Abstract

Metal cans, while boasting excellent barrier properties, raise concerns about leaching and environmental impacts. This study explored plastic trays, a potential alternative for canned food packaging. First we delved into the plastic tray’s characteristics, including its composition and permeability to oxygen and water vapor. Secondly, we conducted a comparison between the newly introduced plastic packaging and traditional metal cans, focusing on their interactions with food during the sterilization process and their effects on the quality of Tunisian pea sauce. The composition analysis revealed that the plastic tray was composed of polypropylene (PP) (with a single endothermic peak at 168 °C), while the film was found to have a mixture of PP internally and polyethylene terephthalate (PET) externally (with two endothermic peaks at 161.96 °C and 243.81 °C). Plastic trays showed good results in water vapor permeability (0.832 g/m2.d) but exhibited higher oxygen permeability (190 g/m2.d), raising oxidation concerns. Migration testing confirmed plastic packaging safety (<10 mg/dm2), while some simulants exceeded limits in metal cans. pH levels remained consistent between both packaging types, but varied significantly over a 28-day storage. Total Volatile Basic Nitrogen (TVBN) levels differed significantly between plastic and metal packaging, with notable variations observed over time with maximums of 0.3 mg/100 g for plastic trays and 0.17 mg/100 g for metal cans. Sensory evaluation revealed that tasters were adept at differentiating between canned pea sauce in plastic trays and metal cans (83%, 10/12), with taste and color exhibiting significant differences (p < 0.05). This underlines the impact of packaging material on canned food quality and consumer preference, with minimal influence on other sensory aspects. This data empowers manufacturers to make informed packaging decisions for a diverse range of canned foods.

1. Introduction

Packaging and food are two essential and inseparable elements in the food industry. Each food item has specific characteristics such as its composition, sensitivity to external influences (oxygen, humidity, light, and microorganisms), and shelf life [1]. To ensure the stability and preservation of the quality of food products throughout their storage, it is crucial to pair them with suitable packaging [2]. The preservation of a packaged food product largely depends on maintaining its original quality by shielding it from external factors that could lead to deterioration. The barrier properties of the packaging material, which include the selective permeability to gases and water vapor, as well as protection against external contaminants, play a crucial role in this preservation [3]. This requirement applies to all food products but is particularly significant for processed foods, where packaging plays an active role and is an integral part in the manufacturing technology, especially during the processing process [4]. This process subjects the packaging to high pressures and temperatures, making it vulnerable to deformation and the compromise of its seal. Therefore, in addition to its protective function, the packaging must be durable in order to maintain the product’s integrity and prevent the risk of leaks or contamination [5]. On the other hand, the interaction between food and packaging is of paramount importance. Some foods may chemically react with certain types of packaging, which can alter their quality or even pose risks to consumer health [1]. Therefore, the judicious choice of the appropriate packaging for each type of food is essential to ensure better preservation, and guarantee the quality and safety of food products [6].

In the intricate domain of food packaging, the choice between plastic and metal materials holds immense significance for the quality and safety of canned foods. While plastic offers versatility, lightweight constructions, and potential cost savings, concerns persist regarding gas permeation and environmental impacts [1]. Conversely, metal packaging, renowned for durability and freshness preservation, grapples with challenges related to weight and sustainability [7]. Balancing these considerations requires a nuanced understanding of the trade-offs between plastic and metal packaging, guiding decisions that prioritize product quality, consumer safety, and environmental stewardship [8].

This study delves into the relationship between plastic trays and conventional metal packaging for canned foods, conducting a comprehensive evaluation of their composition, barrier properties, food interaction, sterilization validation, and stability testing. Its aim is to provide valuable insights into the suitability of plastic tray packaging within the food industry. Additionally, this work aims to study the effect of the two types of packaging on the quality of a Tunisian traditional dish (pea sauce).

2. Materials and Methods

2.1. Packaging Plastic Tray Properties

2.1.1. Composition of Plastic Packaging for Canned Food

In this study, Fourier Transform Infrared Spectroscopy (FTIR) with attenuated total reflection (ATR) was employed to identify the nature of the materials [9]. Spectra were recorded using the AVATER OMNISEMPLER 360, IR-TF spectrometer equipped with an ATR accessory (Omnilab, Bremen, Germany). The obtained infrared spectra were then analyzed using specialized software called Nicolet Omnic version 9.2.

The material structure was studied by Differential Scanning Calorimetry (DSC) during thermal treatment, measuring glass transition, melting, and crystallization temperatures [10]. Samples (5–10 mg for film, tray) were analyzed using a Perkin Elmer Pyris 6 DSC machine (Artisan Technology Group, Champaign, IL, USA), covering a wide melting temperature range. Tray samples were heated from −30 °C to 250 °C, film samples from −30 °C to 300 °C, both at 10 °C/min [10].

2.1.2. Characterization of the Plastic Packaging Tray for Canned Food

The thickness of the plastic tray and transparent film is measured according to ISO4593 [11] using a digital micrometer of 0–25 mm–0.001 mm (Digimatic IP65 0–25 mm Mitutoyo® micrometer, Kawasaki, Japan). It measures the thickness of the samples at regularly spaced points along the length of the samples. Water vapor permeability was assessed using a Labthink C390 permeability instrument (Jinan, China) in accordance with the related standard ISO-15106 [12]. Film samples, cut into 10 cm2 circular areas, were analyzed to determine the water vapor transmission rate (WVTR) by interpreting electrical signals.

Oxygen permeability was measured using a Labthink OX2/231 instrument (Jinan, China) following ASTM1927 [13]. Film samples were placed between the test cell’s two cavities under controlled conditions of 0% relative humidity and 23 °C for oxygen and nitrogen temperatures. Oxygen molecules diffusing through the film were transported by nitrogen, generating a low-intensity current proportional to the quantity of oxygen passing through the film.

2.1.3. Global and Specific Migration

Global and specific migration was studied on both, plastic trays and metal cans. Overall migration in evaporable simulants was assessed following (EU)No.10 [14], EN-1186-3 [15] standards, using simulants A (10% Ethanol), B (3% Acetic Acid), C (20% Ethanol), D1 (50% Ethanol), D2 (Vegetable Oil), and E (Poly(2,6-diphenyl-p-phenylene oxide)) at 40 °C for 10 days. In the current case, the chosen simulants for our prepared dish are A, B, and D2, with a substitution of simulant D2 with isooctane at 20 °C for 2 days and 95% ethanol at 40 °C for 10 days.

Overall migration was determined using the cell method for the plastic cover film and the fill migration method for the plastic trays and metal cans [15]. The specific migration of heavy metals was analyzed via Inductively Coupled Plasma Atomic Emission Spectrometry (ICP/AES) using a 3% acetic acid simulant at 60 °C for 10 days as per (EU)No.10 [14]. The Thermo Scientific iCAP 6000-series instrument (Waltham, MA, USA) was employed for analysis.

