Experimental Investigation on Thermo-Economic Analysis of Direct Contact Membrane Distillation for Sustainable Freshwater Production

Abstract

1. Introduction

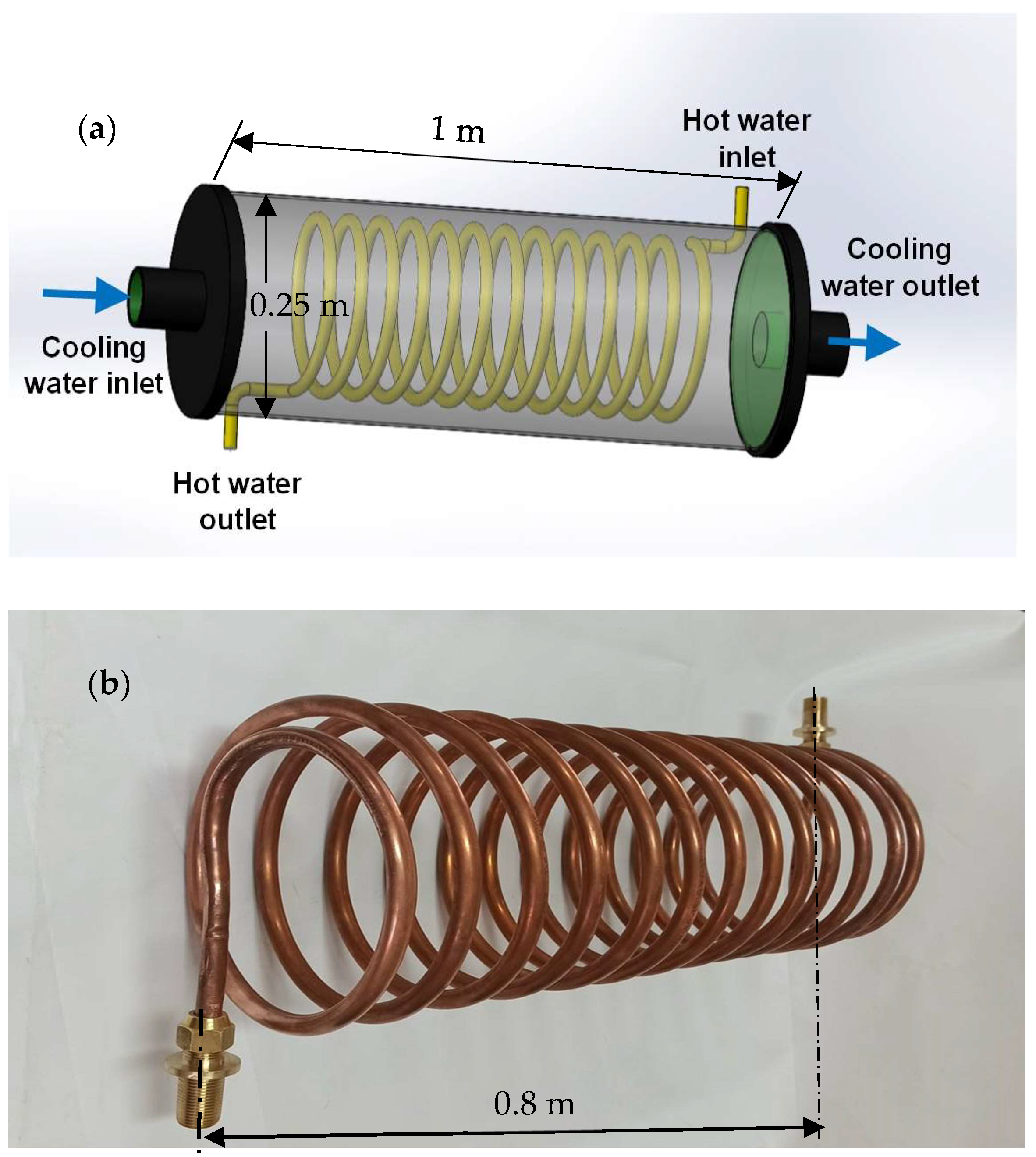

2. Experimental Work

2.1. Experimental Setup and Measuring Devices

2.2. Experimental Procedure

3. Results and Discussions

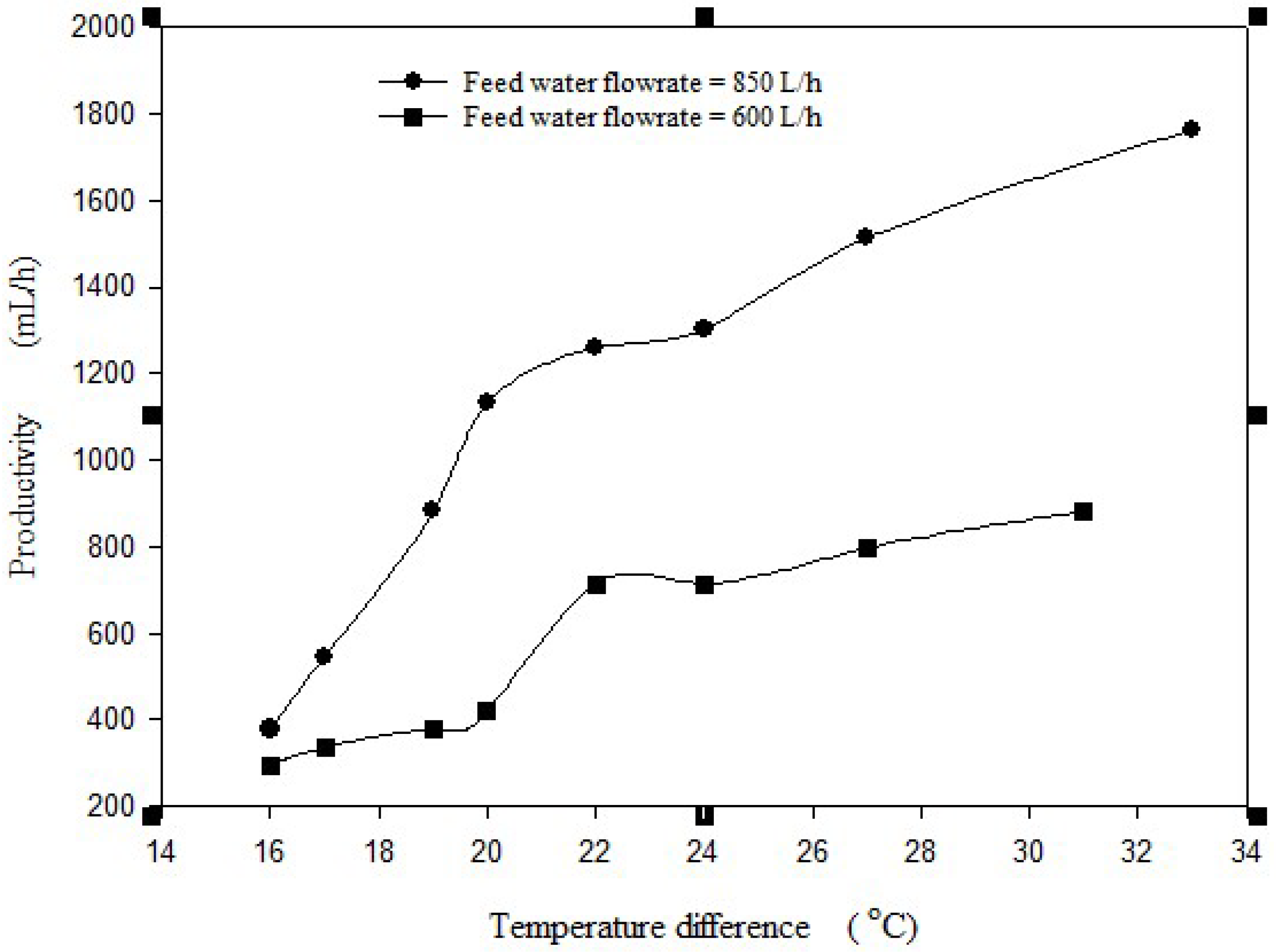

