Development of Functional Bread: Exploring the Nutritional, Bioactive and Microbial Potential of Carob (Ceratonia siliqua L.) Pulp Powder

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Chemicals

2.3. Experimental Plan

2.4. Preparation of Carob Powder

2.5. Rheological Assesment

2.6. Bread Making

2.7. Specific Volume

2.8. Sensory Analysis

2.9. Chemical Characterization

2.9.1. Nutritional Value

2.9.2. Mineral Content

2.9.3. Bioactive Components

2.10. Microbiological Quality

2.10.1. Microbiological Stability

2.10.2. Inoculation Test

2.11. Statistical Analysis

3. Results and Discussion

3.1. Rheological Properties of Dough

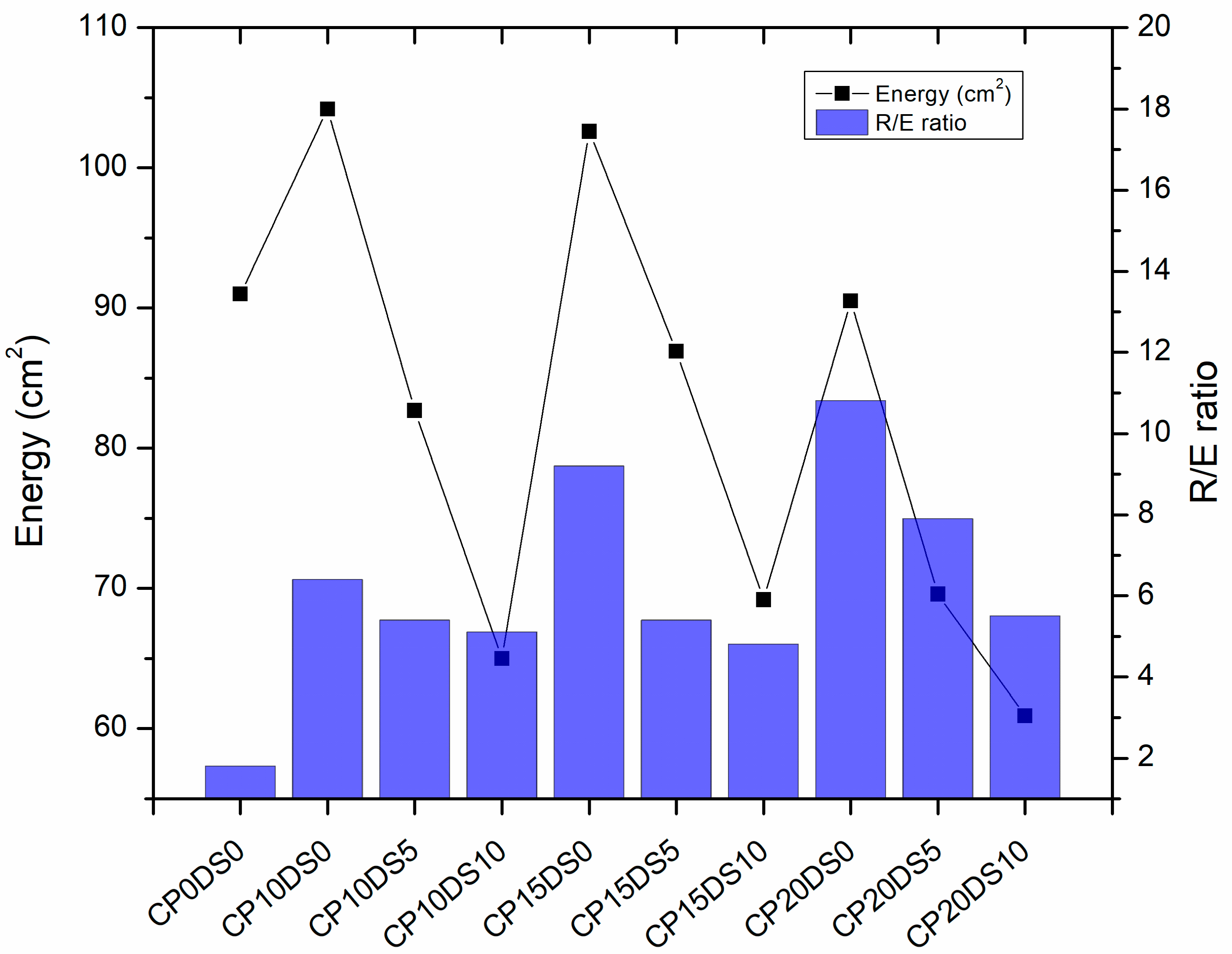

3.2. Physical and Sensory Quality of Bread

3.3. Nutrients and Bioactive Compounds in Bread

3.4. Microbiological Quality of Bread

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Miletić, I.; Šobajić, S.; Đorđević, B. Funkcionalna hrana—Uloga u unapređenju zdravlja. J. Med. Biochem. 2008, 27, 367–370. [Google Scholar] [CrossRef]

