The Impact of Reservoir Parameters and Fluid Properties on Seepage Characteristics and Fracture Morphology Using Water-Based Fracturing Fluid

Abstract

1. Introduction

2. Materials and Methods

2.1. Reservoir Seepage Model of Water-Based Fracturing Fluid

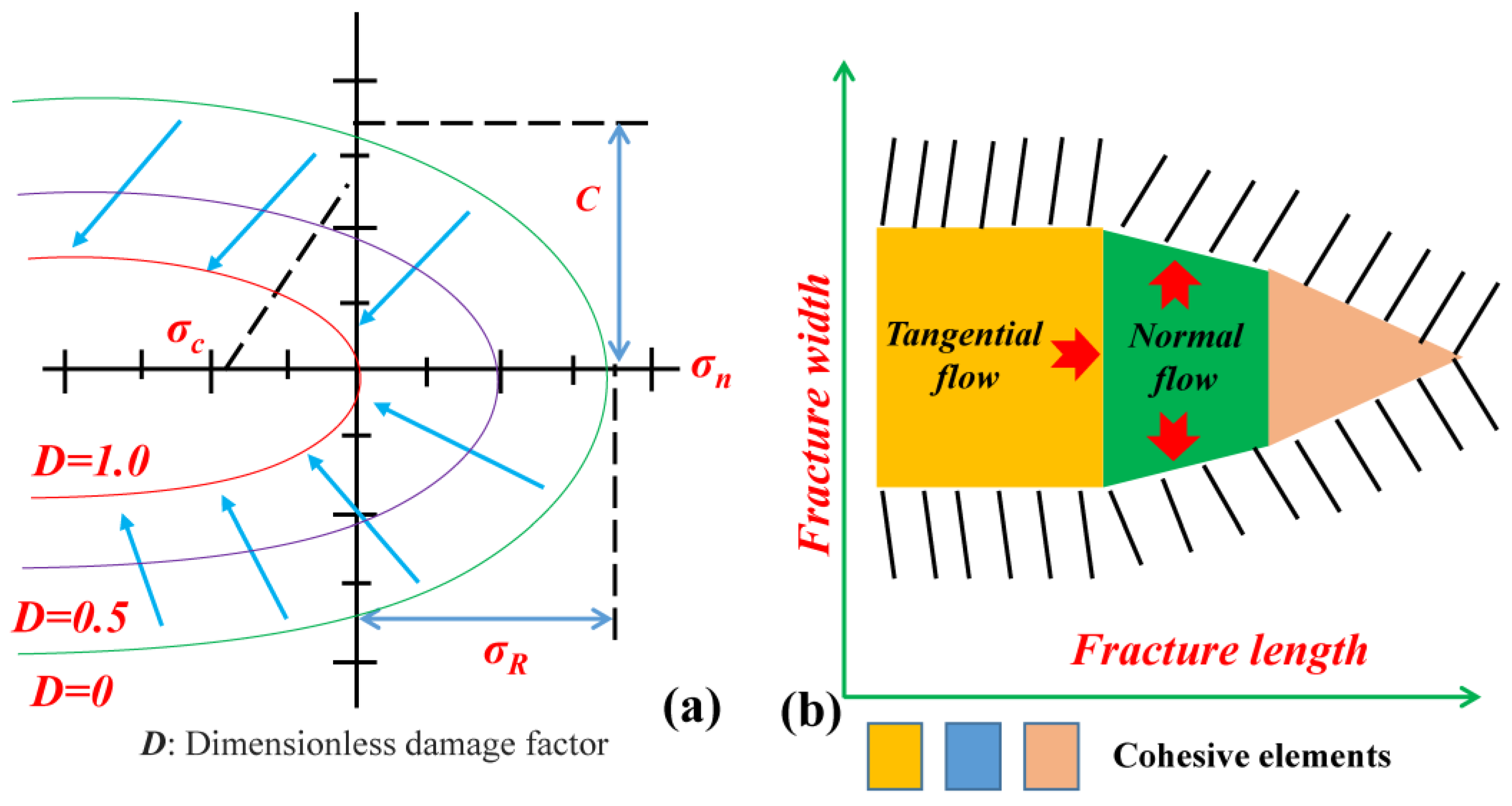

2.2. Material Damage Criterion for Low Permeability Rocks

2.3. Fracture Propagation Criteria and of Low Permeability Reservoirs