3.1. Operating Parameters

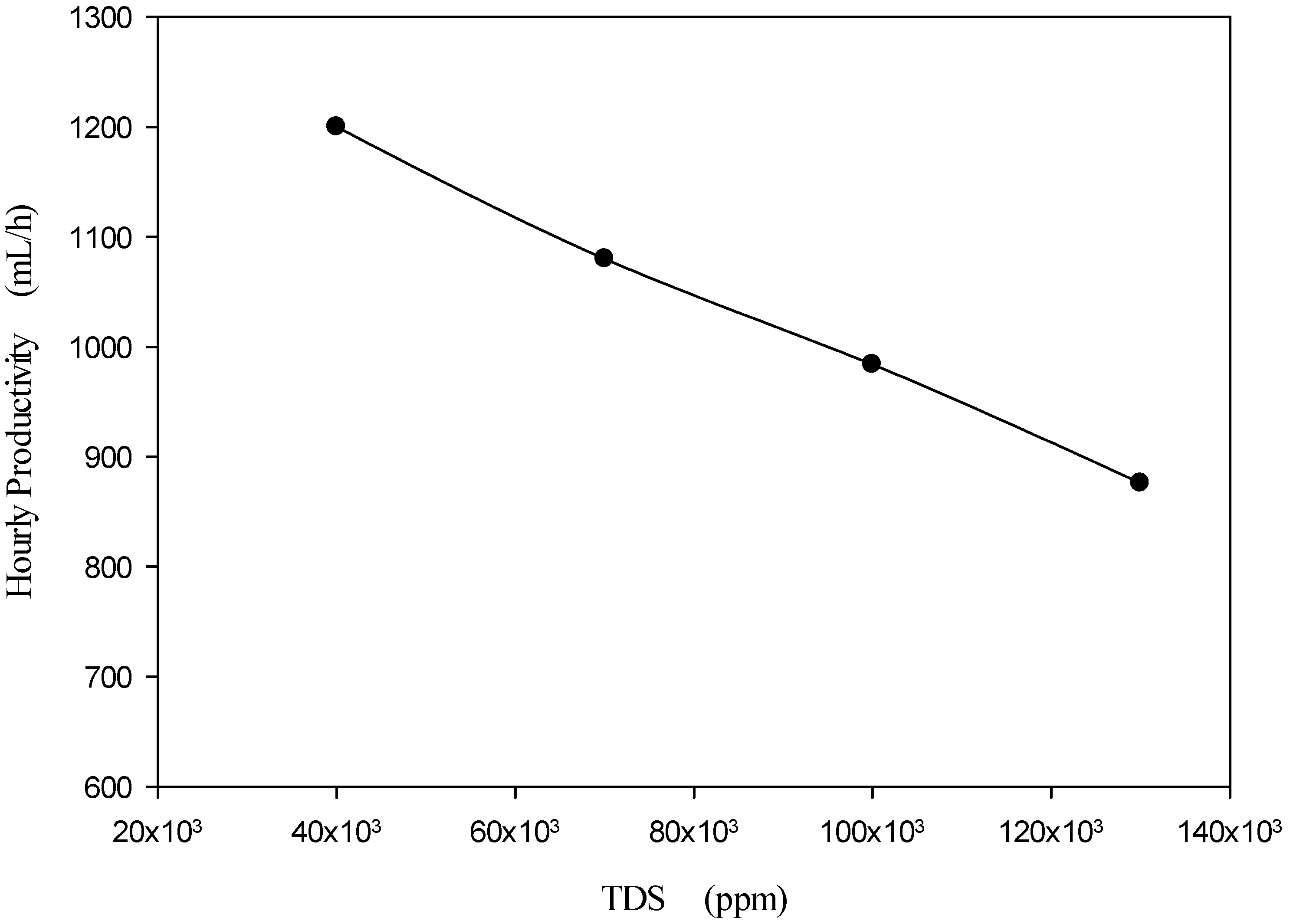

3.2. Investigation of the Performance of the MD for Brackish and Sea Water Desalination

3.3. Investigation of the Performance of the MD for Deslinating Extremely Saline Water

4. Economic Analysis

5. Conclusions

- The productivity of HFMD significantly increases with increasing the hot feed water temperature and mass flow rate under the studied ranges of 65–76 °C and 600–850 L/h, respectively.

- The productivity of HFMD is not significantly affected by increasing the salinity of water even when brackish or sea water is used.

- The productivity of HFMD slightly decreases with increasing salinity when extremely saline water is used.

