Study on Production System Optimization and Productivity Prediction of Deep Coalbed Methane Wells Considering Thermal–Hydraulic–Mechanical Coupling Effects

Abstract

1. Introduction

2. Thermal–Hydraulic–Mechanical (THM) Coupling Model for Production in Deep Coalbed Methane Wells

2.1. Basic Assumptions of the Mathematical Model

2.2. Mathematical Models

2.2.1. Governing Equations for Fluid Flow

- (1)

- CH4 Transport Equation in Coal Matrix

- (2)

- Governing Equations for Fluid Migration in Coal Fracture Systems

- (3)

- Supplementary Equation

2.2.2. Governing Equations for Stress Field

2.2.3. Governing Equations for Temperature Field

2.2.4. Governing Equations for Porosity and Permeability

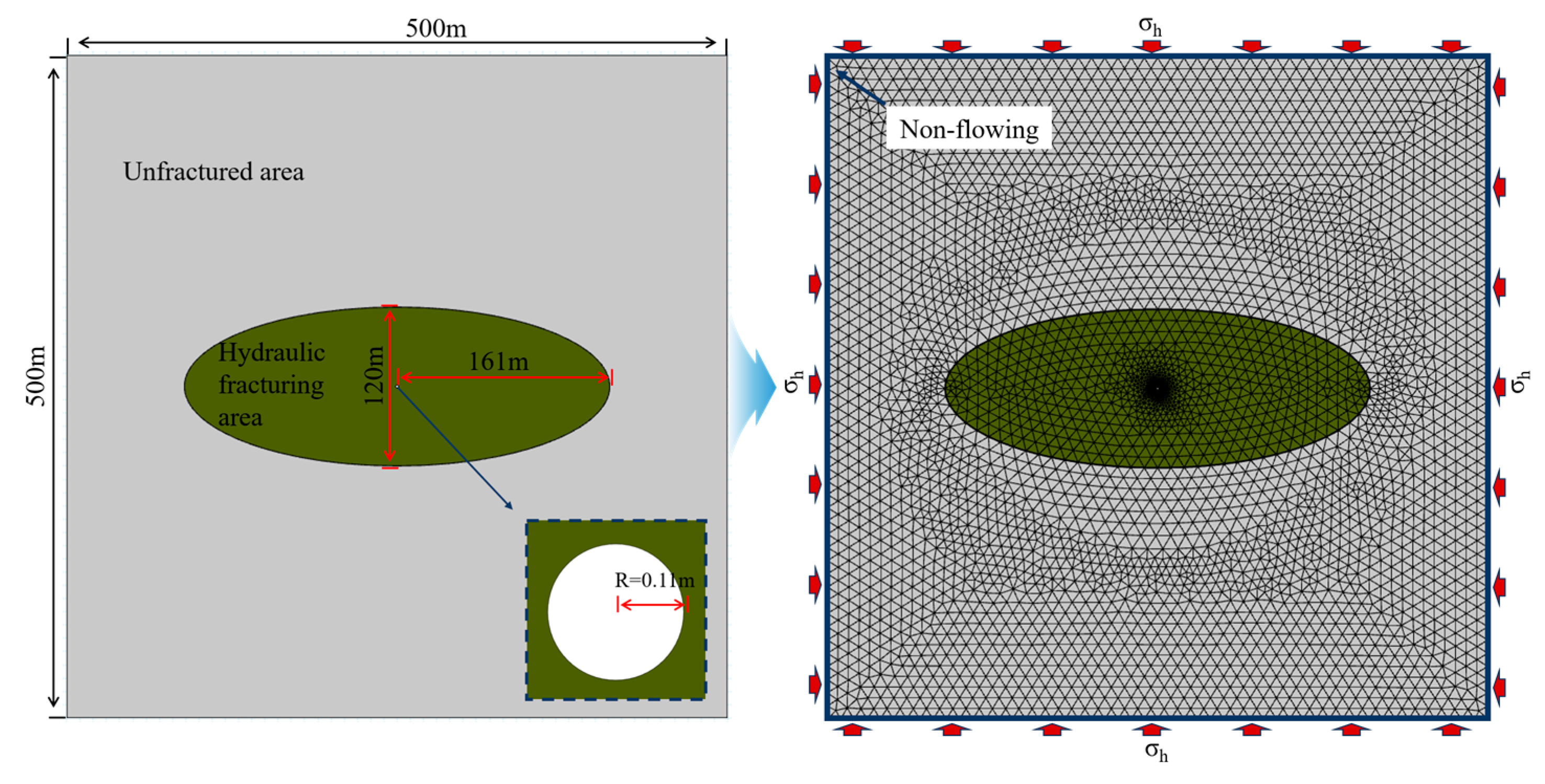

3. Geological Model, Numerical Scheme, and Boundary Conditions