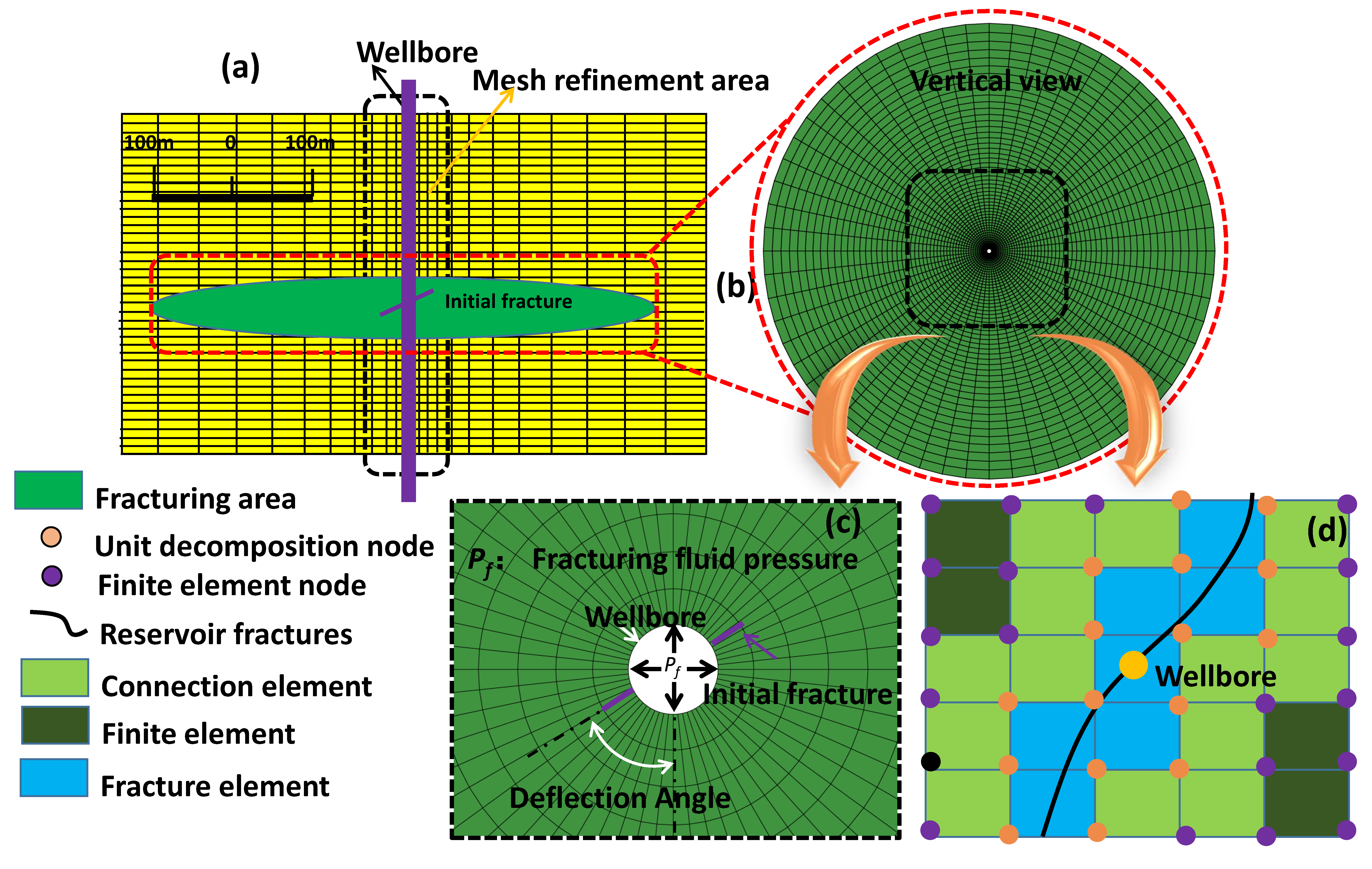

2.4. Water-Based Fracturing Model for Low Permeability Reservoirs

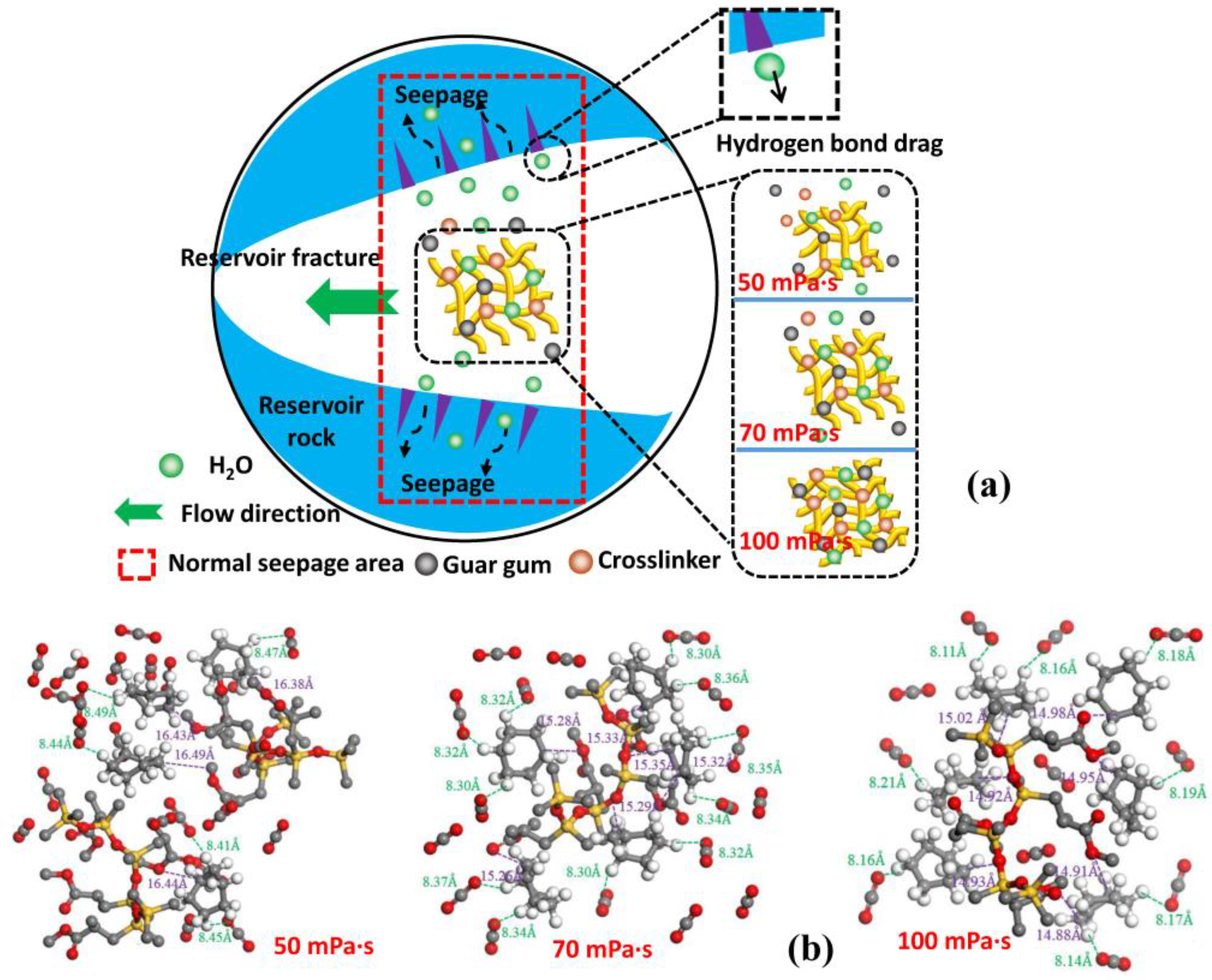

2.5. Molecular Dynamics Model

3. Results and Discussion

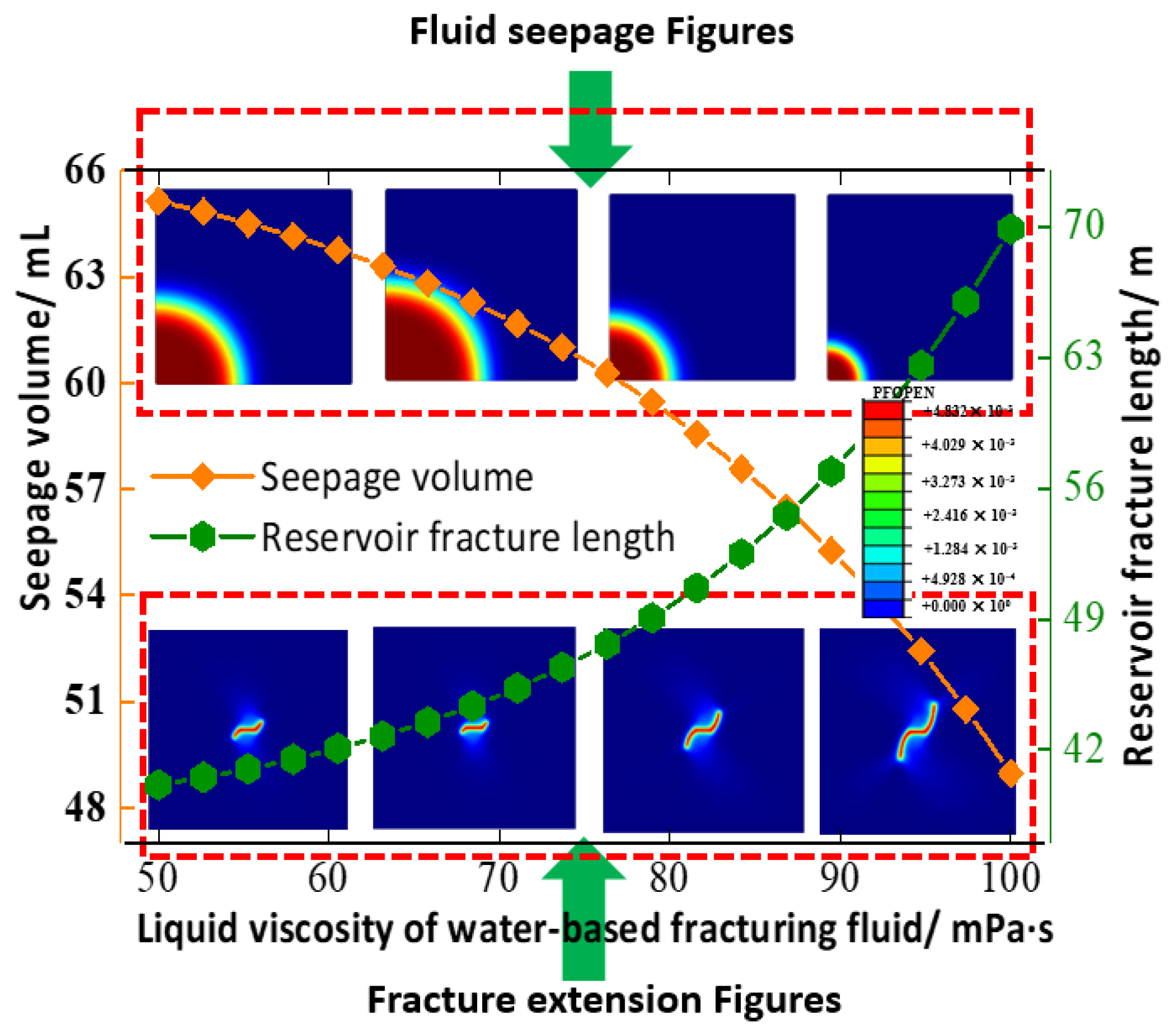

3.1. Effect of Fluid Viscosity on Reservoir Seepage and Fracture Propagation

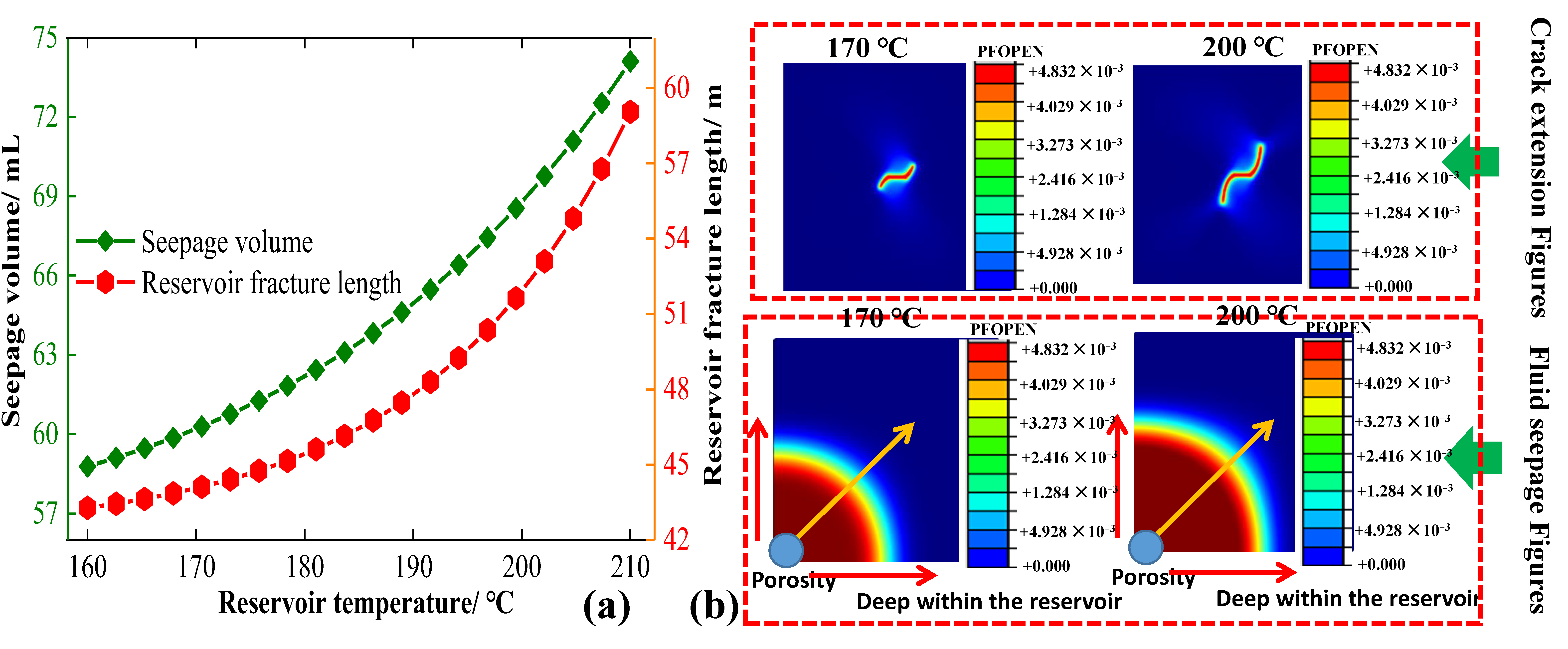

