Comparison of Vacuum and Atmospheric Deep-Fat Frying of Osmo-Dehydrated Goldenberries

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material

2.2. Pretreatment

2.3. Frying

2.4. Analysis

2.4.1. Moisture and Oil Contents

2.4.2. Color

2.4.3. Water Activity (aw)

2.4.4. Hardness

2.5. Experimental Design

2.6. Kinetics Modeling

2.7. Statistical Analysis

3. Results and Discussions

3.1. Effect of Process Conditions on Oil Content

3.2. Effect of Process Conditions on Water Activity (aw) and Moisture Content

3.3. Effect of Process Conditions on Color

3.4. Effect of Process Conditions on Hardness

3.5. Optimization

3.6. Moisture Loss and Oil Uptake Kinetics

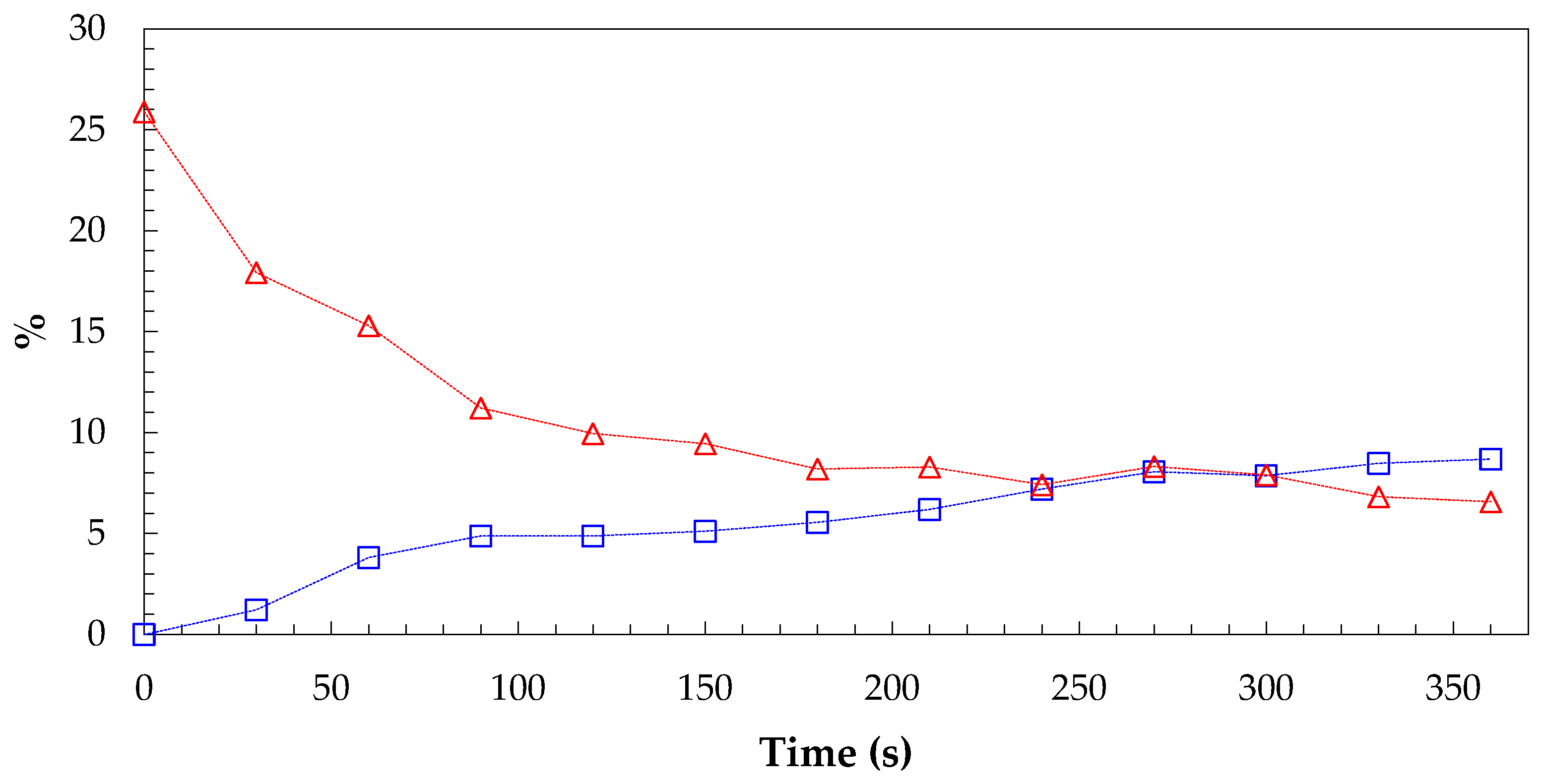

3.6.1. Moisture Loss Kinetics

3.6.2. Oil Uptake Kinetics

3.7. Correlation Between Oil Uptake and Moisture Loss

3.8. Vacuum vs. Atmospheric Frying

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Serna-Saldivar, S.O. Snack Foods, 1st ed.; Serna-Saldivar, S.O., Ed.; CRC Press: Boca Raton, FL, USA, 2022; ISBN 9781003129066. [Google Scholar]

- Almoraie, N.M.; Saqaan, R.; Alharthi, R.; Alamoudi, A.; Badh, L.; Shatwan, I.M. Snacking patterns throughout the life span: Potential implications on health. Nutr. Res. 2021, 91, 81–94. [Google Scholar] [CrossRef]

- Gherasim, A.; Arhire, L.I.; Niță, O.; Popa, A.D.; Graur, M.; Mihalache, L. The relationship between lifestyle components and dietary patterns. Proc. Nutr. Soc. 2020, 79, 311–323. [Google Scholar] [CrossRef] [PubMed]

