1. Introduction

Meat products remain among the most consumed foods worldwide, with comminuted formulations such as beef and poultry patties occupying a central role in everyday diets. However, traditional meat alone cannot fully meet dietary needs for fiber, vitamins, and certain bioactive compounds, motivating the incorporation of plant-based ingredients to enhance nutritional quality [

1,

2]. Cereals are rich in starch, non-starch polysaccharides, vitamins C and E, β carotene, bioflavonoids, polyunsaturated fatty acids, and essential minerals (e.g., potassium, magnesium, manganese) [

3,

4]. This nutrient profile confers both functional and health benefits. Blending animal and plant proteins enables complementary functional improvements in meat systems. In particular, oats contribute β-glucans that enhance gelation and viscosity, buckwheat proteins improve water- and fat-binding capacity, rice provides starch for emulsion stability, and corn supplies carotenoids and dietary fiber that strengthen antioxidant activity and texture. Therefore, the development of hybrid meat–plant formulations represents a promising strategy to increase the nutritional density and functional performance of meat products [

5,

6].

This approach requires selecting plant ingredients that both enhance the nutritional profile and improve the functional properties of the meat matrix. Consequently, four widely available cereals, rice, buckwheat, oats, and corn, were chosen for their complementary nutritional compositions and techno-functional characteristics. Rice is a readily digestible carbohydrate source. It supplies B vitamins and minerals such as magnesium and potassium, which are essential for energy metabolism, nervous system regulation, and electrolyte balance [

7]. Buckwheat provides high-quality protein rich in essential amino acids and abundant iron. Its low glycemic index also supports stable blood sugar control [

8,

9]. Oats deliver significant dietary fiber and B vitamins, support gastrointestinal health, and contribute β-glucans for cholesterol regulation. They further supply bone-supporting minerals such as magnesium and phosphorus [

10,

11]. Corn offers additional carbohydrates, provitamin A, and B complex vitamins, along with minerals including magnesium, potassium, and phosphorus. It contains antioxidant phytochemicals that protect cellular integrity and promote intestinal motility [

12].

Recent research into plant-fortified meat products consistently demonstrates that inclusion of cereal ingredients in a reasonable proportion can enhance both the functional and sensory qualities of the product without compromising its acceptability. Yessengaziyeva et al. showed that adding 6–8% hydrated buckwheat flour to semi-smoked sausage increased moisture binding capacity by up to 1.8% and maintained texture and flavor, highlighting the value of optimized dosing and rigorous sensorial evaluation [

13]. Podvalova et al. reported that 18% corn rice flour blends improved water holding and textural parameters in poultry mince while limiting lipid oxidation during frozen storage, underscoring the importance of stability metrics [

14]. In hybrid chicken gels, Kim et al. demonstrated that 20% rice, pea, or soy isolates differentially influenced gel strength and cooking stability, with soy yielding the strongest network and rice the most elastic [

15]. Similarly, Nikitin et al. identified a 9% amaranth flour inclusion as optimal for gel formation and sensory quality [

16].

Building on these findings, the strategic combination of multiple grains is expected to produce a synergistic effect: cereal-derived carbohydrates from rice and corn supply rapid energy, buckwheat proteins enhance structural and textural properties, and oat and corn fibers stabilize water and fat binding while supporting digestive health. Consequently, this multigrain formulation is anticipated to yield a meat product with a balanced macro- and micronutrient composition, superior functional performance during processing, and elevated nutritional and sensory quality for health-oriented consumers [

17,

18].

The objective of this study was to evaluate the effects of incorporating a multicomponent cereal blend (rice, buckwheat, oats, and corn) at varying inclusion levels (0–15%) on the chemical composition, functional and technological properties, oxidative and hydrolytic stability, and sensory quality of comminuted meat patties. This multicomponent cereal blend was formulated to combine complementary attributes: rice contributes to emulsion stability, buckwheat enhances protein functionality, oats improve water retention and gel strength, and corn provides antioxidants, together highlighting the synergistic potential of cereal combinations in meat systems.

The research hypothesis was that supplementation with the cereal blend would improve the functional and technological properties of meat patties (e.g., water and fat retention, oxidative stability, and sensory quality) without negatively affecting processing compatibility.

2. Materials and Methods

2.1. Samples

Rice, buckwheat, oats and corn were purchased from a regional retail chain (ADAL Supermarket, Semey, Kazakhstan). Beef cuts (M. semimembranosus) and turkey meat were purchased from a local meat market. Turkey thigh meat was used as the poultry component in the formulation. Thigh muscles were selected due to their higher myoglobin and fat content compared with breast meat, which supports juiciness, flavor development, and improved texture in comminuted products. Only fresh, chilled meat (pH 5.8–6.0, no visible defects, within 24 h postmortem) was used to ensure consistent quality.

2.2. Preparation of the Multicomponent Cereal Supplement

The multicomponent cereal supplement was prepared by first cleaning whole grains of rice (35%), buckwheat (20%), oats (20%), and corn (25%) through sequential sieving, air aspiration, and magnetic separation to remove foreign matter. Each grain fraction then underwent hydrothermal treatment—rice at a 1:2 (

w/

v) ratio for 40 min, buckwheat at 1:1 for 30 min, oats at 1:3 for 90 min, and corn at 1:3 for 60 min—at 60–70 °C to promote starch gelatinization and facilitate dehulling. The treated grains were mechanically dehulled, dried in a convective dryer at 50–60 °C to 13–14% moisture, and equilibrated at ambient temperature (18–20 °C) for 90–120 min. Dehulled cereals were used to improve digestibility, enhance nutrient bioavailability, and avoid undesirable bitterness or coarse texture from the hulls. The cooled grains were milled through a hammer mill and sieved to a 325–400 µm particle size, after which the individual fractions were blended in their respective proportions for 10 min in a ribbon mixer [

19].

2.3. Production of Meat Patties

Raw beef and turkey meat were manually deboned and trimmed to remove visible tendons and connective tissue to ensure homogeneity in texture (

Table 1). The trimmed meat was weighed according to the desired formulation and cut into smaller pieces suitable for grinding. Meat was ground using a tabletop meat grinder equipped with a 3 mm perforated plate to achieve a fine, uniform particle size.

The ground meat was then combined with non-meat ingredients (including cereal supplement), pre-weighed spices, and chilled water. All components were loaded into a laboratory meat mixer and mixed thoroughly for 3–5 min to obtain a uniform forcemeat with cohesive binding properties.

Forming of patties was performed using the IPCS-123M patty-forming machine (Elf 4M, Moscow, Russia). The forcemeat was shaped into oval patties with a uniform thickness of 2.0–2.5 cm (

Figure 1). Formed patties were placed onto baking trays lined with parchment paper.

Cooking was conducted in a preheated convection oven at 190 °C for 30–40 min. Patties were considered fully cooked when they reached an internal temperature of at least 75 °C and developed a golden-brown crust. All samples were cooled to room temperature before subsequent analytical procedures. A total of 40 meat patties were prepared, with 10 patties produced for each of the four formulation variants. From each variant, a minimum of five patties were randomly selected and used for physicochemical, functional, oxidative, and sensory analyses, ensuring replication and statistical reliability.

