the roof installation, including structural parts, fastening elements, and any specific tools required for the task. This step includes a detailed inspection of the inventory to confirm the availability and condition of all parts.

The operators then organize the components in an efficient and accessible manner, ensuring that each part is ready for immediate use during the assembly process. This careful preparation of materials, along with strict adherence to the technical drawings, is crucial for executing the roof installation accurately and meeting both quality and safety standards.

All components are organized in a designated location for reinstallation on the last day before departing to the next station.

4.2. Installation of Engine Protection Components

The next step (

Table 1, day 2) involves the initiation of the second phase of vehicle assembly, specifically the installation of engine protection components. This phase is crucial to ensuring the vehicle’s engine area is adequately shielded from external elements, enhancing both performance and durability. The process begins with the timely delivery of the required components from the warehouse. In this stage, the logistics team plays a vital role, ensuring that all necessary parts are accurately picked, packed, and delivered to the assembly station.

The armour protection components are carefully packed in seven specialized boxes, each labelled according to the specific zone of the vehicle where they will be installed. This organization ensures that each part is easily accessible, minimizing downtime and improving the flow of the assembly process. The boxes are designed to protect the components during transportation, preventing any damage before they are used.

Once the components are delivered to the assembly line, the operators, following detailed assembly instructions, begin the installation process, ensuring that each component is securely fitted to provide maximum protection for the engine area.

4.3. Installation of Side Components Part 1

The third day (

Table 1, day 3) is defined by the start of the assembly of the first layer of side armour on the vehicle. This stage requires three boxes of components, which are delivered by the logistics team from the warehouse. The first step involves assembling the supporting elements for the first layer of armour onto the vehicle. These components are carefully positioned and secured to ensure proper alignment and stability of the armour layer.

Once this initial assembly is completed, the next step is to begin pre-assembling the plates along with their supporting brackets for the second layer of armour. This preparation ensures that all necessary components are ready and organized for a smooth transition into the next phase of the assembly process.

The final stage is carried out with the help of an overhead crane, and it involves the installation of the plates onto the pre-assembled supports. These plates are then secured to the vehicle’s chassis using specific fastening elements. The fastening process is performed at a defined torque, as specified in the technical assembly drawings. To ensure the correct application of force, the assembly is checked using a torque wrench, which verifies that the fastening meets the required specifications. This step ensures that the side armour plates are securely attached to the vehicle, providing optimal protection and meeting all quality and safety standards.

4.4. Installation of Side Components Part 2

On the fourth day (

Table 1, day 4), the installation of the second layer of armour plates takes place. These plates are positioned using an overhead crane and are carefully placed on top of the first layer, which is equipped with fastening elements for this purpose. The plates are then secured in position using the specified fastening components, with the tightening torque being verified through a torque wrench. This step ensures compliance with the prescribed torque values detailed in the technical assembly drawings. By following this process, we guarantee that the second layer of armour is installed correctly, securely fastened, and meets all technical and safety standards outlined in the assembly documentation.

After completing the assembly of the second layer, the next stage is the installation of the aluminum frames that enclose both layers of armour. These frames not only secure the armour layers but also provide the vehicle with a well-defined, finished appearance. The aluminum frames are carefully aligned and mounted onto the vehicle, ensuring that they fit precisely around the armour layers. This step contributes both to the structural integrity of the vehicle and its aesthetic presentation, giving it a robust and polished look.

4.5. Installation of Exterior Components

On the fifth day (

Table 1, day 5), the components disassembled in stage 3.1 are reinstalled, along with exterior components such as optical cameras, masking systems, telecommunications systems, and laser warning systems. This stage involves carefully placing each component back onto the vehicle, ensuring proper alignment and secure connections. The reinstallation process requires attention to detail, as each system must function correctly and be securely integrated into the vehicle’s structure. The components are tested after installation to confirm their functionality, ensuring that all systems, including the optical cameras, telecommunications, and warning systems, are fully operational and meet the required specifications.

5. Methodology—Discrete-Event Simulation

The model was constructed based on input data derived from the analyses and findings presented in the preceding chapters. The assembly flow simulation process follows a defined sequence of phases that are detailed below:

5.1. Problem Definition and Objective Setting

The simulation purpose requires identification. The main simulation objectives are aiming for efficiency and bottleneck identification. Also, in this stage it is important to determine essential performance metrics that consist of cycle-time measurement alongside resource usage and work-in-progress (WIP) quantity monitoring. To do so, we propose to analyze the system’s real-life behaviour, observing its functionality as well as collecting the needed information to replicate the model in Witness Horizon Version Release 23.0c (Build 3562).

In our case study, the primary focus was on identifying the recurrent blocking of the forklift during ballistic plate installation and the inefficient allocation of operator time. The simulation objectives were therefore directly linked to reducing forklift idle-time and blocked states while ensuring a consistent weekly output of one vehicle.

5.2. System Modelling/Conceptual Design

The first step involves creating a basic representation of the assembly flow. This includes:

List of processes carried out through the system (assembly operations, transport facilities).

The material flow trajectory in the system (the components’ movements throughout the system).

Resources (operators, assembly station, forklift).

Constraints (capacity limits, downtime, shift patterns).

