Heat Pump Performance Mapping for Energy Recovery from an Industrial Building

Abstract

1. Introduction

2. Methodology

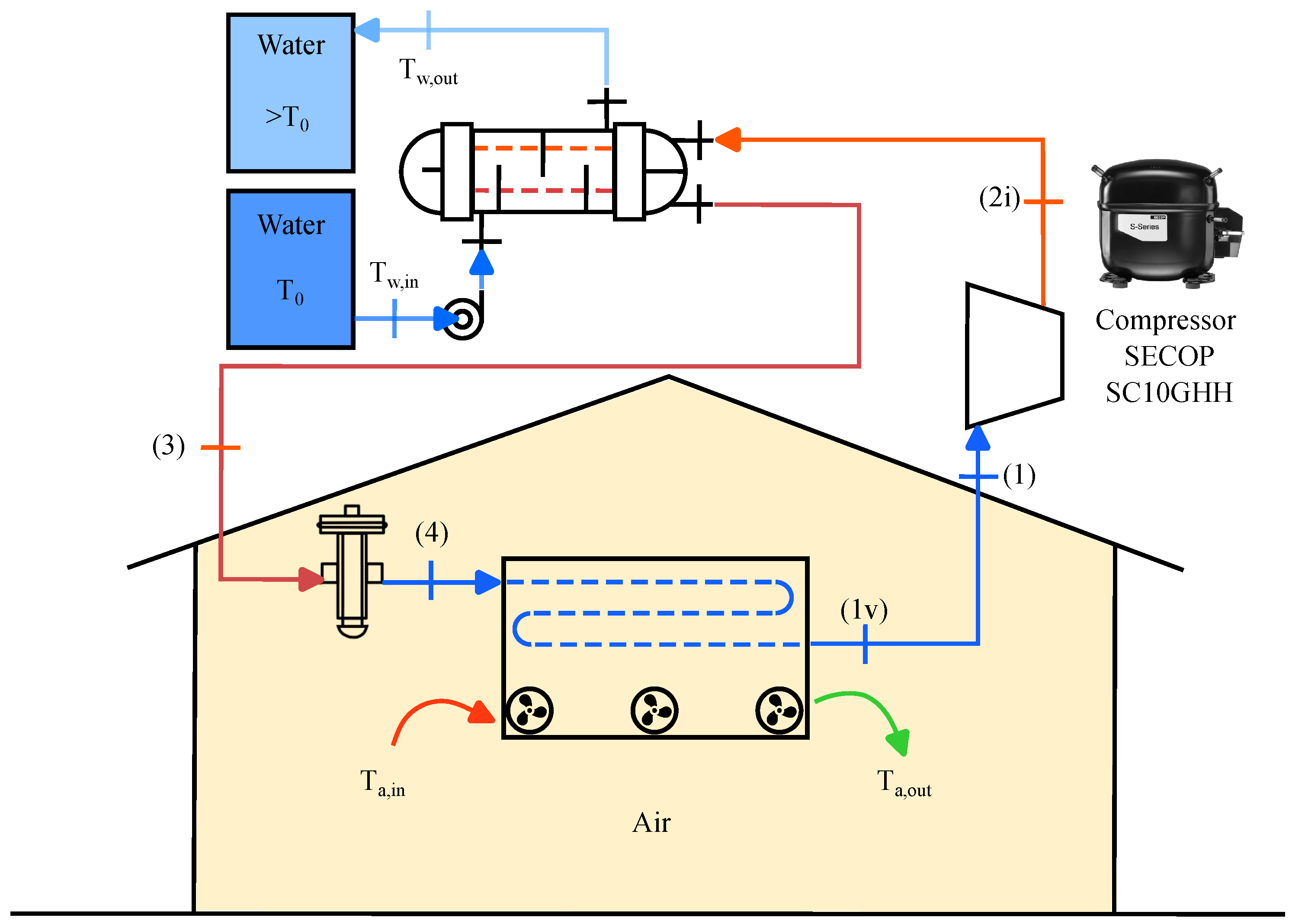

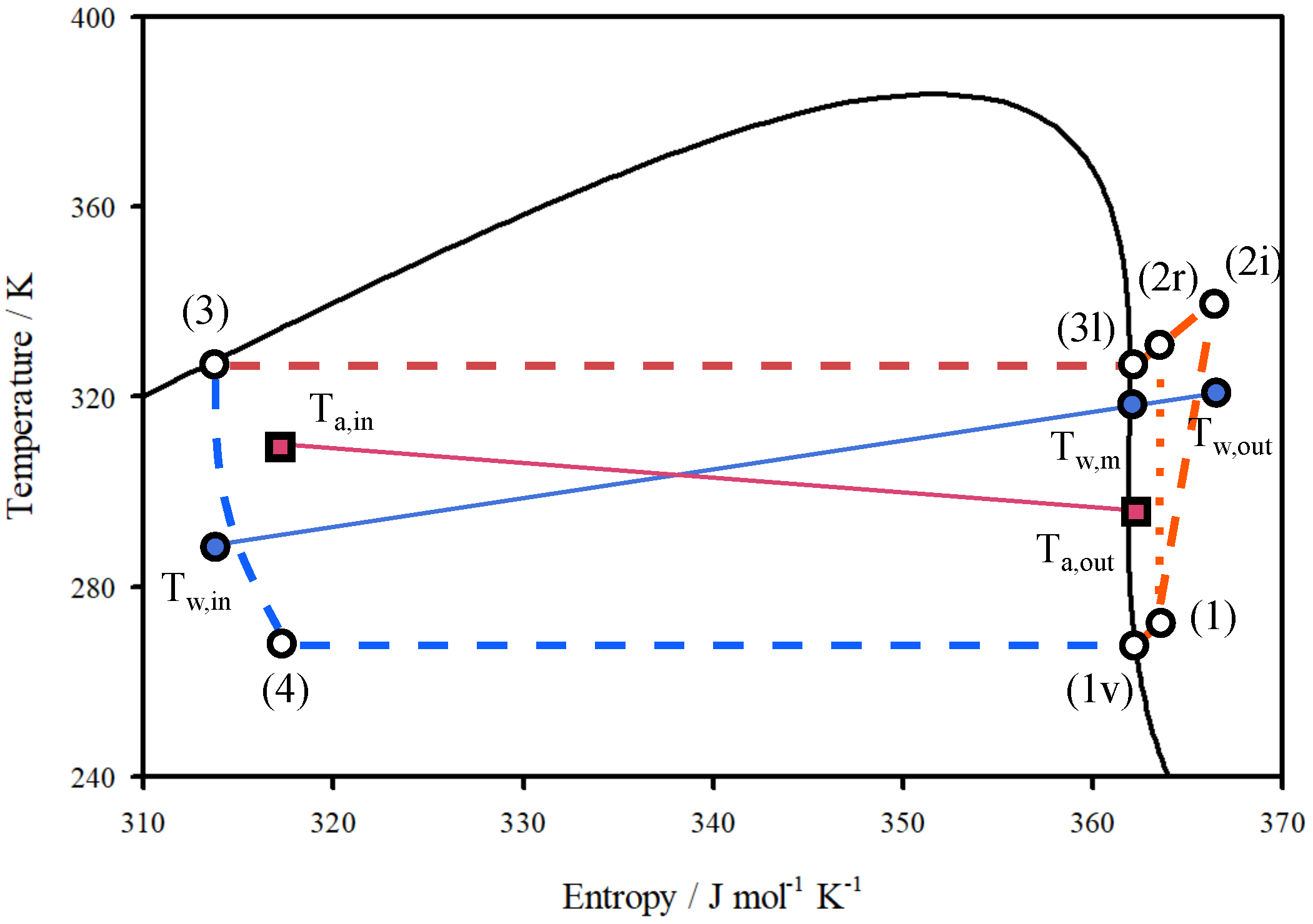

2.1. Description of the System

2.2. Case of Study

2.3. Modelling

3. Results

3.1. Validation

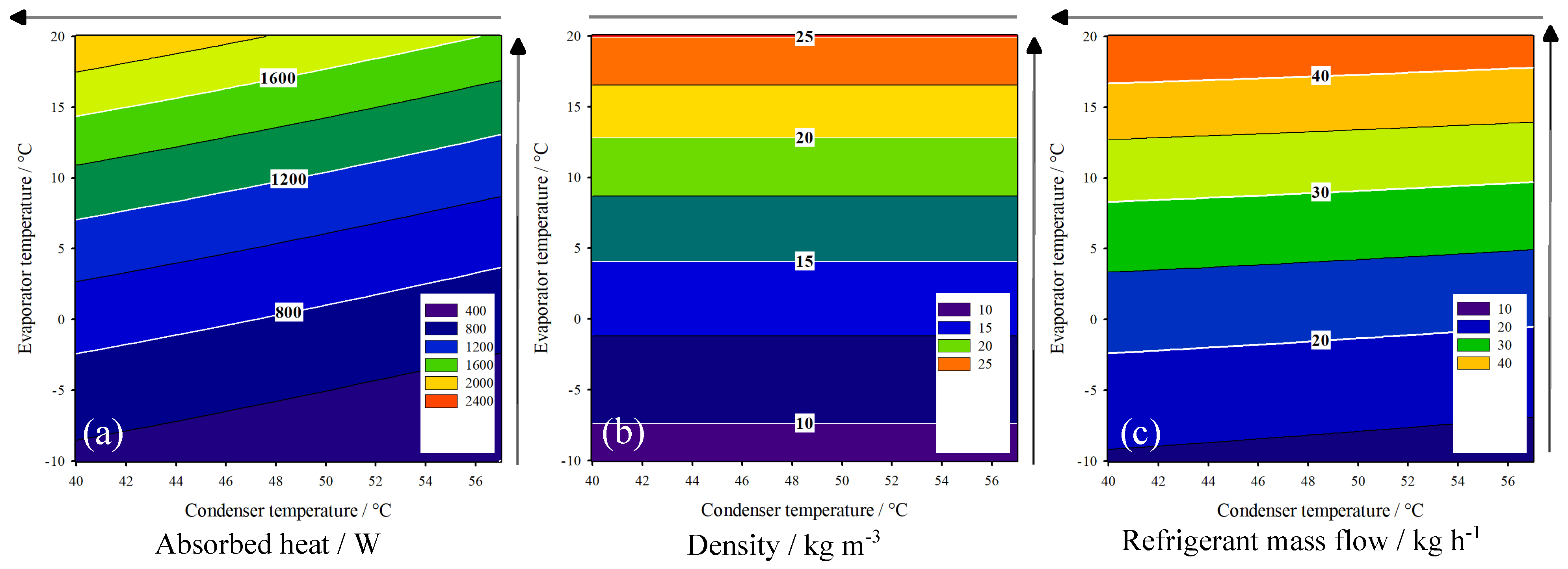

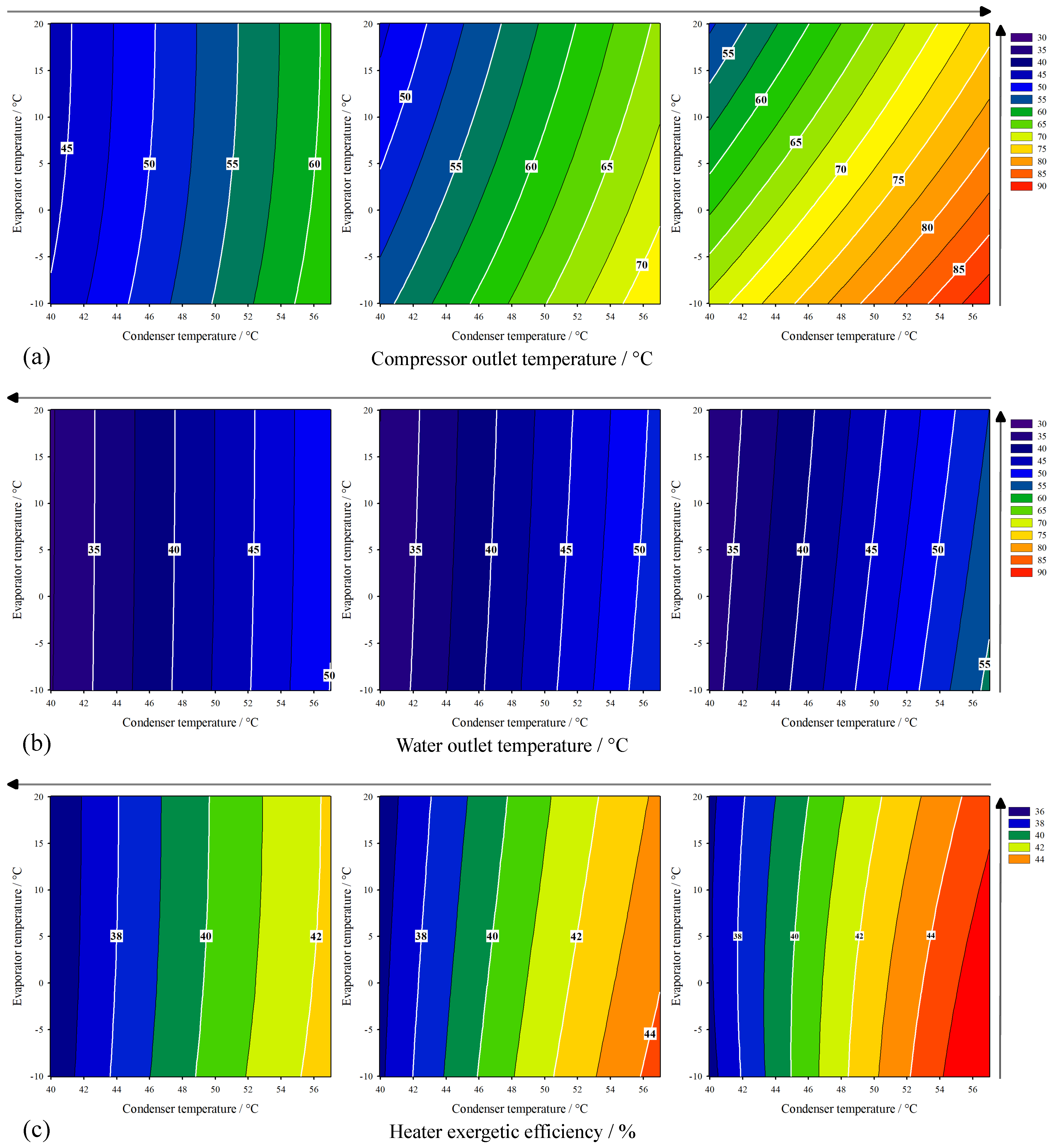

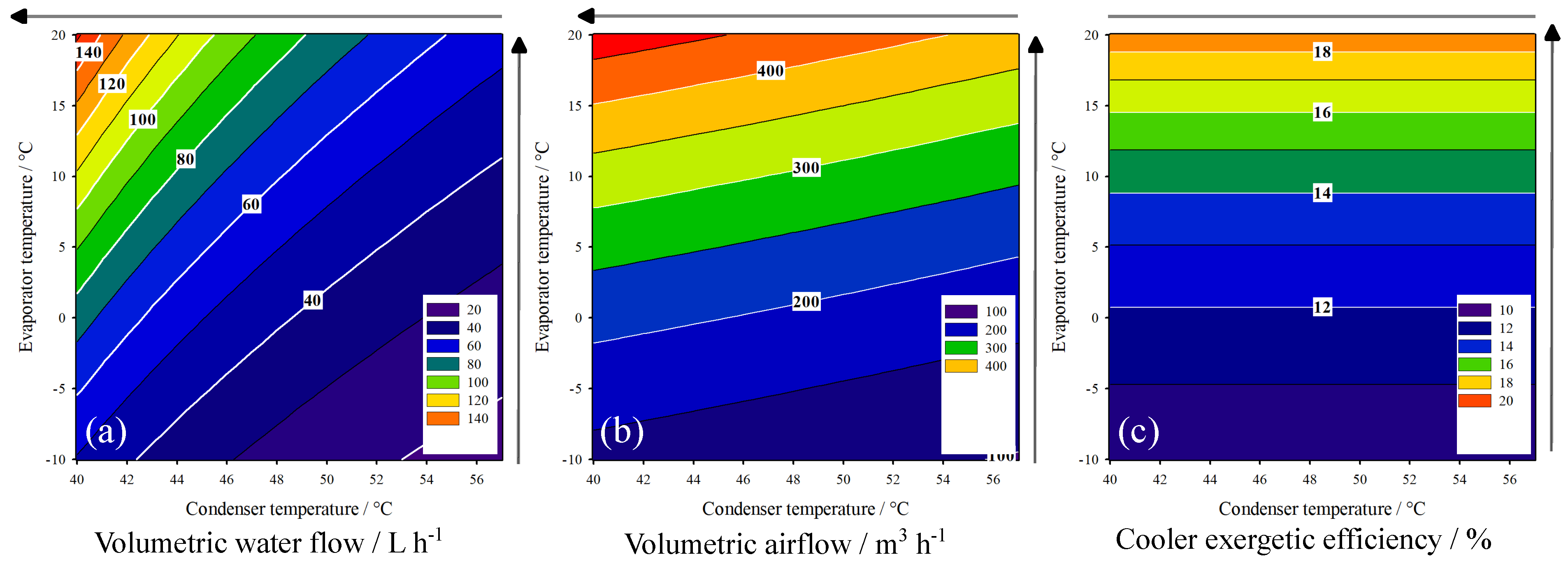

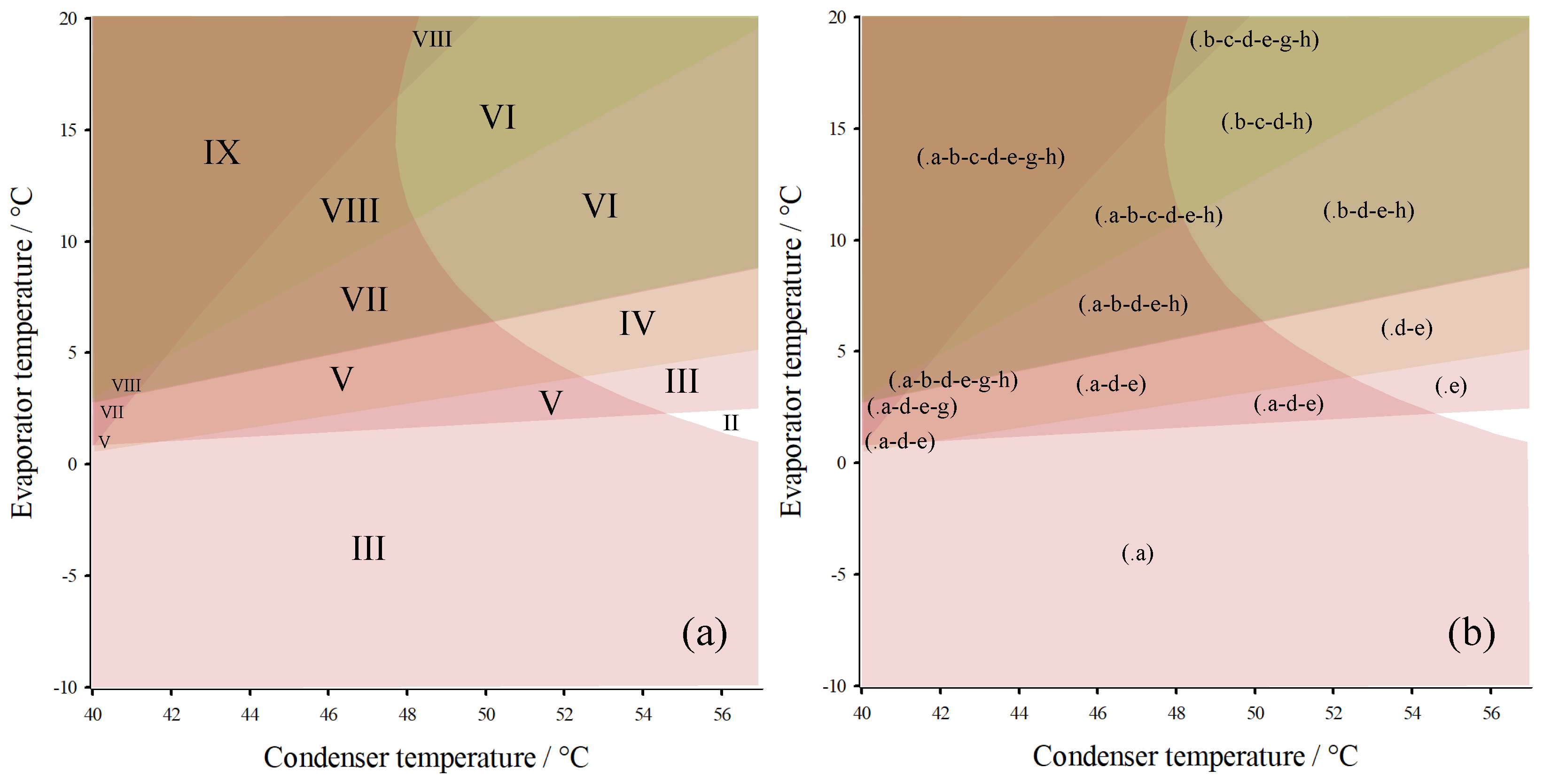

3.2. HP-System Behavior

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| COP | Coefficient of performance |