- Welti-Chanes, J.; Escobedo-Avellaneda, Z.; Tapia, M.S. Snacks from fruits and vegetables. In Snack Foods; Serna-Saldivar, S.O., Ed.; CRC Press: Boca Raton, FL, USA, 2022; p. 26. ISBN 9781003129066. [Google Scholar]

- Montero-Castillo, P.M.; Torres-Díaz, L.; Torres-Díaz, S.; Acevedo-Correa, D.; Martelo-Gómez, R.J. Mass transfer during atmospheric and vacuum frying of chorizo. Int. J. Food Sci. 2021, 2021, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Soto, M.; Pérez, A.M.; Servent, A.; Vaillant, F.; Achir, N. Monitoring and modelling of physicochemical properties of papaya chips during vacuum frying to control their sensory attributes and nutritional value. J. Food Eng. 2021, 299, 110514. [Google Scholar] [CrossRef]

- Da Silva, P.F.; Moreira, R.G. Vacuum frying of high-quality fruit and vegetable-based snacks. LWT-Food Sci. Technol. 2008, 41, 1758–1767. [Google Scholar] [CrossRef]

- Villamizar, R.H.; Quiceno, M.C.; Giraldo, G.A. Effect of vacuum frying process on the quality of a snack of mango (Manguifera indica L.). Acta Agronómica 2012, 61, 40–51. [Google Scholar]

- Dueik, V.; Robert, P.; Bouchon, P. Vacuum frying reduces oil uptake and improves the quality parameters of carrot crisps. Food Chem. 2010, 119, 1143–1149. [Google Scholar] [CrossRef]

- Yamsaengsung, R.; Ariyapuchai, T.; Prasertsit, K. Effects of vacuum frying on structural changes of bananas. J. Food Eng. 2011, 106, 298–305. [Google Scholar] [CrossRef]

- Nunes, Y.; Moreira, R.G. Effect of osmotic dehydration and vacuum-frying parameters to produce high-quality mango chips. J. Food Sci. 2009, 74, E355–E362. [Google Scholar] [CrossRef]