3.2. Effect of Reservoir Temperature on Reservoir Seepage and Fracture Propagation

3.3. Effects of Rock Porosity on Reservoir Seepage and Fracture Propagation

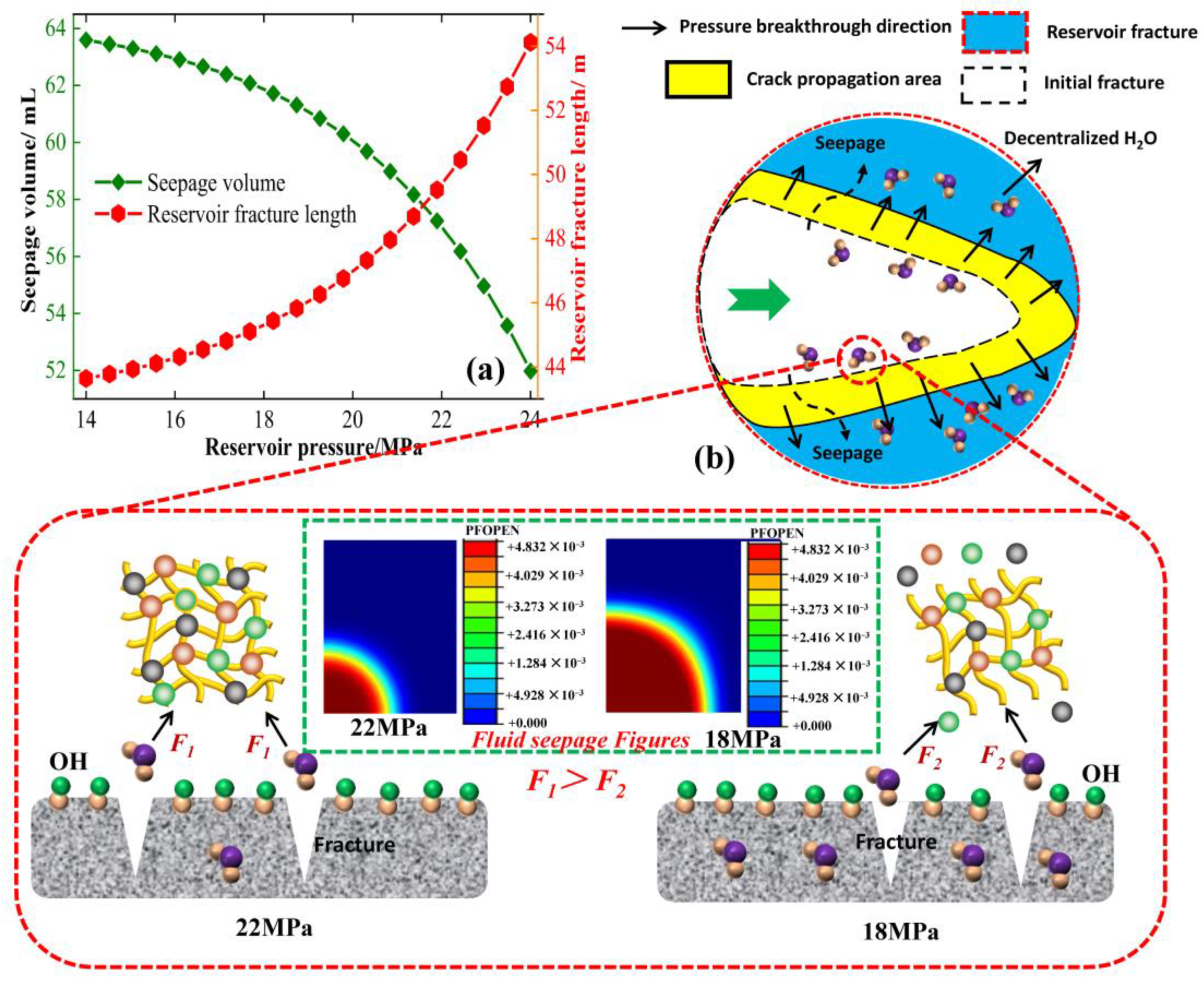

3.4. Effects of Reservoir Pressure on Reservoir Seepage and Fracture Propagation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Physical Parameters | Alphabet Symbols | Physical Parameters | Alphabet Symbols |