2.4. Determination of Chemical Composition

To determine moisture, the samples were dried in a drying oven, and moisture was calculated according to the national standard GOST R 51479-99 [

20]. Crude protein was quantified using the Kjeldahl procedure [

21], whereby approximately 2 g of homogenized sample was digested with concentrated sulfuric acid in the presence of a copper catalyst and potassium sulfate to raise boiling temperature. The digest was rendered alkaline, and ammonia distilled into boric acid, followed by back-titration with standardized hydrochloric acid. The resulting total Kjeldahl nitrogen was multiplied by a factor of 6.25 (standard for meat and meat products) to calculate protein content.

Total crude fat was determined following [

22], which includes acid hydrolysis to liberate bound lipids, followed by hot solvent extraction (petroleum ether or diethyl ether) in Soxhlet apparatus. The extracted fat was dried to constant weight and gravimetrically quantified as a percentage of sample mass.

Ash content was measured according to [

23] by placing 2 g of the homogenized sample into a pre-ignited and pre-weighed porcelain crucible. The crucible was placed into a muffle furnace ramped to 600 °C and held for 2 h. After cooling in a desiccator, the residue was weighed to the nearest 0.01 g, and ash percentage calculated as (residue mass ÷ sample mass) × 100%.

2.5. Determination of Fiber Content

The content of dietary fiber in the product was determined using the gravimetric method as outlined in GOST R 54014-2010 [

24]. This involved enzymatic hydrolysis of starch and non-starch components using α-amylase, protease, and amyloglucosidase, breaking them down into mono-, di-, and oligosaccharides, as well as peptides. Dietary fiber was then precipitated with ethanol, dried, and measured gravimetrically. The analyses were conducted using the Velp FIWE-3 fiber analyzer (“VELP”, Usmate, Italy). The total dietary fiber content was expressed as a percentage (g/100 g).

2.6. Determination of β-Carotene Content

The method involved extracting carotenoids from a precipitate obtained by treating the sample with Carrez I and Carrez II solutions. The extracted carotenoids were then purified using petroleum ether, followed by spectrophotometric analysis to determine the mass concentration of β-carotene [

25]. For the spectrometric determination of total carotenoids, the extract was analyzed using a spectrophotometer SF-56 (OKB Spectr, Saint Petersburg, Russia) at a wavelength of 450 nm, with optical glass cuvettes and an optical path length of 1 cm. Petroleum ether was used as the reference solution.

The mass concentration of carotenoids

C, mg/dm

3, is calculated by Formula (1):

where 4.0—the optical density conversion factor;

A—measured optical density value;

F—dilution factor (ratio of extract volume in petroleum ether, or volumes of different fractions to the volume of sample taken for analysis).

2.7. Determination of Amino Acid Composition

The amino acid composition was analyzed using a SHIMADZU LC-20 Prominence HPLC system (Kyoto, Japan), equipped with fluorimetric and spectro-photometric detectors. A 25 cm × 4.6 mm SUPELCO C18 chromatographic column was employed, preceded by a guard column to protect the main column from contaminants. The analysis was conducted using a gradient elution system at a flow rate of 1.2 mL/min and a column temperature of 40 °C. Fluorimetric and spectro-photometric detection was performed at wavelengths of 246 and 260 nm, respectively. Acid hydrolysis and amino acid derivatization with phenylisothiocyanate in isopropanol were used to produce phenylthiohydantoins. The mobile phase consisted of a mixture of 6.0 mM CH3SONA solution at pH 5.5 (component A), 1% isopropanol in acetonitrile (component B), and 6.0 mM CH3SONA solution at pH 4.05 (component C). Standard amino acid samples were obtained from Sigma Aldrich (Burghausen, Germany) [

26].

2.8. Determination of Water-Soluble Vitamins

Water-soluble vitamins were quantified in accordance with GOST R 55482-2013 [

27]. Samples (5 g) underwent sequential acid and enzymatic hydrolysis, followed by protein precipitation with trichloroacetic acid. The clarified hydrolysate was analyzed by HPLC-UV using a C18 column at the specified wavelength. Vitamin concentrations were determined by comparing chromatographic peak areas to those of external standards of known concentration.

2.9. Determination of Fat-Soluble Vitamins

Fat-soluble vitamins were measured following GOST R 32307-2013 [

28]. Samples (5 g) were saponified with alkaline ethanolic KOH, and vitamins were extracted with diethyl ether. The dried extract was reconstituted in mobile phase and analyzed by HPLC-UV under the prescribed conditions. Quantification was achieved by matching sample peak areas to those of certified vitamin reference solutions.

2.10. Determination of Mineral Content

The mineral content of the samples was analyzed following the AOAC (2000) method [

29]. Each sample, weighing 5 g, was placed in a container and incinerated in a microwave muffle furnace for 12 h at a final temperature of 600 °C. After incineration, the samples were dissolved in 10 mL of a 1:1 hydrochloric acid (HCl) solution in distilled water, mixed thoroughly with a glass rod, and filtered through a paper filter. The mineral elements were then quantified using an atomic emission spectrometer, ICP-OES (Spectro, Boschstr, Burghausen, Germany) [

30].

2.11. Determination of Water-Absorption, Fat-Retention and Swelling Capacities of the Cereal Supplement

Functional and technological properties of the cereal supplement were determined as follows [

31]. Water-absorption capacity (WAC) was measured by mixing 1 g of sample with 10 mL deionized water (1:10

w/

v), stirring briefly, and centrifuging at 1000 rpm for 10 min; the supernatant was decanted, and WBC calculated as grams of water retained per gram of sample. Fat-retention capacity (FRC) was determined using the same protocol with 10 mL refined vegetable oil in place of water. Swelling capacity (SC) was assessed by suspending 1 g of sample in 100 mL water (1%

w/

v) in a graduated cylinder, allowing hydration for 24 h at 20 °C, and expressing SC as milliliters of water absorbed per gram of sample at equilibrium.

2.12. Determining the Water-Binding Capacity of Meat Products

Water-binding capacity (WBC) was measured by a filter-press method. A 0.30 g aliquot of finely ground meat was placed on pre-conditioned filter paper, covered with a polyethylene disk and glass plate, and subjected to a 1 kg static load for 10 min to expel free moisture. The resulting moisture spots were delineated and their areas quantified using a planimeter. Water mass was calculated by applying a conversion factor of 8.4 mg·cm

−2, and WBC was expressed as the percentage of water retained relative to the sample mass [

32].

2.13. Determination of Water-Holding Capacity

Water-holding capacity (WHC) was determined using a gyrometer method. Approximately 5 g of homogenized minced meat was spread uniformly on the device’s inner surface with a glass rod. The gyrometer was sealed and immersed in a boiling water bath (100 °C) for 15 min. Upon removal, the mass of exuded moisture was read directly from the calibrated scale. WHC was calculated as the percentage of water retained by the sample relative to its initial mass [

33].

The water-holding capacity of the meat (WHC, %) was calculated according to Formula (2):

The water-release capacity (WRC, %) was calculated according to Formula (3):

where

W is the total mass fraction of moisture in the sample, %;

a is the gyrometer graduation rate, a = 0.01 cm3;

n is the number of graduations;

m is the mass of the sample, g.

2.14. Determination of Fat-Retention Capacity of Meat Samples

For the determination of fat-retention capacity (FRC), the water-binding capacity (WBC) is first calculated, followed by weighing the meat remaining in the fat meter with an accuracy of ±0.0001 g. The meat is then placed in a weighing bottle and dried to constant mass at 150 °C for 1.5 h. After drying, a sample weighing (2.0000 ± 0.0002) g is transferred to a porcelain mortar, where 2.5 g (1.6 cm

3) of fine calcined sand and 6 g (4.3 cm

3) of

α-monobromonaphthalene are added. The contents are thoroughly ground for 4 min and filtered through a folded paper filter [

34].