- The selection of HFMD system is associated with high cost per liter where it achieves 0.208–0.212 and 0.215–0.222 USD/L when brackish and sea water was used, respectively. So, it is not recommended to use HFMD for desalinating brackish and sea water, where the RO is the first choice as it achieves at least 1/10 of the costs of MD.

- According to the costs achieved by HFMD (0.222–0.304 USD/L) when extremely saline water was used (40,000–130,000 ppm), the HFMD is considered the second choice after hybrid solar HDH.

- It is recommended to use solar collectors to provide the heat required to operate the HFMD.

- It is also recommended to operate the HFMD in vacuum mode to decrease the heat transfer between the hot and cold streams, which leads to decreasing the electrical power consumption.

- The cost of water production decreases by 21.7–23.1% when solar collectors are used to provide the required heat to the HFMD.

- Integrating solar energy and the HFMD system will lead to the extremely saline water desalination technologies or at least compete with the solar HDH technology.

- The integration between RO and MD is the most potential and recommended application of MD where it is used for concentrating the RO brine and improving the productivity of the desalination plant as well.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Burn, S.; Hoang, M.; Zarzo, D.; Olewniak, F.; Campos, E.; Bolto, B.; Barron, O. Desalination techniques—A review of the opportunities for desalination in agriculture. Desalination 2015, 364, 2–16. [Google Scholar] [CrossRef]

- Ahmed, F.E.; Hashaikeh, R.; Hilal, N. Solar powered desalination—Technology, energy and future outlook. Desalination 2019, 453, 54–76. [Google Scholar] [CrossRef]

- Abdelkareem, M.A.; El Haj Assad, M.; Sayed, E.T.; Soudan, B. Recent progress in the use of renewable energy sources to power water desalination plants. Desalination 2018, 435, 97–113. [Google Scholar] [CrossRef]

- Greenlee, L.F.; Lawler, D.F.; Freeman, B.D.; Marrot, B.; Moulin, P. Reverse osmosis desalination: Water sources, technology, and today’s challenges. Water Res. 2009, 43, 2317–2348. (In English) [Google Scholar] [CrossRef]

- Service, R.F. Desalination Freshens Up. Science 2006, 313, 1088–1090. [Google Scholar] [CrossRef]

- Suo, Y.; Ren, Y. Research on the mechanism of nanofiltration membrane fouling in zero discharge process of high salty wastewater from coal chemical industry. Chem. Eng. Sci. 2021, 245, 116810. [Google Scholar] [CrossRef]

- Shalaby, S.M.; Sharshir, S.W.; Kabeel, A.E.; Kandeal, A.W.; Abosheiasha, H.F.; Abdelgaied, M.; Hamed, M.H.; Yang, N. Reverse osmosis desalination systems powered by solar energy: Preheating techniques and brine disposal challenges—A detailed review. Energy Convers. Manag. 2022, 251, 114971. [Google Scholar] [CrossRef]

- Ahmad, M.; Williams, P. Assessment of desalination technologies for high saline brine applications—Discussion Paper. Desalination Water Treat. 2011, 30, 1–15. [Google Scholar] [CrossRef]

- Shalaby, S.M.; Hammad, F.A.; Zayed, M.E. Current progress in integrated solar desalination systems: Prospects from coupling configurations to energy conversion and desalination processes. Process Saf. Environ. Prot. 2023, 178, 494–510. [Google Scholar] [CrossRef]

- Shalaby, S.M.; Kabeel, A.E.; Moharram, B.M.; Fleafl, A.H. Experimental study of hybrid solar humidification dehumidification system for extremely saline water desalination. Energy Convers. Manag. 2021, 235, 114021. [Google Scholar] [CrossRef]

- Thiel, G.P.; Tow, E.W.; Banchik, L.D.; Chung, H.W.; Lienhard, J.H. Energy consumption in desalinating produced water from shale oil and gas extraction. Desalination 2015, 366, 94–112. [Google Scholar] [CrossRef]

- Duong, H.C.; Chivas, A.R.; Nelemans, B.; Duke, M.; Gray, S.; Cath, T.Y.; Nghiem, L.D. Treatment of RO brine from CSG produced water by spiral-wound air gap membrane distillation—A pilot study. Desalination 2015, 366, 121–129. [Google Scholar] [CrossRef]

