Abstract

Most organic waste from food production is still not used for energy production. From the perspective of energy production, one option is to valorise the properties of organic waste. The fruit juice industry is growing rapidly and generates large amounts of waste. One of the main wastes in food and fruit juice processing is peach pits and apple peels. The aim of this study was to analyse the influence of torrefaction temperature on the properties of food waste, namely apple peels, peach pits and pea shells, in order to improve their energy value and determine their potential for further use and valorisation as a renewable energy source. The aim was to analyse the influence of different torrefaction temperatures on the heating value (HHV), mass yield (MY) and energy yield (EY) in order to better understand the behavior of the thermal properties of individual selected samples. The torrefaction process was carried out at temperatures of 250 °C, 350 °C and 450 °C. The obtained biomass was compared with dried biomass. For apple peels, HHV after torrefaction was (28 kJ/kg), MY decreased by (66–34%), while EY fell by (97–83%). Peach pits, despite a higher HHV after torrefaction (18 kJ/kg), achieved low MY (38–89%) and EY (59–99%), which reduces their efficiency in biochar production. Pea peels had EY (82–97%) and a lower HHV after torrefaction (11 kJ/kg), but their high ash content limits their wider use. The results confirm that, with increasing temperature, MY and EY for all selected biomasses decrease, which is a consequence of the degradation of hemicellulose and cellulose and the loss of volatile compounds. In most cases, increasing the torrefaction temperature improved the resistance to moisture adsorption, as this is related to the thermal process that causes structural changes. The results showed that the torrefaction process improved the hydrophobic properties of the biomass samples. Temperature was seen to have a great impact on mass energy efficiency. Apple peels generally had the highest mass and energy yield.

1. Introduction

New renewable energy sources are becoming increasingly important to ensure a safe environment and enhance energy security. Agricultural biomass residues offer a promising alternative fuel due to their high waste volumes and properties [1]. Therefore, significant research is focused on environmentally friendly fuels. An analysis of data in the European Union (EU) shows that around 88 million tonnes of food waste is generated annually [2].

Food waste (FW) is one of the most important types of biological waste generated in the world today. Production, improper storage and the high consumption and processing of food, which has become the fastest growing industry in the last decade, are major contributors to the generation of FW. This is why the fruit and vegetable industry generates much more waste (25–30%) compared to other processing sectors. This is mainly peelings, stones, various seeds and pomace. A major problem in all of this is the disposal of FW, which further increases the overall production of fruit and vegetables. This waste is also biodegradable, which makes the valorisation of this food waste in the circular economy all the more important [3]. Peas are an important legume as world pea production is increasing. It is also due to the high global production that a lot of waste is generated in the actual production of these legumes [4].

The importance of studying alternative energy sources through waste valorisation is important and necessary in order to prevent energy crises due to the depletion of fossil fuel reserves. There are three main technologies for energy recovery from waste with the possibility of valorisation, depending on the characteristics of the waste biomass, the degree of feasibility and the basic reactions of the process itself: (i) thermochemical conversion, (ii) biological conversion and (iii) chemical conversion. The main thermochemical conversions include pyrolysis, incineration, gasification, torrefaction and hydrothermal carbonisation [5]. A large part of biomass waste comes from the agri-food industry, such as peelings, shells, pits and pomace. These types of wastes are mostly used in composting or biogas plants, but biomass can also be used in co-incineration or combustion facilities. Raw biomass has a high moisture content, low bulk density, low heating value and a heterogeneous structure. It is prone to rapid decomposition, which causes problems for storage and subsequent transport [2]. Each biomass chosen has advantages and disadvantages, such as availability and suitability for energy requirements [6]. The susceptibility of biomass to biodegradation is reduced due to the hydrophobic nature of treated biomass [7]. Biorefineries strongly support environmental protection and thus economic growth by converting biomass into energy that is environmentally friendly [8].

In cases where other treatment options are unavailable or unsuitable, combustion provides a viable means of recovering energy from FW. Incineration requires additional pre-treatment due to the low high heating value (HHV) and high moisture content of FW [9]. Pyrolysis involves the thermal decomposition of solid materials in the absence of oxygen at high temperatures, unlike other thermal treatment methods, notably incineration and gasification, where oxygen is required. In particular, the choice of operating conditions, feedstock and reactor is important in pyrolysis because of the desired final yield of the product [10]. Gasification is a low-pollution thermochemical process similar to pyrolysis. Gasification variations occur at high temperatures in the range 800 °C to 1200 °C [11]. Hydrothermal carbonisation (HTC) is a wet conversion thermochemical method for converting high-moisture biomass into valuable products. The process undergoes a series of simultaneous chemical reactions (dehydration, hydrolysis, condensation, etc.) to produce the final product [5].

Torrefaction is a biomass pre-treatment process used to improve fuel properties and one of the most promising processes for biomass valorisation for further use in energy production. The oxygen-free atmosphere inhibits the combustion process and thus allows the thermal decomposition of the torrefied biomass. The torrefaction process increases the HHV and carbon content and converts the biomass into a high-quality fuel [12].

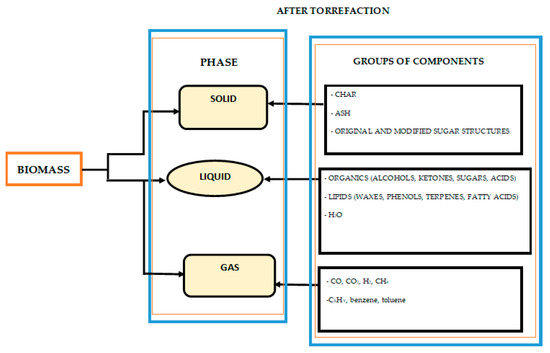

Torrefaction produces a wide variety of products, with yields depending on the operating conditions, such as temperature, time and the type of biomass. Figure 1 gives an overview of the products generated during the torrefaction process, classified according to solid, liquid and gaseous state [13]. The low heating value and high moisture content of biomass present significant challenges and subsequent process optimisation. In all cases, increasing the torrefaction temperature reduces the mass and energy yield, increases carbon content and reduces oxygen content [14]. From the research carried out, the following conclusions can be drawn: torrefaction of raw biomass involves reactions leading to the production of torrefied biomass with reduced moisture content, increased HHV, increased carbon content and reduced oxygen content [12]. Increasing the reheat temperature results in the release of moisture and volatiles from the biomass, and the yield of solids gradually decreases compared to gaseous and liquid products where yields gradually increase [15]. In addition, the torrefaction process removes moisture content by increasing the carbon content of the fuel, making it inherently hydrophobic [16].

Figure 1.

Overview of the products generated during the torrefaction process, classified according to solid, liquid and gaseous state.