Three to four drops of the resulting filtrate are evenly applied with a glass rod to the lower prism of a refractometer. The prisms are closed and secured with a screw. A beam of light is directed onto the prism using a mirror, and the telescope is adjusted so that the intersection of the crosshairs (aliada) is clearly visible. The boundary between the illuminated and dark sections is aligned with the intersection point of the crosshairs, and the refractive index is recorded. The refractive index of pure monobromonaphthalene is determined in parallel.

Measurements are repeated several times, and the average values are used in calculations. The fat-retention capacity of meat (FRC, %) is calculated using the following Formula (4):

where

g1 is the mass fraction of fat in the sample after heat treatment (%);

g2 is the same value before heat treatment (%).

The fat content in the sample (

g, %) is calculated according to the Formula (5):

where

α is a coefficient characterizing the fat content in the solvent that changes the refractive index by 0.0001%;

n1 is the refractive index of the pure solvent;

n2 is the refractive index of the test solution;

m1 is the mass of 4.3 cm3 α-monobromonaphthalene (g);

m2 is the mass of the sample (g).

The coefficient α is established experimentally by comparing the results of fat content determination by the Soxhlet method and the refractometric method using the following Formulas (6) and (7):

where

c1 is the mass fraction of fat in the filtrate (%); ∆

n is the difference between the refractive indices of the pure solvent and the filtrate;

c is the fat content in the sample determined by the Soxhlet method (g);

m0 is the mass of the solvent sample (g).

2.15. Determination of pH

The active acidity (pH) of the medium was measured using the potentiometric method with a pH meter model-340 (Measuring Instruments Factory, Gomel, Belarus). Two electrodes were immersed in the solution, and the pH value was recorded directly from the device’s scale. The solution was prepared by mixing ground product with water in a 1:10 ratio, and the pH was measured after a 30-min infusion at 20 °C. pH was measured in triplicate for each patty sample, with at least five patties per formulation variant analyzed, and mean values were calculated for statistical evaluation.

2.16. Determination of Water Activity

Water activity was measured using an Aqualab 4TE water activity meter (Addium Inc., Pullman, WA, USA). Sausage samples were homogenized by grinding through a food processor fitted with a <3 mm plate opening, repeated three times to ensure uniform moisture distribution. Approximately 7–10 g of the homogenate was placed in disposable sample cups and sealed within the instrument’s sample chamber. After thermal equilibration at 25 °C (±0.1 °C) for ≤5 min, a_w values were recorded. The Aqualab 4TE provided high-precision, reproducible measurements of unbound water in the samples.

2.17. Organoleptic Evaluation of Meat Patties

Sensory evaluation was conducted by a trained panel of nine members (5 females, 4 males, aged 23–45 years) from the Laboratory of Food Analysis, Shakarim University. Panelists were selected based on prior participation in meat product evaluation sessions and trained according to ISO 8586 guidelines [

35]. Patties were cooked under standardized conditions (oven baking at 190 °C for 30 min), cooled for 5 min, and cut into equal portions. Samples were presented in randomized order, coded with three-digit numbers, and served under controlled sensory laboratory conditions (22 ± 2 °C, neutral lighting, individual booths). Each panelist evaluated every sample in triplicate. Attributes were assessed sequentially: (i) appearance and color (visual inspection), (ii) aroma (olfactory evaluation), (iii) texture (finger press and mastication), and (iv) flavor and juiciness (gustatory evaluation). All attributes were scored on a five-point hedonic scale (1 = very poor, 5 = excellent). Water was provided for palate cleansing between samples [

36].

2.18. Determination of the Acid Number

The acid number was assessed by titrimetric analysis of free fatty acids extracted from meat patties. Approximately 5 g of homogenized sample was combined with 50 mL of neutralized ethanol–diethyl ether (1:1,

v/

v) and agitated for 5 min, then incubated at 50–60 °C for 10 min to effect extraction. After cooling to ambient temperature, 2–3 drops of phenolphthalein indicator were added, and the liberated fatty acids were titrated with 0.10 M NaOH until a persistent pink endpoint (10–15 s) was achieved. Acid number (mg KOH/g) was calculated from the volume of titrant consumed [

37].

The acid value (mg KOH/g) was calculated using Formula (8):

V—volume of 0.1 mol/dm3 potassium hydroxide solution consumed for titration, cm3;

K—correction factor to the nominal concentration of solutions;

m—mass of fat in the analyzed sample, g;

5.61—mass of potassium hydroxide corresponding to 1 cm3 0.1 mol/dm3 of potassium hydroxide solution, mg.

2.19. Determination of the Thiobarbituric Acid Reactive Substances

Lipid oxidation was quantified by the thiobarbituric acid reactive substances (TBARS) assay. Approximately 5 g of homogenized meat sample was acidified with 5 mL 1 M HCl and distilled to collect malondialdehyde (MDA)–containing distillate. An aliquot (5 mL) of the distillate was mixed with 5 mL 0.02 M thiobarbituric acid reagent and heated in a boiling water bath for 35 min. After cooling to ambient temperature, absorbance was measured at 535 ± 10 nm using a UV–Vis spectrophotometer. TBARS values were calculated from an MDA standard curve over a range of 0.039–2.000 mg MDA/kg [

38]. The TBARS value (X, mg MDA/kg product) is calculated using Formula (9):

where

A is the absorbance of the solution, 7.8 is a constant coefficient representing the proportional relationship between absorbance and MDA concentration in the solution.

2.20. Statistics

All assays were conducted in 3–5 repetitions, and results are reported as mean ± standard deviation. Data were subjected to one-way analysis of variance (ANOVA) to assess differences among control and treatment groups, followed by Tukey’s post-hoc test for pairwise comparisons. A significance threshold of p < 0.05 was applied. Statistical computations and graphical presentations were performed using Microsoft Excel 2016 (Microsoft Corp., Redmond, WA, USA) and Statistica 12 PL (StatSoft, Tulsa, OK, USA).

3. Results

3.1. The Functional and Technological Properties of the Multicomponent Cereal Supplement

The functional and technological properties of the multicomponent cereal supplement were determined (

Table 2). The water retention capacity was 549.2%, indicating that each gram of supplement can immobilize approximately 5.5 g of water. Fat retention capacity measured 194.7%, demonstrating the blend’s ability to bind nearly twice its weight in oil. Swelling capacity reached 41.5 mL per gram, reflecting significant volumetric expansion in excess water. The pH of the supplement was 6.75, showing that it is near neutral under the conditions tested.

The multicomponent cereal supplement demonstrated functional and technological properties characteristic of cereal-based ingredients. Its high water affinity reflects the presence of hydrophilic constituents such as β-glucans, arabinoxylans, and resistant starch, which contribute to water absorption and retention. The supplement also showed notable fat-binding capacity, indicating the availability of lipophilic interaction sites within its matrix [

39,

40]. In addition, the pronounced swelling capacity suggests the presence of structural polysaccharides capable of forming viscous or gel-like networks. Together, these traits confirm the supplement’s multifunctionality, combining hydration, fat-binding, and swelling characteristics that are advantageous for improving the stability and texture of composite food systems. The near-neutral pH further supports its technological potential by minimizing undesirable shifts in product acidity [

41,

42]. Collectively, these properties confirm the blend’s suitability as a functional binder in comminuted meat products and its compatibility with standard processing conditions.