| relative permeability | rock porosity | ||

| fluid viscosity | matrix injection strength of oil | ||

| volume fraction | the matrix injection strength of water | ||

| pressure | p | fracture injection strength of oil | |

| Matrix-fracture cross-flow strength of oil | fracture injection strength of water | ||

| Matrix-fracture cross-flow strength of water | tensile strength of reservoir rock | R | |

| maximum normal stress threshold for reservoir fracture opening | φ | cohesion of reservoir rocks | C |

| force required for reservoir rock fracture | F | shear stress | σn |

| fracture turning angle | hoop strength | σc | |

| traction in the normal direction | traction in first shear direction | ||

| the second shear direction | mixed-mode fracture energy | ||

| actual energy release rate component | power index | ||

| injection rate | q | reservoir internal pressure | ▽p |

| fracture width | D | normal velocity of first side | |

| normal velocity of second side | filtration coefficient of first side | ||

| filtration coefficient of second side | internal pressure | ||

| pore pressure of first side | pore pressure of second side |

References

- Ma, X.; Sun, Y.; Liu, B.; Guo, W.; Jia, R.; Li, B.; Li, S. Numerical study of depressurization and hot water injection for gas hydrate production in China’s first offshore test site. J. Nat. Gas Sci. Eng. 2020, 83, 103530. [Google Scholar] [CrossRef]

- Kreipl, M.P.; Kreipl, A.T. Hydraulic fracturing fluids and their environmental impact: Then, today, and tomorrow. Environ. Earth Sci. 2017, 76, 160. [Google Scholar] [CrossRef]

- Liu, Y.F.; Zhou, L.; Wan, X.C.; Tang, Y.F.; Liu, Q.; Li, W.; Liao, J.B. Synthesis and characterization of a temperature sensitive microcapsule gelling agent for high-temperature acid release. ACS Omega 2024, 9, 20849–20858. [Google Scholar] [CrossRef] [PubMed]

- Emblemsvåg, J. Wind energy is not sustainable when balanced by fossil energy. Appl. Energy 2022, 305, 117748. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wu, J.; Li, X.; Li, H.; Cheng, Y. Wellhead stability during development process of hydrate reservoir in the Northern South China Sea: Evolution and mechanism. Processes 2024, 13, 40. [Google Scholar] [CrossRef]

- Wang, F.; Li, Q.; Xiao, Z.; Jiang, B.; Ren, J.; Jin, Z.; Li, X. Conversion of rice husk biomass into electrocatalyst for oxygen reduction reaction in Zn-air battery: Effect of self-doped Si on performance. J. Colloid Interface Sci. 2022, 606, 1014–1023. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wang, F.; Wu, J.; Wang, Y. The carrying behavior of water-based fracturing fluid in shale reservoir fractures and molecular dynamics of sand-carrying mechanism. Processes 2024, 12, 2051. [Google Scholar] [CrossRef]

- Lei, Q.; Weng, D.; Liu, H.; Guan, B.; Deng, Q.; Yan, X.; Ma, Z. Progress and development directions of shale oil reservoir stimulation technology of China National Petroleum Corporation. Pet. Explor. Dev. 2021, 48, 1198–1207. [Google Scholar] [CrossRef]

- Amir, M.; Deshmukh, R.G.; Khalid, H.M.; Said, Z.; Raza, A.; Muyeen, S.M.; Sopian, K. Energy storage technologies: An integrated survey of developments, global economical/environmental effects, optimal scheduling model, and sustainable adaption policies. J. Energy Storage 2023, 72, 108694. [Google Scholar] [CrossRef]

- Khan, M.K.; Raza, M.; Shahbaz, M.; Farooq, U.; Akram, M.U. Recent advancement in energy storage technologies and their applications. J. Energy Storage 2024, 92, 112112. [Google Scholar] [CrossRef]

- Seyyedattar, M.; Zendehboudi, S.; Butt, S. Technical and non-technical challenges of development of offshore petroleum reservoirs: Characterization and production. Nat. Resour. Res. 2020, 29, 2147–2189. [Google Scholar] [CrossRef]

- Li, Q.; Liu, J.; Wang, S.; Guo, Y.; Han, X.; Li, Q.; Cheng, Y.; Dong, Z.; Li, X.; Zhang, X. Numerical insights into factors affecting collapse behavior of horizontal wellbore in clayey silt hydrate-bearing sediments and the accompanying control strategy. Ocean Eng. 2024, 297, 117029. [Google Scholar] [CrossRef]

- Du, S.-H.; Shi, Y.-M. Concise extraction and characterization of the pore-throat network in unconventional hydrocarbon reservoirs: A new perspective. Pet. Sci. 2024, 21, 1474–1487. [Google Scholar] [CrossRef]

- Liew, M.S.; Danyaro, K.U.; Zawawi, N.A.W.A. A comprehensive guide to different fracturing technologies: A review. Energies 2020, 13, 3326. [Google Scholar] [CrossRef]

- Guo, J.; Gou, B.; Qin, N.; Zhao, J.; Wu, L.; Wang, K.; Ren, J. An innovative concept on deep carbonate reservoir stimulation: Three-dimensional acid fracturing technology. Nat. Gas Ind. B 2020, 7, 484–497. [Google Scholar] [CrossRef]

- Shang, J.; Dong, Z.; Tan, W.; Zhang, Y.; Liang, T.; Xing, L.; Wang, Z. A review of fracturing and enhanced recovery integration working fluids in tight reservoirs. Processes 2024, 12, 1241. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Cao, H.; Wu, J.; Wang, F.; Wang, Y. The crack Propagation Behaviour of CO2 Fracturing Fluid in Unconventional Low Permeability Reservoirs: Factor Analysis and Mechanism Revelation. Processes 2025, 13, 159. [Google Scholar] [CrossRef]

- Khalil, R.; Emadi, H.; Altawati, F. Investigating the effect of matrix acidizing injection pressure on carbonate-rich Marcellus shale core samples: An experimental study. J. Pet. Explor. Prod. 2021, 11, 725–734. [Google Scholar] [CrossRef]

- Yujie, B.; Bin, H.; Che, Z.; Xuenan, X.; Weibo, L.; Zhe, W.; Ning, Z.; Dan, L. Mechanism of enhanced oil recovery by nanoparticles extracted from flowback fluids of acidizing oil wells. Colloids Surf. A Physicochem. Eng. Asp. 2024, 690, 133782. [Google Scholar] [CrossRef]

- da Silva, D.C.; da Silva, N.P.D.; Lourenço, M.C.d.M.; Schwalbert, M.P.; Neto, A.d.O.W.; Rodrigues, M.A.F. Evaluation of carbonate rock acidizing under different reservoir conditions and damage scenarios: A systematic review. Carbonates Evaporites 2024, 39, 113. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Y.; Wang, X.; Yu, H.; Li, Q.; Wang, F.; Bai, H.; Kobina, F. An application of thickener to increase viscosity of liquid CO2 and the assessment of the reservoir geological damage and CO2 utilization. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 41, 368–377. [Google Scholar]

- Ranjith, P.G.; Zhang, C.P.; Zhang, Z.Y. Experimental study of fracturing behaviour in ultralow permeability formations: A comparison between CO2 and water fracturing. Eng. Fract. Mech. 2019, 217, 106541. [Google Scholar] [CrossRef]

- Maleki, M.; Mehrjoo, H.; Kazemzadeh, Y.; Mohmmadinia, F.; Ranjbar, A. Green innovation in enhanced oil recovery: Pioneering sustainable solution for a cleaner future. Environ. Earth Sci. 2025, 84, 60. [Google Scholar] [CrossRef]