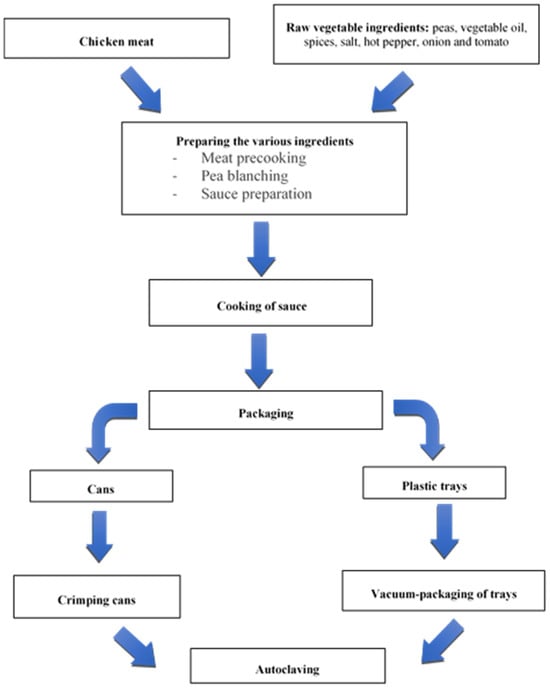

2.2. Pea Sauce Preparation and Canning Process

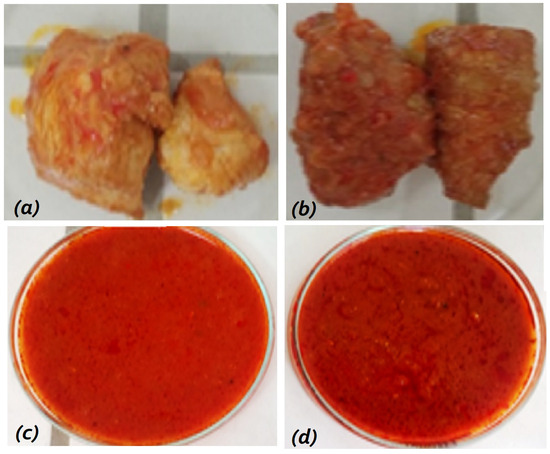

This study is interested in canned pea sauce (a traditional Tunisian dish) which typically consists of a blend of cooked peas, onions, garlic, and olive oil, seasoned with a combination of herbs and spices such as parsley, cumin, and paprika. The manufacturer optimized and validated this dish’s recipe in previous studies (under publication processing). The sauce, peas, and pre-cooked meat were packaged in plastic trays, sealed using a Multivac T 200 tray sealer (Oakaville, ON, Canada), or in metal cans crimped using a Automatic Can Seamer ROBOT 80 JK Somme (Borgos, Spain), and sterilized in a “Surdry” horizontal static autoclave (Bizkaia, Spain), (Figure 1 and Figure 2). The capacity of the 2 types of packaging was 400 g and the filling rate was 87.5% for the cans and it varied from 50% to 100% for the plastic trays.

Figure 1.

Plastic trays (a,b) and metal cans (c,d) used for canned pea sauce.

Figure 2.

Diagram of the canned pea sauce in metal cans and plastic trays adopted in this study.

2.3. Sterilization Scale Validation

The validation of the sterilization scale is based on the criteria of food sterility, assessed by the sterilization value (SV). Thus, the SV is determined using the Bigelow method cited in Equation (1), according to NUMUANG [16]:

where

FT* = ∫10 ((T − T*)/Z).dt,

- -

- FT represents the SV when T* is 121.1 °C;

- -

- Z is relative to Clostridium botulinum [17];

- -

- The effectiveness of the heat treatment is evaluated through the comparison calculated as the area under the Lv curve [18], according to Equation (2):Lv = 10((T − 121)/Z),

This value must exceed 2.52 min to ensure the safety of low-acid products against Clostridium botulinum.

2.4. Optimizing the Packaging Parameters of the Plastic Trays

In order to minimize package deformation, it is crucial that the autoclave pressure and vacuum levels be adjusted to find the ideal balance that ensures effective sterilization while preventing package damage. For this, three tests were conducted across various fill levels to account for product variability as shown in Table 1. By analyzing pressure data and conducting visual inspections, optimized sterilization parameters tailored to each fill level were identified.

Table 1.

Experimental conditions of pressure and vacuum measurements at different filling ratios.

2.5. Quality of the Canned Pea Sauce

2.5.1. Stability Test

Five samples from both plastic and metallic packaging underwent a 7-day stability test post-sterilization at 37 °C, 55 °C, and 25 °C (control), as indicated in the standard NFV08-408 [19]. Stability was determined by the absence of packaging deformations, leaks, or significant changes in odor, color, or texture. pH differences between the ambient, 37 °C, and 55 °C incubated samples must be less than 0.5 pH units.

2.5.2. Physicochemical Analysis

For each type of packaging, twenty-four samples of canned pea sauce were stored in a cool, dry, and dark place at ambient temperature with humidity below 60%. These underwent a 28-day monitoring period post-production, with physicochemical parameters (pH, TVBA, color) assessed at regular intervals (at the 1st, 7th, 14th, 21st, and 28th days). Every test was run through at least three times. pH was measured using an electronic pH meter (HANNA instruments, Romania) following NFV08-409 [20], with calibrations using pH 4 and 7 buffer solutions. TVBN was determined using (EC) No 2074/2005. Color assessment utilized a chromameter CR-410 (Konica MINOLTA, Tokoyo, Japan) in Hunter L, a, b units, and total color difference (TCD) per ISO-7887 [21]. L (lightness), a (red index), and b (yellow index) values were measured, where L* ranges from 0 to 100, and a* and b* range from −60 to +60. TCD, calculated using Equation (3), averaged values from five sampling dates of L*, a*, and b* to quantify color change post-canning, and storage, as described by Hajji [22] in Equation (3):

TCD = √ (L − L0)2 + (a − a0)2 + (b − b0)2

2.5.3. Sensory Analysis

Sensory analysis evaluates the impact of packaging on canned pea’s sensory characteristics using human senses. Following ISO4120 [23], a triangular test with 12 trained panelists was conducted. Panelists identified the different sample among the three presented (two identical, one different). Data analysis employed a one-tailed binomial test to determine the number of tasters identifying the different sample relative to the total tasters.

2.6. Statistical Analysis

Mean values ± standard deviation (SD) were reported and analyzed using a single-factor ANOVA test with (SPSS Statistics 26) and Minitab software (Minitab 20). This analysis examined the effect of packaging on product characteristics and the interaction between packaging and contents, with significance set at p-value ≤ 0.05.

3. Results and Discussion

3.1. Packaging Plastic Tray Composition

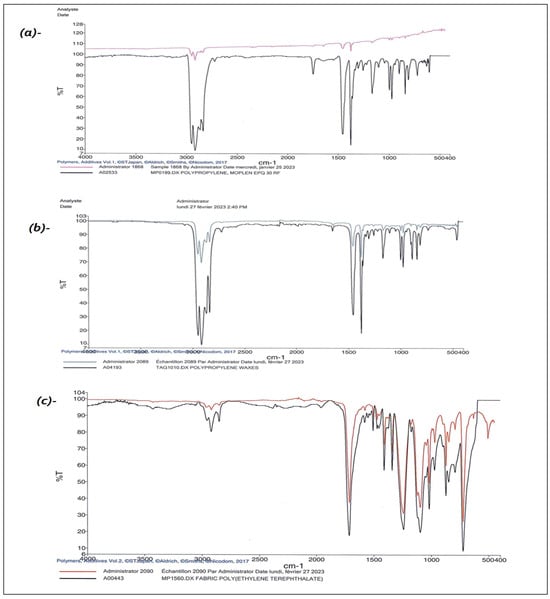

Results revealed distinct FTIR spectra, as shown in Figure 3, for a plastic tray and a film, covering both their internal and external surfaces.