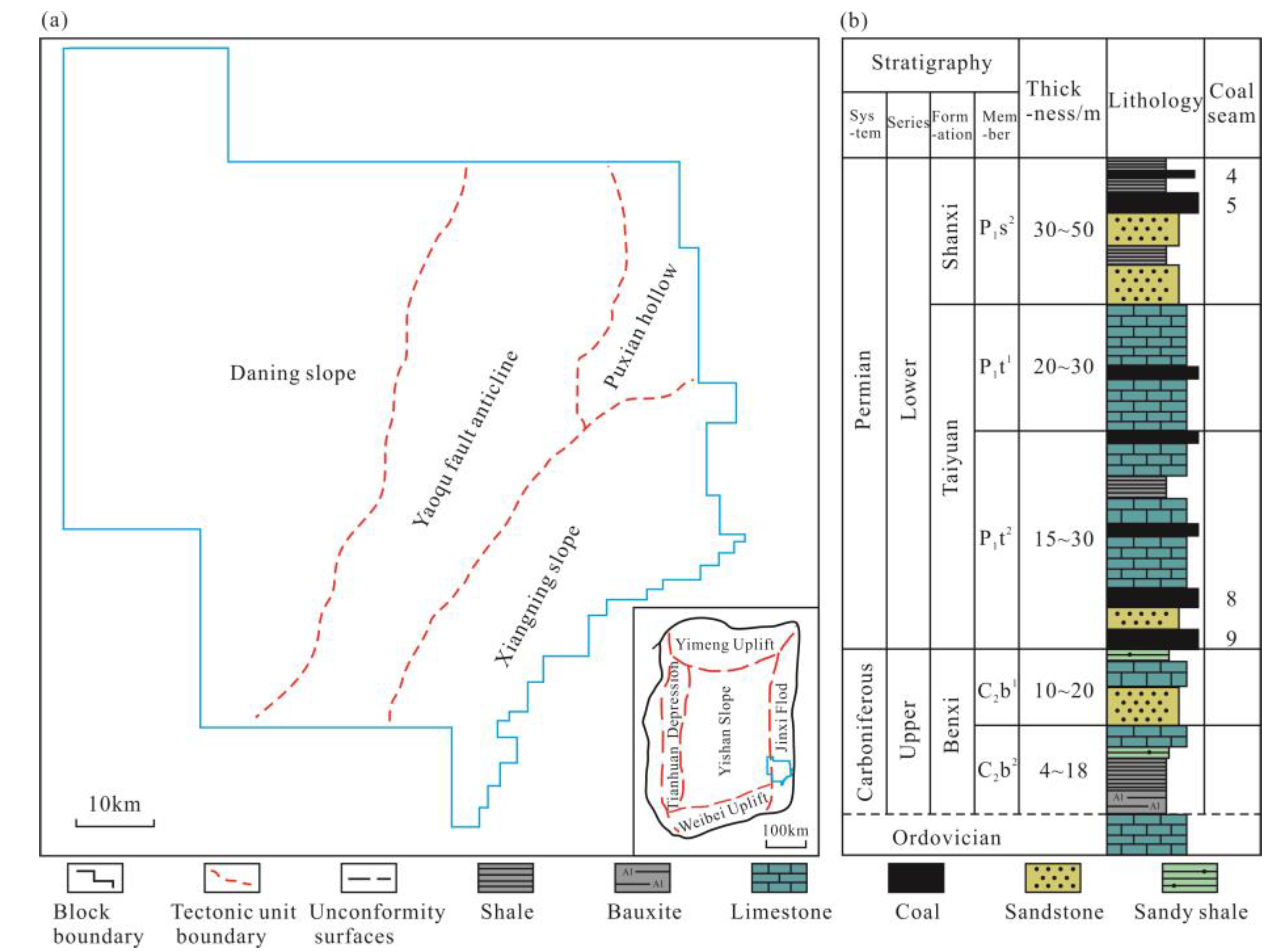

3.1. Geologic Model

3.2. Numerical Scheme

3.3. Boundary Conditions

4. Results

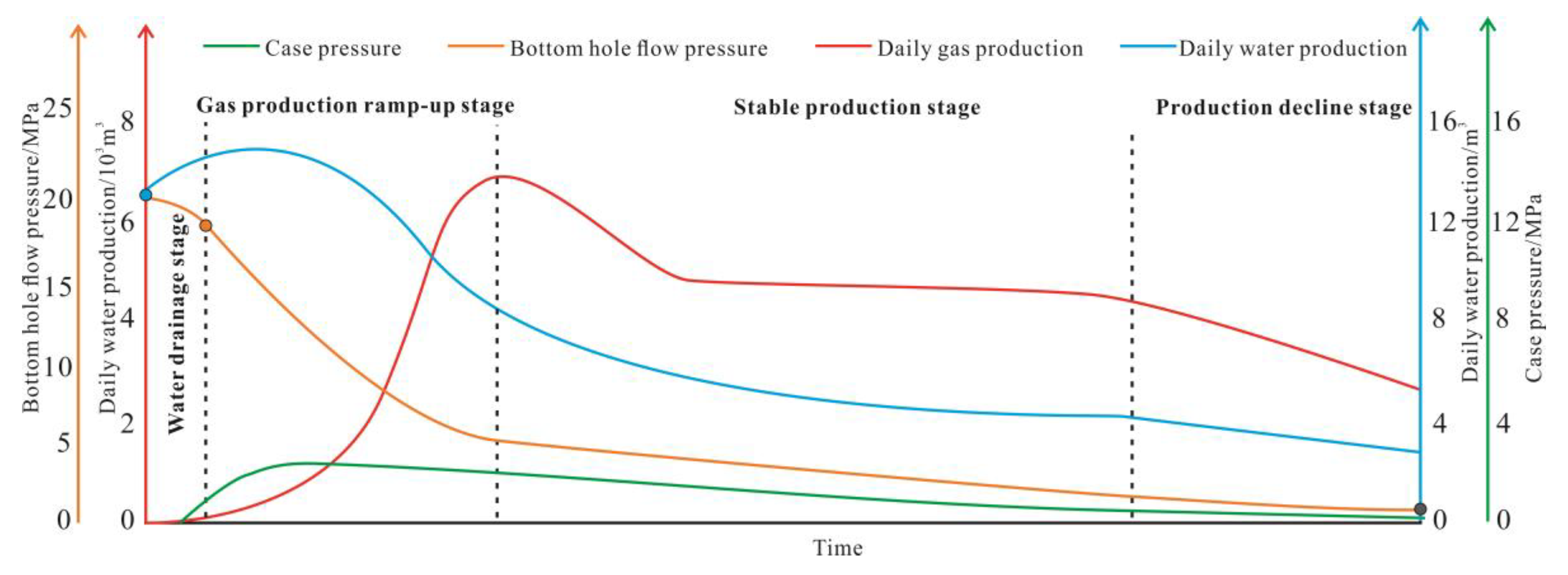

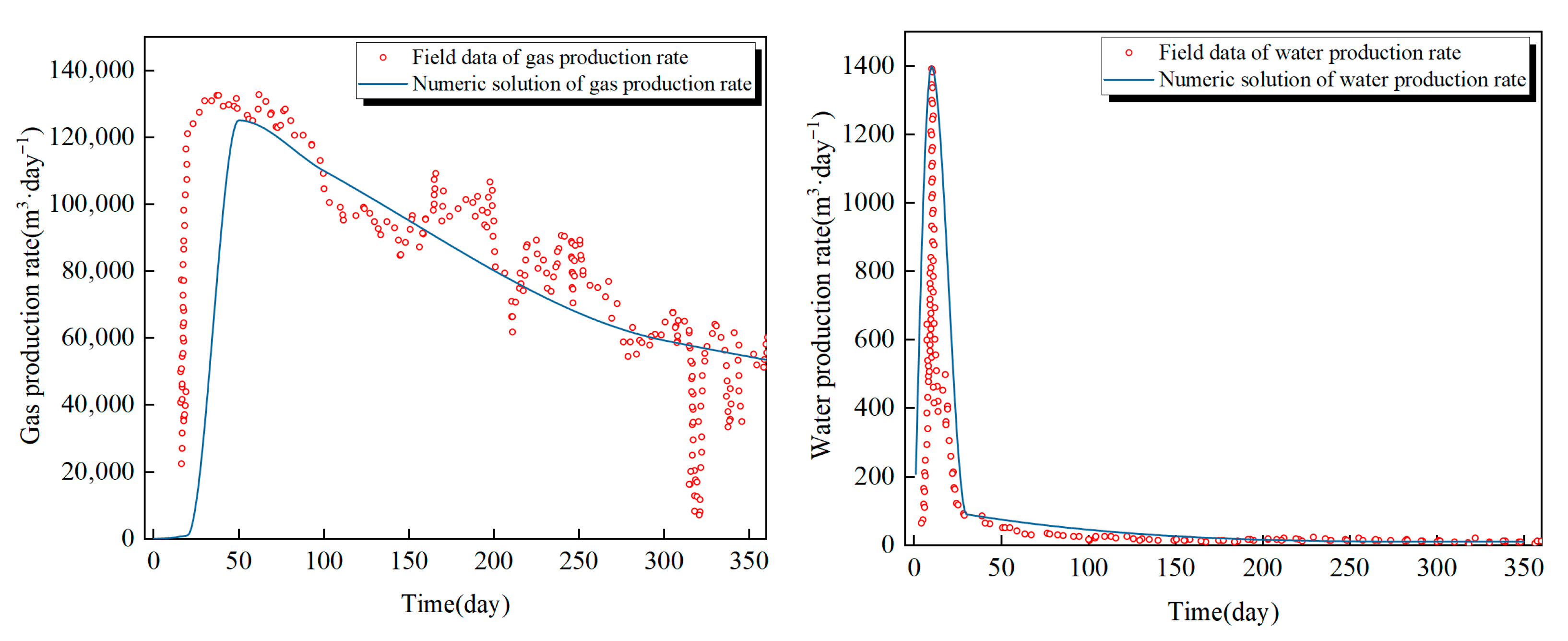

4.1. History Matching and Mathematical Model Validation

4.2. Impact of Production Strategy on Development Effectiveness of Deep CBM Wells

5. Discussion

5.1. Impact of Reservoir Pressure on Gas Production Performance

5.2. Impact of Reservoir Water Saturation on Gas Production Performance

5.3. Impact of Reservoir Temperature on Gas Production Performance

5.4. Impact of Desorption-Diffusion on Gas Production Performance in Deep CBM Reservoirs

5.5. Impact of Reservoir Permeability on Gas Production Performance

5.6. Limitations and Future Work

6. Conclusions

- (1)