- Baumel, A.; Mirleau, P.; Viruel, J.; Bou, M.; Kharrat, D.; La Malfa, S.; Ouahmane, L.; Diadema, K.; Moakhar, M.; Sanguin, H.; et al. Assessment of plant species diversity associated with the carob tree (Ceratonia siliqua, Fabaceae) at the Mediterranean scale. Plant Ecol. Evol. 2018, 151, 185–193. [Google Scholar] [CrossRef]

- Novaković, B.; Mirosavljev, M. Higijena ishrane; Medicinski fakultet: Novi Sad, Serbia, 2002. [Google Scholar]

- Gębski, J.; Jezewska-Zychowicz, M.; Szlachciuk, J.; Kosicka-Gębska, M. Impact of nutritional claims on consumer preferences for bread with varied fiber and salt content. Food Qual. Prefer. 2019, 76, 91–99. [Google Scholar] [CrossRef]

- Almeida, E.L.; Chang, Y.K.; Steel, C.J. Dietary fibre sources in bread: Influence on technological quality. LWT-Food Sci. Technol. 2013, 50, 545–553. [Google Scholar] [CrossRef]

- De Steur, H.; Gellynck, X.; Storozhenko, S.; Liqun, G.; Lambert, W.; Van Der Straeten, D.; Viaene, J. Willingness-to-accept and purchase genetically modified rice with high folate content in Shanxi Province, China. Appetite 2010, 54, 118–125. [Google Scholar] [CrossRef] [PubMed]

- Brassesco, M.E.; Brandão, T.R.S.; Silva, C.L.M.; Pintado, M. Carob bean (Ceratonia siliqua L.): A new perspective for functional food. Trends Food Sci. Technol. 2021, 114, 310–322. [Google Scholar] [CrossRef]

- Spiteri, M.; Soler, L.G. Food reformulation and nutritional quality of food consumption: An analysis based on households panel data in France. Eur. J. Clin. Nutr. 2018, 72, 228–235. [Google Scholar] [CrossRef]

- Stavrou, I.J.; Christou, A.; Kapnissi-Christodoulou, C.P. Polyphenols in carobs: A review on their composition, antioxidant capacity and cytotoxic effects, and health impact. Food Chem. 2018, 269, 355–374. [Google Scholar] [CrossRef]

- Yousif, A.K.; Alghzawi, H.M. Processing and characterization of carob powder. Food Chem. 2000, 69, 283–287. [Google Scholar] [CrossRef]

- Rodríguez-Solana, R.; Carlier, J.D.; Costa, M.C.; Romano, A. Multi-element characterisation of carob, fig and almond liqueurs by MP-AES. J. Inst. Brew. 2018, 124, 300–309. [Google Scholar] [CrossRef]

- Polanowska, K.; Varghese, R.; Kuligowski, M.; Majcher, M. Carob kibbles as an alternative raw material for production of kvass with probiotic potential. J. Sci. Food Agric. 2021, 101, 5487–5497. [Google Scholar] [CrossRef] [PubMed]

- Elfazazi, K.; Harrak, H.; Achchoub, M.; Benbati, M. Physicochemical criteria, bioactive compounds and sensory quality of Moroccan traditional carob drink. Mater. Today Proc. 2020, 27, 3249–3253. [Google Scholar] [CrossRef]

- Rababah, T.M.; Al-u’datt, M.; Ereifej, K.; Almajwal, A.; Al-Mahasneh, M.; Brewer, S.; Alsheyab, F.; Yang, W. Chemical, functional and sensory properties of carob juice: Properties of carob juice. J. Food Qual. 2013, 36, 238–244. [Google Scholar] [CrossRef]

- Moreira, T.C.; Transfeld da Silva, Á.; Fagundes, C.; Ferreira, S.M.R.; Cândido, L.M.B.; Passos, M.; Krüger, C.C.H. Elaboration of yogurt with reduced level of lactose added of carob (Ceratonia siliqua L.). LWT—Food Sci. Technol. 2017, 76, 326–329. [Google Scholar] [CrossRef]

- Mahtout, R.; Zaidi, F.; Ould Saadi, L.; Boudjou, S.; Oomah, B.D.; Hosseinian, F. Carob (Ceratonia siliqua L.) flours and pulp mucilage affect kefir quality and antioxidant capacity during storage. Int. J. Eng. Technol. 2016, 2, 168–180. Available online: http://www.ijetjournal.org/Volume2/Issue2/IJET-V2I2P28.pdf (accessed on 28 August 2024).