Figure 3.

FTIR spectra of the used trays (a), the internal face of the film (b), and the external face of the film (c).

Thus, spectral analysis identified characteristic peaks in the tray and internal film at 1378 cm−1 and 2948 cm−1, respectively. These values strongly resemble the reference spectrum of polypropylene (PP), particularly corresponding to the CH3 (methyl group) and CH2 (methylene group) functional groups prevalent in its structure. In contrast, the external film exhibited a unique spectral signature with prominent peaks at 1715 cm−1 and 1405 cm−1. These values are highly indicative of polyethylene terephthalate (PET), as they correspond to the characteristic carbonyl group (C=O) and aromatic ring stretching vibrations within its chemical structure. Consequently, the plastic tray was solely composed of PP, while the film demonstrated a heterogeneous composition of PP internally and PET externally. This underscores FTIR spectroscopy’s capability in accurately characterizing polymer compositions.

The analysis focused on identifying distinctive peaks corresponding to various polymers. Spectra of the plastic tray and the external face of the film exhibited characteristic peaks aligning with PP [24]. Furthermore, specific absorption bands corresponding to carbon–hydrogen (C-H), carbon–oxygen (C=O), and carbon–carbon (C-C) stretching bonds confirmed the presence of PP [25]. Additionally, distinctive signals at 793 cm−1 and 841 cm−1 served as unique identifiers for PET and PP, respectively, as this was described by [26].

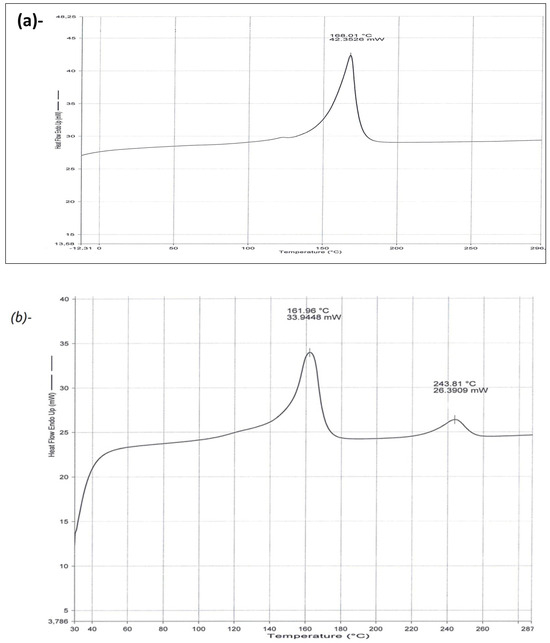

The Differential Scanning Calorimetry (DSC) analysis in this study enabled the identification of plastics in the tray and film by revealing characteristic melting points. Results showed a single endothermic peak at 168 °C in the plastic tray’s thermogram, indicating the presence of the polypropylene (PP) polymer. In contrast, the plastic film exhibited two endothermic peaks: the first at 161.96 °C, corresponding to PP, and the second at 243.81 °C, corresponding to the PET polymer (Figure 4). These findings aligned with the FTIR results, confirming that the plastic tray comprised solely PP, whereas the film comprised PP internally and PET externally. These melting temperature findings of both the plastic tray (168 °C ) and the internal face of the cover film (161.96 °C) were consistent with previous research reporting melting temperatures for neat PP at various ranges, extending from 160 °C to 172.2 °C [3,27]. The semi-crystalline nature of PP and its melting point, usually around 165 °C, were highlighted, despite its limitations in high-temperature settings. However, PP’s prevalence in food packaging persists due to its accessibility and suitability [28].

Figure 4.

Thermogram (DSC) of the used plastic tray (a) and plastic film (b).

Conversely, the finding of the melting temperature of the external face of the cover film, measuring at 243.81 °C, aligned with PET polymer characteristics. Consequently, PET is widely used in trays and bottles for packaging food and drinks due to its ease of manufacture, thermal stability, transparency, and excellent barrier properties [29]. Nevertheless, although PET trays offer a clear and attractive way to display canned foods, their lower CO2 barrier properties showed that they are not ideal for long-term storage. CO2 can slowly seep through the tray, potentially affecting the taste and quality of the food inside [1].

Despite a lower melting point (248–250 °C) compared to polyether ether ketone (PEEK) (334 °C), PET exhibits excellent thermal stability, surpassing common plastics like PP (170 °C), low-density polyethylene (LDPE) (134 °C), polystyrene PS (106 °C), and polyvinyl chloride PVC (199 °C). This thermal resilience, coupled with its inherent rigidity and resistance to hydrolysis and solvents, makes PET a highly suitable material for packaging applications [30].

This study employed two complementary analytical techniques, Fourier Transform Infrared Spectroscopy (FTIR) and Differential Scanning Calorimetry (DSC), to comprehensively characterize the plastic components used in the canned food packaging.

The identification of the multi-layered structure of the plastic film, with PP on the inside and PET on the outside, highlights the deliberate material selection process employed in food packaging design [31]. PP offers advantages like its affordability and suitability for forming the tray and the film’s inner layer. PET, on the other hand, contributes excellent thermal stability and transparency to the outer film layer, potentially enhancing the visual appeal of the packaged food. However, it is crucial to acknowledge potential limitations associated with PET, such as its lower CO2 barrier properties, which could impact the long-term quality of certain food products [1].

As a result of micrometer analysis, the tray thickness was measured at 900 µm, while the plastic cover film exhibited a thickness of 63.5 µm. Assessing thickness is crucial, especially concerning oxygen and water vapor permeability. Semi-flexible packaging typically ranges from 75 to 150 µm in thickness, whereas cover films can be as thin as 0.04 mm [32]. Moreover, and due to the influence of manufacturing factors like temperature and pressure on tray characteristics, optimizing thickness is essential to prevent deformation, contamination, and to manage chemical migration during food storage [33].

3.2. Oxygen and Water Vapor Permeability

The results of the oxygen and water vapor permeability measurements revealed a significant disparity in the plastic cover film’s permeability. Its water vapor permeability (WVP) was low, at 0.832 g/m2 d, which indicates excellent moisture barrier properties. However, the oxygen permeability (OP) was considerably higher at 190 g/m2d.

Due to its composition of PP and PET, identified through spectral analysis, the plastic film in this study exhibits a unique combination of properties. PP likely contributes to the film’s observed low water vapor permeability, while PET might influence its oxygen permeability [3]. Moreover, with a water vapor permeability (WVP) of 0.832 g/m2/day, the studied film surpasses oriented PET (0.381–0.508 g/m2/day) and PP (0.127–0.254 g/m2/day) [34] and remains below the maximum acceptable limit (4.7 g/m2/day) [35], suggesting good potential for food packaging moisture control.

Moreover, in comparison to our studied cover film, PET films present superior barrier properties with an oxygen transmission rate (OTR) of 20.0 cm3/m2·d·bar and a water vapor transmission rate (WVTR) of 4.0 g/m2·d. Conversely, PP films show a higher OTR of 800.0 cm3/m2·d·bar but a lower WVTR of 0.6 g/m2·d [36]. These disparities underscore the varying barrier capabilities of each material, emphasizing the importance of selecting appropriate materials tailored to specific packaging requirements for effective product preservation and shelf-life extension.