3.2. Studying the Chemical Composition of a Multicomponent Cereal Supplement

The supplement’s moisture content of 10.07% ensures good storage stability and facilitates easy mixing into meat batters. The supplement contains 14.43% protein (dry basis), providing extra non-meat protein that strengthens the gel network, boosts water retention, and improves sliceability without overly diluting the meat protein. With 4.48% fat, it does not destabilize ground meat; instead, it works with the cereal fibers to bind released animal fats and reduce cook out losses. An ash value of 11.1% indicates a rich mineral presence (

Table 3). These minerals (e.g., Mg, P, Fe) may fortify the nutritional profile of meat products, addressing dietary micronutrient gaps without requiring synthetic fortification. With carbohydrates comprising 59.92% of the blend, predominantly in the form of starches and non-starch polysaccharides, the supplement contributes bulk and viscosity to the meat batter. The fiber fraction (11.03%) enhanced water-binding and emulsion stability, supporting a moister texture and improved water and fat retention, properties that are typically associated with reduced syneresis in comminuted meat systems. The supplement provides 0.083 mg/100 g of β-carotene.

3.3. The Amino Acid Profile of the Multicomponent Cereal Supplement

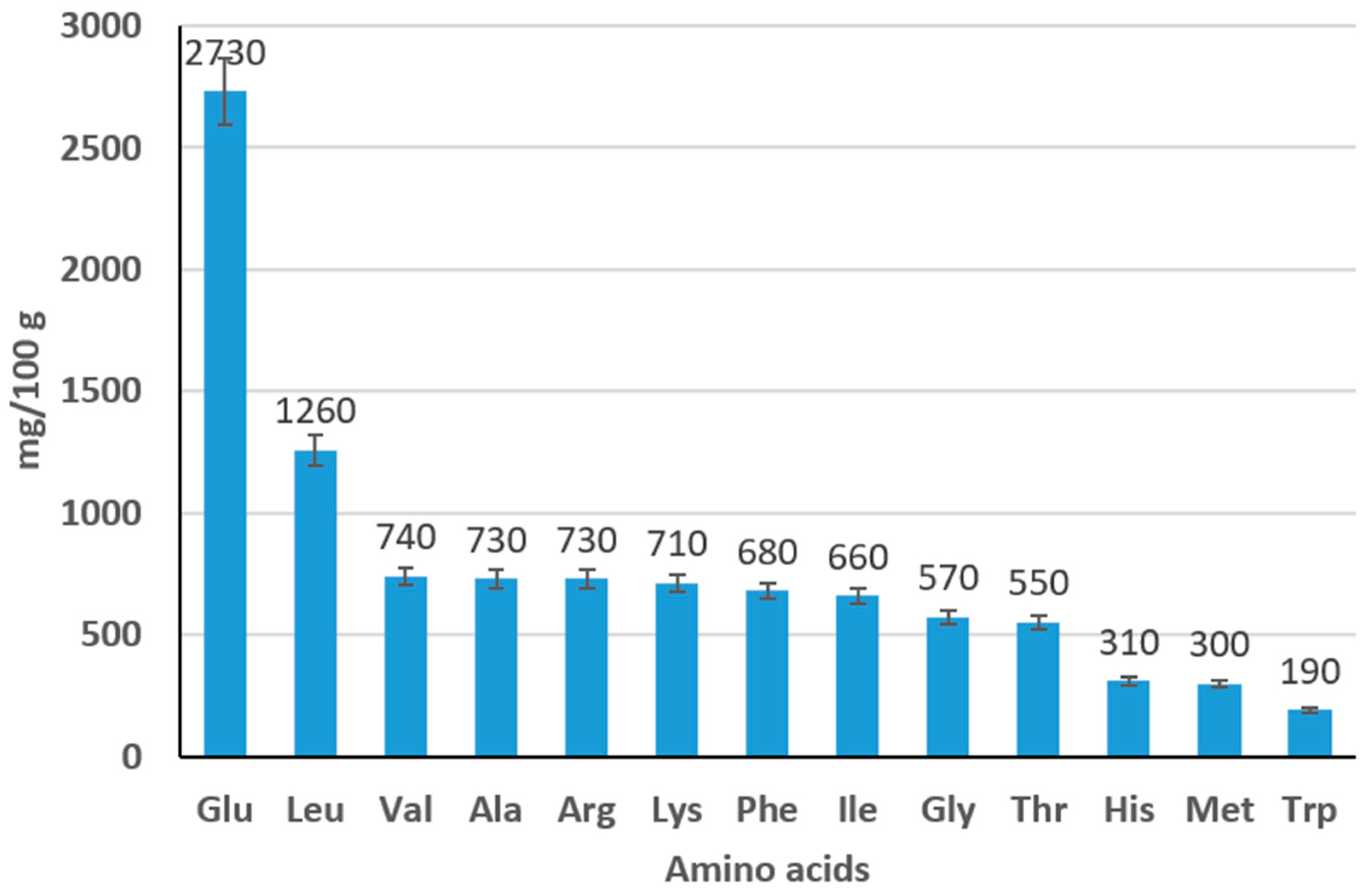

The amino acid profile of the multicomponent cereal supplement was quantified on a dry-weight basis. Glutamic acid was the most abundant residue, accounting for 2.73% of total weight, followed by leucine at 1.26%. Valine (0.74%), alanine (0.73%), and arginine (0.73%) were present at similar levels, while glycine (0.57%), threonine (0.55%), and phenylalanine (0.68%) comprised the bulk of the remaining non-aromatic residues. Isoleucine (0.66%), lysine (0.71%), histidine (0.31%), methionine (0.30%), and tryptophan (0.19%) were detected at lower concentrations (

Figure 2).

The predominance of glutamic acid and branched-chain amino acids (leucine, valine, isoleucine) suggests that the supplement will contribute positively to the development of flavor and to the functional interactions within meat protein matrices, as these residues are known to participate in Maillard-type reactions and hydrophobic interactions during heating. Leucine accounted for 1.26% of the amino acid profile of the supplement. This relatively high proportion is beneficial for stimulating muscle protein synthesis and complements the amino acid composition of meat [

43]. The modest levels of lysine (0.71%) and threonine (0.55%) are noteworthy, as these essential residues often limit the biological value of cereal-based proteins; however, when combined with meat proteins—which are rich in lysine and threonine—the overall formulation is likely to achieve a balanced essential amino acid pattern. Methionine and tryptophan were the least abundant, reflecting typical cereal protein limitations. Overall, the amino acid composition of the blend is well suited to both the technological needs of meat product formulation and to enhancing the nutritional quality of the final product.

3.4. The Vitamin and Mineral Composition of the Multicomponent Cereal Supplement

The detailed vitamin (E, B

1, B

2, B

3, B

5, B

6, B

12) and mineral (Fe, Zn, Mg, Ca, P, I) profiles of the multicomponent cereal supplement are presented in

Table 4. The high level of vitamin E (92 mg/100 g) positions the supplement as a potent source of lipid-soluble antioxidants, which may protect against oxidative degradation in meat matrices and contribute to cellular membrane stabilization in consumers [

44]. B-vitamins are present in moderate amounts; niacin (2.45 mg) and pantothenic acid (1.448 mg) support coenzyme functions in energy metabolism, while thiamine and pyridoxine levels (0.89 mg and 0.53 mg, respectively) help maintain carbohydrate catabolism and amino acid conversions [

45].