- Srour, N.; Daroub, H.; Toufeili, I.; Olabi, A. Developing a carob-based milk beverage using different varieties of carob pods and two roasting treatments and assessing their effect on quality characteristics: Effect of roasting on a carob-based milk beverage. J. Sci. Food Agric. 2016, 96, 3047–3057. [Google Scholar] [CrossRef]

- Červenka, L.; Frühbauerová, M.; Velichová, H. Functional properties of muffin as affected by substituing wheat flour with carob powder. Slovak J. Food Sci. 2019, 13, 212–217. [Google Scholar] [CrossRef]

- Farias, J.N.; do Nascimento, F.P.B.; Salvador, A.A.; da Silva, A.A.N.; dos Anjos Tamasia, G.; Rossetti, F.X.; de Brito Bello, S.R.; Vicentini, M.S. Desenvolvimento de biscoitos integrais à base de farinha de alfarroba como uma alternativa para substituição do cacau em pó. Int. J. Nutr. 2019, 12, 41–47. [Google Scholar] [CrossRef]

- Youssef, M.K.E.; Ali, H.M.; El-Manfaloty, M.M. Nutritional assessment of wheat biscuits and fortified wheat biscuits with carob pod powder (Ceratonia siliqua L.). Food Public Health 2013, 3, 336–340. [Google Scholar]

- Rosa, C.S.; Tessele, K.; Prestes, R.C.; Silveira, M.; Franco, F. Effect of substituting of cocoa powder for carob flour in cakes made with soy and banana flours. Int. Food Res. J. 2015, 22, 2111–2118. [Google Scholar]

- Herken, E.; Aydin, N. Use of carob flour in the production of tarhana. Pol. J. Food Nutr. Sci. 2015, 65, 167–174. [Google Scholar] [CrossRef]

- Sęczyk, Ł.; Świeca, M.; Gawlik-Dziki, U. Effect of carob (Ceratonia siliqua L.) flour on the antioxidant potential, nutritional quality, and sensory characteristics of fortified durum wheat pasta. Food Chem. 2016, 194, 637–642. [Google Scholar] [CrossRef]

- Salinas, M.V.; Carbas, B.; Brites, C.; Puppo, M.C. Influence of different carob flours (Ceratonia siliqua L.) on wheat dough performance and bread quality. Food Bioprocess Technol. 2015, 8, 1561–1570. [Google Scholar] [CrossRef]

- Šoronja-Simović, D.; Smole-Možina, S.; Raspor, P.; Maravić, N.; Zahorec, J.; Luskar, L.; Šereš, Z. Carob flour and sugar beet fiber as functional additives in bread. Acta Period. Technol. 2016, 47, 83–93. [Google Scholar] [CrossRef]

- Šoronja-Simović, D.; Zahorec, J.; Šereš, Z.; Maravić, N.; Smole Možina, S.; Luskar, L.; Luković, J. Challenges in determination of rheological properties of wheat dough supplemented with industrial by-products: Carob pod flour and sugar beet fibers. J. Food Meas. Charact. 2021, 15, 914–922. [Google Scholar] [CrossRef]

- Rico, D.; Alonso De Linaje, A.; Herrero, A.; Asensio-Vegas, C.; Miranda, J.; Martínez-Villaluenga, C.; De Luis, D.A.; Martin-Diana, A.B. Carob by-products and seaweeds for the development of functional bread. J. Food Process. Preserv. 2018, 42, e13700. [Google Scholar] [CrossRef]

- Adams, V.; Ragaee, S.; Abdel-Aal, E.-S.M. Impact of wheat fiber on frozen dough shelf life and bread quality. Cereal Chem. 2015, 92, 370–377. [Google Scholar] [CrossRef]

- Miś, A.; Krekora, M.; Niewiadomski, Z.; Dziki, D.; Nawrocka, A. Water redistribution between model bread dough components during mixing. J. Cereal Sci. 2020, 95, 103035. [Google Scholar] [CrossRef]

- Betoret, E.; Rosell, C.M. Enrichment of bread with fruits and vegetables: Trends and strategies to increase functionality. Cereal Chem. 2020, 97, 9–19. [Google Scholar] [CrossRef]

- Islam, M.A.; Islam, S. Sourdough Bread Quality: Facts and Factors. Foods 2024, 13, 2132. [Google Scholar] [CrossRef]

- Raghavendra, S.N.; Rastogi, N.K.; Raghavarao, K.S.M.S.; Tharanathan, R.N. Dietary Fiber from Coconut Residue: Effects of Different Treatments and Particle Size on the Hydration Properties. Eur. Food Res. Technol. 2004, 218, 563–567. [Google Scholar] [CrossRef]