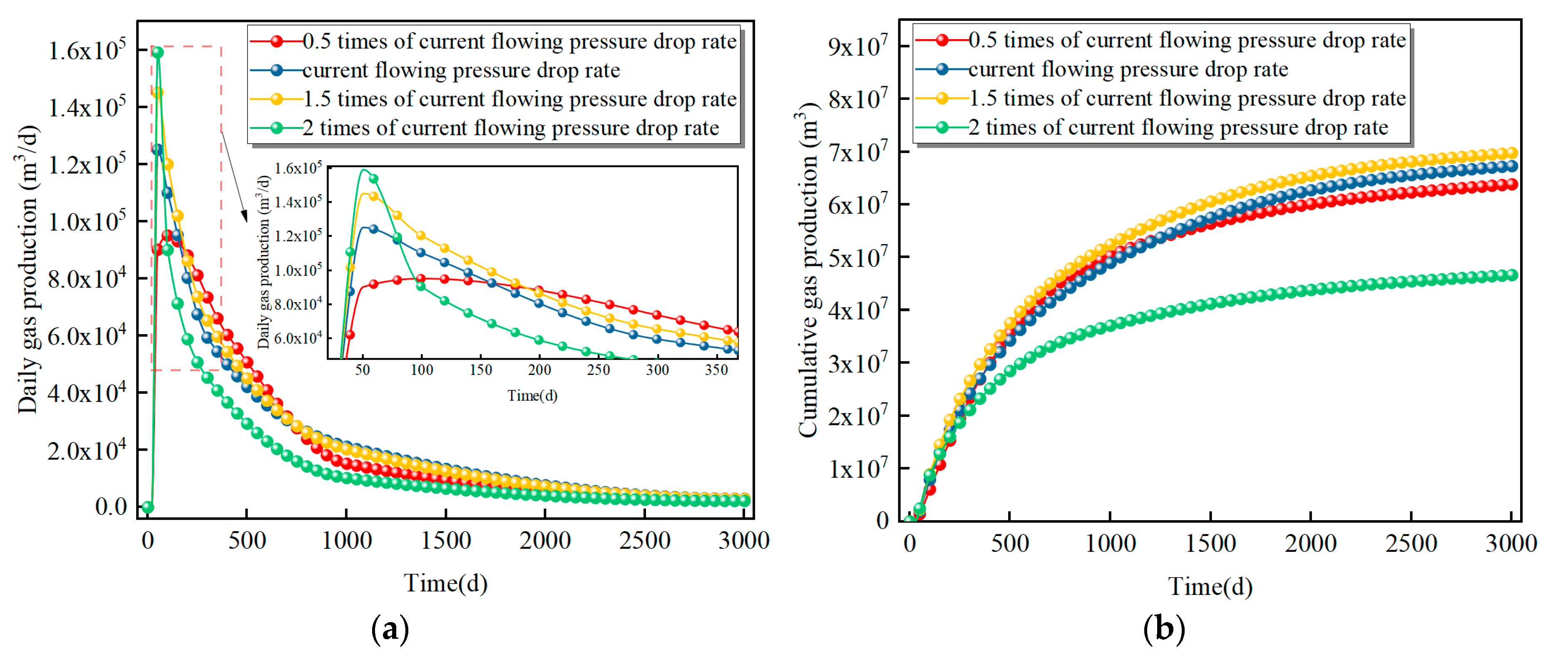

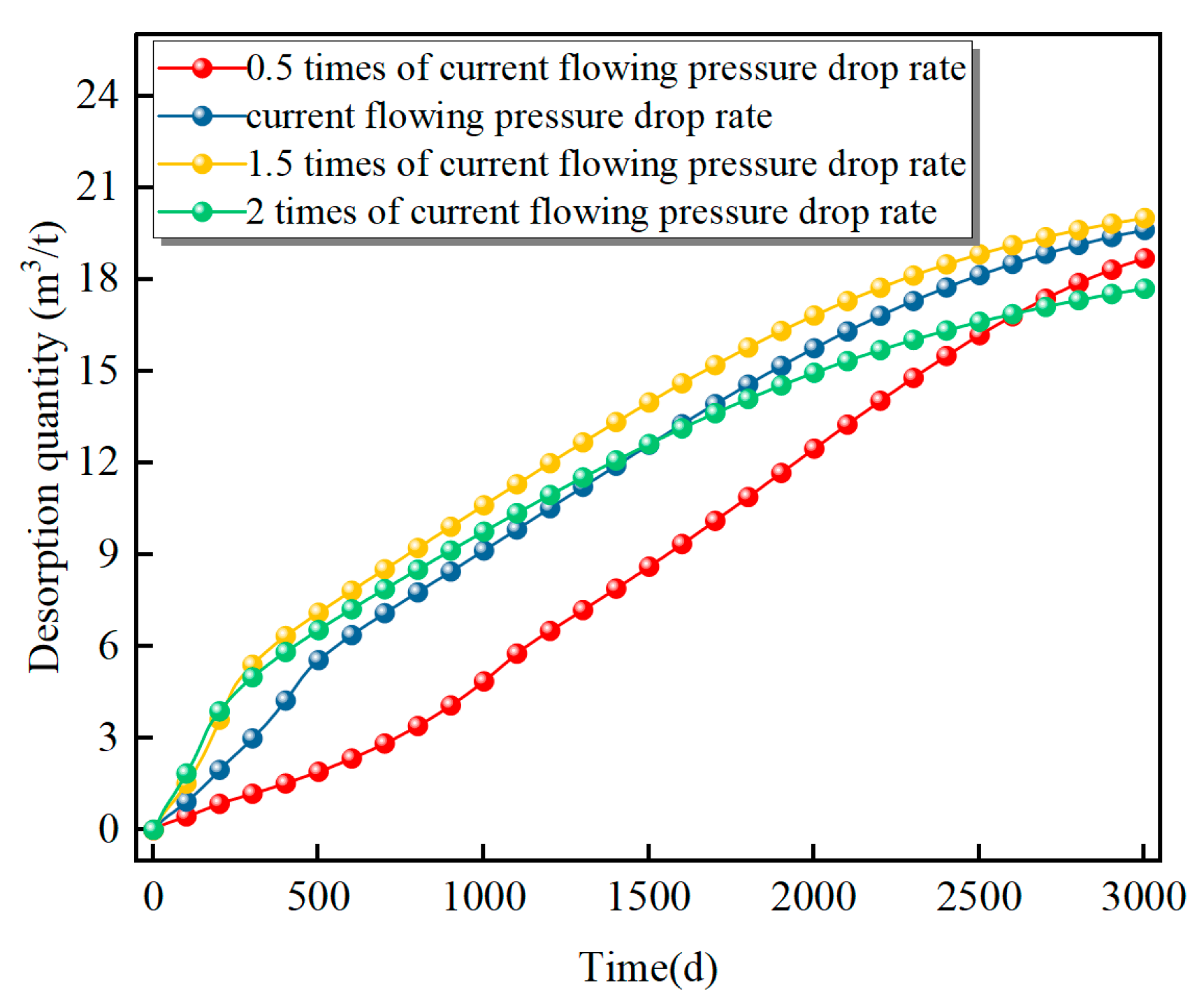

- A bottom-hole flowing pressure drop rate of 1.5 times the current value is recommended as optimal. The specific rates are 0.15 MPa/d (dewatering), 0.057 MPa/d (ramp-up), 0.035 MPa/d (stable production), and 0.01 MPa/d (decline). This strategy accelerates the early-stage pressure drop, bringing forward the gas production peak and increasing the peak daily rate by 15.90%. Crucially, it also avoids the sharp production decline associated with higher drawdown rates (e.g., 2×), leading to a 3.68% increase in cumulative production over the lifecycle. Lower rates offer insignificant gains, while higher rates risk reservoir damage.

