Design and Evaluation of Drilling Fluid Systems for Wellbore Stabilization During Drilling in Deep Coalbed Gas Reservoirs in the Ordos Basin

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Structural Characterization

2.2.2. Drilling Fluid Performance Evaluation

- (1)

- Rheology of drilling fluid

- (2)

- Drilling fluid filtration property

- (3)

- Drilling fluid lubricity

- (4)

- Inhibition capability

- (5)

- Sand packing filtration loss test

- (6)

- Uniaxial compression strength test

- (7)

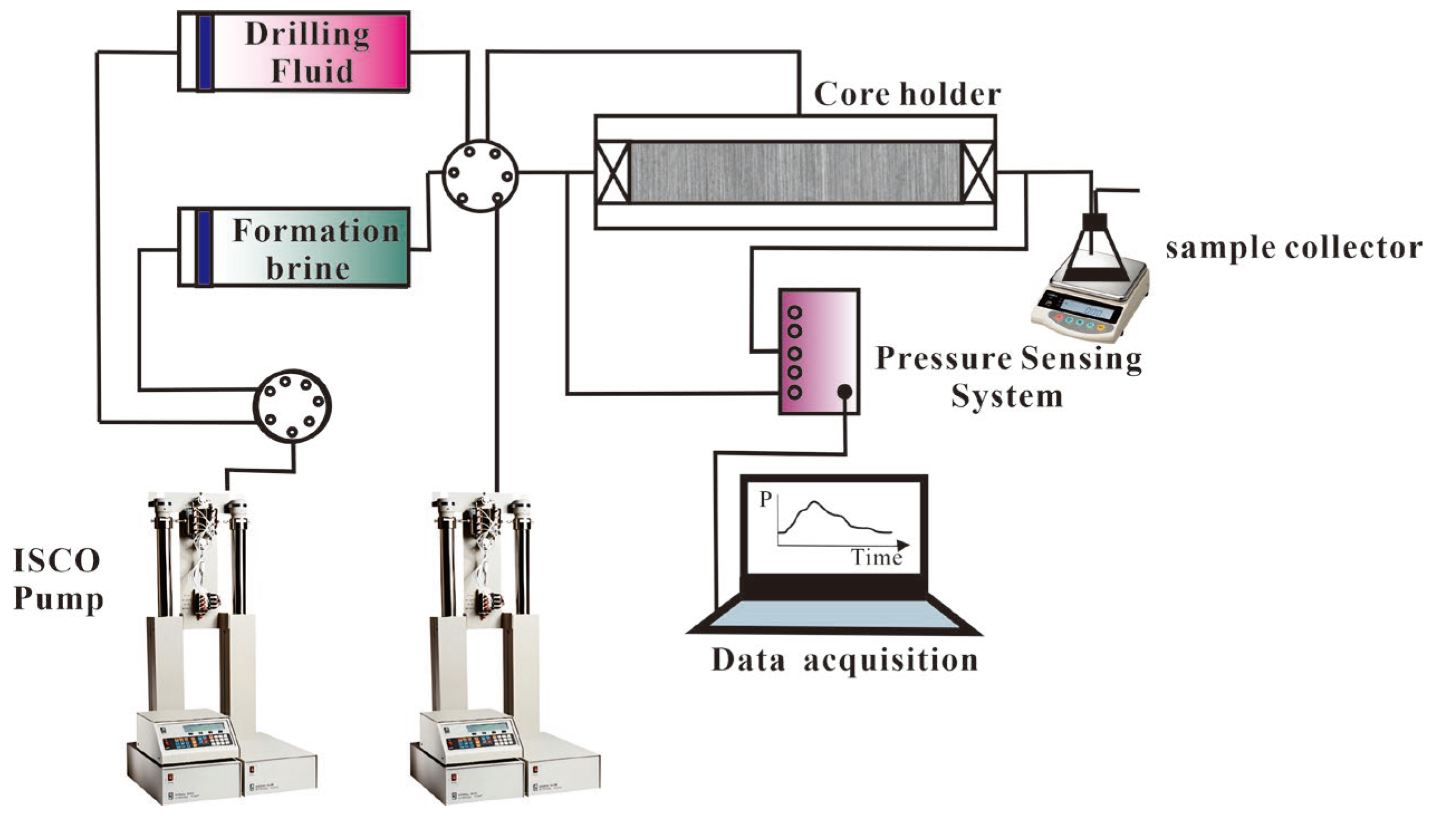

- Reservoir damage test

3. Results and Discussion

3.1. Structural Characterization

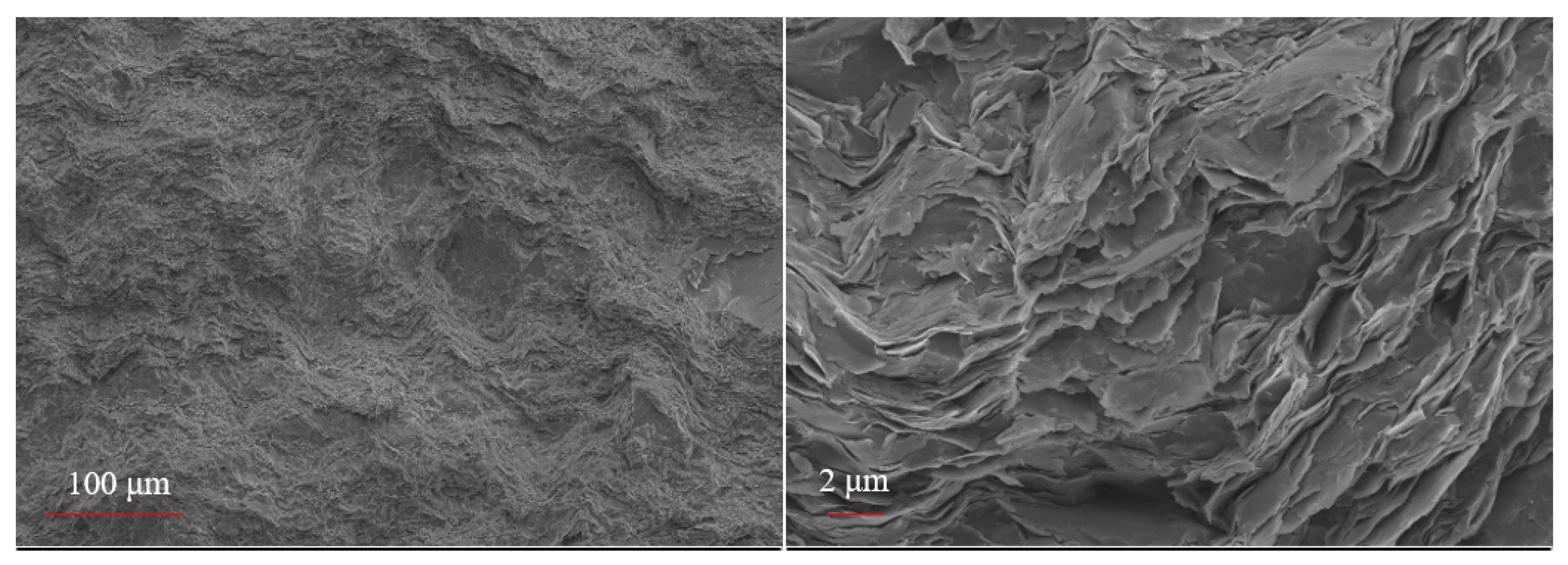

3.1.1. Shale Sample Surface Morphology

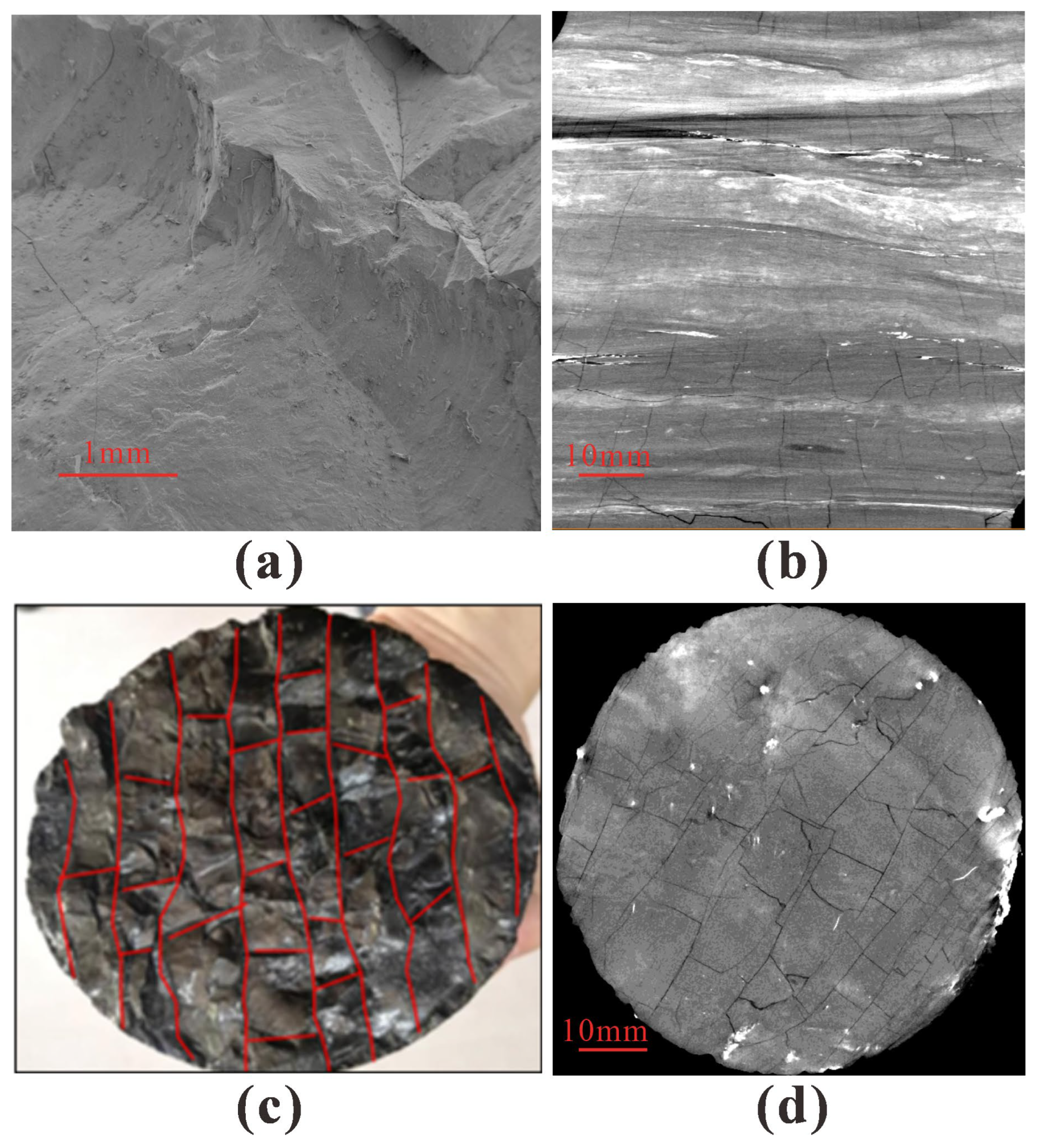

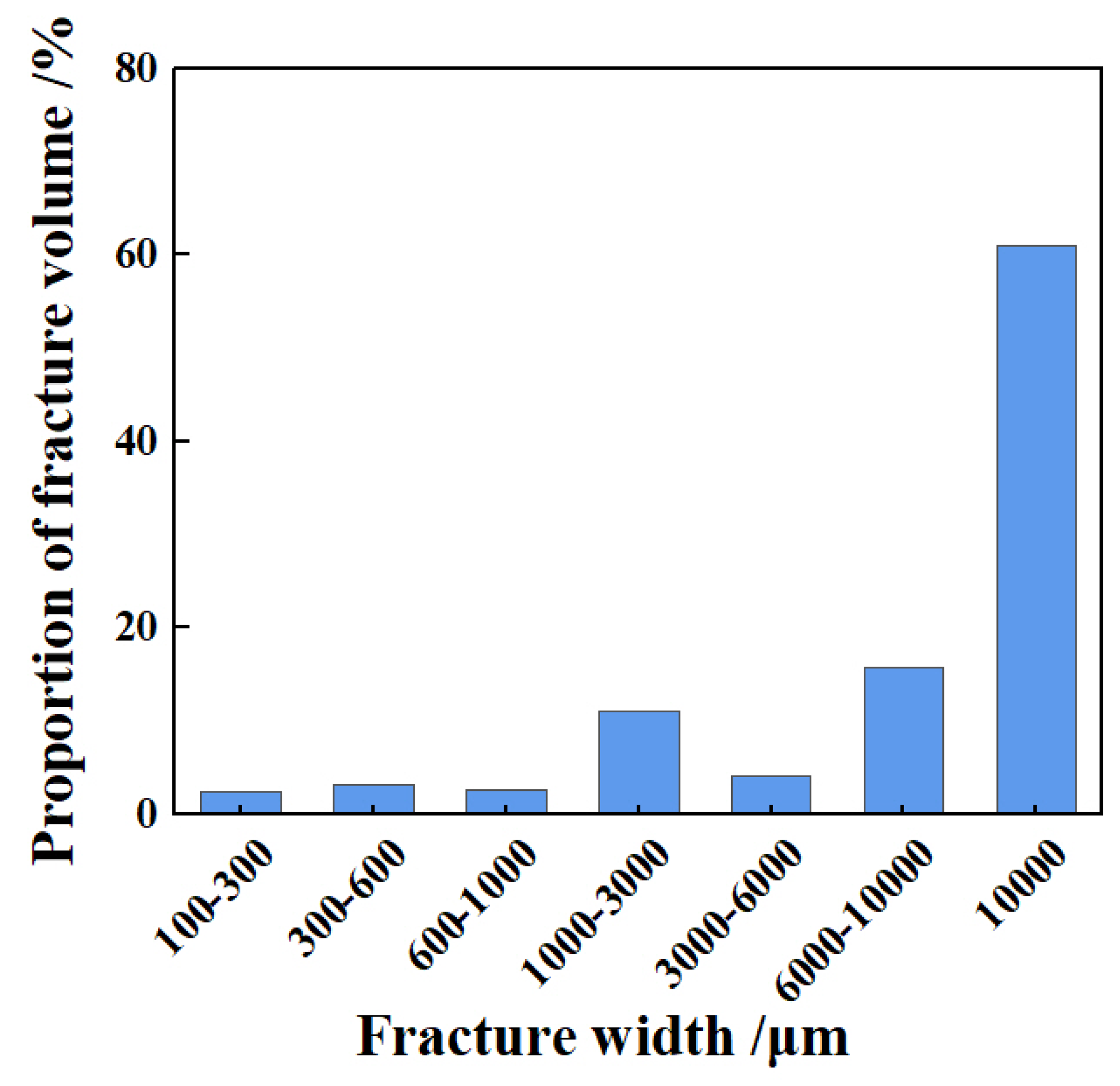