| EOS | Equation of state |

| HP | Heat pump |

| LTTE | Low-temperature thermal energy |

| PC-SAFT | Perturbed-Chain Statistical Associating Fluid Theory |

References

- Al-Mansour, F. Energy efficiency trends and policy in Slovenia. Energy 2011, 36, 1868–1877. [Google Scholar] [CrossRef]

- de la Rue du Can, S.; Letschert, V.; Agarwal, S.; Park, W.Y.; Kaggwa, U. Energy efficiency improves energy access affordability. Energy Sustain. Dev. 2022, 70, 560–568. [Google Scholar] [CrossRef]

- Chen, T.; Zhang, Y.; Jiang, C.; Li, H. How does energy efficiency affect employment? Evidence from Chinese cities. Energy 2023, 280, 128071. [Google Scholar] [CrossRef]

- González, J.; Llovell, F.; Garrido, J.M.; Quinteros-Lama, H. A rigorous approach for characterising the limiting optimal efficiency of working fluids in organic Rankine cycles. Energy 2022, 124191, 254. [Google Scholar] [CrossRef]

- Yekoladio, P.J.; Bello-Ochende, T.; Meyer, J.P. Thermodynamic analysis and performance optimization of organic rankine cycles for the conversion of low-to-moderate grade geothermal heat. Int. J. Energy Res. 2015, 39, 1256–1271. [Google Scholar] [CrossRef]