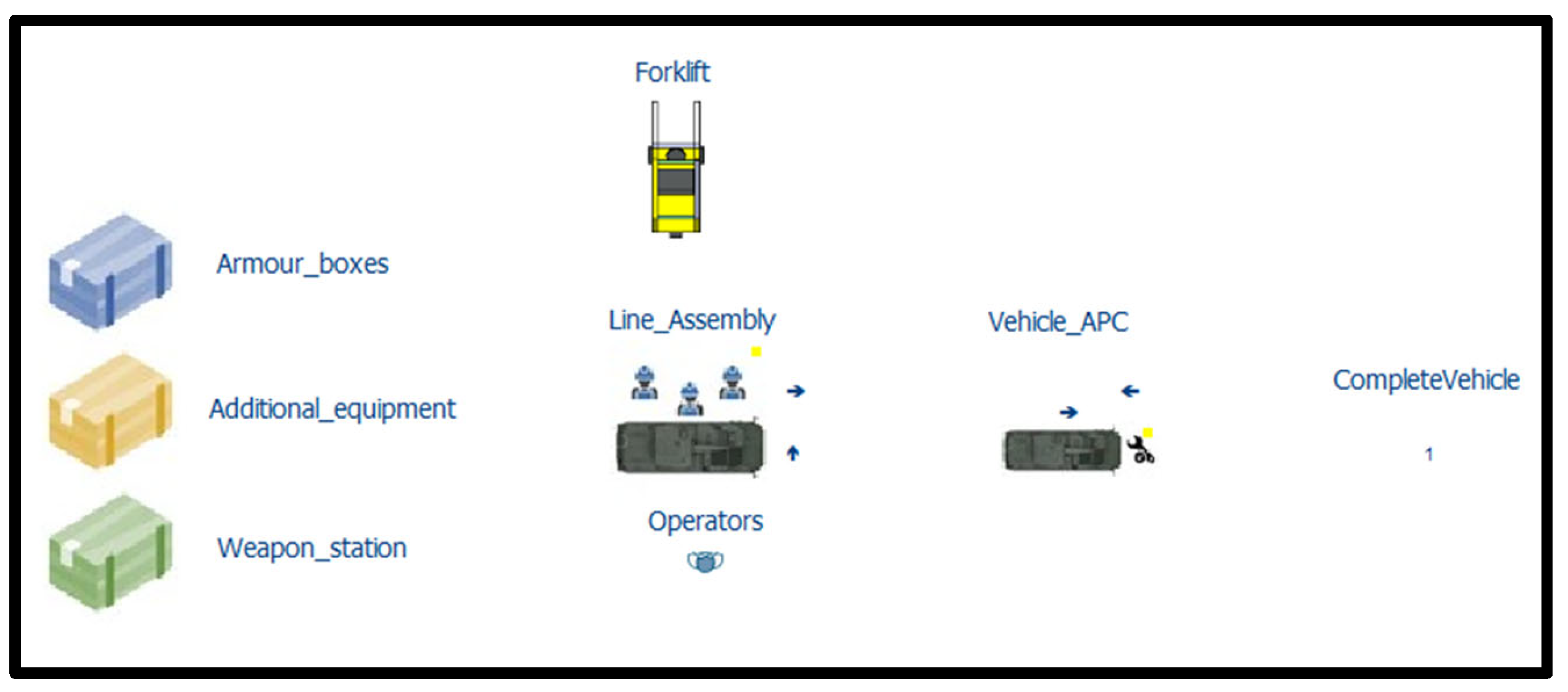

A more detailed explanation of the equipment present in the case study is given in

Table 2. Here we have identified and explained all elements present in the system.

5.3. Data Collection and Input Analysis

The next step is to establish input parameters based on the previous step. The data collection process that we used includes information regarding capacity limits, downtime, shift patterns, cycle times, arrival rates, and batch size of all components.

Data collection from two main sources was necessary to create realistic models. For this study case, we used process sheets (technical documentation present in the assembly line) and direct-time studies (manual timekeeping/chronometry) for data collection.

Specifically, these data were obtained from process sheets provided by the vehicle manufacturer and complemented with direct time-and-motion studies at the manual assembly station. For example, forklift travel times and blocking incidents were logged on-site during day three of the observation campaign.

5.4. The Model Implementation

In this stage, we began to construct the simulation model. The conceptual model was replicated using Witness simulation software.

The system’s dynamic parameters were simulated using discrete-event logic in the model. The simulation model included defined routes as well as events, setups, and resource dependencies. The simulation model included specific programming codes for material transportation systems and processing times.

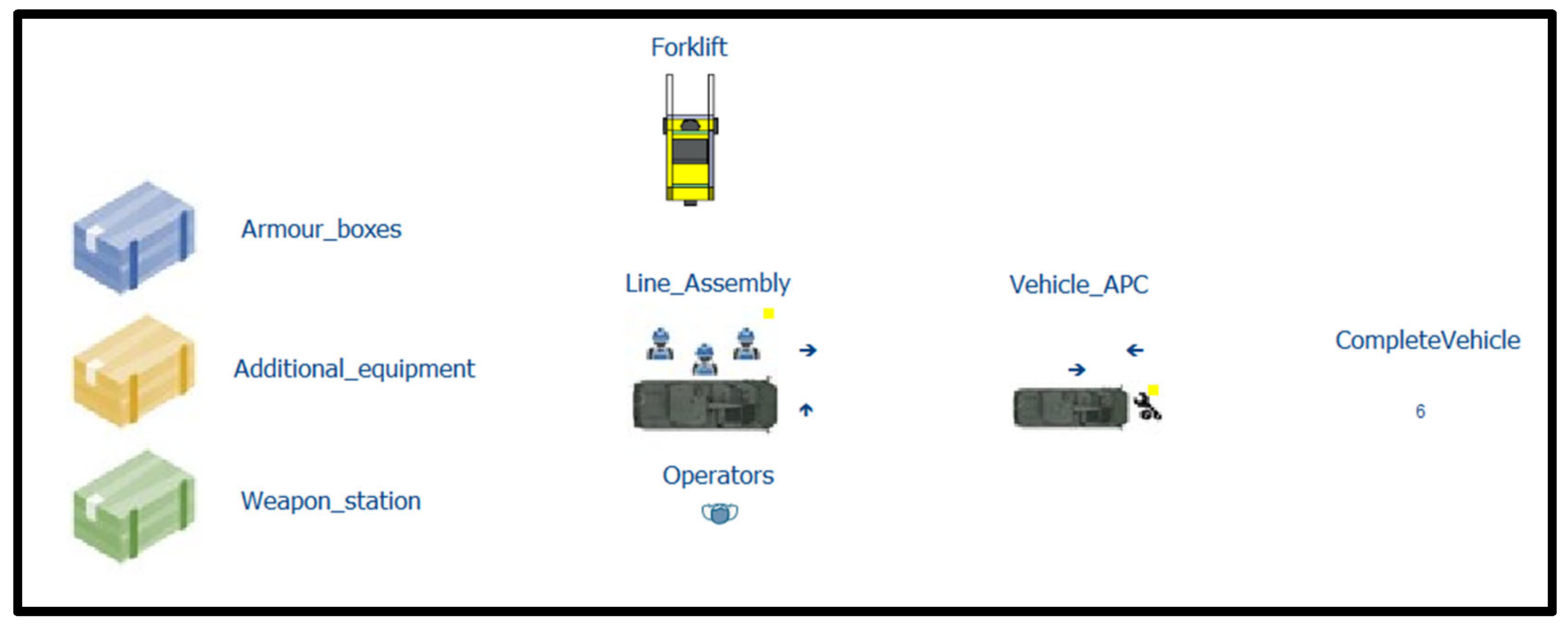

The conceptual model shows the core design elements of the assembly station which the study aims to evaluate. It includes:

Vehicles (final assembled product)

Lots of parts (components required during assembly)

Five operators assigned to specific tasks across shifts

One forklift (for material transport)

The simulation model for our study case uses an 8 h standard shift.