- AACC International. AACCI Method 54-10.01 Physical Dough Tests Methods: Extensigraph Method, General. In Approved Methods of the American Association of Cereal Chemists, 11th ed.; AACC International: St. Paul, MN, USA, 2010. [Google Scholar]

- AACC International. AACCI Method 54-21.02 Physical Dough Tests Methods: Rheological Behavior of Flour by Farinograph: Constant Flour Weight Procedure. In Approved Methods of the American Association of Cereal Chemists, 11th ed.; AACC International: St. Paul, MN, USA, 2010. [Google Scholar]

- AACC International. AACCI Method 10-05 Baking Quality Methods: Guidelines for Measurement of Volume by Rapeseed Displacement. In Approved Methods of the American Association of Cereal Chemists, 11th ed.; AACC International: St. Paul, MN, USA, 2008. [Google Scholar]

- Šoronja-Simović, D.; Pajin, B.; Šubarić, D.; Dokić, L.; Šereš, Z.; Nikolić, I. Quality, Sensory and Nutritional Characteristics of Cookies Fortified with Chestnut Flour. J. Food Sci. 2017, 41, e12887. [Google Scholar] [CrossRef]

- Carpenter, R.P.; Lyon, D.H.; Hasdell, T.A. Guidelines for Sensory Analysis in Food Product Development and Quality Control, 2nd ed.; Aspen Publishers, Inc.: Gaithersburg, MD, USA, 2000. [Google Scholar]

- ISO 8586:2012; Sensory Analysis—General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Expert Sensory Assessors. ISO: Geneva, Switzerland, 2012.

- ISO 8589:2007; Sensory Analysis—General Guidance for the Design of Test Rooms. ISO: Geneva, Switzerland, 2007.

- AOAC (Association of Official Analytical Chemists). Official Methods of Analysis of the Association of Official Analytical Chemists International, 17th ed.; Association of Official Analytical Communities: Gaithersburg, MD, USA, 2000. [Google Scholar]

- European Commission. Commission Directive 2008/100/EC, of 28 October 2008 amending Council Directive 90/496/EEC on nutrition labelling for foodstuffs as regards recommended daily allowances, energy conversion factors, and definitions. Off. J. Eur. Union 2008, L285, 9–12. [Google Scholar]

- SRPS EN ISO 6869/2008; Animal Feeding Stuffs–Determination of the Contents of Calcium, Copper, Iron, Magnesium, Manganese, Potassium, Sodium and Zinc—Method Using Atomic Absorption Spectrometry. Institute for Standardization of Serbia: Belgrade, Serbia, 2008.

- Peić Tukuljac, L.; Krulj, J.; Kojić, J.; Šurlan, J.; Bodroža-Solarov, M.; Miljević, B.; Šereš, Z.; Maravić, N. Biosorption of Na+, K+, and Ca2+ from Alkalized Sugar Juice by Unmodified Pressed Sugar Beet Pulp in Closed-Loop Column System. Sugar Tech 2023, 25, 766–776. [Google Scholar] [CrossRef]

- Gumul, D.; Korus, J.; Ziobro, R.; Kruczek, M. Enrichment of Wheat Bread with Apple Pomace as a Way to Increase Pro-Health Constituents. Qual. Assur. Saf. Crop. Foods 2019, 11, 231–240. [Google Scholar] [CrossRef]

- Zahorec, J.; Šoronja-Simović, D.; Kocić-Tanackov, S.; Bulut, S.; Martić, N.; Bijelić, K.; Božović, D.; Pavlić, B. Carob Pulp Flour Extract Obtained by a Microwave-Assisted Extraction Technique: A Prospective Antioxidant and Antimicrobial Agent. Separations 2023, 10, 465. [Google Scholar] [CrossRef]

- ISO 4833-1:2013; Microbiology of the Food Chain–Horizontal Method for the Enumeration of Microorganisms–Part 1: Colony Count at 30 °C by the Pour Plate Technique. International Organization for Standardization: Geneva, Switzerland, 2013.

- ISO 21528-1:2017; Microbiology of the Food Chain–Horizontal Method for the Detection and Enumeration of Enterobacteriaceae–Part 1: Detection of Enterobacteriaceae. International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 7954:1987; Microbiology–General Guidance for Enumeration of Yeasts and Moulds–Colony Count Technique at 25 °C. International Organization for Standardization: Geneva, Switzerland, 1987.

- ISO 7932:2003; Microbiology of Food and Animal Feeding Stuffs–Horizontal Method for the Enumeration of Presumptive Bacillus cereus–Colony-Count Technique at 30 °C. International Organization for Standardization: Geneva, Switzerland, 2003.

- ISO 20976-1:2019; Microbiology of the Food Chain–Requirements and Guidelines for Conducting Challenge Tests of Food and Feed Products. International Organization for Standardization: Geneva, Switzerland, 2019.