- Fan, K.; Zhang, M.; Bhandari, B. Osmotic-ultrasound dehydration pretreatment improves moisture adsorption isotherms and water state of microwave-assisted vacuum fried purple-fleshed sweet potato slices. Food Bioprod. Process. 2019, 115, 154–164. [Google Scholar] [CrossRef]

- Ramadan, M.F. Bioactive phytochemicals, nutritional value, and functional properties of cape gooseberry (Physalis peruviana): An overview. Food Res. Int. 2011, 44, 1830–1836. [Google Scholar] [CrossRef]

- Embaby, H.E.; Miyakawa, T.; Hachimura, S.; Muramatsu, T.; Nara, M.; Tanokura, M. Crystallization and melting properties studied by DSC and FTIR spectroscopy of goldenberry (Physalis peruviana) oil. Food Chem. 2022, 366, 130645. [Google Scholar] [CrossRef]

- Tobar-Delgado, E.; Torres-Castañeda, H.; Serna-Cock, L.; Osorio-Mora, O.; Tirado, D.F. Valorisation of goldenberry calyx: Ultrasound-assisted extraction of phenolic compounds. Food Sci. Technol. 2023, 43, e5623. [Google Scholar] [CrossRef]

- Ramadan, M.F. Handbook of Goldenberry (Physalis peruviana); Ramadan, M.F., Ed.; Elsevier: Amsterdam, The Netherlands, 2024; ISBN 9780443154331. [Google Scholar]

- Nuñez-Zarantes, V.M.; Puertas, D.R.; Luna Mancilla, L.T.; Ramos Zambrano, H.S. Cape gooseberry: Crop production system in Colombia. In Handbook of Goldenberry (Physalis Peruviana); Ramadan, M.F., Ed.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 55–66. [Google Scholar]

- ICONTEC. NTC 4580: Frutas frescas. Uchuva. Especificaciones; ICONTEC: Bogotá, Colombia, 1999; p. 17. [Google Scholar]

- Luchese, C.L.; Gurak, P.D.; Marczak, L.D.F. Osmotic dehydration of physalis (Physalis peruviana L.): Evaluation of water loss and sucrose incorporation and the quantification of carotenoids. LWT-Food Sci. Technol. 2015, 63, 1128–1136. [Google Scholar] [CrossRef]

- Ayala-Aponte, A.; Giraldo-Cuartas, C.J.; Serna-Cock, L. Kinetics of osmotic dehydration of yellow pitahaya fruit (Selenicereus megalanthus). Interciencia 2010, 35, 539–544. [Google Scholar]

- AOAC. AOAC International Official Methods of Analysis, 18th ed.; Horwitz, W., Latimer, G., Eds.; AOAC International: Rockville, MD, USA, 2005. [Google Scholar]

- Esan, T.A.; Sobukola, O.P.; Sanni, L.O.; Bakare, H.A.; Munoz, L. Process optimization by response surface methodology and quality attributes of vacuum fried yellow fleshed sweetpotato (Ipomoea batatas L.) chips. Food Bioprod. Process. 2015, 95, 27–37. [Google Scholar] [CrossRef]

- Garayo, J.; Moreira, R. Vacuum frying of potato chips. J. Food Eng. 2002, 55, 181–191. [Google Scholar] [CrossRef]

- Sosa-Morales, M.E.; Solares-Alvarado, A.P.; Aguilera-Bocanegra, S.P.; Muñoz-Roa, J.F.; Cardoso-Ugarte, G.A. Reviewing the effects of vacuum frying on frying medium and fried foods properties. Int. J. Food Sci. Technol. 2022, 57, 3278–3291. [Google Scholar] [CrossRef]

- Tirado, D.F.; Acevedo, D.; Montero, P.M. Transferencia de calor y materia durante el proceso de freído de alimentos: Tilapia (Oreochromis niloticus) y fruta de pan (Artocarpus communis). Inf. Tecnológica 2015, 26, 85–94. [Google Scholar] [CrossRef]