- Lokare, O.R.; Tavakkoli, S.; Wadekar, S.; Khanna, V.; Vidic, R.D. Fouling in direct contact membrane distillation of produced water from unconventional gas extraction. J. Membr. Sci. 2017, 524, 493–501. [Google Scholar] [CrossRef]

- Xu, J.; Singh, Y.B.; Amy, G.L.; Ghaffour, N. Effect of operating parameters and membrane characteristics on air gap membrane distillation performance for the treatment of highly saline water. J. Membr. Sci. 2016, 512, 73–82. [Google Scholar] [CrossRef]

- Al-Obaidani, S.; Curcio, E.; Macedonio, F.; Di Profio, G.; Al-Hinai, H.; Drioli, E. Potential of membrane distillation in seawater desalination: Thermal efficiency, sensitivity study and cost estimation. J. Membr. Sci. 2008, 323, 85–98. [Google Scholar] [CrossRef]

- Pan, J.; Zhang, F.; Wang, Z.; Sun, S.-P.; Cui, Z.; Jin, W.; Bamaga, O.; Abulkhair, H.; Albeirutty, M.; Drioli, E. Enhanced anti-wetting and anti-fouling properties of composite PFPE/PVDF membrane in vacuum membrane distillation. Sep. Purif. Technol. 2022, 282, 120084. [Google Scholar] [CrossRef]

- Manawi, Y.M.; Khraisheh, M.; Fard, A.K.; Benyahia, F.; Adham, S. Effect of operational parameters on distillate flux in direct contact membrane distillation (DCMD): Comparison between experimental and model predicted performance. Desalination 2014, 336, 110–120. [Google Scholar] [CrossRef]

- Hejazi, M.-A.A.; Bamaga, O.A.; Al-Beirutty, M.H.; Gzara, L.; Abulkhair, H. Effect of intermittent operation on performance of a solar-powered membrane distillation system. Sep. Purif. Technol. 2019, 220, 300–308. [Google Scholar] [CrossRef]

- Mustafa, I.; Kilibay, A.; Alhseinat, E.; Almarzooqi, F. Enhanced Membrane Distillation Water Flux through Electromagnetism. Chem. Eng. Process. -Process Intensif. 2021, 169, 108597. [Google Scholar] [CrossRef]

- Elcik, H.; Fortunato, L.; Alpatova, A.; Soukane, S.; Orfi, J.; Ali, E.; AlAnsary, H.; Leiknes, T.; Ghaffour, N. Multi-effect distillation brine treatment by membrane distillation: Effect of antiscalant and antifoaming agents on membrane performance and scaling control. Desalination 2020, 493, 114653. [Google Scholar] [CrossRef]

- Naidu, G.; Jeong, S.; Vigneswaran, S. Influence of feed/permeate velocity on scaling development in a direct contact membrane distillation. Sep. Purif. Technol. 2014, 125, 291–300. [Google Scholar] [CrossRef]

- Khayet, M. Membranes and theoretical modeling of membrane distillation: A review. Adv. Colloid Interface Sci. 2011, 164, 56–88. [Google Scholar] [CrossRef] [PubMed]

- Oxymo Technology Company, China. Available online: https://oxymembrane.com/product/membrane-distillation-ptfe-membrane/ (accessed on 1 April 2021).

- Ali Ahmed, H.J.; Lee, T.L.; Shaikh, J.M. An investigation on asset allocation and performance measurement for unit trust funds in Malaysia using multifactor model: A post crisis period analysis. Int. J. Manag. Financ. Account. 2011, 3, 22–31. [Google Scholar] [CrossRef]

- Park, K.; Burlace, L.; Dhakal, N.; Mudgal, A.; Stewart, N.A.; Davies, P.A. Design, modelling and optimisation of a batch reverse osmosis (RO) desalination system using a free piston for brackish water treatment. Desalination 2020, 494, 114625. [Google Scholar] [CrossRef]

- Eykens, L.; Reyns, T.; De Sitter, K.; Dotremont, C.; Pinoy, L.; Van der Bruggen, B. How to select a membrane distillation configuration? Process conditions and membrane influence unraveled. Desalination 2016, 399, 105–115. [Google Scholar] [CrossRef]