The total weekly operational time is set at 2370 min, which corresponds to the real-life system. The remaining 30 min from the rest of the working hours in a week are allocated for cleaning the workstation and predictable maintenance operations.

The model includes two buffers: Vehicle_APC (Armoured Personnel Carrier) work-in-progress assembly buffer and CompleteVehicle (finished assembly buffer).

For confidentiality reasons specific to the military production domain, not all technical details of the input parameters can be disclosed. Nevertheless, all essential information has been reported to ensure scientific transparency and replicability of the simulation model.

5.5. Verification

The model requires verification to confirm that it operates correctly and follows logical rules. The model needs verification to ensure that part processing operates as expected, along with realistic behaviour of resources and queues.

The verification process made sure that the model functions according to the real-life implemented internal behaviour checks. In this stage, the focus was aimed at reproducing an exact replica of the real-life system in Witness software regarding all involved parameters (time schedule of the workers, assembled parts quantities and their arrival at the assembly station, forklift parameters, etc.) present in our case study.

Verification was performed to confirm that the simulation model was logically coherent and appropriately represented the documented input data. The cycle times, trip times, and resource availability distributions utilized in the model were juxtaposed with those delineated in the process sheets and accessible documentation. Furthermore, the model’s flow logic was validated by systematically tracing components and ensuring that routing, workstation capacity, and resource allocations aligned with the intended process description. This verification phase confirmed the accurate implementation of the simulation model prior to validation and output analysis.

5.6. Validation

Validation in discrete-event simulation is generally accomplished by juxtaposing model outputs with empirical system performance data. In the examined case study, the actual assembly line manufactures one vehicle weekly, equating to roughly 2370 min of manufacturing time. The baseline simulation replicated the identical throughput, validating that the model adequately represents the actual system behaviour.