- Tapia, M.S.; Alzamora, S.M.; Chirife, J. Effects of water activity (aW) on microbial stability as a hurdle in food preservation. In Water Activity in Foods; Barbosa-Cánovas, G.V., Fontana, A.J., Jr., Schmidt, S.J., Labuza, T.P., Eds.; Wiley: New York, NY, USA, 2020; pp. 323–355. [Google Scholar]

- Wexler, L.; Perez, A.M.; Cubero-Castillo, E.; Vaillant, F. Use of response surface methodology to compare vacuum and atmospheric deep-fat frying of papaya chips impregnated with blackberry juice. CyTA-J. Food 2016, 14, 578–586. [Google Scholar] [CrossRef][Green Version]

- Saberian, H.; Amooi, M.; Hamidi-Esfahani, Z. Modeling of vacuum drying of loquat fruit. Nutr. Food Sci. 2014, 44, 24–31. [Google Scholar] [CrossRef]

- Mir-Bel, J.; Oria, R.; Salvador, M.L. Influence of the vacuum break conditions on oil uptake during potato post-frying cooling. J. Food Eng. 2009, 95, 416–422. [Google Scholar] [CrossRef]

- Mariscal, M.; Bouchon, P. Comparison between atmospheric and vacuum frying of apple slices. Food Chem. 2008, 107, 1561–1569. [Google Scholar] [CrossRef]

- Ziaiifar, A.M.; Courtois, F.; Trystram, G. Porosity development and its effect on oil uptake during frying process. J. Food Process Eng. 2010, 33, 191–212. [Google Scholar] [CrossRef]

| Run | T (°C) | t (min) | P (bar) | Oil (%) | Moisture (%) | L* | a* | b* | ΔE | aw | Hardness (N) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 110 | 6.0 | 0.5 | 8.4 ± 0.3 | 8.0 ± 0.0 | 50.1 ± 0.1 | 11.3 ± 0.2 | 35.5 ± 0.2 | 9.0 ± 0.8 | 0.28 ± 0.00 | 24.8 ± 0.6 |

| 2 | 120 | 4.0 | 0.4 | 13.6 ± 0.1 | 7.4 ± 0.1 | 49.0 ± 0.7 | 18.5 ± 0.3 | 35.5 ± 0.1 | 8.0 ± 0.1 | 0.32 ± 0.00 | 13.6 ± 2.3 |

| 3 | 110 | 6.0 | 0.3 | 13.3 ± 0.2 | 8.6 ± 0.3 | 45.9 ± 0.3 | 14.8 ± 0.2 | 31.0 ± 1.1 | 8.5 ± 0.3 | 0.37 ± 0.01 | 16.5 ± 1.3 |

| 4 | 110 | 2.0 | 0.5 | 13.1 ± 0.1 | 8.5 ± 0.0 | 46.3 ± 0.4 | 12.8 ± 0.2 | 40.4 ± 1.1 | 4.6 ± 1.1 | 0.31 ± 0.01 | 8.7 ± 2.2 |

| 5 | 130 | 6.0 | 0.5 | 13.0 ± 0.4 | 5.8 ± 0.2 | 33.6 ± 0.4 | 16.5 ± 0.5 | 27.9 ± 2.0 | 14.2 ± 1.5 | 0.27 ± 0.00 | 8.3 ± 1.3 |

| 6 | 110 | 2.0 | 0.3 | 9.6 ± 0.2 | 11.7 ± 0.1 | 43.2 ± 0.6 | 11.0 ± 0.3 | 37.5 ± 1.1 | 4.3 ± 1.6 | 0.38 ± 0.00 | 19.6 ± 0.3 |

| 7 | 120 | 4.0 | 0.4 | 15.4 ± 0.1 | 7.3 ± 0.1 | 47.0 ± 1.3 | 17.2 ± 0.3 | 31.9 ± 1.5 | 8.5 ± 0.2 | 0.30 ± 0.00 | 13.2 ± 2.1 |