- (2)

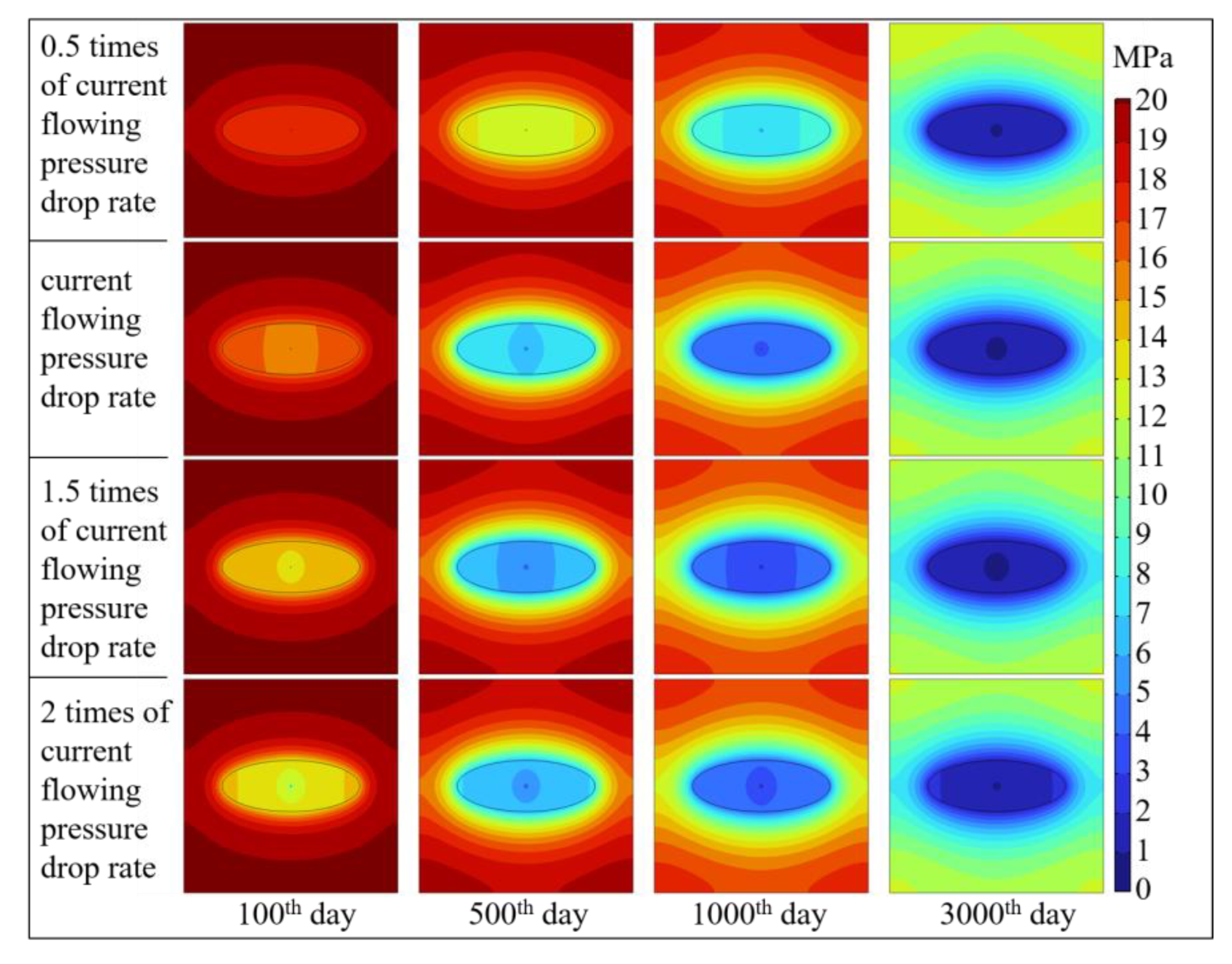

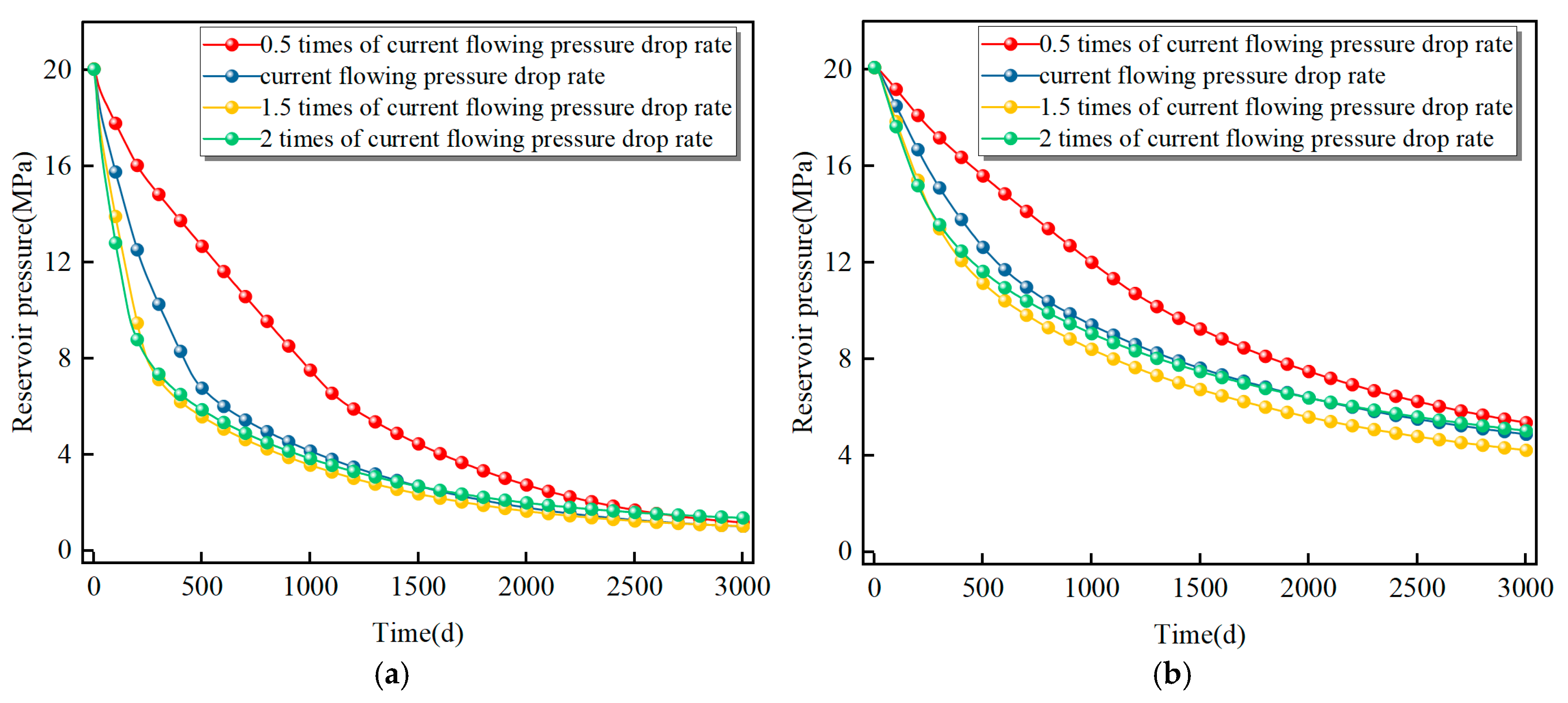

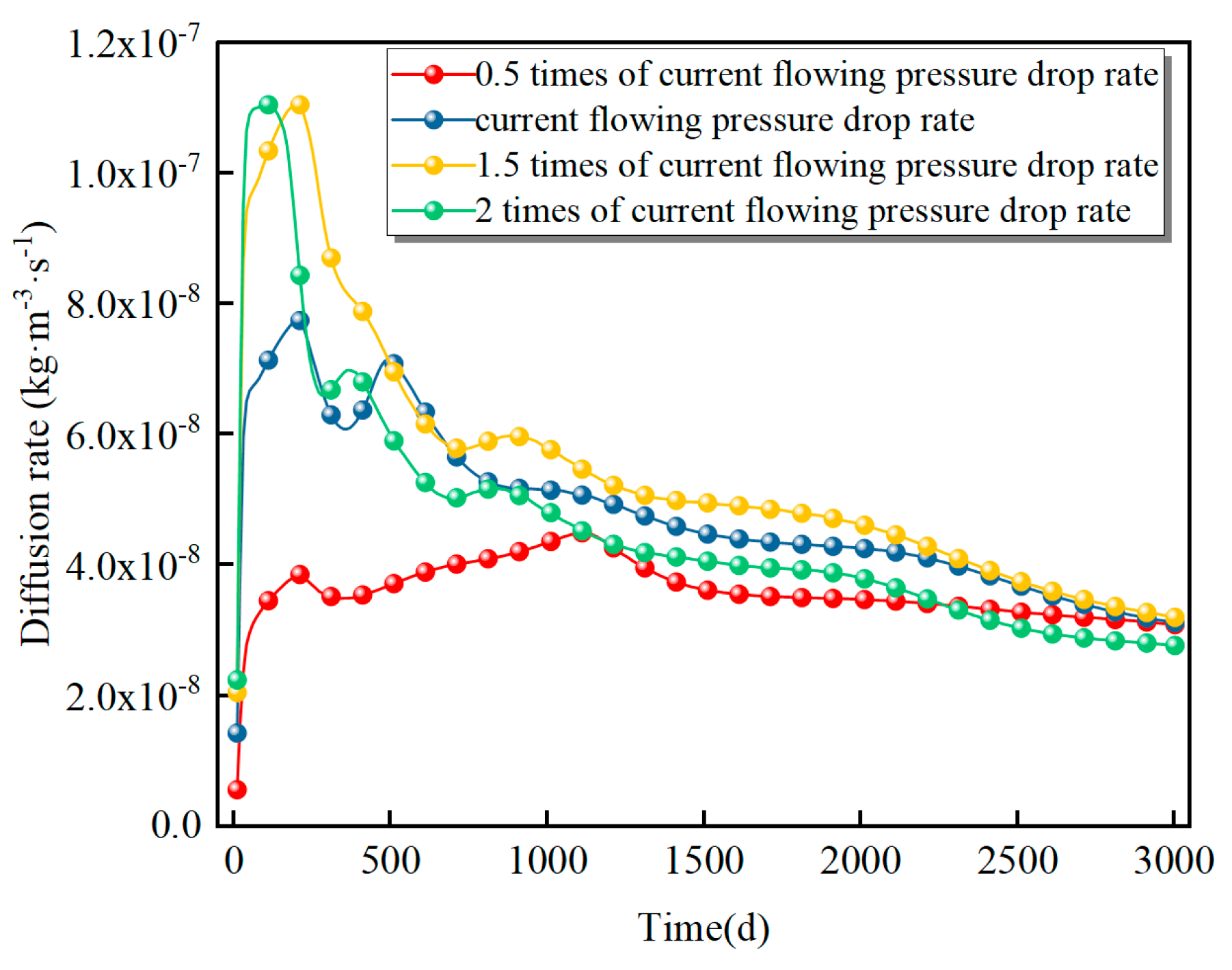

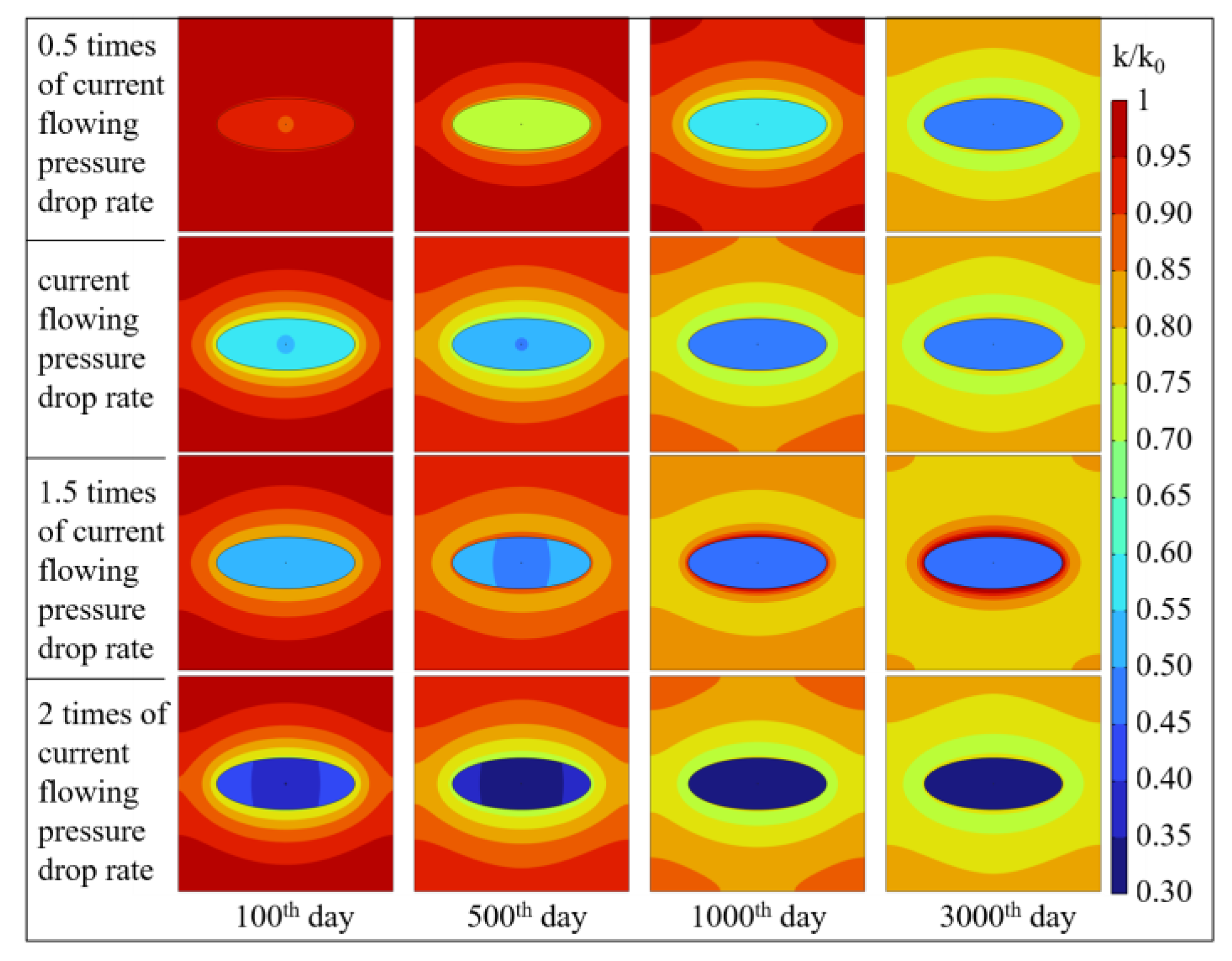

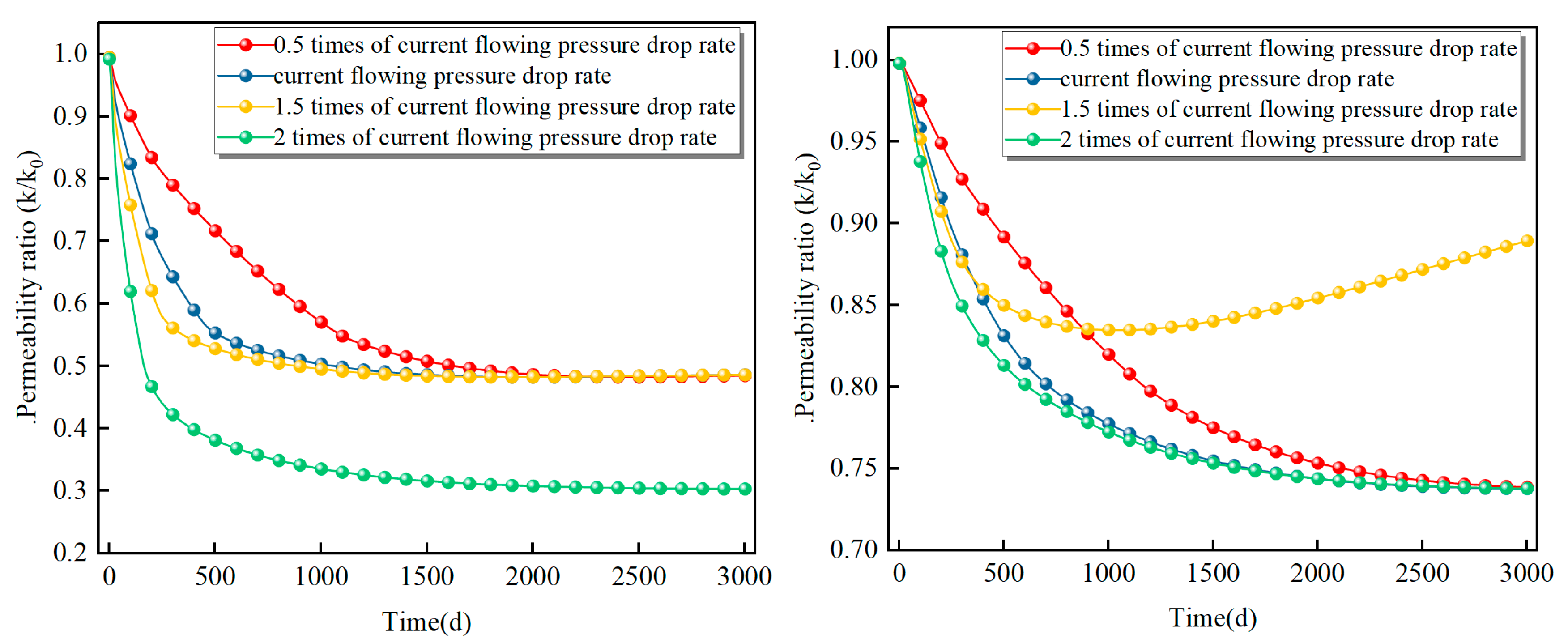

- Increasing the bottom-hole pressure drop rate to 1.5–2 times the reference value shortens the dewatering and ramp-up stages by rapidly lowering the reservoir pressure to the critical desorption point. The 1.5× rate achieves the most effective pressure depletion, optimally facilitating gas desorption and diffusion and thereby enhancing productivity. While a higher drawdown rate accelerates pressure decline in the stimulated zone during early stages, it has limited effect on the non-stimulated