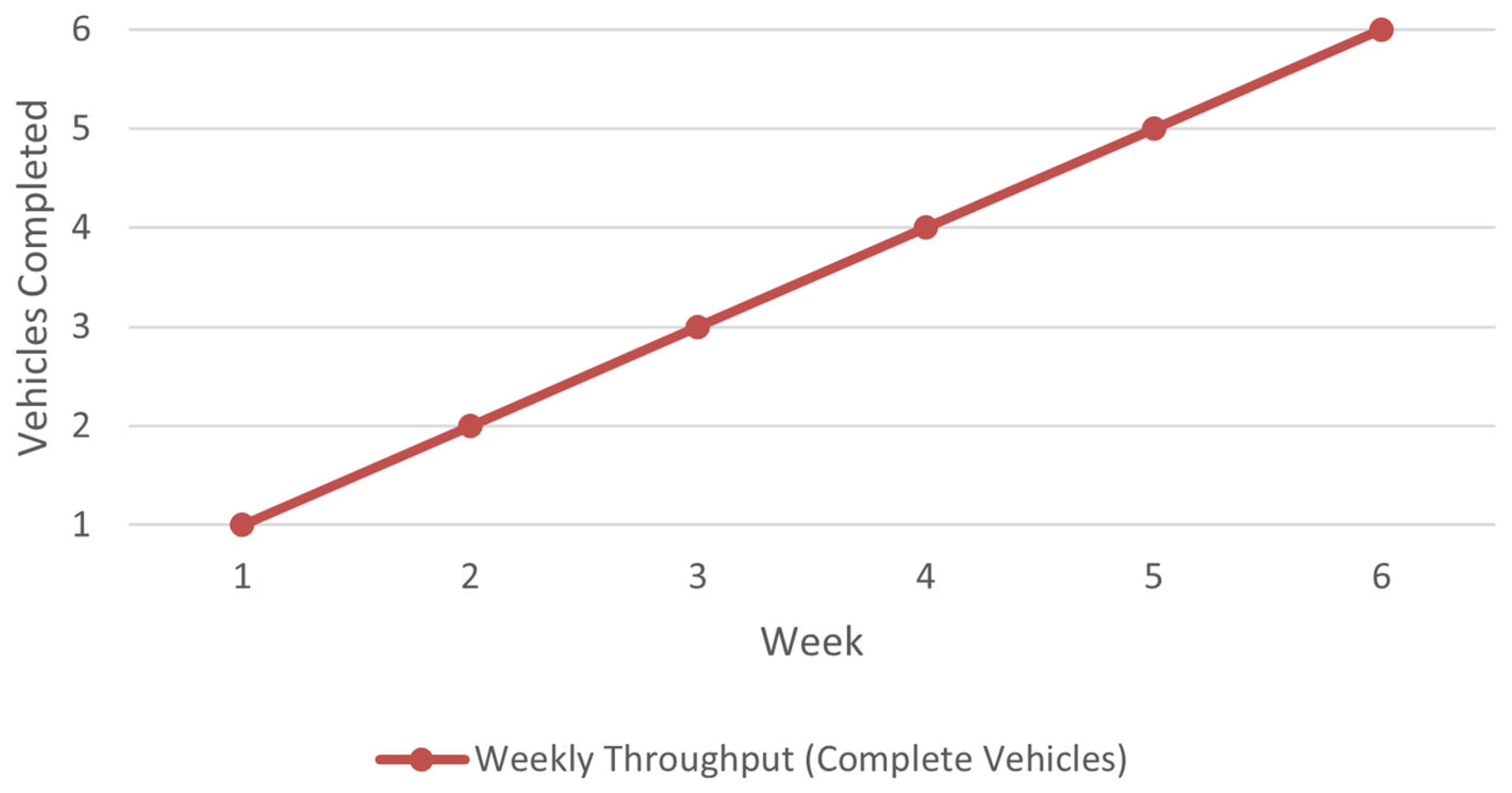

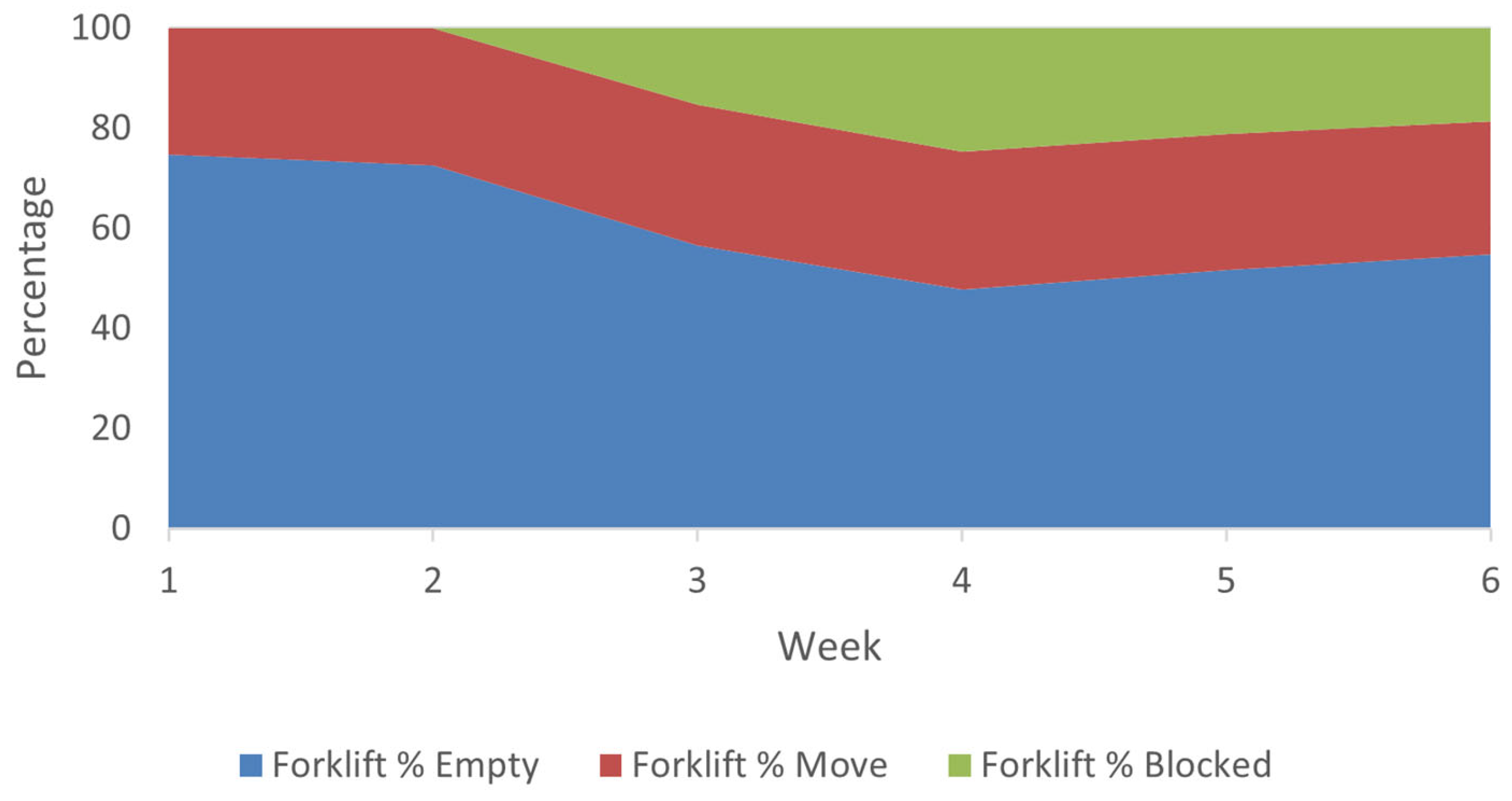

To enhance the validity, the simulation was prolonged for six consecutive weeks.

Table 3 delineates the key performance indicators (KPIs) derived from the simulation, whereas

Figure 2,

Figure 3 and

Figure 4 depict the trends in throughput, line/operator utilization, and forklift performance.

Table 3 demonstrates that the simulation accurately replicated a throughput of one car per week, with line assembly and operator utilization stabilizing at approximately 98–99%. Forklift performance exhibited fluctuation over the weeks, with blocked time fluctuating between 0% and 24.7%. These outcomes corroborate the model with actual production benchmarks.

This alignment between the simulated and actual system performance confirms the validity of the model and provides confidence that subsequent analyses can realistically capture forklift utilization patterns and operator workload distribution.

5.7. Experimentation/Scenario Analysis

We ran two different simulation scenarios to collect data for our case study.

The case study system focused on measuring two primary performance indicators: vehicles per week and lead time in minutes per vehicle as well as resource utilization. Another important element studied in this case study is the forklift delivery times.