Torrefaction was chosen as a suitable method due to several properties that improve the energy potential of the selected materials from fruit and vegetable processing. The process converts waste biomass into products with a higher carbon content, which increases its energy value. This is particularly important for apple waste, which is rich in moisture and cellulose. The process itself also increases the stability of the waste biomass, in particular peach pits and apple peels have a more homogeneous structure, which improves milling and thus the conversion into biofuels. Fruit and vegetable waste is usually naturally high in oxygen, which is not optimal. In the torrefaction process, the oxygen ratio of the material is reduced, thereby increasing the combustion efficiency. In addition, the process itself allows for the sustainable use of fruit and vegetable waste, which reduces its impact on the environment [17].

The study investigates the factors influencing the torrefaction process and the final properties of the torrefied material. Temperature, type of biomass and processing conditions were examined. The precise adjustment of these factors is crucial to achieve the desired quality and efficiency of the biomass, which is particularly important for fruit and vegetable wastes because they have specific physicochemical properties.

In this study, apple peels, pea skins and peach pits were therefore torrefied in a laboratory furnace with a non-oxidative atmosphere and analysed for potential usage as a biofuel. The effects of torrefaction temperature on the mass and energy yields for selected waste food materials were investigated. In addition, the thermal stability of the raw and torrefied solid products was analysed using Fourier transform infrared spectroscopy (FTIR) and other methods to assess the physico-chemical properties, while the thermogravimetric method (TGA) was used to study the thermogravimetric characteristics. The aim and the objective of this study are to use torrefaction as a pre-treatment of solid waste materials to improve fuel properties, such as HHV, hydrophobicity and H/C and O/C ratios. Additionally, the influence of the torrefaction temperature on the hydrophobic properties of selected biomass wastes from food production was evaluated. The moisture, ash contents and HHV of the raw and torrefied samples were also determined using TGA and bomb calorimetry.

Innovations in the torrefaction of these specific materials include research into the impact of their composition on the process and the final products, the adaptation of process parameters to improve energy efficiency and the development of high-quality products that support the circular economy and reduce environmental impact. From our results, peach pits are not suitable for torrefaction due to their high lignin content, ash content, preparation costs and lower energy yield. The study contributes significantly to the understanding of selected food wastes, highlighting differences in the suitability of samples for torrefaction with respect to moisture content, high HHV, mass yield and energy yield.

2. Materials and Methods

2.1. Materials and Sample Preparation

Figure 2 presents the different types of waste biomass from fruit and vegetable processing.

Figure 2.

Waste materials used in the study: (a) peach pits, (b) apple peels and (c) pea shells.

Processing of apples, peaches and peas was carried out in a purpose-built plant specialising in agri-food processing, located close to raw material sources in north-eastern Slovenia. The samples were collected during the summer season, when apples, peaches and peas are seasonally harvested and their processing potential is highest, as they are available in the largest quantities and of optimum quality.

Before processing, all samples were air-dried for three days and then oven-dried at 105 °C for a further 3 h to reduce moisture content and ensure that the weight of all samples remained constant. This ensured a uniform initial state of the samples and optimised further processing. After drying, all samples were ground and the weight of each sample was determined using an analytical laboratory balance. The dried materials were crushed and ground with an IKA MultiDrive basic grinder to a particle size of 0.50 mm and stored in a desiccator to prevent moisture reabsorption and exposure to air. Correct storage ensured that the samples were ready for further analysis, which is essential for the reliability of the process.

Industrial conversions require a balance between the quality of the end product and the costs associated with energy losses during processing. The influence of different temperatures of the torrefaction process in this study provides further guidance for the optimisation of waste biomass valorisation. Also, each sample treatment was carried out at least three times to reduce errors.

2.2. Torrefaction Experiments

In this study, samples of apple peel, peach pit and pea shells were torrefied at different temperatures (250–450 °C) to produce biochar as a renewable energy source. The process itself was carried out in a N2 atmosphere in a laboratory tube furnace. In the laboratory tube furnace, 15 g of the selected biomass was treated in one batch process. The process lasted 60 min with 3 repetitions for each sample. After the treatment, the material was sealed in a desiccator to prevent adsorption of moisture from the air as mentioned above. The discussion uses the average values of the results obtained. In the study, the choice of temperature and combustion time was based on previous studies of biomass torrefaction, where these values were selected as optimal for improving product quality [18,19]. This temperature allows for efficient decomposition of organic components. Lower temperatures would not be sufficient for complete decomposition, while higher temperatures could lead to a reduction in the quality of the final products.

Torrefied biomass has a high HHV and thus an increased energy density for thermochemical conversion. One of the main improvements of torrefied biomass is the reduced oxygen to carbon (O/C) ratio. The strong fibres present in the biomass become brittle following the torrefaction process, which improves the flammability and thus increases the efficiency during pyrolysis. The main objective is to reduce the oxygen content in the sample compared to untreated biomass. The digestion of the selected biomass was investigated in terms of energy properties, the influence of heat treatment on the final analysis and HHV and the hydrophobicity of the selected wastes [20].

2.3. Analytical Methods

2.3.1. Higher Heating Value Analysis, Mass Yield and Energy Yield

Various analyses and analytical methods have been carried out to determine the physical properties of the torrefied biomass.

HHVs were measured in an IKA C6000 adiabatic bomb calorimeter (Isoperibol; Staufen, Germany) according to the UNI EN 14918:2019 [21], ASTM DIN 51900 [22] and ISO 1928 standards [23]. Important parameters such as weight loss (WL), mass yield (MY), enhancement factor and energy yield (EY) were determined and calculated according to Equations (1)–(4), respectively [6,8,15].

Energy yield is defined as the product of the enhancement factor and the mass yield. The determination of optimum torrefaction parameters improves the quantity and quality of the torrefied material by reducing mass loss and increasing HHV [24].

where:

- mr = weight of the raw sample;

- mt = weight of the torrefied sample.

The ash was determined in an incandescent furnace at 815 °C. The sample (1 g) was placed into an annealing crucible and heated to 815 °C in an air atmosphere and left at this constant temperature for 3 h. The cooled crucibles were then reweighed and the difference in mass of the sample represents the ash content. These results are also presented in Table 1 and Table 2. The fixed carbon (FC) value was determined as the difference (Equation (5)) and the fuel ratio (FR) (Equation (6)) [2,6] was estimated to assess the decomposition properties from FC and volatile matter (VM) content.

Table 1.

Parameters for the efficiency of the torrefaction process.

Table 2.

Proximate and ultimate analyses of raw and torrefied biomass samples.

Volatiles were determined using a Mettler Toledo TGA/DSC3+ apparatus. The material was placed into a covered crucible and then heated in an oxygen atmosphere (10 mL/min). The heating was carried out from 25 °C to 105 °C at a rate of 10 mL/min, after which the temperature was kept constant for 10 min. In the second part, the sample was heated at 100 K/min to 900 °C and then kept at this temperature for 7 min. The difference in mass represents the volatile matter in Table 2.

The moisture content of each sample is determined from the thermogravimetric analysis data as follows. The analysis is carried out on the loss of mass, which occurs mainly at low temperatures, usually during heating to about 100–200 °C. In this range, mass losses are usually due to evaporation of water still present in the sample.