Minerally, the supplement is exceptionally rich in phosphorus (582 mg/100 g) and magnesium (263 mg/100 g). Phosphorus and magnesium are indispensable for bone health, energy production, muscle and nerve function, and chronic disease prevention. Maintaining balanced levels through diet is crucial for optimal health and the prevention of deficiency-related complications [

46]. The supplement provides 200 mg of calcium per 100 g, enhancing its nutritional profile. Calcium supports bone strength and overall health, reducing the risk of osteoporosis and fractures, and should be obtained from highly bioavailable dietary sources tailored to individual life stages [

47]. Iron (11.7 mg/100 g) and zinc (3.56 mg/100 g) exceed typical cereal levels, offering significant contributions toward daily micronutrient requirements and promoting redox reactions in cooked meat. The supplement contains low iodine concentration (0.0069 mg/100 g). Collectively, these vitamin and mineral levels not only fortify the nutritional profile of meat products but also may enhance oxidative stability, gelation, and sensory quality in finished formulations.

3.5. Sensory Evaluation of a Multicomponent Cereal Supplement

Panelists described the supplement as a free-flowing, homogeneous powder with a neutral beige–light brown color (

Table 5). The aroma was clean and grain-typical, with no off-notes detected. Taste was characterized as mild and cereal-like, without any sourness, bitterness, or residual aftertaste. Incorporation of this powder into meat systems is expected to enhance batch uniformity and dosing accuracy, owing to its free-flowing nature. Its neutral color and aroma should preserve product appearance and sensory consistency, while the cereal fibers may improve water- and fat-binding, reduce cook-out losses, and strengthen gel networks. Overall, the supplement is likely to boost yield, texture, and juiciness without introducing off-flavors or visual defects.

3.6. Studying the Chemical Composition of Meat Patties

Table 6 summarizes the chemical composition of each patty variant as weight percentages of moisture, protein, fat, ash, and carbohydrates. As the supplement level increases from 0% (Variant 1) to 15% (Variant 4), moisture content declines from 71.98% to 62.54%, reflecting the low water content of the supplement. The decline in moisture content with cereal supplementation reflects the replacement of high-water meat tissue with a relatively dry cereal blend. However, the supplement’s strong water- and fat-binding capacities improved retention during cooking, offsetting moderate reductions in raw moisture and preserving juiciness at 10% inclusion. At 15%, the sharper decline in compositional water, combined with higher fiber load, led to drier texture and grainy mouthfeel, lowering sensory scores and highlighting the balance required for optimal formulation.

Protein content shows a slight downward trend (18.25% to 17.81%) due to the lower protein level of the supplement compared to turkey, while fat content decreases modestly (8.39% to 7.85%). Ash (mineral) content rises substantially, from 1.38% in the control to 2.82% in Variant 4, owing to the supplement’s high mineral fraction. Carbohydrates, absent in meat, increase proportionally with supplement addition, reaching 8.99% in Variant 4.

These data indicate that inclusion of the multicomponent cereal supplement alters the patty’s composition in predictable ways: lowering moisture and fat while enriching minerals and introducing dietary carbohydrates. The modest decrease in protein remains acceptable for most meat products, and the carbohydrate addition (up to 9%) can enhance water-binding and textural properties without excessively diluting meat proteins. Increased ash content suggests improved mineral fortification. Overall, Variant 2 or 3 (5–10% supplement) may offer optimal balance between functional benefits and minimal changes to the traditional meat composition.

The compositional changes observed in the experimental patties align closely with those reported in diverse meat systems fortified with plant powders. As supplement inclusion increased from 0% to 15%, moisture content declined from 71.98% to 62.54%, a trend opposite to the modest moisture gains seen with low-level rice flour (2–6%) in emulsified sausages [

48], likely reflecting differences between batter-based and comminuted matrices and the relative hydration capacities of single-grain versus multigrain blends. Protein and fat contents in our patties decreased slightly (18.25% to 17.81% and 8.39% to 7.85%, respectively), similar reported in duck sausages with 10% cereal flour [

49] and orange maize–extended beef sausages [

50]. In contrast, sausages with chickpea–corn-flour demonstrated protein enrichment at higher legume levels [

51], underscoring the influence of ingredient selection on nutritional outcomes. Ash content rose substantially in our formulations (1.38% to 2.82%), which is consistent with increased mineral fractions in plant-fortified systems. The carbohydrate content (up to 8.99%) provided a dietary fibre content comparable to that observed in beef patties blended with pea, oat and rice proteins [

52].

3.7. Functional and Technological Properties of Meat Patties

The inclusion of the multicomponent cereal supplement into the patties’ formulations produced clear, dose-dependent improvements in all measured functional and technological parameters (

Figure 3). Water-binding capacity (WBC) rose from 65.98% in the control (Variant 1) to 71.58% in the 10% supplement formulation (Variant 3) and 73.21% in the 15% variant (Variant 4), with both Variants 3 and 4 differing significantly from the control (

p < 0.05). This enhancement indicates that cereal-derived polysaccharides and proteins increasingly contribute to immobilizing free water within the meat matrix, thereby reinforcing the gel network formed during thermal processing.

Similarly, moisture-retention capacity increased from 73.36% in Variant 1 to 82.02%, 90.69%, and 92.36% in Variants 2, 3, and 4, respectively, with all supplemented variants showing statistically significant gains over the control (

p < 0.05). These results demonstrate the supplement’s efficacy in reducing cooking losses and preserving juiciness. The fat-retention capacity also showed significant improvement: it rose from 38.3% in the control group to 46.22%, 54.14%, and 62.07% in Variants 2–4 (with all

p < 0.05). This trend reflects the supplement’s hydrophobic interaction sites, such as non-polar amino acids and lipid-associating polysaccharides, effectively entrapping free animal fats released during cooking [

53]. Enhanced fat retention supports a cohesive texture and prevents greasy exudate, addressing both processing stability and mouthfeel.

Taken together, these data confirm that the 10% supplement formulation (Variant 3) most effectively balances functional benefits with minimal deviation from the control’s baseline properties. A 10% inclusion of the multicomponent cereal additive demonstrates its effectiveness as a functional binder and juiciness enhancer in comminuted meat products, offering processing advantages and improving yield and sensory quality.

The observed enhancements in water- and fat-binding capacities with the multicomponent cereal supplement align closely with previous reports on grain fortification. For example, study [

48] demonstrated that 4–6% rice flour reduced sausage cooking loss from 6.42% to as low as 1.25% and improved emulsion stability, paralleling our finding that 10% supplement elevates moisture retention to over 90% and lowers cooking losses. Similarly, [

50] reported that orange maize flour increased water-holding capacity from 74% to over 100% at 50% inclusion without compromising emulsion stability, similar to our 5–15% supplement’s ability to hold both water and lipids. The work [

52] found that 4.5% oat protein increased cooking yield from 85% to 90.5%.