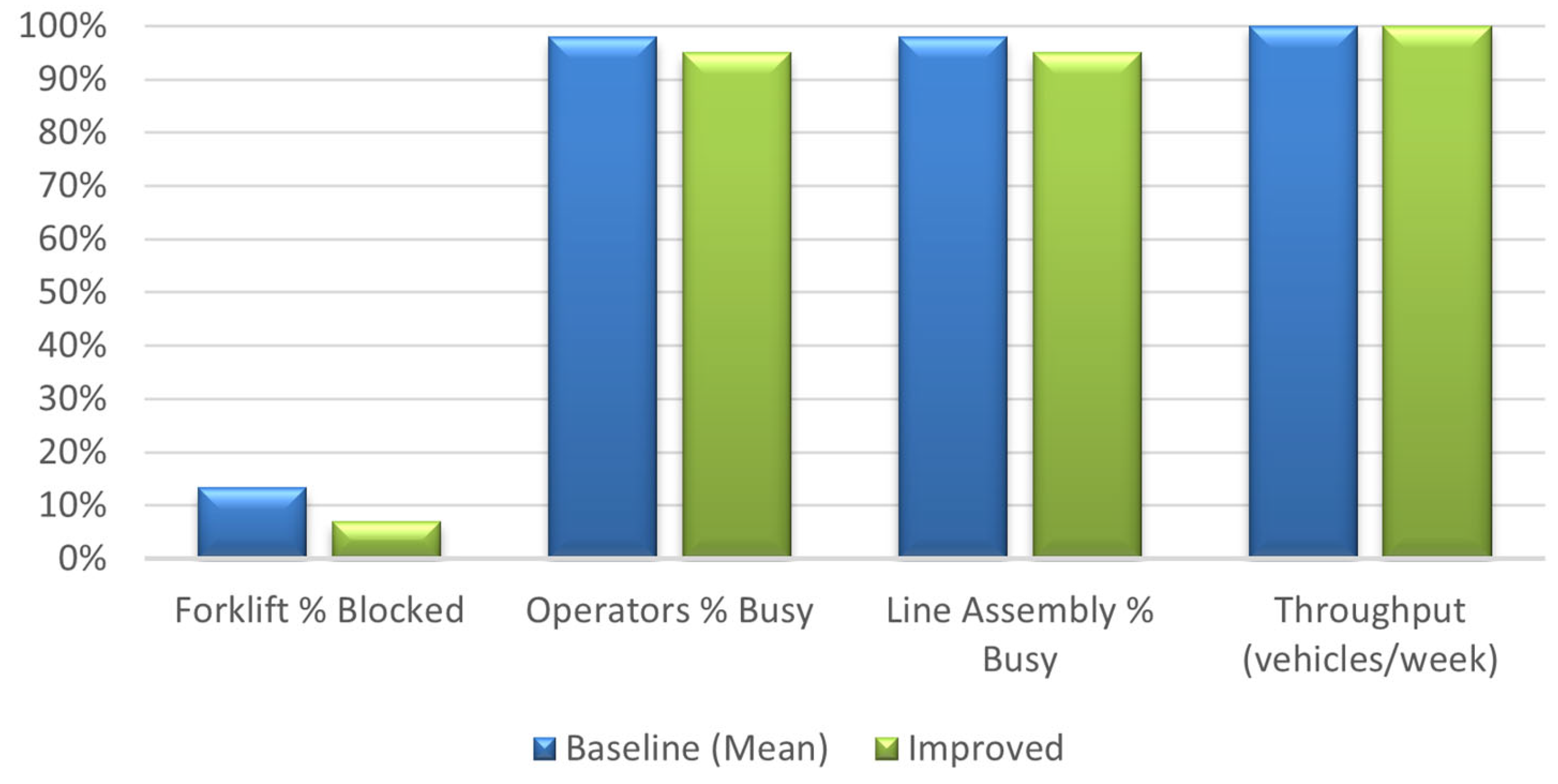

In the baseline scenario, forklift blocked time averaged 13.31% over six simulated weeks (ranging from 0% in weeks one and two to 24.69% in week four), revealing a major efficiency gap. In the improved scenario, which integrates actions derived from the Ishikawa analysis and 5S reorganization, forklift blocked time decreased to 7.00% (47% reduction), while operator utilization remained high and essentially stable (97.94% ± 1.58 → 95.00%), with throughput maintained at one vehicle per week.

5.8. Output Analysis

The analysis of simulation results focusses on identifying the problems or areas that can be improved in the case study system. Basically, the simulation results are looking for bottlenecks, idle times, queue lengths, and throughputs. The focus is to observe areas that are not working at maximum capacity in the case study system.

To quantify variability, weekly results were treated as independent replications and mean and standard deviation (SD) values were computed (

Table 4). Forklift blocked time averaged 13.31% (SD = 10.77%), while line assembly utilization averaged 97.94% (SD = 1.58%). This confirms that the model captures both the expected system behaviour and its variability.

The forklift’s performance varied greatly. The average amount of stopped time was 13.3%, and the standard deviation was very high. This suggests that the forklift’s availability is the main factor that causes changes in the system’s efficiency. These numbers show that even though the assembly process is strong, forklift operations need more tweaking to make them less unpredictable and improve performance.

5.9. Decision-Making

The assembly process requires adjustments based on simulation findings which will guide the process improvements.

In this phase, the best layout configuration will be determined according to production demands in this case study.

5.10. Implementation and Monitoring

The selected modifications will be applied to the actual system.

A digital twin development should begin for ongoing monitoring and future simulation requirements.

All proposed solutions for the present case study should be taken into consideration by the company.

6. Structural Overview of the Assembly Line

To gain a comprehensive understanding of the assembly line in terms of time and processes, a diagram of the entire workflow was created using WITNESS Horizon. This diagram helps identify new opportunities to improve work times, pinpoint bottlenecks, and ultimately select the most effective optimization strategies.

The model starts on Monday at 08:00 and follows the observed shift calendar. We use a one-week baseline (no warm-up) to match the real output of one vehicle/week, then a six-week run with a one-week warm-up to capture medium-term dynamics.

Figure 5 provides a preliminary simulation of the manufacturing architecture modelled and simulated using WITNESS Horizon software.

During the manufacturing process, specific work points were established for each operation required to produce the vehicle. To determine clear production capacity values for a work week consisting of one shift per day, with each shift lasting eight hours, a simulation was conducted. The total duration of this simulation for the assembly architecture was 2370 min.

Following the simulation of assembly architecture, the result was obtained, which can be visualized below.

Figure 6 illustrates the assembly line work time, marked in green to indicate 95% efficiency for the week. Variations due to operator breaks are highlighted in yellow.