3.1.2. Coal Rock Sample Surface and Cross-Sectional Morphology

3.2. Evaluation and Selection of Drilling Fluid Agents

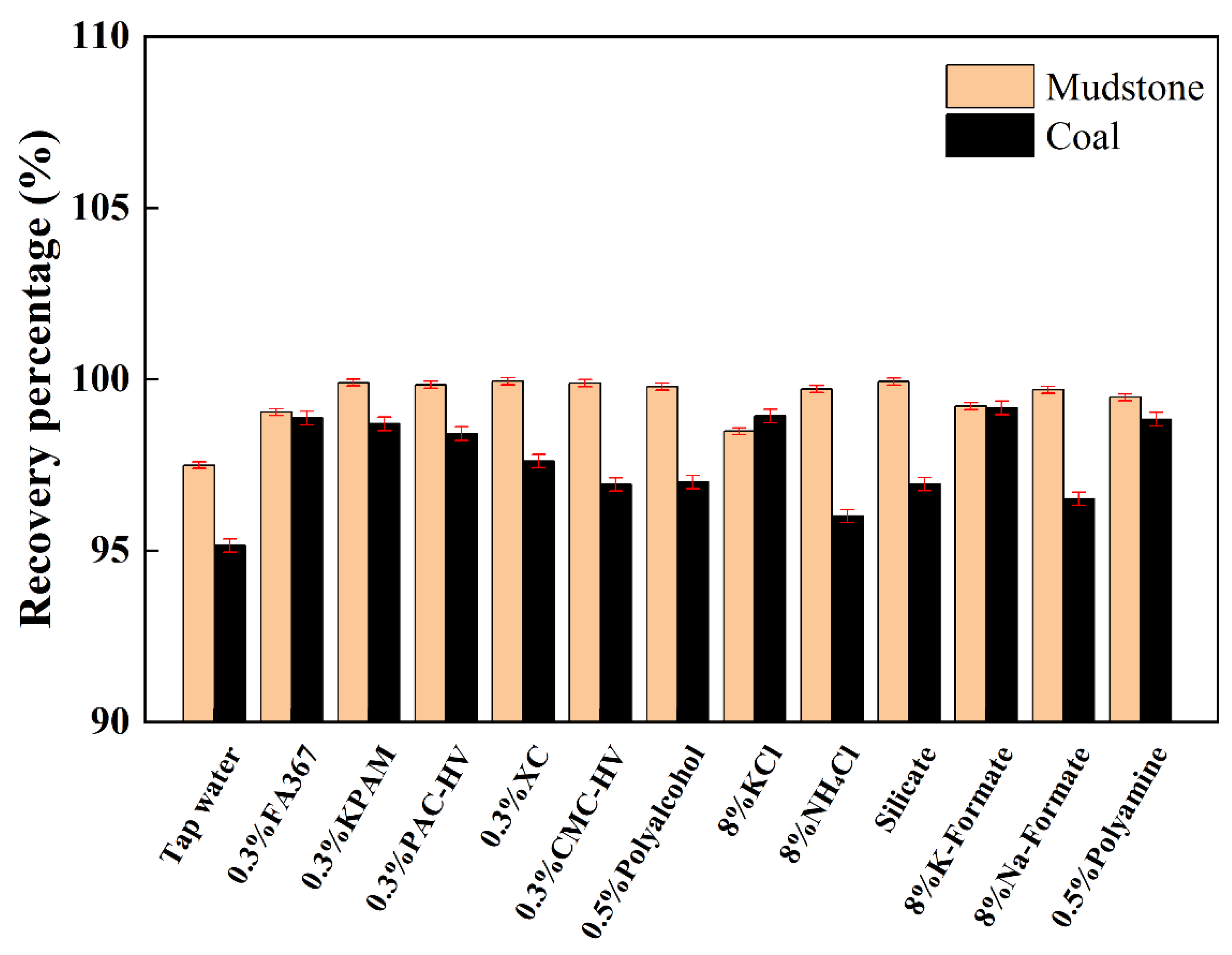

3.2.1. Inhibition and Coating Agents

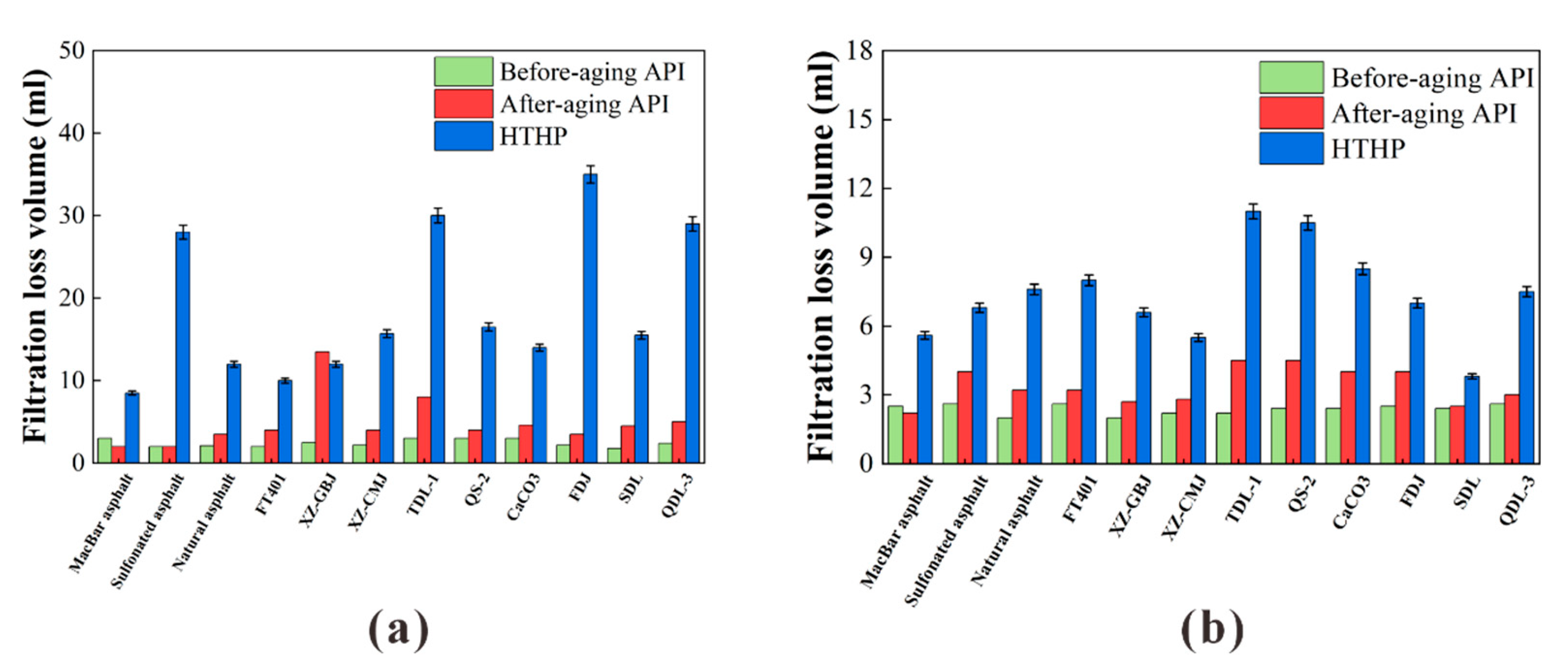

3.2.2. Filtration Reducer

3.2.3. Sealing Agent

3.2.4. Lubrication Agent

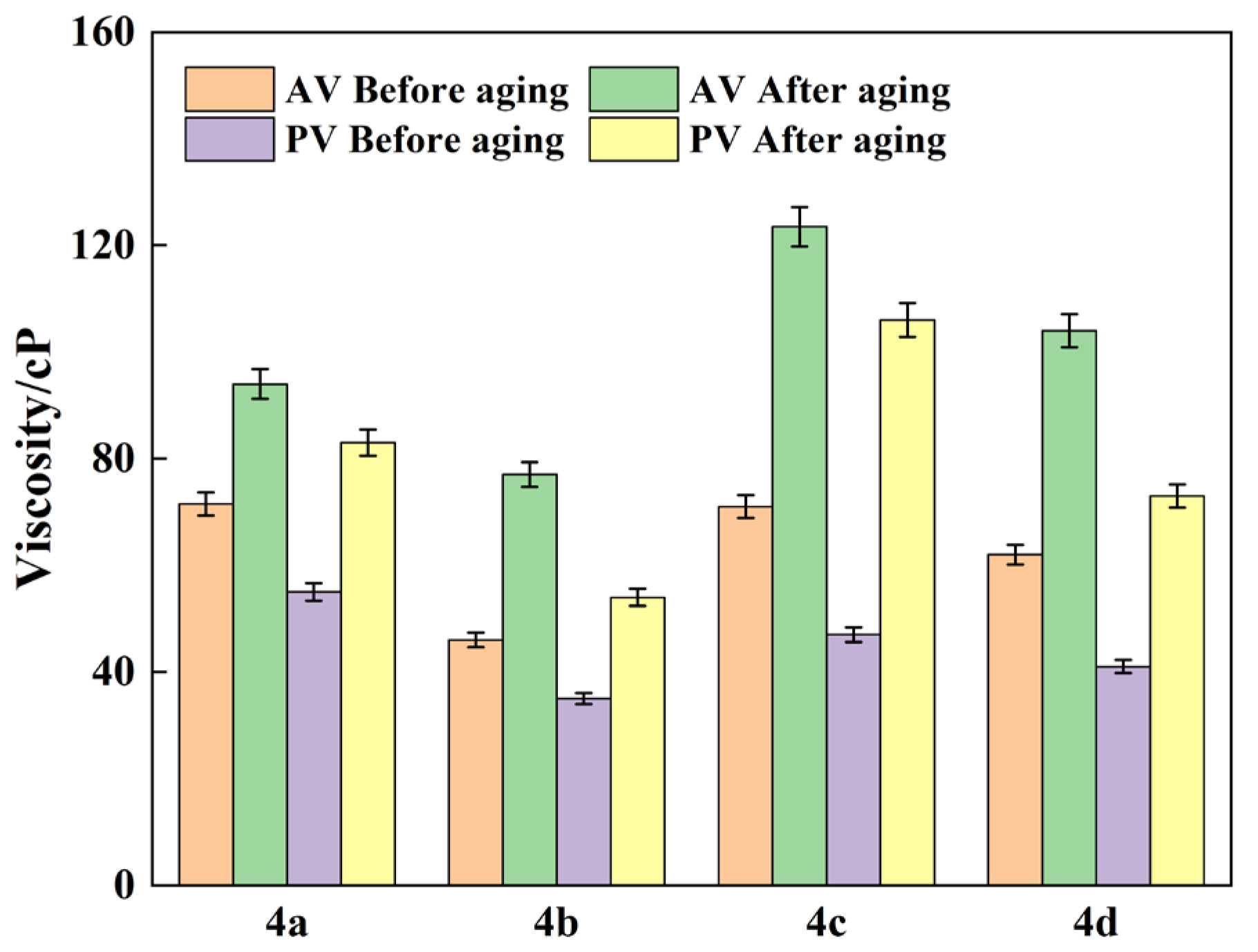

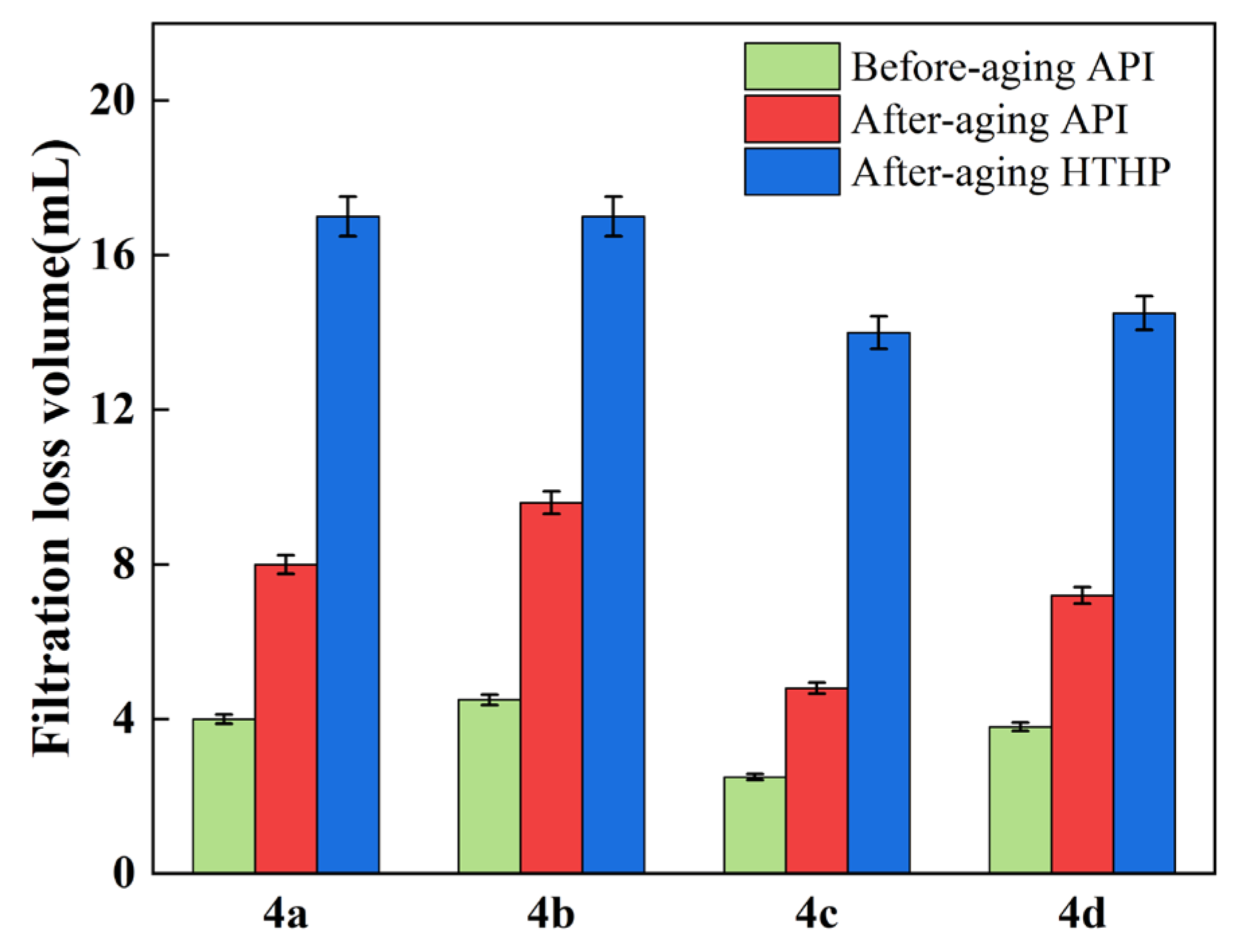

3.2.5. Optimization of Drilling Fluid System

3.3. Evaluation of Optimized Drilling Fluid System

3.3.1. Drilling Fluid Contamination Test

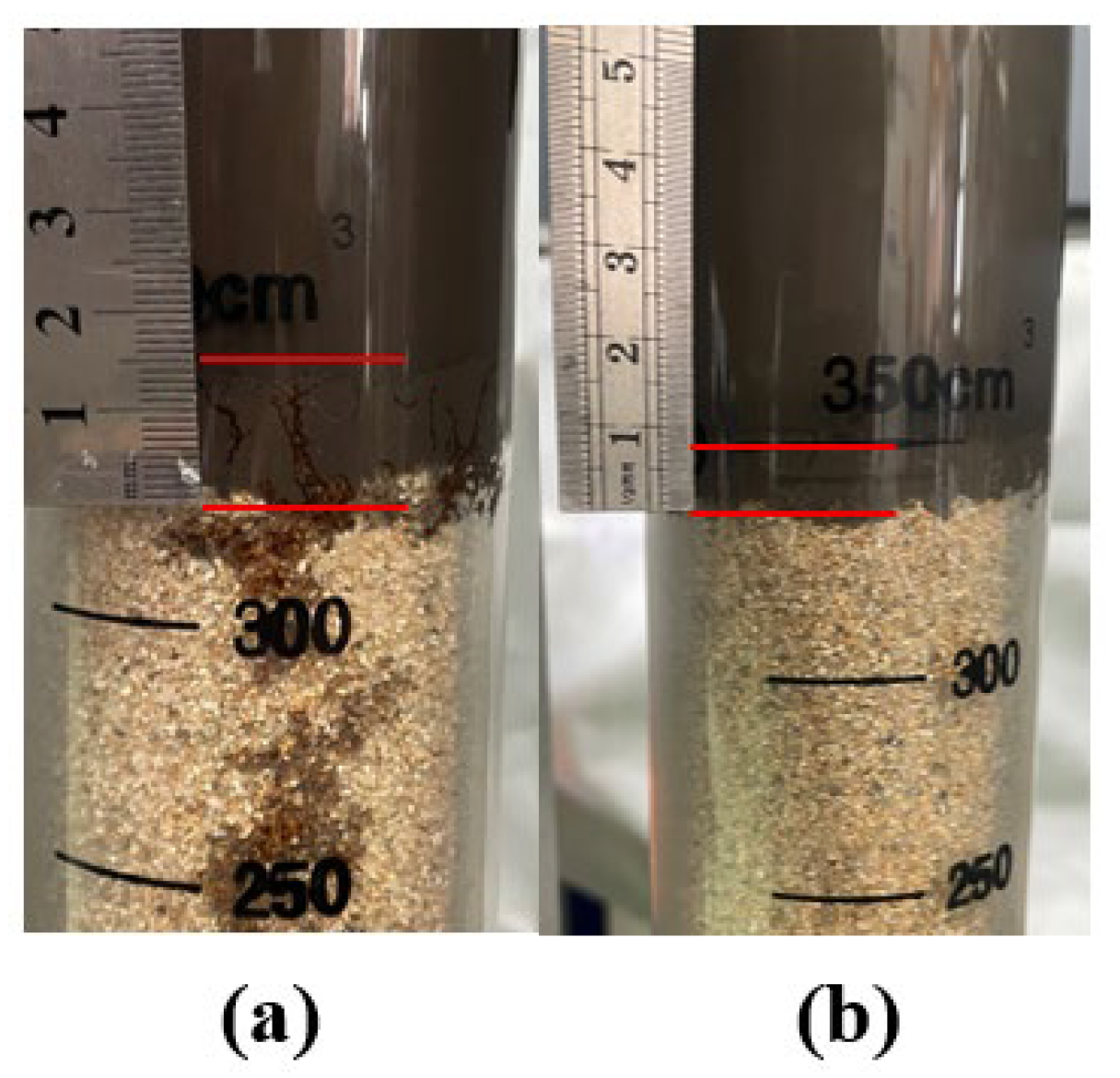

3.3.2. Sand Packing Filtration Test

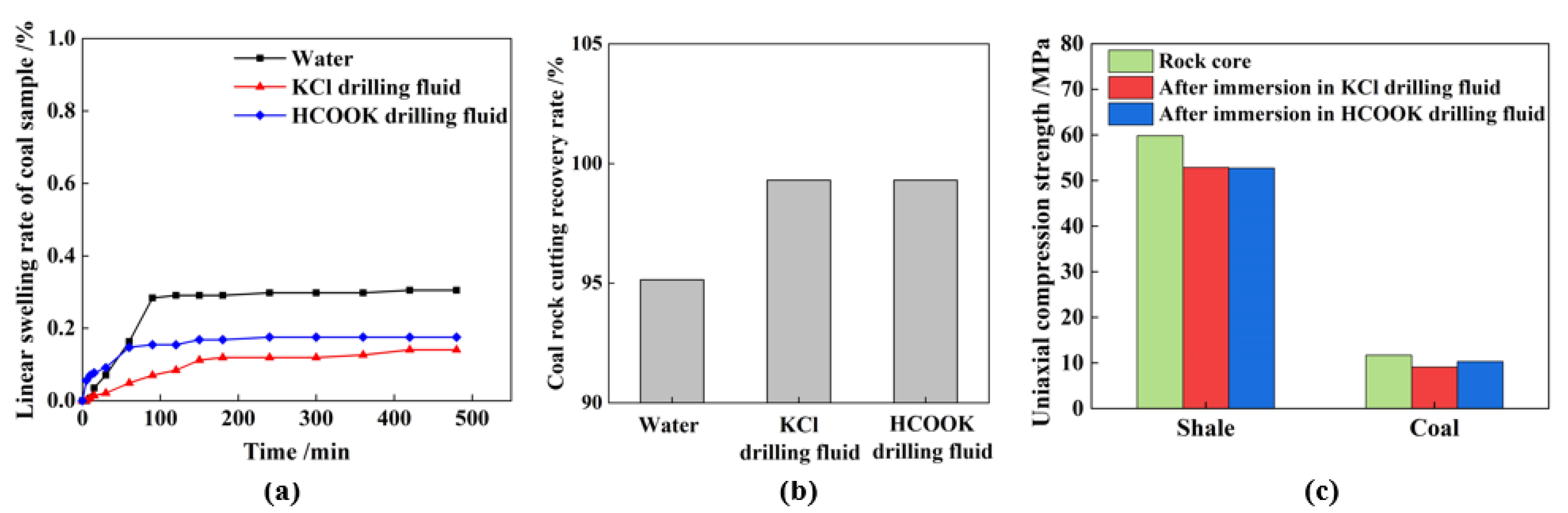

3.3.3. Inhibition Performance Test

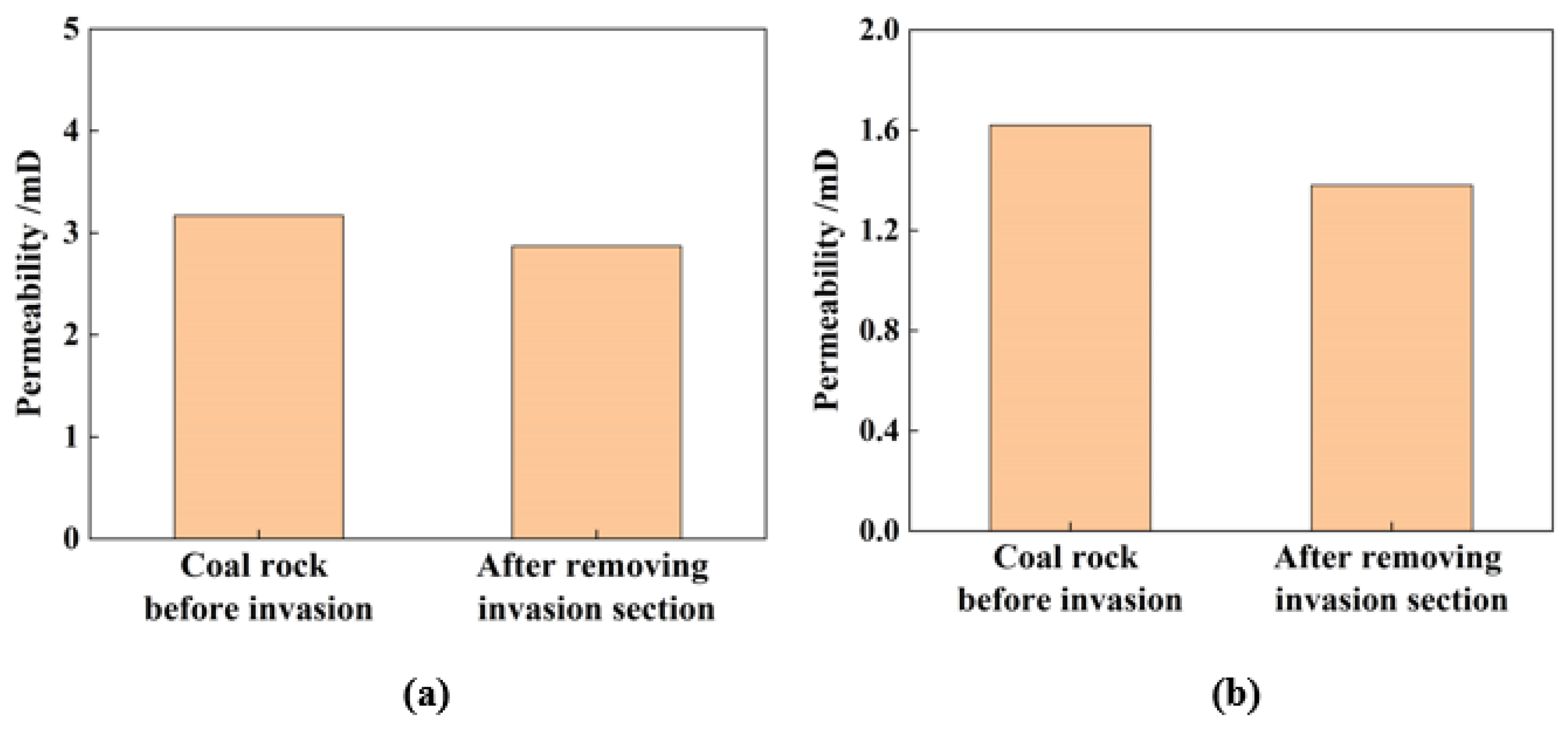

3.3.4. Reservoir Damage Evaluation

4. Conclusions