- Zhao, J.; Wu, T.; Pu, W.; Daijun, D.; Chen, Q.; Chen, B.; Li, J.; Huang, Y. Application status and research progress of CO2 fracturing fluid in petroleum engineering: A brief review. Petroleum 2024, 10, 1–10. [Google Scholar] [CrossRef]

- Wanniarachchi, W.A.M.; Ranjith, P.G.; Perera, M.S.A.; Lashin, A.; Al Arifi, N.; Li, J.C. Current opinions on foam-based hydro-fracturing in deep geological reservoirs. Geomech. Geophys. Geo-Energy Geo-Resour. 2015, 1, 121–134. [Google Scholar] [CrossRef]

- Pouya, A.; Yazdi, P.B. A damage-plasticity model for cohesive fractures. Int. J. Rock Mech. Min. Sci. 2015, 73, 194–202. [Google Scholar] [CrossRef]

- Benzeggagh, M.L.; Kenane, M. Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus. Compos. Sci. Technol. 1996, 56, 439–449. [Google Scholar] [CrossRef]

- Kanninen, M.F. Applications of dynamic fracture mechanics for the prediction of fracture arrest in engineering structures. Int. J. Fract. 1985, 27, 299–312. [Google Scholar] [CrossRef]

- Gillemot, L.F. Criterion of fracture initiation and spreading. Eng. Fract. Mech. 1976, 8, 239–253. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Y.; Owusu, A.B. A modified Ester-branched thickener for rheology and wettability during CO2 fracturing for improved fracturing property. Environ. Sci. Pollut. Res. 2019, 26, 20787–20797. [Google Scholar] [CrossRef]

- Wang, G.; Wang, S.; Liu, Y.; Huang, Q.; Li, S.; Xie, S.; Zheng, J.; Fan, J. Influences of clean fracturing fluid viscosity and horizontal in-situ stress difference on hydraulic fracture propagation and morphology in coal seam. Int. J. Coal Sci. Technol. 2024, 11, 38. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wu, J.; He, K.; Xia, Y.; Liu, J.; Wang, F.; Cheng, Y. Wellhead Stability During Development Process of Hydrate Reservoir in the Northern South China Sea: Sensitivity Analysis. Processes 2025, 13, 1630. [Google Scholar] [CrossRef]

- Shi, Z.; Yao, Q.; Wu, C.; Xu, Y.; Wang, F.; Wang, W.; Sun, J. Interaction between Groundwater and Rock Fractures under Stress and Seepage Based on Extractive Water Resource Utilisation. Processes 2023, 11, 3380. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, J.; Zhou, X.; Liu, Y.; Wang, Y.; Luo, X. Damage-seepage evolution mechanism of fractured rock masses considering the influence of lateral stress on fracture deformation under loading and unloading process. Rock Mech. Rock Eng. 2024, 57, 10973–10999. [Google Scholar] [CrossRef]

- Li, L.; Hao, Y.; Lv, Y.; Wang, C.; Yao, C.; Zhao, Q.; Xiao, P. Experimental investigation on low-velocity seepage characteristics and influencing factors in a shale oil reservoir. J. Pet. Sci. Eng. 2020, 195, 107732. [Google Scholar] [CrossRef]

- Li, Q.; Wang, F.; Wang, Y.; Zhang, J.; Yu, X.; Zhao, M.; Zhou, C.; Forson, K.; Shi, S.; Zhao, Y.; et al. Influence of organoboron crosslinker and reservoir characteristics on filtration and reservoir residual of guar gum fracturing fluid in low-permeability shale gas reservoirs. Environ. Sci. Pollut. Res. 2022, 29, 82975–82985. [Google Scholar] [CrossRef]

- Gong, X.; Mu, L.; Liu, L. Performance Optimisation of Low—Damage Foam Fracturing Fluid System in Unconventional Reservoirs. Int. J. Chem. Eng. 2025, 2025, 6519044. [Google Scholar] [CrossRef]

- Liu, W.; Yang, Y.; Qiao, C.; Liu, C.; Lian, B.; Yuan, Q. Progress of seepage law and development technologies for shale condensate gas reservoirs. Energies 2023, 16, 2446. [Google Scholar] [CrossRef]

- Song, H.; Liu, J. Effects of Modified Cross-Linkers on the Rheology of Water-Based Fracturing Fluids and Reservoir Water Environment. Processes 2024, 12, 2896. [Google Scholar] [CrossRef]

- Gao, M.; Liu, H.; Hu, X.; Wang, Y.; Wang, D.; Qiao, H.; Liu, C.; Yu, W. Shale Gas Three-Dimensional Development Adjustment Workflow Based on Dynamic Changes of Geostress and Artificial Intelligence Algorithm to Achieve Efficient Shale Gas Extraction. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia (SPE 2025), Muscat, Oman, 12–14 May 2025. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, H.; Cai, J.; Zhang, S. Application of micro-Seismic monitoring in post-fracturing evaluation of shale gas: A case study of well X from Puguang area, China. Processes 2023, 11, 1863. [Google Scholar] [CrossRef]

- Mousavi, N.; Kothapalli, G.; Habibi, D.; Khiadani, M.; Das, C.K. An improved mathematical model for a pumped hydro storage system considering electrical, mechanical, and hydraulic losses. Appl. Energy 2019, 247, 228–236. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wang, F.; Wu, J.; Wang, Y.; Jin, J. Effects of Geological and Fluid Characteristics on the Injection Filtration of Hydraulic Fracturing Fluid in the Wellbores of Shale Reservoirs: Numerical Analysis and Mechanism Determination. Processes 2025, 13, 1747. [Google Scholar] [CrossRef]

- Matovu, S.; Al Shafloot, T.; Raza, A.; Mahmoud, M.A.; Hassan, A.; Alarifi, S.; Abu-Mahfouz, I.S. A Novel Approach to Stimulating Tight Reservoirs Using Cyclic Thermochemical Fluids. Energy Fuels 2025, 39, 14158–14172. [Google Scholar] [CrossRef]

- Cai, J.; Yang, J.; Huang, Z.; Xu, S.; Zhang, L.; Wang, H. Quantitative Evaluation of Residual Acid Invasion and Flowback in Fractured-Vuggy Carbonate Reservoirs Using Microfluidics. Energies 2025, 18, 1162. [Google Scholar] [CrossRef]

- Ao, F.; Qingchao, L.; Qiang, L.; Jingjuan, W.; Fuling, W.; Chuanliang, Y. Numerical Simulation Investigation of Fracture Propagation Behavior Patterns and Sensitivity Factors of Oil Shale Reservoirs in the Xunyi Region Considering the Influence of Natural Fracture. Geofluids 2025, 2025, 2762142. [Google Scholar] [CrossRef]

- Li, Q.; Wang, F.; Wang, Y.; Bai, B.; Zhang, J.; Lili, C.; Sun, Q.; Wang, Y.; Forson, K. Adsorption behavior and mechanism analysis of siloxane thickener for CO2 fracturing fluid on shallow shale soil. J. Mol. Liq. 2023, 376, 121394. [Google Scholar] [CrossRef]

- Zhang, C.P.; Ranjith, P.G.; Perera, M.S.A.; Li, X.; Zhao, J. Simulation of flow behaviour through fractured unconventional gas reservoirs considering the formation damage caused by water-based fracturing fluids. J. Nat. Gas Sci. Eng. 2018, 57, 100–121. [Google Scholar] [CrossRef]

- Liu, Y.; Pei, X.; Yang, F.; Zhong, J.; Dai, L.; Wang, C.; Zhou, T.; Li, Y.; Xiao, S. Molecular Simulation Study of Gas–Water Adsorption Behavior and Mobility Evaluation in Ultra-Deep, High-Pressure Fractured Tight Sandstone Reservoirs. Energies 2025, 18, 2175. [Google Scholar] [CrossRef]