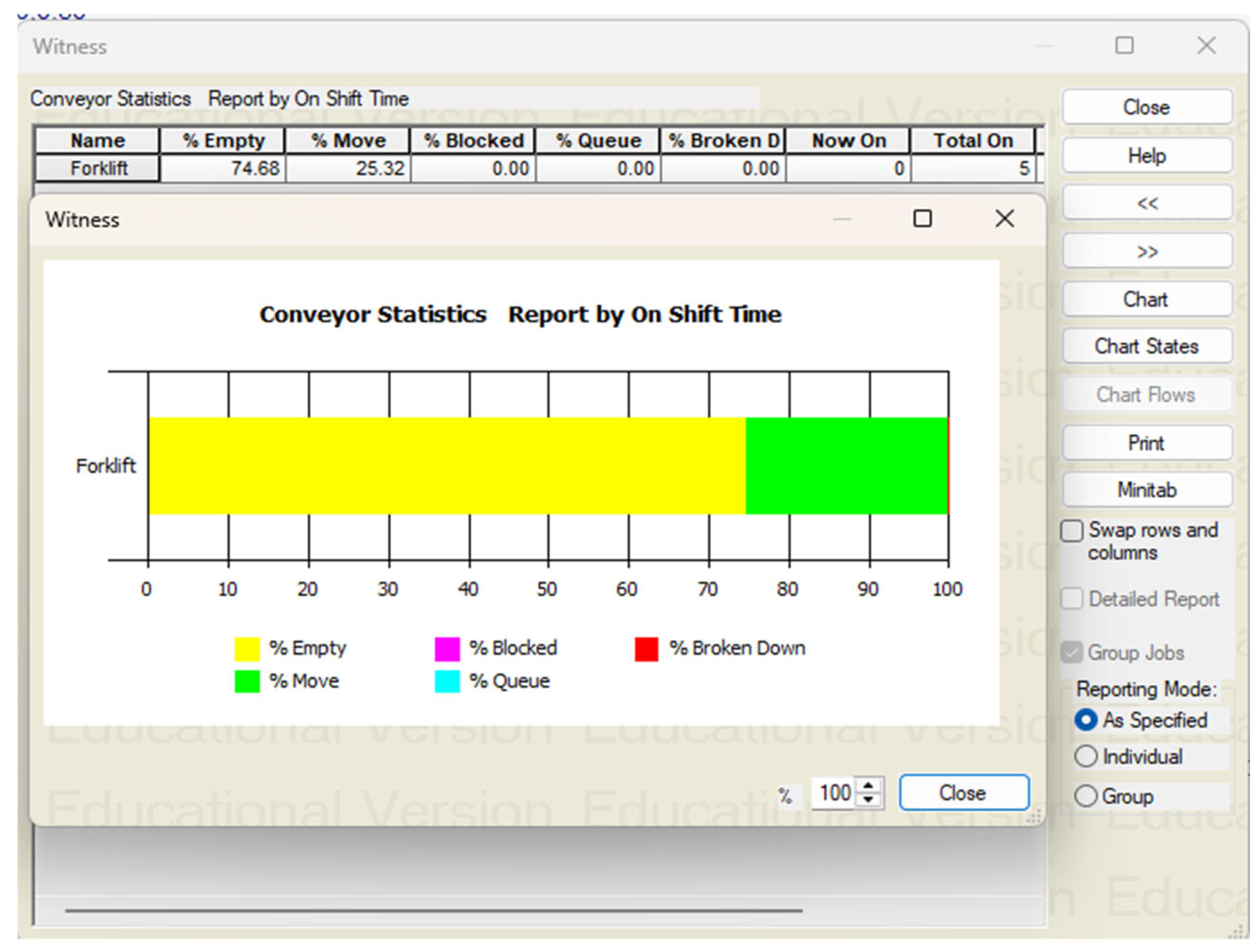

Figure 7 illustrates the operating percentage of the forklift specifically for this workstation. It is utilized to transport all the parts needed to complete the vehicle from the warehouse to the assembly line. The forklift’s usage at this station is 25% of the working time.

Figure 8 presents a graphical representation of the percentage of labour work. The green colour vividly highlights that an impressive 95% of the time is dedicated to effective work, signifying our commitment to productivity, while the remaining 5% is allocated for essential breaks to recharge and maintain focus.

7. Assembly Flow Simulation: A Six-Week Study

In this phase of the simulation, two different scenarios were compared: one where the simulation is conducted over a one-week period and another where it lasts for six weeks. In

Figure 9, one can see the behaviour of the simulated system after a period of six weeks.

In the first scenario, one vehicle per week is produced, which corresponds to a total of 2370 min allocated for the assembly process at this workstation. This data can be found in the previous section, where relevant tables for the simulation are presented.

While

Figure 3 illustrates the baseline weekly throughput (CompleteVehicle = 1),

Figure 7 confirms that after six weeks of continuous simulation the productivity remains stable at one vehicle per week (CompleteVehicle = 6), thereby validating the model over a longer horizon.

Through a comprehensive six-week simulation, six vehicles were produced, maintaining an efficient pace of one vehicle per week. The main change was regarding the efficiency of the forklift.

While blocked time increased in week six (18.72%), as you can see in

Figure 10, the six-week average was 13.31% with significant variability, as detailed in

Section 5.

Table 5 points out that there still is a lot of unused time in this element. To reduce the blockage phase or to minimize this percentage, more optimization solutions will need to be applied to ensure a constant workload and a continuous improvement of the workspace.

The higher blocked time in week six reflects the variability observed across the simulation horizon. The average amount of delayed time over the six weeks was 13.31% (SD = 10.77%), which suggests that the forklift’s inefficiency changes depending on the amount of work that needs to be done.

Table 6 shows how Ishikawa and 5S, two lean tools, affect performance. The amount of time that the forklift was stopped dropped sharply, from 13.31% to 7.00%, which means that blocking time dropped by 47%. The fact that the processes worked to make the forklift work more smoothly shows that they were effective. At the same time, both the Operators % Busy and Line Assembly % Busy metrics stayed stable, around 95% to 99%, showing that the change in workflow did not have a negative effect on either human or line efficiency. The throughput stayed at one vehicle per week, which showed that the improvements were mostly about reducing variation and making the best use of resources without lowering total capacity.

The comparison chart in

Figure 11 makes the effect of Ishikawa and 5S lean tools on system performance very clear. The bars that show operator and line usage do not change much, which means that the workforce and assembly-line efficiency stayed the same even though the order was changed. The output stays the same in both cases, at one car per week. This shows that the steps taken increased efficiency and decreased uncertainty without changing the manufacturing capacity.

We also converted forklift states into absolute time per week:

For the six consecutive weeks, the blocked time of the forklift was approximately 0, 0, 360, 585, 504, and 444 min, respectively. This quantifies the operational impact behind the percentages (0–24.7% across weeks) and pinpoints when blocking episodes become critical for station performance.

To significantly enhance our operations, one should consider implementing an AGV (Automated Guided Vehicle) system alongside a barcode system. This will empower the logistics team to efficiently verify that all materials have been used, ensuring optimal resource management and timely refills for the production line.

By adopting these technologies, one can streamline the processes and drive greater productivity. Implementing a barcode system can significantly minimize the blocked time segment by providing real-time access to critical information about stocks and materials. This technology is a proven solution widely adopted in the industry, enhancing efficiency and accuracy in inventory management.

8. Application of Lean Tools: Root-Cause Analysis and 5S Methodology

To identify and eliminate performance inefficiencies at the manual assembly station for military vehicles, a structured approach based on lean management tools was employed. Two key methodologies were used: the Ishikawa (fishbone) diagram for root-cause analysis and the 5S framework for workspace optimization.

The inefficiencies identified in previous sections are directly addressed by the deployment of lean methods in this section through simulation analysis. The baseline model was established in

Section 5,

Section 6 and

Section 7, and it was validated with empirical data. Performance deficiencies, such as forklift blocking time and operator burden distribution, were quantified. The Ishikawa diagram and 5S methodology are presented in

Section 8 as systematic strategies for eliminating the underlying causes of these inefficiencies. As a result,

Section 8 represents the practical implementation phase of the issues that were identified in previous assessments.

8.1. Root-Cause Analysis with Ishikawa Diagram

The Ishikawa diagram functions as an organized visual system which helps teams discover the different elements that lead to specific outcomes [

16]. The “fishbone diagram” name comes from its fish-like shape while the “cause-and-effect diagram” term emerges from its focus on identifying causes behind specific effects.

The complete Ishikawa diagram is presented in

Figure 12, summarizing the key findings and their categorization.

The Ishikawa diagram was utilized to systematically explore potential causes for recurring inefficiencies and quality issues. Each problem category was analyzed according to the six major factors: Man, Method, Machine, Measurement, Environment, and Material.