- Peyrovedin, H.; Haghbakhsh, R.; Duarte, A.R.C.; Shariati, A. Deep Eutectic Solvents as Phase Change Materials in Solar Thermal Power Plants: Energy and Exergy Analyses. Molecules 2022, 27, 1427. [Google Scholar] [CrossRef] [PubMed]

- Daniarta, S.; Nemś, M.; Kolasiński, P.; Pomorski, M. Sizing the Thermal Energy Storage Device Utilizing Phase Change Material (PCM) for Low-Temperature Organic Rankine Cycle Systems Employing Selected Hydrocarbons. Energies 2022, 15, 956. [Google Scholar] [CrossRef]

- Bellocchi, S.; Guizzi, G.L.; Manno, M.; Pentimalli, M.; Salvatori, M.; Zaccagnini, A. Adsorbent materials for low-grade waste heat recovery: Application to industrial pasta drying processes. Energy 2017, 140, 729–745. [Google Scholar] [CrossRef]

- Urbano, D.G.; Aquino, A.; Scrucca, F. Energy Performance, Environmental Impacts and Costs of a Drying System: Life Cycle Analysis of Conventional and Heat Recovery Scenarios. Energies 2023, 16, 1523. [Google Scholar] [CrossRef]

- Hervás-Blasco, E.; Navarro-Peris, E.; Barceló-Ruescas, F.; Corberán, J.M. Improved water to water heat pump design for low-temperature waste heat recovery based on subcooling control. Int. J. Refrig. 2019, 106, 374–383. [Google Scholar] [CrossRef]