region. Conversely, an excessively high rate (e.g., 2×) results in a smaller pressure decrease during the stable and decline stages compared to other stages.

- (3)

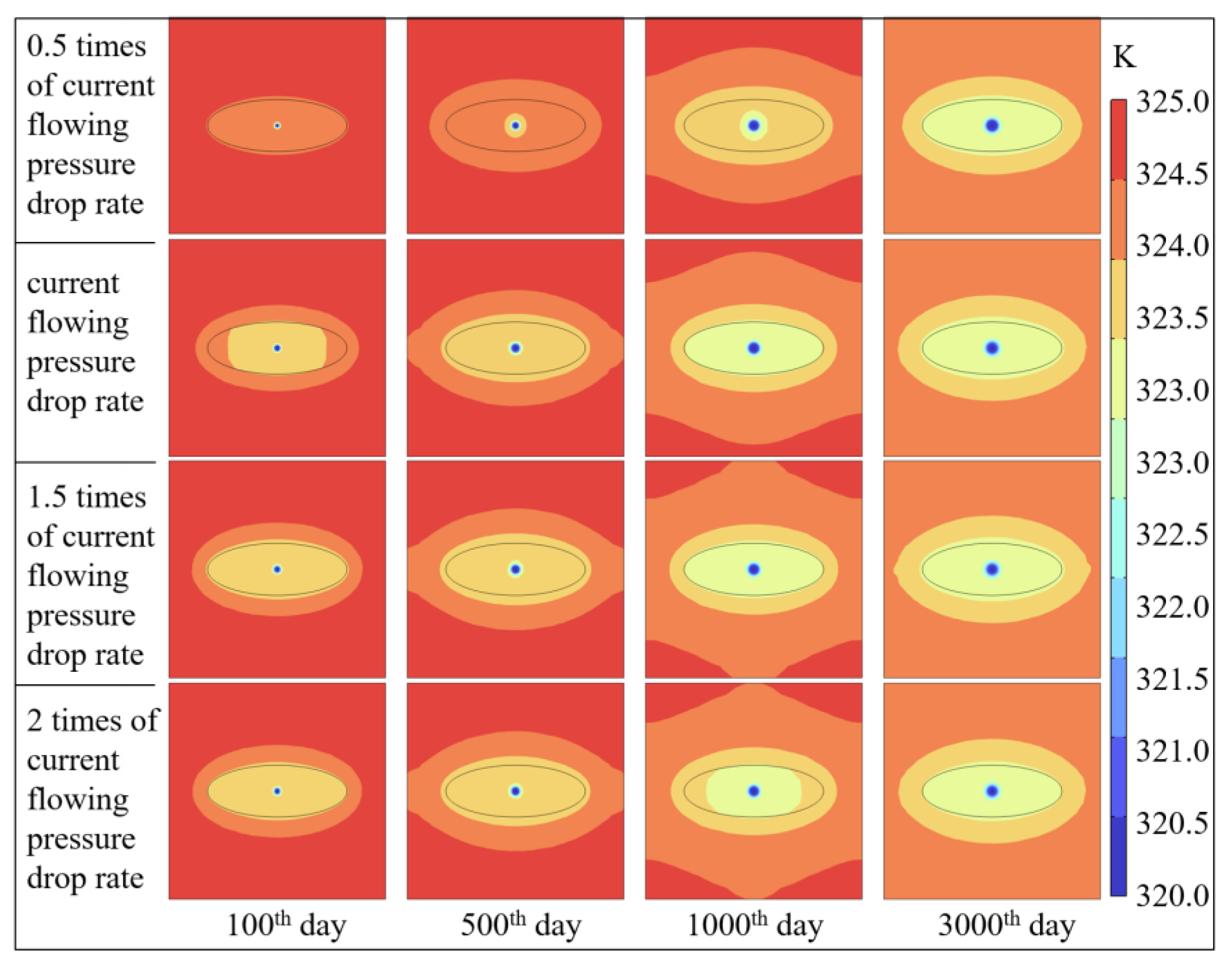

- Employing a drawdown rate 1.5 times the current value achieves synergistic optimization of water saturation, temperature, and gas transport. This approach accelerates early stage drainage in fractures, shortening the time to initial gas production, while avoiding the water-blocking effect induced by excessive drawdown (e.g., 2×). Consequently, it increases the desorbed gas volume by 1.9% and elevates the peak diffusion rate by 39.2%. By ensuring balanced depletion and mitigating water-blocking and thermal fluctuations, the method maximizes desorption-diffusion efficiency. Furthermore, it promotes matrix shrinkage, leading to a permeability rebound of up to 88.9% and preventing the stress-induced damage associated with higher drawdown rates.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, S.; Qin, Y.; Tang, D.; Shen, J.; Wang, J.; Chen, S. A comprehensive review of deep coalbed methane and recent developments in China. Int. J. Coal Geol. 2023, 279, 104369. [Google Scholar] [CrossRef]

- Yang, X.; Xu, F.; Wang, H.; Li, S.; Lin, W.; Wang, W.; Hao, S. Exploration and development process of coalbed methane in eastern margin of Ordos Basin and its enlightenment. Coal Geol. Explor. 2022, 50, 30–41. [Google Scholar]