| 8 | 120 | 0.6 | 0.4 | 10.9 ± 0.5 | 15.8 ± 0.1 | 40.3 ± 2.3 | 17.8 ± 0.2 | 31.6 ± 0.9 | 8.1 ± 0.2 | 0.43 ± 0.00 | 30.0 ± 2.5 |

| 9 | 120 | 4.0 | 0.4 | 14.3 ± 0.1 | 6.9 ± 0.0 | 46.9 ± 1.1 | 16.6 ± 0.3 | 31.6 ± 1.4 | 8.6 ± 0.2 | 0.33 ± 0.00 | 14.6 ± 1.9 |

| 10 | 120 | 4.0 | 0.4 | 13.5 ± 0.0 | 6.6 ± 0.1 | 47.2 ± 1.1 | 18.5 ± 0.3 | 32.9 ± 1.5 | 8.3 ± 0.1 | 0.33 ± 0.01 | 14.0 ± 2.5 |

| 11 | 120 | 4.0 | 0.2 | 12.8 ± 0.2 | 7.7 ± 0.4 | 57.9 ± 0.6 | 18.0 ± 0.3 | 52.7 ± 1.1 | 20.9 ± 1.6 | 0.35 ± 0.00 | 24.9 ± 2.3 |

| 12 | 120 | 4.0 | 0.4 | 13.2 ± 0.2 | 6.4 ± 0.0 | 49.7 ± 0.3 | 18.5 ± 0.4 | 35.0 ± 0.3 | 8.8 ± 0.3 | 0.33 ± 0.00 | 14.3 ± 2.1 |

| 13 | 120 | 4.0 | 0.4 | 13.6 ± 0.0 | 6.5 ± 0.1 | 45.9 ± 1.2 | 17.3 ± 0.4 | 31.9 ± 0.4 | 8.0 ± 0.3 | 0.32 ± 0.00 | 14.0 ± 2.4 |

| 14 | 130 | 2.0 | 0.3 | 9.2 ± 0.1 | 7.8 ± 0.3 | 50.6 ± 0.2 | 15.0 ± 0.1 | 37.7 ± 1.0 | 8.1 ± 0.1 | 0.32 ± 0.00 | 17.8 ± 1.3 |

| 15 | 137 | 4.0 | 0.4 | 11.1 ± 0.0 | 5.4 ± 0.3 | 42.1 ± 0.5 | 22.5 ± 0.4 | 28.6 ± 2.6 | 12.7 ± 1.1 | 0.32 ± 0.00 | 28.8 ± 2.0 |

| 16 | 120 | 7.4 | 0.4 | 14.7 ± 0.1 | 6.3 ± 0.3 | 46.6 ± 0.3 | 16.6 ± 0.3 | 32.5 ± 0.3 | 7.6 ± 1.2 | 0.31 ± 0.01 | 20.0 ± 2.7 |

| 17 | 130 | 6.0 | 0.3 | 11.9 ± 0.1 | 6.8 ± 0.3 | 33.1 ± 2.1 | 14.8 ± 0.2 | 22.2 ± 2.5 | 19.1 ± 0.6 | 0.31 ± 0.00 | 25.2 ± 1.6 |

| 18 | 130 | 2.0 | 0.5 | 10.1 ± 0.0 | 7.1 ± 0.2 | 49.5 ± 0.5 | 22.4 ± 0.2 | 48.8 ± 1.5 | 14.2 ± 0.2 | 0.28 ± 0.00 | 14.4 ± 1.7 |

| 19 | 120 | 4.0 | 0.6 | 13.4 ± 0.1 | 4.7 ± 0.1 | 58.6 ± 3.1 | 18.5 ± 0.1 | 36.6 ± 0.2 | 16.5 ± 0.9 | 0.29 ± 0.00 | 11.4 ± 1.5 |

| 20 | 103.182 | 4.0 | 0.4 | 8.7 ± 0.3 | 9.4 ± 0.2 | 46.7 ± 1.1 | 21.0 ± 0.2 | 40.6 ± 2.1 | 7.5 ± 0.5 | 0.40 ± 0.00 | 19.0 ± 1.3 |