- Ammar, Y.; Joyce, S.; Norman, R.; Wang, Y.; Roskilly, A.P. Low grade thermal energy sources and uses from the process industry in the UK. Appl. Energy 2012, 89, 3–20. [Google Scholar] [CrossRef]

- Zendehboudi, A. Optimal discharge pressure and performance characteristics of a transcritical CO2 heat pump system with a tri-partite gas cooler for combined space and water heating. Renew. Energy 2024, 226, 120359. [Google Scholar] [CrossRef]

- Zendehboudi, A. Experimental analysis of a tri-partite brazed plate gas cooler for CO2 heat pump water heaters. Appl. Therm. Eng. 2024, 241, 122376. [Google Scholar] [CrossRef]

- Zendehboudi, A. Energy, exergy, and exergoeconomic analyses of an air source transcritical CO2 heat pump for simultaneous domestic hot water and space heating. Energy 2024, 290, 130295. [Google Scholar] [CrossRef]

- Sun, D.; Wang, C.; Liu, Z.; Qin, J.; Liu, Z. Experimental and simulation study on R134a/RE170/R152a mixture as R134a replacement in a moderately-high temperature heat pump. Appl. Therm. Eng. 2024, 236, 121643. [Google Scholar] [CrossRef]

- Song, Y.; Li, D.; Yang, D.; Jin, L.; Cao, F.; Wang, X. Comparaison de performances entre une pompe à chaleur combinée au R134a/CO2 et une pompe à chaleur en cascade au R134a/CO2 pour chauffage de locaux. Int. J. Refrig. 2017, 74, 590–603. [Google Scholar] [CrossRef]

- Bianchi, M.; De Pascale, A. Bottoming cycles for electric energy generation: Parametric investigation of available and innovative solutions for the exploitation of low and medium temperature heat sources. Appl. Energy 2011, 88, 1500–1509. [Google Scholar] [CrossRef]

- Brogioli, D.; La Mantia, F. Heat recovery in energy production from low temperature heat sources. AIChE J. 2019, 65, 980–991. [Google Scholar] [CrossRef]

- Linton, J.W.; Snelson, W.K.; Hearty, P.F.; Triebe, A.R.; Linton, J.W.; Snelson, W.K.; Hearty, P.F. The Potential of HFC-134a and HFC-152a to Replace CFC-12 in Medium Temperature Heat Pump Applications. In Proceedings of the International Refrigeration and Air Conditioning Conference, West Lafayette, IN, USA, 14–17 July 1992; pp. 203–209. [Google Scholar]

- Carrington, C.G.; Bannister, P.; Liu, Q. Performance of a scroll compressor with R134a at medium temperature heat pump conditions. Int. J. Energy Res. 1996, 20, 733–743. [Google Scholar] [CrossRef]

- Lee, J.Y.; Chen, P.Y. Optimization of Heat Recovery Networks for Energy Savings in Industrial Processes. Processes 2023, 11, 321. [Google Scholar] [CrossRef]

- Pandey, G.K.; Sikha, S.S.; Thakur, A.; Yarlagadda, S.S.; Thatikonda, S.S.; Baiju suja, B.; Mystkowski, A.; Dragašius, E.; Gundabattini, E. Thermal Mapping and Heat Transfer Analysis of an Induction Motor of an Electric Vehicle Using Nanofluids as a Cooling Medium. Sustainability 2023, 15, 8124. [Google Scholar] [CrossRef]

- Borgeson, S.; Brager, G. Comfort standards and variations in exceedance for mixed-mode buildings. Build. Res. Inf. 2011, 39, 118–133. [Google Scholar] [CrossRef]

- Singh, S.; Hanna, E.G.; Kjellstrom, T. Working in Australia’s heat: Health promotion concerns for health and productivity. Health Promot. Int. 2015, 30, 239–250. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.; Zhang, Y.; Mi, H.; Zhou, Y.; Zhang, Y. Experimental research of a water-source heat pump water heater system. Energies 2018, 11, 1205. [Google Scholar] [CrossRef]

- Janghorban Esfahani, I.; Ifaei, P. Optimal Design of a Renewable-Energy-Driven Integrated Cooling–Freshwater Cogeneration System. Processes 2024, 12, 1164. [Google Scholar] [CrossRef]

- Masip, X.; Navarro-Peris, E.; Corberán, J.M. Influence of the thermal energy storage strategy on the performance of a booster heat pump for domestic hot water production system based on the use of low temperature heat source. Energies 2020, 13, 6576. [Google Scholar] [CrossRef]

- Dávila, P.; Bourouis, M.; Francisco Nicolalde, J.; Martínez-Gómez, J. Modelling and analysis of a compression/resorption heat pump system with a zeotropic mixture of acetone/CO2. Appl. Therm. Eng. 2023, 227, 120388. [Google Scholar] [CrossRef]

- Min, M.; Kim, Y.; Lee, S.; Ko, C. Performance evaluation of a water-to-water heat pump with a floor panel heating system. KSME Int. J. 1999, 13, 642–649. [Google Scholar] [CrossRef]