Furthermore, combining PP and PET in a film creates a promising barrier against water vapor, potentially surpassing single-polymer options. This aligns with research on multi-layer films, where combining polymers allows for the fine-tuning of both water and oxygen protection [37]. Additionally, incorporating compatibilizers during blending could further enhance water resistance [34]. However, the notably high OP observed in the cover film (190 g/m2 d) poses a risk for food oxidation, compromising food preservation against oxidative processes [38]. Consequently, as a solution to enhance the findings of the research, incorporating high-barrier materials like EVOH (Ethylene Vinyl Alcohol) stands out. EVOH has proven to be effective in bolstering gas barrier properties in packaging materials, with transmission rates ranging from 0.1 to 1.4 g/m2·d. By reformulating the composition of the plastic cover film to include EVOH, we can directly address its weaker oxygen barrier properties. This strategic adjustment offers a practical and clear pathway to improving the film’s overall barrier performance, ensuring the better preservation of products and extending their shelf life [39].

3.3. Global and Specific Migration

The overall migration of the cover film, the tray forming the plastic package, and the metal cans was assessed using regulated simulants. The results, presented in Table 2, revealed a significant difference (p < 0.05) in overall migration rates between the plastic and metal packaging for the four food simulants used.

Table 2.

Estimated level of overall migration according to packaging type.

The results of the total migration of components in the plastic packaging material practically complied with the regulatory limit of 10 mg/dm2 according to European legislation [40]. However, the overall migration of metal packaging exceeded this limit, particularly for 95% ethanol, reaching a value of 22 mg/dm2. Furthermore, based on EN-1186-3 [15], the overall migration of food packaging materials should not exceed 10 mg/dm2 or 60 mg/kg [41].

These findings were consistent with Trăistaru [42], who found that overall migration with low-density polyethylene LDPE into simulants A, B, and C (Table 1) at 70 °C and 40 ± 0.5 °C for 2 h and 10 days varied from 4.06 to 5.80, 4.10 to 5.90, and 4.20 to 5.90 mg/dm2, respectively. Moreover, Dumitru [43] studied the overall migration of various types of plastics and concluded that PVC had the highest migration values, while other materials, primarily composed of polypropylene, polyethylene, and polyethylene terephthalate, showed migration levels below 0.31 mg/dm2 in different simulants (water, 15% ethanol, 3% acetic acid).

Overall migration was found to depend on the nature of the packaging, inks, coatings, polymer characteristics, food nature, storage conditions, package thickness, production process, temperature, and contact duration between the food and packaging materials [1,41]. Furthermore, Kang [44] highlighted the influence of polar solvents on migration rates, with polypropylene (PP) showing higher migration concentrations in ethanol due to its hydrophobic nature. The lack of reinforcement of packaging materials and insufficient varnish thickness in metal cans could contribute to high overall migration values [45].

Our study investigated the specific migration of nine metals (Aluminum, Barium, Cobalt, Copper, Iron, Lithium, Manganese, Nickel, and Zinc) from a tray, plastic film, and metal cans. It also assessed their limits of quantification (LQ) and specific migration limits (LMS) [40]. Results shown in Table 3 indicated that all measured concentrations were below the limit of quantification (LQ) for every metal in the examined packaging components. This implies that the levels of heavy metals detected were too low to be reliably measured by the analytical method employed, suggesting no detectable migration from the tray and plastic film under the experimental conditions.

Table 3.

Specific migrations of heavy metals through the tray and plastic film.

These findings are consistent with prior research demonstrating very low or undetectable concentrations of heavy metals in plastic packaging [46]. Schmid and Welle [40] support this, noting that the specific migration never reached detection limits in their experimental setup, conducted for less than 10 days at 40 °C.

Furthermore, Khan and Khan [47] reported that specific migration limits (LMSs) for metals typically remain below 1 ppm, except for Cadmium, which should not exceed 0.1 ppm. Their study observed migration rates ranging from 1.001 ppm to 1.9 ppm for certain metals, influenced by various testing conditions such as the type of simulant and the temperature.

Conversely, Eti [48] documented elevated migration rates of Cadmium (Cd), Chromium (Cr), and Nickel (Ni) in recycled PET food packaging, surpassing permitted limits. This highlights potential health risks associated with heavy metal migration into food [1,47].

3.4. Sterilization Scale Validation

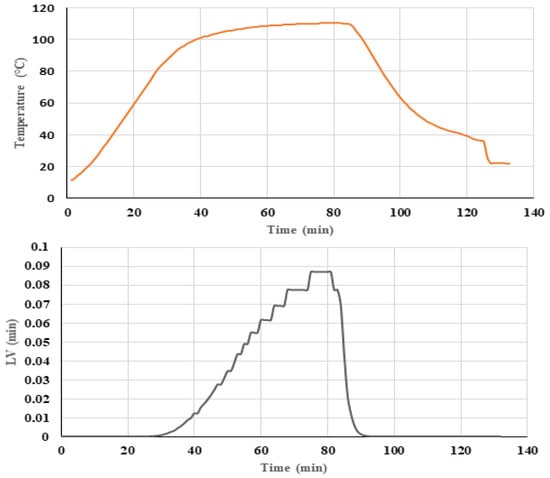

3.4.1. Determination of VS

The sterilizing value was determined using trays and metal cans, with a filling ratio of 87.5%, and sterilized in an autoclave at a pressure of 1.7 bars. The evolution of the biological destruction value (Lv) as a function of time for scales B1 and B2 is, respectively, illustrated in Figure 5.

Figure 5.

Evolution of the biological destruction value Lv = f(t) for scale B1 (110 °C, 60 min) (a) and scale B2 (115 °C, 45 min) (b).

Based on the Bigelow method, the SV obtained is 2.3 min for scale B1, which is less than the minimum sterilizing value of 2.52 min required to destroy the reference germ (Clostridium botulinum). Consequently, this scale is not sufficient to ensure the sterilization of trays. In contrast, concerning scale B2, the sterilizing value obtained is 4 min, which is higher than the minimum sterilizing value, but very close to the limit. Thus, an F0 value greater than 3 min is sought in industrial thermal processes, which corresponds to a minimum reduction of 12 logarithmic units (log) in C. botulinum spores relative to a D121 °C value [49].

Indeed, the canned pea sauce was treated at 115 °C which is sufficient to destroy the spores of the reference pathogenic bacteria, C. botulinum, and to guarantee its biological stability at ambient temperature [18,50]. In order to guarantee food safety, it is necessary to increase the sterilizing value. Consequently, the scale of (118 °C, 45 min) has been chosen for the sterilizing process in this study.

3.4.2. Optimizing the Sterilization Pressure and Vacuum Level to Prevent Package Deformation for Plastic Trays

In order to optimize packaging integrity across industry-standard filling levels (200–400 g), multiple sterilization trials were tested (1, 2, and 3) at 118 °C for 45 min. These trials varied pressure (1.7–1.9 bar) and vacuum (500–1000 mbar) levels as presented in Table 1.

As shown in Figure 6, Trial 1 found that trays filled with 400 g had no deformation, while significant deformation occurred with lower fill levels (200 g and 300 g). This revealed a direct correlation between the fill level and deformation rate. The chosen parameters were suitable for trays up to 400 g, with a vacuum level of 500 mbar enhancing dish stability.