The FTIR spectra were obtained using an FTIR spectrometer coupled to an attenuated total reflection. The torrefied samples were analysed to identify the functional groups that exist in the sample. The analyses for the samples were carried out between 500 and 4000 cm−1. Prior to the analysis of the samples themselves, the diamond surface was cleaned with acetone to remove any impurities. The samples were then arranged and pressed onto the diamond crystal of the attenuated total reflection method (ATR). All spectra for the torrefied biomass were obtained at room temperature at 25 °C [25].

The effect of the torrefaction temperature on the hydrophobic properties of the tested materials depends on the type and characteristics of the waste biomass. Investigations confirmed that torrefaction temperature significantly influences these properties [2].

2.3.2. Thermogravimetric Analysis (TGA)

Thermogravimetric analysis (TGA) is an analytical method that studies the change in mass of a sample during heating and temperature maintenance in an inert environment with respect to time and temperature. It examines the thermal properties of materials, including degradation, thermal stability and composition. It is used to obtain data for pyrolysis of lignocellulosic biomass [26]. TGA allows the processes involved in biochar valorisation to be understood. To ensure consistency of the process, the TGA was conducted three times on each sample [27].

3. Results and Discussion

The results of the final analysis of the raw and torrefied waste samples at different torrefaction temperatures are shown in Table 1. The reasons for the mass losses are likely moisture evaporation and evolved thermal decomposition products such as CO, CO2 and CH4 [28].

3.1. Parameters for the Efficiency of the Torrefaction Process

The parameters that indicate the torrefaction efficiency are shown in Table 1. The MY and EY of the samples at different temperatures are shown. It can be seen from the results that the mass of the sample decreases significantly as the temperature of the torrefaction increases.

The data in Table 1 show that, in all three cases, the HHV of the raw sample is lower than that of the torrefied sample at different temperatures. From the results it can be concluded that the HHV increases with increased temperature of torrefaction. The HHV increases during the torrefaction process due to an increase in carbon content and thus a decrease in oxygen content [28].

Table 1 also shows the results of MYs and EYs. The EYs for torrefaction at 250 °C are higher. As the torrefaction temperature was increased from 250 °C to 350 °C and later to 450 °C, the MY efficiencies decreased steadily, which was also shown in other studies [29]. Slightly higher yields are found for torrefied peach pits. The highest MY and EY were obtained for peach pits and pea shells torrefied at 250 °C. The effect of torrefaction temperature on EY and final biochar composition is of great importance, with higher temperatures leading to lower MY and higher energy densities and lower masses and EY. The type of biomass is also important, as feedstocks react differently to the torrefaction process [30].

During the torrefaction process, there is an increase in HHV and a decrease in MY and EY. The HHV increases with increasing torrefaction temperature (250–450 °C) as the carbon content increases. The process improves the energy density of the biomass, which is important for the subsequent production of a high-quality product. MY and EY values decrease due to the loss of mass during the process as hemicellulose and cellulose decompose. At higher torrefaction temperatures, the values can drop by up to 30%, which reduces the volume of the final product [18].

Other studies have also determined the MY and EY values of torrefied biomass to assess the efficiency of torrefaction. As the temperature increases, both efficiencies decrease with a constant tendency for the EY value to always be higher than the MY value [31]. The reduction in moisture and volatile content is an indicator of the efficiency of the torrefaction process, leading to high HHVs, which in turn increase the fuel properties. In addition, the increase in fixed carbon in the torrefied biomass showed that the temperature of the torrefaction process improved the energy value of the biomass [32]. Apple peels contain more carbohydrates, mainly cellulose, and a moderate amount of lignin, which contributes to the high HHVs. The MY values remain relatively stable, allowing high EY and thus providing a selected biomass to be suitable for biochar production [33]. Peach pits contain high lignin content. EY values are low due to higher mass losses. Although they have higher HHVs this is not sufficient for biochar production due to the low EY and MY values [34]. Pea shells contain low lignin contents and moderate amounts of cellulose and hemicellulose, which is observed with a significant decrease in HHV [35].

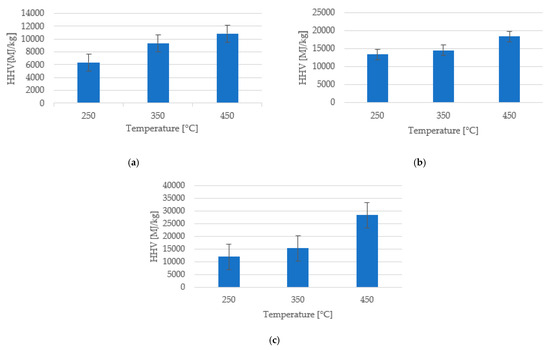

The HHVs are also shown graphically in Figure 3. When the temperature was increased from 250 to 450 °C, the HHV of the samples increased from the lowest values obtained at 250 °C (i.e., 12.098 MJ/kg, 13.352 MJ/kg and 6.366 MJ/kg, respectively) to the highest values obtained during 60 min of operation at 450 °C (i.e., 28.481 MJ/kg, 18.370 MJ/kg and 10.888 MJ/kg, respectively). The HHVs of raw samples studied were 10.019 MJ/kg, 11.898 MJ/kg and 4.811 MJ/kg for apple peels, peach pits and pea shells, respectively.

Figure 3.

HHV of torrefied samples of pea shells (a), peach pits (b) and apple peels (c).

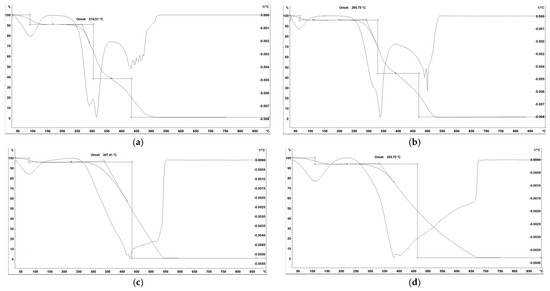

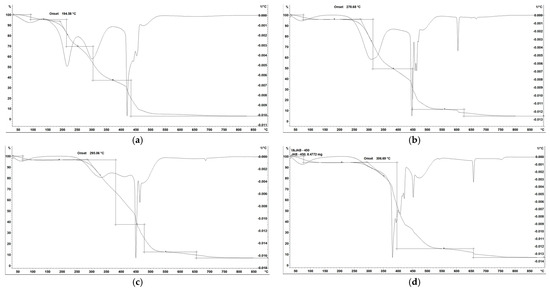

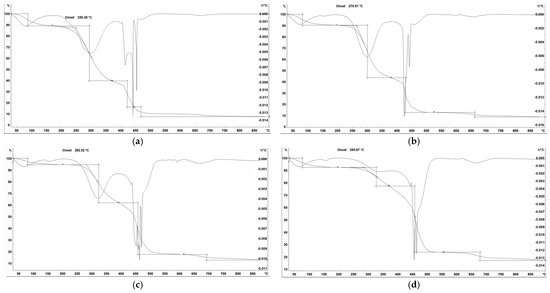

3.2. TGA/DTG Analysis

The results of the TG and DTG analyses are presented in Table 2 and shown in Figure 4, Figure 5 and Figure 6. The DTG curve for the untreated sample showed a higher peak compared to the treated samples, where a gradual decrease in peak height is observed. The thermal decomposition of the samples took place in four stages. The first weight loss step is a result of moisture evaporation in the first stage, which typically occurs up to 200 °C. The second stage, thermal decomposition, was carried out at temperatures between 200 °C and 400 °C and contributed to the large weight loss resulting from the degradation of hemicellulose and cellulose in the biomass and also from the degradation of proteins and carbohydrates. The third stage is the degradation of lipids (350–550 °C), while the last stage of char degradation took place between 400 °C and 900 °C and resulted in the remaining mass loss [36].