- Ritchie, M.J.; Engelbrecht, J.A.; Booysen, M.J. Which strategy saves the most energy for stratified water heaters? Energies 2021, 14, 4859. [Google Scholar] [CrossRef]

- Oh, S.; Cho, Y.; Yun, R. Raw-water source heat pump for a vertical water treatment building. Energy Build. 2014, 68, 321–328. [Google Scholar] [CrossRef]

- Pitarch, M.; Hervas-Blasco, E.; Navarro-Peris, E.; Corberán, J.M. Exergy analysis on a heat pump working between a heat sink and a heat source of finite heat capacity rate. Int. J. Refrig. 2019, 99, 337–350. [Google Scholar] [CrossRef]

- Stene, J. Residential CO2 heat pump system for combined space heating and hot water heating. Int. J. Refrig. 2005, 28, 1259–1265. [Google Scholar] [CrossRef]

- SECOP. Technical Data Model SC10GHH. 2023. Available online: https://www.secop.com/fileadmin/user_upload/SEPS/datasheets/en/sc1212g_104g8280_r134a_220v_50hz_03-2024_ds.pdf (accessed on 1 June 2024).

- Portal, E.E. Electrical Characteristic of the Motor. 2024. Available online: https://electrical-engineering-portal.com/electrical-characteristics-motor (accessed on 3 June 2024).

- Moshinsky, M. Chapter 3. In Manual de Refrigeración; Reverté: Barcelona, Spain, 2012. [Google Scholar]

- SECOP. SECOP LBP-MBP-HBP COMPRESSORS: Evaporation Pressures. 2023. Available online: https://www.secop.com/fileadmin/user_upload/products/product-selector/secop-lbp-mbp-hbp.pdf (accessed on 5 June 2024).

- Wagner, W.; Pruß, A. The IAPWS Formulation 1995 for the Thermodynamic Properties of Ordinary Water Substance for General and Scientific Use. J. Phys. Chem. Ref. Data 2002, 31, 387–535. [Google Scholar] [CrossRef]

- Keenan, J.; Chao, J.; Kaye, J. Gas Tables: Thermodynamic Properties of Air Products of Combustion and Component Gases, Compressible Flow Functions; Wiley: Hoboken, NJ, USA, 1980. [Google Scholar]

- Siddiqui, M.U.; Owes, A.; Al-Amri, F.G.; Saeed, F. Recent developments in the search for alternative low-global-warming-potential refrigerants: A review. Int. J.-Air-Cond. Refrig. 2020, 28, 2030004. [Google Scholar] [CrossRef]

- Shaik, S.V.; Babu, T.P. Theoretical Performance Investigation of Vapour Compression Refrigeration System Using HFC and HC Refrigerant Mixtures as Alternatives to Replace R22. Energy Procedia 2017, 109, 235–242. [Google Scholar] [CrossRef]

- Gross, J.; Sadowski, G. Perturbed-Chain SAFT: An equation of state based on a perturbation theory for chain molecules. Ind. Eng. Chem. Res. 2001, 40, 1244–1260. [Google Scholar] [CrossRef]

- Gross, J.; Sadowski, G. Application of the Perturbed-Chain SAFT equation of state to associating systems. Ind. Eng. Chem. Res. 2002, 41, 5510–5515. [Google Scholar] [CrossRef]

- Chapman, W.G.; Gubbins, K.E.; Jackson, G.; Radosz, M. SAFT: Equation-of-state solution model for associating fluids. Fluid Ph. Equilibria 1989, 52, 31–38. [Google Scholar] [CrossRef]

- Chapman, W.G.; Gubbins, K.E.; Jackson, G.; Radosz, M. New reference equation of state for associating liquids. Ind. Eng. Chem. Res. 1990, 29, 1709–1721. [Google Scholar] [CrossRef]

- González, J.; Llovell, F.; Garrido, J.M.; Quinteros-Lama, H. Accurate and Model-Free Control Function for a Single Stage Transcritical Refrigerator Cycle. ACS Omega 2020, 5, 19217–19226. [Google Scholar] [CrossRef]

- Parvaneh, K.; Rasoolzadeh, A.; Shariati, A. Modeling the phase behavior of refrigerants with ionic liquids using the QC-PC-SAFT equation of state. J. Mol. Liq. 2019, 274, 497–504. [Google Scholar] [CrossRef]

- Cea-Klapp, E.; Polishuk, I.; Canales, R.I.; Quinteros-Lama, H.; Garrido, J.M. Estimation of Thermodynamic Properties and Phase Equilibria in Systems of Deep Eutectic Solvents by PC-SAFT EoS. Ind. Eng. Chem. Res. 2020, 59, 22292–22300. [Google Scholar] [CrossRef]

- González, J.; Llovell, F.; Garrido, J.M.; Quinteros-Lama, H. Selection of a suitable working fluid for a combined organic Rankine cycle coupled with compression refrigeration using molecular approaches. Fluid Ph. Equilibria 2023, 572, 113847. [Google Scholar] [CrossRef]

- Standards and Technology National Institute. Search for Species Data by Chemical Name. Available online: https://webbook.nist.gov/chemistry/name-ser/ (accessed on 2 June 2024).