Figure 6.

Aspects of the intact (a,b) and deformed (c,d) packaging of the used plastic trays.

In Trial 1, trays filled with 300 g and 200 g experienced can deformation, likely due to the lower pressure inside them compared to the autoclave. To address this, Trial 2 increased the vacuum level within the trays, aiming to reduce the pressure difference and effectively raise the internal pressure. This approach successfully eliminated crushing at 800 mbar for a 300 g fill and 1000 mbar for a 200 g fill (Figure 6). However, the higher vacuum also caused unwanted swelling and a film-like appearance, highlighting the need to find a balance between vacuum levels and other parameters for optimal packaging integrity.

In Trial 3, an improved tray appearance was observed compared to Trial 2, particularly for trays filled up to 300 g at an 800 mbar vacuum. A minimum acceptable filling rate without deformation was determined as 250 g, with optimal results achieved at vacuum levels of 900 and 1000 mbar. Therefore, a vacuum rate of 900 mbar was selected to ensure the conservation and stability of the dish.

In conclusion, the trials reaffirm the importance of optimizing pressure and vacuum levels to prevent package deformation during sterilization. They align with existing data and emphasize the need to consider both sterilization parameters and packaging material properties. An integrated approach combining trial results and the scientific literature can aid in developing effective preservation strategies for packaged products. The parameter values adopted for the three filling rates in the three trials are summarized in Table 4.

Table 4.

Filling ratio, vacuum, and pressure values retained for the three tests.

These results are consistent with the provided bibliographic data, which underscores the importance of minimizing void space in packaging to avoid deformation during the sterilization process [51]. For example, previous studies have demonstrated that the compression of the fiber structure within packaging can lead to the irreversible deformation of packages under pressure [52]. Additionally, it is noted that selecting the appropriate packaging material is essential to maintain the dimensional stability of the packages during high-pressure processing [53].

Furthermore, prior research has also highlighted the importance of balancing pressure and vacuum levels in packaging to ensure effective pressure transmission within the food product [53]. For instance, it is noted that packaging materials must be sufficiently flexible to allow for reversible deformation during high-pressure treatment [54].

3.5. Effect of Packaging and Storage on Pea Sauce Quality

3.5.1. Stability Test of Canned Pea Sauce within Two Packages

According to the results obtained after the 7-day incubation period, the packages showed no deformation, bulging, or leakage. Furthermore, the product had not undergone any organoleptic changes (texture, odor, taste), and the pH variation was very slight, not exceeding 0.5 units. This shows that the ready-cooked dish is stable and complies with the current standard in both types of packaging.

3.5.2. Effect on pH

The statistical analysis indicated no significant distinction in pH levels for both the sauce (p = 0.201) and meat (p = 0.191) between the plastic and metal food packaging (Table 5). However, significant pH variations were observed during storage for both meat and sauce in both types of packaging. Plastic-packaged items exhibited fluctuations (meat: p = 0.003, sauce: p = 0.002), as did metal-packaged items (sauce: p = 0.000, meat: p = 0.003).

Table 5.

Physiochemical parameters during 28 days of post-production according to packaging type.

However, the observed acidification during storage in canned pea sauce is not solely particular to metal packaging. Natural processes within the food itself, like non-bulging souring in carbohydrate-rich foods, can also contribute to acidity [55]. Additionally, interactions between the metal can and the food can cause further pH fluctuations [7]. These combined factors make understanding pH changes in canned foods more complex.

Enzymatic reactions, interactions with metal packaging, and the leaching of trace elements like aluminum, iron, and manganese can all contribute to these changes [56]. Additionally, both the food itself (intrinsic factors) and storage conditions (extrinsic factors) play a role in pH fluctuations through chemical reactions [57]. Chemical contaminants from packaging can further influence pH stability, highlighting the importance of managing these factors for food safety [58]. Despite these influences, some studies suggest overall pH stability in canned foods during storage. Nevertheless, monitoring pH remains crucial for determining shelf life and ensuring food quality [59].

3.5.3. Effect on Total Volatile Basic Nitrogen

Statistical analysis comparing the TVBN variation between different package types revealed a highly significant difference (p < 0.001), indicating a substantial impact of the packaging type on TVBN levels. Additionally, TVBN levels displayed significant variation over storage time (p = 0.000), suggesting changes in product freshness and stability during the storage period. The significant variation underscores the importance of the packaging material in influencing TVBN levels, which are crucial indicators of food spoilage and freshness.

The difference in TVBN levels between plastic and metal packaging can be explained by the presence of free space in plastic packaging, which allows direct contact between the meat and oxygen, thus promoting the activity of the enzymes responsible for protein degradation. Proteolytic enzymes act on proteins to release amino acids, which are then decarboxylated to give amines that are often volatile. On the other hand, metal packaging does not have this free space, which limits air diffusion and protein degradation [60].

Furthermore, TVBN levels during the packaging and storage of canned foods are influenced by oxygen exposure, storage temperature, and microbial activity. Effective packaging methods that minimize oxygen exposure and maintain low temperatures can reduce TVBN formation. In meat products, packaging and storage time significantly impact TVBN levels. Proper techniques like vacuum-sealing or modified atmosphere packaging reduce TVBN formation, while prolonged storage at higher temperatures can elevate TVBN levels [61]. Similarly, in canned foods, packaging and storage time affect TVBN levels. Proper packaging slows down TVBN accumulation, but prolonged storage at higher temperatures can increase TVBN levels [60]. TVBN serves as a reliable predictor of beef spoilage, showing associations with microbial count, pH, and color-related factors [62].

3.5.4. Effect on Color Measurement

The total color difference (TCD) serves as a valuable tool for assessing color stability in canned sauce during storage in this study (Table 6).

Table 6.

TCD measurement of pea sauce during storage within two packages during 28 days of storage.

Initially, the TCD values remained below 1.5 for the first 21 days, indicating that the color of the sauce in both plastic trays and metal cans remained relatively unchanged. However, the TCD measured after 28 days of storage displayed a significant increase, suggesting a noticeable difference in the color of the sauce. This shift in color could be attributed to increased oxidation within the plastic packaging compared to the metal cans (Figure 7). By monitoring TCD throughout the storage period, we can gain valuable insights into the color stability of canned sauce and ensure it maintains a visually appealing appearance for consumers.

Figure 7.

Aspects of meat appearance (a,b) and sauce color (c,d) after 28 days of storage in cans and plastic trays, respectively.

The color of canned sauce can change significantly during storage, influenced by factors like the packaging material, light exposure, and the sauce itself. Metal cans, limiting light and oxygen; generally preserve the sauce’s original color better than transparent plastic packaging, which promotes oxidation [63]. Substances leaching, such as bisphenol A, lead, cadmium, and nickel, from metal-based packaging can also contribute to color shifts [45]. Various factors contribute to color changes in packaged food products, including oxygen exposure, light, and moisture. Polymer packaging materials act as barriers against oxygen and water vapor, while modified atmosphere packaging reduces oxygen levels, mitigating oxidation [64]; they may not be ideal for all sauces. For example, certain plastics as polypropylene (PP) and polyethylene (PE) can interact with color components like lycopene in darker sauces, leading to undesired changes [65]. Further, thermal treatments may not completely prevent enzymatic browning, highlighting the importance of optimized processing and storage [66].