3.8. The pH and Water Activity

The pH of all patty variants remained within a narrow range (5.92–6.04) and did not differ significantly from the control (Variant 1;

p > 0.05). Water activity (a

w), however, declined progressively with increasing supplement inclusion: 0.988 in Variant 1, 0.955 in Variant 2, 0.921 in Variant 3, and 0.889 in Variant 4. Variants 3 and 4 exhibited significantly lower a

w than the control (

p < 0.05), whereas Variant 2 did not (

Table 7). The relatively low water activity observed in Variant 4, despite its higher moisture content, reflects the distinction between total and free water. The cereal supplement immobilized water within a fiber- and starch-rich matrix, reducing its availability for microbial growth. Thus, aw decreased independently of total compositional moisture.

The pH remained stable across all formulations, indicating that the multicomponent cereal supplement does not alter the acid–base balance of the meat matrix during mixing. Maintaining this stability is essential for preserving protein functionality, gelation behavior, and sensory attributes in comminuted products [

54]. The slight upward trend in pH (from 5.92 to 6.04) with higher supplement levels reflects the supplement’s intrinsic pH (6.7) but remains within the optimal processing window (5.8–6.2) for myofibrillar protein solubility and water-holding capacity.

In contrast, the marked decrease in water activity in Variants 3 and 4 (to 0.921 and 0.889, respectively) directly addresses our research question regarding the supplement’s potential to enhance shelf-life stability. Lowering aw below 0.95 inhibits the growth of many spoilage and pathogenic microorganisms, and values near 0.89 can significantly slow enzymatic and microbial degradation pathways. Thus, the 10% and 15% supplement levels confer a measurable hurdle to spoilage, likely extending refrigerated shelf life without resorting to synthetic preservatives. The 5% inclusion (Variant 2) achieved only a modest aw reduction (to 0.955), suggesting a threshold near 10% supplement is required to attain substantive microbial control.

These findings confirm that while pH stability ensures process compatibility, the cereal blend’s exceptional water-binding and moisture-retention properties reduce free water activity in the finished product. Consequently, formulations containing at least 10% supplement (aw ≤ 0.92) are most promising for achieving both functional enhancement and improved microbial safety in comminuted meat products.

The stability of pH across all patties variants aligns with numerous reports demonstrating that moderate cereal inclusion does not disrupt the acid–base equilibrium essential for myofibrillar protein functionality. A modest pH increase was observed in rice-flour sausages (from 6.67 to 6.85 at 6% inclusion) without exiting the optimal 5.8–6.2 range [

48]. Similarly, orange maize flour raised pH from 5.93 to 6.03 [

50], and chickpea–corn formulations exhibited pH values of 6.06–6.13 [

51]. In each instance, these slight upward shifts mirror the supplement’s intrinsic pH and do not compromise gelation or sensory quality.

3.9. TBARS

Lipid oxidation, as measured by TBARS (mg MDA/kg), increased progressively in all patties variants over five days of refrigerated storage at +2 °C (

Figure 4). On Day 0, the control (Variant 1) registered 1.05 mg MDA/kg, while variants containing the supplement exhibited lower values: 1.02 (Variant 2), 0.91 (Variant 3) and 0.98 (Variant 4). Variant 3 and Variant 4 differed significantly from the control (

p < 0.05). By Day 1, TBARS rose to 1.10 in Variant 1 but remained significantly lower in Variant 3 (0.95;

p < 0.05). Across Days 2 and 3, oxidation continued to accelerate in the control (1.23 → 1.31) and in Variant 2 (1.20 → 1.26), whereas Variants 3 and 4 maintained significantly reduced TBARS (1.05 → 1.12 and 1.15 → 1.23, respectively;

p < 0.05). On Day 4, Variant 3’s TBARS (1.20) remained significantly below the control (1.37;

p < 0.05), and by Day 5, all supplemented formulations (1.48 in Variant 2; 1.31 in Variant 3; 1.46 in Variant 4) were significantly lower than the control’s 1.55 mg MDA/kg (

p < 0.05).

The data demonstrate that the inclusion of the multicomponent cereal supplement reduces lipid oxidation in comminuted meat products throughout storage. The reduction in lipid oxidation can be explained by the supplement’s natural antioxidants, such as β-carotene and tocopherols, which neutralize free radicals. In addition, polyphenols associated with cereal fibers can bind pro-oxidant metals, while strong water- and fat-binding capacities limit oxygen exposure and help stabilize lipids within the meat matrix. From the start, Variant 3 (10% supplement) exhibited the lowest TBARS, suggesting that its balance of cereal-derived antioxidants and fibers most effectively retards primary lipid peroxidation. The sustained separation between supplemented and control samples over five days indicates that bioactive compounds, such as β-carotene and water- and fat-soluble antioxidants quantified in the supplement, remain active within the meat matrix and reduce malondialdehyde formation. Variant 4 (15% supplement) also conferred significant protection, though to a slightly lesser extent than Variant 3, implying that excessive fiber or mineral load may marginally impair antioxidant efficacy or extractability. Although Variant 4 contained more antioxidants overall, its higher fiber and mineral load may have reduced their accessibility within the meat matrix. Excessive fiber can physically entrap antioxidants, while divalent minerals may complex with phenolic compounds, lowering their activity. This helps explain why Variant 3 exhibited stronger oxidative protection despite lower total supplement inclusion. Notably, Variant 2 (5% supplement) only achieved significance by Day 5, indicating a threshold level of 10% supplement is optimal for early inhibition of lipid oxidation.