Man: Lack of adherence to work instructions, insufficient training, and poor quality verification practices were identified. Team leader intervention and scheduled audits were introduced to mitigate these.

Method: Problems included unclear instructions and poor visibility due to crane operation. Solutions involved updating standard operating procedures and introducing verification checkpoints.

Machine: Minimal machine involvement due to the manual nature of the station meant few issues were identified. Most problems were classified as “not a cause”.

Measurement: Key issues involved misaligned templates and inconsistent verification processes. Five inspections per vehicle were implemented for standardization.

Environment: Poor lighting and high heat/moisture levels were identified. Lumen measurements and environmental audits were initiated to improve working conditions.

Material: Material rigidity and constrained installation spaces led to improper cable routing. Design reviews and cable protection strategies were proposed.

The primary sections in the diagram allow teams to identify additional detailed factors which contribute to the fundamental issue. This branching structure enables teams to visually break down complex issues into smaller, more manageable components. The systematic evaluation of these potential causes enables organizations to recognize patterns while discovering fundamental causes that lead to the development of specific solutions.

The Ishikawa diagram serves both problem-solving needs and predictive capabilities for identifying potential issues during proactive planning. The tool enables team collaboration with critical thinking abilities, making it an essential tool for continuous improvement work and decision-making.

The main problem arose from a cable that suffered damage because an armour plate was needed for engine zone protection. The assembly space between the plate and vehicle remains narrow, thus requiring close attention to the cable installation. Each problem receives classification based on its root cause, which shows its essential importance. We organize multiple problems inside the Ishikawa structure to establish a systematic investigation, which results in finding solutions to stop this issue from occurring in future vehicles.

As you can see in

Table 7, we found three main problems in the “Man” section that can be solved through work instruction review and checkpoint implementation. The team leader who ensures quality in their work area must perform these important tasks.

The “Methods” category contains details about particular operational and procedural difficulties which arose during vehicle assembly. The table shows problems with assembly methods such as inadequate work instructions and poor visibility from crane operations and proposes necessary investigative steps. The team leader must analyze current instructions while adding verification points and evaluate alternative work procedures to enhance both safety and visibility. The table serves two main purposes: it helps identify weaknesses in current procedures and it guides assembly process improvements.

The “Environment” category in the root-cause analysis table requires organizations to identify factors which affect both workplace performance and safety. The document describes two particular problems that include insufficient lighting throughout the workspace as well as difficult working conditions because of heat and moisture. The table contains investigations for both lumen meter measurements to check lighting standards and assessments of thermal discomfort effects on employee productivity. The tool serves to perform a systematic evaluation of environmental factors and their impact on operational quality.

We identified three essential problems in the measurement section which require focused audits during the assembly procedure for resolution. The established work instructions, when strictly followed, will stop these fundamental problems from happening again, which results in better operational quality and efficiency. We will perform process audits five times for each vehicle to guarantee complete understanding of instructions from the station responsible. The individual will conduct a check of the template’s condition to verify its state of repair.

The last two sections analyze machine and material issues, through which we determined that all problems derive from “not a cause” because of their fundamental root causes. The manual nature of most of our production made it difficult to identify machine-related problems. Our thorough examination revealed only one issue that met the criteria for “not a cause”, thus highlighting the complex nature of handmade production while showing our dedication to detailed analysis. We found three material problems in the concluding section that also fit the “not a cause” classification. The constrained space between the plate and the vehicle played a major role in determining this classification. The protection of cables requires immediate attention although it could potentially limit their flexibility. Our production process demonstrates a balanced commitment to product quality as well as reliability because of this complex understanding.

8.2. Implementation of 5S Methodology

To support the improvements identified through the Ishikawa analysis, the 5S methodology was applied to the assembly station layout and operations. The following steps were executed:

Sort (Seiri): All nonessential tools and materials were removed from the workspace to reduce clutter.

Set in Order (Seiton): Frequently used tools were organized using visual management aids. Yellow and blue markings were applied to indicate optimal storage positions and equipment zones.

Shine (Seiso): A comprehensive cleaning protocol was introduced. Regular maintenance checks were scheduled to maintain cleanliness and detect wear.

Standardize (Seiketsu): New work standards and cleaning procedures were documented. Visual guides and instructions were added to ensure uniformity.

Sustain (Shitsuke): A training programme and internal audit system were established to ensure continued adherence and discipline.

The assembly station received a new layout according to 5S methodologies which improved operational efficiency and streamlined production processes [

17]. The first step involved removing all nonessential items from the workspace, followed by the selection of fundamental tools and materials needed for assembly operations. The elimination of unnecessary items and redundant components transformed the workspace into a more organized and efficient area.

The remaining tools and materials received organized placement to achieve fast access and reduce movement. The layout in

Figure 1 demonstrates the setup through yellow and blue square markings. The placement of essential items near operators reduced their need to move excessively while saving time. The blue-filled square in the layout figure represents the optimized area, which provides operators with all necessary materials needed to finish assembly work. The green-filled square marks the designated parking space for vehicles needed during assembly operations.

A complete cleaning operation followed inspection to create a safe environment that maintained workplace pleasantness [

18]. The team established a scheduled maintenance programme to preserve this standard and detect problems before they become major issues.

Standard operating procedures received documentation to guarantee uniformity in maintaining workstation organization and cleanliness. Visual aids consisting of labels, outlines, and instructions were implemented to support these standards while making it simple for any team member to follow.

The team established routines together with defined responsibilities to maintain improvements over time. The team received ongoing training and regular audits to develop discipline and accountability while maintaining continuous improvement.

8.3. Correlation with Simulation Results

The application of the Ishikawa and 5S methodologies directly contributed to measurable improvements in both the simulation outcomes generated with WITNESS Horizon and the operational data collected at the workstation. To ensure clarity, the results reported below distinguish between simulation-derived indicators and on-site operational observations.

Table 8 presents a consolidated view of both simulation-derived indicators and operational observations before and after the application of Ishikawa and 5S. In the baseline scenario, values are presented as mean ± SD across six simulated weeks, assuring statistical rigour. In the enhanced scenario, the findings reflect the mean values derived from the six-week improved run; standard deviations are omitted due to the availability of only a single duplicated dataset. The simulation results are further substantiated, and the tangible effects of lean implementation are underscored using operational data such as cable damage events and material search duration.