Figure 4.

TGA and DTG curves after torrefaction for peach pits at different torrefaction temperatures: (a) raw sample, (b) sample at 250 °C, (c) sample at 350 °C and (d) sample at 450 °C.

Figure 5.

TGA and DTG curves after torrefaction for apple peelings at different torrefaction temperatures: (a) raw sample, (b) sample at 250 °C, (c) sample at 350 °C and (d) sample at 450 °C.

Figure 6.

TGA and DTG curves after torrefaction for pea shells at different torrefaction temperatures: (a) raw sample, (b) sample at 250 °C, (c) sample at 350 °C and (d) sample at 450 °C.

After 800 °C, the mass remains mostly constant. As can be seen from Figure 4, Figure 5 and Figure 6 the mass of the sample decreases the most in the second phase and the DTG curve shows the fastest rate of thermal decomposition in the temperature range of 200–300 °C.

The lower decomposition temperature is reached by the raw samples. The shape of each curve is determined by or depends on conditions such as heating rate, shape and mass of the sample and gas type. From the curve, it is possible to determine the mass loss and the content of components in individual samples such as volatiles, moisture, ash, etc. While the TGA measures the mass change during heating, the DTG curve represents a set of peak areas representing different rates of mass loss of the substance during the process itself. During combustion of the samples, the volatile material burns first, followed by the charcoal. After heat treatment, peak temperature (Tp), initial temperature (Ti) and burnout temperature (Tb) increased for most samples, while mass losses decreased.

The weight loss was less pronounced in the torrefied samples due to the hydrophobicity of the biomass after torrefaction. From the diagrams in Figure 4, Figure 5 and Figure 6, it can be seen that the thermal degradation in the torrefied samples starts at higher temperatures, approximately above 330 °C. It can also be observed from the comparison between the TGA curves of the raw and torrefied samples that the thermal stability of the biomass samples tested is improved after torrefaction. This is demonstrated by the amount of mass remaining after 700 °C, which increased from 25% in the raw sample to 55% in the torrefied sample. The temperatures at which the maximum mass losses are determined are shown by the DTG curves. In the samples not subjected to torrefaction, the maximum thermal decomposition is reached at 300 °C, while in the torrefied samples the maximum mass losses were at higher temperatures, around 405 °C. At the moment when the temperatures exceed the 500 °C range, the DTG curves move into the low-reactivity range. At this stage, slow decomposition of carbon takes place; similar results have been reported by Galvis Sandoval et al. [37]. The ignition temperature is the lowest temperature at which the fuel starts to burn without external influence and is thus lower in raw materials than in torrefied samples. Ignition is prolonged and consequently starts at higher temperatures [16].

Higher Tb values are typical for more stable materials, such as high-molecular-weight polymers or materials with a high fixed carbon content. Peach pits and apple peels contain the most fixed carbon at a torrefaction temperature of 450 °C.

The fuel ratio (FR) values of the torrefied biomass are higher than those of the raw biomass samples due to the release of volatiles resulting from the cleavage of weak chemical bonds during the process itself [31].

The data obtained reveal that pea shell waste has promising properties for thermochemical conversion processes due to its low lignin content and high volatile content. Other authors have also reported a low moisture content of 7.06% and a high volatile matter content of 91.39%. However, it has a relatively low HHV, which makes it less promising [38].

In all three selected samples, the fixed carbon increases with increasing torrefaction temperature as a result of the removal of volatiles. This improves the properties of the biomass for further energy use, making it more similar to fossil fuels.

The data show that torrefied samples contain more carbon than raw samples. The carbon content increases at higher temperatures, as confirmed by a study [39]. In all cases, the heat treatment resulted in an increase in the carbon content.

The moisture content, VM, ash content and fixed carbon (FC) content of the selected samples were determined, and the results are given in Table 2. The highest moisture content (7.11% w/w) was found in apple peels, while the lowest moisture content (5.23% w/w) was found in peach pits. The pea shell sample also had the lowest FC content (0.20 wt.%) at a torrefaction temperature of 450 °C, which is in contrast to achieving a high fixed carbon content. The apple peel sample had the highest FC content and the lowest VM content at a torrefaction temperature of 450 °C. For the samples treated at 250 °C, the VM content increased, except for the apple peel sample. Treating samples at different temperatures has a significant effect on their properties. These results highlight the potential of valorising the processing of selected samples to improve their properties for different applications. A higher FC content is associated with a higher heating value of torrefied biomass, which makes the fuel less reactive [40]. This observation is confirmed by performed analyses in which torrefied samples show higher HHV.

The weight loss was generally greater for the peach pit sample, as it contained less ash than the other samples.

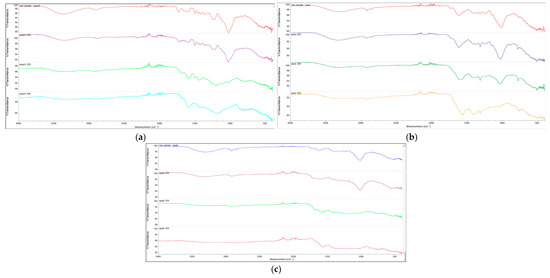

Figure 7 shows the spectra of samples treated at different torrefaction temperatures (250–450 °C) and a summary of the results is shown in Table 3.

Figure 7.

FTIR analyses for peach pits (a), pea shells (b) and apple peels (c).

Table 3.

Summary of FTIR results.

The FTIR method analyses individual infrared adsorption spectra associated with functional groups in the specific samples that we analysed. The images allow for direct comparison of spectra at different temperatures, highlighting the influence of torrefaction temperature on the chemical composition and functional groups in the biomass.

The bands belonging to the different chemical groups in the apple peel, peach pit and pea shell waste samples are presented in Table 3. As shown in Figure 7, most of the spectral bands are similar in all samples. For example, the O-H bond stretching, which could be related to moisture, alcohols and carboxylic acids (3340–3700 cm−1). In addition, the band at 2920–2930 cm−1 is related to the asymmetric stretching of C-H aliphatic groups and carbonyl groups, mainly esters and ketones [41].