- (1)

- Shale is mainly composed of quartz, kaolinite, illite, and illite/montmorillonite interbedded mineral, and coal rock contained coal, quartz, and kaolinite. No obvious bedding or microcracks were observed in the shale, and a layered structure of minerals could be observed. The fracture width in coal rock ranged from 100 μm to 100,000 μm. Cleavage contributed to the smaller fractures, while major fractures mainly existed between beddings.

- (2)

- With the optimal drilling agents, KCl and HCOOK polymer drilling fluid systems were designed. The two systems show good inhibition performance, with the recovery rate of shale cuttings reaching more than 99.0%, while the linear swelling rate can be controlled at less than 0.18%. Both systems demonstrate superior sealing performance, and the invasion depth was less than 15.5 mm during the packed sand filtration loss test. Coal rock permeability was recovered by more than 90.0% after the removal of 10 mm of the invasion section, indicating that the drilling fluid does not cause significant damage and can protect deep coalbed gas reservoirs.

- (3)

- Compared to the KCl system, the HCOOK drilling fluid system shows better inhibition and sealing capacity. The uniaxial compression strength reduced from 11.74 MPa to 10.35 MPa after immersion in HCOOK drilling fluid, whereas it decreased to 9.13 MPa in KCl drilling fluid. The invasion depth in packed sand was only 8.0 mm for HCOOK drilling fluid, whereas it was 15.5 mm for KCl drilling fluid. As a result, the HCOOK drilling fluid system is more suitable for addressing wellbore collapse