- Samapundo, S.; Devlieghere, F.; Vroman, A.; Eeckhout, M. Antifungal Activity of Fermentates and Their Potential to Replace Propionate in Bread. LWT—Food Sci. Technol. 2017, 76 Pt A, 101–107. [Google Scholar] [CrossRef]

- Thebaudin, J.Y.; Lefebvre, A.C.; Harrington, M.; Bourgeois, C.M. Dietary Fibres: Nutritional and Technological Interest. Trends Food Sci. Technol. 1997, 8, 41–48. [Google Scholar] [CrossRef]

- Gänzle, M.G.; Lopponen, J.; Gobetti, M. Proteolysis in Sourdough Fermentations: Mechanisms and Potential for Improved Bread Quality. Trends Food Sci. Technol. 2008, 19, 513–521. [Google Scholar] [CrossRef]

- Nawrocka, A.; Krekora, M.; Niewiadomski, Z.; Szymańska-Chargot, M.; Krawęcka, A.; Sobota, A.; Miś, A. Effect of Moisturizing Pre-treatment of Dietary Fibre Preparations on Formation of Gluten Network During Model Dough Mixing–A Study with Application of FT-IR and FT-Raman Spectroscopy. LWT—Food Sci. Technol. 2020, 121, 108959. [Google Scholar] [CrossRef]

- Dapčević Hadnađev, T.; Pojić, M.; Hadnađev, M.; Torbica, A. The Role of Empirical Rheology on Flour Quality Control. In Wide Spectra of Quality Control; Akyar, I., Ed.; InTech: Rijeka, Croatia, 2011; pp. 335–360. [Google Scholar]

- Krekora, M.; Nawrocka, A. Effect of a Polyphenol Molecular Size on the Gluten Proteins–Polyphenols Interactions Studied with FT-Raman Spectroscopy. Food Biophys. 2022, 17, 535–544. [Google Scholar] [CrossRef]

- Issaoui, M.; Flamini, G.; Delgado, A. Sustainability Opportunities for Mediterranean Food Products Through New Formulations Based on Carob Flour (Ceratonia siliqua L.). Sustainability 2021, 13, 8026. [Google Scholar] [CrossRef]

- Šoronja-Simović, D.; Zahorec, J.; Šereš, Z.; Griz, A.; Sterniša, M.; Smole Možina, S. The Food Industry By-products in Bread Making: Single and Combined Effect of Carob Pod Flour, Sugar Beet Fibers and Molasses on Dough Rheology, Quality and Food Safety. J. Food Sci. Technol. 2022, 59, 1429–1439. [Google Scholar] [CrossRef]

- Miś, A.; Dziki, D. Extensograph Curve Profile Model Used for Characterising the Impact of Dietary Fibre on Wheat Dough. J. Cereal Sci. 2013, 57, 471–479. [Google Scholar] [CrossRef]

- Miś, A.; Nawrocka, A.; Dziki, D. Behaviour of Dietary Fibre Supplements During Bread Dough Development Evaluated Using Novel Farinograph Curve Analysis. Food Bioprocess Technol. 2017, 10, 1031–1041. [Google Scholar] [CrossRef]

- Kieffer, R.; Garnreiter, F.; Belitz, H.D. Beurteilung von Teigeigenschaften Durch Zugversuche im Mikromassstab. Z. Lebensm.-Unters. Forsch. 1981, 127, 193–194. [Google Scholar] [CrossRef]

- Oshiro, M.; Zendo, T.; Nakayama, J. Diversity and Dynamics of Sourdough Lactic Acid Bacteriota Created by a Slow Food Fermentation System. J. Biosci. Bioeng. 2021, 131, 333–340. [Google Scholar] [CrossRef] [PubMed]

- Atwell, W.A.; Finnie, S. Wheat Flour, 2nd ed.; Woodhead Publishing: Sawston, UK, 2016; ISBN 978-1-891127-90-8. [Google Scholar]

- Kaluđerski, G.; Filipović, N. Metode Ispitivanja Kvaliteta Žita, Brašna i Gotovih Proizvoda; Tehnološki fakultet, Zavod za tehnologiju žita i brašna: Novi Sad, Serbia, 1998. [Google Scholar]

- Gao, X.; Tong, J.; Guo, L.; Yu, L.; Li, S.; Yang, B.; Wang, L.; Liu, Y.; Guo, J.; Zhai, S.; et al. Influence of Gluten and Starch Granules Interactions on Dough Mixing Properties in Wheat (Triticum aestivum L.). Food Hydrocoll. 2020, 106, 105885. [Google Scholar] [CrossRef]

- European Parliament and Council. Regulation (EC) No 1924/2006 on Nutrition and Health Claims Made on Foods. Off. J. Eur. Union 2007, L12, 3–18.