From the simulation’s perspective, forklift blocked time decreased from an average of 13.31% (SD = 10.77) across six simulated weeks to 7.00% in the improved scenario, a 47% reduction, while throughput remained at one vehicle per week. Operator utilization was 97.94% (SD = 1.58) in the baseline and 95.00% in the improved scenario. Given the unchanged throughput, this slight decrease indicates a more balanced operator load rather than a loss of productivity. Baseline values are reported as mean ± SD over six weeks to capture variability; for the improved scenario we report mean values from the six-week run (SD where only one replicated dataset is available).

Operational measurements corroborate the simulation: cable damage incidents dropped from 3/week to 0/week, and material search time decreased from ~5 min/task to <1 min/task (~80% reduction). These field results validate that the lean interventions translated into practical shop-floor gains beyond the simulated effects.

These findings demonstrate that the integration of lean tools provides a practical foundation for implementing and validating digital optimization strategies. The combination of structured root-cause analysis and physical workspace improvements established a reliable framework for sustained operational excellence.

9. Conclusions

The proposed methodology provides a replicable framework for high-reliability environments, contributing both theoretically and practically to the domains of lean manufacturing and digital twin optimization. This research addresses the critical challenge of optimizing a production line station, achieving enhanced operational efficiency, cost reduction, and improved product quality. By leveraging advanced virtual simulation tools, the study has moved beyond traditional static analysis, employing dynamic modelling to accurately reflect the complexities and variances of real-world production scenarios. This approach successfully uncovers performance bottlenecks, inefficiencies, and suboptimal workflows that often remain undetected in conventional analyses.

The use of the Ishikawa diagram facilitated a systematic root-cause analysis to identify factors contributing to inefficiencies. The implementation of the 5S methodology significantly improved workplace organization, cleanliness, and process standardization, thereby fostering a disciplined environment that enhances both efficiency and safety. The case study highlights the effective application of Ishikawa analysis and the 5S methodology, validated through dynamic simulations in WITNESS Horizon, which collectively improved assembly station performance by addressing root causes and optimizing workspace layout. Conducted at a military vehicle assembly station, this research demonstrates the symbiotic relationship between root-cause analysis and lean practices, reinforced by simulation-based validation.

An innovative aspect of the research is the integration of real-time performance tracking systems with adaptive feedback mechanisms. This continuous monitoring framework enabled teams to implement incremental improvements by analyzing key performance metrics, such as cycle time, equipment utilization, and defect rates. Data-driven insights facilitated change validation through iterative evaluation cycles, resulting in quantifiable enhancements in efficiency, quality, and responsiveness.

The optimized system achieved notable reductions in operational downtime and waste minimization, enabling sustainable, scalable manufacturing operations. The findings underscore that combining simulation-based insights with lean management principles establishes a robust methodology for enhancing contemporary production systems. The research establishes a transferable framework applicable to various industrial contexts, particularly for high-mix, high-reliability manufacturing operations. It illustrates how digital tools can be effectively integrated with continuous improvement strategies to foster agile, resilient production systems that consistently outperform traditional methods.

This study significantly contributes to industrial engineering and production optimization by demonstrating the collaborative impact of technological innovation and lean methodologies on transforming manufacturing practices. The successful integration of virtual simulation tools with lean principles and systematic performance tracking has proven effective in enhancing operational efficiency in manual assembly within the military vehicle sector. A comprehensive assessment of current production processes, coupled with WITNESS Horizon dynamic modelling, provided a data-driven approach to pinpoint inefficiencies and evaluate the effects of interventions.

Implementing lean tools, such as the 5S methodology and Ishikawa analysis, allowed for a structured examination of waste sources and workflow disruptions, leading to targeted and effective solutions. The six-week comparative study confirmed that comprehensive operational enhancements necessitate ongoing monitoring and adaptive strategies focused on optimizing material flow, labour distribution, and equipment utilization. Incorporating barcode tracking and AGV systems fosters semi-automated operations, yielding improved transparency, responsiveness, and inventory control in high-mix, low-volume manufacturing settings.

The implications of the study extend beyond the specific case analysis, indicating the necessity for an integrated approach in manufacturing system design that marries human-centred design principles with cutting-edge digital technologies. The established framework not only caters to defence manufacturing applications but also shows promise for utilization across diverse high-precision sectors demanding both flexibility and operational efficiency without compromising quality standards. This research contributes a validated station-level optimization framework that combines discrete-event simulation with lean quality tools (Ishikawa and 5S) and real-time monitoring concepts to improve a manual assembly station for military vehicles. The DES model was verified and validated against a one-week baseline (2370 min per week/shift pattern) delivering one vehicle per week, providing a reliable reference for experimentation. Over a six-week horizon, the model revealed dynamic effects—most notably forklift blocking averaging 13.31% of working time (SD = 10.77) and peaking at 24.69% in week four—on constraints that are not visible in single-week analyses. Implementing the Ishikawa findings and 5S-driven layout changes in both the model and at the workstation yielded measurable improvements: cable-damage incidents were eliminated (3/week → 0/week), forklift blocked time decreased from 13.31% to 7.00% (47% reduction), operator utilization remained high and stable (97.94% → 95.00%) with throughput maintained at one vehicle per week, and material search time dropped from ~5 min/task to <1 min/task. Finally, these insights were translated into implementable logistics upgrades—barcode-enabled material control and AGV assistance—and a transferable workflow for high-mix, high-reliability manufacturing, linking statistically characterized simulation evidence with pragmatic operational change.

The research demonstrates how continuous improvement requires both practical and academic collaboration for production system optimization through technological integration. Research should investigate automation’s long-term effects, data analytics implementation, and Industry 4.0 principles to boost operational resilience. The findings demonstrate that a manufacturing strategy supported by digital technology and thoughtful engineering can achieve excellence in contemporary industrial practices.

Managerial Implications and Future Work

This research offers crucial insights for industrial managers seeking to implement lean methodologies enhanced by digital technologies. The structured methodology illustrates how conducting root-cause analysis and reorganizing the workspace can significantly influence key performance indicators, including downtime, quality control issues, and material flow efficiency.

Future investigations could explore the advantages of incorporating artificial intelligence and predictive analytics to bolster system adaptability and enhance decision-making capabilities. Upcoming initiatives may focus on deploying AI systems for real-time monitoring of workstation activities, along with predictive analytics for early detection of potential inefficiencies.

The validated framework has potential applicability beyond traditional manufacturing, extending to semi-automated production lines and sectors with high customization demands, such as aerospace and rail manufacturing. To ensure the sustainability of a real-time monitoring framework, it is essential to propose a flexible data collection system that enables on-the-ground decision-making while navigating the limitations imposed by fixed optimization models.