problems in deep coalbed gas reservoirs in the Ordos Basin. In future studies, the proposed formulation will be applied in field operations, and the results will be compared with laboratory data to improve the entire drilling fluid system, thereby enabling the resolution of practical drilling engineering problems.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rightmire, C.T.; Eddy, G.E.; Kirr, J.N. Coalbed Methane Resources of the United States; American Association of Petroleum Geologists: Tulsa, OK, USA, 1984. [Google Scholar]

- Bao, Y.; Wei, C.; Neupane, B. Generation and accumulation characteristics of mixed coalbed methane controlled by tectonic evolution in Liulin CBM field, eastern Ordos Basin, China. J. Nat. Gas Sci. Eng. 2016, 28, 262–270. [Google Scholar] [CrossRef]

- Qin, Y.S.; Yang, S.Z. Accumulation effects and coupling relationship of deep coalbed methane. Acta Pet. Sin. 2012, 33, 48. [Google Scholar]

- Qin, Y.; Shen, J. On the fundamental issues of deep coalbed methane geology. Acta Pet. Sin. 2016, 37, 125. [Google Scholar]

- Niu, X.; Fan, L.; Yan, X.; Zhou, G.; Zhang, H.; Jing, X.; Zhang, M. Enrichment conditions and resource potential of coal-rock gas in Ordos Basin, NW China. Pet. Explor. Dev. 2024, 51, 1122–1137. [Google Scholar] [CrossRef]

- Li, J.; Cao, H.; Li, X.; Liu, H. Characteristics of coalbed methane resource and the development strategies. Nat. Gas Ind. 2009, 29, 9–13. [Google Scholar]

- Song, Y.L.; Qin, S. Geochemical characteristics and genesis of coalbed methane in China. Acta Pet. Sin. 2012, 33 (Suppl. S1), 99. [Google Scholar]