- Özcan, M.M.; Arslan, D.; Gökçalik, H. Some Compositional Properties and Mineral Contents of Carob (Ceratonia siliqua) Fruit, Flour, and Syrup. Int. J. Food Sci. Nutr. 2009, 58, 652–658. [Google Scholar] [CrossRef]

- Oziyci, H.R.; Tetik, N.; Turhan, I.; Yatmaz, E.; Ucgun, K.; Akgul, H.; Gubbuk, H.; Karhan, M. Mineral Composition of Pods and Seeds of Wild and Grafted Carob (Ceratonia siliqua L.) Fruits. Sci. Hortic. 2014, 167, 149–152. [Google Scholar] [CrossRef]

- Papaefstathiou, E.; Agapiou, A.; Giannopoulos, S.; Kokkinofta, R. Nutritional Characterization of Carobs and Traditional Carob Products. Food Sci. Nutr. 2018, 6, 2151–2161. [Google Scholar] [CrossRef]

- Babiker, E.E.; Özcan, M.M.; Ghafoor, K.; Al Juhaimi, F.; Ahmed, I.A.M.; Almusallam, I.A. Physico-Chemical and Bioactive Properties, Fatty Acids, Phenolic Compounds, Mineral Contents, and Sensory Properties of Cookies Enriched with Carob Flour. J. Food Process. Preserv. 2020, 44, e14745. [Google Scholar] [CrossRef]

- Mrduljaš, N.; Krešić, G.; Bilušić, T. Polyphenols: Food Sources and Health Benefits. In Functional Food-Improve Health Through Adequate Food; Heda, M.C., Ed.; InTech: Rijeka, Croatia, 2017; pp. 23–41. [Google Scholar]

- Badr, S.A. Quality and Antioxidant Properties of Pan Bread Enriched with Watermelon Rind Powder. Curr. Sci. Int. 2015, 4, 117–126. [Google Scholar]

- Bhatt, S.M.; Gupta, R.K. Bread (Composite Flour) Formulation and Study of Its Nutritive, Phytochemical, and Functional Properties. J. Pharmacogn. Phytochem. 2015, 4, 254–268. [Google Scholar]

- Özcan, M.M. The Effect of Ginger (Zingiber officinale) Powders at Different Concentrations on Bioactive Compounds, Antioxidant Activity, Phenolic Constituents, Nutrients, and Sensory Characteristics of Wheat Bread. Int. J. Gastron. Food Sci. 2022, 28, 100532. [Google Scholar] [CrossRef]

- Michalska, A.; Amigo-Benavent, M.; Zielinski, H.; del Castillo, M.D. Effect of Bread Making on Formation of Maillard Reaction Products Contributing to the Overall Antioxidant Activity of Rye Bread. J. Cereal Sci. 2008, 48, 123–132. [Google Scholar] [CrossRef]

- Echavarría, A.P.; Pagán, J.; Ibarz, A. Melanoidins Formed by Maillard Reaction in Food and Their Biological Activity. Food Eng. Rev. 2012, 4, 203–223. [Google Scholar] [CrossRef]

- Gilbert, R.; De Louvois, J.; Donovan, T.; Little, C.; Nye, K.; Ribeiro, C.; Richards, J.; Roberts, D.; Bolton, F.J. Guidelines for the Microbiological Quality of Some Ready-to-Eat Foods Sampled at the Point of Sale. Commun. Dis. Public Health 2000, 3, 163–167. [Google Scholar] [PubMed]

- Ali, M.A.; Hashish, M.H.; Fekry, M.M. Microbiological Quality of Some Packed and Unpacked Bread Products in Alexandria, Egypt. J. Egypt. Public Health Assoc. 2023, 98, 16. [Google Scholar] [CrossRef] [PubMed]

- Hoornstra, E.; Notermans, S. Quantitative Microbiological Risk Assessment. Int. J. Food Microbiol. 2001, 66, 21–29. [Google Scholar] [CrossRef] [PubMed]

- Saranraj, P.; Geetha, M. Microbial Spoilage of Bakery Products and Its Control by Preservatives. Int. J. Pharm. Biol. Arch. 2012, 3, 38–48. [Google Scholar]

| Independent Variables 1 | Levels | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| CP (%, g/100 g of wheat flour) | 10 | 15 | 20 |

| DS (%, g/100 g of wheat flour) | 0 | 5 | 10 |

| Sample 1 | Water Absorption (%) | Development Time (min) | Stability (min) | Degree of Softening (FU) |