- Kim, J.; Park, M.; Shon, H.K.; Kim, J.H. Performance analysis of reverse osmosis, membrane distillation, and pressure-retarded osmosis hybrid processes. Desalination 2016, 380, 85–92. [Google Scholar] [CrossRef]

- Alkhudhiri, A.; Darwish, N.; Hilal, N. Treatment of high salinity solutions: Application of air gap membrane distillation. Desalination 2012, 287, 55–60. [Google Scholar] [CrossRef]

- Banat, F.A.; Simandl, J. Theoretical and experimental study in membrane distillation. Desalination 1994, 95, 39–52. [Google Scholar] [CrossRef]

- Fath, H.E.S.; El-Samanoudy, M.; Fahmy, K.; Hassabou, A. Thermal-economic analysis and comparison between pyramid-shaped and single-slope solar still configurations. Desalination 2003, 159, 69–79. [Google Scholar] [CrossRef]

- Kumar, S.; Tiwari, G.N. Life cycle cost analysis of single slope hybrid (PV/T) active solar still. Appl. Energy 2009, 86, 1995–2004. [Google Scholar] [CrossRef]

- Ettouney, H.M.; El-Dessouky, H.T.; Faibish, R.S.; Gowin, P.J. Evaluating the Economics of Desalination. Chem. Eng. Prog. 2002, 98, 32–39. [Google Scholar]

- Nthunya, L.N.; Bopape, M.F.; Mahlangu, O.T.; Mamba, B.B.; Van der Bruggen, B.; Quist-Jensen, C.A.; Richards, H. Fouling, performance and cost analysis of membrane-based water desalination technologies: A critical review. J. Environ. Manag. 2022, 301, 113922. [Google Scholar] [CrossRef] [PubMed]

- Hamed, M.H.; Kabeel, A.E.; Omara, Z.M.; Sharshir, S.W. Mathematical and experimental investigation of a solar humidification–dehumidification desalination unit. Desalination 2015, 358, 9–17. [Google Scholar] [CrossRef]

- El-Agouz, S.A.; Abugderah, M. Experimental analysis of humidification process by air passing through seawater. Energy Convers. Manag. 2008, 49, 3698–3703. [Google Scholar] [CrossRef]

- Abdel Dayem, A. A Pioneer Solar Water Desalination System: Experimental Testing and Numerical Simulation. Energy Sci. Technol. J. 2011, 1, 33. [Google Scholar]

- Shalaby, S.; Kabeel, A.E.; Moharram, B.E.; Shama, A.; Abosheiasha, H.A. Experimental study on the single basin solar still integrated with shell and spiral finned tube latent heat storage system enhanced by copper oxide nanoparticles. Environ. Sci. Pollut. Res. 2023, 30, 27458–27468. [Google Scholar] [CrossRef]

- Shalaby, S.M.; Elfakharany, M.K.; Mujtaba, I.M.; Moharram, B.M.; Abosheiasha, H.F. Development of an efficient nano-fluid cooling/preheating system for PV-RO water desalination pilot plant. Energy Convers. Manag. 2022, 268, 115960. [Google Scholar] [CrossRef]

- Manolakos, D.; Mohamed, E.S.; Karagiannis, I.; Papadakis, G. Technical and economic comparison between PV-RO system and RO-Solar Rankine system. Case study: Thirasia island. Desalination 2008, 221, 37–46. [Google Scholar] [CrossRef]

- Banat, F.; Jumah, R.; Garaibeh, M. Exploitation of solar energy collected by solar stills for desalination by membrane distillation. Renew. Energy 2002, 25, 293–305. [Google Scholar] [CrossRef]

| Parameter | Specification |

|---|---|

| Membrane material | PTFE |

| Housing material | CPVC |

| Module dimensions, diameter/length (mm) | 90/1230 |

| Pore size (µm) | 0.15 |

| Fiber inner/outer diameter (mm) | 0.8/1.53 |

| Porosity % | 55% |

| Water penetration pressure (bar) | >3 |

| Maximum feed water flow rate (L/h) | 1000 |

| Effective area (m2) | 7 |

| Maximum feed water pressure (bar) | 0.5 |

| Operation temperature (°C) | ≤90 |

| Item | Number of Units | Cost/Unit (USD) | Total Cost (USD) (Electrical Heaters/Solar Collector) |