3.6. Effect of Packaging Type on Sensorial Parameters

In a taste test involving a trained panel of 12 tasters, 10 successfully distinguished between canned peas packaged in metal cans and those in plastic containers. The triangular test revealed significant differences between pea sauces in plastic trays and metal cans. The taste and color of the pea sauce in the metal containers were significantly preferred over those of the sauce in plastic containers (taste: p < 0.05, color: p < 0.001). However, other sensory attributes, including smell (p = 0.523), sauce viscosity (p = 0.086), meat texture (p = 0.047), and pea texture (p = 0.027), showed fewer tasters detecting noticeable differences.

This emphasizes the influential role of packaging on the gustatory, olfactory, and textural characteristics of ready-made meals. Consumer rejection of packaged food can stem from issues like off-flavors, off-odors, and texture loss, often due to oxygen and moisture ingress and reactions between packaging and food components. Thermal processing can mitigate such problems, preserving food quality [66]. Similarly, the choice of packaging materials significantly affects the proximate composition, heavy metal content, sensory attributes, and volatile compounds of foods [67]. While certain packaging types offer benefits such as improved taste and texture, others may pose slight concerns regarding heavy metal levels. Therefore, the careful selection of packaging materials is crucial for maintaining the sensory quality of canned sauce [67].

4. Conclusions

In conclusion, this study investigated the use of plastic packaging for canned food, specifically focusing on its composition, barrier properties, sterilization optimization, and the impact on food quality. The plastic tray was composed of polypropylene (PP), while the film utilized a combination of PP internally and polyethylene terephthalate (PET) externally. This combination provided a good water vapor barrier property with a permeability of only 0.832 g/m2 d, which is well below the maximum acceptable limit. However, the oxygen permeability of the film was significantly higher at 190 g/m2 d, indicating a potential area for improvement. Importantly, both plastic and metal packaging met regulatory limits for overall migration, and minimal metal migration was observed from either. The sterilization parameters were successfully optimized to 118 °C for 45 min with a 900 mbar vacuum level to prevent package deformation during the process. The 28-day storage revealed minimal changes in sensory properties, with slight variations in pH and Total Volatile Basic Nitrogen (TVBN) levels between the packaging types. Notably, metal cans exhibited better color preservation compared to plastic trays, with a total color difference (TCD) below 1.5 for the first 21 days of storage compared to a noticeable increase in plastic trays after 28 days. Overall, the findings underscore the crucial role of packaging materials and sterilization optimization in preserving the safety, stability, and sensory attributes of canned food products, with implications for industry practices and consumer satisfaction.

Author Contributions

Conceptualization, H.A., W.H., M.J., and I.E.; formal analysis, H.A., W.H., H.M., and I.B.K.; investigation, H.A.; methodology, H.A., H.M., I.B.K., M.J., and I.E.; project administration, M.J., and I.E.; resources, H.A.; software, R.S.; supervision, I.B.K., S.B., M.J., and I.E.; validation, W.H., S.B., and M.J.; visualization, W.H., R.S., and I.E.; writing—original draft, H.A.; writing—review and editing, H.A., W.H., R.S., S.B., M.J., and I.E. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the project GREaT (PRI, Impact Research Project), IRESA (Institute of Agricultural Research and Higher Education), Tunisia (2020–2024).

Institutional Review Board Statement

Ethical review and approval were waived for this study due to the fact that the only part involving non-scientist participants is the sensory analysis. In this part, the protocol was clearly stated in a sensory analysis sheet approved by the trained panel before starting this part.

Data Availability Statement

The data and materials related to this study are available upon request.

Acknowledgments

The authors extend special thanks to Ben Achour Lobna for her invaluable help and contributions to this study. Additionally, the authors express their gratitude to all technical staff of the Essanaoubar Company for their exceptional assistance and contributions to the completion of this research.

Conflicts of Interest

Authors Imen Ben Khalifa was employed by the company PACKTEC. The remaining author declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. The PACKTEC had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Alamri, M.; Qasem, A.A.; Mohamed, A.A.; Hussain, S.; Ibraheem, M.A.; Shamlan, G.; Alqah, H.A.; Qasha, A.S. Food packaging’s materials: A food safety perspective. Saudi J. Biol. Sci. 2021, 28, 4490–4499. [Google Scholar] [CrossRef] [PubMed]

- Fadiji, T.; Rashvand, M.; Daramola, M.O.; Iwarere, S.A. A review on antimicrobial packaging for extending the shelf life of food. Processes 2023, 11, 590. [Google Scholar] [CrossRef]

- Sarkar, S.; Aparna, K. Food packaging and storage. In Research Trends in Home Science and Extension; AkiNik Publications: New Delhi, India, 2020; Volume 3, pp. 27–51. [Google Scholar]

- Yan, M.R.; Hsieh, S.; Ricacho, N. Innovative food packaging, food quality and safety, and consumer perspectives. Processes 2022, 10, 747. [Google Scholar] [CrossRef]

- Lambert, Y.; Demazeau, G.; Largeteau, A.; Bouvier, J.M.; Laborde-Croubit, S.; Cabannes, M. Packaging for high-pressure treatments in the food industry. Packag. Technol. Sci. Int. J. 2000, 13, 63–71. [Google Scholar] [CrossRef]

- Kaushani, K.; Rathnasinghe, N.L.; Katuwawila, N.; Jayasinghe, R.; Nilmini, A.; Priyadarshana, G. Trends in Smart Packaging Technologies for Sustainable Monitoring of Food Quality and Safety. Int. J. Res. Innov. Appl. Sci. 2022, 7, 7–30. [Google Scholar] [CrossRef]

- Perera, K.Y.; Jaiswal, A.K.; Jaiswal, S. Biopolymer-based sustainable food packaging materials: Challenges, solutions, and applications. Foods 2023, 12, 2422. [Google Scholar] [CrossRef] [PubMed]

- Millican, J.M.; Agarwal, S. Plastic pollution: A material problem? Macromolecules 2021, 54, 4455–4469. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, K.; Chen, M.; Zhao, P.; Wang, Y.; Wang, X.; Han, X.; Wang, J. Development and characterization of biodegradable bilayer packaging films based on corn starch-polylactic acid as raw material. J. Food Meas. Charact. 2024, 18, 625–639. [Google Scholar] [CrossRef]

- ISO11357-3:2018; Plastics—Differential Scanning Calorimetry (DSC) Part 3: Determination of Temperature and Enthalpy of Melting and Crystallization. ISO: Geneva, Switzerland, 2018.

- ISO4593; Plastics—Film and Sheeting—Determination of Thickness by Mechanical Scanning. ISO: Geneva, Switzerland, 1993.

- ISO-15106; Plastics—Film and Sheeting—Determination of Water Vapour Transmission Rate. International Organization for Standardization: Geneva, Switzerland, 2003.

- ASTM1927; Standard Test Method for Determination of Oxygen Gas Transmission Rate, Permeability and Permeance at Controlled Relative Humidity Through Barrier Materials Using a Coulometric Detector. ASTM: Washington, DC, USA, 2020.

- (EU) No. 10; Commission Regulation (EU) No. 10/2011 on Plastic Materials and Articles Intended to Come into Contact with Food. 2011. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32011R0010&from=EN (accessed on 8 July 2024).