- Qian, T.; Li, J.; Min, X.; Fan, B. Integration of pore confinement and hydrogen-bond influence on the crystallization behavior of C18 PCMs in mesoporous silica for form-stable phase change materials. ACS Sustain. Chem. Eng. 2018, 6, 897–908. [Google Scholar] [CrossRef]

- Liu, G.; Xie, S.; Tian, W.; Wang, J.; Li, S.; Wang, Y.; Yang, D. Effect of pore-throat structure on gas-water seepage behaviour in a tight sandstone gas reservoir. Fuel 2022, 310, 121901. [Google Scholar] [CrossRef]

- Wang, F.; Kobina, F. The influence of geological factors and transmission fluids on the exploitation of reservoir geothermal resources: Factor discussion and mechanism analysis. Reserv. Sci. 2025, 1, 3–18. [Google Scholar] [CrossRef]

- Zeng, L.; Hosseini, M.; Keshavarz, A.; Iglauer, S.; Lu, Y.; Xie, Q. Hydrogen wettability in carbonate reservoirs: Implication for underground hydrogen storage from geochemical perspective. Int. J. Hydrogen Energy 2022, 47, 25357–25366. [Google Scholar] [CrossRef]

- Tao, X.; Zheng, Z.; Yu, H.; Liu, H.; Li, Y.; Zhang, J.; Liu, J.; Zheng, L. Internal blocking and bonding to strengthen the mechanical properties and prevent collapse and leakage of fragmented coalbed methane (CBM) reservoirs by cohesive drilling fluids. Geoenergy Sci. Eng. 2024, 241, 213136. [Google Scholar] [CrossRef]

- Li, Q. Reservoir Science: A Multi-Coupling Communication Platform to Promote Energy Transformation, Climate Change and Environmental Protection. Reserv. Sci. 2025, 1, 1–2. [Google Scholar] [CrossRef]

- Nikravesh, M.; Aminzadeh, F. Past, present and future intelligent reservoir characterization trends. J. Pet. Sci. Eng. 2001, 31, 67–79. [Google Scholar] [CrossRef]

- Wu, J.; Ansari, U. From CO2 Sequestration to Hydrogen Storage: Further Utilization of Depleted Gas Reservoirs. Reserv. Sci. 2025, 1, 19–35. [Google Scholar] [CrossRef]

- Huang, Q.; Liu, S.; Wang, G.; Cheng, W. Evaluating the changes of sorption and diffusion behaviors of Illinois coal with various water-based fracturing fluid treatments. Fuel 2021, 283, 118884. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Y.; Wang, F.; Ning, X.; Chuanbao, Z.; Zhang, J.; Zhang, C. Factor analysis and mechanism disclosure of supercritical CO2 filtration behavior in tight shale reservoirs. Environ. Sci. Pollut. R 2022, 29, 17682–17694. [Google Scholar] [CrossRef]

- Al-Hajri, S.; Negash, B.M.; Rahman, M.M.; Haroun, M.; Al-Shami, T.M. Perspective Review of polymers as additives in water-based fracturing fluids. ACS Omega 2022, 7, 7431–7443. [Google Scholar] [CrossRef]

- Tang, H.; Tang, H.; He, J.; Zhao, F.; Zhang, L.; Liao, J.; Wang, Q.; Yuan, X. Damage mechanism of water-based fracturing fluid to tight sandstone gas reservoirs: Improvement of The Evaluation Measurement for Properties of Water-based Fracturing Fluid: SY/T 5107-2016. Nat. Gas Ind. B 2021, 8, 163–172. [Google Scholar] [CrossRef]

- Zhang, Y.; Gu, Y.; Sun, Q.; Rui, F.; Ge, Z.; Jia, H. Influence of microwave irradiation and water-based cooling on the fracturing behavior and failure mode transition of CSTBD granite. Eng. Fract. Mech. 2024, 296, 109832. [Google Scholar] [CrossRef]

- Li, Q.; Wu, J.; Li, Q.; Wang, F.; Cheng, Y. Sediment Instability Caused by Gas Production from Hydrate-Bearing Sediment in Northern South China Sea by Horizontal Wellbore: Sensitivity Analysis. Nat. Resour. Res. 2025, 34, 1667–1699. [Google Scholar] [CrossRef]

- Hu, H.; Wang, Z.; Wang, M.; Zeng, M.; Liu, C.; Chen, H. Effects of different water-based fracturing fluids on mechanical properties and energy evolution of deep coal under true triaxial loading. Phys. Fluids 2025, 37, 016620. [Google Scholar] [CrossRef]

- Papavasileiou, K.D.; Michalis, V.K.; Peristeras, L.D.; Vasileiadis, M.; Striolo, A.; Economou, I.G. Molecular dynamics simulation of water-based fracturing fluids in kaolinite slit pores. J. Phys. Chem. C 2018, 122, 17170–17183. [Google Scholar] [CrossRef]

- Soomro, N.A.; Ansari, U.; Shams, B.; Memon, M.K.; Bhutto, D.K.; Rui, Z.; Pan, Y. Experimental assessment of the stability and impact of water-based fracturing fluid with and without Triethanolamine (TEA). Fuel Commun. 2025, 23, 100137. [Google Scholar] [CrossRef]

- Huang, Q.; Liu, S.; Cheng, W.; Wang, G. Fracture permeability damage and recovery behaviors with fracturing fluid treatment of coal: An experimental study. Fuel 2020, 282, 118809. [Google Scholar] [CrossRef]

- Fan, M.; Lai, X.; Tang, M.; Li, J.; Wang, L.; Gao, J. Preparation and properties of a clean, low--damage waterproof locking damage multifunctional integrated water--based fracturing fluid. J. Appl. Polym. Sci. 2022, 139, e53207. [Google Scholar] [CrossRef]

- Wang, L.; Yao, B.; Cha, M.; Alqahtani, N.B.; Patterson, T.W.; Kneafsey, T.J.; Miskimins, J.L.; Yin, X.; Wu, Y.S. Waterless fracturing technologies for unconventional reservoirs-opportunities for liquid nitrogen. J. Nat. Gas Sci. Eng. 2016, 35, 160–174. [Google Scholar] [CrossRef]

- Li, S.; Zhang, S.; Ma, X.; Zou, Y.; Li, N.; Chen, M.; Cao, T.; Bo, Z. Hydraulic fractures induced by water-/carbon dioxide-based fluids in tight sandstones. Rock Mech. Rock Eng. 2019, 52, 3323–3340. [Google Scholar] [CrossRef]

- Hassen, B.; Zotskine, Y.; Gulewicz, D. Hydraulic fracture containment in the Bakken with a synthetic polymer water based fracture fluid. In Proceedings of the SPE Canada Unconventional Resources Conference, Alberta, Canada, 30 October–1 November 2012; p. SPE-162670. [Google Scholar] [CrossRef]

- Mahajan, M.; Rauf, N.; Gilmore, T.; Maylana, A. Water Control and Fracturing: A Reality. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Adelaide, Australia, 11–13 September 2006; p. SPE-101019. [Google Scholar] [CrossRef]

- Wei, Z.; Yang, W.; Zhai, C.; Zhang, Z.; Xu, J.; Pan, R. Fracture characteristics and energy dissipation law of shale under water-based impact loads. Eng. Fract. Mech. 2024, 306, 110240. [Google Scholar] [CrossRef]

- Wu, G.; Pan, J.; Anwaier, M.; Wu, J.; Xiao, P.; Zheng, L.; Wang, W.; Meng, X.; Wang, P.; Liu, J.; et al. Effect of nano-SiO2 on the flowback-flooding integrated performance of water-based fracturing fluids. J. Mol. Liq. 2023, 379, 121686. [Google Scholar] [CrossRef]

- Li, Q.; Han, Y.; Liu, X.; Ansari, U.; Cheng, Y.; Yan, C. Hydrate as a by-product in CO2 leakage during the long-term sub-seabed sequestration and its role in preventing further leakage. Environ. Sci. Pollut. Res. 2022, 29, 77737–77754. [Google Scholar] [CrossRef]