- Chen, S.; Tang, D.; Hou, W.; Li, Y.; Tao, S.; Xu, H.; Zhang, B. Geological particularity and reservoir engineering response of deep coalbed methane. Acta Pet. Sin. 2023, 44, 1993. [Google Scholar]

- Zhu, G.; Ji, H.; Mi, H.; Zhang, Y.; Sun, Q.; Zhao, W.; Zhu, X.; Kang, L.; Wang, Y. Discovery of a large gas field of deep coalbed methane in the Shenfu block and its implications. Coal Geol. Explor. 2024, 52, 12–21. [Google Scholar]

- Liu, J.; Zhu, G.; Liu, Y.; Chao, W.; Du, J.; Yang, Q.; Mi, H.; Zhang, S. Breakthrough, future challenges and countermeasures of deep coalbed methane in the eastern margin of Ordos Basin: A case study of Linxing-Shenfu block. Acta Pet. Sin. 2023, 44, 1827. [Google Scholar]

- Geng, M.; Chen, H.; Chen, Y.; Zeng, L.; Chen, S.; Jiang, X. Methods and results of the fourth round national CBM resources evaluation. Coal Sci. Technol. 2018, 46, 64–68. [Google Scholar]

- Zhang, S.; Tang, S.; Qian, Z.; Pan, Z.; Guo, Q. Evaluation of geological features for deep coalbed methane reservoirs in the Dacheng Salient, Jizhong Depression, China. Int. J. Coal Geol. 2014, 133, 60–71. [Google Scholar] [CrossRef]

- Liu, S.; Fan, K.; Jin, Y. Stress sensitivity characteristics of deep coal reservoirs and its influence on coalbed methane productivity. Coal Geol. Explor. 2022, 50, 56–64. [Google Scholar]

- Xie, H.; Sang, S.; Li, X.; Yan, Z.; Liu, S.; Zhou, X.; Han, S. Evolution of pore-fracture and permeability prediction in soft coal rock under variable-pressure water saturation. Phys. Fluids 2025, 37, 076646. [Google Scholar] [CrossRef]

- Zhang, X.; Lai, F.; Meng, Y.; Xu, X.; Li, H.; Liu, K. Dynamic production characteristics of deep coalbed methane: A case study of Daning-Jixian Block. Energy Fuels 2024, 38, 8700–8711. [Google Scholar] [CrossRef]

- Nie, Z.; Shi, X.; Sun, W.; Yan, X.; Huang, H.; Liu, Y.; Feng, Y. Production characteristics of deep coalbed methane gas reservoirs in Daning-Jixian block and its development technology countermeasures. Coal Geol. Explor. 2022, 50, 193–200. [Google Scholar]

- Li, S.; Tang, D.; Pan, Z.; Xu, H.; Tao, S.; Liu, Y.; Ren, P. Geological conditions of deep coalbed methane in the eastern margin of the Ordos Basin, China: Implications for coalbed methane development. J. Nat. Gas Sci. Eng. 2018, 53, 394–402. [Google Scholar] [CrossRef]

- Zhao, J.; Tang, D.; Xu, H.; Lv, Y.; Tao, S. High production indexes and the key factors in coalbed methane production: A case in the Hancheng block, southeastern Ordos Basin, China. J. Pet. Sci. Eng. 2015, 130, 55–67. [Google Scholar] [CrossRef]

- Wang, X.; Shi, J.; Hao, P.; Wang, Y.; Cao, J.; Wang, T.; Fan, Q.; Zhang, Y. Optimal design of rational drainage schedule for deep coalbed methane wells: Taking the Shenfu Block in eastern Ordos Basin as an example. Geol. Explor. 2024, 60, 0850–0862. [Google Scholar]

- Chen, M.; Wang, D.; Yu, L.; Sun, J.; Feng, X.; Zhang, K.; Gu, X.; Wang, L.; Yin, Z.; Zhang, H. Drainage system research and application of deep coalbedmethane gas reservoirs in Daning-Jixian block. J. China Coal Soc. 2025, 50, 2188–2197. [Google Scholar]

- Li, S.; Fan, C.; Han, J.; Luo, M.; Yang, Z.; Bi, H. A fully coupled thermal-hydraulic-mechanical model with two-phase flow for coalbed methane extraction. J. Nat. Gas Sci. Eng. 2016, 33, 324–336. [Google Scholar] [CrossRef]

- Zhang, N.; Luo, Z.; Chen, Z.; Liu, F.; Liu, P.; Chen, W.; Zhao, L. Thermal–hydraulic–mechanical–chemical coupled processes and their numerical simulation: A comprehensive review. Acta Geotech. 2023, 18, 6253–6274. [Google Scholar] [CrossRef]

- Ma, Q.; Li, H.; Ji, K.; Huang, F. Thermal-hydraulic-mechanical coupling simulation of CO2 enhanced coalbed methane recovery with regards to Low-Rank but relatively shallow coal seams. Appl. Sci. 2023, 13, 2592. [Google Scholar] [CrossRef]

- Teng, T.; Zhao, Y.; Gao, F.; Wang, J.G.; Wang, W. A fully coupled thermo-hydro-mechanical model for heat and gas transfer in thermal stimulation enhanced coal seam gas recovery. Int. J. Heat Mass Transf. 2018, 125, 866–875. [Google Scholar] [CrossRef]

- Ma, T.; Liu, J.; Fu, J.; Qiu, Y.; Fan, X.; Martyushev, D.A. Fully coupled thermo-hydro-mechanical model for wellbore stability analysis in deep gas-bearing unsaturated formations based on thermodynamics. Rock Mech. Rock Eng. 2025, 58, 33–64. [Google Scholar] [CrossRef]

- Shang, X.; Zhang, Z.; Yang, W.; Wang, J.G.; Zhai, C. A thermal-hydraulic-gas-mechanical coupling model on permeability enhancement in heterogeneous shale volume fracturing. Mathematics 2022, 10, 3473. [Google Scholar] [CrossRef]

- Su, E.; Wei, J.; Chen, H.; Chen, X.; Liang, Y.; Zou, Q.; Zhu, X. Effect of CO2 injection on coalbed permeability based on a thermal–hydraulic–mechanical coupling model. Energy Fuels 2024, 38, 11078–11092. [Google Scholar] [CrossRef]

- Fang, T.; Feng, Q.; Zhou, R.; Guo, C.; Wang, S.; Gao, K. A coupled thermal–hydrological–mechanical model for geothermal energy extraction in fractured reservoirs. J. Pet. Explor. Prod. Technol. 2023, 13, 2315–2327. [Google Scholar] [CrossRef]

- Rene, N.N.; Liang, W.; Ali, A.; Butt, I.A.; Hussain, S. Modeling of thermo-hydro-mechanical coupling in coalbed seam seepage based on impact factor framework. Phys. Fluids 2025, 37, 055114. [Google Scholar] [CrossRef]

- Fan, C.; Yang, L.; Xiao, B.; Zhou, L.; Wen, H.; Sun, H. Reasonable start time of carbon dioxide injection in enhanced coalbed methane recovery involving thermal-hydraulic-mechanical couplings. Front. Earth Sci. 2023, 17, 832–843. [Google Scholar] [CrossRef]

- Fang, H.; Yu, S.; Zhang, S.; Sang, S.; Guo, J.; Wang, Z.; Wang, X. Coupling mechanism of THMC fields in crushed soft coal with low permeability after CO2 injection and its application in CO2-ECBM technology. Energy Fuels 2024, 38, 6891–6911. [Google Scholar] [CrossRef]

- Wan, J.; Li, Z.; Gao, T.; Xu, Z.; Yan, Z.; Gao, Y. Numerical study on the effect of injection pressure on hot flue gas induced coal deformation and enhanced coalbed methane recovery. Energy 2025, 335, 137985. [Google Scholar] [CrossRef]