The FTIR spectra at 250 °C are similar to those of the raw samples. Some changes occur when the temperature of the torrefaction is increased. The peak, which is broader in the range 3200–3600 cm−1, is due to vibrations of the hydroxyl groups (-OH) of cellulose. The ranges between 2800 cm−1 and 3000 cm−1 are due to C-H and OH groups in aromatic and aliphatic compounds. In the range 1000–1500 cm−1 and in some samples around 2900 cm−1, the intensity of some minor peaks decreases after the torrefaction process due to the release of volatiles from the biomass. Some peaks shift, others disappear or become more intense (C-C and C-O). The cellulose and hemicellulose content decreases with increasing torrefaction temperature, as can also be seen in the individual peaks [42].

The raw apple peel sample had a higher OH intensity peak at 2800–3000 cm−1, indicating that the raw apple sample had a higher water-bound content than the raw pea peel and peach pit samples.

The intensity of the characteristic adsorption bands decreased significantly as the torrefaction temperature increased [43,44]. The removal of hydroxyl and carboxyl groups in biomass generally increases the hydrophobicity of the biomass, which is a desirable property for the end use of a biomass fuel [45].

The peaks between 1200 and 1000 cm−1 that correspond to these began to decrease and, together with the OH groups, decreased further with increasing temperature. In contrast, the amount of ester groups (C=O), represented by the peak at 1740 cm−1, increased significantly at temperatures above 280 °C. This indicates that ester groups were formed during torrefaction and that oxygen compounds in the biomass were degraded at temperatures above 280 °C [46].

Other authors [47] have also performed very good studies of the chemical compounds of raw apple peels. The broad band in the range 3760–3204 cm−1 corresponds to the O−H bond. The adsorptions in the ranges 1600–1585 cm−1 and 1500–1400 cm−1 are stretching of the C=C bond in aromatic compounds. The peaks of the C−H bonds of aromatic rings (1300–1000 cm−1), the C-O bonds in phenols (1260–1000 cm−1) and the C−O bonds in −COOH (1320–1210 cm−1) are also found. It can be confirmed that the analysis of the functional groups in the apple peel agrees with the literature data.

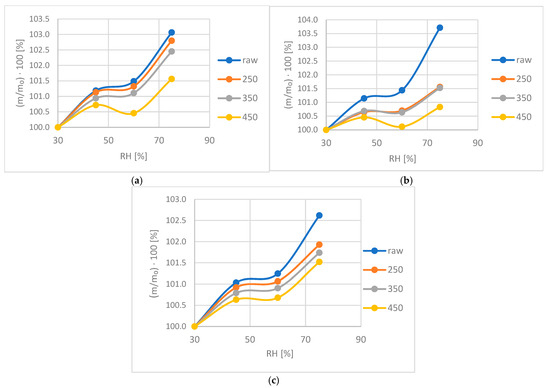

3.3. Hydrophobicity

The biomass samples are dried before the actual torrefaction process. This removes all water and moisture from the sample, creating a partially hydrophobic biomass that is used in the further torrefaction. During the torrefaction process, the hydroxyl groups are completely degraded, which leads to an improvement in the hydrophobicity of the biomass [48].

Sokhansanj et al. [49] observed a 25% reduction in water content of torrefied biomass compared to the untreated sample. A significant improvement in the hydrophobicity of the biomass material, on the level of a 50% reduction in hygroscopicity, was achieved in studies conducted by Chen et al. [49] and Chen et al. [50].

Higher process temperature causes dissolution and dehydration of the OH bonds, thus improving the hydrophobicity of the material and consequently leading to a decrease in the moisture uptake coefficient [2]. Higher temperatures cause the degradation of hemicellulose, which destroys the functional groups, making the biomass hydrophobic and thus increasing storage stability [51].

Figure 8 shows the percentage increase in mass as a function of relative humidity (RH) due to moisture adsorption. It can be seen that the percentage increase in mass is the highest for raw samples. The greatest difference in the percentage increase in mass was obtained for the apple peel sample (Figure 8b). The difference decreases with increasing torrefaction temperature. The results are in agreement with other studies [52] that the hydrophobicity of the biomass increases with the torrefaction temperature, making the final sample more resistant to moisture. The more torrefied the biomass becomes, the more resistant it is to adsorbing moisture [52]. When comparing raw materials (Figure 8), the moisture content of apple peels, peach pits and pea shells may differ due to the natural properties of these materials; apple peels contain a higher moisture content as they are derived from fresh fruit containing cellulose, hemicellulose and pectins, which are naturally hydrophilic (water attracting). Peach pits are moderately hydrophobic, mainly due to their compact structure which reduces their interaction with water, and after torrefaction they are the most hydrophobic due to their natural composition. Raw peach pits are therefore the only material with naturally good hydrophobicity, while other materials become hydrophobic only after torrefaction.

Figure 8.

Percentage increase in mass as a function of relative humidity for (a) pea shells, (b) apple peelings and (c) peach pits.

Pea shells usually have a moderate moisture content before torrefaction. After the treatment, their moisture content is low, as they become drier and more stable. Peach pits are already a naturally dry biomass with a much lower initial moisture content than pea shells. After torrefaction, their moisture content drops, which means minimal residual moisture. Apple peels are moister raw but lose most of their initial moisture during the torrefaction process. Comparing the results, peach pits have the lowest moisture content after torrefaction because they are already less moist before the process. Pea shells and apple peels have a slightly higher residual moisture content after torrefaction due to the higher initial moisture content and the different textures of the material.

Apple peels only reached higher hydrophobic properties at temperatures above 300 °C. In most cases, increasing the torrefaction temperature improved the resistance to moisture adsorption, which is probably related to the removal of hydroxyl groups and the structural changes that occur during the thermal process [2].

The obtained results show that the torrefaction process improved the hydrophobic properties of the biomass. Additionally, in all samples, increasing the torrefaction temperature improved the resistance to moisture adsorption, which is related to the structural changes occurring during the thermal process and probably to the removal of hydroxyl groups. As already mentioned, one of the main factors affecting the hydrophobic properties of biomass is the temperature of the torrefaction process [2].

From Figure 8 it can be seen that the raw apple peel sample has the highest moisture content. In other work, it has been shown that pectic polysaccharides from apple pomace can have hydrophobic properties, mainly due to covalently linked polyphenols [53].

Other authors such as Acharjee et al. [54] also confirmed that higher temperature of the torrefaction had a positive effect on hydrophobicity [55]. Pea pods contain a fair amount of moisture, which makes them more difficult to store. Pea shells can be dehydrated without significant deterioration in their quality for further use [56].

Studies have shown that peach pits, due to their higher lignin content, are more likely to retain their structure and strength even in conditions with higher moisture. This property makes peach pits a better choice in terms of hydrophobicity compared to other types of biomass such as apple peels or pea shells, which have a lower lignin content [57,58].

The improved hydrophobicity of peach pits allows them to be stable and reduces the risk of decomposition during storage and transportation. The high lignin content protects against moisture, which reduces oxidative processes that lead to a lower biomass quality.