- EN-1186-3; Materials and Articles in Contact with Foodstuffs—Plastics—Part 3: Test Methods for Overall Migration in Evaporable Simulants. European Standards s.r.o.: Plzen, Czech Republic, 2022.

- Numuang, C. CFD Simulation of Heat Conduction in Curry Paste during Sterilization. Food Appl. Biosci. J. 2022, 10, 43–59. [Google Scholar]

- Pakdel, M.; Olsen, A.; Bar, E.M.S. A Review of Food Contaminants and Their Pathways within Food Processing Facilities Using Open Food Processing Equipment. J. Food Prot. 2023, 86, 100184. [Google Scholar] [CrossRef]

- Munir, M.T.; Mtimet, N.; Guillier, L.; Meurens, F.; Fravalo, P.; Federighi, M.; Kooh, P. Physical Treatments to Control Clostridium botulinum Hazards in Food. Foods 2023, 12, 1580. [Google Scholar] [CrossRef] [PubMed]

- NFV08-408; Microbiology of Foodstuffs. Stability Control of Appertised and Similar Products. French Standards Association (AFNOR): Paris, France, 1997; pp. 1–12.

- NFV08-409; Microbiology of Foodstuffs—Determination of the pH of Sterilised and Similar Products. French Standards Association (AFNOR): Paris France, 1997.

- ISO-7887; Water Quality—Examination and Determination of Colour. ISO: Geneva, Switzerland, 2011.

- Hajji, W.; Gliguem, H.; Bellagha, S.; Allaf, K. Structural and textural improvements of strawberry fruits by partial water removal prior to conventional freezing process. J. Food Meas. Charact. 2022, 16, 3344–3353. [Google Scholar] [CrossRef]

- ISO4120; Sensory Analysis—Methodology—Triangular Test. ISO: Geneva, Switzerland, 2021.

- Khoironi, A.; Anggoro, S.; Sudarno, S. Evaluation of the Interaction Among Microalgae Spirulina sp., Plastics Polyethylene Terephthalate and Polypropylene in Freshwater Environment. J. Ecol. Eng. 2019, 20, 161–173. [Google Scholar] [CrossRef] [PubMed]

- Fan, C.; Huang, Y.-Z.; Lin, J.-N.; Li, J. Microplastic constituent identification from admixtures by Fourier-transform infrared (FTIR) spectroscopy: The use of polyethylene terephthalate (PET), polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC) and nylon (NY) as the model constituents. Environ. Technol. Innov. 2021, 23, 101798. [Google Scholar] [CrossRef]

- Jung, M.R.; Horgen, F.D.; Orski, S.V.; Viviana, R.C.; Beers, K.L.; Balazs, G.H.; Jones, T.T.; Work, T.M.; Brignac, K.C.; Royer, S.-J.; et al. Validation of ATR FT-IR to identify polymers of plastic marine debris, including those ingested by marine organisms. Mar. Pollut. Bull. 2018, 127, 704–716. [Google Scholar] [CrossRef]

- Li, Z.; Shi, Y.; Liu, H.; Chen, F.; Zhang, Q.; Wang, K.; Fu, Q. Effect of melting temperature on interfacial interaction and mechanical properties of polypropylene (PP) fiber reinforced olefin block copolymers (OBCs). RSC Adv. 2014, 4, 45234–45243. [Google Scholar] [CrossRef]

- Kassab, A.; Al Nabhani, D.; Mohanty, P.; Pannier, C.; Ayoub, G.Y. Advancing Plastic Recycling: Challenges and Opportunities in the Integration of 3D Printing and Distributed Recycling for a Circular Economy. Polymers 2023, 15, 3881. [Google Scholar] [CrossRef]

- Tsironi, T.N.; Chatzidakis, S.M.; Stoforos, N.G. The future of polyethylene terephthalate bottles: Challenges and sustainability. Packag. Technol. Sci. 2022, 35, 317–325. [Google Scholar] [CrossRef]

- Olam, M. Mechanical and Thermal Properties of HDPE/PET Microplastics, Applications, and Impact on Environment and Life; IntechOpen: Rijeka, Croatia, 2023. [Google Scholar]

- van Velzen, E.U.T.; Chu, S.; Molenveld, K.; Jašo, V. Effect of poly lactic acid trays on the optical and thermal properties of recycled poly(ethylene terephthalate). Packag. Technol. Sci. 2022, 35, 351–360. [Google Scholar] [CrossRef]

- Chang, S.-H.; Chen, Y.-J.; Tseng, H.-J.; Hsiao, H.-I.; Chai, H.-J.; Shang, K.-C.; Pan, C.-L.; Tsai, G.-J. Applications of Nisin and EDTA in food packaging for improving fabricated chitosan-polylactate plastic film performance and fish fillet preservation. Membranes 2021, 11, 852. [Google Scholar] [CrossRef]

- Singh, A.K.; Itkor, P.; Lee, M.; Shin, J.; Lee, Y.S. Promoting sustainable packaging applications in the circular economy by exploring and advancing molded pulp materials for food products: A review. Crit. Rev. Food Sci. Nutr. 2023, 63, 11010–11025. [Google Scholar] [CrossRef] [PubMed]

- Wu, F.; Misra, M.; Mohanty, A.K. Challenges and new opportunities on barrier performance of biodegradable polymers for sustainable packaging. Prog. Polym. Sci. 2021, 117, 101395. [Google Scholar] [CrossRef]

- Elsabee, M.Z.; Abdelghany, N.; Aboelela, M. Surface modification of polypropylene by grafting films for active food packaging. Egypt. J. Chem. 2023, 66, 439–458. [Google Scholar] [CrossRef]

- Seier, M.; Archodoulaki, V.-M.; Koch, T.; Duscher, B.; Gahleitner, M. Prospects for Recyclable Multilayer Packaging: A Case Study. Polymers 2023, 15, 2966. [Google Scholar] [CrossRef]

- Tariq, A.; Afzal, A.; Rashid, I.A.; Shakir, M.F. Study of thermal, morphological, barrier and viscoelastic properties of PP grafted with maleic anhydride (PP-g-MAH) and PET blends. J. Polym. Res. 2020, 27, 309. [Google Scholar] [CrossRef]

- Ge, C.; Lansing, B.; Lewis, C.L. Thermoplastic starch and poly(vinyl alcohol) blends centered barrier film for food packaging applications. Food Packag. Shelf Life 2021, 27, 100610. [Google Scholar] [CrossRef]

- Dhawan, S.; Barbosa-Cànovas, G.V.; Tang, J.; Sablani, S.S. Oxygen barrier and enthalpy of melting of multilayer EVOH films after pressure-assisted thermal processing and during storage. J. Appl. Polym. Sci. 2011, 122, 1538–1545. [Google Scholar] [CrossRef]

- Schmid, P.; Welle, F. Chemical Migration from Beverage Packaging Materials—A Review. Beverages 2020, 6, 37. [Google Scholar] [CrossRef]

- Fasihnia, S.H.; Peighambardoust, S.H.; Peighambardoust, S.J.; Oromiehie, A.; Soltanzadeh, M.; Peressini, D. Migration analysis, antioxidant, and mechanical characterization of polypropylene-based active food packaging films loaded with BHA, BHT, and TBHQ. J. Food Sci. 2020, 85, 2317–2328. [Google Scholar] [CrossRef]