| Response | Temperature (T) | Pressure (P) | Time (t) | T × P | P × t | T × t |

|---|---|---|---|---|---|---|

| Oil | 0.2499 | 0.5711 | 0.0129 | 0.1768 | 0.0139 | 0.0325 |

| Moisture | 0.0002 | 0.0012 | 0.0000 | 0.1434 | 0.1149 | 0.3356 |

| aw | 0.0005 | 0.0004 | 0.0010 | 0.0357 | 0.5517 | 0.2930 |

| ΔE | 0.0000 | 0.0007 | 0.0000 | 0.6760 | 0.0001 | 0.0457 |

| Hardness | 0.0009 | 0.0000 | 0.2254 | 0.0000 | 0.0086 | 0.0003 |

| Parameter | Optimized Snack | Osmodehydrated | Fresh |

|---|---|---|---|

| Sample mass (g) | 0.4 ± 0.0 | 0.3 ± 0.1 | 0.9 ± 0.2 |

| L* | 49.6 ± 0.8 | 48.6 ± 0.8 | 42.6 ± 1.8 |

| a* | 11.8 ± 0.7 | 13.2 ± 1.0 | 15.0 ± 1.0 |

| b* | 36.6 ± 1.6 | 38.2 ± 1.8 | 38.8 ± 2.0 |

| ∆E | 8.0 ± 1.4 | 6.6 ± 0.7 | - |

| aw | 0.29 ± 0.00 | 0.76 ± 0.01 | 0.95 ± 0.01 |

| Moisture (%) | 7.6 ± 0.4 | 26.3 ± 0.8 | 81.5 ± 0.9 |

| Hardness (Newtons) | 13.8 ± 2.4 | - | |

| Oil (%) | 8.6 ± 0.1 | - |

| Newton | Henderson-Pabis | Page | |||

|---|---|---|---|---|---|

| RMSEP (%) | RMSEP (%) | RMSEP (%) | |||

| 97.66 | 0.04162 | 97.85 | 0.03989 | 98.95 | 0.02784 |

| Monod | Moyano-Pedreschi | First Order | |||

|---|---|---|---|---|---|

| R2 | RMSEP (%) | R2 | RMSEP (%) | R2 | RMSEP (%) |

| 91.09 | 0.7042 | 93.02 | 0.6824 | 96.12 | 0.5087 |

| Sample | Oil (%) | |

|---|---|---|

| Atmospheric | Vacuum | |

| Fresh | 27.1 ± 1.5 | 17.2 ± 0.9 |

| Osmo-dehydrated | 14.2 ± 1.9 | 8.3 ± 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guevara-Betancourth, C.; Arango, O.; Suárez-Montenegro, Z.J.; Tirado, D.F.; Osorio, O. Comparison of Vacuum and Atmospheric Deep-Fat Frying of Osmo-Dehydrated Goldenberries. Processes 2025, 13, 50. https://doi.org/10.3390/pr13010050

Guevara-Betancourth C, Arango O, Suárez-Montenegro ZJ, Tirado DF, Osorio O. Comparison of Vacuum and Atmospheric Deep-Fat Frying of Osmo-Dehydrated Goldenberries. Processes. 2025; 13(1):50. https://doi.org/10.3390/pr13010050

Chicago/Turabian StyleGuevara-Betancourth, Christiam, Oscar Arango, Zully J. Suárez-Montenegro, Diego F. Tirado, and Oswaldo Osorio. 2025. "Comparison of Vacuum and Atmospheric Deep-Fat Frying of Osmo-Dehydrated Goldenberries" Processes 13, no. 1: 50. https://doi.org/10.3390/pr13010050

APA StyleGuevara-Betancourth, C., Arango, O., Suárez-Montenegro, Z. J., Tirado, D. F., & Osorio, O. (2025). Comparison of Vacuum and Atmospheric Deep-Fat Frying of Osmo-Dehydrated Goldenberries. Processes, 13(1), 50. https://doi.org/10.3390/pr13010050