- Zhao, H.; Chen, M.; Li, Y.; Zhang, W. Discrete element model for coal wellbore stability. Int. J. Rock Mech. Min. 2012, 54, 43–46. [Google Scholar] [CrossRef]

- Gentzis, T.; Deisman, N.; Chalaturnyk, R.J. Effect of drilling fluids on coal permeability: Impact on horizontal wellbore stability. Int. J. Coal Geol. 2009, 78, 177–191. [Google Scholar] [CrossRef]

- Li, Q.; Zhu, D.-Y.; Zhuang, G.-Z.; Li, X.-L. Advanced development of chemical inhibitors in water-based drilling fluids to improve shale stability: A review. Pet. Sci. 2025, 22, 1977–1996. [Google Scholar] [CrossRef]

- de Carvalho Balaban, R.; Vidal, E.L.F.; Borges, M.R. Design of experiments to evaluate clay swelling inhibition by different combinations of organic compounds and inorganic salts for application in water base drilling fluids. Appl. Clay Sci. 2015, 105, 124–130. [Google Scholar] [CrossRef]

- Chen, S.; Shi, Y.; Yang, X.; Xie, K.; Cai, J. Design and evaluation of a surfactant–mixed metal hydroxide-based drilling fluid for maintaining wellbore stability in coal measure strata. Energies 2019, 12, 1862. [Google Scholar] [CrossRef]

- Patel, A.; Stamatakis, E.; Young, S.; Friedheim, J. Advances in inhibitive water-based drilling fluids–can they replace oil-based muds? In SPE International Conference on Oilfield Chemistry; SPE: Houston, TX, USA, 2007; p. SPE–106476-MS. [Google Scholar]

- Muhammed, N.S.; Olayiwola, T.; Elkatatny, S. A review on clay chemistry, characterization and shale inhibitors for water-based drilling fluids. J. Pet. Sci. Eng. 2021, 206, 109043. [Google Scholar] [CrossRef]

- Abbas, M.A.; Zamir, A.; Elraies, K.A.; Mahmood, S.M.; Rasool, M.H. A critical parametric review of polymers as shale inhibitors in water-based drilling fluids. J. Pet. Sci. Eng. 2021, 204, 108745. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wu, J.; He, K.; Xia, Y.; Liu, J.; Cheng, Y. Wellhead Stability During Development Process of Hydrate Reservoir in the Northern South China Sea: Sensitivity Analysis. Processes 2025, 13, 1630. [Google Scholar] [CrossRef]

- Zhang, S.; He, Y.; Chen, Z.; Sheng, J.J.; Fu, L. Application of polyether amine, poly alcohol or KCl to maintain the stability of shales containing Na-smectite and Ca-smectite. Clay Miner. 2018, 53, 29–39. [Google Scholar] [CrossRef]

- Fadhil, E.Y.; Hadi, F. Enhancing drilling mud efficiency and environmental safety with biodegradable materials. Iraqi J. Chem. Pet. Eng. 2024, 25, 73–79. [Google Scholar] [CrossRef]

- Bohoslavets, V.; Kolisnyk, V.; Hrymanyuk, V.; Voloshyn, Y. Research of the Properties of Potassium Format for the Preparation of Drilling Fluid. In Proceedings of the 16th International Conference Monitoring of Geological Processes and Ecological Condition of the Environment, Kyiv, Ukraine, 15–18 November 2022; European Association of Geoscientists & Engineers: Bunnik, The Netherlands, 2022; Volume 2022, pp. 1–5. [Google Scholar]

- Villabona-Estupiñan, S.; de Abreu, C.F.; Nascimento, R.S.V. Mechanism of shales stabilization by hydrophobized poly (ethylene glycol)/K+ in water-base drilling fluids. Pet. Explor. DEV+ 2021, 48, 721–731. [Google Scholar] [CrossRef]

- Xu, J.-G.; Luo, T.; Wang, J.; Zhu, S.; Azadbakht, S.; Lyu, X.; Li, M.; Wang, L. Investigation of alcohol-based deep eutectic solvents for inhibiting hydration in shale formations. J. Mol. Liq. 2023, 392, 123551. [Google Scholar] [CrossRef]

- Zhang, S.; Qiu, Z.; Huang, W.; Cao, J.; Luo, X. Characterization of a novel aluminum-based shale stabilizer. J. Pet. Sci. Eng. 2013, 103, 36–40. [Google Scholar] [CrossRef]

- Zhang, S.; Sheng, J.J.; Qiu, Z. Maintaining shale stability using polyether amine while preventing polyether amine intercalation. Appl. Clay Sci. 2016, 132, 635–640. [Google Scholar] [CrossRef]

- Zhang, S.; Qiu, Z.; Huang, W. Water-adsorption properties of Xiazijie montmorillonite intercalated with polyamine. Clay Miner. 2015, 50, 537–548. [Google Scholar] [CrossRef]

- Zhang, S.; Sheng, J.J. Effect of water imbibition on hydration induced fracture and permeability of shale cores. Gas Sci. Eng. 2017, 45, 726–737. [Google Scholar] [CrossRef]

- Bai, X.; Wang, H.; Luo, Y.; Zheng, X.; Zhang, X.; Zhou, S.; Pu, X. The structure and application of amine-terminated hyperbranched polymer shale inhibitor for water-based drilling fluid. J. Appl. Polym. Sci. 2017, 134, 45466. [Google Scholar] [CrossRef]

- Patel, A.D. Design and development of quaternary amine compounds: Shale inhibition with improved environmental profile. In Proceedings of the SPE International Conference on Oilfield Chemistry, The Woodlands, TX, USA, 20–22 April 2009; SPE: Houston, TX, USA, 2009; p. SPE-121737-MS. [Google Scholar]

- Zhong, H.; Qiu, Z.; Huang, W.; Cao, J. Shale inhibitive properties of polyether diamine in water-based drilling fluid. J Pet. Sci. Eng. 2011, 78, 510–515. [Google Scholar] [CrossRef]

- SY/T 5162-2014; Analytical Method of Rock Sample by Scanning Electron Microscope. Petroleum Industry Press: Beijing, China, 2014.

- Lin, C.; Jia, X.; Chen, X.; Liu, W.; Mao, J.; Yang, X.; Zhang, Y.; He, J. Failure and fractal characteristics of anisotropic oil shale using real-time CT technology. Powder Technol. 2025, 466, 121522. [Google Scholar] [CrossRef]

- API Recommendation 13B-1/ISO 10414-1:2009; Recommended Practice for Field Testing Water-Based Drilling Fluids. ISO: Geneva, Switzerland, 2009.