4. Conclusions

In the present study, torrefaction was investigated as a promising alternative for pre-treatment to improve fuel properties. The aim of this study was to analyse the influence of the torrefaction temperature on the properties of food wastes such as pea shells, apple peels and peach pits.

Based on the investigations carried out, it can be concluded that the increase in temperature during the torrefaction process resulted in an increase in the hydrophobic properties of the materials studied, as it improves the resistance to moisture adsorption. In addition, the increased torrefaction temperature also improved other properties of the char, namely the HHV and consequently the associated scaling factor. Apple peels had the highest HHV of all the samples, with the highest HHV achieved at the highest operating temperature of torrefaction, which also has the highest fixed carbon content. Pea peels have a high ash content at higher torrefaction temperatures, which reduces the efficiency of the conversion of this biomass to biochar. Peach pits contain a high lignin content, which degrades more slowly during the torrefaction process than hemicellulose and cellulose, requiring longer processing times. In summary, the torrefaction process improved the fuel properties of all selected biomass samples. Based on the thermal treatment and chemical composition, apple peels are the most suitable biomass for torrefaction and biochar production. Peach pits are the least suitable for torrefaction, mainly due to the complex processing and low energy efficiency of the process, which means that they retain a lower proportion of their initial energy value in the form of a usable product than biochar. This method is still at the ecological experimental stage and is of growing interest in various sectors, precisely because of the characteristics of the resulting products. Future work may be based on the further use of thermal treatment products in various fields.

Author Contributions

Conceptualisation, investigation, writing—original draft: A.Š.; editing, investigation: S.G.; editing, investigation: K.R.; editing, supervision: D.U.; supervision: D.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

| ATR | Attenuated total reflection |

| DTG | Derivative thermogravimetric |

| ED | Energy density |

| EF | Enhancement factor |

| EY | Energy yield |

| FC | Fixed carbon |

| FR | Fuel ratio |

| FTIR | Fourier transform infrared spectroscopy |

| FW | Food waste |

| HHV | Higher heating value |

| MY | Mass yield |

| RH | Relative humidity |

| TGA | Thermogravimetric analysis |

| WL | Weight loss |

References

- Orisaleye, J.I.; Jekayinfa, S.O.; Pecenka, R.; Ogundare, A.A.; Akinseloyin, M.O.; Fadipe, O.L. Investigation of the Effects of Torrefaction Temperature and Residence Time on the Fuel Quality of Corncobs in a Fixed-Bed Reactor. Energies 2022, 15, 5284. [Google Scholar] [CrossRef]

- Dyjakon, A.; Noszczyk, T.; Smędzik, M. The Influence of Torrefaction Temperature on Hydrophobic Properties of Waste Biomass from Food Processing. Energies 2019, 12, 4609. [Google Scholar] [CrossRef]

- Sarker, A.; Ahmmed, R.; Ahsan, S.M.; Rana, J.; Ghosh, M.K.; Nandi, R. A Comprehensive Review of Food Waste Valorization for the Sustainable Management of Global Food Waste. Sustain. Food Technol. 2024, 2, 48–69. [Google Scholar] [CrossRef]

- Kende, Z.; Piroska, P.; Szemők, G.E.; Khaeim, H.; Sghaier, A.H.; Gyuricza, C.; Tarnawa, Á. Optimizing Water, Temperature, and Density Conditions for In Vitro Pea (Pisum sativum L.) Germination. Plants 2024, 13, 2776. [Google Scholar] [CrossRef]

- Economou, F.; Voukkali, I.; Papamichael, I.; Phinikettou, V.; Loizia, P.; Naddeo, V.; Sospiro, P.; Liscio, M.C.; Zoumides, C.; Țîrcă, D.M.; et al. Turning Food Loss and Food Waste into Watts: A Review of Food Waste as an Energy Source. Energies 2024, 17, 3191. [Google Scholar] [CrossRef]

- Ibitoye, S.E.; Mahamood, R.M.; Jen, T.-C.; Loha, C.; Akinlabi, E.T. An Overview of Biomass Solid Fuels: Biomass Sources, Processing Methods, and Morphological and Microstructural Properties. J. Bioresour. Bioprod. 2023, 8, 333–360. [Google Scholar] [CrossRef]

- Álvarez, A.; Nogueiro, D.; Pizarro, C.; Matos, M.; Bueno, J.L. Non-Oxidative Torrefaction of Biomass to Enhance Its Fuel Properties. Energy 2018, 158, 1–8. [Google Scholar] [CrossRef]

- Catchpole, O.; Tallon, S.; Dyer, P.; Montanes, F.; Moreno, T.; Vagi, E.; Eltringham, W.; Billakanti, J. Integrated Supercritical fluid extraction and Bioprocessing. Am. J. Biochem. Biotechnol. 2012, 8, 263–287. [Google Scholar] [CrossRef]

- Caton, P.A.; Carr, M.A.; Kim, S.S.; Beautyman, M.J. Energy Recovery from Waste Food by Combustion or Gasification with the Potential for Regenerative Dehydration: A Case Study. Energy Convers. Manag. 2010, 51, 1157–1169. [Google Scholar] [CrossRef]

- Wang, T.; Zhai, Y.; Zhu, Y.; Li, C.; Zeng, G. A Review of the Hydrothermal Carbonization of Biomass Waste for Hydrochar Formation: Process Conditions, Fundamentals, and Physicochemical Properties. Renew. Sustain. Energy Rev. 2018, 90, 223–247. [Google Scholar] [CrossRef]

- Murugesan, P.; Raja, V.; Dutta, S.; Moses, J.A.; Anandharamakrishnan, C. Food Waste Valorisation via Gasification—A Review on Emerging Concepts, Prospects and Challenges. Sci. Total Environ. 2022, 851, 157955. [Google Scholar] [CrossRef] [PubMed]

- Naveed, M.H.; Gul, J.; Khan, M.N.A.; Naqvi, S.R.; Štěpanec, L.; Ali, I. Torrefied Biomass Quality Prediction and Optimization Using Machine Learning Algorithms. Chem. Eng. J. Adv. 2024, 19, 100620. [Google Scholar] [CrossRef]

- Bergman, P.; Boersma, A.; Zwart, R.; Kiel, J. Torrefaction for Biomass Co-Firing in Existing Coal-Fired Power Stations; Energy Research Centre of the Netherlands ECN: Petten, The Netherlands, 2005. [Google Scholar]

- Ivanovski, M.; Goričanec, D.; Urbancl, D. The Evaluation of Torrefaction Efficiency for Lignocellulosic Materials Combined with Mixed Solid Wastes. Energies 2023, 16, 3694. [Google Scholar] [CrossRef]

- Ong, H.C.; Yu, K.L.; Chen, W.-H.; Pillejera, M.K.; Bi, X.; Tran, K.-Q.; Pétrissans, A.; Pétrissans, M. Variation of Lignocellulosic Biomass Structure from Torrefaction: A Critical Review. Renew. Sustain. Energy Rev. 2021, 152, 111698. [Google Scholar] [CrossRef]