- Trăistaru, E.; Rivis, A.; Ciprian Moldovan, R.; Menelaou, A.; Georgescu, C. Study regarding the overall migration from plastic packaging materials used in food industry. J. Agroaliment. Process. Technol. 2013, 19, 305–308. [Google Scholar]

- Dumitru, O.M.; Ungureanu, E.L.; Iorga, C.S.; Mustățea, G. Overall migration aspects for plastic food contact materials with food simulants using SPSS statistics. J. Hyg. Eng. Des. 2021, 34, 8. [Google Scholar]

- Kang, K.; Chang, Y.; Choi, J.C.; Park, S.; Han, J. Migration study of butylated hydroxytoluene and Irganox 1010 from polypropylene treated with severe processing conditions. J. Food Sci. 2018, 83, 1005–1010. [Google Scholar] [CrossRef]

- Deshwal, G.K.; Panjagari, N.R. Review on metal packaging: Materials, forms, food applications, safety and recyclability. J. Food Sci. Technol. 2020, 57, 2377–2392. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Ni, P.; Yi, Y. Comparison of reactive magnesia, quick lime, and ordinary Portland cement for stabilization/solidification of heavy metal-contaminated soils. Sci. Total Environ. 2019, 671, 741–753. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.; Khan, A.R. Migrating levels of toxic heavy metals in locally made food packaging containers. Egypt. J. Chem. 2022, 65, 521–527. [Google Scholar] [CrossRef]

- Eti, S.A.; Islam, M.S.; Shourove, J.H.; Saha, B.; Ray, S.K.; Sultana, S.; Shaikh, A.A.; Rahman, M.M. Assessment of heavy metals migrated from food contact plastic packaging: Bangladesh perspective. Heliyon 2023, 9, e19667. [Google Scholar] [CrossRef]

- Ross, C.; Sablani, S.; Tang, J. Preserving ready-to-eat meals using microwave technologies for future space programs. Foods 2023, 12, 1322. [Google Scholar] [CrossRef]

- González Sandoval, D.C.; Sosa, B.L.; Martínez-Ávila, G.C.G.; Fuentes, H.R.; Abarca, V.H.A.; Rojas, R. Formulation and Characterization of Edible Films Based on Organic Mucilage from Mexican Opuntia ficus-indica. Coatings 2019, 9, 506. [Google Scholar] [CrossRef]

- Long, J.; Zhang, W.; Zhao, M.; Ruan, C.-Q. The reduce of water vapor permeability of polysaccharide-based films in food packaging: A comprehensive review. Carbohydr. Polym. 2023, 321, 121267. [Google Scholar] [CrossRef]

- Nilsen-Nygaard, J.; Fernández, E.N.; Radusin, T.; Rotabakk, B.T.; Sarfraz, J.; Sharmin, N.; Sivertsvik, M.; Sone, I.; Pettersen, M.K. Current status of biobased and biodegradable food packaging materials: Impact on food quality and effect of innovative processing technologies. Compr. Rev. Food Sci. Food Saf. 2021, 20, 1333–1380. [Google Scholar] [CrossRef]

- Ilhan, I.; Turan, D.; Gibson, I.; Klooster, R.T. Understanding the factors affecting the seal integrity in heat sealed flexible food packages: A review. Packag. Technol. Sci. 2021, 34, 321–337. [Google Scholar] [CrossRef]

- Sterr, J.; Fleckenstein, B.S.; Langowski, H.-C. The theory of decompression failure in polymers during the high-pressure processing of food. Food Eng. Rev. 2018, 10, 14–33. [Google Scholar] [CrossRef]

- Arvanitoyannis, I.S.; Kotsanopoulos, K.V. Migration phenomenon in food packaging. Food–package interactions, mechanisms, types of migrants, testing and relative legislation—A review. Food Bioprocess Technol. 2014, 7, 21–36. [Google Scholar]

- Bubelová, Z.; Černí ková, M.; Buňková, L.; Talár, J.; Zají ček, V.; Foltin, P.; Buňka, F. Quality changes of long-life foods during three-month storage at different temperatures. Potravinarstvo Slovak J. Food Sci. 2017, 11, 43–51. [Google Scholar] [CrossRef] [PubMed]

- Kuznetsova, T.; Krylova, V.; Gustova, T. The effect of storage conditions on the microstructure of sterilized canned meat. Slovak J. Food Sci. 2022, 16, 233–243. [Google Scholar] [CrossRef] [PubMed]

- Zheng, J.; Tian, L.; Bayen, S. Chemical contaminants in canned food and can-packaged food: A review. Crit. Rev. Food Sci. Nutr. 2023, 63, 2687–2718. [Google Scholar] [CrossRef] [PubMed]

- Giménez, C.G.; Traffano-Schiffo, M.V.; Sgroppo, S.C.; Sosa, C.A. Development of a bioactive sauce: Effect of the packaging and storage conditions. ChemEngineering 2022, 6, 34. [Google Scholar] [CrossRef]

- Tirtawijaya, G.; Lee, M.-J.; Negara, B.F.S.P.; Cho, W.-H.; Sohn, J.-H.; Kim, J.-S.; Choi, J.-S. Effects of vacuum frying on the preparation of ready-to-heat batter-fried and sauced chub mackerel (Scomber japonicus). Foods 2021, 10, 1962. [Google Scholar] [CrossRef] [PubMed]

- Bekhit, A.E.-D.A.; Holman, B.W.; Giteru, S.G.; Hopkins, D.L. Total volatile basic nitrogen (TVB-N) and its role in meat spoilage: A review. Trends Food Sci. Technol. 2021, 109, 280–302. [Google Scholar] [CrossRef]

- Holman, B.W.B.; El-Din A Bekhit, A.; Waller, M.; Bailes, K.L.; Kerr, M.J.; Hopkins, D.L. The association between total volatile basic nitrogen (TVB-N) concentration and other biomarkers of quality and spoilage for vacuum packaged beef. Meat Sci. 2021, 179, 108551. [Google Scholar] [CrossRef] [PubMed]

- Dai, H.; Leung, C.E.; Corradini, M.G.; Xiao, H.; Kinchla, A.J. Increasing the nutritional value of strawberry puree by adding xylo-oligosaccharides. Heliyon 2020, 6, e03769. [Google Scholar] [CrossRef] [PubMed]

- Koontz, J.L. Packaging Technologies to Control Lipid Oxidation, in Oxidative Stability and Shelf Life of Foods Containing Oils and Fats; Elsevier: Amsterdam, The Netherlands, 2016; pp. 479–517. [Google Scholar]

- Kohan-nia, N.; Pakbin, B.; Mahmoudi, R.; Fakhri, O. Effect of packaging material on color properties of catsup tomato sauce. J. Appl. Packag. Res. 2016, 8, 4. [Google Scholar]

- Forsido, S.F.; Welelaw, E.; Belachew, T.; Hensel, O. Effects of storage temperature and packaging material on physico-chemical, microbial and sensory properties and shelf life of extruded composite baby food flour. Heliyon 2021, 7, e06821. [Google Scholar] [CrossRef] [PubMed]

- Ezeocha, V.C. Effects of different packaging materials on the chemical and sensory properties of moi-moi. Niger. Agric. J. 2021, 52, 201–211. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).