- Downs, J. Formate brines: Novel drilling and completion fluids for demanding environments. In Proceedings of the SPE International Conference on Oilfield Chemistry, New Orleans, LA, USA, 2–5 March 1993; SPE: Houston, TX, USA, 1993; p. SPE-25177-MS. [Google Scholar]

- Gallino, G.; Guarneri, A.; Maglione, R.; Nunzi, P.; Xiao, L. New formulations of potassium acetate and potassium formate polymer muds greatly improved drilling and waste disposal operations in South Italy. In Proceedings of the SPE Oklahoma City Oil and Gas Symposium/Production and Operations Symposium, Oklahoma City, OK, USA, 9–11 March 1997; SPE: Houston, TX, USA, 1997; p. SPE-37471-MS. [Google Scholar]

- Liu, Y.F.; Zhou, L.; Wan, X.C.; Tang, Y.F.; Liu, Q.; Li, W.; Liao, J.B. Synthesis and characterization of a temperature sensitive microcapsule gelling agent for high-temperature acid release. ACS Omega 2024, 9, 20849–20858. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Li, Q.; Han, Y. A numerical investigation on kick control with the displacement kill method during a well test in a deep-water gas reservoir: A case study. Processes 2024, 12, 2090. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Cao, H.; Wu, J.; Wang, F.; Wang, Y. The Fracture Propagation Behaviour of CO2 Fracturing Fluid in Unconventional Low Permeability Reservoirs: Factor Analysis and Mechanism Revelation. Processes 2025, 13, 159. [Google Scholar] [CrossRef]

- Zhang, C.P.; Ranjith, P.G.; Perera, M.S.A.; Li, X.; Zhao, J. Simulation of flow behaviour through fractured unconventional gas reservoirs considering the formation damage caused by water-based fracturing fluids. J. Nat. Gas Sci. Eng. 2018, 57, 100–121. [Google Scholar] [CrossRef]

- Li, Q. Reservoir Science: A Multi-Coupling Communication Platform to Promote Energy Transformation, Climate Change and Environmental Protection. Reserv. Sci. 2025, 1, 1–2. [Google Scholar]

- Zhao, J.; Wu, T.; Pu, W.; Daijun, D.; Chen, Q.; Chen, B.; Li, J.; Huang, Y. Application status and research progress of CO2 fracturing fluid in petroleum engineering: A brief review. Petroleum 2024, 10, 1–10. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wang, F.; Wu, J.; Wang, Y.; Jin, J. Effects of Geological and Fluid Characteristics on the Injection Filtration of Hydraulic Fracturing Fluid in the Wellbores of Shale Reservoirs: Numerical Analysis and Mechanism Determination. Processes 2025, 13, 1747. [Google Scholar] [CrossRef]

- Ao, F.; Li, Q.C.; Li, Q.; Wu, J.J.; Wang, F.L.; Yan, C.L. Numerical Simulation Investigation of Fracture Propagation Behavior Patterns and Sensitivity Factors of Oil Shale Reservoirs in the Xunyi Region Considering the Influence of Natural Fracture. Geofluids 2025, 1, 2762142. [Google Scholar] [CrossRef]

- Wang, F.; Kobina, F. The influence of geological factors and transmission fluids on the exploitation of reservoir geothermal resources: Factor discussion and mechanism analysis. Reserv. Sci. 2025, 1. [Google Scholar]

- Huang, M.; Wu, L.; Ning, F.; Wang, J.; Dou, X.; Zhang, L.; Liu, T.; Jiang, G. Research progress in natural gas hydrate reservoir stimulation. Nat. Gas Ind. B 2023, 10, 114–129. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wu, J.; Li, X.; Li, H.; Cheng, Y. Wellhead stability during development process of hydrate reservoir in the Northern South China Sea: Evolution and mechanism. Processes 2024, 13, 40. [Google Scholar] [CrossRef]

- Xiong, C.; Shi, Y.; Zhou, F.; Liu, X.; Yang, X.; Yang, X. High efficiency reservoir stimulation based on temporary plugging and diverting for deep reservoirs. Pet. Explor. Dev. 2018, 45, 948–954. [Google Scholar] [CrossRef]

| Shale Mineral Composition | |||||||

|---|---|---|---|---|---|---|---|

| Quartz | Potassium Feldspar | Siderite | Iron pyrite | Kaolinite | Chlorite | Illite | Illite/Montmorillonite Interbedded Mineral |

| 53.15 | 1.44 | 8.96 | 1.43 | 21.7 | 2.82 | 6.3 | 4.2 |

| Coal Rock Mineral Composition | |||||||

| Quartz | Calcite | Anatase | Ammonium Mica | Kaolinite | Coal | ||

| 17.89 | 0.21 | 0.52 | 5.22 | 6.16 | 70 | ||

| Base Mud | Composition of Base Mud Systems |

|---|---|

| 1a | 4% bentonite slurry + 7% KCl + 0.5% PA |

| 1b | 4% bentonite slurry + 15% HCOOK |

| 2a | 4% bentonite slurry + 0.1% KPAM + 1%NPAN + 3% M-SMC + 7% KCl + 0.5% PA |

| 2b | 4% bentonite slurry + 0.1% KPAM + 1% SPNH + 3% M-SMC + 15% HCOOK |

| 3a | 4% bentonite slurry + 0.1% KPAM + 1% NPAN + 3% M-SMC + 3% Asphalt MK + 2% XZ-GBJ + 7% KCl + 0.5% PA |

| 3b | 4% bentonite slurry + 0.1% KPAM + 1% SPNH + 3% M-SMC + 3% Asphalt MK + 15% HCOOK. |

| 4a | 4% bentonite slurry + 0.1% KPAM + 1%NPAN + 3% M-SMC + 3% Asphalt MK+ 2%XZ-GBJ + 7%KCl + 0.5% PA+ 2% PGCS-1. |

| 4b | 4% bentonite slurry + 0.1% KPAM + 1% SPNH + 3% M-SMC+ 3% Asphalt MK + 15% HCOOK+ 2% PGCS-1 |

| 4c | 4% bentonite slurry + 0.1% KPAM + 1% PAC-LV + 4% SPNH + 4% FT-401 + 7% KCl + 0.5% PA+ 2% PGCS-1 |

| 4d | 4% bentonite slurry + 0.1% KPAM + 1% PAC-LV + 4% SPNH + 2% XZ-CMJ + 15% HCOOK+ 2% PGCS-1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, G.; Zhang, C.; Li, Z.; Ma, H.; Cai, D.; Zhou, X.; Zhang, X.; Bai, L.; Zhang, P.; Zhao, J. Design and Evaluation of Drilling Fluid Systems for Wellbore Stabilization During Drilling in Deep Coalbed Gas Reservoirs in the Ordos Basin. Processes 2025, 13, 3150. https://doi.org/10.3390/pr13103150

Cao G, Zhang C, Li Z, Ma H, Cai D, Zhou X, Zhang X, Bai L, Zhang P, Zhao J. Design and Evaluation of Drilling Fluid Systems for Wellbore Stabilization During Drilling in Deep Coalbed Gas Reservoirs in the Ordos Basin. Processes. 2025; 13(10):3150. https://doi.org/10.3390/pr13103150

Chicago/Turabian StyleCao, Gang, Chaoqun Zhang, Zhenxing Li, Hongliang Ma, Dongsheng Cai, Xin Zhou, Xinchen Zhang, Lu Bai, Peng Zhang, and Junjie Zhao. 2025. "Design and Evaluation of Drilling Fluid Systems for Wellbore Stabilization During Drilling in Deep Coalbed Gas Reservoirs in the Ordos Basin" Processes 13, no. 10: 3150. https://doi.org/10.3390/pr13103150

APA StyleCao, G., Zhang, C., Li, Z., Ma, H., Cai, D., Zhou, X., Zhang, X., Bai, L., Zhang, P., & Zhao, J. (2025). Design and Evaluation of Drilling Fluid Systems for Wellbore Stabilization During Drilling in Deep Coalbed Gas Reservoirs in the Ordos Basin. Processes, 13(10), 3150. https://doi.org/10.3390/pr13103150