- Wanniarachchi, W.A.M.; Ranjith, P.G.; Perera, M.S.A. Shale gas fracturing using foam-based fracturing fluid: A review. Environ. Earth Sci. 2017, 76, 91. [Google Scholar] [CrossRef]

- Wilkins, R.; Menefee, A.H.; Clarens, A.F. Environmental life cycle analysis of water and CO2-based fracturing fluids used in unconventional gas production. Environ. Sci. Technol. 2016, 50, 13134–13141. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Zhang, C.; Yang, Y.; Ansari, U.; Han, Y.; Li, X.; Cheng, Y. Preliminary experimental investigation on long-term fracture conductivity for evaluating the feasibility and efficiency of fracturing operation in offshore hydrate-bearing sediments. Ocean Eng. 2023, 281, 114949. [Google Scholar] [CrossRef]

- Jiang, G.; Sun, J.; He, Y.; Cui, K.; Dong, T.; Yang, L.; Yang, X.; Wang, X. Novel water-based drilling and completion fluid technology to improve wellbore quality during drilling and protect unconventional reservoirs. Engineering 2022, 18, 129–142. [Google Scholar] [CrossRef]

- Ghanbari, E.; Dehghanpour, H. The fate of fracturing water: A field and simulation study. Fuel 2016, 163, 282–294. [Google Scholar] [CrossRef]

- Zhang, C.P.; Cheng, P.; Ma, Z.Y.; Ranjith, P.G.; Zhou, J.P. Comparison of fracturing unconventional gas reservoirs using CO2 and water: An experimental study. J. Pet. Sci. Eng. 2021, 203, 108598. [Google Scholar] [CrossRef]

- Abdelaal, A.; Aljawad, M.S.; Alyousef, Z.; Almajid, M.M. A review of foam-based fracturing fluids applications: From lab studies to field implementations. J. Nat. Gas Sci. Eng. 2021, 95, 104236. [Google Scholar] [CrossRef]

- Qiang, L.i.; Li, Q.; Han, Y. A numerical investigation on kick control with the displacement kill method during a well test in a deep-water gas reservoir: A case study. Processes 2024, 12, 2090. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Q.; Dong, W.; Li, Q.; Wang, F.; Bai, H.; Zhang, R.; Owusu, A.B. Effect of different factors on the yield of epoxy-terminated polydimethylsiloxane and evaluation of CO2 thickening. RSC Adv. 2018, 8, 39787–39796. [Google Scholar] [CrossRef]

- Zhang, Z.; Mao, J.; Yang, X.; Zhao, J.; Smith, G.S. Advances in waterless fracturing technologies for unconventional reservoirs. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 41, 237–251. [Google Scholar] [CrossRef]

- Li, Q.; Cheng, Y.; Li, Q.; Ansari, U.; Liu, Y.; Yan, C.; Lei, C. Development and verification of the comprehensive model for physical properties of hydrate sediment. Arab. J. Geosci. 2018, 11, 325. [Google Scholar] [CrossRef]

- Guo, Y.; Huang, L.; Li, X. Influence of 3D forced water-based working fluid imbibition on dynamic responses of deep anisotropic shale reservoir. Int. J. Rock Mech. Min. Sci. 2025, 194, 106195. [Google Scholar] [CrossRef]

- Barati, R.; Liang, J.T. A review of fracturing fluid systems used for hydraulic fracturing of oil and gas wells. J. Appl. Polym. Sci. 2014, 131, 40735. [Google Scholar] [CrossRef]

- Zhong, C.; Zolfaghari, A.; Hou, D.; Goss, G.G.; Lanoil, B.D.; Gehman, J.; Tsang, D.C.; He, Y.; Alessi, D.S. Comparison of the hydraulic fracturing water cycle in China and North America: A critical review. Environ. Sci. Technol. 2021, 55, 7167–7185. [Google Scholar] [CrossRef]

- Zhu, D.; Gu, Z.; Guo, F. Evolution of the breakdown pressure and fracture induced by water-/liquid CO2-based indirect fracturing. Eng. Fract. Mech. 2025, 322, 111190. [Google Scholar] [CrossRef]

- Li, Q.; Cheng, Y.; Ansari, U.; Han, Y.; Liu, X.; Yan, C. Experimental investigation on hydrate dissociation in near-wellbore region caused by invasion of drilling fluid: Ultrasonic measurement and analysis. Environ. Sci. Pollut. Res. 2022, 29, 36920–36937. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, Z.; Weng, L.; Wu, L.; Xu, X.; Liu, Q. Experimental study on the grouting diffusion process in fractured sandstone with flowing water based on the low-field nuclear magnetic resonance technique. Rock Mech. Rock Eng. 2023, 56, 7509–7533. [Google Scholar] [CrossRef]

- Shariatpanahi, S.F.; Strand, S.; Austad, T. Evaluation of water-based enhanced oil recovery (EOR) by wettability alteration in a low-permeable fractured limestone oil reservoir. Energy Fuels 2010, 24, 5997–6008. [Google Scholar] [CrossRef]

- Kondash, A.; Vengosh, A. Water footprint of hydraulic fracturing. Environ. Sci. Technol. Lett. 2015, 2, 276–280. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, Y.; Tang, L. The compressive-shear fracture strength of rock containing water based on Druker-Prager failure criterion. Arab. J. Geosci. 2019, 12, 452. [Google Scholar] [CrossRef]

- Wanniarachchi, W.A.M.; Ranjith, P.G.; Perera, M.S.A.; Rathnaweera, T.D.; Zhang, D.C.; Zhang, C. Investigation of effects of fracturing fluid on hydraulic fracturing and fracture permeability of reservoir rocks: An experimental study using water and foam fracturing. Eng. Fract. Mech. 2018, 194, 117–135. [Google Scholar] [CrossRef]

- Li, Q.; Li, Y.; Cheng, Y.; Li, Q.; Wang, F.; Wei, J.; Liu, Y.; Zhang, C.; Song, B.; Yan, C.; et al. Numerical simulation of fracture reorientation during hydraulic fracturing in perforated horizontal well in shale reservoirs. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 1807–1813. [Google Scholar] [CrossRef]

- Zhang, R.; Zheng, X.; Li, S.; Jin, K.; Zheng, H.; Wang, L. Environmentally friendly hydraulic fracturing and water-free fracturing technologies. Int. J. Oil Gas Coal Technol. 2018, 17, 375–390. [Google Scholar] [CrossRef]

- Lai, F.; Li, Z.; Wang, Y. Impact of water blocking in fractures on the performance of hydraulically fractured horizontal wells in tight gas reservoir. J. Pet. Sci. Eng. 2017, 156, 134–141. [Google Scholar] [CrossRef]

- Wang, X.; Ge, J.; Ren, Q.; Huang, K.; Ge, H. The failure mode and fracture morphology of shale under dry and water fracturing situation. Phys. Fluids 2025, 37, 026633. [Google Scholar] [CrossRef]

- Tokunaga, T.K.; Omosebi, O.A.; Wan, J. Surfactants are ineffective for reducing imbibition of water-based fracturing fluids in deep gas reservoirs. Energy Fuels 2021, 35, 11239–11245. [Google Scholar] [CrossRef]

- Lv, L.; Lin, J.; Feng, Y.; Wang, W.; Li, S. Coated recombinant Escherichia coli for delayed release of β-mannanase in the water-based fracturing fluid. Process Biochem. 2021, 107, 121–128. [Google Scholar] [CrossRef]

- Gao, J.; Zou, C.; Zhang, X.; Guo, W.; Yu, R.; Ni, Y.; Liu, D.; Kang, L.; Liu, Y.; Kondash, A.; et al. The water footprint of hydraulic fracturing for shale gas extraction in China. Sci. Total Environ. 2024, 907, 168135. [Google Scholar] [CrossRef]