|---|---|---|---|---|

| CP0DS0 2 | 58.3 ± 0.20 a | 1.5 ± 0.17 a | 0.5 ± 0.30 a | 60 ± 1.0 e |

| CP10DS0 | 58.7 ± 0.25 a | 1.8 ± 0.16 a | 1.0 ± 0.05 b | 110 ± 0.0 g |

| CP10DS5 | 63.8 ± 0.17 b | 8.5 ± 0.14 c | 2.0 ± 0.01 d | 55 ± 1.5 d |

| CP10DS10 | 68.3 ± 0.43 d | 9.0 ± 0.17 d | 2.0 ± 0.00 d | 45 ± 1.0 b |

| CP15DS0 | 58.5 ± 0.14 a | 2.0 ± 0.15 a | 1.0 ± 0.01 b | 105 ± 0.5 f |

| CP15DS5 | 65.1 ± 0.17 c | 9.0 ± 0.10 d | 1.5 ± 0.07 c | 55 ± 0.5 d |

| CP15DS10 | 69.0 ± 0.19 d | 8.5 ± 0.12 c | 2.0 ± 0.15 d | 50 ± 0.5 c |

| CP20DS0 | 59.2 ± 0.16 a | 5.5 ± 0.11 b | 1.5 ± 0.02 c | 110 ± 0.5 g |

| CP20DS5 | 64.9 ± 0.15 b | 9.0 ± 0.12 d | 1.5 ± 0.07 c | 40 ± 1.0 a |

| CP20DS10 | 69.7 ± 0.11 e | 9.2 ± 0.16 d | 1.5 ± 0.05 c | 55 ± 1.5 d |

| Sample 1 | External Appearance | Crumb Structure | Smell | Taste | Total Score | Quality Category |

|---|---|---|---|---|---|---|

| CP0DS0 2 | 20.0 ± 0.0 a | 24.0 ± 0.6 a | 20.0 ± 0.0 a | 24.0 ± 0.6 a | 88.0 | Very good |

| CP10DS0 | 18.0 ± 0.5 b | 21.0 ± 0.5 b | 20.0 ± 0.0 a | 24.0 ± 0.0 a | 83.0 | Very good |

| CP10DS5 | 20.0 ± 0.0 a | 27.0 ± 0.5 c | 20.0 ± 0.0 a | 30.0 ± 0.0 b | 97.0 | Excellent |

| CP10DS10 | 18.0 ± 0.5 b | 24.0 ± 0.6 a | 20.0 ± 0.0 a | 30.0 ± 0.0 b | 92.0 | Excellent |

| CP15DS0 | 18.0 ± 0.0 b | 18.0 ± 0.6 d | 20.0 ± 0.0 a | 18.0 ± 0.6 c | 74.0 | Good |

| CP15DS5 | 18.0 ± 0.6 b | 21.0 ± 0.5 b | 20.0 ± 0.0 a | 24.0 ± 0.6 a | 83.0 | Very good |

| CP15DS10 | 18.0 ± 0.6 b | 21.0 ± 0.8 b | 20.0 ± 0.0 a | 27.0 ± 0.5 d | 86.0 | Very good |

| CP20DS0 | 12.0 ± 0.0 c | 15.0 ± 0.5 e | 20.0 ± 0.0 a | 12.0 ± 0.0 e | 59.0 | Acceptable |

| CP20DS5 | 12.0 ± 0.0 c | 18.0 ± 0.0 d | 20.0 ± 0.0 a | 18.0 ± 0.0 c | 68.0 | Good |

| CP20DS10 | 12.0 ± 0.0 c | 20.0 ± 0.5 b | 20.0 ± 0.0 a | 18.0 ± 0.6 c | 71.0 | Good |

| Nutrients (g/100 g) | CP0DS0 | CP15DS10 |

|---|---|---|

| Moisture | 34.60 ± 0.05 b | 33.80 ± 0.07 a |

| Ash | 0.51 ± 0.01 a | 0.76 ± 0.01 b |

| Fat | 0.25 ± 0.12 b | 0.18 ± 0.09 a |

| Proteins | 9.47 ± 0.05 a | 10.02 ± 0.06 b |

| Available carbohydrates | 53.90 ± 0.19 b | 48.76 ± 0.15 b |

| Total dietary fiber | 1.27 ± 0.11 a | 6.48 ± 0.08 b |

| Insoluble dietary fiber | 0.51 ± 0.18 a | 3.25 ± 0.23 b |

| Soluble dietary fiber | 0.76 ± 0.14 a | 3.23 ± 0.17 b |

| Energy value (kJ/100 g) (kcal/100 g) | 1096.70 258.27 | 1057.76 249.70 |

| Minerals | NRV 1 (mg) | 15% NRV 2 (mg/100 g) | CP0DS0 (mg/100 g) | CP15DS10 (mg/100 g) |