- Farooq, M.U.; Sadiq, K.; Anis, M.; Hussain, G.; Usman, M.; Fouad, Y.; Mujtaba, M.A.; Fayaz, H.; Silitonga, A.S. Turning Trash into Treasure: Torrefaction of Mixed Waste for Improved Fuel Properties. A Case Study of Metropolitan City. Heliyon 2024, 10, e28980. [Google Scholar] [CrossRef]

- Râpă, M.; Darie-Niță, R.N.; Coman, G. Valorization of Fruit and Vegetable Waste into Sustainable and Value-Added Materials. Waste 2024, 2, 258–278. [Google Scholar] [CrossRef]

- Ribeiro, J.M.C.; Godina, R.; Matias, J.C.D.O.; Nunes, L.J.R. Future Perspectives of Biomass Torrefaction: Review of the Current State-Of-The-Art and Research Development. Sustainability 2018, 10, 2323. [Google Scholar] [CrossRef]

- Alcazar-Ruiz, A.; Dorado, F.; Sanchez-Silva, L. Influence of Temperature and Residence Time on Torrefaction Coupled to Fast Pyrolysis for Valorizing Agricultural Waste. Energies 2022, 15, 7914. [Google Scholar] [CrossRef]

- Głód, K.; Lasek, J.A.; Supernok, K.; Pawłowski, P.; Fryza, R.; Zuwała, J. Torrefaction as a Way to Increase the Waste Energy Potential. Energy 2023, 285, 128606. [Google Scholar] [CrossRef]

- UNI EN 14918:2019; Solid Recovered Fuels—Method for the Determination of Calorific Value. UNI: Milano, Italy, 2019.

- ASTM DIN 51900; Determining the Gross Calorific Value of Solid and Liquid Fuels Using the Bomb Calorimeter, and Calculation of Net Calorific Value—Part 1: General Information. DIN: Berlin, Germany, 2000.

- ISO 1928; Solid Mineral Fuels—Determination of Gross Calorific Value by the Bomb Calorimeter and Calculation of the Net Calorific Value. ISO: Geneva, Switzerland, 2009.

- Mamvura, T.A.; Pahla, G.; Muzenda, E. Torrefaction of Waste Biomass for Application in Energy Production in South Africa. S. Afr. J. Chem. Eng. 2018, 25, 1–12. [Google Scholar] [CrossRef]

- Patra, B.R. Slow Pyrolysis of Agro-Food Waste to Produce Biochar and Activated Carbon for Adsorption of Pollutants from Model Wastewater. Ph.D. Thesis, University of Saskatchewan, Saskatoon, SK, Canada, 2021. [Google Scholar] [CrossRef]

- Călin, C.; Sîrbu, E.-E.; Tănase, M.; Győrgy, R.; Popovici, D.R.; Banu, I. A Thermogravimetric Analysis of Biomass Conversion to Biochar: Experimental and Kinetic Modeling. Appl. Sci. 2024, 14, 9856. [Google Scholar] [CrossRef]

- Elkhalifa, S.; Mariyam, S.; Mackey, H.R.; Al-Ansari, T.; McKay, G.; Parthasarathy, P. Pyrolysis Valorization of Vegetable Wastes: Thermal, Kinetic, Thermodynamics, and Pyrogas Analyses. Energies 2022, 15, 6277. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Wright, C.T.; Boardman, R.D.; Kremer, T. Proximate and Ultimate Compositional Changes in Corn Stover during Torrrefaction Using Thermogravimetric Analyzer and Microwaves. In Proceedings of the 2012, Dallas, TX, USA, 29 July–1 August 2012; American Society of Agricultural and Biological Engineers: St. Joseph, MA, USA, 2012. [Google Scholar]

- Lin, B.-J.; Silveira, E.A.; Colin, B.; Chen, W.-H.; Pétrissans, A.; Rousset, P.; Pétrissans, M. Prediction of Higher Heating Values (HHVs) and Energy Yield during Torrefaction via Kinetics. Energy Procedia 2019, 158, 111–116. [Google Scholar] [CrossRef]

- Correia, R.; Gonçalves, M.; Nobre, C.; Mendes, B. Impact of Torrefaction and Low-Temperature Carbonization on the Properties of Biomass Wastes from Arundo Donax L. and Phoenix Canariensis. Bioresour. Technol. 2017, 223, 210–218. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Yang, H.; Yang, J.; Liu, F. Prediction of Fuel Properties of Torrefied Biomass Based on Back Propagation Neural Network Hybridized with Genetic Algorithm Optimization. Energies 2023, 16, 1483. [Google Scholar] [CrossRef]

- Oyebode, W.A.; Ogunsuyi, H.O. Impact of Torrefaction Process Temperature on the Energy Content and Chemical Composition of Stool Tree (Alstonia Congenisis Engl) Woody Biomass. Curr. Res. Green Sustain. Chem. 2021, 4, 100115. [Google Scholar] [CrossRef]

- Filip, M.; Vlassa, M.; Petean, I.; Țăranu, I.; Marin, D.; Perhaiță, I.; Prodan, D.; Borodi, G.; Dragomir, C. Structural Characterization and Bioactive Compound Evaluation of Fruit and Vegetable Waste for Potential Animal Feed Applications. Agriculture 2024, 14, 2038. [Google Scholar] [CrossRef]

- Dardick, C.D.; Callahan, A.M.; Chiozzotto, R.; Schaffer, R.J.; Piagnani, M.C.; Scorza, R. Stone Formation in Peach Fruit Exhibits Spatial Coordination of the Lignin and Flavonoid Pathways and Similarity to Arabidopsisdehiscence. BMC Biol. 2010, 8, 13. [Google Scholar] [CrossRef]

- Fatani, A.M.N.; Suh, J.H.; Auger, J.; Alabasi, K.M.; Wang, Y.; Segal, M.S.; Dahl, W.J. Pea Hull Fiber Supplementation Does Not Modulate Uremic Metabolites in Adults Receiving Hemodialysis: A Randomized, Double-Blind, Controlled Trial. Front. Nutr. 2023, 10, 1179295. [Google Scholar] [CrossRef]

- Chen, W.-H.; Ye, S.-C.; Sheen, H.-K. Hydrothermal Carbonization of Sugarcane Bagasse via Wet Torrefaction in Association with Microwave Heating. Bioresour. Technol. 2012, 118, 195–203. [Google Scholar] [CrossRef]

- Torres Ramos, R.; Valdez Salas, B.; Montero Alpírez, G.; Coronado Ortega, M.A.; Curiel Álvarez, M.A.; Tzintzun Camacho, O.; Beleño Cabarcas, M.T. Torrefaction under Different Reaction Atmospheres to Improve the Fuel Properties of Wheat Straw. Processes 2023, 11, 1971. [Google Scholar] [CrossRef]