- Du, X.; Carlson, K.H.; Tong, T. The water footprint of hydraulic fracturing under different hydroclimate conditions in the Central and Western United States. Sci. Total Environ. 2022, 840, 156651. [Google Scholar] [CrossRef] [PubMed]

- Wisen, J.; Chesnaux, R.; Wendling, G.; Werring, J. Water footprint of hydraulic fracturing in Northeastern British Columbia, Canada. Environ. Earth Sci. 2019, 78, 689. [Google Scholar] [CrossRef]

- Liu, D.; Li, J.; Zou, C.; Cui, H.; Ni, Y.; Liu, J.; Wu, W.; Zhang, L.; Coyte, R.; Kondash, A.; et al. Recycling flowback water for hydraulic fracturing in Sichuan Basin, China: Implications for gas production, water footprint, and water quality of regenerated flowback water. Fuel 2020, 272, 117621. [Google Scholar] [CrossRef]

- Raimi, D. Comment on “The intensification of the water footprint of hydraulic fracturing”. Sci. Adv. 2020, 6, eaav2110. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Xia, J.; Guan, B.; Liu, P.; Ning, L.; Yi, X.; Yang, L.; Hu, S. Water scarcity assessment based on estimated ultimate energy recovery and water footprint framework during shale gas production in the Changning play. J. Clean. Prod. 2019, 241, 118312. [Google Scholar] [CrossRef]

- Ikonnikova, S.A.; Male, F.; Scanlon, B.R.; Reedy, R.C.; McDaid, G. Projecting the water footprint associated with shale resource production: Eagle Ford shale case study. Environ. Sci. Technol. 2017, 51, 14453–14461. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Y.; Wang, F.; Li, Q.; Kobina, F.; Bai, H.; Yuan, L. Effect of a modified silicone as a thickener on rheology of liquid CO2 and its fracturing capacity. Polymers 2019, 11, 540. [Google Scholar] [CrossRef]

- Nicot, J.P.; Scanlon, B.R.; Reedy, R.C.; Costley, R.A. Source and fate of hydraulic fracturing water in the Barnett Shale: A historical perspective. Environ. Sci. Technol. 2014, 48, 2464–2471. [Google Scholar] [CrossRef]

- Rosa, L.; Rulli, M.C.; Davis, K.F.; D’Odorico, P. The water—Energy nexus of hydraulic fracturing: A global hydrologic analysis for shale oil and gas extraction. Earth’s Future 2018, 6, 745–756. [Google Scholar] [CrossRef]

- Zhang, D.; Tingyun, Y.A.N.G. Environmental impacts of hydraulic fracturing in shale gas development in the United States. Pet. Explor. Dev. 2015, 42, 876–883. [Google Scholar] [CrossRef]

- Gilmore, K.R.; Hupp, R.L.; Glathar, J. Transport of hydraulic fracturing water and wastes in the Susquehanna river basin, Pennsylvania. J. Environ. Eng. 2014, 140, B4013002. [Google Scholar] [CrossRef]

- Alessi, D.S.; Zolfaghari, A.; Kletke, S.; Gehman, J.; Allen, D.M.; Goss, G.G. Comparative analysis of hydraulic fracturing wastewater practices in unconventional shale development: Water sourcing, treatment and disposal practices. Can. Water Resour. J./Rev. Can. Ressour. Hydr. 2017, 42, 105–121. [Google Scholar] [CrossRef]

- Zemlick, K.; Kalhor, E.; Thomson, B.M.; Chermak, J.M.; Graham, E.J.S.; Tidwell, V.C. Mapping the energy footprint of produced water management in New Mexico. Environ. Res. Lett. 2018, 13, 024008. [Google Scholar] [CrossRef]

- Li, Q.; Cheng, Y.; Li, Q.; Zhang, C.; Ansari, U.; Song, B. Establishment and evaluation of strength criterion for clayey silt hydrate-bearing sediments. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 742–750. [Google Scholar] [CrossRef]

- Fu, C.; Liu, N. Waterless fluids in hydraulic fracturing–A review. J. Nat. Gas Sci. Eng. 2019, 67, 214–224. [Google Scholar] [CrossRef]

- Du, J.; Whittle, A.J.; Hu, L.; Divoux, T.; Meegoda, J.N. Mechanical degradation of Longmaxi shale exposed to water-based fluids and supercritical carbon dioxide. J. Rock Mech. Geotech. Eng. 2025, 17, 3378–3394. [Google Scholar] [CrossRef]

- Yang, B.; Wang, H.; Wang, B.; Shen, Z.; Zheng, Y.; Jia, Z.; Yan, W. Digital quantification of fracture in full-scale rock using micro-CT images: A fracturing experiment with N2 and CO2. J. Pet. Sci. Eng. 2021, 196, 107682. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Elastic Modulus, E/GPa | 26 | Poisson’s ratio, ν | 0.19 |

| Minimum horizontal principal stress, σh/MPa | 33 | Maximum horizontal principal stress, σH/MPa | 36 |

| Tensile strength, C/MPa | 6.5 | Initial pore pressure, Pip/MPa | 21 |

| Initial porosity, ϕ/% | 7–10 | Permeability, K/m2 | 5.8 × 10−16 |

| Leak-off coefficient | 2.6 × 10−12 | Total fracturing time, T/min | 12 |

| Initial Conditions | Value | Boundary Conditions | Value |

|---|---|---|---|

| Initial fracturing length/m | 0.3 | Injection rate/m3/min | 16 |

| Initial fracturing width/m | 0.01 | Far-field pore pressure/MPa | 33 |

| Deflection angle of the fracturing/° | 45 | Pressure on the fracturing surface/MPa | 21 |

| Initial pressure of fluid in the fracture/MPa | 33 | Rock heat transfer coefficient/W/(m·K) | 3.1 |

| Initial pressure at injection point/MPa | 35 | Far-field displacement/m | 0 |

| Data Source | 100s | 200s | 300s | 400s |

|---|---|---|---|---|

| Simulation results of this study | 17.2 | 25.4 | 32.7 | 36.1 |

| Comparative Data | 17.1 | 25.2 | 32.4 | 35.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Sun, Q.; Wang, H.; Chen, C.; Chen, C.; Zhou, Q.; Gong, Q.; Zhuo, X.; Zhuo, P. The Impact of Reservoir Parameters and Fluid Properties on Seepage Characteristics and Fracture Morphology Using Water-Based Fracturing Fluid. Processes 2025, 13, 3166. https://doi.org/10.3390/pr13103166

Zhang Z, Sun Q, Wang H, Chen C, Chen C, Zhou Q, Gong Q, Zhuo X, Zhuo P. The Impact of Reservoir Parameters and Fluid Properties on Seepage Characteristics and Fracture Morphology Using Water-Based Fracturing Fluid. Processes. 2025; 13(10):3166. https://doi.org/10.3390/pr13103166

Chicago/Turabian StyleZhang, Zhaowei, Qiang Sun, Hongge Wang, Chaoxian Chen, Changyu Chen, Qian Zhou, Qisen Gong, Xiaoyue Zhuo, and Peng Zhuo. 2025. "The Impact of Reservoir Parameters and Fluid Properties on Seepage Characteristics and Fracture Morphology Using Water-Based Fracturing Fluid" Processes 13, no. 10: 3166. https://doi.org/10.3390/pr13103166

APA StyleZhang, Z., Sun, Q., Wang, H., Chen, C., Chen, C., Zhou, Q., Gong, Q., Zhuo, X., & Zhuo, P. (2025). The Impact of Reservoir Parameters and Fluid Properties on Seepage Characteristics and Fracture Morphology Using Water-Based Fracturing Fluid. Processes, 13(10), 3166. https://doi.org/10.3390/pr13103166