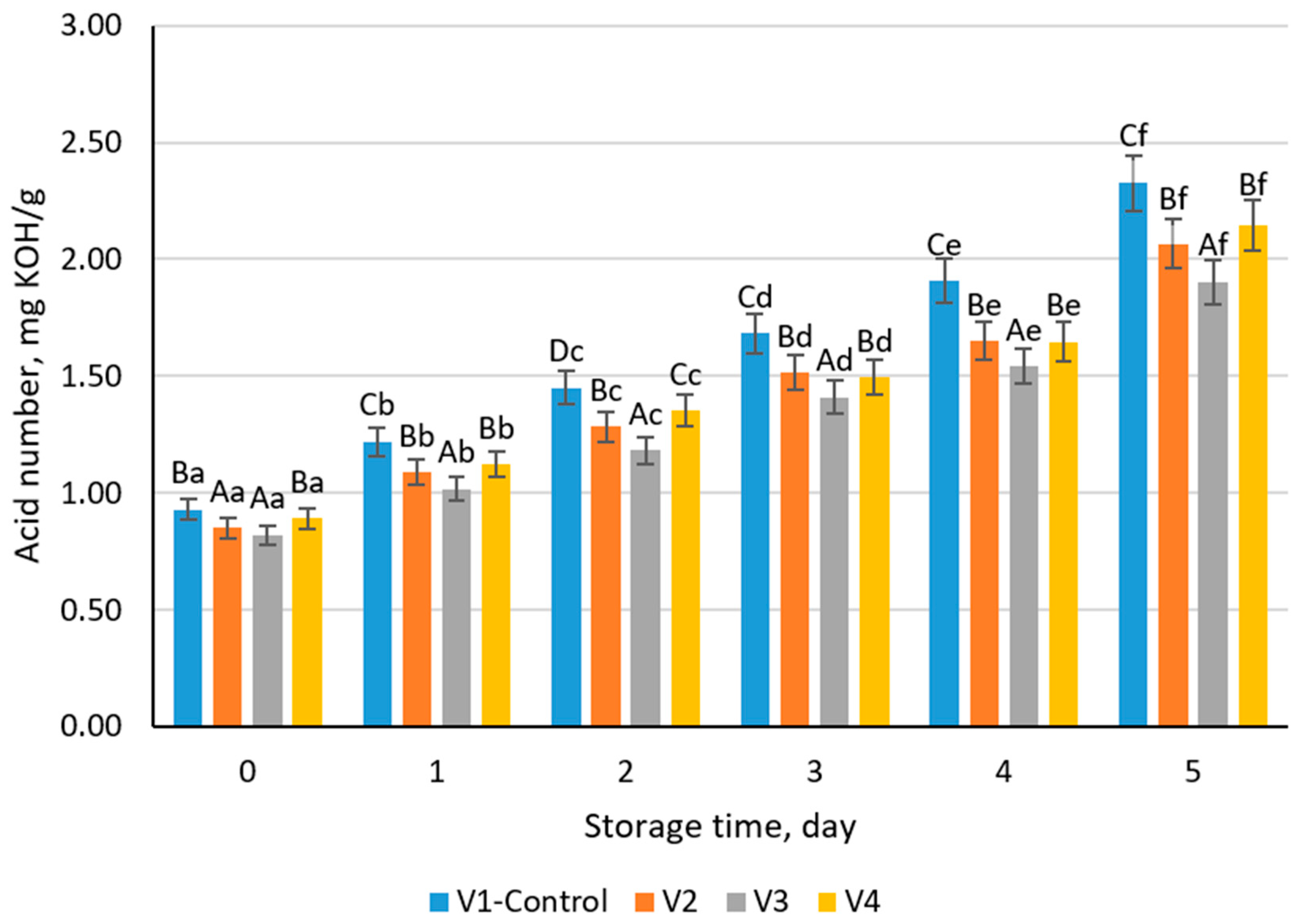

3.10. The Acid Number of Meat Patties Variants

The acid number of all meat patties variants increased steadily over five days of refrigerated storage at +2 °C, indicating progressive lipid hydrolysis and free fatty acid (FFA) formation. On Day 0, the control (Variant 1) recorded an acid number of 0.93 mg KOH/g, whereas Versions 2 (0.85 mg KOH/g) and 3 (0.82 mg KOH/g) were significantly lower (

p < 0.05), and Variant 4 measured 0.89 mg KOH/g. By Day 1, all supplemented formulations (1.09 mg KOH/g for Variant 2; 1.02 mg KOH/g for Variant 3; 1.12 mg KOH/g for Variant 4) remained significantly below the control’s 1.22 mg KOH/g (

p < 0.05). This trend persisted through Days 2–5: on Day 2, control 1.45 vs. supplemented 1.28–1.35; Day 3, control 1.68 vs. 1.41–1.51; Day 4, control 1.91 vs. 1.54–1.65; and Day 5, control 2.33 vs. 1.90–2.14 mg KOH/g. Throughout storage, Variants 2–4 exhibited consistently lower acid numbers than the control (

p < 0.05), with Variant 3 (10% supplement) showing the greatest suppression of FFA accumulation (

Figure 5).

Acid number reflects the extent of lipid hydrolysis and is a critical indicator of meat patties quality, as elevated FFA content can negatively affect flavor, texture, and shelf life. The significantly lower acid numbers in supplemented variants demonstrate that the multicomponent cereal additive retards lipolytic activity or FFA release within the meat matrix. Variant 3, containing 10% supplement, consistently exhibited the lowest acid values among all formulations, suggesting an optimal concentration for inhibiting endogenous lipases or stabilizing lipid–protein interactions. Potential mechanisms include the supplement’s high fiber content, which may hold water and limit enzyme mobility, and its bioactive antioxidant fraction, which can protect glyceridic bonds from oxidative cleavage that often precedes hydrolysis. Moreover, the mineral components (e.g., calcium, magnesium) present in the supplement could complex with free fatty acids, reducing measurable acidity. The gradual widening of differences between the control and supplemented variants over time indicates a sustained protective effect. These findings confirm that inclusion of the cereal blend, particularly at 10%, significantly enhances the hydrolytic stability of comminuted meat products during refrigerated storage. This enhanced stability demonstrates the blend’s efficacy in retarding lipid hydrolysis and preserving product quality.

The pronounced inhibition of lipid oxidation and hydrolytic degradation observed with the multicomponent cereal supplement parallels but also extends prior findings in plant-fortified meat systems. In this study, 10% supplement inclusion reduced TBARS by 13% on Day 0 and maintained ~20–25% lower values than the control throughout five days, whereas [

55] reported only transient TBARS reductions with 1.5–4.5% oat protein. Similarly, acid number increases were significantly attenuated in the 10% supplement variant (from 0.82 to 1.90 mg KOH/g over five days) compared with the control (from 0.93 to 2.33 mg KOH/g).