- Liu, T.; Wang, J.; Lin, B.; Wang, X.; Xu, J. Research on multi-parameter collaborative control method for enhancing coalbed methane recovery by hot flue gas displacement. Phys. Fluids 2025, 37, 056615. [Google Scholar] [CrossRef]

- Hosking, L.J.; Chen, M.; Thomas, H.R. Numerical analysis of dual porosity coupled thermo-hydro-mechanical behaviour during CO2 sequestration in coal. Int. J. Rock Mech. Min. Sci. 2020, 135, 104473. [Google Scholar] [CrossRef]

- Shu, C.; Wang, H.; Li, X.; Fan, J.; Ye, X. A thermo–hydro–mechanical model: Capturing the effects of initial permeability and gas pressure on outburst-prone indicators. Nat. Resour. Res. 2020, 29, 1897–1914. [Google Scholar] [CrossRef]

- Yang, S.; Li, S.; Hou, W.; Ji, Y.; Zhang, K. Hydrocarbon Generation Processes of the Upper Carboniferous Coal in the Daning-Jixian Block, Eastern Ordos Basin: Insights From Geochemical and Three-Dimensional Basin Modeling. Energy Fuels 2025, 39, 8926–8939. [Google Scholar] [CrossRef]

- Xu, F.; Yan, X.; Li, S. Theoretical and technological difficulties and countermeasures of deep CBM exploration and development in the eastern edge of Ordos Basin. Coal Geol. Explor. 2023, 51, 115–130. [Google Scholar]

- Khormali, A.; Ahmadi, S.; Kazemzadeh, Y.; Karami, A. Evaluating the efficacy of binary benzimidazole derivatives as corrosion inhibitors for carbon steel using multi-modal analysis and optimization techniques. Results Eng. 2025, 26, 104671. [Google Scholar] [CrossRef]

- Wang, X.; Hou, S.; Wang, X.; Yuan, Y.; Dang, Z.; Tu, M. Geological and hydrological controls on the pressure regime of coalbed methane reservoir in the Yanchuannan field: Implications for deep coalbed methane exploitation in the eastern Ordos Basin, China. Int. J. Coal Geol. 2024, 294, 104619. [Google Scholar] [CrossRef]

- Chang, Y.; Yao, Y.; Liu, D.; Liu, Y.; Cui, C.; Wu, H. Behavior and mechanism of water imbibition and its influence on gas permeability during hydro-fracturing of a coalbed methane reservoir. J. Pet. Sci. Eng. 2022, 208, 109745. [Google Scholar] [CrossRef]

- Fan, L.; Zhou, G.; Yang, Z. Geological control of differential enrichment of deep coalbed methane in the Ordos Basin. Coal Sci. Technol. 2025, 53, 203–215. [Google Scholar]

- Xie, H.; Sang, S.; Li, X.; Yan, Z.; Zhou, X.; Liu, S.; Cai, J. Competitive adsorption-penetration characteristics of multi-component gases in micro-nano pore of coal. Chem. Eng. J. 2025, 506, 159965. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, H.; Long, R.; Yang, M. Health economic loss measurement and risk assessment of new cases of coal worker’s pneumoconiosis in China. Saf. Sci. 2020, 122, 104529. [Google Scholar] [CrossRef]

- Yıldız, T. Loss of profits occurring due to the halting of mining operations arising from occupational accidents or reasons related to legislation. Gospod. Surowcami Miner. Miner. Resour. Manag. 2021, 37, 153–176. [Google Scholar]

| Production Phase | Water Drainage Stage | Gas Production Ramp-Up Stage | Stable Production Stage | Production Decline Stage |

|---|---|---|---|---|

| Flowing pressure drop rate (MPa/d) | 0.10 | 0.038 | 0.023 | 0.01 |

| Time (day) | 26 | 17~20 | 185 | >230 |

| Casing pressure (MPa) | 4.9 | 5.7 | 3.8 | 3 |

| Production Strategy (Flowing Pressure Drop) | Water Drainage Stage | Gas Production Ramp-Up Stage | Stable Production Stage | Production Decline Stage |

|---|---|---|---|---|

| 0.5 times of current flowing pressure drop rate (MPa/d) | 0.05 | 0.019 | 0.0115 | 0.005 |

| Current flowing pressure drop rate (MPa/d) | 0.10 | 0.038 | 0.023 | 0.01 |

| 1.5 times of current flowing pressure drop rate (MPa/d) | 0.15 | 0.057 | 0.0345 | 0.015 |

| 2 times of current flowing pressure drop rate (MPa/d) | 0.20 | 0.076 | 0.046 | 0.02 |

| Step | Time/Day | Simulation Stage | Initial and Boundary Conditions |

|---|---|---|---|

| Stage 1 | 300 | History matching stage | ① The bottom-hole flowing pressure is set according to the actual measured values from the coalbed methane well. ② All other boundaries are defined as constant-pressure boundaries. |

| Stage 2 | 2700 | Gas production prediction stage | ① The bottom-hole flowing pressure is set to the value measured after 300 days of production. ② All other boundaries are defined as constant-pressure boundaries. |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Permeability in fractured zone/(10−3 μm2) | 45.5 | Water viscosity/Pa·s | 1 × 10−3 |

| Elastic modulus of coal/GPa | 3.0 | Methane viscosity/Pa·s | 1.84 × 10−5 |

| Poisson’s ratio of coal/dimensionless | 0.350 | Langmuir pressure of coal pL/MPa | 2.95 |

| Specific heat capacity of water/J·(kg·K)−1 | 4190 | Langmuir volume of coal VL/m3·kg−1 | 0.0276 |

| Thermal conductivity of water/W·(m·K)−1 | 0.598 | Klinkenberg factor/MPa | 0.76 |

| Endpoint relative permeability of water/dimensionless | 1.0 | Elastic modulus of coal matrix/GPa | 7.340 |

| Original formation temperature/K | 325 | Specific heat capacity of methane/J·(kg·K)−1 | 2220 |

| Endpoint relative permeability of gas/dimensionless | 0.756 | Thermal conductivity of methane/W·(m·K)−1 | 0.031 |

| Isosteric heat of adsorption/kJ·mol−1 | 33.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Li, Y.; Liu, W.; Zhang, S.; Zhang, L.; Liang, Y.; Liu, X.; Gan, Q.; Liu, S.; Wang, W. Study on Production System Optimization and Productivity Prediction of Deep Coalbed Methane Wells Considering Thermal–Hydraulic–Mechanical Coupling Effects. Processes 2025, 13, 3090. https://doi.org/10.3390/pr13103090

Wang S, Li Y, Liu W, Zhang S, Zhang L, Liang Y, Liu X, Gan Q, Liu S, Wang W. Study on Production System Optimization and Productivity Prediction of Deep Coalbed Methane Wells Considering Thermal–Hydraulic–Mechanical Coupling Effects. Processes. 2025; 13(10):3090. https://doi.org/10.3390/pr13103090

Chicago/Turabian StyleWang, Sukai, Yonglong Li, Wei Liu, Siyu Zhang, Lipeng Zhang, Yan Liang, Xionghui Liu, Quan Gan, Shiqi Liu, and Wenkai Wang. 2025. "Study on Production System Optimization and Productivity Prediction of Deep Coalbed Methane Wells Considering Thermal–Hydraulic–Mechanical Coupling Effects" Processes 13, no. 10: 3090. https://doi.org/10.3390/pr13103090

APA StyleWang, S., Li, Y., Liu, W., Zhang, S., Zhang, L., Liang, Y., Liu, X., Gan, Q., Liu, S., & Wang, W. (2025). Study on Production System Optimization and Productivity Prediction of Deep Coalbed Methane Wells Considering Thermal–Hydraulic–Mechanical Coupling Effects. Processes, 13(10), 3090. https://doi.org/10.3390/pr13103090