- Yang, L.; Zhao, L.X.; Zhang, C.L.; Gu, B. Loss-efficiency model of single and variable-speed compressors using neural networks. Int. J. Refrig. 2009, 32, 1423–1432. [Google Scholar] [CrossRef]

- Willem, H.; Lin, Y.; Lekov, A. Review of energy efficiency and system performance of residential heat pump water heaters. Energy Build. 2017, 143, 191–201. [Google Scholar] [CrossRef]

| Value | Range | |

|---|---|---|

| HP system compressor technical conditions | ||

| Displaced volume | 10.29 | – |

| Revolutions per minute | 2900.00 rpm | 2900.00 to 3500.00 rpm |

| Pressure operation maximum | 1600.00 kPa | – |

| Temperature operation maximum | 330.15 K | – |

| Isentropic performance | – | 60 to 100% |

| General boundary and limit conditions | ||

| Condenser temperature | – | 313.15 to 330.15 K |

| Evaporator temperature | – | 263.15 to 293.15 K |

| Initial water temperature | 293.15 K | – |

| Initial industrial building temperature | 313.15 K | – |

| Comfort industrial building temperature | 297.15 K | – |

| i | |||

|---|---|---|---|

| 1 | J | J | J |

| 5.8341 | 9.6110 | 6.6642 | |

| 2 | J | J | J |

| 0.4713 | 4.9931 | −2.9897 |

| R134a | m | |||

|---|---|---|---|---|

| Residual | K | |||

| 3.2483 | 3.0157 | 170.60 | ||

| Ideal gas | ||||

| 7.4912 | 0.01707 | −6.0249 | −115,348.62 |

| AARE of the Equilibrium Properties/% | ||||

|---|---|---|---|---|

| Pressure | Liquid Density | Vapor Density | Enthalpy Difference | Entropy Difference |

| 0.0800 | 0.3299 | 3.3205 | 3.5697 | 3.5706 |

| AARE of the Equilibrium Properties/% | ||||

|---|---|---|---|---|

| Pressure | Liquid Density | Vapor Density | Enthalpy Difference | Entropy Difference |

| 0.1057 | 0.5328 | 4.0941 | 4.6929 | 4.6935 |

| AARE of the Key Parameters/% | ||

|---|---|---|

| Heat Delivery | Coefficient of Performance | Compression Relation |

| 3.8219 | 3.7433 | 1.3864 |

| of the Key Parameters/% | ||||||

|---|---|---|---|---|---|---|

| Temperature Increase | Compressor Power/ | Heat Delivery/ | Coefficient of Performance/COP | |||

| = 80% | = 60% | = 80% | = 60% | = 80% | = 60% | |

| Condenser | 25.000 | 66.670 (o) | 5.960 | 15.892 (+) | 15.232 | 30.465 (−) |

| Evaporator | 25.000 | 66.670 (o) | 3.332 | 8.884 (−) | 17.335 | 34.670 (+) |

| of the Key Parameters/% | ||||||

|---|---|---|---|---|---|---|

| Temperature Increase | Compressor Outlet Temperature/ | Water Outlet Temperature/ | Heater Exergetic Efficiency/ | |||

| = 80% | = 60% | = 80% | = 60% | = 80% | = 60% | |

| Condenser | 17.780 | 47.340 (−) | 3.053 | 8.142 (+) | 3.106 | 5.264 (+) |

| Evaporator | 13.078 | 34.775 (−) | 1.269 | 3.383 (−) | 1.339 | 1.879 (−) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

González, L.; Romero, J.; Saavedra, N.; Garrido, J.M.; Quinteros-Lama, H.; González, J. Heat Pump Performance Mapping for Energy Recovery from an Industrial Building. Processes 2024, 12, 1955. https://doi.org/10.3390/pr12091955

González L, Romero J, Saavedra N, Garrido JM, Quinteros-Lama H, González J. Heat Pump Performance Mapping for Energy Recovery from an Industrial Building. Processes. 2024; 12(9):1955. https://doi.org/10.3390/pr12091955

Chicago/Turabian StyleGonzález, Leonardo, Jerson Romero, Nicolás Saavedra, José Matías Garrido, Héctor Quinteros-Lama, and Johan González. 2024. "Heat Pump Performance Mapping for Energy Recovery from an Industrial Building" Processes 12, no. 9: 1955. https://doi.org/10.3390/pr12091955

APA StyleGonzález, L., Romero, J., Saavedra, N., Garrido, J. M., Quinteros-Lama, H., & González, J. (2024). Heat Pump Performance Mapping for Energy Recovery from an Industrial Building. Processes, 12(9), 1955. https://doi.org/10.3390/pr12091955