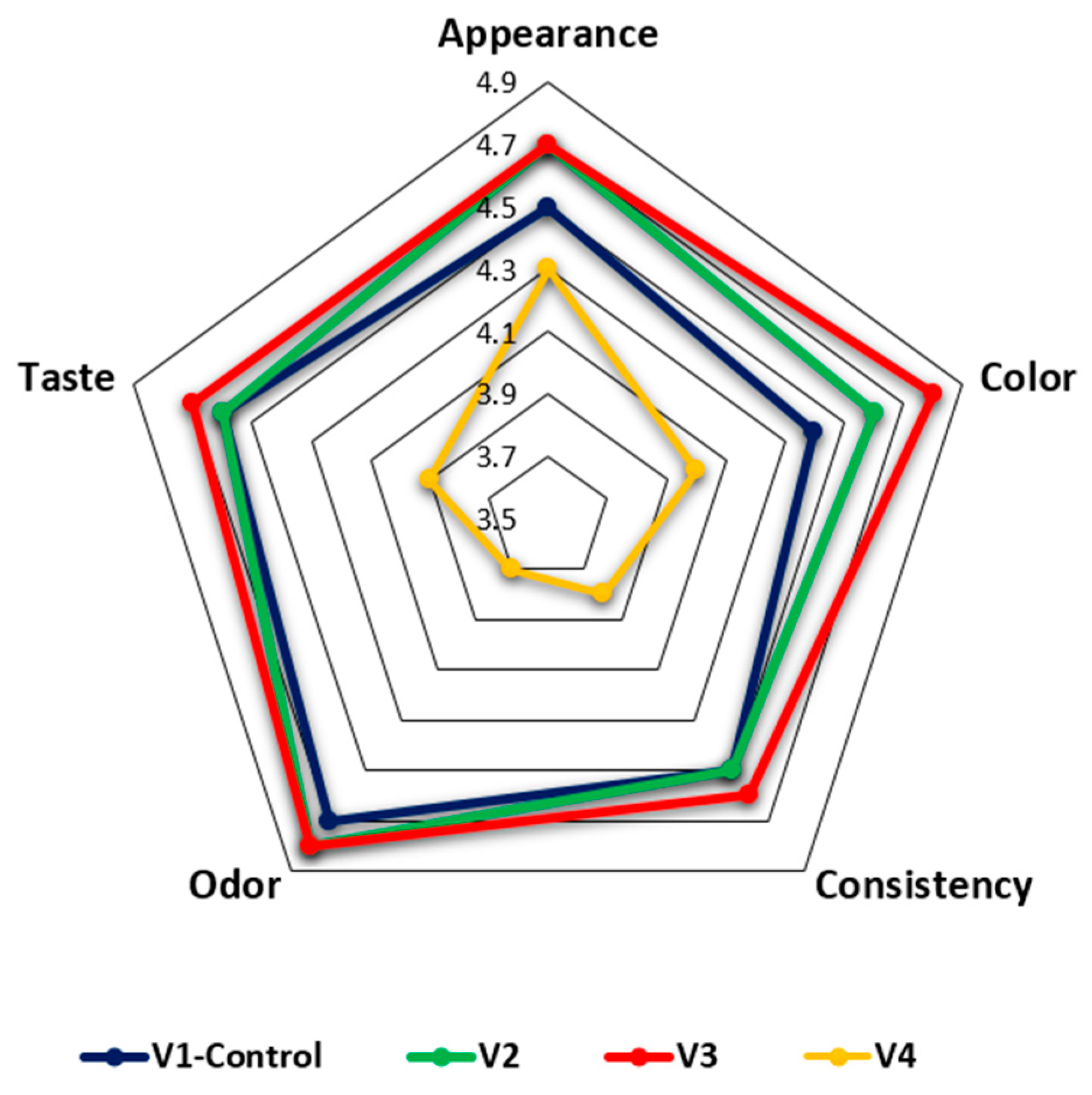

3.11. The Sensory Evaluation of Meat Patty Variants

The sensory evaluation of meat patties revealed high overall acceptability for formulations containing up to 10% supplement, with mean total scores of 22.7, 23.2, and 23.6 for Variants 1–3, respectively. Variant 1 (control) scored 4.5 for appearance, 4.4 for colour, 4.5 for consistency, 4.7 for odor, and 4.6 for taste. Variant 2 (5% supplement) achieved slight improvements in appearance (4.7) and colour (4.6), while maintaining consistency (4.5), odor (4.8), and taste (4.6), yielding a total of 23.2. Variant 3 (10% supplement) attained the highest marks for colour (4.8), consistency (4.6), odor (4.8), and taste (4.7), and scored 4.7 for appearance, giving a total of 23.6. In contrast, Variant 4 (15% supplement) scored significantly lower (

p < 0.05) across all attributes—appearance 4.3, colour 4.0, consistency 3.8, odor 3.7, and taste 3.9—for a total of 19.7 (

Figure 6,

Table S1).

These data indicate that incorporation of the multicomponent cereal supplement up to 10% enhances or maintains the desirable sensory properties of meat patties, whereas excessive inclusion (15%) impairs key attributes. The marginal increases in appearance and colour scores for Variants 2 and 3 reflect the supplement’s fine particle size and natural cereal hues, which blend well with the meat matrix. The improved consistency and odor in Variant 3 suggest that the supplement’s fibers and bioactive compounds contribute to a firmer yet tender texture and reinforce the meat’s characteristic aroma by stabilizing volatile compounds. The highest taste score at 10% inclusion further supports that this level optimally balances meat and cereal flavors without introducing off-notes or dryness. Although the inclusion difference between Variant 3 and Variant 4 was only 5%, the sharp decline in sensory scores suggests that excessive cereal addition substantially altered the product matrix. At 15% inclusion, cereal components diluted characteristic meat flavors, produced a grainier texture, and reduced juiciness. The sharp decline in sensory scores at 15% inclusion is likely due to the higher fiber and cereal particle load, which can introduce a coarse or grainy mouthfeel and dilute meat-derived flavors. In addition, excess fiber may bind more fat and water than is optimal, reducing juiciness and softening flavor intensity. These negative changes outweighed the improvements seen at lower levels.

By contrast, the significant decline in all sensory parameters for variant 4 shows that a supplement concentration of 15% exceeds the amount at which cereal components start to dominate or disrupt the sensory profile. This is probably due to an alteration in the fat–water balance, an increase in the grainy mouthfeel and a dilution of meat-derived flavours. These findings directly address the research question by identifying 10% supplement inclusion as the optimal level that maximizes functional benefits while preserving or enhancing sensory quality in comminuted meat products. Future work should examine consumer acceptability and cost–benefit analyses to validate this formulation for commercial application.

Sensory outcomes for meat patty variants containing up to 10% multicomponent cereal supplement are consistent with the optimal inclusion levels reported in other meat systems. Emulsified sausages with 4% rice flour achieved peak acceptability and significant flavor and juiciness improvements beyond 4% but no gains at 2% inclusion [

48]. Likewise, rice-fortified duck sausages exhibited higher overall scores and enhanced juiciness, mirroring our increased appearance, color, and odor ratings at 5–10% supplement [

49]. Maximum consumer acceptability was observed at 20% orange maize flour, followed by declines at 50% inclusion [

50]. Gluten-free sausages based on chickpea and corn flour retained high sensory scores up to 6% flour, with declines at 8% [

51], underscoring a narrow acceptable range (6–10%) that aligns with these findings. Stability of appearance and texture scores in meatballs with 5% buckwheat, corn, or millet flours, despite reduced flavor acceptability for millet, suggests that flour type and particle characteristics influence mouthfeel and taste [

56]. Collectively, these studies employ standardized sensory scales and consistently identify moderate plant inclusion (typically between 4% and 20%) as optimal for enhancing juiciness, texture, and flavor. The multicomponent blend’s ability to deliver comparable or superior sensory enhancements at a 10% inclusion level highlights its synergistic advantage, leveraging complementary particle sizes, colors, and bioactive profiles to achieve balanced functionality and consumer appeal.

3.12. Applications in the Meat Processing Industry

From an industrial perspective, incorporating a multicomponent cereal blend provides several clear benefits. The observed improvements in water and fat retention lead to higher cooking yields, reduced purge, and extended shelf life, which directly support processing efficiency and profitability. The reductions in TBARS and acid number indicate that the blend contributes to lipid stabilization during storage, reducing reliance on synthetic preservatives and supporting clean label formulations. Furthermore, maintaining high sensory quality at 10% inclusion demonstrates the commercial feasibility of developing meat products with enhanced fiber, vitamin, and mineral content while preserving consumer acceptance. Collectively, these findings align with industry trends toward functional, sustainable, and label-friendly formulations and offer manufacturers a practical strategy for differentiation in health-conscious markets.

4. Conclusions

This study demonstrated that incorporating a multicomponent cereal supplement into meat patties influenced compositional, functional, oxidative, and sensory characteristics in a dose-dependent manner. Among the tested levels, 10% inclusion proved optimal, as it enhanced water- and fat-binding, reduced lipid oxidation and hydrolysis, and maintained high consumer acceptability. This balance likely reflects the point at which cereal fibers and bioactive compounds contribute positively without overwhelming the meat matrix. Simultaneously, water- and fat-binding improved, and TBARS and acid number fell by 13–20%. Sensory evaluation confirmed peak acceptability at this level, whereas 15% inclusion impaired texture and flavor. To address this limitation, formulation strategies such as finer particle size reduction, partial replacement with more neutral-tasting grains, or incorporation of natural flavor enhancers could be considered. Incorporating a multicomponent cereal supplement delivered significant improvements without altering standard processing parameters or sensory quality. This label-friendly approach uses common cereal ingredients to enhance functional and nutritional attributes, offering meat manufacturers a cost-effective means to extend shelf life and meet growing consumer demand for clean-label, value-added products. Future pilot-scale validation will support seamless integration into existing production lines.