- Galvis Sandoval, D.E.; Lozano Pérez, A.S.; Guerrero Fajardo, C.A. Pea Pod Valorization: Exploring the Influence of Biomass/Water Ratio, Particle Size, Stirring, and Catalysts on Chemical Platforms and Biochar Production. Sustainability 2024, 16, 7352. [Google Scholar] [CrossRef]

- Reza, M.T.; Freitas, A.; Yang, X.; Hiibel, S.; Lin, H.; Coronella, C. Hydrothermal Carbonization (HTC) of Cow Manure: Carbon and Nitrogen Distributions in HTC Products. Environ. Prog. Sustain. Energy 2016, 35, 1002–1011. [Google Scholar] [CrossRef]

- Gan, Y.Y.; Ong, H.C.; Ling, T.C.; Chen, W.-H.; Chong, C.T. Torrefaction of De-Oiled Jatropha Seed Kernel Biomass for Solid Fuel Production. Energy 2019, 170, 367–374. [Google Scholar] [CrossRef]

- Mekonnen, K.D. Fourier Transform Infrared Spectroscopy as a Tool for Identifying the Unique Characteristic Bands of Lipid in Oilseed Components: Confirmed via Ethiopian Indigenous Desert Date Fruit. Heliyon 2023, 9, e14699. [Google Scholar] [CrossRef]

- Ivanovski, M.; Goricanec, D.; Krope, J.; Urbancl, D. Torrefaction Pretreatment of Lignocellulosic Biomass for Sustainable Solid Biofuel Production. Energy 2022, 240, 122483. [Google Scholar] [CrossRef]

- Kaewtrakulchai, N.; Wisetsai, A.; Phongaksorn, M.; Thipydet, C.; Jongsomjit, B.; Laosiripojana, N.; Worasuwannarak, N.; Pimsamarn, J.; Jadsadajerm, S. Parametric Study on Mechanical-Press Torrefaction of Palm Oil Empty Fruit Bunch for Production of Biochar. Carbon Resour. Convers. 2024; 100285, in press. [Google Scholar] [CrossRef]

- Lu, X.; Xu, R.; Sun, K.; Jiang, J.; Sun, Y.; Zhang, Y. Study on the Effect of Torrefaction on Pyrolysis Kinetics and Thermal Behavior of Cornstalk Based On a Combined Approach of Chemical and Structural Analyses. ACS Omega 2022, 7, 13789–13800. [Google Scholar] [CrossRef]

- Soh, M.; Khaerudini, D.S.; Chew, J.J.; Sunarso, J. Wet Torrefaction of Empty Fruit Bunches (EFB) and Oil Palm Trunks (OPT): Effects of Process Parameters on Their Physicochemical and Structural Properties. S. Afr. J. Chem. Eng. 2021, 35, 126–136. [Google Scholar] [CrossRef]

- Pimsamarn, J.; Kaewtrakulchai, N.; Wisetsai, A.; Mualchontham, J.; Muidaeng, N.; Jiraphothikul, P.; Autthanit, C.; Eiad-Ua, A.; Laosiripojana, N.; Jadsadajerm, S. Torrefaction of Durian Peel in Air and N2 Atmospheres: Impact on Chemical Properties and Optimization of Energy Yield Using Multilevel Factorial Design. Results Eng. 2024, 23, 102767. [Google Scholar] [CrossRef]

- Mallampati, R.; Valiyaveettil, S. Apple Peels—A Versatile Biomass for Water Purification? ACS Appl. Mater. Interfaces 2013, 5, 4443–4449. [Google Scholar] [CrossRef]

- Ivanovski, M.; Petrovič, A.; Goričanec, D.; Urbancl, D.; Simonič, M. Exploring the Properties of the Torrefaction Process and Its Prospective in Treating Lignocellulosic Material. Energies 2023, 16, 6521. [Google Scholar] [CrossRef]

- Chen, D.; Zheng, Z.; Fu, K.; Zeng, Z.; Wang, J.; Lu, M. Torrefaction of Biomass Stalk and Its Effect on the Yield and Quality of Pyrolysis Products. Fuel 2015, 159, 27–32. [Google Scholar] [CrossRef]

- Chen, W.-H.; Lin, B.-J.; Colin, B.; Chang, J.-S.; Pétrissans, A.; Bi, X.; Pétrissans, M. Hygroscopic Transformation of Woody Biomass Torrefaction for Carbon Storage. Appl. Energy 2018, 231, 768–776. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Ghiasi, B.; Soelberg, N.R.; Sokhansanj, S. Biomass Torrefaction Process, Product Properties, Reactor Types, and Moving Bed Reactor Design Concepts. Front. Energy Res. 2021, 9, 728140. [Google Scholar] [CrossRef]

- Grycova, B.; Pryszcz, A.; Krzack, S.; Klinger, M.; Lestinsky, P. Torrefaction of Biomass Pellets Using the Thermogravimetric Analyser. Biomass Convers. Biorefinery 2021, 11, 2837–2842. [Google Scholar] [CrossRef]

- Fernandes, P.A.R.; Silva, A.M.S.; Evtuguin, D.V.; Nunes, F.M.; Wessel, D.F.; Cardoso, S.M.; Coimbra, M.A. The Hydrophobic Polysaccharides of Apple Pomace. Carbohydr. Polym. 2019, 223, 115132. [Google Scholar] [CrossRef]

- Dyjakon, A.; Noszczyk, T.; Sobol, Ł.; Misiakiewicz, D. Influence of Torrefaction Temperature and Climatic Chamber Operation Time on Hydrophobic Properties of Agri-Food Biomass Investigated Using the EMC Method. Energies 2021, 14, 5299. [Google Scholar] [CrossRef]

- Acharjee, T.C.; Coronella, C.J.; Vasquez, V.R. Effect of Thermal Pretreatment on Equilibrium Moisture Content of Lignocellulosic Biomass. Bioresour. Technol. 2011, 102, 4849–4854. [Google Scholar] [CrossRef]

- Beniwal, A.; Sangwan, V.; Punia, D.; Savita, V.S. Pea Shells (Pisum sativum L.) Powder: A Study on physiochemical, in vitro Digestibility and Phytochemicals Screening. Multilogic Sci. 2022, XII, 251–257. [Google Scholar]

- Shaikhiev, I.G.; Kraysman, N.V.; Sverguzova, S.V. Review of Peach (Prúnus Pérsica) Shell Use to Remove Pollutants from Aquatic Environments. Biointerface Res. Appl. Chem. 2024, 13, 49. [Google Scholar] [CrossRef]

- Fernández, V.; Khayet, M.; Montero-Prado, P.; Heredia-Guerrero, J.A.; Liakopoulos, G.; Karabourniotis, G.; Del Río, V.; Domínguez, E.; Tacchini, I.; Nerín, C.; et al. New Insights into the Properties of Pubescent Surfaces: Peach Fruit as a Model. Plant Physiol. 2011, 156, 2098–2108. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).