|---|---|---|---|

| Hollow fiber MD4040 | 3 | 1500 | 4500 |

| Electrical heater/solar collector (2 kW) | 2 | 25 | 50/600 |

| Heat exchanger | 1 | 100 | 100 |

| Pump (0.5 hp) | 2 | 50 | 100 |

| Other | -- | 100 | 100 |

| Total cost | 4850/5400 | ||

| Parameter | References | Value (Electricity/Solar) |

|---|---|---|

| P (USD) | From Table 2 | 4850/5400 |

| i (%/year) | 5% [32] | 5% |

| n (year) | 30 [32] | 30 |

| SFF (dimensionless) | Equation (1) | 0.015 |

| CRF (dimensionless) | Equation (2) | 0.065 |

| FAC (USD) | Equation (3) | 315.26/351 |

| S (USD) | Equation (4) | 970 |

| ASV (USD) | Equation (5) | 14.55 |

| AMC (USD) | Equation (6) | 47.3 |

| EEC (kWh) | The consumed power × operational time | 85.4/4.47 |

| AEEC (USD) | Equation (7) | 1402.7/73.4 |

| AC (USD) | Equation (8) | 1750.7/457.15 |

| CPL (USD/L) | Equation (9) | |

| AP (L) | Calculated based on the measured productivity | |

| Salinity (ppm) | AP (L) (Using Electrical Heaters) | CPL (USD/L) (Using Electrical Heaters) | AP (L) (If Solar Collectors Are Used) | CPL (USD/L) (If Solar Collectors Are Used) |

|---|---|---|---|---|

| 3000 | 8409.6 | 0.208 | 2803.2 | 0.16 |

| 6000 | 8350.5 | 0.209 | 2783.5 | 0.164 |

| 9000 | 8317.6 | 0.211 | 2772.5 | 0.165 |

| 12,000 | 8245.4 | 0.212 | 2748.5 | 0.166 |

| 25,000 | 8146.8 | 0.215 | 2715.6 | 0.168 |

| 30,000 | 8100.8 | 0.216 | 2700.3 | 0.169 |

| 35,000 | 8015.4 | 0.218 | 2671.8 | 0.171 |

| 40,000 | 7884 | 0.222 | 2628 | 0.174 |

| 70,000 | 7095.6 | 0.248 | 2365.2 | 0.193 |

| 100,000 | 6464.9 | 0.271 | 2155 | 0.212 |

| 130,000 | 5755.3 | 0.304 | 1918.4 | 0.238 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shalaby, S.M.; Hammad, F.A.; Ebeid, H.A.; Armanuos, A.M.; Mujtaba, I.M.; Gado, T.A. Experimental Investigation on Thermo-Economic Analysis of Direct Contact Membrane Distillation for Sustainable Freshwater Production. Processes 2025, 13, 240. https://doi.org/10.3390/pr13010240

Shalaby SM, Hammad FA, Ebeid HA, Armanuos AM, Mujtaba IM, Gado TA. Experimental Investigation on Thermo-Economic Analysis of Direct Contact Membrane Distillation for Sustainable Freshwater Production. Processes. 2025; 13(1):240. https://doi.org/10.3390/pr13010240

Chicago/Turabian StyleShalaby, Saleh M., Farid A. Hammad, Hamdy A. Ebeid, Asaad M. Armanuos, Iqbal M. Mujtaba, and Tamer A. Gado. 2025. "Experimental Investigation on Thermo-Economic Analysis of Direct Contact Membrane Distillation for Sustainable Freshwater Production" Processes 13, no. 1: 240. https://doi.org/10.3390/pr13010240

APA StyleShalaby, S. M., Hammad, F. A., Ebeid, H. A., Armanuos, A. M., Mujtaba, I. M., & Gado, T. A. (2025). Experimental Investigation on Thermo-Economic Analysis of Direct Contact Membrane Distillation for Sustainable Freshwater Production. Processes, 13(1), 240. https://doi.org/10.3390/pr13010240