|---|---|---|---|---|

| K | 2000 | 300 | 130.63 ± 24.27 a | 247.44 ± 12.52 b |

| Ca | 800 | 120 | 26.54 ± 2.11 a | 62.17 ± 4.59 b |

| Mg | 375 | 53.25 | 17.04 ± 0.90 a | 32.83 ± 1.17 b |

| Fe | 14 | 2.10 | 1.43 ± 0.24 a | 1.95 ± 0.53 a |

| Zn | 10 | 1.50 | 1.67 ± 0.55 a | 1.39 ± 0.35 a |

| Mn | 2 | 0.30 | 0.33 ± 0.01 a | 0.76 ± 0.01 b |

| Cu | 1 | 0.15 | 0.18 ± 0.00 a | 0.21 ± 0.00 b |

| Sample 1 | TP (mg GAE/100 g) | TF (mg CE/100 g) | DPPH (µM TE/100 g) | FRAP (µM Fe2+/100 g) | ABTS (µM TE/100 g) |

|---|---|---|---|---|---|

| CP0DS0C | 11.52 ± 0.45 a | 38.29 ± 1.76 a | 32.92 ± 4.32 a | 154.95 ± 6.69 a | 17.09 ± 9.08 a |

| CP0DS0W | 12.67 ± 0.88 a | 45.45 ± 1.09 b | 40.85 ± 1.14 b | 157.66 ± 4.71 a | 27.40 ± 9.10 a |

| CP15DS10C | 117.77 ± 2.71 b | 51.78 ± 0.99 c | 402.69 ± 16.24 c | 857.53 ± 35.37 b | 450.04 ± 33.73 b |

| CP15DS10W | 140.55 ± 8.41 c | 60.14 ± 2.93 d | 498.15 ± 10.06 d | 1260.40 ± 57.95 c | 727.35 ± 80.57 c |

| Day | TBC (log CFU/g) | TSC (log CFU/g) | TMC (log CFU/g) | |||

|---|---|---|---|---|---|---|

| CP0DS0 | CP15DS10 | CP0DS0 | CP15DS10 | CP0DS0 | CP15DS10 | |

| 1 | <1.0 a | <1.0 a | <1.0 a | <1.0 a | 1.00 ± 0.00 a | <1.0 a |

| 4 | 5.30 ± 0.09 b | <1.0 a | 2.34 ± 0.00 b | 1.30 ± 0.00 a | 2.57 ± 0.11 b | <1.0 a |

| 7 | 5.21 ± 0.03 b | 2.45 ± 0.18 a | <1.0 a | <1.0 a | <1.0 a | <1.0 a |

| 11 | 5.73 ± 0.09 b | 4.66 ± 0.04 a | 2.98 ± 0.02 a | 3.22 ± 0.53 b | <1.0 a | <1.0 a |

| 14 | 5.80 ± 0.00 b | 5.50 ± 0.00 a | 2.59 ± 0.00 b | <1.0 a | <1.0 a | <1.0 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zahorec, J.; Šoronja-Simović, D.; Petrović, J.; Šereš, Z.; Pavlić, B.; Božović, D.; Perović, L.; Martić, N.; Bulut, S.; Kocić-Tanackov, S. Development of Functional Bread: Exploring the Nutritional, Bioactive and Microbial Potential of Carob (Ceratonia siliqua L.) Pulp Powder. Processes 2024, 12, 2882. https://doi.org/10.3390/pr12122882

Zahorec J, Šoronja-Simović D, Petrović J, Šereš Z, Pavlić B, Božović D, Perović L, Martić N, Bulut S, Kocić-Tanackov S. Development of Functional Bread: Exploring the Nutritional, Bioactive and Microbial Potential of Carob (Ceratonia siliqua L.) Pulp Powder. Processes. 2024; 12(12):2882. https://doi.org/10.3390/pr12122882

Chicago/Turabian StyleZahorec, Jana, Dragana Šoronja-Simović, Jovana Petrović, Zita Šereš, Branimir Pavlić, Danica Božović, Lidija Perović, Nikola Martić, Sandra Bulut, and Sunčica Kocić-Tanackov. 2024. "Development of Functional Bread: Exploring the Nutritional, Bioactive and Microbial Potential of Carob (Ceratonia siliqua L.) Pulp Powder" Processes 12, no. 12: 2882. https://doi.org/10.3390/pr12122882

APA StyleZahorec, J., Šoronja-Simović, D., Petrović, J., Šereš, Z., Pavlić, B., Božović, D., Perović, L., Martić, N., Bulut, S., & Kocić-Tanackov, S. (2024). Development of Functional Bread: Exploring the Nutritional, Bioactive and Microbial Potential of Carob (Ceratonia siliqua L.) Pulp Powder. Processes, 12(12), 2882. https://doi.org/10.3390/pr12122882